lock DODGE DURANGO 2019 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2019, Model line: DURANGO, Model: DODGE DURANGO 2019Pages: 598, PDF Size: 4.32 MB

Page 383 of 598

7. Install the bulb and connector assembly into the head-lamp housing and rotate clockwise to lock in place.

8. Install the bulb access cap in the headlamp housing and rotate clockwise to lock it in place.

9. Install the access cap in the wheel liner and rotate clockwise to lock it in place.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

Front Turn Signal

1. Open the hood.

2. Turn the turn signal bulb one–quarter turn counter-clockwise to remove from housing.

3. Disconnect the electrical connector and replace the bulb.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

Front Fog Lamps

1. Reach through the cutout in the splash shield and rotate the bulb’s electrical connector one-quarter turn counter-

clockwise and remove it from the fog lamp housing.

2. Remove the bulb from the connector and install the replacement bulb.

3. Install the bulb and connector assembly into the fog lamp housing and rotate the connector one-quarter turn

clockwise to lock it in place.

CAUTION!

• Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

(Continued)

7

IN CASE OF EMERGENCY 381

Page 384 of 598

CAUTION!(Continued)

•Always use the correct bulb size and type for replace-

ment. An incorrect bulb size or type may overheat

and cause damage to the lamp, the socket or the lamp

wiring.

Rear Tail, Stop And Turn Signal Lamps

The rear tail, stop, and turn signal lamps are LED. See your

authorized dealer for replacement.

Rear Liftgate Mounted Back-up Lamps

1. Raise the liftgate.

2. Use a fiber stick or flat blade screw driver to pry the

lower trim from the liftgate.

3. Back-up lamps are now visible. Rotate socket(s) counter clockwise.

4. Remove/replace bulb(s).

5. Reinstall the socket(s).

6. Reverse process to reinstall the liftgate trim.

Center High-Mounted Stop Lamp (CHMSL)

The center high-mounted stop lamp is an LED assembly.

See your authorized dealer for replacement.

Rear License Lamp

The rear license lamps are LEDs. See your authorized

dealer for service.

FUSES

WARNING!

• When replacing a blown fuse, always use an appro-

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown

fuse with metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity or vice

versa. Failure to use proper fuses may result in

serious personal injury, fire and/or property damage.

• Before replacing a fuse, make sure that the ignition is

off and that all the other services are switched off

and/or disengaged.

(Continued)

382 IN CASE OF EMERGENCY

Page 386 of 598

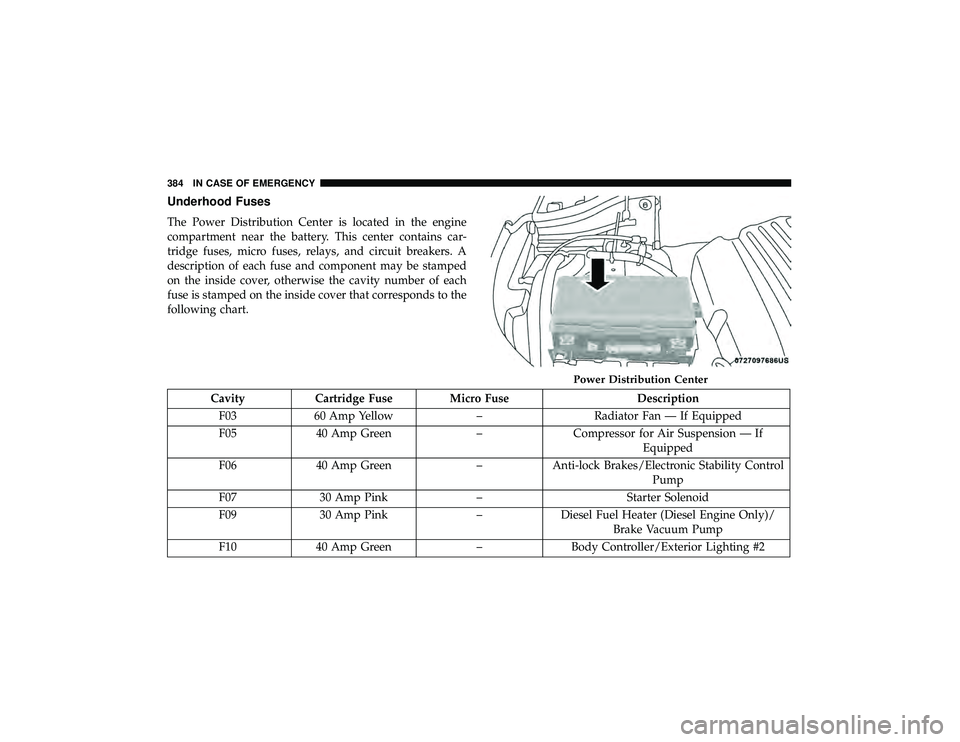

Underhood Fuses

The Power Distribution Center is located in the engine

compartment near the battery. This center contains car-

tridge fuses, micro fuses, relays, and circuit breakers. A

description of each fuse and component may be stamped

on the inside cover, otherwise the cavity number of each

fuse is stamped on the inside cover that corresponds to the

following chart.

CavityCartridge Fuse Micro Fuse Description

F03 60 Amp Yellow –Radiator Fan — If Equipped

F05 40 Amp Green –Compressor for Air Suspension — If

Equipped

F06 40 Amp Green –Anti-lock Brakes/Electronic Stability Control

Pump

F07 30 Amp Pink –Starter Solenoid

F09 30 Amp Pink –Diesel Fuel Heater (Diesel Engine Only)/

Brake Vacuum Pump

F10 40 Amp Green –Body Controller/Exterior Lighting #2

Power Distribution Center

384 IN CASE OF EMERGENCY

Page 387 of 598

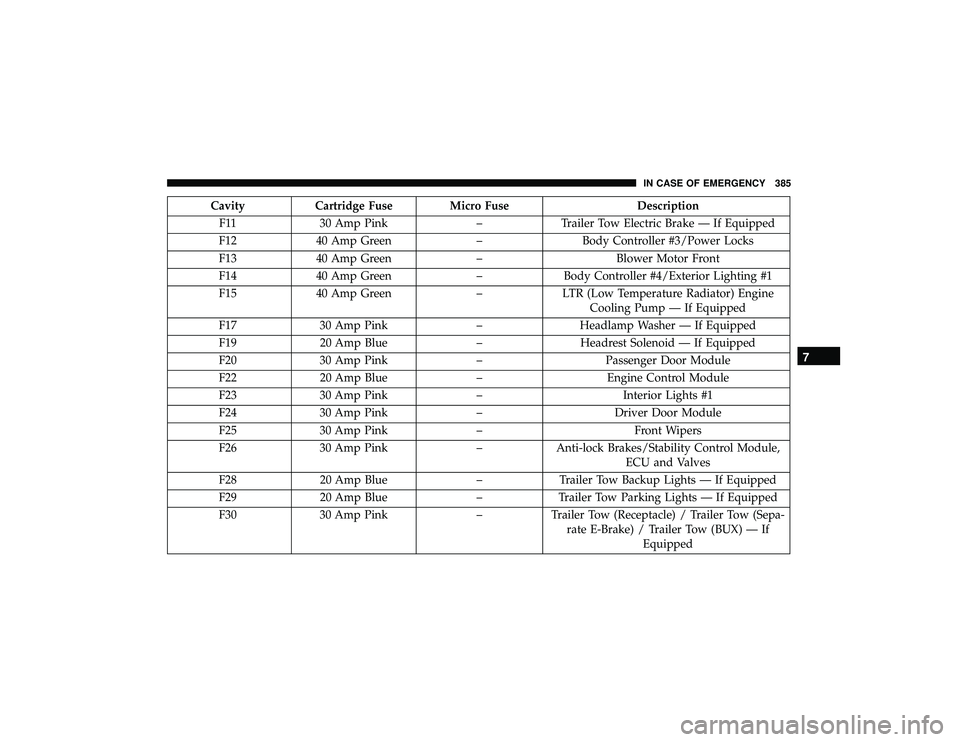

CavityCartridge Fuse Micro Fuse Description

F11 30 Amp Pink –Trailer Tow Electric Brake — If Equipped

F12 40 Amp Green –Body Controller #3/Power Locks

F13 40 Amp Green –Blower Motor Front

F14 40 Amp Green –Body Controller #4/Exterior Lighting #1

F15 40 Amp Green –LTR (Low Temperature Radiator) Engine

Cooling Pump — If Equipped

F17 30 Amp Pink –Headlamp Washer — If Equipped

F19 20 Amp Blue –Headrest Solenoid — If Equipped

F20 30 Amp Pink –Passenger Door Module

F22 20 Amp Blue –Engine Control Module

F23 30 Amp Pink –Interior Lights #1

F24 30 Amp Pink –Driver Door Module

F25 30 Amp Pink – Front Wipers

F26 30 Amp Pink –Anti-lock Brakes/Stability Control Module,

ECU and Valves

F28 20 Amp Blue –Trailer Tow Backup Lights — If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights — If Equipped

F30 30 Amp Pink –Trailer Tow (Receptacle) / Trailer Tow (Sepa-

rate E-Brake) / Trailer Tow (BUX) — If Equipped

7

IN CASE OF EMERGENCY 385

Page 388 of 598

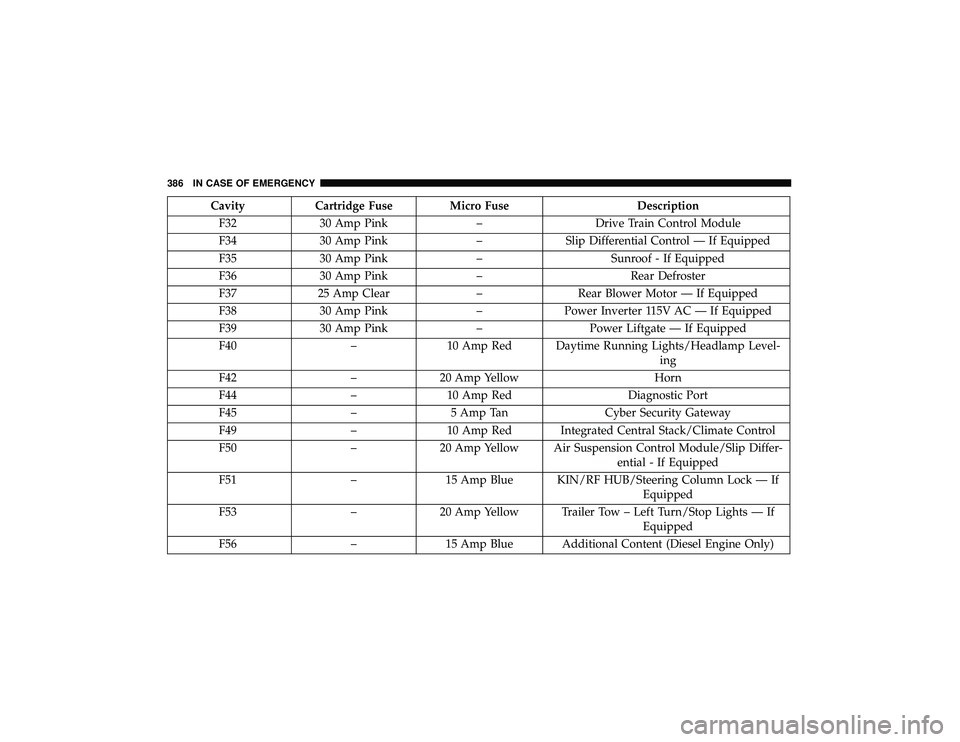

CavityCartridge Fuse Micro Fuse Description

F32 30 Amp Pink –Drive Train Control Module

F34 30 Amp Pink –Slip Differential Control — If Equipped

F35 30 Amp Pink –Sunroof - If Equipped

F36 30 Amp Pink –Rear Defroster

F37 25 Amp Clear –Rear Blower Motor — If Equipped

F38 30 Amp Pink –Power Inverter 115V AC — If Equipped

F39 30 Amp Pink –Power Liftgate — If Equipped

F40 –10 Amp Red Daytime Running Lights/Headlamp Level-

ing

F42 –20 Amp Yellow Horn

F44 –10 Amp Red Diagnostic Port

F45 –5 Amp Tan Cyber Security Gateway

F49 –10 Amp Red Integrated Central Stack/Climate Control

F50 –20 Amp Yellow Air Suspension Control Module/Slip Differ-

ential - If Equipped

F51 –15 Amp Blue KIN/RF HUB/Steering Column Lock — If

Equipped

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights — If

Equipped

F56 –15 Amp Blue Additional Content (Diesel Engine Only)

386 IN CASE OF EMERGENCY

Page 390 of 598

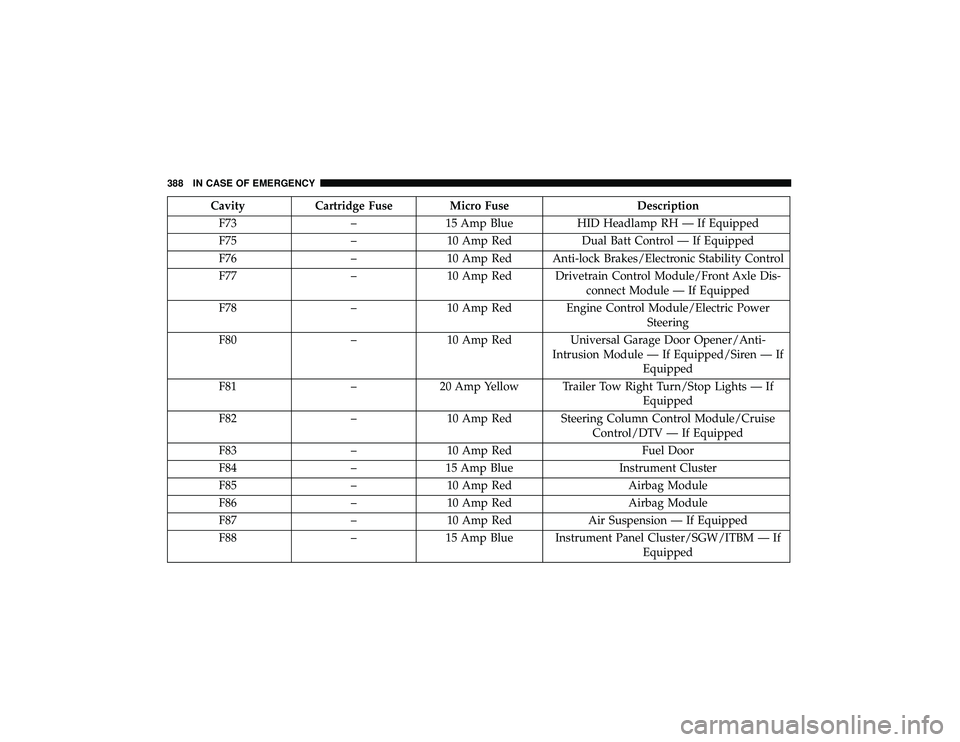

CavityCartridge Fuse Micro Fuse Description

F73 –15 Amp Blue HID Headlamp RH — If Equipped

F75 –10 Amp Red Dual Batt Control — If Equipped

F76 –10 Amp Red Anti-lock Brakes/Electronic Stability Control

F77 –10 Amp Red Drivetrain Control Module/Front Axle Dis-

connect Module — If Equipped

F78 –10 Amp Red Engine Control Module/Electric Power

Steering

F80 –10 Amp Red Universal Garage Door Opener/Anti-

Intrusion Module — If Equipped/Siren — If Equipped

F81 –20 Amp Yellow Trailer Tow Right Turn/Stop Lights — If

Equipped

F82 –10 Amp Red Steering Column Control Module/Cruise

Control/DTV — If Equipped

F83 –10 Amp Red Fuel Door

F84 –15 Amp Blue Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp Red Air Suspension — If Equipped

F88 –15 Amp Blue Instrument Panel Cluster/SGW/ITBM — If

Equipped

388 IN CASE OF EMERGENCY

Page 397 of 598

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the

road to avoid being hit when operating the jack or

changing the wheel.

2. Turn on the Hazard Warning flashers.

3. Apply the parking brake.

4. Place the gear selector into PARK.

5. Turn OFF the ignition.

6. Block both the front and rear of the wheel diagonally opposite the jacking position. For example, if the right

front wheel is being changed, block the left rear wheel.

NOTE:Passengers should not remain in the

vehicle when the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

• Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be

raised.

• Apply the parking brake firmly and set the transmis-

sion in PARK.

• Never start or run the engine with the vehicle on a

jack.

• Do not let anyone sit in the vehicle when it is on a

jack.

• Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

(Continued)

7

IN CASE OF EMERGENCY 395

Page 399 of 598

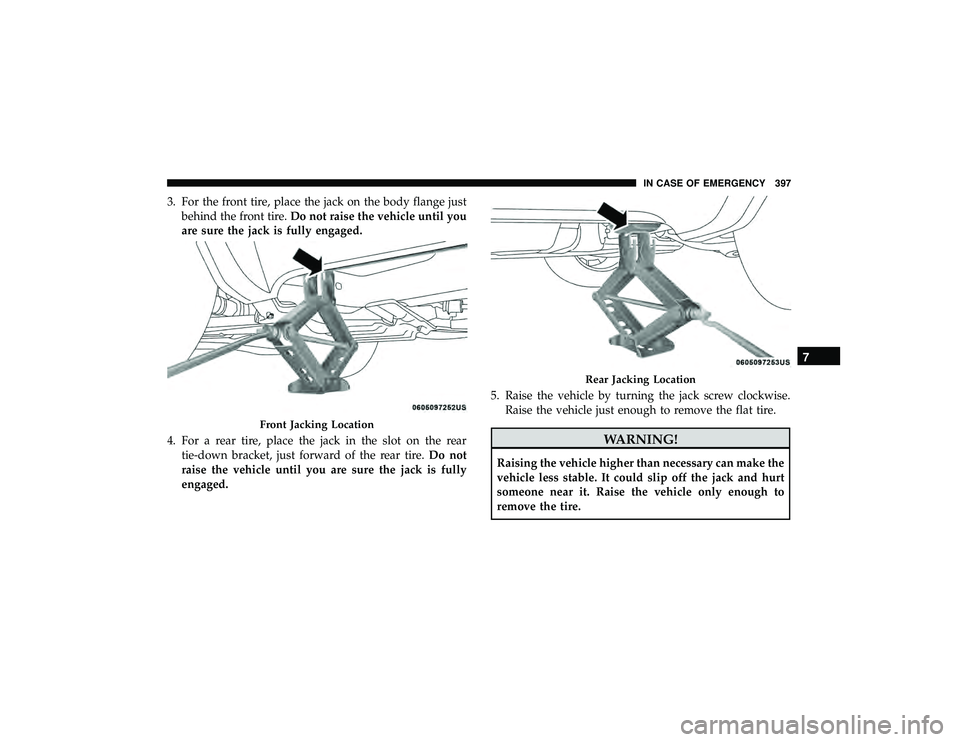

3. For the front tire, place the jack on the body flange justbehind the front tire. Do not raise the vehicle until you

are sure the jack is fully engaged.

4. For a rear tire, place the jack in the slot on the rear tie-down bracket, just forward of the rear tire. Do not

raise the vehicle until you are sure the jack is fully

engaged. 5. Raise the vehicle by turning the jack screw clockwise.

Raise the vehicle just enough to remove the flat tire.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

Front Jacking Location

Rear Jacking Location

7

IN CASE OF EMERGENCY 397

Page 400 of 598

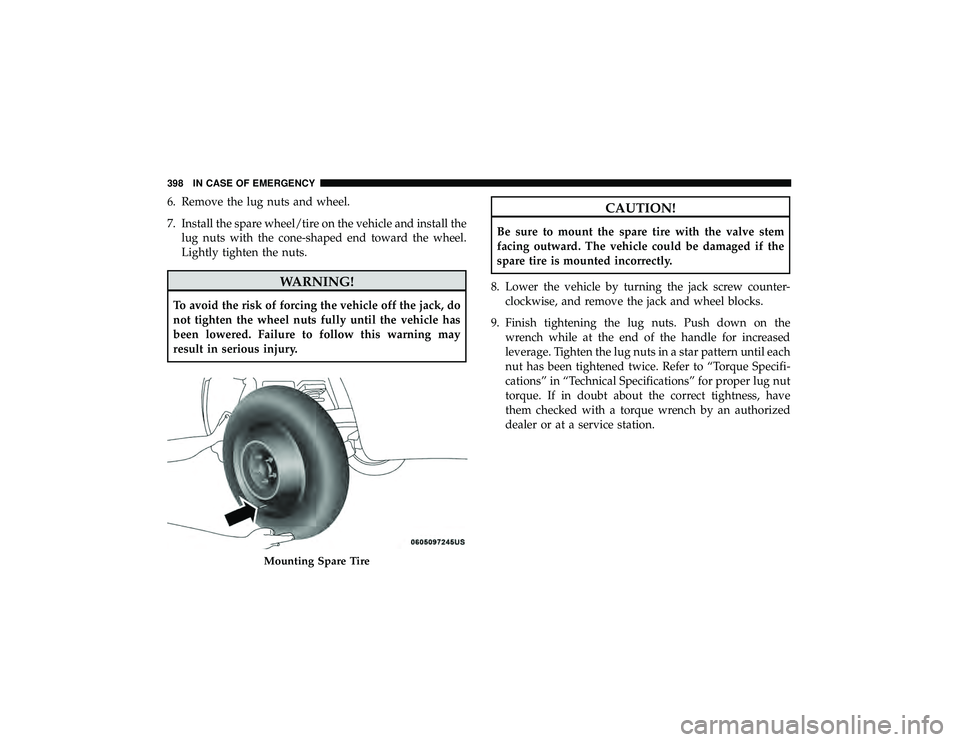

6. Remove the lug nuts and wheel.

7. Install the spare wheel/tire on the vehicle and install thelug nuts with the cone-shaped end toward the wheel.

Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

8. Lower the vehicle by turning the jack screw counter- clockwise, and remove the jack and wheel blocks.

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. Refer to “Torque Specifi-

cations” in “Technical Specifications” for proper lug nut

torque. If in doubt about the correct tightness, have

them checked with a torque wrench by an authorized

dealer or at a service station.

Mounting Spare Tire

398 IN CASE OF EMERGENCY

Page 402 of 598

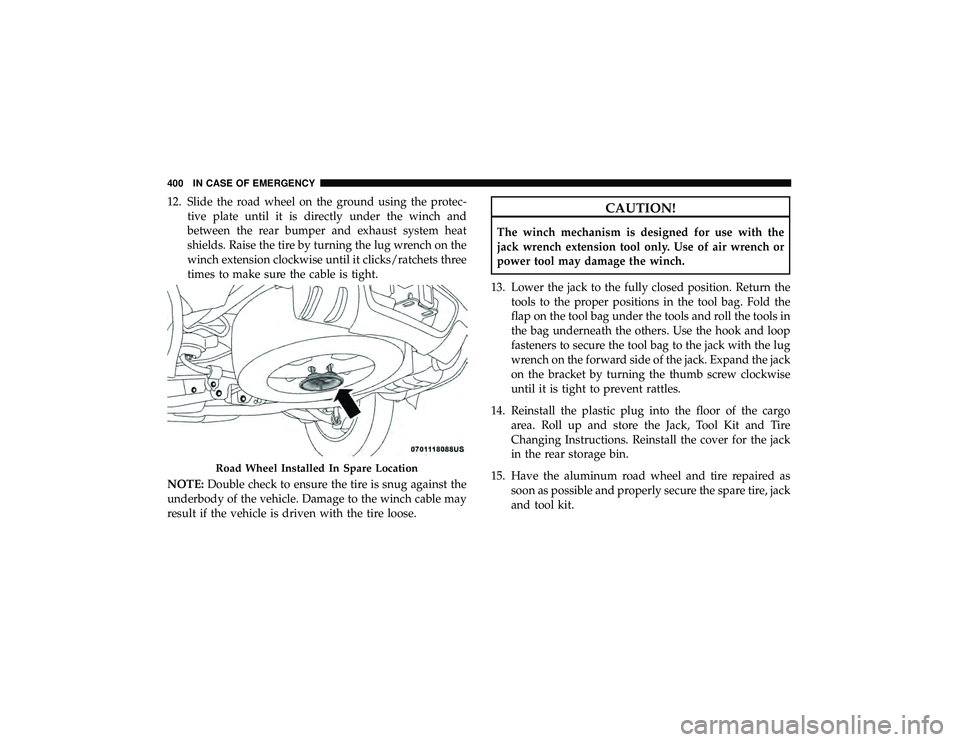

12. Slide the road wheel on the ground using the protec-tive plate until it is directly under the winch and

between the rear bumper and exhaust system heat

shields. Raise the tire by turning the lug wrench on the

winch extension clockwise until it clicks/ratchets three

times to make sure the cable is tight.

NOTE: Double check to ensure the tire is snug against the

underbody of the vehicle. Damage to the winch cable may

result if the vehicle is driven with the tire loose.CAUTION!

The winch mechanism is designed for use with the

jack wrench extension tool only. Use of air wrench or

power tool may damage the winch.

13. Lower the jack to the fully closed position. Return the tools to the proper positions in the tool bag. Fold the

flap on the tool bag under the tools and roll the tools in

the bag underneath the others. Use the hook and loop

fasteners to secure the tool bag to the jack with the lug

wrench on the forward side of the jack. Expand the jack

on the bracket by turning the thumb screw clockwise

until it is tight to prevent rattles.

14. Reinstall the plastic plug into the floor of the cargo area. Roll up and store the Jack, Tool Kit and Tire

Changing Instructions. Reinstall the cover for the jack

in the rear storage bin.

15. Have the aluminum road wheel and tire repaired as soon as possible and properly secure the spare tire, jack

and tool kit.

Road Wheel Installed In Spare Location

400 IN CASE OF EMERGENCY