width DODGE DURANGO 2022 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2022, Model line: DURANGO, Model: DODGE DURANGO 2022Pages: 332, PDF Size: 19.82 MB

Page 139 of 332

STARTING AND OPERATING137

vehicle is shifted into PARK, the vehicle’s ignition is

placed in the OFF position, or the touchscreen X

button to disable the display of the Rear View

Camera is pressed.

When enabled, active guidelines are overlaid on

the image to illustrate the width of the vehicle and

its projected backup path based on the steering

wheel position. A dashed center line overlay

indicates the center of the vehicle to assist with

parking or aligning to a hitch/receiver. Different

colored zones indicate the distance to the rear of

the vehicle.

The following table shows the approximate

distances for each zone:

NOTE:If snow, ice, mud, or any foreign substance builds

up on the camera lens, clean the lens, rinse with

water, and dry with a soft cloth. Do not cover the

lens.

Rear View Camera — Viewing At Speed When the vehicle is in PARK, NEUTRAL or

DRIVE, the Rear View Camera can be

activated with the Rear View Camera

button in the Controls tab of the Vehicle

Menu. This feature allows the customer to monitor

the area directly behind the vehicle (or trailer, if

equipped) for up to 10 seconds while driving. If the

vehicle speed remains below 8 mph (13 km/h),

the Rear View Camera image will be displayed

continuously until deactivated via the X button on

the touchscreen.

REFUELING THE VEHICLE

1. Open the fuel filler door by pushing on the outer edge of the fuel door.

NOTE:There is no fuel filler cap. Two flapper doors inside

the pipe seal the system.

2. Insert the fuel nozzle fully into the filler pipe – the nozzle opens and holds the flapper doors

while refueling.

Zone

Distance To The Rear Of

The Vehicle

Red 0 - 1 ft (0 - 30 cm)

Yellow 1 ft - 6.5 ft (30 cm - 2 m)

Green 6.5 ft or greater

(2 m or greater)

WARNING!

Drivers must be careful when backing up even

when using the ParkView Rear Back Up Camera.

Always check carefully behind your vehicle, and

be sure to check for pedestrians, animals, other

vehicles, obstructions, or blind spots before

backing up. You are responsible for the safety of

your surroundings and must continue to pay

attention while backing up. Failure to do so can

result in serious injury or death.

CAUTION!

To avoid vehicle damage, ParkView should

only be used as a parking aid. The ParkView

camera is unable to view every obstacle or

object in your drive path.

To avoid vehicle damage, the vehicle must be

driven slowly when using ParkView to be able

to stop in time when an obstacle is seen. It is

recommended that the driver look frequently

over his/her shoulder when using ParkView.

4

22_WD_OM_EN_USC_t.book Page 137

Page 142 of 332

140STARTING AND OPERATING

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Ú page 138.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link that

can be installed between the hitch receiver and the

trailer tongue that typically provides adjustable

friction associated with the telescoping motion to

dampen any unwanted trailer swaying motions

while traveling.

If equipped, the electronic TSC recognizes a

swaying trailer and automatically applies individual

wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and

the trailer axle(s). When used in accordance with

the manufacturer's directions, it provides for a

more level ride, offering more consistent steering

and brake control thereby enhancing towing

safety. The addition of a friction/hydraulic sway control also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. Trailer Sway Control

(TSC) and a weight distributing (load equalizing)

hitch are recommended for heavier Tongue

Weights (TW) and may be required depending on

vehicle and trailer configuration/loading to comply

with Gross Axle Weight Rating (GAWR)

requirements.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the vehicle

and have a collision.

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability,

braking performance, and could result in a

collision.

Weight-distributing hitch systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

22_WD_OM_EN_USC_t.book Page 140

Page 190 of 332

188SAFETY

AUXILIARY DRIVING SYSTEMS

BLIND SPOT MONITORING (BSM) —

I

F EQUIPPED

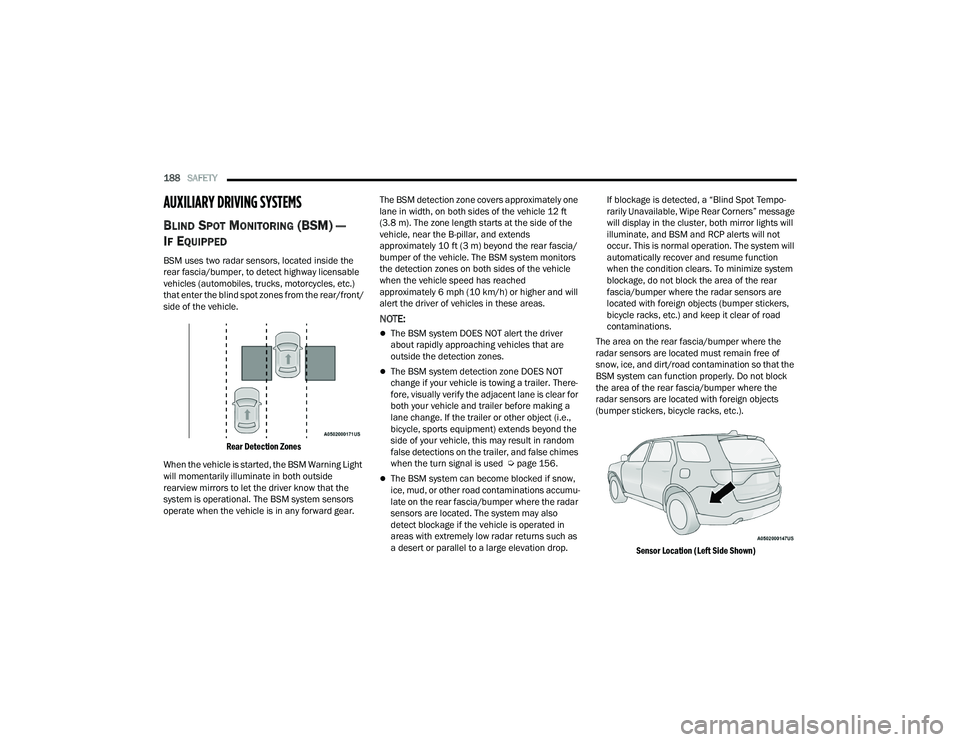

BSM uses two radar sensors, located inside the

rear fascia/bumper, to detect highway licensable

vehicles (automobiles, trucks, motorcycles, etc.)

that enter the blind spot zones from the rear/front/

side of the vehicle.

Rear Detection Zones

When the vehicle is started, the BSM Warning Light

will momentarily illuminate in both outside

rearview mirrors to let the driver know that the

system is operational. The BSM system sensors

operate when the vehicle is in any forward gear. The BSM detection zone covers approximately one

lane in width, on both sides of the vehicle 12 ft

(3.8 m). The zone length starts at the side of the

vehicle, near the B-pillar, and extends

approximately 10 ft (3 m) beyond the rear fascia/

bumper of the vehicle. The BSM system monitors

the detection zones on both sides of the vehicle

when the vehicle speed has reached

approximately 6 mph (10 km/h) or higher and will

alert the driver of vehicles in these areas.

NOTE:

The BSM system DOES NOT alert the driver

about rapidly approaching vehicles that are

outside the detection zones.

The BSM system detection zone DOES NOT

change if your vehicle is towing a trailer. There

-

fore, visually verify the adjacent lane is clear for

both your vehicle and trailer before making a

lane change. If the trailer or other object (i.e.,

bicycle, sports equipment) extends beyond the

side of your vehicle, this may result in random

false detections on the trailer, and false chimes

when the turn signal is used Ú page 156.

The BSM system can become blocked if snow,

ice, mud, or other road contaminations accumu -

late on the rear fascia/bumper where the radar

sensors are located. The system may also

detect blockage if the vehicle is operated in

areas with extremely low radar returns such as

a desert or parallel to a large elevation drop. If blockage is detected, a “Blind Spot Tempo-

rarily Unavailable, Wipe Rear Corners” message

will display in the cluster, both mirror lights will

illuminate, and BSM and RCP alerts will not

occur. This is normal operation. The system will

automatically recover and resume function

when the condition clears. To minimize system

blockage, do not block the area of the rear

fascia/bumper where the radar sensors are

located with foreign objects (bumper stickers,

bicycle racks, etc.) and keep it clear of road

contaminations.

The area on the rear fascia/bumper where the

radar sensors are located must remain free of

snow, ice, and dirt/road contamination so that the

BSM system can function properly. Do not block

the area of the rear fascia/bumper where the

radar sensors are located with foreign objects

(bumper stickers, bicycle racks, etc.).

Sensor Location (Left Side Shown)

22_WD_OM_EN_USC_t.book Page 188

Page 288 of 332

286SERVICING AND MAINTENANCE

REAR LIFTGATE MOUNTED BACK-UP LAMPS

See the following steps to replace:

1. Raise the liftgate.

2. Use a fiber stick or flat blade screw driver to

pry the lower trim from the liftgate.

3. Back-up lamps are now visible. Rotate socket(s) counterclockwise.

4. Remove/replace bulb(s).

5. Reinstall the socket(s).

6. Reverse process to reinstall the liftgate trim.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

The Center High Mounted Stop Lamp is an LED

assembly. See an authorized dealer for

replacement.

REAR LICENSE LAMP

The rear license lamps are LEDs. See an

authorized dealer for service.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

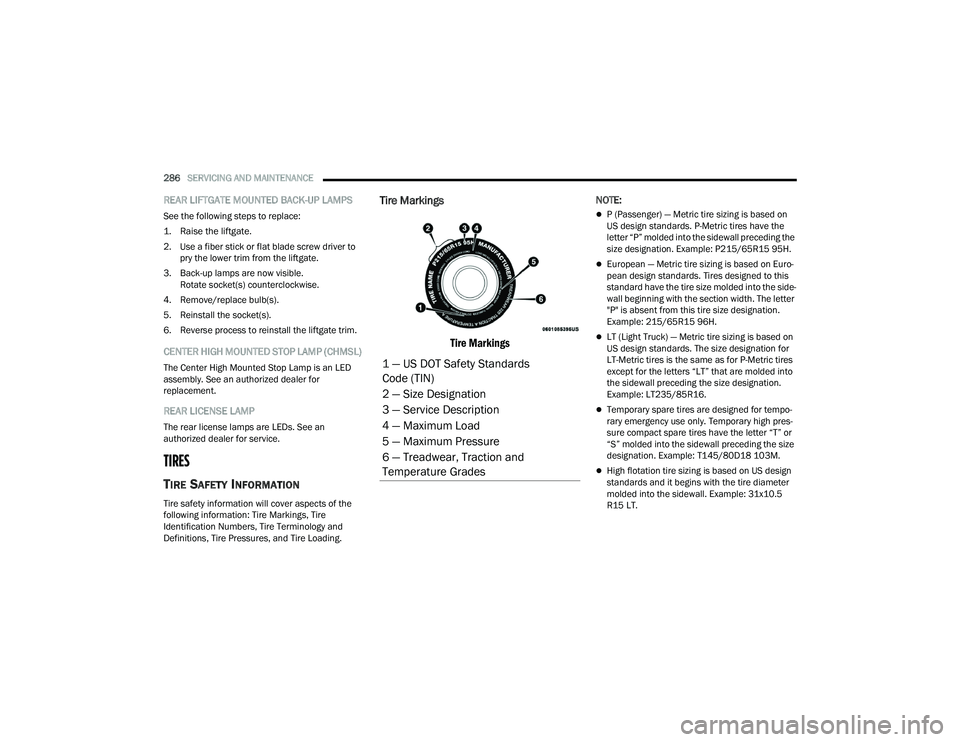

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on

US design standards. P-Metric tires have the

letter “P” molded into the sidewall preceding the

size designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on Euro -

pean design standards. Tires designed to this

standard have the tire size molded into the side -

wall beginning with the section width. The letter

"P" is absent from this tire size designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for tempo -

rary emergency use only. Temporary high pres -

sure compact spare tires have the letter “T” or

“S” molded into the sidewall preceding the size

designation. Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall. Example: 31x10.5

R15 LT.

1 — US DOT Safety Standards

Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

22_WD_OM_EN_USC_t.book Page 286

Page 289 of 332

SERVICING AND MAINTENANCE287

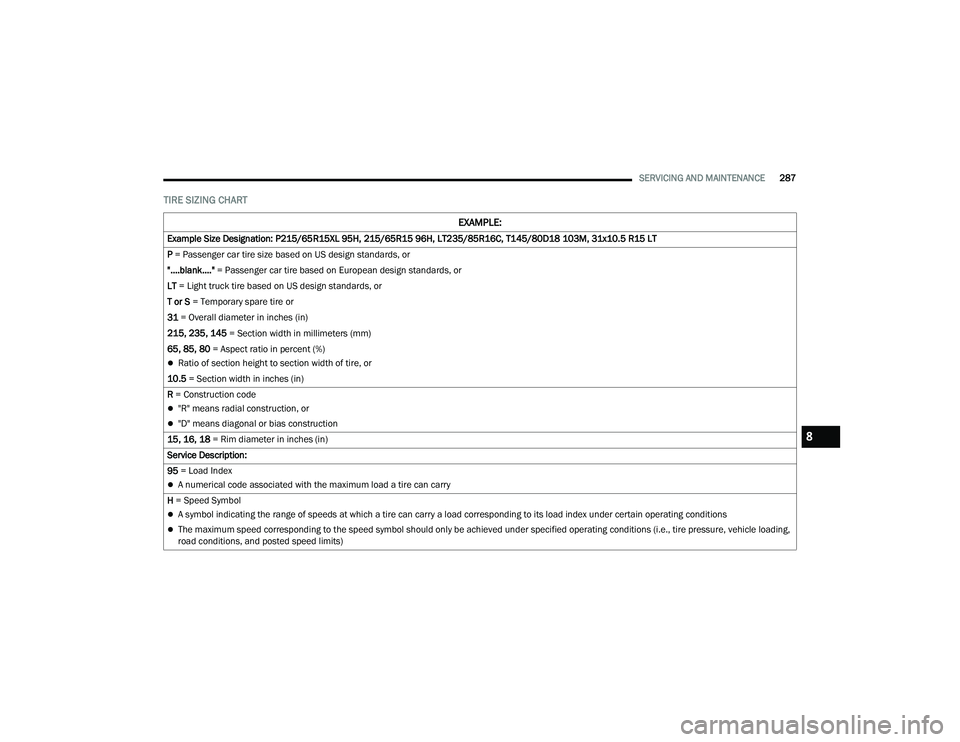

TIRE SIZING CHART

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading,

road conditions, and posted speed limits)

8

22_WD_OM_EN_USC_t.book Page 287