ABS DODGE DURANGO 2023 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: DURANGO, Model: DODGE DURANGO 2023Pages: 328, PDF Size: 13.82 MB

Page 179 of 328

177

(Continued)

SAFETY

SAFETY FEATURES

ANTI-LOCK BRAKE SYSTEM (ABS)

The ABS provides increased vehicle stability and

brake performance under most braking conditions.

The system automatically prevents wheel lock and

enhances vehicle control during braking.

The ABS performs a self-check cycle to ensure that

the ABS is working properly each time the vehicle

is started and driven. During this self-check, you

may hear a slight clicking sound as well as some

related motor noises.

The ABS is activated during braking when the

system detects one or more wheels are beginning

to lock. Road conditions such as ice, snow, gravel,

bumps, railroad tracks, loose debris, or panic stops

may increase the likelihood of ABS activation(s).

You also may experience the following normal

characteristics when the ABS activates:

ABS motor noise or clicking sounds (you may

continue to hear for a short time after the stop).

Brake pedal pulsations.

A slight drop of the brake pedal at the end of the

stop.The ABS is designed to function with the Original

Equipment Manufacturer (OEM) tires. Modification

may result in degraded ABS performance.

Anti-Lock Brake System (ABS) Warning

Light

The yellow ABS Warning Light will turn on when the

ignition is placed in the ON/RUN mode and may

stay on for as long as four seconds.

If the ABS Warning Light remains on or comes on

while driving, it indicates that the anti-lock portion

of the brake system is not functioning and that

service is required. However, the conventional

brake system will continue to operate normally if

the ABS Warning Light is on.

WARNING!

The ABS contains sophisticated electronic

equipment that may be susceptible to interfer

-

ence caused by improperly installed or high

output radio transmitting equipment. This

interference can cause possible loss of

anti-lock braking capability. Installation of

such equipment should be performed by qual -

ified professionals.

Pumping of the Anti-Lock Brakes will diminish

their effectiveness and may lead to a collision.

Pumping makes the stopping distance longer.

Just press firmly on your brake pedal when you

need to slow down or stop.

The ABS cannot prevent the natural laws of

physics from acting on the vehicle, nor can it

increase braking or steering efficiency beyond

that afforded by the condition of the vehicle

brakes and tires or the available traction.

The ABS cannot prevent collisions, including

those resulting from excessive speed in turns,

following another vehicle too closely, or hydro -

planing.

The capabilities of an ABS equipped vehicle

must never be exploited in a reckless or

dangerous manner that could jeopardize the

user’s safety or the safety of others.

WARNING!

6

23_WD_OM_EN_USC_t.book Page 177

Page 180 of 328

178SAFETY

(Continued)

If the ABS Warning Light is on, the brake system

should be serviced as soon as possible to restore

the benefits of Anti-Lock Brakes. If the ABS

Warning Light does not come on when the ignition

is placed in the ON/RUN mode, have the light

repaired as soon as possible.

REAR SEAT REMINDER ALERT (RSRA)

RSRA alerts you through a visual and auditory

notification of the possible presence of an object,

passenger, or pet in the rear seats if a rear door

was opened up to 10 minutes before the ignition

was placed in the ON/RUN position. RSRA does not

directly detect objects, passengers, or pets in the

rear seats. When the previous conditions are met,

RSRA displays the message “Check Rear Seat” on

the instrument cluster display and sounds an

auditory alert upon the driver placing the ignition in

the OFF position to exit the vehicle.

To enable or disable RSRA, see Ú

page 153.

ELECTRONIC BRAKE CONTROL (EBC)

S

YSTEM

Your vehicle is equipped with an advanced

Electronic Brake Control (EBC) system. This system

includes Anti-Lock Brake System (ABS), Brake

Assist System (BAS), Electronic Brake Force

Distribution (EBD), Electronic Roll Mitigation

(ERM), Electronic Stability Control (ESC), Hill Start

Assist (HSA), and Traction Control System (TCS).

These systems work together to enhance both

vehicle stability and control in various driving

conditions. Your vehicle may also be equipped with Dynamic

Steering Torque (DST), Rain Brake Support (RBS),

Ready Alert Braking (RAB), and Trailer Sway

Control (TSC).

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s

braking capability during emergency braking

maneuvers. The system detects an emergency

braking situation by sensing the rate and amount

of brake application and then applies optimum

pressure to the brakes. This can help reduce

braking distances. The BAS complements the

Anti-Lock Brake System (ABS). Applying the brakes

very quickly results in the best BAS assistance. To

receive the benefit of the system, you must apply

continuous braking pressure during the stopping

sequence (do not “pump” the brakes). Do not

reduce brake pedal pressure unless braking is no

longer desired. Once the brake pedal is released,

the BAS is deactivated.

WARNING!

Before exiting a vehicle, always come to a

complete stop, then shift the automatic trans

-

mission into PARK and apply the parking

brake.

Always make sure the keyless ignition node is

in the OFF position, key fob is removed from

the vehicle and vehicle is locked.

Never leave children alone in a vehicle, or with

access to an unlocked vehicle. Leaving chil -

dren in a vehicle unattended is dangerous for

a number of reasons. A child or others could

be seriously or fatally injured. Children should

be warned not to touch the parking brake,

brake pedal or the gear selector.

Do not leave children or animals inside parked

vehicles in hot weather. Interior heat buildup

may cause serious injury or death.

WARNING!

23_WD_OM_EN_USC_t.book Page 178

Page 181 of 328

SAFETY179

Brake System Warning Light

The red Brake System Warning Light will turn on

when the ignition is placed in the ON/RUN mode

and may stay on for as long as four seconds.

If the Brake System Warning Light remains on or

comes on while driving, it indicates that the brake

system is not functioning properly and that

immediate service is required. If the Brake System

Warning Light does not come on when the ignition

is placed in the ON/RUN mode, have the light

repaired as soon as possible.

Dynamic Steering Torque (DST)

DST is a feature of the ESC and Electric Power

Steering (EPS) modules that, when equipped,

provides torque at the steering wheel for certain

driving conditions in which the ESC module is

detecting vehicle instability. The torque that the

steering wheel receives is only meant to help the

driver realize optimal steering behavior in order to

reach/maintain vehicle stability. The only

notification the driver receives that the feature is

active is the torque applied to the steering wheel.

NOTE:The DST feature is only meant to help the driver

realize the correct course of action through small

torques on the steering wheel, which means the

effectiveness of the DST feature is highly

dependent on the driver’s sensitivity and overall

reaction to the applied torque. It is very important

to realize that this feature will not steer the vehicle,

meaning the driver is still responsible for steering

the vehicle.

Electronic Brake Force Distribution (EBD)

EBD manages the distribution of the braking

torque between the front and rear axles by limiting

braking pressure to the rear axle. This is done to

prevent overslip of the rear wheels to avoid vehicle

instability, and to prevent the rear axle from

entering ABS before the front axle.

Electronic Roll Mitigation (ERM)

ERM anticipates the potential for wheel lift by

monitoring the driver’s steering wheel input and

the speed of the vehicle. When Electronic Roll

Mitigation (ERM) determines that the rate of

change of the steering wheel angle and vehicle’s

speed are sufficient to potentially cause wheel lift,

it then applies the appropriate brake and may also

reduce engine power to lessen the chance that

wheel lift will occur. ERM can only reduce the

chance of wheel lift occurring during severe or

evasive driving maneuvers; it cannot prevent

wheel lift due to other factors, such as road

conditions, leaving the roadway, or striking objects

or other vehicles.WARNING!

The Brake Assist System (BAS) cannot prevent

the natural laws of physics from acting on the

vehicle, nor can it increase the traction afforded

by prevailing road conditions. BAS cannot

prevent collisions, including those resulting from

excessive speed in turns, driving on very slippery

surfaces, or hydroplaning. The capabilities of a

BAS-equipped vehicle must never be exploited in

a reckless or dangerous manner, which could

jeopardize the user's safety or the safety of

others.

WARNING!

Many factors, such as vehicle loading, road

conditions and driving conditions, influence the

chance that wheel lift or rollover may occur. ERM

cannot prevent all wheel lift or roll overs,

especially those that involve leaving the roadway

or striking objects or other vehicles. The

capabilities of an ERM-equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

6

23_WD_OM_EN_USC_t.book Page 179

Page 208 of 328

206SAFETY

Supplemental Side Air Bags

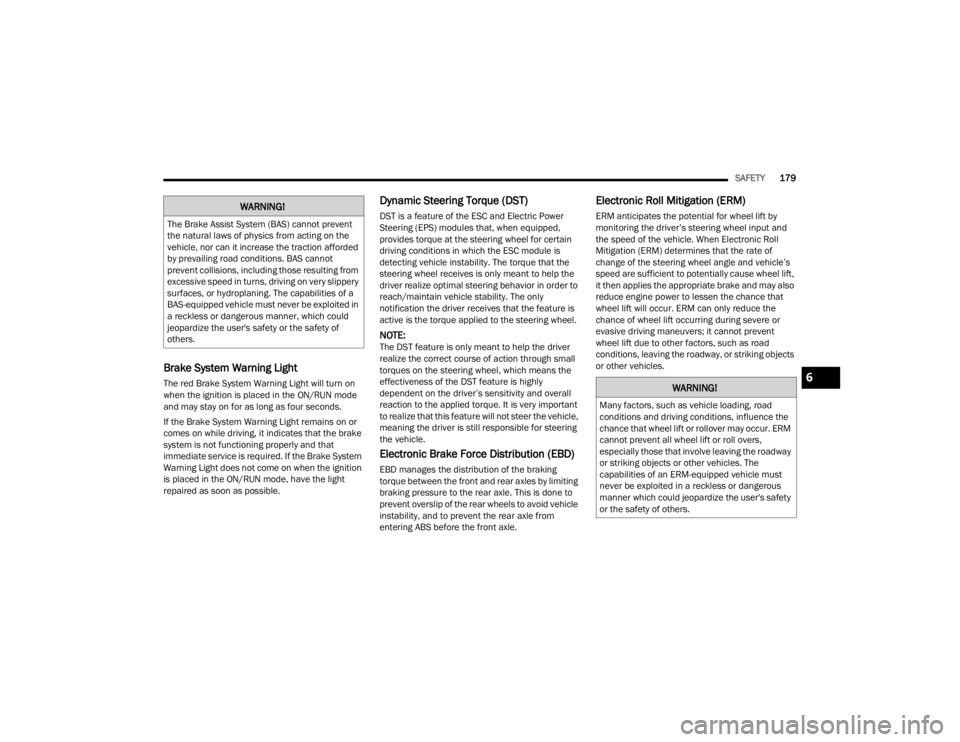

Supplemental Seat-Mounted Side Air Bags (SABs)

This vehicle is equipped with Supplemental

Seat-Mounted Side Air Bags (SABs).

Supplemental Seat-Mounted Side Air Bags (SABs)

are located in the outboard side of the front seats.

The SABs are marked with “SRS AIRBAG” or

“AIRBAG” on a label or on the seat trim on the

outboard side of the seats.

The SABs may help to reduce the risk of occupant

injury during certain side impacts, in addition to

the injury reduction potential provided by the seat

belts and body structure.

Front Supplemental Seat-Mounted Side Air Bag Label

When the SAB deploys, it opens the seam on the

outboard side of the seatback’s trim cover. The

inflating SAB deploys through the seat seam into

the space between the occupant and the door. The

SAB moves at a very high speed and with such a

high force that it could injure occupants if they are

not seated properly, or if items are positioned in

the area where the SAB inflates. Children are at an

even greater risk of injury from a deploying air bag.

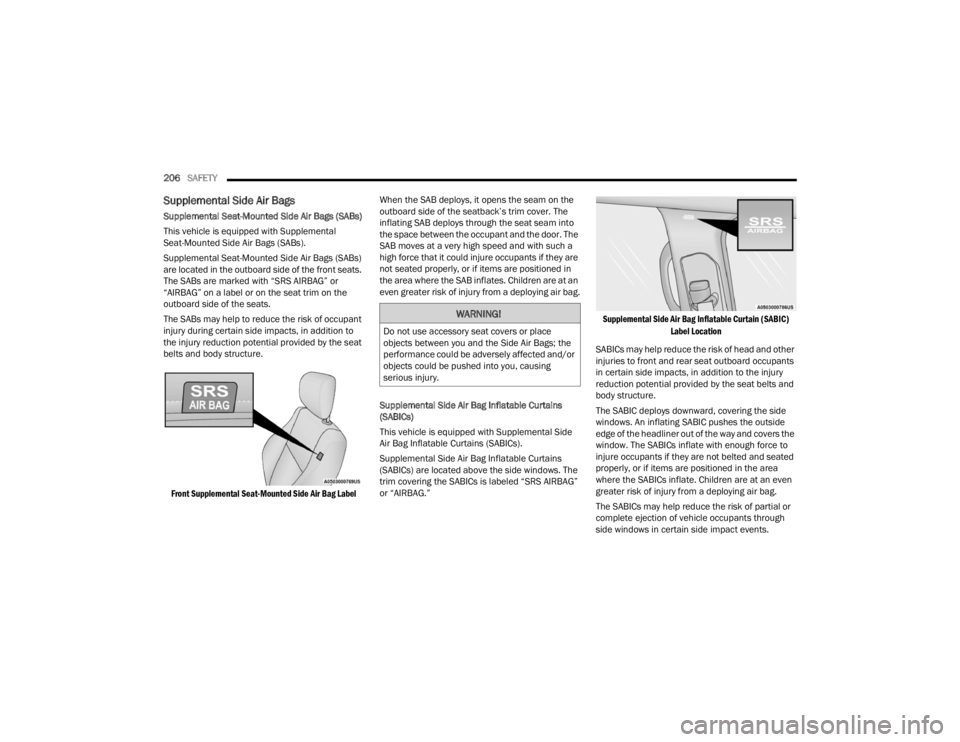

Supplemental Side Air Bag Inflatable Curtains

(SABICs)

This vehicle is equipped with Supplemental Side

Air Bag Inflatable Curtains (SABICs).

Supplemental Side Air Bag Inflatable Curtains

(SABICs) are located above the side windows. The

trim covering the SABICs is labeled “SRS AIRBAG”

or “AIRBAG.”

Supplemental Side Air Bag Inflatable Curtain (SABIC)

Label Location

SABICs may help reduce the risk of head and other

injuries to front and rear seat outboard occupants

in certain side impacts, in addition to the injury

reduction potential provided by the seat belts and

body structure.

The SABIC deploys downward, covering the side

windows. An inflating SABIC pushes the outside

edge of the headliner out of the way and covers the

window. The SABICs inflate with enough force to

injure occupants if they are not belted and seated

properly, or if items are positioned in the area

where the SABICs inflate. Children are at an even

greater risk of injury from a deploying air bag.

The SABICs may help reduce the risk of partial or

complete ejection of vehicle occupants through

side windows in certain side impact events.

WARNING!

Do not use accessory seat covers or place

objects between you and the Side Air Bags; the

performance could be adversely affected and/or

objects could be pushed into you, causing

serious injury.

23_WD_OM_EN_USC_t.book Page 206

Page 235 of 328

IN CASE OF EMERGENCY233

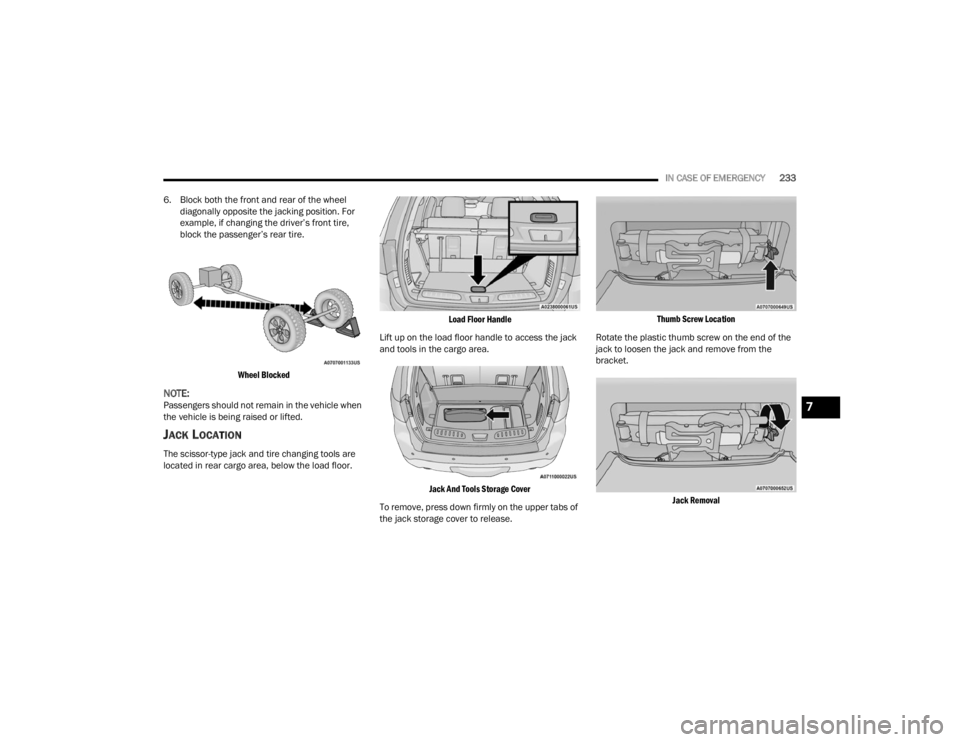

6. Block both the front and rear of the wheel diagonally opposite the jacking position. For

example, if changing the driver’s front tire,

block the passenger’s rear tire.

Wheel Blocked

NOTE:Passengers should not remain in the vehicle when

the vehicle is being raised or lifted.

JACK LOCATION

The scissor-type jack and tire changing tools are

located in rear cargo area, below the load floor.

Load Floor Handle

Lift up on the load floor handle to access the jack

and tools in the cargo area.

Jack And Tools Storage Cover

To remove, press down firmly on the upper tabs of

the jack storage cover to release.

Thumb Screw Location

Rotate the plastic thumb screw on the end of the

jack to loosen the jack and remove from the

bracket.

Jack Removal

7

23_WD_OM_EN_USC_t.book Page 233

Page 260 of 328

258SERVICING AND MAINTENANCE

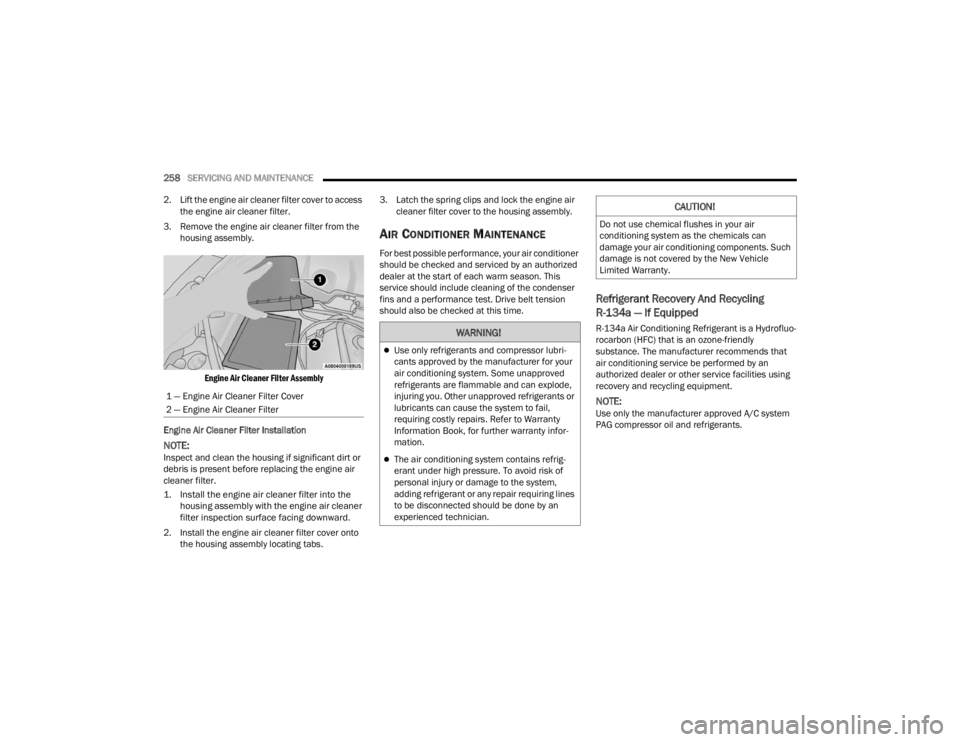

2. Lift the engine air cleaner filter cover to access the engine air cleaner filter.

3. Remove the engine air cleaner filter from the housing assembly.

Engine Air Cleaner Filter Assembly

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing if significant dirt or

debris is present before replacing the engine air

cleaner filter.

1. Install the engine air cleaner filter into the housing assembly with the engine air cleaner

filter inspection surface facing downward.

2. Install the engine air cleaner filter cover onto the housing assembly locating tabs. 3. Latch the spring clips and lock the engine air

cleaner filter cover to the housing assembly.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner

should be checked and serviced by an authorized

dealer at the start of each warm season. This

service should include cleaning of the condenser

fins and a performance test. Drive belt tension

should also be checked at this time.

Refrigerant Recovery And Recycling

R-134a — If Equipped

R-134a Air Conditioning Refrigerant is a Hydrofluo -

rocarbon (HFC) that is an ozone-friendly

substance. The manufacturer recommends that

air conditioning service be performed by an

authorized dealer or other service facilities using

recovery and recycling equipment.

NOTE:Use only the manufacturer approved A/C system

PAG compressor oil and refrigerants.

1 — Engine Air Cleaner Filter Cover

2 — Engine Air Cleaner Filter

WARNING!

Use only refrigerants and compressor lubri

-

cants approved by the manufacturer for your

air conditioning system. Some unapproved

refrigerants are flammable and can explode,

injuring you. Other unapproved refrigerants or

lubricants can cause the system to fail,

requiring costly repairs. Refer to Warranty

Information Book, for further warranty infor -

mation.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring lines

to be disconnected should be done by an

experienced technician.

CAUTION!

Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning components. Such

damage is not covered by the New Vehicle

Limited Warranty.

23_WD_OM_EN_USC_t.book Page 258

Page 262 of 328

260SERVICING AND MAINTENANCE

(Continued)

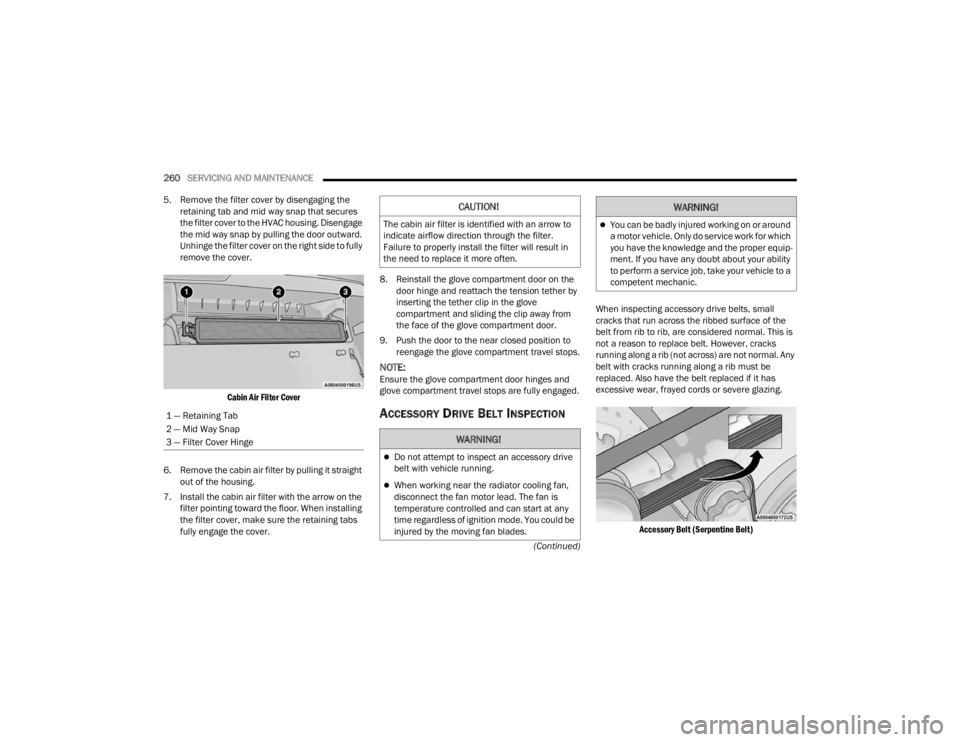

5. Remove the filter cover by disengaging the

retaining tab and mid way snap that secures

the filter cover to the HVAC housing. Disengage

the mid way snap by pulling the door outward.

Unhinge the filter cover on the right side to fully

remove the cover.

Cabin Air Filter Cover

6. Remove the cabin air filter by pulling it straight out of the housing.

7. Install the cabin air filter with the arrow on the filter pointing toward the floor. When installing

the filter cover, make sure the retaining tabs

fully engage the cover. 8. Reinstall the glove compartment door on the

door hinge and reattach the tension tether by

inserting the tether clip in the glove

compartment and sliding the clip away from

the face of the glove compartment door.

9. Push the door to the near closed position to reengage the glove compartment travel stops.

NOTE:Ensure the glove compartment door hinges and

glove compartment travel stops are fully engaged.

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts, small

cracks that run across the ribbed surface of the

belt from rib to rib, are considered normal. This is

not a reason to replace belt. However, cracks

running along a rib (not across) are not normal. Any

belt with cracks running along a rib must be

replaced. Also have the belt replaced if it has

excessive wear, frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

1 — Retaining Tab

2 — Mid Way Snap

3 — Filter Cover Hinge

CAUTION!

The cabin air filter is identified with an arrow to

indicate airflow direction through the filter.

Failure to properly install the filter will result in

the need to replace it more often.

WARNING!

Do not attempt to inspect an accessory drive

belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could be

injured by the moving fan blades.

You can be badly injured working on or around

a motor vehicle. Only do service work for which

you have the knowledge and the proper equip

-

ment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

WARNING!

23_WD_OM_EN_USC_t.book Page 260

Page 270 of 328

268SERVICING AND MAINTENANCE

(Continued)

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces-

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

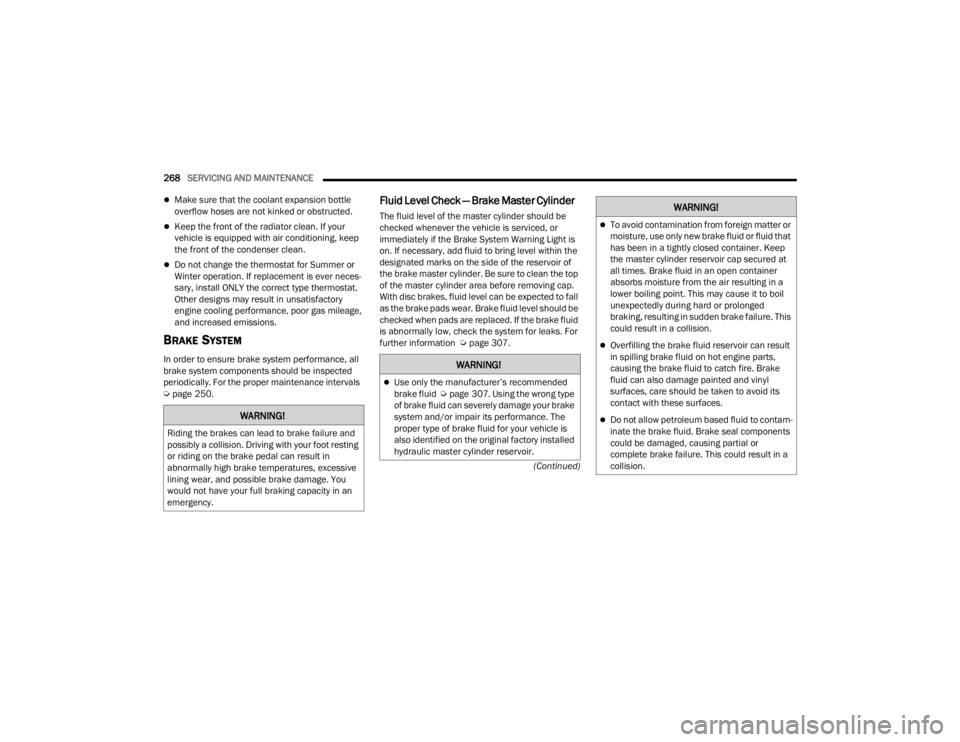

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Ú page 250.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked whenever the vehicle is serviced, or

immediately if the Brake System Warning Light is

on. If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the top

of the master cylinder area before removing cap.

With disc brakes, fluid level can be expected to fall

as the brake pads wear. Brake fluid level should be

checked when pads are replaced. If the brake fluid

is abnormally low, check the system for leaks. For

further information Ú page 307.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only the manufacturer’s recommended

brake fluid Úpage 307. Using the wrong type

of brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

23_WD_OM_EN_USC_t.book Page 268

Page 275 of 328

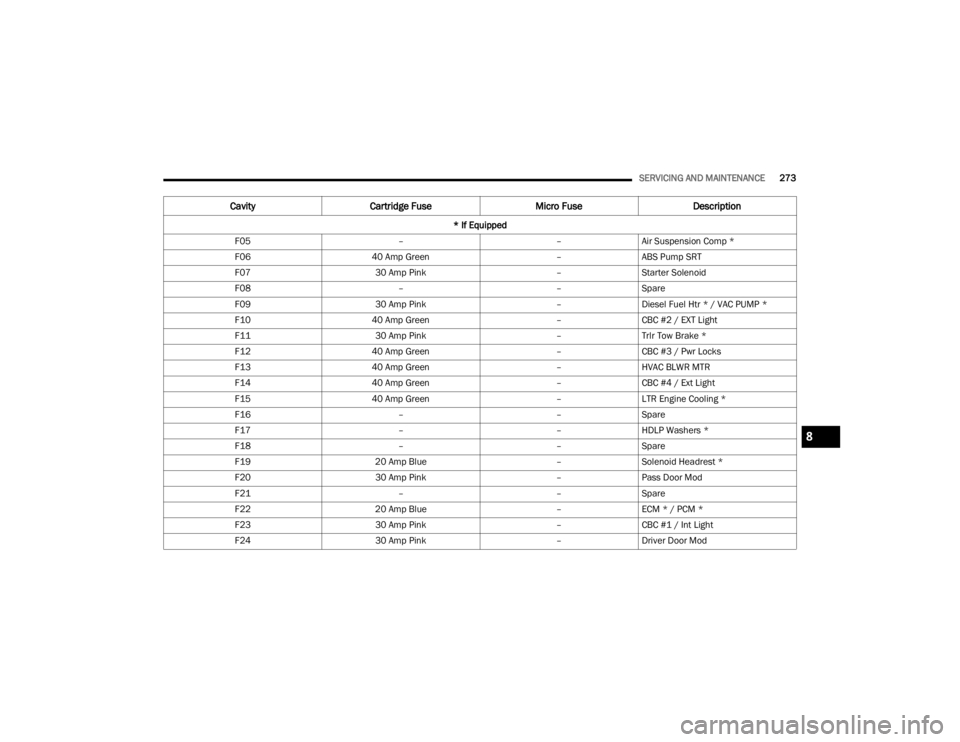

SERVICING AND MAINTENANCE273

F05 ––Air Suspension Comp *

F06 40 Amp Green –ABS Pump SRT

F07 30 Amp Pink –Starter Solenoid

F08 ––Spare

F09 30 Amp Pink –Diesel Fuel Htr * / VAC PUMP *

F10 40 Amp Green –CBC #2 / EXT Light

F11 30 Amp Pink –Trlr Tow Brake *

F12 40 Amp Green –CBC #3 / Pwr Locks

F13 40 Amp Green –HVAC BLWR MTR

F14 40 Amp Green –CBC #4 / Ext Light

F15 40 Amp Green –LTR Engine Cooling *

F16 ––Spare

F17 ––HDLP Washers *

F18 ––Spare

F19 20 Amp Blue –Solenoid Headrest *

F20 30 Amp Pink –Pass Door Mod

F21 ––Spare

F22 20 Amp Blue –ECM * / PCM *

F23 30 Amp Pink –CBC #1 / Int Light

F24 30 Amp Pink –Driver Door Mod

Cavity Cartridge Fuse Micro FuseDescription

* If Equipped

8

23_WD_OM_EN_USC_t.book Page 273

Page 283 of 328

SERVICING AND MAINTENANCE281

TIRES

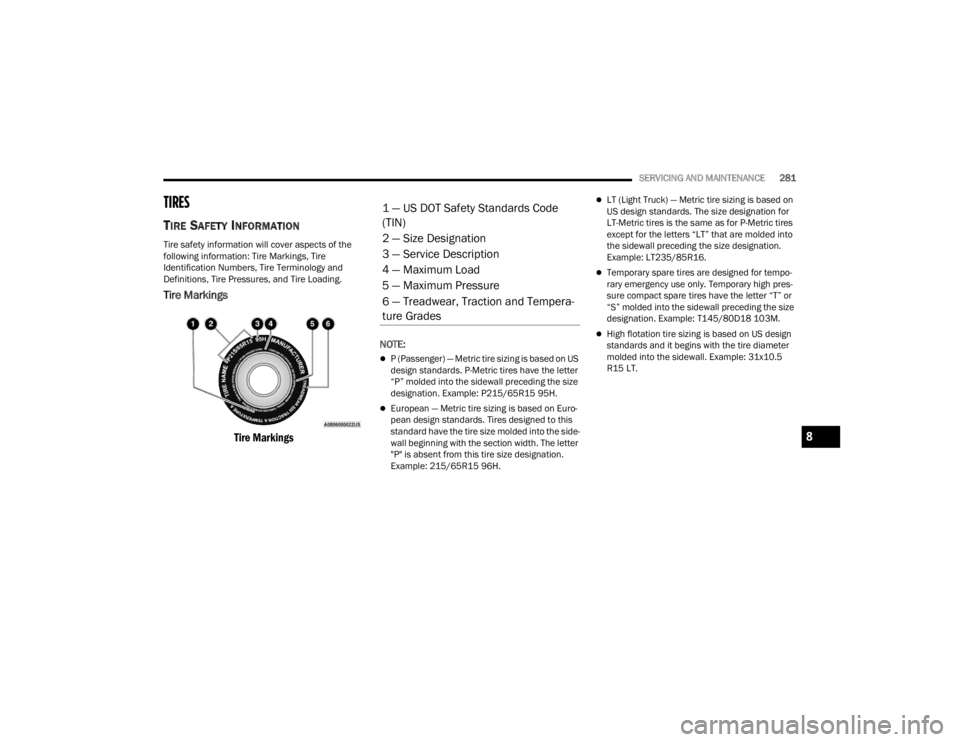

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on Euro -

pean design standards. Tires designed to this

standard have the tire size molded into the side -

wall beginning with the section width. The letter

"P" is absent from this tire size designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for tempo -

rary emergency use only. Temporary high pres -

sure compact spare tires have the letter “T” or

“S” molded into the sidewall preceding the size

designation. Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall. Example: 31x10.5

R15 LT.

1 — US DOT Safety Standards Code

(TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

8

23_WD_OM_EN_USC_t.book Page 281