DODGE DURANGO SRT 2018 Owners Manual

Manufacturer: DODGE, Model Year: 2018, Model line: DURANGO SRT, Model: DODGE DURANGO SRT 2018Pages: 568, PDF Size: 6.54 MB

Page 371 of 568

JACKING AND TIRE CHANGING

WARNING!

•Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

• Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service center

where it can be raised on a lift.

• Never start or run the engine while the vehicle is on

a jack.

• The jack is designed to be used as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should be

jacked on a firm level surface only. Avoid ice or

slippery areas.

Run Flat Tires

SRT models are equipped with “run flat” tires. Run flat

tires allow the vehicle to be driven approximately 50 miles

(80 km) at 55 mph (88 km/h). Tire service should be

obtained to avoid prolonged run flat feature usage.

WARNING!

Do not exceed 50 mph (80 km/h) if the “Tire Pressure

Monitoring Telltale Light” is illuminated. Vehicle han-

dling and braking may be reduced. You could have a

collision and be severely or fatally injured.

7

IN CASE OF EMERGENCY 369

Page 372 of 568

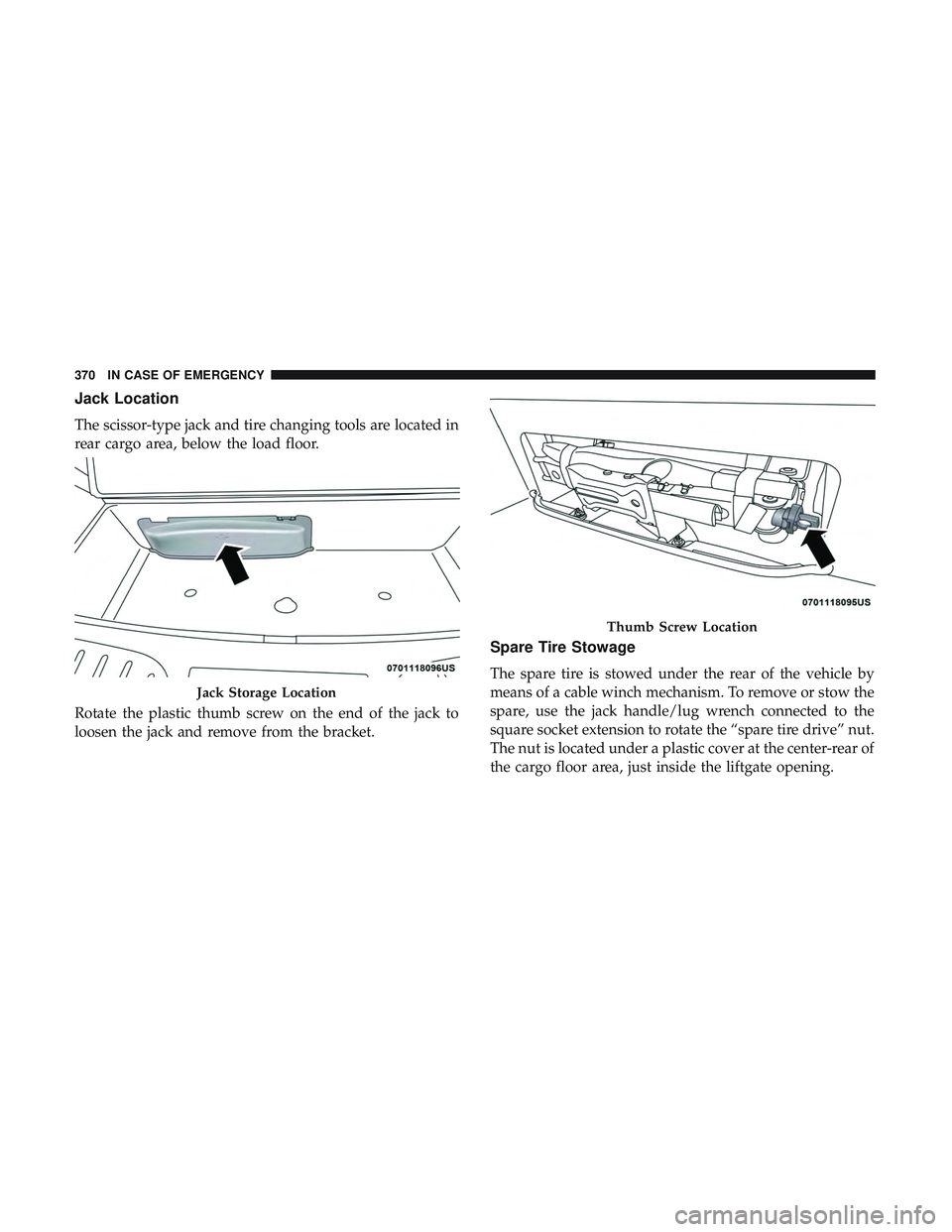

Jack Location

The scissor-type jack and tire changing tools are located in

rear cargo area, below the load floor.

Rotate the plastic thumb screw on the end of the jack to

loosen the jack and remove from the bracket.

Spare Tire Stowage

The spare tire is stowed under the rear of the vehicle by

means of a cable winch mechanism. To remove or stow the

spare, use the jack handle/lug wrench connected to the

square socket extension to rotate the “spare tire drive” nut.

The nut is located under a plastic cover at the center-rear of

the cargo floor area, just inside the liftgate opening.

Jack Storage Location

Thumb Screw Location

370 IN CASE OF EMERGENCY

Page 373 of 568

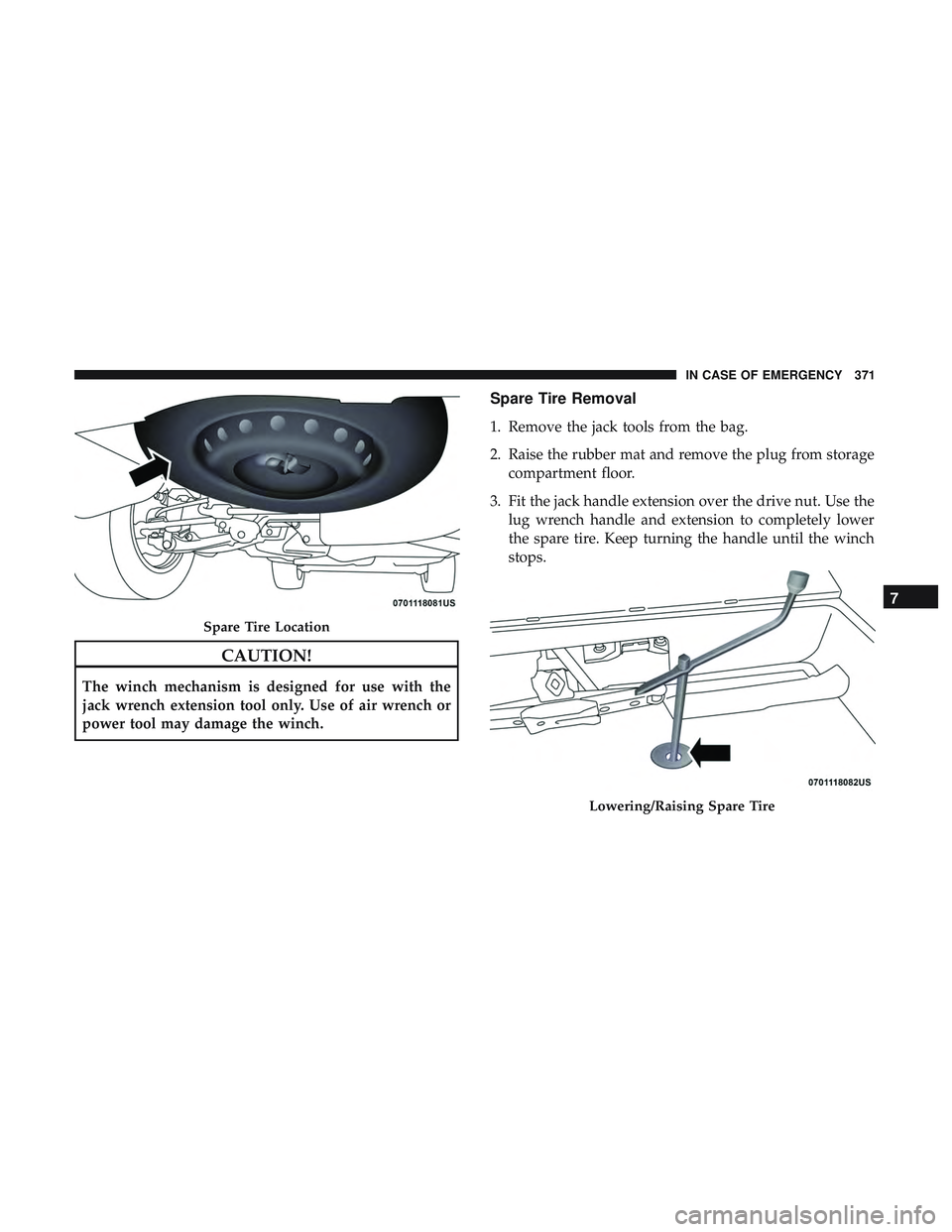

CAUTION!

The winch mechanism is designed for use with the

jack wrench extension tool only. Use of air wrench or

power tool may damage the winch.

Spare Tire Removal

1. Remove the jack tools from the bag.

2. Raise the rubber mat and remove the plug from storagecompartment floor.

3. Fit the jack handle extension over the drive nut. Use the lug wrench handle and extension to completely lower

the spare tire. Keep turning the handle until the winch

stops.

Spare Tire Location

Lowering/Raising Spare Tire

7

IN CASE OF EMERGENCY 371

Page 374 of 568

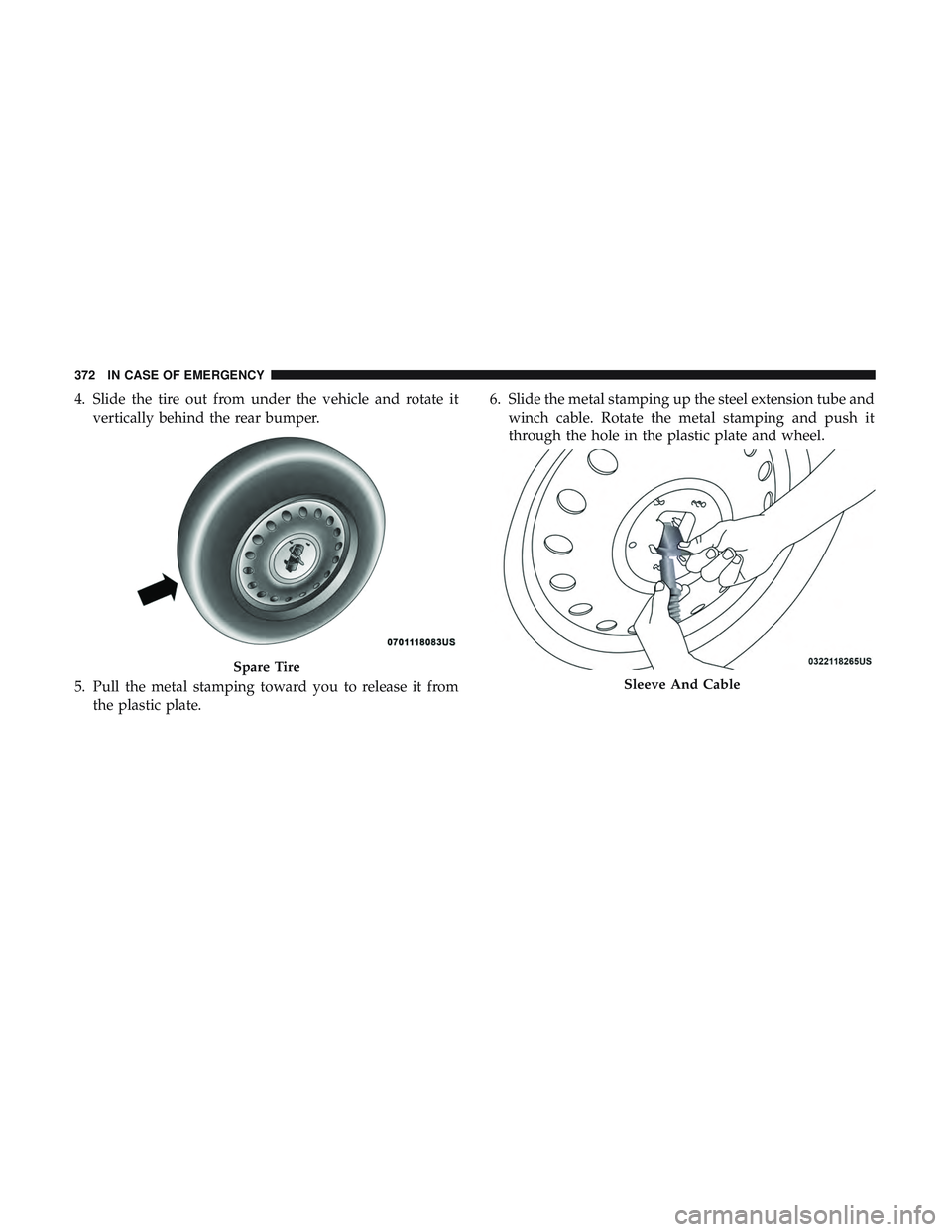

4. Slide the tire out from under the vehicle and rotate itvertically behind the rear bumper.

5. Pull the metal stamping toward you to release it from the plastic plate. 6. Slide the metal stamping up the steel extension tube and

winch cable. Rotate the metal stamping and push it

through the hole in the plastic plate and wheel.

Spare Tire

Sleeve And Cable

372 IN CASE OF EMERGENCY

Page 375 of 568

7. Pinch the three short and two long tubes to remove theprotective plate from the steel spare wheel.

Preparations For Jacking

1. Park the vehicle on a firm, level surface as far from theedge of the roadway as possible. Avoid icy or slippery

areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the

road to avoid being hit when operating the jack or

changing the wheel.

2. Turn on the Hazard Warning flashers.

3. Apply the parking brake.

4. Place the gear selector into PARK.

5. Turn OFF the ignition.

6.

Block both the front and rear of the wheel diagonally

opposite the jacking position. For example, if the right front

wheel is being changed, block the left rear wheel.

NOTE: Passengers should not remain in the

vehicle when the vehicle is being jacked.

Releasing Protective Plate

7

IN CASE OF EMERGENCY 373

Page 376 of 568

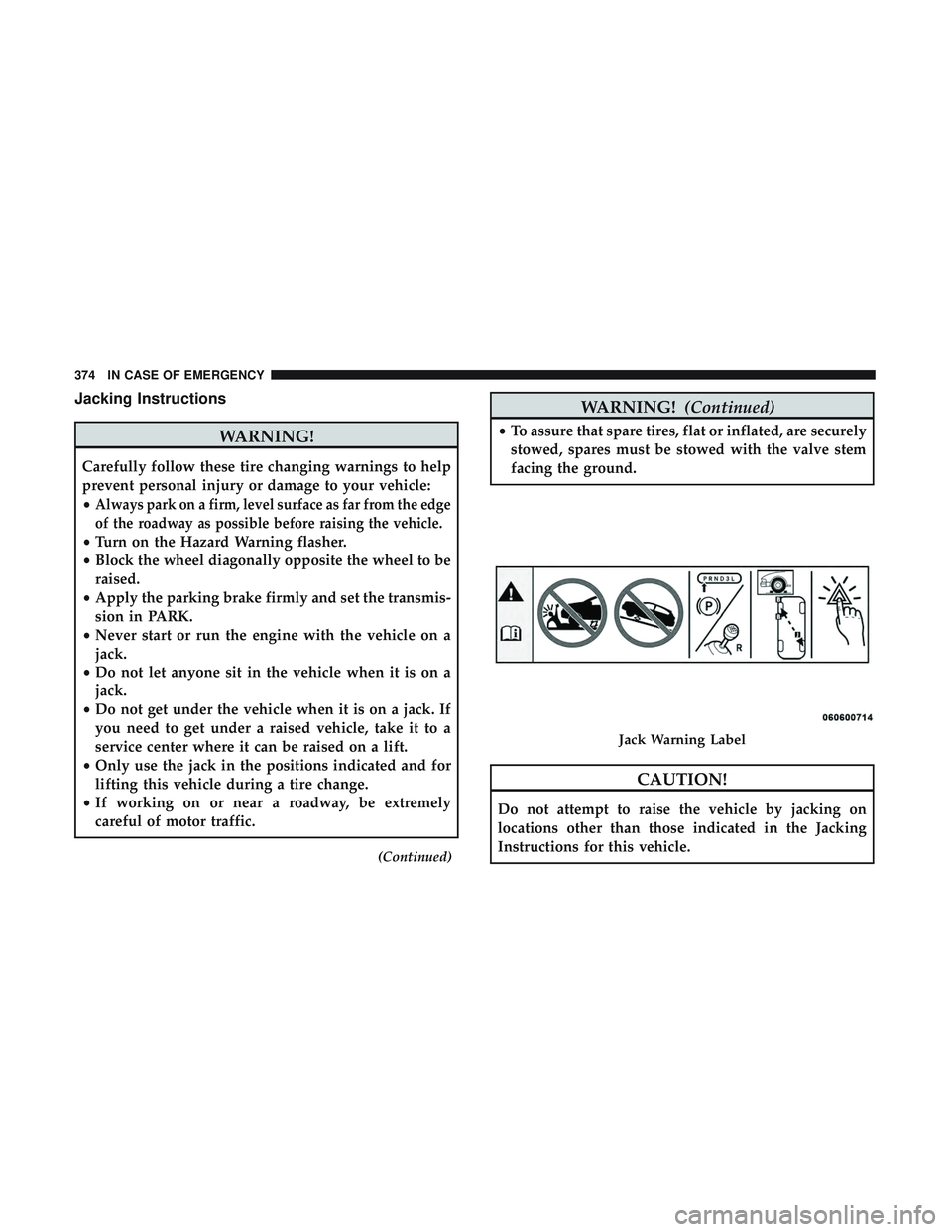

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

•

Always park on a firm, level surface as far from the edge

of the roadway as possible before raising the vehicle.

•Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be

raised.

• Apply the parking brake firmly and set the transmis-

sion in PARK.

• Never start or run the engine with the vehicle on a

jack.

• Do not let anyone sit in the vehicle when it is on a

jack.

• Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

• Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

• If working on or near a roadway, be extremely

careful of motor traffic.

(Continued)

WARNING! (Continued)

•To assure that spare tires, flat or inflated, are securely

stowed, spares must be stowed with the valve stem

facing the ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

Jack Warning Label

374 IN CASE OF EMERGENCY

Page 377 of 568

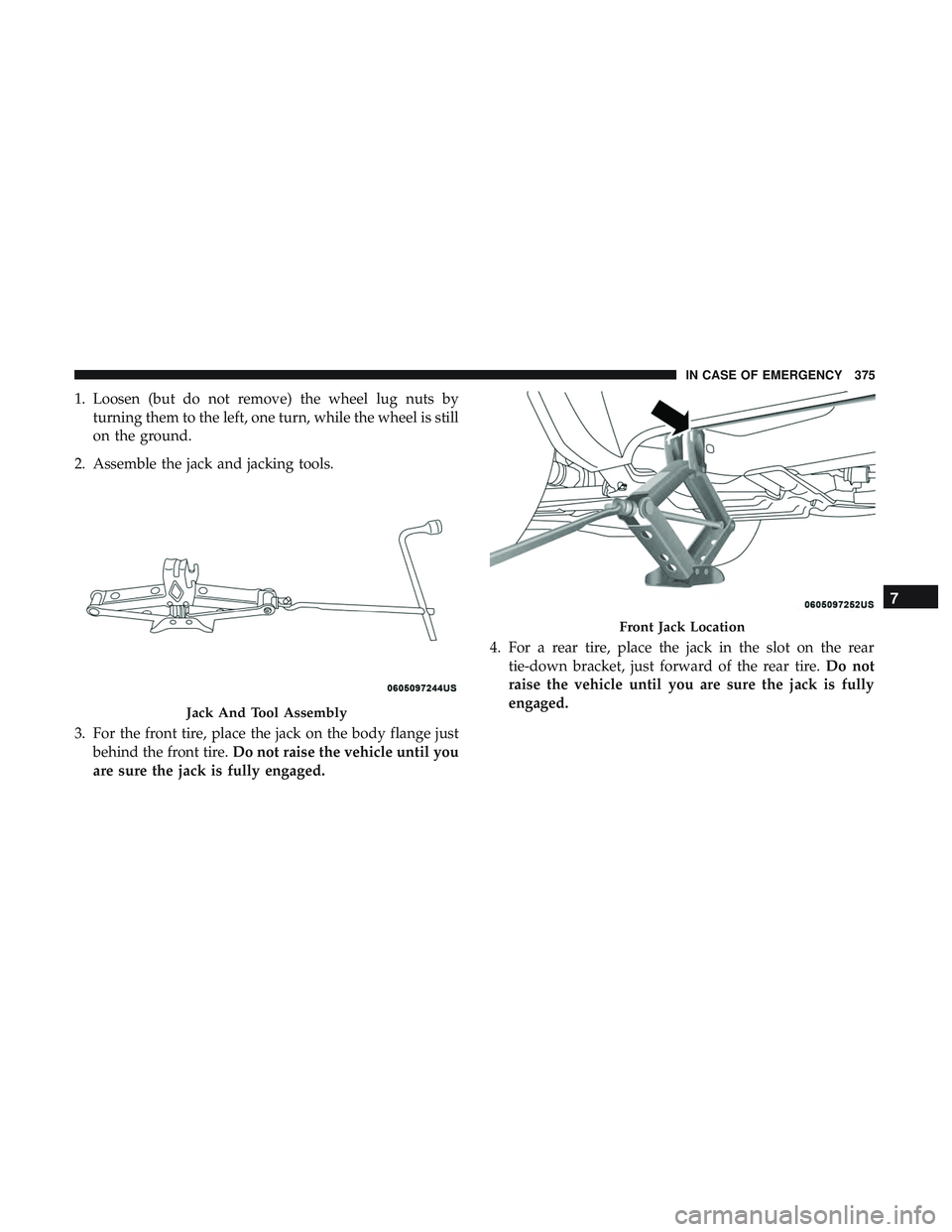

1. Loosen (but do not remove) the wheel lug nuts byturning them to the left, one turn, while the wheel is still

on the ground.

2. Assemble the jack and jacking tools.

3. For the front tire, place the jack on the body flange just behind the front tire. Do not raise the vehicle until you

are sure the jack is fully engaged. 4. For a rear tire, place the jack in the slot on the rear

tie-down bracket, just forward of the rear tire. Do not

raise the vehicle until you are sure the jack is fully

engaged.

Jack And Tool Assembly

Front Jack Location

7

IN CASE OF EMERGENCY 375

Page 378 of 568

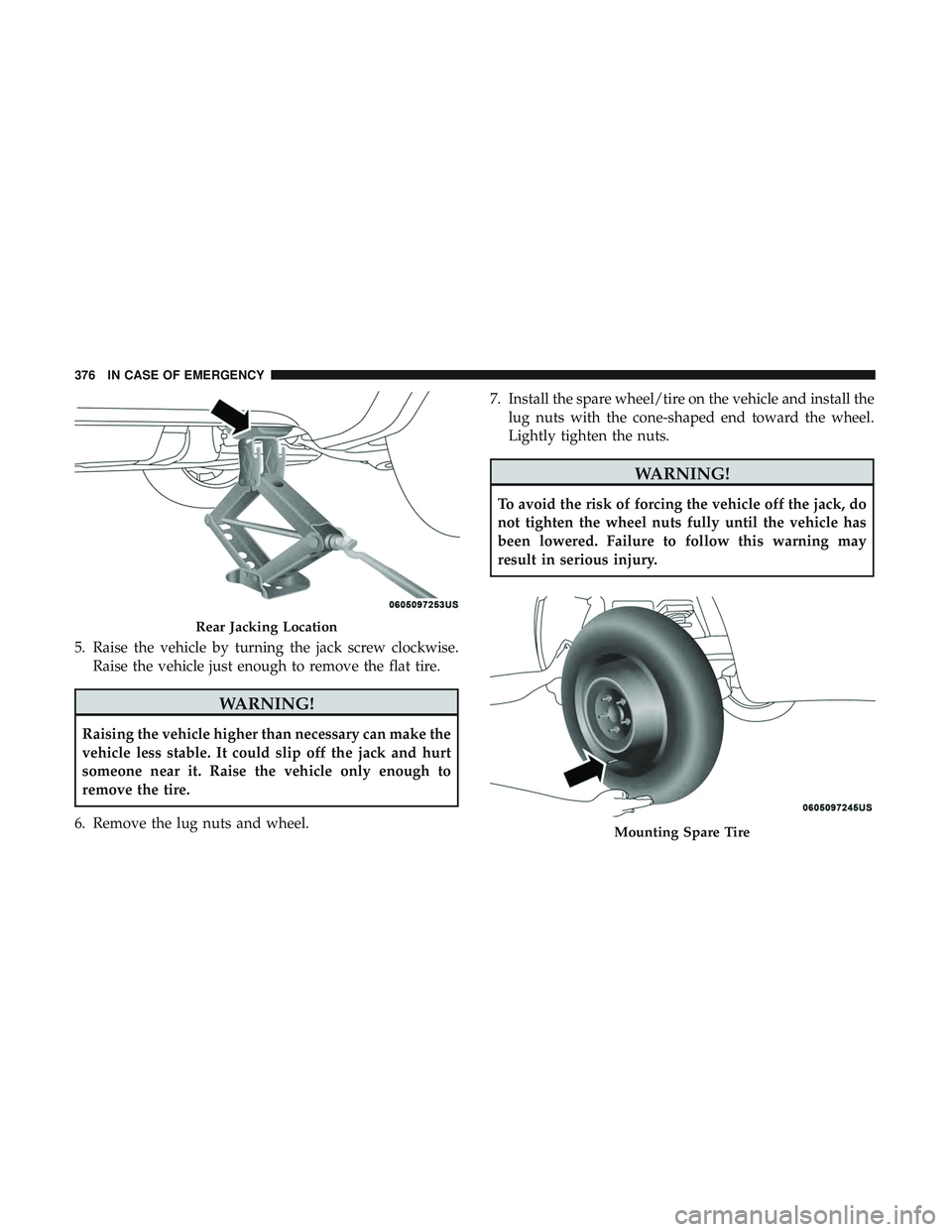

5. Raise the vehicle by turning the jack screw clockwise.Raise the vehicle just enough to remove the flat tire.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

6. Remove the lug nuts and wheel. 7. Install the spare wheel/tire on the vehicle and install the

lug nuts with the cone-shaped end toward the wheel.

Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

Rear Jacking Location

Mounting Spare Tire

376 IN CASE OF EMERGENCY

Page 379 of 568

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

8. Lower the vehicle by turning the jack screw counter- clockwise, and remove the jack and wheel blocks.

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. Refer to “Torque Specifi-

cations” in “Technical Specifications” for proper lug nut

torque. If in doubt about the correct tightness, have

them checked with a torque wrench by an authorized

dealer or at a service station.

10. Push out the small center cap using the jack tool from inside the aluminum road wheel and position the

wheel behind the rear bumper with the protective plate

facing outward. NOTE:

The plastic plate will prevent the road wheel from

being scratched when sliding it under the vehicle.

Installing Protective Plate On Damaged Wheel

7

IN CASE OF EMERGENCY 377

Page 380 of 568

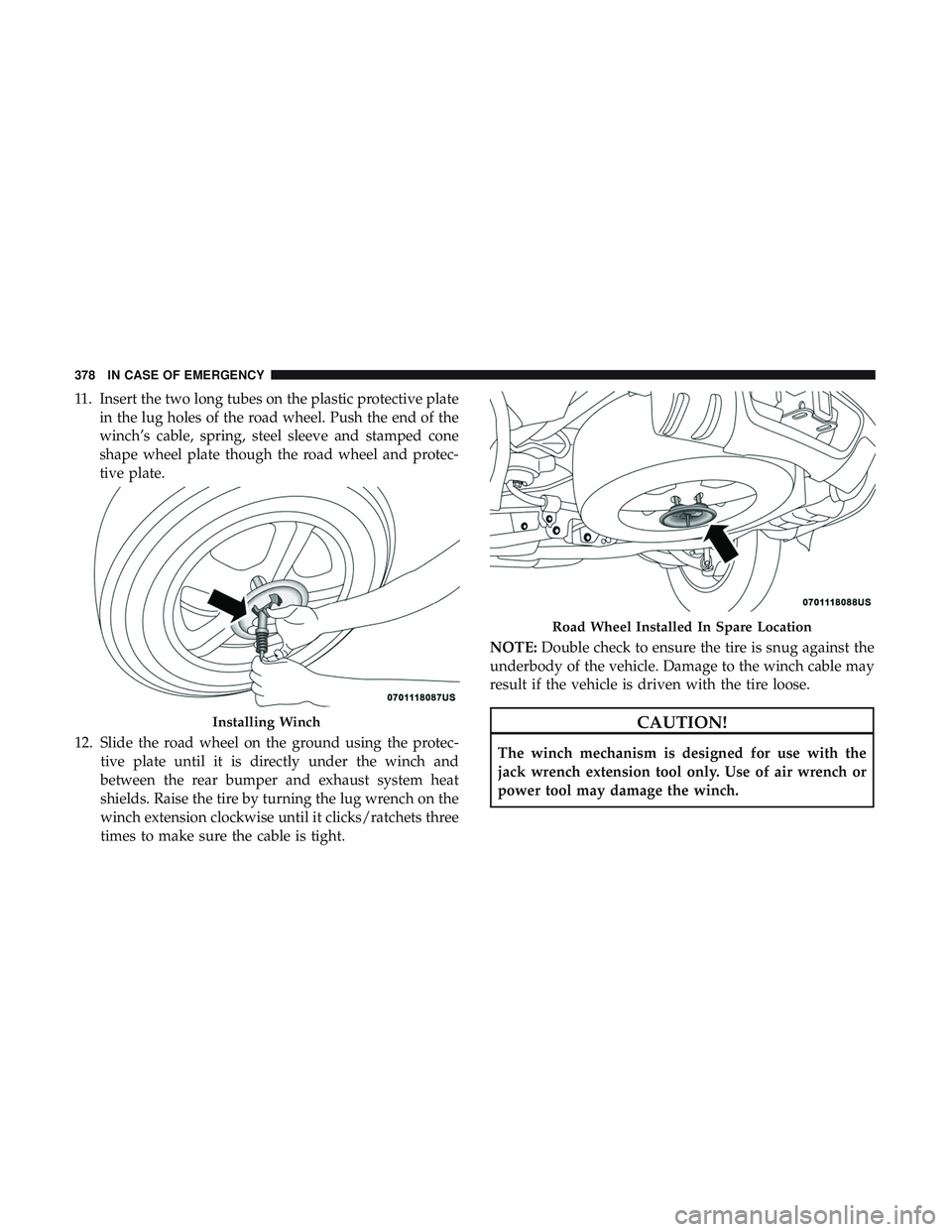

11. Insert the two long tubes on the plastic protective platein the lug holes of the road wheel. Push the end of the

winch’s cable, spring, steel sleeve and stamped cone

shape wheel plate though the road wheel and protec-

tive plate.

12. Slide the road wheel on the ground using the protec- tive plate until it is directly under the winch and

between the rear bumper and exhaust system heat

shields. Raise the tire by turning the lug wrench on the

winch extension clockwise until it clicks/ratchets three

times to make sure the cable is tight. NOTE:

Double check to ensure the tire is snug against the

underbody of the vehicle. Damage to the winch cable may

result if the vehicle is driven with the tire loose.

CAUTION!

The winch mechanism is designed for use with the

jack wrench extension tool only. Use of air wrench or

power tool may damage the winch.

Installing Winch

Road Wheel Installed In Spare Location

378 IN CASE OF EMERGENCY