wiring DODGE DURANGO SRT 2019 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2019, Model line: DURANGO SRT, Model: DODGE DURANGO SRT 2019Pages: 572, PDF Size: 6.59 MB

Page 214 of 572

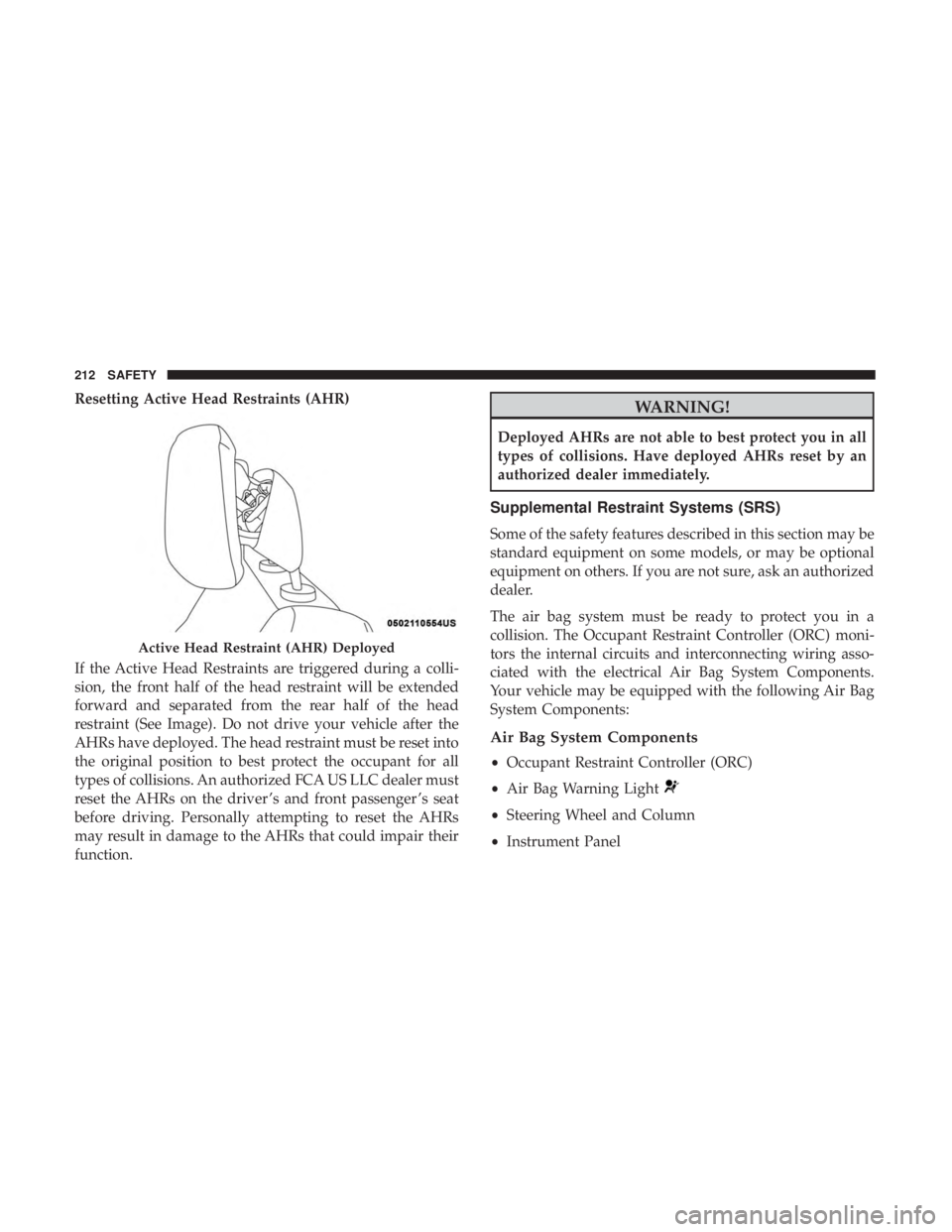

Resetting Active Head Restraints (AHR)

If the Active Head Restraints are triggered during a colli-

sion, the front half of the head restraint will be extended

forward and separated from the rear half of the head

restraint (See Image). Do not drive your vehicle after the

AHRs have deployed. The head restraint must be reset into

the original position to best protect the occupant for all

types of collisions. An authorized FCA US LLC dealer must

reset the AHRs on the driver ’s and front passenger ’s seat

before driving. Personally attempting to reset the AHRs

may result in damage to the AHRs that could impair their

function.WARNING!

Deployed AHRs are not able to best protect you in all

types of collisions. Have deployed AHRs reset by an

authorized dealer immediately.

Supplemental Restraint Systems (SRS)

Some of the safety features described in this section may be

standard equipment on some models, or may be optional

equipment on others. If you are not sure, ask an authorized

dealer.

The air bag system must be ready to protect you in a

collision. The Occupant Restraint Controller (ORC) moni-

tors the internal circuits and interconnecting wiring asso-

ciated with the electrical Air Bag System Components.

Your vehicle may be equipped with the following Air Bag

System Components:

Air Bag System Components

•Occupant Restraint Controller (ORC)

• Air Bag Warning Light

•Steering Wheel and Column

• Instrument Panel

Active Head Restraint (AHR) Deployed

212 SAFETY

Page 223 of 572

WARNING!

•Side Air Bags need room to inflate. Do not lean

against the door or window. Sit upright in the center

of the seat.

• Being too close to the Side Air Bags during deploy-

ment could cause you to be severely injured or

killed.

• Relying on the Side Air Bags alone could lead to

more severe injuries in a collision. The Side Air Bags

work with your seat belt to restrain you properly. In

some collisions, Side Air Bags won’t deploy at all.

Always wear your seat belt even though you have

Side Air Bags.

NOTE: Air bag covers may not be obvious in the interior

trim, but they will open during air bag deployment.

Rollover Events

Side Air Bags are designed to activate in certain rollover

events. The ORC determines whether the deployment of

the Side Air Bags in a particular rollover event is appro-

priate, based on the severity and type of collision. Vehicle

damage by itself is not a good indicator of whether or not

Side Air Bags should have deployed. The Side Air Bags will not deploy in all rollover events. The

rollover sensing system determines if a rollover event may

be in progress and whether deployment is appropriate. In

the event the vehicle experiences a rollover or near rollover

event, and deployment of the Side Air Bags is appropriate,

the rollover sensing system will also deploy the seat belt

pretensioners on both sides of the vehicle.

The SABICs may help reduce the risk of partial or complete

ejection of vehicle occupants through side windows in

certain rollover or side impact events.

Air Bag System Components

NOTE:

The Occupant Restraint Controller (ORC) monitors

the internal circuits and interconnecting wiring associated

with electrical Air Bag System Components listed below:

• Occupant Restraint Controller (ORC)

• Air Bag Warning Light

•Steering Wheel and Column

• Instrument Panel

• Knee Impact Bolsters

• Driver and Front Passenger Air Bags

• Seat Belt Buckle Switch

5

SAFETY 221

Page 226 of 572

Enhanced Accident Response System Reset

Procedure

In order to reset the Enhanced Accident Response System

functions after an event, the ignition switch must be

changed from ignition START or ON/RUN to ignition OFF.

Carefully check the vehicle for fuel leaks in the engine

compartment and on the ground near the engine compart-

ment and fuel tank before resetting the system and starting

the engine.

Maintaining Your Air Bag System

WARNING!

•Modifications to any part of the air bag system could

cause it to fail when you need it. You could be

injured if the air bag system is not there to protect

you. Do not modify the components or wiring, in-

cluding adding any kind of badges or stickers to the

steering wheel hub trim cover or the upper passenger

side of the instrument panel. Do not modify the front

bumper, vehicle body structure, or add aftermarket

side steps or running boards.

(Continued)

WARNING! (Continued)

•It is dangerous to try to repair any part of the air bag

system yourself. Be sure to tell anyone who works on

your vehicle that it has an air bag system.

• Do not attempt to modify any part of your air bag

system. The air bag may inflate accidentally or may

not function properly if modifications are made.

Take your vehicle to an authorized dealer for any air

bag system service. If your seat, including your trim

cover and cushion, needs to be serviced in any way

(including removal or loosening/tightening of seat

attachment bolts), take the vehicle to an authorized

dealer. Only manufacturer approved seat accessories

may be used. If it is necessary to modify the air bag

system for persons with disabilities, contact an au-

thorized dealer.

Event Data Recorder (EDR)

This vehicle is equipped with an event data recorder

(EDR). The main purpose of an EDR is to record, in certain

crash or near crash-like situations, such as an air bag

deployment or hitting a road obstacle, data that will assist

in understanding how a vehicle’s systems performed. The

EDR is designed to record data related to vehicle dynamics

224 SAFETY

Page 346 of 572

The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the left to activate

power to the trailer’s electric brakes independent of the

tow vehicle’s brakes. If the manual brake control lever is

activated while the brake is also applied, the greater of the

two inputs determines the power sent to the trailer brakes.

The trailer and the vehicle’s brake lamps will come on

when either vehicle braking or manual trailer brakes are

applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical connection status.

If no electrical connection is detected after the ignition is

turned on, pushing the GAIN adjustment button or sliding

the manual brake control lever will display the GAIN

setting for 10 seconds and the “Trailer Brake Status Indi-

cator Light” will not be displayed.

If a fault is detected in the trailer wiring or the Integrated

Trailer Brake Module (ITBM), the “Trailer Brake Status

Indicator Light” will flash.GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake control power

output to the trailer brakes in 0.5 increments. The GAIN

setting can be increased to a maximum of 10 or decreased

to a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake control for

the specific towing condition and should be changed as

towing conditions change. Changes to towing conditions

include trailer load, vehicle load, road conditions and

weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately 20–25 mph

(30–40 km/h).

1. Make sure the trailer brakes are in good working condition, functioning normally and properly adjusted.

See your trailer dealer if necessary.

2. Hook up the trailer and make the electrical connections according to the trailer manufacturer’s instructions.

344 STARTING AND OPERATING

Page 348 of 572

CAUTION!

Connecting a trailer that is not compatible with the

ITBM system may result in reduced or complete loss of

trailer braking. There may be a increase in stopping

distance or trailer instability which could result in

damage to your vehicle, trailer, or other property.

NOTE:

• An aftermarket controller may be available for use with

trailers with air or electric-over-hydraulic trailer brake

systems. To determine the type of brakes on your trailer

and the availability of controllers, check with your

trailer manufacturer or dealer.

• Removal of the ITBM will cause errors and it may cause

damage to the electrical system and electronic modules

of the vehicle. See your authorized dealer if an aftermar-

ket module is to be installed.

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-pin

wiring harness. Use a factory approved trailer harness and

connector.

NOTE: Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector. Refer

to the following illustrations.

NOTE:

• Disconnect trailer wiring connector from the vehicle

before launching a boat (or any other device plugged

into vehicle’s electrical connect) into water.

• Be sure to reconnect once clear from water area.

346 STARTING AND OPERATING

Page 365 of 572

3. Disconnect the electrical connector and replace the bulb.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

Front Fog Lamps

1. Reach through the cutout in the splash shield and rotatethe bulb’s electrical connector one-quarter turn counter-

clockwise and remove it from the fog lamp housing.

2. Remove the bulb from the connector and install the replacement bulb.

3. Install the bulb and connector assembly into the fog lamp housing and rotate the connector one-quarter turn

clockwise to lock it in place.

CAUTION!

• Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

(Continued)

CAUTION! (Continued)

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

• Always use the correct bulb size and type for replace-

ment. An incorrect bulb size or type may overheat

and cause damage to the lamp, the socket or the lamp

wiring.

Rear Tail, Stop And Turn Signal Lamps

The rear tail, stop, and turn signal lamps are LED. See your

authorized dealer for replacement.

Rear Liftgate Mounted Back-up Lamps

1. Raise the liftgate.

2. Use a fiber stick or flat blade screw driver to pry the lower trim from the liftgate.

3. Back-up lamps are now visible. Rotate socket(s) counter clockwise.

4. Remove/replace bulb(s).

5. Reinstall the socket(s).

6. Reverse process to reinstall the liftgate trim.

7

IN CASE OF EMERGENCY 363

Page 569 of 572

Tire Safety Information...................... .424

Tongue Weight/Trailer Weight .................340

To Open Hood ........................... .104

Towing ................................. .335

Behind A Motorhome ..................... .349

Guide ................................ .338

Recreational ........................... .349

Weight ............................... .338

Towing Behind A Motorhome ..................349

Traction ................................ .349

Traction Control .......................... .174

Trailer Sway Control (TSC) ....................179

Trailer Towing ............................ .335

Cooling System Tips ..................... .348

Hitches ............................... .337

Minimum Requirements ....................341

Tips ................................. .347

Trailer And Tongue Weight ..................340

Wiring ............................... .346

Trailer Towing Guide ....................... .338

Trailer Weight ............................ .338

Transfer Case ............................ .423

Electronically Shifted ..................... .281

Maintenance ........................... .423

Transmission ............................. .269Automatic

......................... .269, 421

Maintenance ........................... .421

Shifting .............................. .267

Transmitter, Garage Door Opener (Homelink) ......109

Transporting Pets ......................... .250

Tread Wear Indicators ...................... .436

Turn Signals ....................... .163, 362, 363

Uconnect Settings Customer Programmable Features ...........35, 40

Passive Entry Programming ...............35, 40

Uniform

Tire Quality Grades ..................445

Universal Transmitter ....................... .109

Untwisting Procedure, Seat Belt ................204

Vanity Mirrors .............................69

Vehicle Identification Number (VIN) .............454

Vehicle Loading ....................... .333, 430

Vehicle Modifications/Alterations .................6

Vehicle Security Alarm ........................32

Vehicle Storage .............................96

Vehicle User Guide In Vehicle Help ...........................17

Navigation ..............................17

Operating Instructions ......................17

12

INDEX 567

Page 571 of 572

INSTALLATION OF RADIO TRANSMITTING

EQUIPMENT

Special design considerations are incorporated into this

vehicle’s electronic system to provide immunity to radio

frequency signals. Mobile two-way radios and telephone

equipment must be installed properly by trained person-

nel. The following must be observed during installation.

The positive power connection should be made directly

to the battery and fused as close to the battery as possible.

The negative power connection should be made to body

sheet metal adjacent to the negative battery connection.

This connection should not be fused.

Antennas for two-way radios should be mounted on the

roof or the rear area of the vehicle. Care should be used

in mounting antennas with magnet bases. Magnets may

affect the accuracy or operation of the compass on

vehicles so equipped.

The antenna cable should be as short as practical and

routed away from the vehicle wiring when possible. Use

only fully shielded coaxial cable.

Carefully match the antenna and cable to the radio to

ensure a low Standing Wave Ratio (SWR).Mobile radio equipment with output power greater than

normal may require special precautions.

All installations should be checked for possible interfer-

ence between the communications equipment and the

vehicle’s electronic systems.

WARNING:

Operating, servicing and maintaining a

passenger vehicle or off-road highway

motor vehicle can expose you to chemicals

including engine exhaust, carbon monoxide,

phthalates, and lead, which are known to

the State of California to cause cancer and

birth defects or other reproductive harm.

To minimize exposure, avoid breathing

exhaust, do not idle the engine except as

necessary, service your vehicle in a

well-ventilated area and wear gloves or

wash your hands frequently when servicing

your vehicle. For more information go to

www.P65Warnings.ca.gov/passenger-vehicle.