lock DODGE GRAND CARAVAN 2013 5.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2013, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2013 5.GPages: 132, PDF Size: 4.51 MB

Page 75 of 132

Sound Horn With Lock

• To turn the horn chirp on or off when the doors are locked:• Press the LOCK button for at least four seconds, but no longer than 10 seconds. Then,

press the PANIC button while still holding the LOCK button.

• Release both buttons at the same time.

Flashing Lights With Lock

• The turn signal lights flashing, when the doors are locked or unlocked, feature can be turned on or off. To turn this feature on or off:•

Press and hold the UNLOCK button for at least four seconds, but no longer than 10 sec-

onds. Then, press and hold the LOCK button while still holding the UNLOCK button.

• Release both buttons at the same time.

UNIVERSAL GARAGE DOOR OPENER (HomeLink®)

•HomeLink® replaces up to three hand-held transmitters that operate devices such as

garage door openers, motorized gates, lighting or home security systems. The HomeLink®

unit is powered by your vehicles 12 Volt battery.

• The HomeLink® buttons that are located in the overhead console or sunvisor designate the three different HomeLink® channels.

• The HomeLink® indicator is located above the center button.

Before You Begin Programming HomeLink®

• Ensure that your vehicle is parked outside of the garage before you begin program-

ming.

• For efficient programming and accurate transmission of the radio-frequency sig-

nal, it is recommended that a new battery

be placed in the hand-held transmitter of

the device that is being programmed to

the HomeLink® system.

• Erase all channels before you begin pro- gramming. To erase the channels, place the ignition switch into the ON/RUN position,

then press and hold the two outside HomeLink® buttons (I and III) for up to 20 seconds or

until the red indicator flashes.

NOTE:

Erasing all channels should only be performed when programming HomeLink® for the first

time. Do not erase channels when programming additional buttons.

• If you have any problems, or require assistance, please call toll-free 1–800–355–3515 or, on the Internet at www.HomeLink.com for information or assistance.

ELECTRONICS

73

Page 77 of 132

• Press and hold the programmed HomeLink® button and observe the indicator light.

NOTE:• If the indicator light stays on constantly, programming is complete and the garagedoor (or device) should activate when the HomeLink® button is pressed.

• To program the two remaining HomeLink® buttons, repeat each step for each remain- ing button. DO NOT erase the channels.

Using HomeLink®

• To operate, press and release the programmed HomeLink® button. Activation will now occur for the programmed device (i.e., garage door opener, gate operator, security

system, entry door lock, home/office lighting, etc.,). The hand-held transmitter of the

device may also be used at any time.

WARNING!

• Your motorized door or gate will open and close while you are programming the universal transceiver. Do not program the transceiver if people or pets are in the path

of the door or gate.

• Do not run your vehicle in a closed garage or confined area while programming the

transceiver. Exhaust gas from your vehicle contains Carbon Monoxide (CO) which is

odorless and colorless. Carbon Monoxide is poisonous when inhaled and can cause

you and others to be severely injured or killed.

POWER INVERTER

• There is a 115 Volt, 150 Watt power inverteroutlet located on the left rear trim panel

immediately behind the second row left

passenger seat. This outlet can power

cellular phones, electronics and other

low power devices requiring power up to

150 Watts.

• Press the switch located in the center of the instrument panel to turn the power to

the outlet on.

• Press the switch again to turn the power off.

• The status indicator of the AC power inverter indicates whether the inverter is producing AC power.

ELECTRONICS

75

Page 80 of 132

IN-FLOOR STORAGE – STOW'N GO®

Second Row Seat Storage Bins

• Storage bins are located in the floor in front of the second row seats that can be usedwhen the second row seat is in the upright position. Pull up on the storage bin latch to

open the cover. Slide the storage bin locking mechanism to the "Lock" position to allow

greater access to the storage bin.

Cargo Area Storage

• The liftgate sill plate has a raised line with the statement “Load To This Line”. This line indicates how far rearward cargo can be placed without interfering with liftgate closing.

WARNING!

In a collision, serious injury could result if the seat storage bin covers are not properly

latched. Do not drive the vehicle with the storage bin covers open. Keep the storage bin

covers closed and latched while the vehicle is in motion. Do not use a storage bin latch

as a tie down.

ROOF LUGGAGE RACK

•The crossbars on your vehicle are delivered

stowed within the roof rack side rails. When

installed, the roof rack can hold a maxi-

mum of 150 lbs (68 kg) of evenly distributed

weight.

Installing The Crossbars

•

To install the crossbars, completely loosen

the thumb screws at both ends and lift the

crossbar from its stowed position.

• Bend the pivot points at each end of the crossbar and slide the thumb screw down.

• Set the crossbars into position and tighten the thumb screws.

NOTE:

Make sure the directional arrow on the crossbar aligns with the directional arrow on the side

rail.

• Refer to the Owner's Manual on the DVD for further details.

UTILITY

78

Page 84 of 132

BRAKE- Brake Warning Light

• The Brake Warning light illuminates when there is either a system malfunction or the parking brake is applied. If the light is on and the parking brake is not applied, it indicates

a possible brake hydraulic malfunction, brake booster problem or an Anti-Lock Brake

System problem.

• Please have your vehicle serviced immediately.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system may

have failed. It will take longer to stop the vehicle. You could have a collision. Have the

vehicle checked immediately.

- Malfunction Indicator Light (MIL)

• Certain conditions, such as a loose or missing gas cap, poor fuel quality, etc., may illuminate the MIL after engine start. The vehicle should be serviced if the light stays on

through several typical driving cycles. In most situations, the vehicle will drive normally

and not require towing.

• If the MIL flashes when the engine is running, serious conditions may exist that could lead to immediate loss of power or severe catalytic converter damage. We recommend

you do not operate the vehicle. Have the vehicle serviced immediately.

- Electronic Stability Control (ESC) OFF Indicator Light

• This light indicates the Electronic Stability Control (ESC) is off.

- Charging System Light

•

This light shows the status of the electrical charging system. If the charging system light

remains on, it means that the vehicle is experiencing a problem with the charging system.

• We recommend you do not continue driving if the charging system light is on. Have the vehicle serviced immediately.

- Oil Pressure Warning Light

•

This light indicates low engine oil pressure. If the light turns on while driving, stop the vehicle

and shut off the engine as soon as possible. A chime will sound when this light turns on.

• We recommend you do not operate the vehicle or engine damage will occur. Have the vehicle serviced immediately.

- Anti-Lock Brake (ABS) Light

• This light monitors the Anti-Lock Brake System (ABS).

• If the light is not on during starting, stays on, or turns on while driving, we recommend you drive to the nearest authorized dealer immediately and have the vehicle serviced

immediately.

WHAT TO DO IN EMERGENCIES

82

Page 85 of 132

- Electronic Throttle Control (ETC) Indicator Light

• This light informs you of a problem with the system.

• If a problem is detected, the light will come on while the engine is running. Cycle the ignition when the vehicle has completely stopped and the shift lever is placed in the

PARK position; the light should turn off.

• If the light remains lit with the engine running, your vehicle will usually be drivable; however, see an authorized dealer immediately. If the light is flashing when the engine is

running, immediate service is required and you may experience reduced performance,

an elevated/rough idle or engine stall and your vehicle may require towing.

- Air Bag Warning Light

• If the light is not on during starting, stays on, or turns on while driving, have the vehicle serviced by an authorized dealer immediately.

Fuel Cap/Loose Gas Cap Message

• If a “gas cap” message (shown as gASCAP) appears, tighten the gas cap until a “clicking” sound is heard.

• Press the odometer reset button, located below the tachometer, to turn the message off.

• If the message continues to appear for more than three days after tightening the gas cap, see your authorized service center.

“CHANGE OIL” MESSAGE

• If a “Change Oil” message appears and a single chime sounds, it is time for your next required oil change.

Resetting The Light After Servicing

Vehicles Equipped With Keyless Enter-N-Go™

• Without pressing the brake pedal, push the ENGINE START/STOP button and cycle theignition to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Without pressing the brake pedal, push the ENGINE START/STOP button once to return the ignition to the OFF/LOCK position.

Vehicles Not Equipped With Keyless Enter-N-Go™

• Turn the ignition switch to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator

system did not reset. If necessary, repeat this procedure.

WHAT TO DO IN EMERGENCIES

83

Page 91 of 132

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn OFF the ignition.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

• Block both the front and rear of the wheeldiagonally opposite the jacking position.

For example, if changing the right front

tire, block the left rear wheel.

Jacking Instructions

1. Loosen (but do not remove) the wheel lug nuts by turning them to the left one turn

while the wheel is still on the ground.

WHAT TO DO IN EMERGENCIES

89

Page 94 of 132

Securing The Spare Tire

1. Assemble the winch handle extensions to form a T-handle and fit the winch T-handle overthe drive nut. Rotate the nut to the left until the winch mechanism stops turning freely.

This will allow enough slack in the cable to allow you to pull the wheel spacer out from

under the vehicle.

2. Assemble the winch handle extensions to form the spare tire hook, and pull the wheel spacer from under the vehicle.

3. Turn the compact spare tire so that the valve stem is down, and place the tire into the spare tire/cover assembly. Slide the wheel spacer through the center of the wheel and

spare tire/cover assembly, so that the two retainer tabs snap out and engage the spare

tire cover on the opposite side.

4. Using the winch T-handle, rotate the drive nut to the right until the compact spare tire/cover assembly is drawn into place against the underside of the vehicle.

5. Continue to rotate the nut to the right until you hear the winch mechanism click three times. It cannot be overtightened. Check under the vehicle to ensure the compact spare

tire/cover assembly is positioned correctly against the underside of the vehicle.

Road Tire Installation

Vehicles Equipped With Wheel Covers

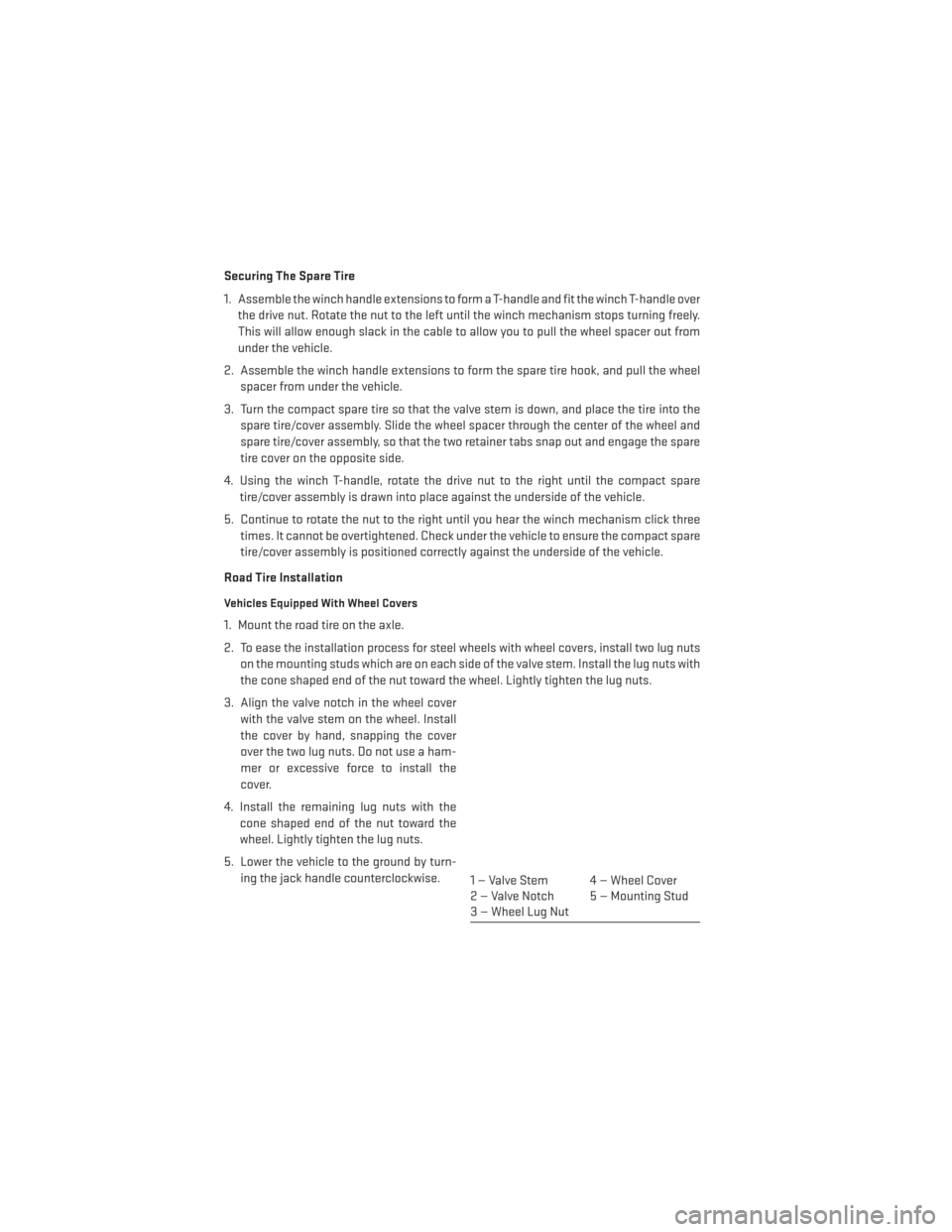

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts on the mounting studs which are on each side of the valve stem. Install the lug nuts with

the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two lug nuts. Do not use a ham-

mer or excessive force to install the

cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by turn- ing the jack handle counterclockwise.

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut

WHAT TO DO IN EMERGENCIES

92

Page 95 of 132

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle forincreased leverage. Tighten the lug nuts in a star pattern until each nut has been

tightened twice. The correct tightness of each lug nut is 102 ft/lbs (138 N·m). If in doubt

about the correct tightness, have them checked with a torque wrench by your authorized

dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut has been

tightened twice. The correct tightness of each lug nut is 102 ft/lbs (138 N·m). If in doubt

about the correct tightness, have them checked with a torque wrench by your authorized

dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

CAUTION!

• The winch mechanism is designed for use with the winch T-handle only. Use of air wrench or other power tools is not recommended and can damage the winch.

• Do not attempt to raise the vehicle by jacking on locations other than those indicated

in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle could

be damaged if the spare tire is mounted incorrectly.

• The compact spare tire/cover assembly must be used when the compact spare tire is

stored. Failure to use this cover could drastically reduce the life of the compact spare

tire.

• The winch mechanism is designed specifically to stow a compact spare tire only. Do

not attempt to use the winch to stow the full size flat tire, or any other full-size tire.

Vehicle damage may result.

WHAT TO DO IN EMERGENCIES

93

Page 96 of 132

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pullfar enough off the road to avoid the danger of being hit when operating the jack or

changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the jack and

fall on you. You could be crushed. Never put any part of your body under a vehicle that

is on a jack. If you need to get under a raised vehicle, take it to a service center where

it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack should not

be used to lift the vehicle for service purposes. The vehicle should be jacked on a firm

level surface only. Avoid ice or slippery areas.

• Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible

before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK; a manual

transmission in REVERSE.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire

change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

• Raising the vehicle higher than necessary can make the vehicle less stable. It could

slip off the jack and hurt someone near it. Raise the vehicle only enough to remove

the tire.

• To avoid the risk of forcing the vehicle off the jack, do not tighten the wheel nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

personal injury.

• A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired or replaced immediately.

• Verify that both retainer tabs of the wheel spacer have been properly extended

through the center of the wheel and spare tire/cover assembly. Failure to properly

engage both retainer tabs could result in loss of the spare tire and cover assembly,

which will cause vehicle damage and may cause loss of vehicle control.

WHAT TO DO IN EMERGENCIES

94

Page 97 of 132

JUMP-STARTING

• If your vehicle has a discharged battery itcan be jump-started using a set of jumper

cables and a battery in another vehicle or

by using a portable battery booster pack.

• Jump-starting can be dangerous if done improperly so please follow the proce-

dures in this section carefully.

NOTE:

When using a portable battery booster pack

follow the manufacturer’s operating instruc-

tions and precautions.

Preparations for Jump-Start

• The battery in your vehicle is located on the left side of the engine compartment.

• Set the parking brake, shift the automatic transmission into PARK and turn the ignition to LOCK.

• Turn off the heater, radio, and all unnecessary electrical accessories.

• If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

Jump-Starting Procedure

• Connect the positive (+)end of the jumper cable to the positive (+)post of the discharged

vehicle.

• Connect the opposite end of the positive (+)jumper cable to the positive (+)post of the

booster battery.

• Connect the negative end (-)of the jumper cable to the negative (-)post of the booster

battery.

• Connect the opposite end of the negative (-)jumper cable to a good engine ground

(exposed metal part of the discharged vehicle's engine) away from the battery and fuel

injection system.

• Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery.

Once the engine is started, remove the jumper cables in the reverse sequence:

• Disconnect the negative (-)jumper cable from the negative (-)post of the vehicle with the

discharged battery.

• Disconnect the negative end (-)of the jumper cable from the negative (-)post of the

booster battery.

WHAT TO DO IN EMERGENCIES

95