wheel size DODGE GRAND CARAVAN 2017 5.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2017, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2017 5.GPages: 530, PDF Size: 5.01 MB

Page 409 of 530

•Vehicle Identification Number (VIN)

• Type of vehicle

• Month Day and Hour of Manufacture (MDH)

The bar code allows a computer scanner to read the VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your vehicle.

This includes driver, passengers, and cargo. The total load

must be limited so that you do not exceed the GVWR.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front and rear

axles. Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either front or

rear GAWR.

WARNING!

Because the front wheels steer the vehicle, it is impor-

tant that you do not exceed the maximum front or rear

GAWR. A dangerous driving condition can result if

either rating is exceeded. You could lose control of the

vehicle and have a collision.

Tire Size

The tire size on the Vehicle Certification Label represents

the actual tire size on your vehicle. Replacement tires must

be equal to the load capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire size

listed.

Inflation Pressure

This is the cold tire inflation pressure for your vehicle for

all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total weight

of the vehicle with all fluids, including vehicle fuel, at full

capacity conditions, and with no occupants or cargo loaded

into the vehicle. The front and rear curb weight values are

determined by weighing your vehicle on a commercial

scale before any occupants or cargo are added.

5

STARTING AND OPERATING 407

Page 412 of 530

If equipped, the electronic Trailer Sway Control (TSC)

recognizes a swaying trailer and automatically applies

individual wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue weight,

just as if it were luggage located at a hitch ball or some

other connecting point of the vehicle. These kinds of

hitches are the most popular on the market today and they

are commonly used to tow small and medium sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying leverage

through spring (load) bars. They are typically used for

heavier loads to distribute trailer tongue weight to the tow

vehicle’s front axle and the trailer axle(s). When used in

accordance with the manufacturer’s directions, it provides

for a more level ride, offering more consistent steering and

brake control thereby enhancing towing safety. The addi-

tion of a friction/hydraulic sway control also dampenssway caused by traffic and crosswinds and contributes

positively to tow vehicle and trailer stability. Trailer sway

control and a weight distributing (load equalizing) hitch

are recommended for heavier Tongue Weights (TW) and

may be required depending on vehicle and trailer

configuration/loading to comply with Gross Axle Weight

Rating (GAWR) requirements.

WARNING!

•

An improperly adjusted Weight Distributing Hitch

system may reduce handling, stability, braking per-

formance, and could result in a collision.

• Weight Distributing Systems may not be compatible

with Surge Brake Couplers. Consult with your hitch

and trailer manufacturer or a reputable Recreational

Vehicle dealer for additional information.

410 STARTING AND OPERATING

Page 433 of 530

6. Replace the Sealant Bottle (1) and Sealant Hose (6)assembly at your Authorized Dealer as soon as possible.

Refer to (F) “Sealant Bottle and Hose Replacement”.

NOTE: When having the tire serviced, advise the Autho-

rized Dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the bottle and dispose of it

accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (6) aligns with the hose slot in the front

of the housing. Push the bottle into the housing. An

audible click will be heard indicating the bottle is locked

into place. 6. Verify that the cap is installed on the fitting at the end of

the Sealant Hose (6) and return the hose to its storage

area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.

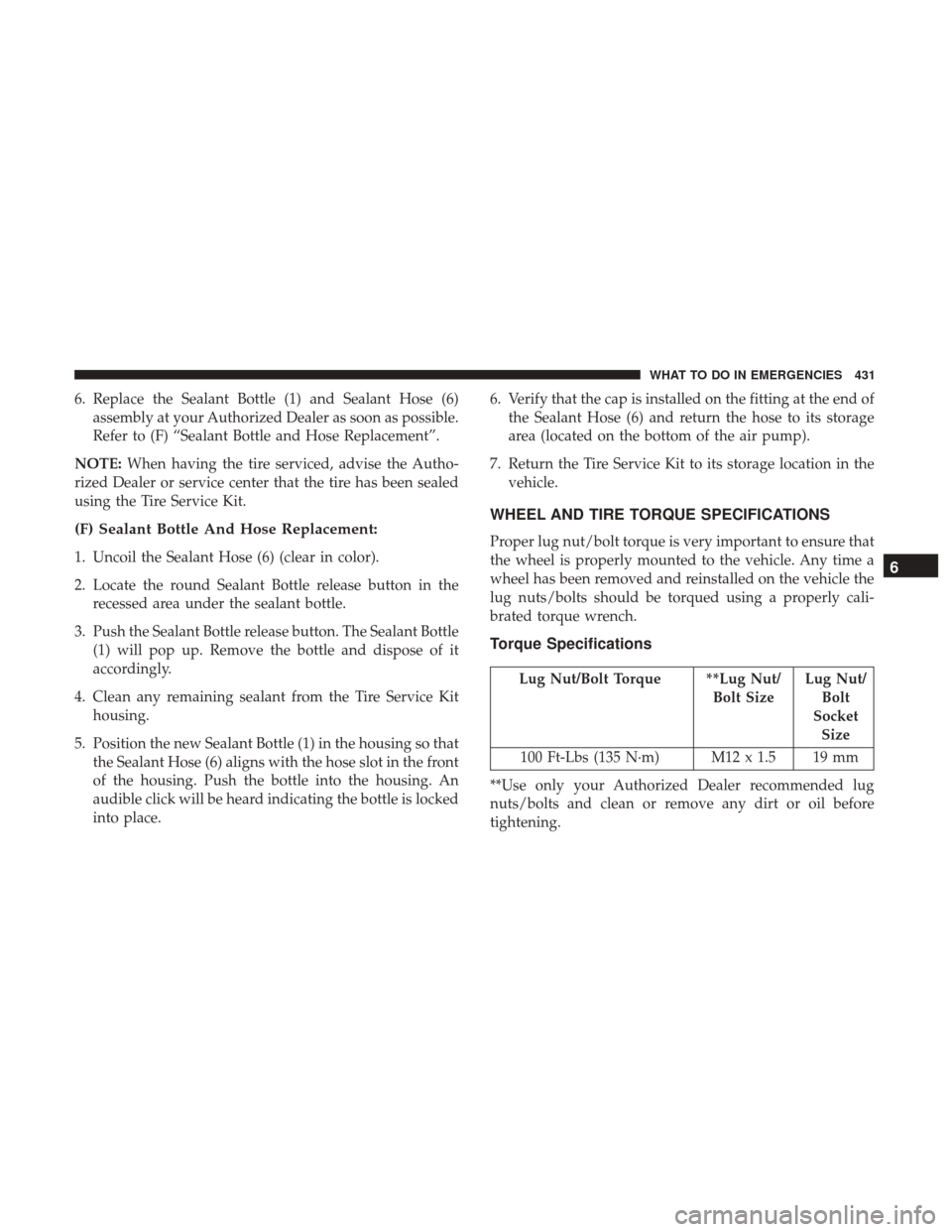

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle the

lug nuts/bolts should be torqued using a properly cali-

brated torque wrench.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/ Bolt SizeLug Nut/

Bolt

Socket Size

100 Ft-Lbs (135 N·m) M12 x 1.5 19 mm

**Use only your Authorized Dealer recommended lug

nuts/bolts and clean or remove any dirt or oil before

tightening.

6

WHAT TO DO IN EMERGENCIES 431

Page 446 of 530

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

NOTE: Do not install the wheel cover on the compact

spare.

7. Lower the vehicle by turning the jack screw to the left.

8. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. For correct lug nut torque

refer to Torque Specifications in this section. If in doubt

about the correct tightness, have them checked with a

torque wrench by your Authorized Dealer or at a service

station.

9. Lower the jack to its fully-closed position.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

10. Place the deflated (flat) tire and compact spare tire cover assembly in the rear cargo area. Do not stow the

deflated tire in the compact spare tire location. Have

the full-sized tire repaired or replaced, as soon as

possible.

11. Stow the cable and wheel spacer before driving the vehicle. Reassemble the winch handle extensions to

form a “T” and fit the winch T-handle over the drive

nut. Rotate the nut to the right until the winch mecha-

nism clicks at least three times.

NOTE: Refer to the “Spare Tire Tools” section for instruc-

tions on assembling the T-handle.

12. Stow the jack, jack handle and winch handle tools back in the stowage compartment.

444 WHAT TO DO IN EMERGENCIES

Page 448 of 530

CAUTION!(Continued)

this cover could drastically reduce the life of the

compact spare tire.

4. Using the winch T-handle, rotate the drive nut to the right until the compact spare tire/cover assembly is

drawn into place against the underside of the vehicle.

5. Continue to rotate the nut to the right until you hear the winch mechanism click three times. It cannot be over-

tightened. Check under the vehicle to ensure the com-

pact spare tire/cover assembly is positioned correctly

against the underside of the vehicle.

CAUTION!

The winch mechanism is designed specifically to stow

a compact spare tire only. Do not attempt to use the

winch to stow the full size deflated tire, or any other

full-size tire, as the tire may not be held securely.

Vehicle damage may result.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle. 2. To ease the installation process for steel wheels with

wheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut toward

the wheel. Lightly tighten the lug nuts.

Tire And Wheel Cover Or Center Cap

1 — Mounting Stud 4 — Wheel Cover

2 — Wheel Lug Nut 5 — Valve Stem

3 — Valve Notch

446 WHAT TO DO IN EMERGENCIES

Page 526 of 530

Starting Procedures........................ .342

Steering Power ............................... .356

Tilt Column ............................180

Wheel, Heated ..........................181

Wheel, Tilt ............................ .180

Steering Wheel Audio Controls .................321

Steering Wheel Mounted Sound System Controls . . . .321

Storage ................................. .490

Storage Bin ...............................214

Storage, Vehicle ........................337, 490

Storing Your Vehicle ........................490

Stow N Go (Fold in Floor) Seats ................151

Sunglasses Storage ..........................195

Sun Roof ............................... .204

Supplemental Restraint System - Air Bag ...........60

Sway Control, Trailer ........................368

Synthetic Engine Oil ........................465

System, Remote Starting ......................23

Telescoping Steering Column ..................180

Temperature Control, Automatic (ATC) ...........329

Tilt Steering Column ........................180

Tire And Loading Information Placard ........374, 375

Tire Markings ............................ .368Tires..........................

.95, 379, 383, 390

Aging (Life Of Tires) ..................... .387

Air Pressure ........................ .374, 379

Chains ............................... .388

Changing ............................. .433

Compact Spare ..........................384

General Information ...................379, 383

High Speed ............................ .381

Inflation Pressures ........................380

Jacking ............................433, 439

Life Of Tires ............................387

Load Capacity .......................374, 376

Pr

essure Monitor System (TPMS) .............391

Pressure Warning Light ....................254

Quality Grading ........................ .390

Radial ............................... .381

Replacement ............................387

Rotation ...............................389

Safety ............................ .368, 379

Sizes .................................370

Snow Tires ............................ .382

Spare Tire .......................383, 385, 434

Spinning ...............................386

Trailer Towing .......................... .415

Tread Wear Indicators .....................386

524 INDEX