inflation pressure DODGE HORNET 2023 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: HORNET, Model: DODGE HORNET 2023Pages: 288, PDF Size: 14.2 MB

Page 7 of 288

5

TRAILER TOWING............................................................. 121Common Towing Definitions .................................... 121

Trailer Towing Weights

(Maximum Trailer Weight Ratings) .......................... 122Trailer And Tongue Weight ....................................... 123

Towing Requirements .............................................. 123

Towing Tips ............................................................... 125

RECREATIONAL TOWING (BEHIND MOTORHOME) .... 126 Towing This Vehicle Behind Another Vehicle .......... 126

Recreational Towing ................................................. 127

DRIVING TIPS ................................................................... 127 Driving On Slippery Surfaces.................................... 127

Driving Through Water ............................................. 128

MULTIMEDIA

UCONNECT SYSTEMS ..................................................... 129

CYBERSECURITY ............................................................. 129

UCONNECT SETTINGS ..................................................... 130Customer Programmable Features ......................... 130

STEERING WHEEL AUDIO CONTROLS —

IF EQUIPPED .................................................................... 150 Steering Wheel Rotary Control ................................. 150Controls on Central Tunnel....................................... 151

MY CAR ............................................................................. 151

PERFORMANCE PAGES .................................................. 152 Technical Gauges...................................................... 152Consumption History ................................................ 152Accessory Gauges ..................................................... 153

RADIO OPERATION AND MOBILE PHONES .................. 153 Regulatory And Safety Information .......................... 153

SAFETY

SAFETY FEATURES .......................................................... 154Anti-Lock Brake System (ABS) ................................ 154

Electronic Brake Control (EBC) System .................. 155

AUXILIARY DRIVING SYSTEMS ...................................... 159 Blind Spot Monitoring (BSM) —

If Equipped ................................................................ 159Forward Collision Warning (FCW)

With Mitigation — If Equipped .................................. 162

Tire Pressure Monitoring System (TPMS) ............... 165

OCCUPANT RESTRAINT SYSTEMS ............................... 168 Occupant Restraint Systems Features ................... 168

Important Safety Precautions .................................. 168

Seat Belt Systems .................................................... 169

Supplemental Restraint Systems (SRS).................. 175

Child Restraints ........................................................ 188

SAFETY TIPS .................................................................... 199 Transporting Passengers ......................................... 199

Transporting Pets .................................................... 199

Connected Vehicles .................................................. 199Safety Checks You Should Make Inside

The Vehicle ............................................................... 200Periodic Safety Checks You Should Make Outside

The Vehicle ................................................................ 201Exhaust Gas .............................................................. 202

Carbon Monoxide Warnings ..................................... 202

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS ......................................203

SOS SYSTEM — IF EQUIPPED.......................................... 203

JACKING AND TIRE CHANGING —

IF EQUIPPED

b

...............................................................206

Preparations For Jacking ......................................... 206

Jack And Tools Location/Spare Tire Stowage —

If Equipped................................................................. 207

Jacking Instructions ................................................. 208

TIRE INFLATOR KIT — IF EQUIPPED

b

........................211

Description................................................................. 211

Inflation Procedure.................................................... 212

Checking And Restoring Tire Pressure..................... 214

Sealant Cartridge Replacement ............................... 214

JUMP STARTING ...............................................................215 Preparations For Jump Start..................................... 215

Jump Starting Procedure .......................................... 216

REFUELING IN EMERGENCY ........................................... 217

IF YOUR ENGINE OVERHEATS ........................................218

GEAR SELECTOR OVERRIDE .......................................... 218

FREEING A STUCK VEHICLE ........................................... 219

TOWING A DISABLED VEHICLE.......................................220 Without The Key Fob ................................................. 221

All-Wheel Drive (AWD) Models ................................. 221

Tow Eye — If Equipped .............................................. 221

ENHANCED ACCIDENT RESPONSE

SYSTEM (EARS) ...............................................................222

EVENT DATA RECORDER (EDR)......................................222

23_GG_OM_EN_USC_t.book Page 5

Page 78 of 288

76GETTING TO KNOW YOUR INSTRUMENT PANEL

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer on

the vehicle placard or tire inflation pressure label. If your

vehicle has tires of a different size than the size indicated

on the vehicle placard or tire inflation pressure label, you

should determine the proper tire inflation pressure for

those tires.

As an added safety feature, your vehicle has been equipped

with a TPMS that illuminates a low tire pressure telltale

when one or more of your tires is significantly underinflated.

Accordingly, when the low tire pressure telltale illuminates,

you should stop and check your tires as soon as possible,

and inflate them to the proper pressure. Driving on a

significantly underinflated tire causes the tire to overheat

and can lead to tire failure. Underinflation also reduces fuel

efficiency and tire tread life, and may affect the vehicle’s

handling and stopping ability.

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver’s responsibility to

maintain correct tire pressure, even if underinflation has

not reached the level to trigger illumination of the TPMS

low tire pressure telltale. Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon subsequent

vehicle start-ups as long as the malfunction exists. When

the malfunction indicator is illuminated, the system may

not be able to detect or signal low tire pressure as

intended. TPMS malfunctions may occur for a variety of

reasons, including the installation of replacement or

alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the TPMS

malfunction telltale after replacing one or more tires or

wheels on your vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to continue to

function properly.

Towing Hook Breakdown Warning Light —

If Equipped

This light illuminates when there is a failure

with the tow hook. Contact an authorized

dealer for service.

Traffic Sign Recognition (TSR) Fault

Warning Light

This light will illuminate to indicate a TSR fault.

Contact an authorized dealer if the light

remains on after restarting the engine.

Transmission Temperature Warning Light

This warning light will illuminate to warn of a

high transmission fluid temperature. This may

occur with strenuous usage such as trailer

towing. If this light turns on, stop the vehicle

and run the engine at idle or slightly faster, with the

transmission in PARK or NEUTRAL, until the light turns off.

Once the light turns off, you may continue to drive

normally.

CAUTION!

Do not continue driving with one or more flat tires as

handling may be compromised. Stop the vehicle,

avoiding sharp braking and steering. If a tire puncture

occurs, repair immediately using the dedicated tire

repair kit and contact an authorized dealer as soon

as possible.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system

operation or sensor damage may result when using

replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Using aftermarket tire sealants may

cause the Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended that you

take your vehicle to an authorized dealer to have your

sensor function checked.

WARNING!

If you continue operating the vehicle when the

Transmission Temperature Warning Light is illuminated

you could cause the fluid to boil over, come in contact

with hot engine or exhaust components and cause a

fire.

23_GG_OM_EN_USC_t.book Page 76

Page 123 of 288

STARTING AND OPERATING121

Inflation Pressure

This is the cold tire inflation pressure for your vehicle for

all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total weight

of the vehicle with all fluids, including vehicle fuel, at full

capacity conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb weight

values are determined by weighing your vehicle on a

commercial scale before any occupants or cargo are

added.

Loading

The actual total weight and the weight of the front and rear

of your vehicle at the ground can best be determined by

weighing it when it is loaded and ready for operation.

The entire vehicle should first be weighed on a commercial

scale to ensure that the GVWR has not been exceeded.

The weight on the front and rear of the vehicle should then

be determined separately to be sure that the load is

properly distributed over the front and rear axle. Weighing

the vehicle may show that the GAWR of either the front or

rear axles has been exceeded but the total load is within

the specified GVWR. If so, weight must be shifted from

front to rear or rear to front as appropriate until the

specified weight limitations are met. Store the heavier

items down low and be sure that the weight is distributed

equally. Stow all loose items securely before driving.

Improper weight distributions can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.

TRAILER TOWING

In this section you will find safety tips and information on

limits to the type of towing you can reasonably do with your

vehicle. Before towing a trailer, carefully review this

information to tow your load as efficiently and safely as

possible.

To maintain the New Vehicle Limited Warranty coverage,

follow the requirements and recommendations in this

manual concerning vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing related definitions will assist

you in understanding the following information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your vehicle.

This includes driver, passengers, cargo and tongue

weight. The total load must be limited so that you do not

exceed the GVWR

Úpage 120.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the weight of all

cargo, consumables and equipment (permanent or

temporary) loaded in or on the trailer in its "loaded and

ready for operation" condition.

The recommended way to measure GTW is to put your fully

loaded trailer on a vehicle scale. The entire weight of the

trailer must be supported by the scale.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front and rear

axles. Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either front or

rear GAWR

Úpage 120.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch ball by

the trailer. You must consider this as part of the load on

your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multiplied by the

maximum width of the front of a trailer.

WARNING!

Do not load your vehicle any heavier than the GVWR or

the maximum front and rear GAWR. If you do, parts on

your vehicle can break, or it can change the way your

vehicle handles. This could cause you to lose control.

Overloading can shorten the life of your vehicle.

WARNING!

It is important that you do not exceed the maximum

front or rear GAWR. A dangerous driving condition can

result if either rating is exceeded. You could lose control

of the vehicle and have a collision.

4

23_GG_OM_EN_USC_t.book Page 121

Page 126 of 288

124STARTING AND OPERATING

Towing Requirements — Tires

Do not attempt to tow a trailer while using a compact

spare tire.

Do not drive more than 50 mph (80 km/h) when towing

while using a full size spare tire.

Proper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle.

Check the trailer tires for proper tire inflation pressures

before trailer usage.

Check for signs of tire wear or visible tire damage

before towing a trailer.

Replacing tires with a higher load carrying capacity will

not increase the vehicle's GVWR and GAWR limits.

For further information

Úpage 246.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury.

An electronically actuated trailer brake controller is

required when towing a trailer with electronically

actuated brakes. When towing a trailer equipped with

a hydraulic surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers over

1,000 lb (453 kg) and required for trailers in excess of

1,543 lb (700 kg).

Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-pin

wiring harness. Use a factory-approved trailer harness and

connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following illustrations.

NOTE:

Disconnect the trailer wiring connector from the vehicle

(or any other device plugged into vehicle’s electrical

connectors) before launching a boat into water.

Be sure to reconnect once clear from water area.

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your brake

system and cause it to fail. You might not have

brakes when you need them and could have an

accident.

Towing any trailer will increase your stopping

distance. When towing, you should allow for

additional space between your vehicle and the

vehicle in front of you. Failure to do so could result

in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

23_GG_OM_EN_USC_t.book Page 124

Page 167 of 288

SAFETY165

Turning PEB On Or Off

NOTE:The default status of PEB is “On.” This allows the system

to warn you of a possible frontal collision with the pedes -

trian/cyclist.

The PEB button is located in the Uconnect Settings

Úpage 130.

To turn the PEB system off, push the Pedestrian

Emergency Braking OFF button.

To turn the PEB system back on, push the Warning Active

Braking button.

Changing the PEB status to “Only Warning” prevents the

system from providing autonomous braking, or additional

brake support if the driver is not braking adequately in the

event of a potential frontal collision with a pedestrian/cyclist.

Changing the PEB status to “Off” deactivates the system,

so no warning or active braking will be available in case of

a possible frontal collision with a pedestrian/cyclist.

NOTE:The PEB system will retain the last setting selected by the

driver after ignition shut down. The system will not reset to

the default setting when the vehicle is restarted.

TIRE PRESSURE MONITORING SYSTEM

(TPMS)

The TPMS will warn the driver of a low tire pressure based

on the vehicle recommended cold placard pressure.

The tire pressure will vary with temperature by

approximately 1 psi (7 kPa) for every 12°F (6.5°C). This

means that when the outside temperature decreases, the

tire pressure will decrease. Tire pressure should always be

set based on cold inflation tire pressure. This is defined as

the tire pressure after the vehicle has not been driven for

at least three hours, or driven less than 1 mile (1.6 km)

after a three hour period. The cold tire inflation pressure

must not exceed the maximum inflation pressure molded

into the tire sidewall. The tire pressure will also increase

as the vehicle is driven. This is normal and there should be

no adjustment for this increased pressure.

For more information on how to properly inflate the

vehicle’s tires, see

Úpage 246.

The TPMS will warn the driver of a low tire pressure if the

tire pressure falls below the low-pressure warning limit for

any reason, including low temperature effects and natural

pressure loss through the tire. The TPMS will continue to

warn the driver of low tire pressure as long as the

condition exists, and will not turn off until the tire pressure

is at or above the recommended cold placard pressure.

NOTE:Once the low tire pressure warning (Tire Pressure

Monitoring System Warning Light) illuminates, you must

increase the tire pressure to the recommended cold

placard pressure in order for the Tire Pressure Monitoring

System Warning Light to turn off.

The system will automatically update and the Tire

Pressure Monitoring System Warning Light will turn off

once the system receives the updated tire pressures. The

vehicle may need to be driven for up to 20 minutes above

15 mph (24 km/h) in order for the TPMS to receive this information.

For example, your vehicle may have a recommended cold

(parked for more than three hours) placard pressure of

33 psi (227 kPa). If the ambient temperature is 68°F

(20°C) and the measured tire pressure is 28 psi

(193 kPa), a temperature drop to 20°F (-7°C) will

decrease the tire pressure to approximately 24 psi

(165 kPa). This tire pressure is low enough to turn on

the Tire Pressure Monitoring System Warning Light.

Driving the vehicle may cause the tire pressure to rise to

approximately 28 psi (193 kPa), but the Tire Pressure

Monitoring System Warning Light will still be on. In this

situation, the Tire Pressure Monitoring System Warning

Light will turn off only after the tires are inflated to the

vehicle’s recommended cold placard pressure value

Úpage 275.

NOTE:When filling warm tires, the tire pressure may need to be

increased up to an additional 4 psi (28 kPa) above the

recommended cold placard pressure in order to turn the

Tire Pressure Monitoring System Warning Light off.

6

23_GG_OM_EN_USC_t.book Page 165

Page 168 of 288

166SAFETY

NOTE:

The TPMS is not intended to replace normal tire care

and maintenance, or to provide warning of a tire failure

or condition.

The TPMS should not be used as a tire pressure gauge

while adjusting your tire pressure.

Driving on a significantly underinflated tire causes the

tire to overheat and can lead to tire failure. Underinfla -

tion also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire mainte -

nance, and it is the driver’s responsibility to maintain

correct tire pressure using an accurate tire pressure

gauge, even if underinflation has not reached the level

to trigger illumination of the Tire Pressure Monitoring

System Warning Light.

Seasonal temperature changes will affect tire pres -

sure, and the TPMS will monitor the actual tire pres -

sure in the tire.

Premium System

The Tire Pressure Monitoring System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire pressure

readings to the receiver module.

NOTE:It is particularly important for you to check the tire

pressure in all of the tires on your vehicle monthly and to

maintain the proper pressure.

The TPMS consists of the following components:

Receiver module

Four Tire Pressure Monitoring System sensors

Various Tire Pressure Monitoring System messages,

which will display in the instrument cluster display

Tire Pressure Monitoring System Warning Light

Tire Pressure Monitoring System Low

Pressure Warnings

The Tire Pressure Monitoring System Warning

Light will illuminate in the instrument cluster

and a chime will sound when tire pressure is

low in one or more of the four active road tires.

In addition, the instrument cluster will display a "Tire Low"

message, an “Inflate to XX” message, and a graphic

showing the pressure values of each tire with the low tire

pressure values highlighted or in a different color.

Tire Pressure Monitoring System Low Pressure Warning

Should this occur, you should stop as soon as possible and

inflate the tires with low pressure (those highlighted or in a

different color in the instrument cluster display graphic) to

the vehicle’s recommended cold placard pressure value, as

shown in the “Inflate to XX” message. Once the system

receives the updated tire pressures, the system will

automatically update, the pressure values in the graphic

display in the instrument cluster will stop being highlighted

or return to their original color, and the Tire Pressure

Monitoring System Warning Light will turn off.

CAUTION!

The TPMS has been optimized for the original equip -

ment tires and wheels. TPMS pressures and warning

have been established for the tire size equipped on

your vehicle. Undesirable system operation or sensor

damage may result when using replacement equip -

ment that is not of the same size, type, and/or style.

The TPMS sensor is not designed for use on after -

market wheels and may contribute to a poor overall

system performance or sensor damage. Customers

are encouraged to use Original Equipment Manufac -

turer (OEM) wheels to ensure proper TPMS feature

operation.

Using aftermarket tire sealants may cause the Tire

Pressure Monitoring System (TPMS) sensor to

become inoperable. After using an aftermarket tire

sealant it is recommended that you take your vehicle

to an authorized dealer to have your sensor function

checked.

After inspecting or adjusting the tire pressure always

reinstall the valve stem cap. This will prevent mois -

ture and dirt from entering the valve stem, which

could damage the TPMS sensor.

23_GG_OM_EN_USC_t.book Page 166

Page 203 of 288

SAFETY201

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nut/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn

signal and high beam indicator lights on the instrument

panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight parking for

fuel, coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel or brake fluid leaks are

suspected, the cause should be located and corrected

immediately.

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

NEVER place any objects under the floor mat (e.g.,

towels, keys, etc.). These objects could change the

position of the floor mat and may cause interference

with the accelerator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

6

23_GG_OM_EN_USC_t.book Page 201

Page 214 of 288

212IN CASE OF EMERGENCY

(Continued)

INFLATION PROCEDURENOTE:Always follow applicable state and provincial laws. Contact

state and provincial Highway Safety offices for additional

details.

To use your Tire Inflator Kit, proceed as follows:

1. Stop the vehicle in a position where you can repair

the tire safely. Activate the Hazard Warning Flashers

to make other drivers aware of your presence.

2. If equipped, use all available safety equipment required by law.

3. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the

ground. This will allow the Tire Inflator Kit hoses to

reach the valve stem and keep the tire repair kit flat

on the ground.

4. Place the gear selector to PARK (P).

5. Apply the Electric Park Brake and cycle the engine OFF.

6. Insert the sealant cartridge containing the sealing fluid in the proper compressor holder, pushing down

hard. Unscrew the tire valve cap, take out the filler

tube and tighten the fitting on the tire valve.

WARNING!

The information required by current legislation is

shown on the kit cartridge label. Read the cartridge

label before use, avoid improper use.

Do not attempt to seal a tire on the side of the

vehicle closest to traffic. Pull far enough off the

road to avoid the danger of being hit when using

the Tire Service Kit.

Do not remove foreign bodies from the tire.

Do not leave the compressor running for more than

20 minutes, this may cause overheating.

Do not use the Tire Service Kit or drive the vehicle

under the following circumstances:

If the puncture in the tire tread is approximately

1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

If the tire has any damage from driving with

extremely low tire pressure.

If the tire has any damage from driving on a

flat tire.

If the wheel has any damage.

If you are unsure of the condition of the tire or

the wheel.

Keep the Tire Service Kit away from open flames or

heat sources.

A loose Tire Service Kit thrown forward in a collision

or hard stop could endanger the occupants of the

vehicle. Always stow the Tire Service Kit in the place

provided. Failure to follow these warnings can result

in injuries that are serious or fatal to you, your

passengers, and others around you.

Take care not to allow the contents of the Tire

Service Kit to come in contact with hair, eyes, or

clothing. Tire Service Kit sealant is harmful if inhaled,

swallowed, or absorbed through the skin. It causes

skin, eye, and respiratory irritation. Flush immedi -

ately with plenty of water if there is any contact with

eyes or skin. Change clothing as soon as possible, if

there is any contact with clothing.

Tire Service Kit sealant solution contains latex. In

case of an allergic reaction or rash, consult a physi -

cian immediately. Keep the Tire Service Kit out of

reach of children. If swallowed, rinse mouth immedi -

ately with plenty of water and drink plenty of water.

Do not induce vomiting! Consult a physician immedi -

ately.

WARNING!

23_GG_OM_EN_USC_t.book Page 212

Page 215 of 288

IN CASE OF EMERGENCY213

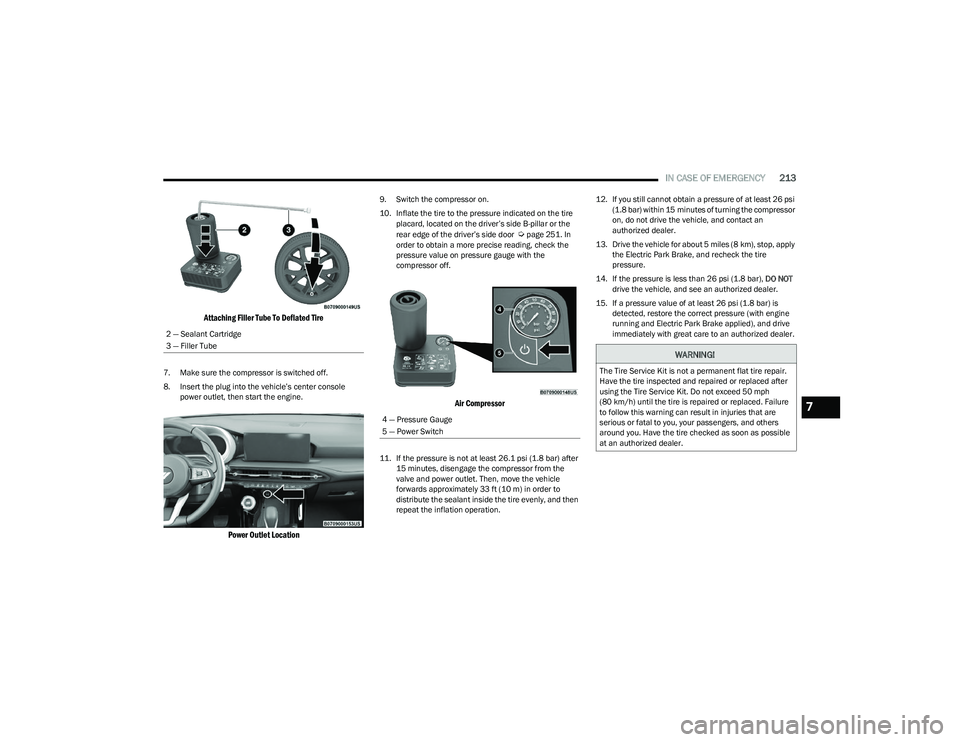

Attaching Filler Tube To Deflated Tire

7. Make sure the compressor is switched off.

8. Insert the plug into the vehicle’s center console

power outlet, then start the engine.

Power Outlet Location

9. Switch the compressor on.

10. Inflate the tire to the pressure indicated on the tire placard, located on the driver’s side B-pillar or the

rear edge of the driver’s side door

Úpage 251. In

order to obtain a more precise reading, check the

pressure value on pressure gauge with the

compressor off.

Air Compressor

11. If the pressure is not at least 26.1 psi (1.8 bar) after 15 minutes, disengage the compressor from the

valve and power outlet. Then, move the vehicle

forwards approximately 33 ft (10 m) in order to

distribute the sealant inside the tire evenly, and then

repeat the inflation operation. 12. If you still cannot obtain a pressure of at least 26 psi

(1.8 bar) within 15 minutes of turning the compressor

on, do not drive the vehicle, and contact an

authorized dealer.

13. Drive the vehicle for about 5 miles (8 km), stop, apply the Electric Park Brake, and recheck the tire

pressure.

14. If the pressure is less than 26 psi (1.8 bar), DO NOT

drive the vehicle, and see an authorized dealer.

15. If a pressure value of at least 26 psi (1.8 bar) is detected, restore the correct pressure (with engine

running and Electric Park Brake applied), and drive

immediately with great care to an authorized dealer.

2 — Sealant Cartridge

3 — Filler Tube

4 — Pressure Gauge

5 — Power Switch

WARNING!

The Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced after

using the Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced. Failure

to follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others

around you. Have the tire checked as soon as possible

at an authorized dealer.

7

23_GG_OM_EN_USC_t.book Page 213

Page 225 of 288

223

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate in the instrument cluster.

This means that service is required for your vehicle.

Operating conditions such as frequent short-trips, trailer

towing, and extremely hot or cold ambient temperatures

will influence when the “Change Oil” or “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next 500 miles

(805 km).An authorized dealer will reset the oil change indicator

message after completing the scheduled oil change. If a

scheduled oil change is performed by someone other than

an authorized dealer, the message can be reset by

referring to the steps described under Instrument Cluster

Display

Úpage 66.

NOTE:Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km), one year or 350 hours

of engine run time, whichever comes first. The 350 hours

of engine run or idle time is generally only a concern for

fleet customers.

Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check the tire inflation pressures and look for unusual

wear or damage. Rotate tires at the first sign of irreg -

ular wear, even if it occurs before the oil indicator

system turns on.

Check the fluid levels of the coolant reservoir, and

brake master cylinder reservoir, and fill as needed.

Check function of all interior and exterior lights.

8

23_GG_OM_EN_USC_t.book Page 223