check engine DODGE INTREPID 2004 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: INTREPID, Model: DODGE INTREPID 2004 2.GPages: 249, PDF Size: 4.87 MB

Page 173 of 249

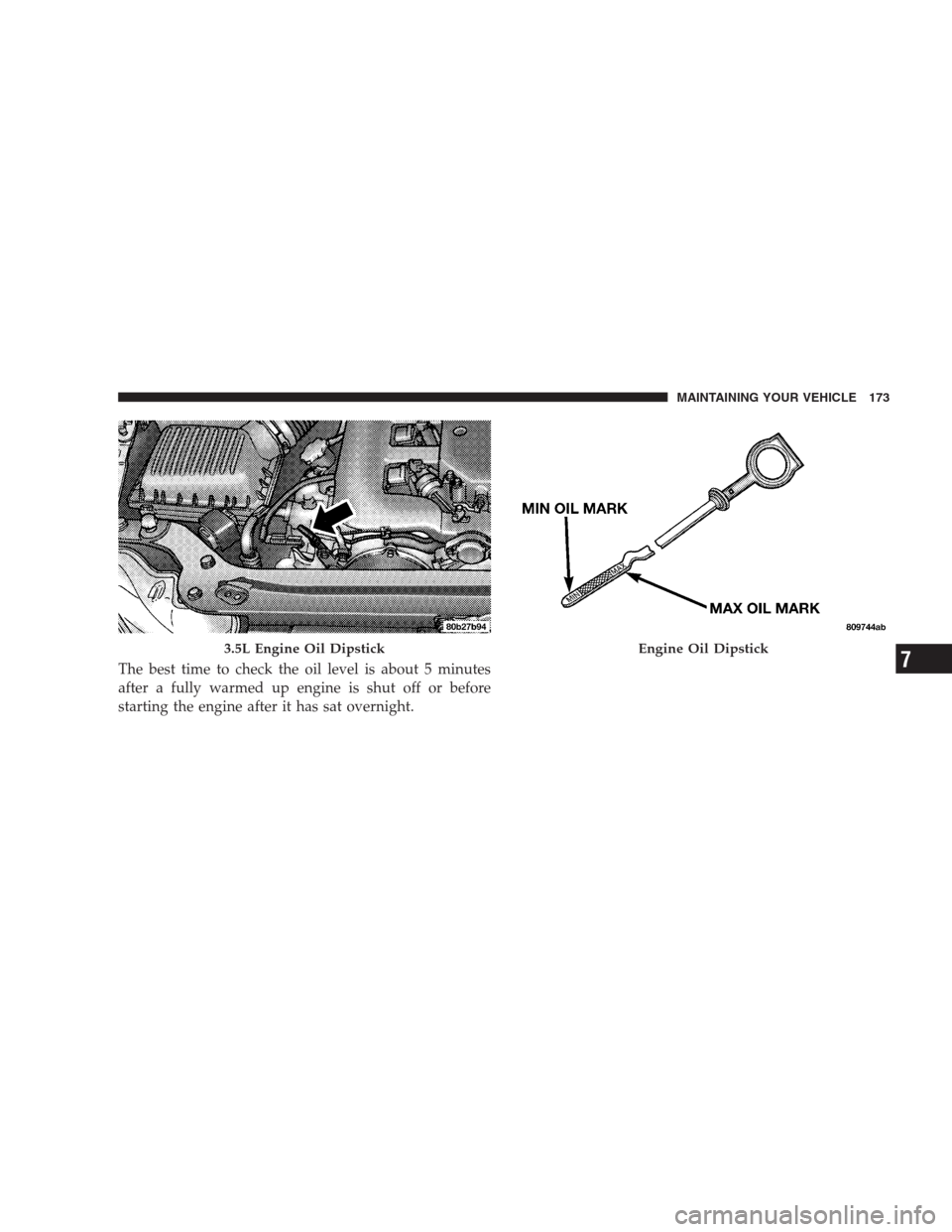

The best time to check the oil level is about 5 minutes

after a fully warmed up engine is shut off or before

starting the engine after it has sat overnight.

3.5L Engine Oil DipstickEngine Oil Dipstick

MAINTAINING YOUR VEHICLE 173

7

Page 174 of 249

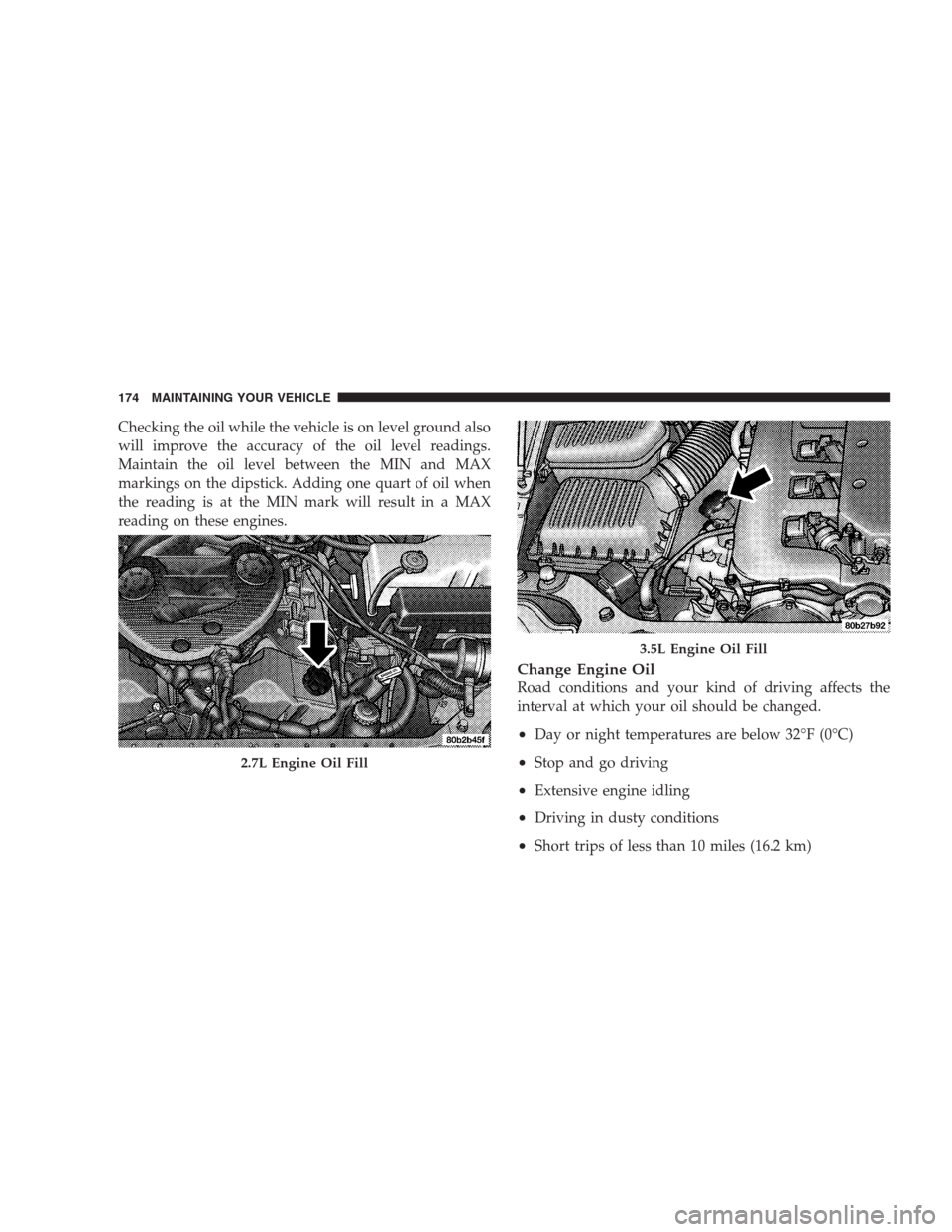

Checking the oil while the vehicle is on level ground also

will improve the accuracy of the oil level readings.

Maintain the oil level between the MIN and MAX

markings on the dipstick. Adding one quart of oil when

the reading is at the MIN mark will result in a MAX

reading on these engines.

Change Engine Oil

Road conditions and your kind of driving affects the

interval at which your oil should be changed.

•Day or night temperatures are below 32°F (0°C)

•Stop and go driving

•Extensive engine idling

•Driving in dusty conditions

•Short trips of less than 10 miles (16.2 km)

2.7L Engine Oil Fill

3.5L Engine Oil Fill

174 MAINTAINING YOUR VEHICLE

Page 178 of 249

on how and where used oil can be safely discarded in

your area.

Engine Oil Filter

The engine oil filter should be replaced at every engine

oil change.

Engine Oil Filter Selection

All of this manufacturer’s engines have a full-flow type

disposable oil filter. Use a filter of this type for replace-

ment. The quality of replacement filters varies consider-

ably. Only high quality filters should be used to assure

most efficient service. Mopar Engine Oil Filters are high

quality oil filters and are recommended.

Drive Belts – Check Condition and Tension

At the mileage shown in the maintenance schedules,

check all drive belts for condition and proper tension.

Improper belt tension can cause belt slippage and failure.

Inspect the drive belts for evidence of cuts, cracks, or

glazing and replace them if there is any sign of damage

which could result in belt failure. If adjustment is re-

quired, adjust the belts according to the specificationsand procedures shown in the Service Manual. See the

Consumer Assistance section for information on ordering

a Service Manual.

Special tools are required to properly measure tension

and to restore belt tension to factory specifications. Also,

check belt routing to make sure there is no interference

between the belts and other engine components.

Spark Plugs

Spark plugs must fire properly to assure engine perfor-

mance and emission control. New plugs should be in-

stalled at the mileage specified in the appropriate main-

tenance chart. The entire set should be replaced if there is

any malfunction due to a faulty spark plug. Check the

specifications section for the proper type of spark plug

for use in your vehicle.

Catalytic Converter

The catalytic converter requires the use of unleaded fuel

only. Leaded gasoline will destroy the effectiveness of the

catalyst as an emission control device.

178 MAINTAINING YOUR VEHICLE

Page 180 of 249

Engine Timing Belt

Replace the engine timing belt at the intervals described

in the appropriate maintenance schedule.

Crankcase Emission Control System

Proper operation of this system depends on freedom

from sticking or plugging due to deposits. As vehicle

mileage builds up, the PCV valve and passages may

accumulate deposits. If a valve is not working properly,

replace it with a new valve. DO NOT ATTEMPT TO

CLEAN THE OLD PCV VALVE!

Check ventilation hose for indication of damage or

plugging deposits. Replace if necessary.

Fuel Filter

A plugged fuel filter can cause hard starting or limit the

speed at which a vehicle can be driven. Should an

excessive amount of dirt accumulate in the fuel tank,

frequent replacement of the fuel filter which is mounted

in the fuel tank may be necessary. See your dealer for

service.

Air Cleaner Filter

Under normal driving conditions, replace the air filter at

the intervals shown on Schedule “A”. If, however, you

drive the vehicle frequently under dusty or severe con-

ditions, the filter element should be inspected periodi-

cally and replaced if necessary at the intervals shown on

Schedule “B”.

WARNING!

The air cleaner can provide a measure of protection

in the case of engine backfire. Do not remove the air

cleaner unless such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle with

the air cleaner removed. Failure to do so can result in

serious personal injury.

180 MAINTAINING YOUR VEHICLE

Page 183 of 249

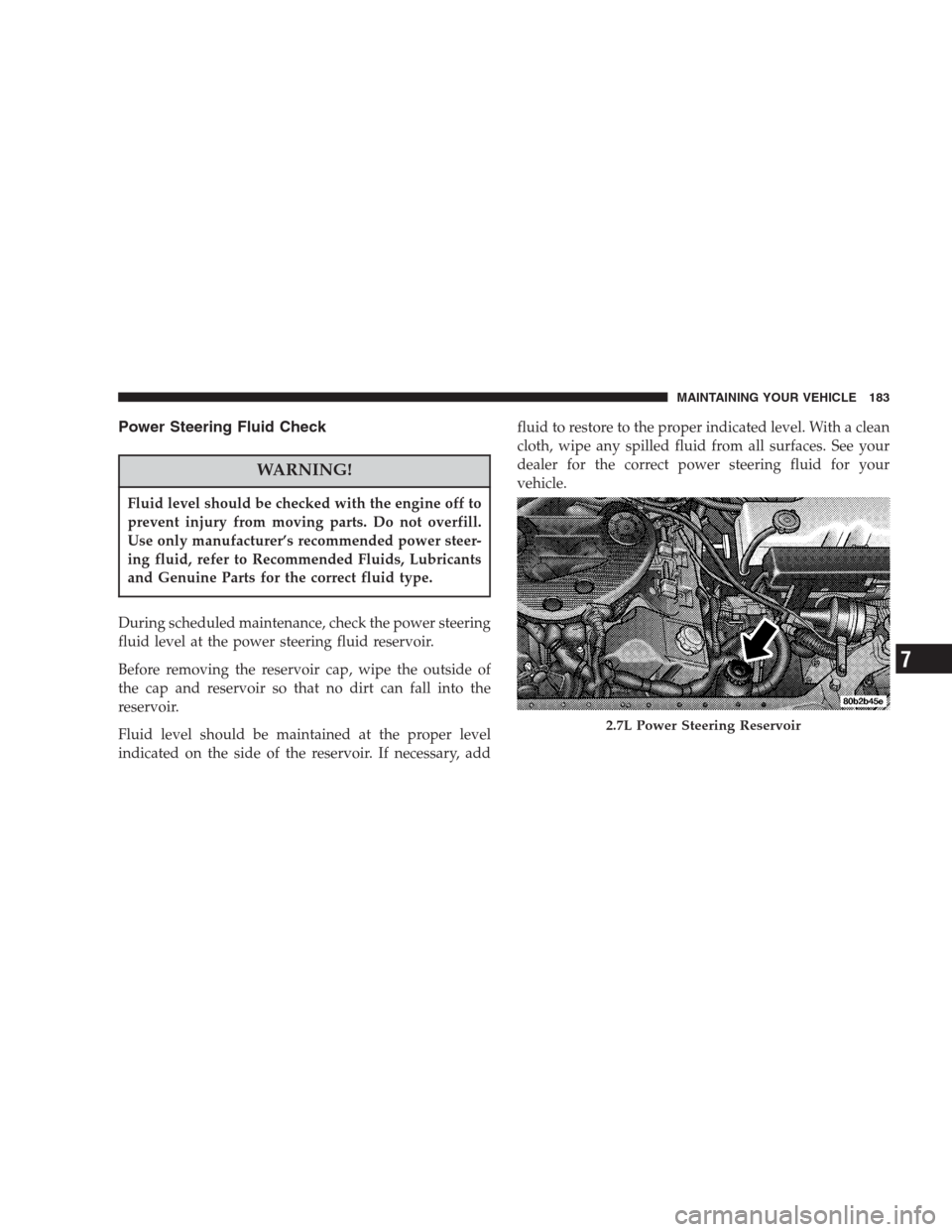

Power Steering Fluid Check

WARNING!

Fluid level should be checked with the engine off to

prevent injury from moving parts. Do not overfill.

Use only manufacturer’s recommended power steer-

ing fluid, refer to Recommended Fluids, Lubricants

and Genuine Parts for the correct fluid type.

During scheduled maintenance, check the power steering

fluid level at the power steering fluid reservoir.

Before removing the reservoir cap, wipe the outside of

the cap and reservoir so that no dirt can fall into the

reservoir.

Fluid level should be maintained at the proper level

indicated on the side of the reservoir. If necessary, addfluid to restore to the proper indicated level. With a clean

cloth, wipe any spilled fluid from all surfaces. See your

dealer for the correct power steering fluid for your

vehicle.

2.7L Power Steering Reservoir

MAINTAINING YOUR VEHICLE 183

7

Page 186 of 249

•Trunk latches

•Ash tray

•Door Check Straps

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild non abrasive cleaner. This will remove accumula-

tions of salt or road film.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield. Avoid using the wiper blades to

remove frost or ice from the windshield. Keep the blade

rubber out of contact with petroleum products such as

engine oil, gasoline, etc.

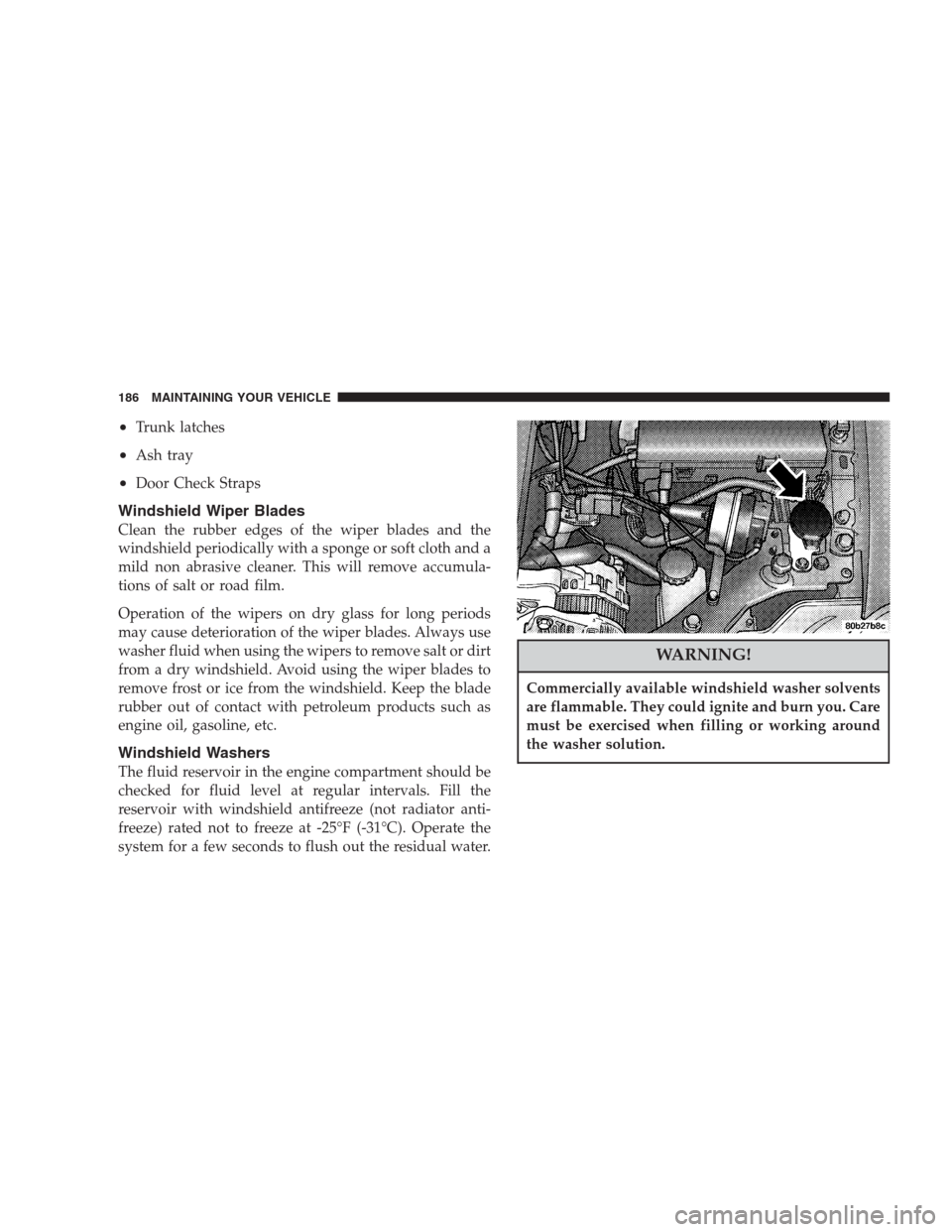

Windshield Washers

The fluid reservoir in the engine compartment should be

checked for fluid level at regular intervals. Fill the

reservoir with windshield antifreeze (not radiator anti-

freeze) rated not to freeze at -25°F (-31°C). Operate the

system for a few seconds to flush out the residual water.

WARNING!

Commercially available windshield washer solvents

are flammable. They could ignite and burn you. Care

must be exercised when filling or working around

the washer solution.

186 MAINTAINING YOUR VEHICLE

Page 188 of 249

Cooling System

WARNING!

•When working near the radiator cooling fan, dis-

connect the fan motor lead or turn the ignition key

to the OFF position. The fan is temperature con-

trolled and can start at any time the ignition key is

in the ON position.

•You or others can be badly burned by hot coolant

or steam from your radiator. If you see or hear

steam coming from under the hood, don’t open

the hood until the radiator has had time to cool.

Never try to open a cooling system pressure cap

when the radiator is hot.

Coolant Checks

Check coolant protection every 12 months (before the

onset of freezing weather, where applicable). If coolant is

dirty or rusty in appearance, the system should be

drained, flushed and refilled with fresh coolant.Check the front of the radiator and condenser for any

accumulation of bugs, leaves, etc. Clean the radiator and

condenser by gently spraying water from a garden hose

at the back of the core.

Check the engine cooling system hoses for condition and

tightness of connection. Inspect the entire system for

leaks. Any hoses that show cuts or severe abrasion must

be replaced.

Cooling System — Drain, Flush and Refill

At the intervals shown on the Maintenance Schedules (5

years/100,000 miles), the system should be drained,

flushed and refilled.

If the solution is dirty and contains a considerable

amount of sediment, clean and flush with a reliable

cooling system cleaner. Follow with a thorough rinsing to

remove all deposits and chemicals.

Engine Coolant Disposal

Used ethylene glycol based engine coolant is a regulated

substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. Do not store ethylene glycol based engine

188 MAINTAINING YOUR VEHICLE

Page 191 of 249

Points to Remember

NOTE:

When the vehicle is stopped after a few miles of

operation, you may observe vapor coming from the front

of the engine compartment. This is normally a result of

moisture from rain, snow, or high humidity accumulat-

ing on the radiator and being vaporized when the

thermostat opens, allowing hot water to enter the radia-

tor.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

•Do not overfill the coolant bottle.

•Check coolant freeze point in the system.

•If frequent coolant additions are required, or if the

level in the recovery bottle does not drop when the

engine cools, the cooling system should be pressure

tested for leaks.

•Maintain coolant concentration of a minimum of 50%

ethylene glycol and high quality water with recom-

mended antifreeze for proper corrosion protection of

your engine cooling system that contains aluminum

components.

•Make sure that the radiator and coolant bottle hoses

are not kinked or obstructed.

•Keep the front of the radiator and air conditioning

condenser clean.

•Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine cooling performance,

poor gas mileage, and increased emissions.

Hoses and Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, checking, tears, cuts, abrasions,

and excessive swelling indicate deterioration of the rub-

ber.

MAINTAINING YOUR VEHICLE 191

7

Page 193 of 249

NOTE:Often, fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation)

should be noted before hose is replaced based on leakage.

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

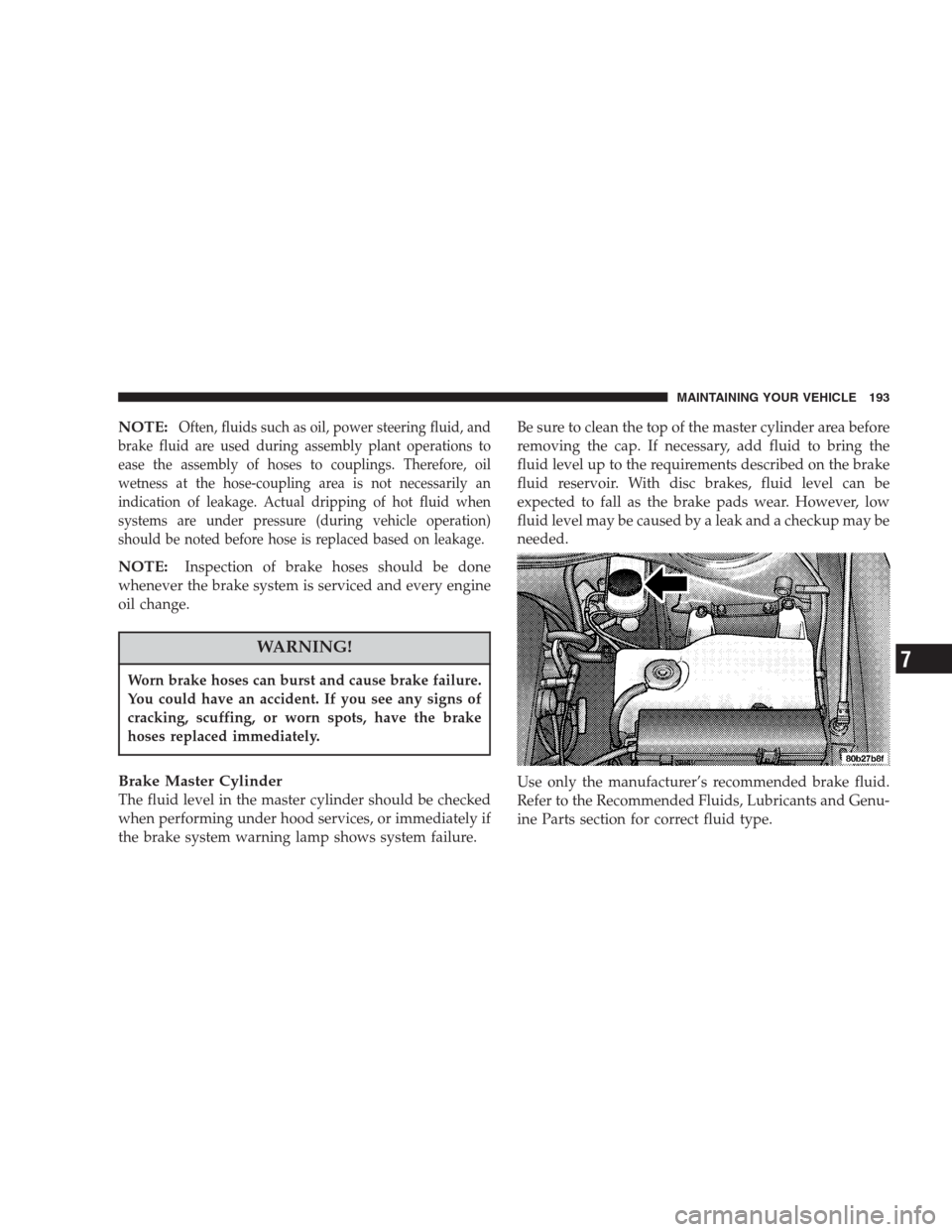

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp shows system failure.Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear. However, low

fluid level may be caused by a leak and a checkup may be

needed.

Use only the manufacturer’s recommended brake fluid.

Refer to the Recommended Fluids, Lubricants and Genu-

ine Parts section for correct fluid type.

MAINTAINING YOUR VEHICLE 193

7

Page 196 of 249

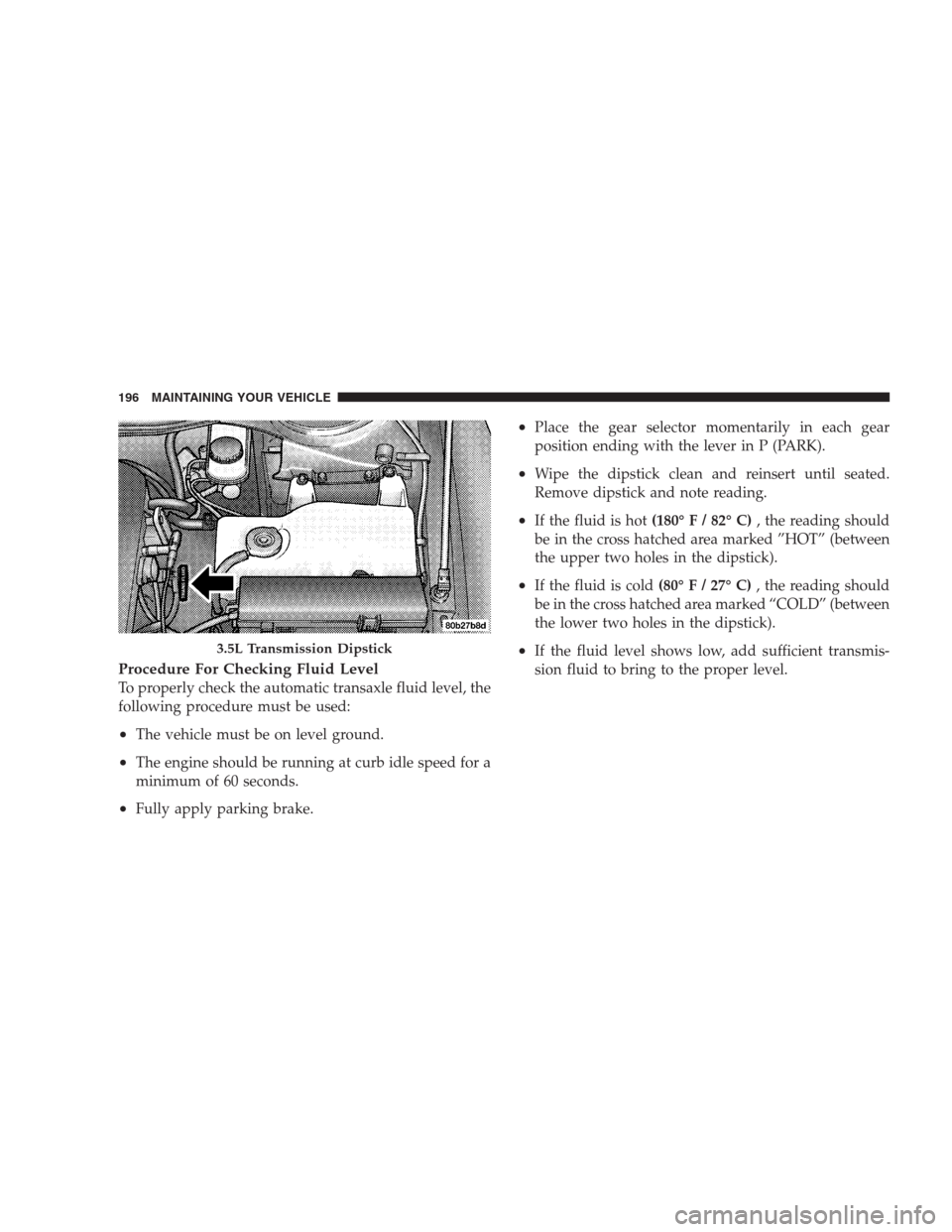

Procedure For Checking Fluid Level

To properly check the automatic transaxle fluid level, the

following procedure must be used:

•The vehicle must be on level ground.

•The engine should be running at curb idle speed for a

minimum of 60 seconds.

•Fully apply parking brake.

•Place the gear selector momentarily in each gear

position ending with the lever in P (PARK).

•Wipe the dipstick clean and reinsert until seated.

Remove dipstick and note reading.

•If the fluid is hot(180° F / 82° C), the reading should

be in the cross hatched area marked ”HOT” (between

the upper two holes in the dipstick).

•If the fluid is cold(80° F / 27° C), the reading should

be in the cross hatched area marked “COLD” (between

the lower two holes in the dipstick).

•If the fluid level shows low, add sufficient transmis-

sion fluid to bring to the proper level.3.5L Transmission Dipstick

196 MAINTAINING YOUR VEHICLE