warning DODGE INTREPID 2004 2.G Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: INTREPID, Model: DODGE INTREPID 2004 2.GPages: 249, PDF Size: 4.87 MB

Page 188 of 249

Cooling System

WARNING!

•When working near the radiator cooling fan, dis-

connect the fan motor lead or turn the ignition key

to the OFF position. The fan is temperature con-

trolled and can start at any time the ignition key is

in the ON position.

•You or others can be badly burned by hot coolant

or steam from your radiator. If you see or hear

steam coming from under the hood, don’t open

the hood until the radiator has had time to cool.

Never try to open a cooling system pressure cap

when the radiator is hot.

Coolant Checks

Check coolant protection every 12 months (before the

onset of freezing weather, where applicable). If coolant is

dirty or rusty in appearance, the system should be

drained, flushed and refilled with fresh coolant.Check the front of the radiator and condenser for any

accumulation of bugs, leaves, etc. Clean the radiator and

condenser by gently spraying water from a garden hose

at the back of the core.

Check the engine cooling system hoses for condition and

tightness of connection. Inspect the entire system for

leaks. Any hoses that show cuts or severe abrasion must

be replaced.

Cooling System — Drain, Flush and Refill

At the intervals shown on the Maintenance Schedules (5

years/100,000 miles), the system should be drained,

flushed and refilled.

If the solution is dirty and contains a considerable

amount of sediment, clean and flush with a reliable

cooling system cleaner. Follow with a thorough rinsing to

remove all deposits and chemicals.

Engine Coolant Disposal

Used ethylene glycol based engine coolant is a regulated

substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. Do not store ethylene glycol based engine

188 MAINTAINING YOUR VEHICLE

Page 190 of 249

WARNING!

The warning words “DO NOT OPEN HOT” on the

cooling system pressure cap are a safety precaution.

Never add coolant when the engine is overheated.

Do not loosen or remove the cap to cool an over-

heated engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or injury, do

not remove the pressure cap while the system is hot

or under pressure.

WARNING!

Do not use a pressure cap other than the one speci-

fied for your vehicle. Personal injury or engine

damage may result.

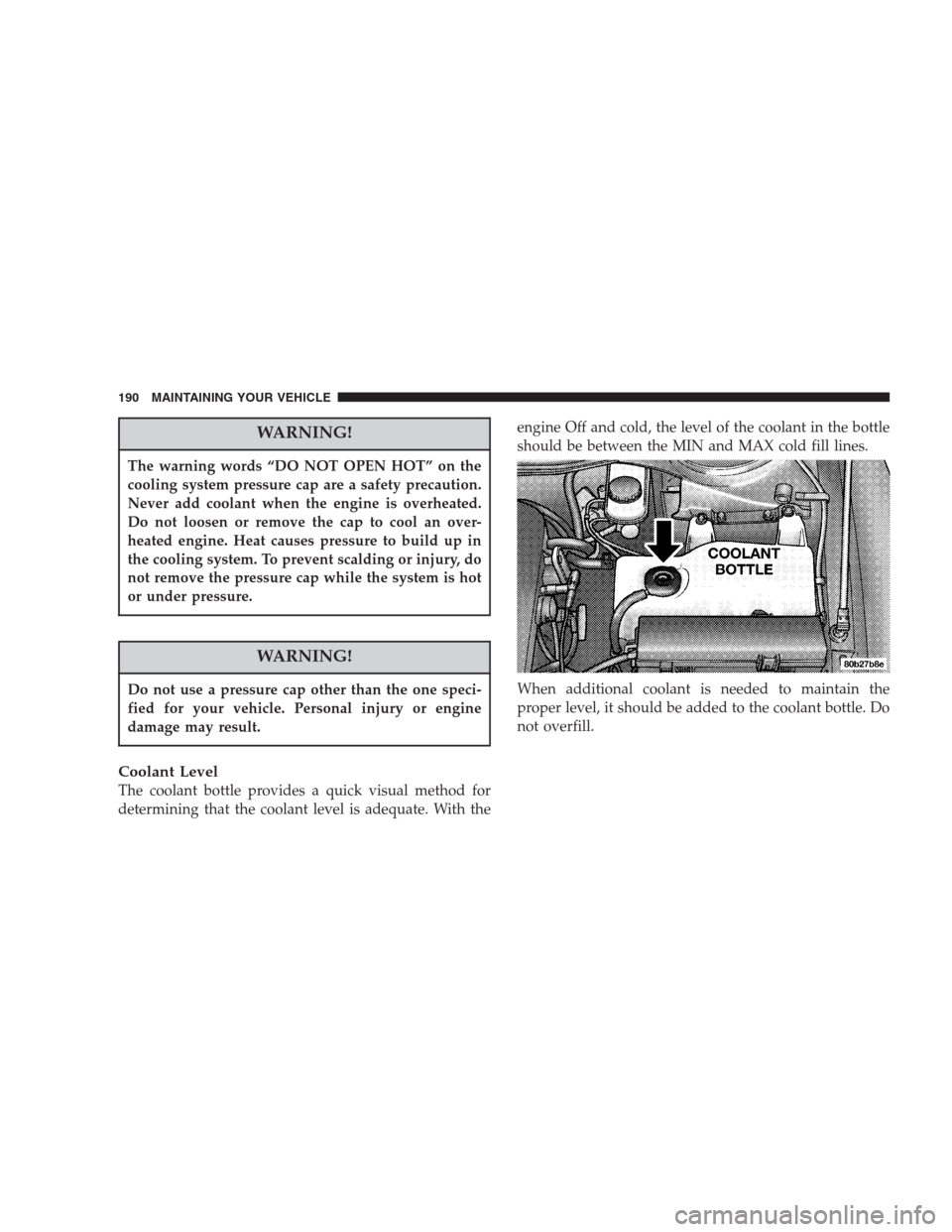

Coolant Level

The coolant bottle provides a quick visual method for

determining that the coolant level is adequate. With theengine Off and cold, the level of the coolant in the bottle

should be between the MIN and MAX cold fill lines.

When additional coolant is needed to maintain the

proper level, it should be added to the coolant bottle. Do

not overfill.

190 MAINTAINING YOUR VEHICLE

Page 192 of 249

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed. Inspect all hose connections such as clamps

and couplings to make sure they are secure and no leaks

are present. Components should be replaced immedi-

ately if there is any evidence of degradation that could

cause failure.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in Section 8.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn’t have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses for evidence of heat and me-

chanical damage. Hard and brittle rubber, cracking,

checking, tears, cuts, abrasion, and excessive swelling

suggest deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

192 MAINTAINING YOUR VEHICLE

Page 193 of 249

NOTE:Often, fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation)

should be noted before hose is replaced based on leakage.

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

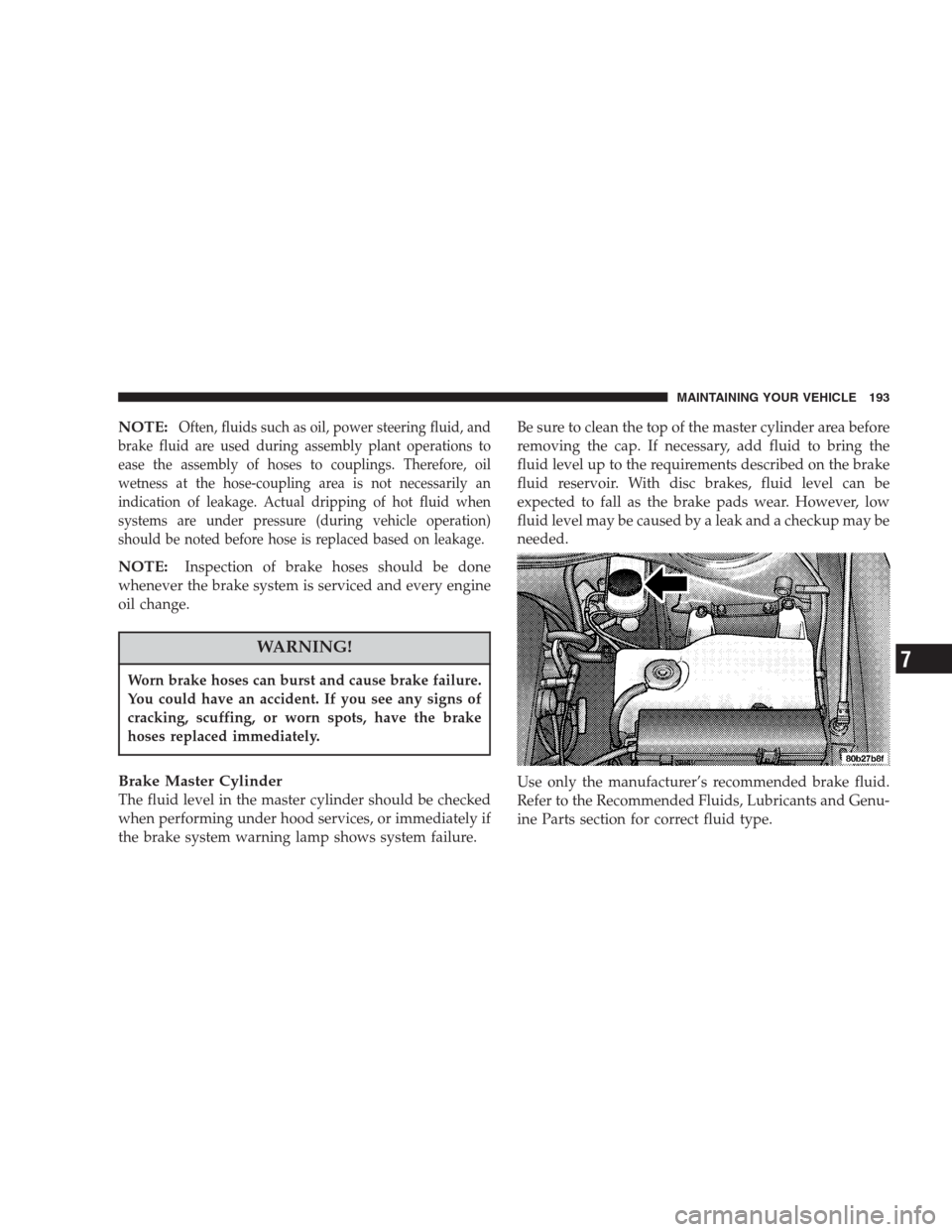

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp shows system failure.Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear. However, low

fluid level may be caused by a leak and a checkup may be

needed.

Use only the manufacturer’s recommended brake fluid.

Refer to the Recommended Fluids, Lubricants and Genu-

ine Parts section for correct fluid type.

MAINTAINING YOUR VEHICLE 193

7

Page 194 of 249

WARNING!

Use of a brake fluid that may have a lower initial

boiling point or unidentified as to specification, may

result in sudden brake failure during hard pro-

longed braking. You could have an accident.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Do not allow petroleum base fluid to contaminate the

brake fluid as seal damage will result!

Fuel System Hoses

Electronic Fuel Injection high pressure fuel systems are

designed with hoses and clamps which have unique

material characteristics to provide adequate sealing and

resist attack by deteriorated gasoline.You are urged to use only manufacturer specified hoses

and clamps, or their equivalent in material and specifi-

cation, in any fuel system servicing. It is mandatory to

replace all clamps that have been loosened or removed

during service. Care should be taken in installing new

clamps to insure they are properly torqued.

Automatic Transaxle

All front wheel drive vehicles have a transaxle and

differential assembly contained within a single housing.

Selection of Lubricant

It is important that the proper lubricant is used in the

transaxle to assure optimum transaxle performance. Use

only the manufacturer’s recommended transmission

fluid. Refer to the Recommended Fluids, Lubricants and

Genuine Parts section for correct fluid type. It is impor-

tant that the transmission fluid be maintained at the

prescribed level using the recommended fluid.

194 MAINTAINING YOUR VEHICLE

Page 199 of 249

•It is important that the drain holes in the lower edges

of the doors, rocker panels and rear deck lid be kept

clear and open.

•If you detect any stone chips or scratches in the paint,

touch them up immediately. The cost of such repairs is

considered the responsibility of the owner.

•Use Mopar touch up paint on scratches or chips as

soon as possible. Your dealer has touch up paint to

match the color of your vehicle.

•If your vehicle is damaged due to an accident or

similar cause which destroys the paint and protective

coating have your vehicle repaired as soon as possible.

The cost of such repairs is considered the responsibil-

ity of the owner.

•Aluminum wheels should be cleaned regularly with

mild soap and water to prevent corrosion. To remove

heavy soil, select a non abrasive, non-acidic cleaner.

Do not use scouring pads or metal polishes. Avoid

automatic car washes that use acidic solutions or harsh

brushes that may damage the wheels’ protective fin-

ish.

•If you carry special cargo such as chemicals, fertilizers,

deicer salt, etc., be sure that such materials are well

packaged and sealed.

•If a lot of driving is done on gravel roads, consider

mud or stone shields behind each wheel.

Interior Care

Use Mopar Fabric Cleaner to clean fabric upholstery and

carpeting.

Use a mild soap and warm water solution to clean vinyl

or leather upholstery. For stubborn stains, use Mopar

Vinyl Cleaner.

Mopar Vinyl Cleaner is specifically recommended for

vinyl trim.

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in

closed areas they may cause respiratory harm.

MAINTAINING YOUR VEHICLE 199

7

Page 225 of 249

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which

you have the knowledge and the right equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent me-

chanic.

SCHEDULE “A” 225

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 235 of 249

DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES

The following describes the tire grading categories estab-

lished by the National highway Traffic Safety Adminis-

tration. The specific grade rating assigned by the tire’s

manufacturer in each category is shown on the sidewall

of the tires on your car.

All Passenger Car Tires Must Conform to Federal Safety

Requirements in Addition to These Grades.

Treadwear

The treadwear grade is a comparative rating based on the

wear rate of the tire when tested under controlled con-

ditions on a specified government test course. For ex-

ample, a tire graded 150 would wear one and a half (1

1/2) times as well on the government course as a tire

graded 100. The relative performance of tires depends

upon the actual conditions of their use, however, and

may depart significantly from the norm due to variations

in driving habits, service practices and differences in road

characteristics and climate.

Traction Grades

The traction grades, from highest to lowest, are A, B, and

C, and they represent the tire’s ability to stop on wet

pavement as measured under controlled conditions on

specified government test surfaces of asphalt and con-

crete. A tire marked C may have poor traction perfor-

mance.

WARNING!

The traction grade is based on braking (straight-

ahead) traction tests and does not include cornering

(turning) performance.

IF YOU NEED CONSUMER ASSISTANCE 235

9

Page 236 of 249

Temperature Grades

The temperature grades are A (highest), B, and C, repre-

senting the tire’s resistance to the generation of heat and

its ability to dissipate heat when tested under controlled

conditions on a specified indoor laboratory test wheel.

Sustained high temperature can cause the material of the

tire to degenerate and reduce tire life, and excessive

temperature can lead to sudden tire failure. The grade C

corresponds to a level of performance which all passen-

ger car tires must meet under the Federal Motor Vehicle

Safety Standard No. 109. Grades B and A represent

higher levels of performance on the laboratory test wheel

than the minimum required by law.WARNING!

The temperature grade is established for a tire that is

properly inflated and not overloaded. Excessive

speed, underinflation, or excessive loading, either

separately or in combination, can cause heat buildup

and possible tire failure.

236 IF YOU NEED CONSUMER ASSISTANCE

Page 238 of 249

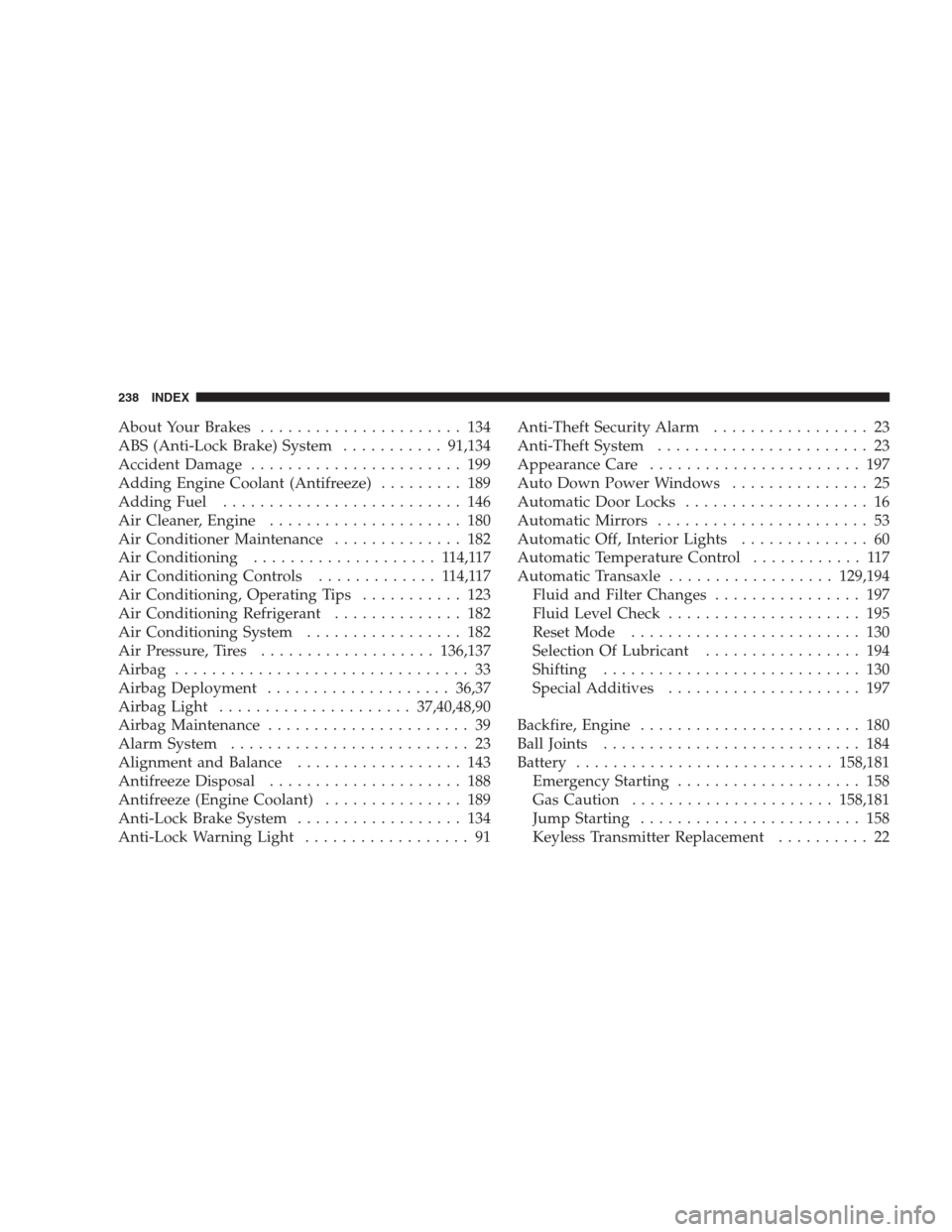

About Your Brakes...................... 134

ABS (Anti-Lock Brake) System...........91,134

Accident Damage....................... 199

Adding Engine Coolant (Antifreeze)......... 189

Adding Fuel.......................... 146

Air Cleaner, Engine..................... 180

Air Conditioner Maintenance.............. 182

Air Conditioning.................... 114,117

Air Conditioning Controls............. 114,117

Air Conditioning, Operating Tips........... 123

Air Conditioning Refrigerant.............. 182

Air Conditioning System................. 182

Air Pressure, Tires...................136,137

Airbag................................ 33

Airbag Deployment....................36,37

Airbag Light.....................37,40,48,90

Airbag Maintenance...................... 39

Alarm System.......................... 23

Alignment and Balance.................. 143

Antifreeze Disposal..................... 188

Antifreeze (Engine Coolant)............... 189

Anti-Lock Brake System.................. 134

Anti-Lock Warning Light.................. 91Anti-Theft Security Alarm................. 23

Anti-Theft System....................... 23

Appearance Care....................... 197

Auto Down Power Windows............... 25

Automatic Door Locks.................... 16

Automatic Mirrors....................... 53

Automatic Off, Interior Lights.............. 60

Automatic Temperature Control............ 117

Automatic Transaxle..................129,194

Fluid and Filter Changes................ 197

Fluid Level Check..................... 195

Reset Mode......................... 130

Selection Of Lubricant................. 194

Shifting............................ 130

Special Additives..................... 197

Backfire, Engine........................ 180

Ball Joints............................ 184

Battery............................158,181

Emergency Starting.................... 158

Gas Caution......................158,181

Jump Starting........................ 158

Keyless Transmitter Replacement.......... 22

238 INDEX