clock DODGE JOURNEY 2009 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2009, Model line: JOURNEY, Model: DODGE JOURNEY 2009 1.GPages: 523

Page 406 of 523

4. Raise the vehicle by turning the jack screw clockwise

with the jack handle. Raise the vehicle until the tire just

clears the road surface and enough clearance is obtained

to install the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

5. Remove the wheel nuts. For vehicles so equipped,

remove the wheel cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.

WARNING!

To avoid possible personal injury, handle the wheel

covers with care to avoid contact with any sharp

edges.

NOTE: For vehicles so equipped, the wheel cover is

held on the wheel by the wheel nuts. When reinstalling

the original wheel, properly align the wheel cover to the

valve stem, place the wheel cover onto the wheel, and

then install the wheel nuts.

6. Install the spare tire.

NOTE:

•For vehicles so equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

404 WHAT TO DO IN EMERGENCIES

Page 407 of 523

•Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires — General Information” in Sec-

tion 5 for additional warnings, cautions, and informa-

tion about the spare tire, its use, and operation.

7. Install the wheel nuts with the cone shaped end of the

nut toward the wheel. Lightly tighten the wheel nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the vehicle

has been lowered. Failure to follow this warning may

result in personal injury or death.

8. Lower the vehicle by turning the jack screw counter-

clockwise with the jack handle. 9. Finish tightening the wheel nuts. Push down on the

wrench while tightening for increased leverage. Alternate

wheel nuts until each nut has been tightened twice.

Correct wheel nut tightness is 95 ft lbs (130 N·m). If in

doubt about the correct tightness, have them checked

with a torque wrench by your authorized dealer or at a

service station.

10. Lower the jack to its fully closed position.WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

WHAT TO DO IN EMERGENCIES 405

6

Page 408 of 523

11. Place the deflated (flat) tire in the cargo area.Do not

stow the deflated tire in the spare tire stowage location.

Have the deflated (flat) tire repaired or replaced as soon

as possible.

12. To stow the winch cable and retainer, fit the as-

sembled jack-handle over the winch drive nut. Rotate the

jack-handle assembly clockwise until you hear the winch

mechanism click three times. It cannot be over tightened.

13. Stow the jack-handle and jack.

14. Check the tire pressure as soon as possible. Adjust the

tire pressure as required.Wheel Nuts

Tighten all wheel nuts occasionally to eliminate the

possibility of wheel studs being sheared or the bolt holes

in the wheels becoming elongated. This is especially

important during the first few hundred miles (kilome-

ters) of operation and after changing a tire. This allows

the wheel nuts to seat properly. All wheel nuts should

first be firmly seated against the wheel. The wheel nuts

should then be tightened to recommended torque.

Tighten the wheel nuts to the final torque in increments.

Progress around the bolt circle, tightening the nut oppo-

site of the one you previously tightened until the final

torque is achieved. Recommended torque is 95 ft lbs (130

N·m).

406 WHAT TO DO IN EMERGENCIES

Page 468 of 523

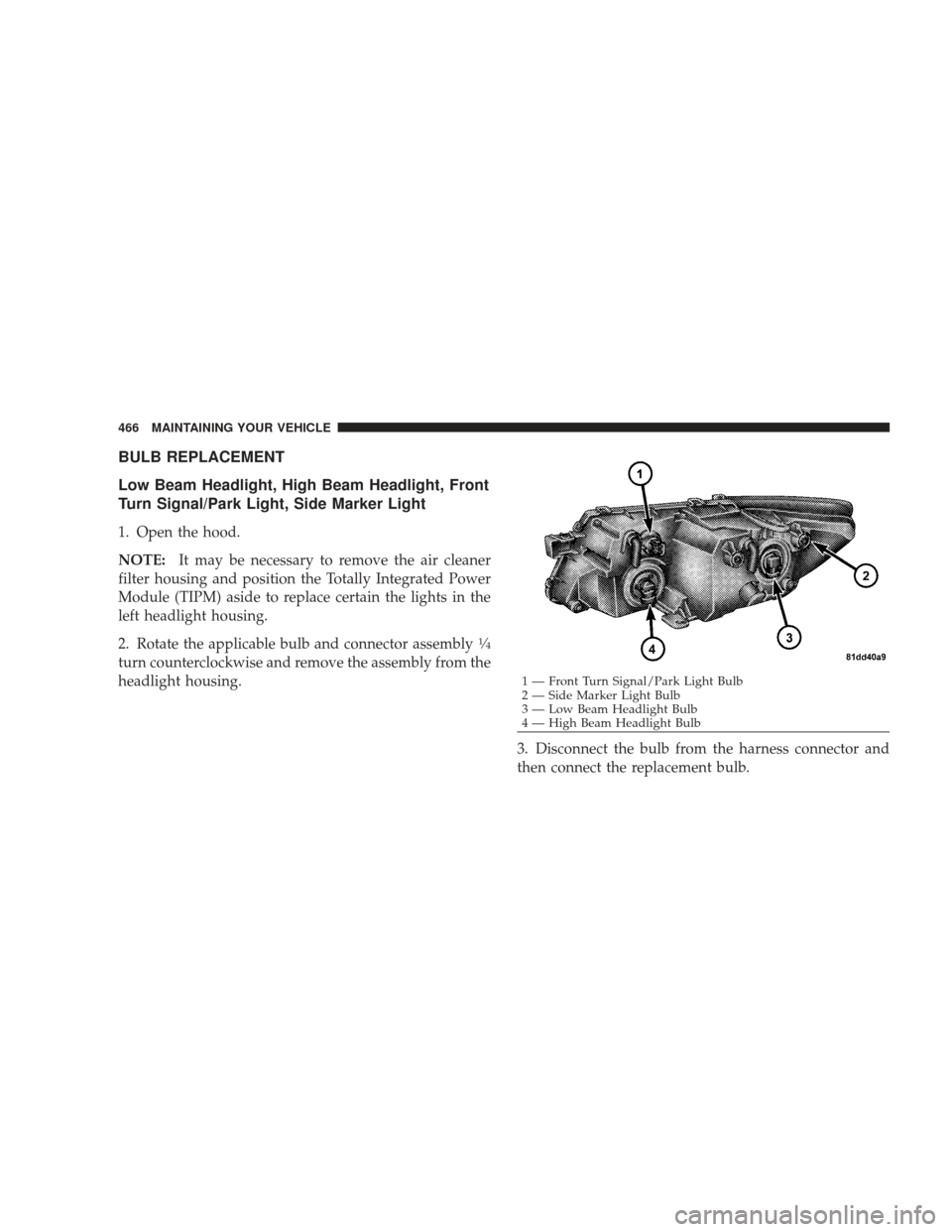

BULB REPLACEMENT

Low Beam Headlight, High Beam Headlight, Front

Turn Signal/Park Light, Side Marker Light

1. Open the hood.

NOTE:It may be necessary to remove the air cleaner

filter housing and position the Totally Integrated Power

Module (TIPM) aside to replace certain the lights in the

left headlight housing.

2. Rotate the applicable bulb and connector assembly

1�4

turn counterclockwise and remove the assembly from the

headlight housing.

3. Disconnect the bulb from the harness connector and

then connect the replacement bulb.

1 — Front Turn Signal/Park Light Bulb

2 — Side Marker Light Bulb

3 — Low Beam Headlight Bulb

4 — High Beam Headlight Bulb

466 MAINTAINING YOUR VEHICLE

Page 469 of 523

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

4. Install the bulb and connector assembly into the

headlight housing and rotate it

1�4turn clockwise to lock

it in place.

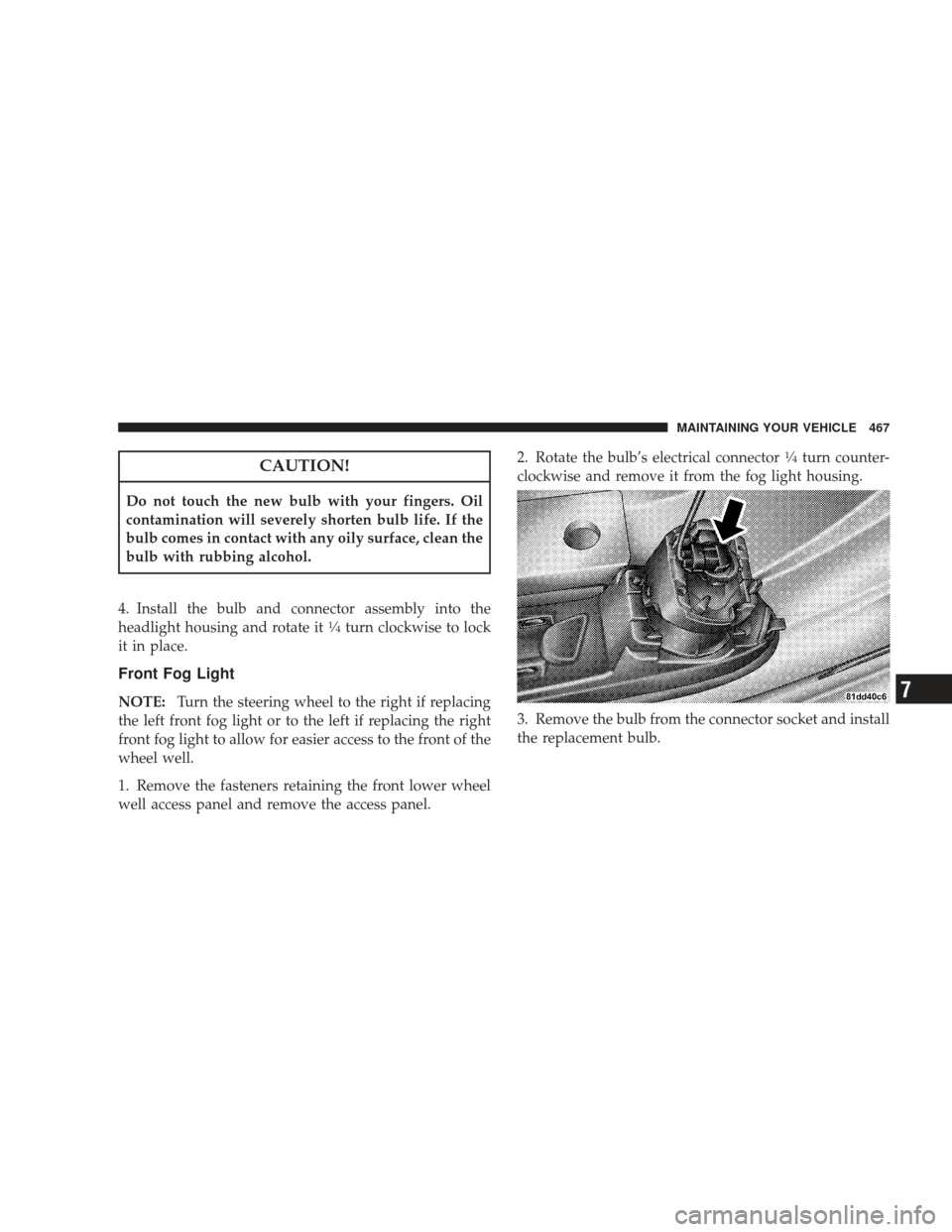

Front Fog Light

NOTE: Turn the steering wheel to the right if replacing

the left front fog light or to the left if replacing the right

front fog light to allow for easier access to the front of the

wheel well.

1. Remove the fasteners retaining the front lower wheel

well access panel and remove the access panel. 2. Rotate the bulb’s electrical connector

1�4turn counter-

clockwise and remove it from the fog light housing.

3. Remove the bulb from the connector socket and install

the replacement bulb.

MAINTAINING YOUR VEHICLE 467

7

Page 470 of 523

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

4. Install the bulb and connector assembly into the fog

light housing and rotate the connector

1�4turn clockwise

to lock it in place.

5. Reinstall the front lower wheel well access panel and

fasteners.

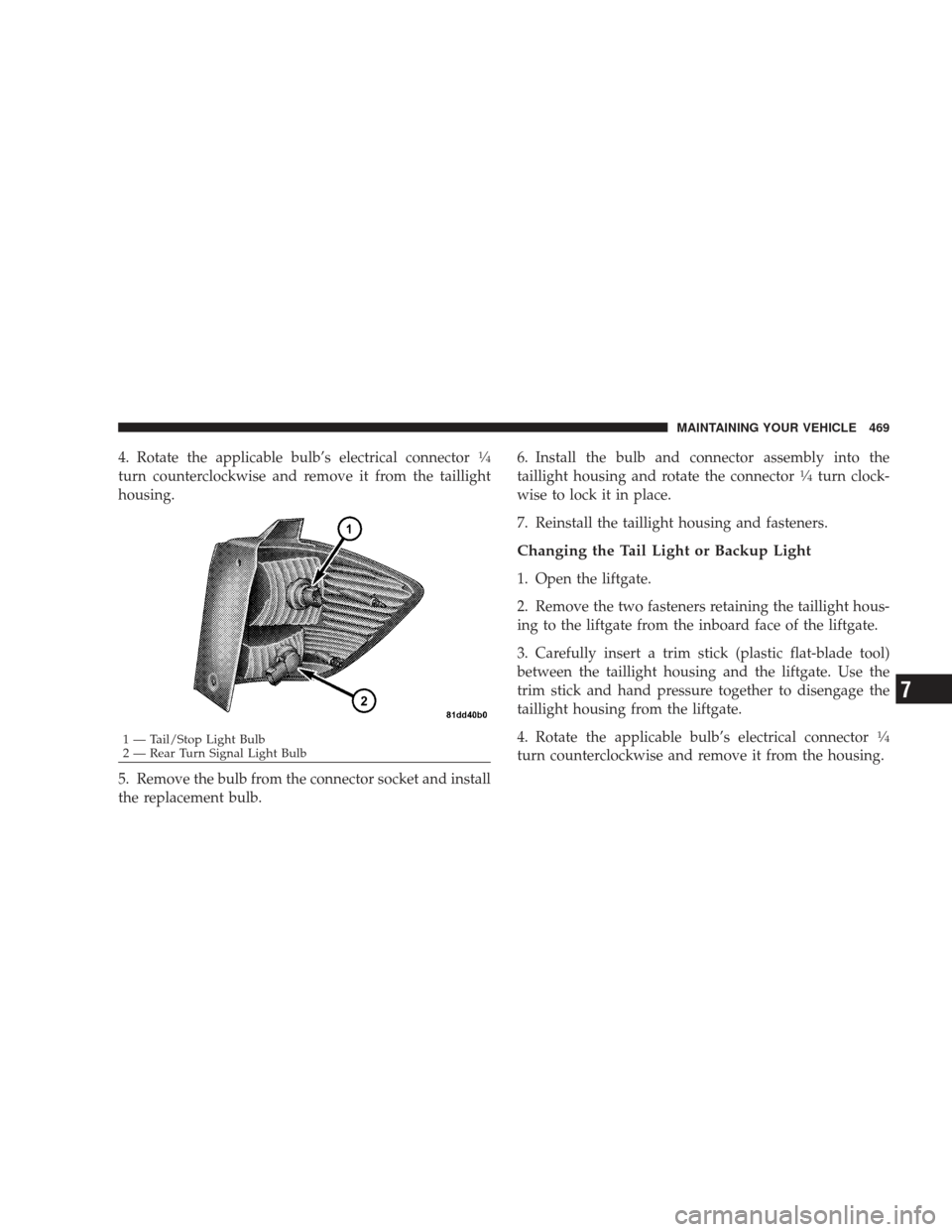

Tail/Stop Light, Rear Turn Signal Light, Tail Light,

Backup Light

The taillights are a two-piece design. The tail/stop lights

and rear turn signal lights are located in the rear corner

body panels. The tail and backup lights are located in the

liftgate.

Changing the Tail/Stop Light or Rear Turn Signal

Light

1. Open the liftgate.

2. Remove the two fasteners from the inboard side of the

taillight housing.

3. Carefully insert a trim stick (plastic flat-blade tool)

between the body panel and the outboard side of the

taillight housing with one hand and grasp the flange on

the inboard side of the taillight housing with the other

hand. Use the trim stick and hand pressure together to

disengage the taillight housing from the vehicle.

468 MAINTAINING YOUR VEHICLE

Page 471 of 523

4. Rotate the applicable bulb’s electrical connector1�4

turn counterclockwise and remove it from the taillight

housing.

5. Remove the bulb from the connector socket and install

the replacement bulb.6. Install the bulb and connector assembly into the

taillight housing and rotate the connector1�4turn clock-

wise to lock it in place.

7. Reinstall the taillight housing and fasteners.

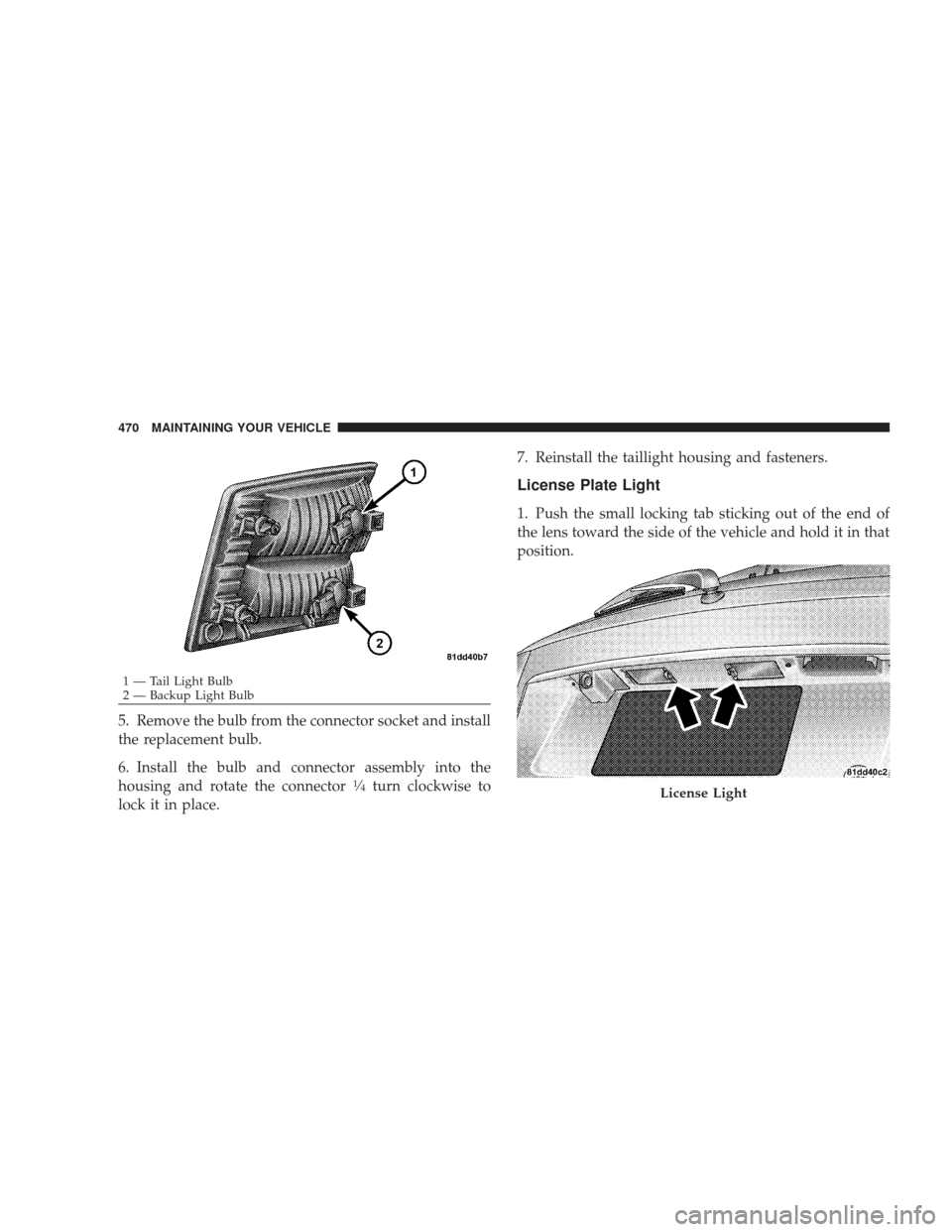

Changing the Tail Light or Backup Light

1. Open the liftgate.

2. Remove the two fasteners retaining the taillight hous-

ing to the liftgate from the inboard face of the liftgate.

3. Carefully insert a trim stick (plastic flat-blade tool)

between the taillight housing and the liftgate. Use the

trim stick and hand pressure together to disengage the

taillight housing from the liftgate.

4. Rotate the applicable bulb’s electrical connector

1�4

turn counterclockwise and remove it from the housing.

1 — Tail/Stop Light Bulb

2 — Rear Turn Signal Light Bulb MAINTAINING YOUR VEHICLE 469

7

Page 472 of 523

5. Remove the bulb from the connector socket and install

the replacement bulb.

6. Install the bulb and connector assembly into the

housing and rotate the connector

1�4turn clockwise to

lock it in place. 7. Reinstall the taillight housing and fasteners.

License Plate Light

1. Push the small locking tab sticking out of the end of

the lens toward the side of the vehicle and hold it in that

position.

1 — Tail Light Bulb

2 — Backup Light Bulb

License Light

470 MAINTAINING YOUR VEHICLE

Page 473 of 523

2. Insert a small flat-blade tool between the end of the

lens with the locking tab and the surrounding housing

and then pivot the tool to separate the lens from the

housing.

3. Hold the lens with one hand and rotate the bulb’s

electrical connector

1�4turn counterclockwise with the

other hand and then separate the bulb and connector

assembly from the lens.

4. Remove the bulb from the connector socket and install

the replacement bulb. 5. Install the bulb and connector assembly into the lens

and rotate the connector

1�4turn clockwise to lock it in

place.

6. Insert the end of the lens without the locking tab into

the housing on the liftgate and then push the opposite

end of the lens into the housing, making sure it locks in

the housing.

MAINTAINING YOUR VEHICLE 471

7

Page 501 of 523

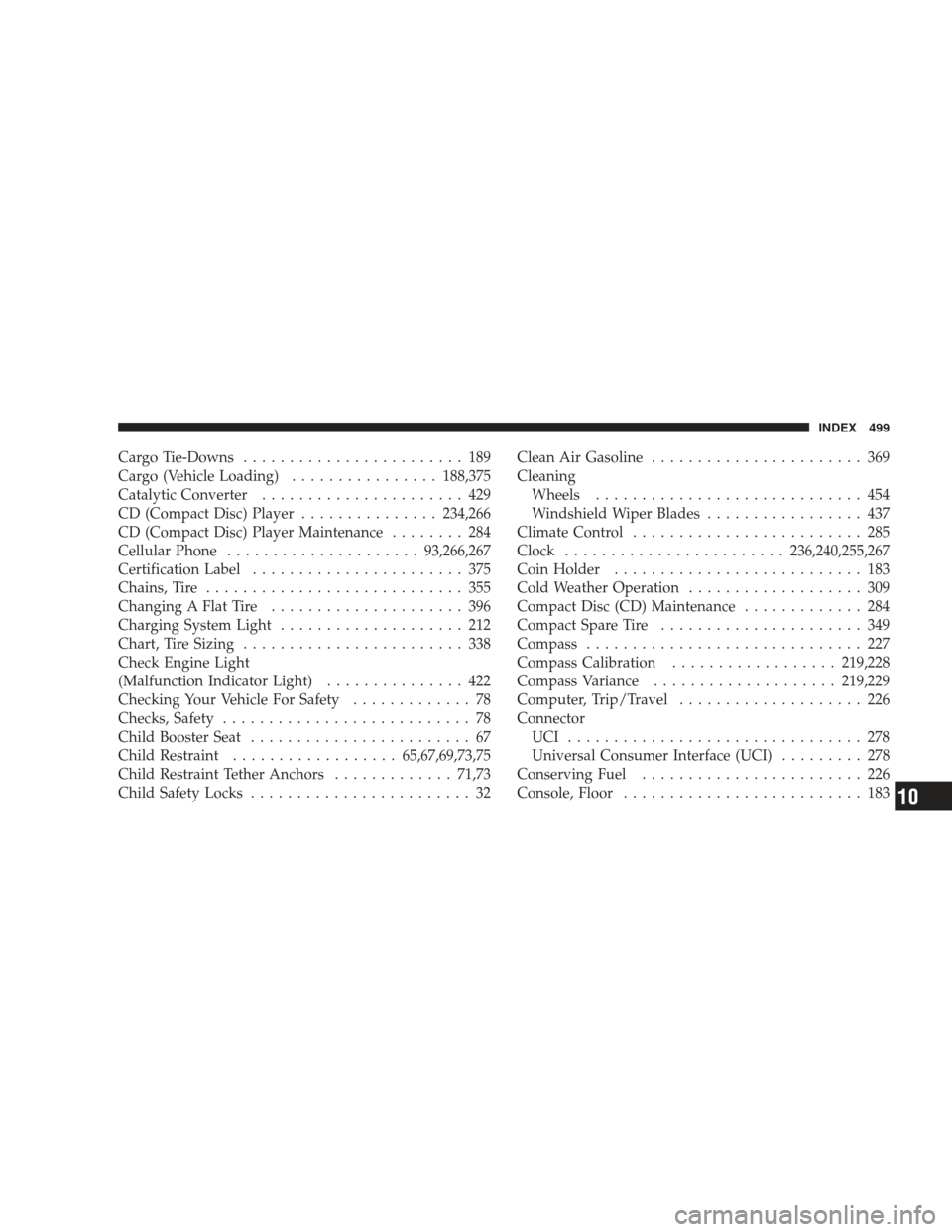

Cargo Tie-Downs........................ 189

Cargo (Vehicle Loading) ................188,375

Catalytic Converter ...................... 429

CD (Compact Disc) Player ...............234,266

CD (Compact Disc) Player Maintenance ........ 284

Cellular Phone ..................... 93,266,267

Certification Label ....................... 375

Chains, Tire ............................ 355

Changing A Flat Tire ..................... 396

Charging System Light .................... 212

Chart, Tire Sizing ........................ 338

Check Engine Light

(Malfunction Indicator Light) ............... 422

Checking Your Vehicle For Safety ............. 78

Checks, Safety ........................... 78

Child Booster Seat ........................ 67

Child Restraint .................. 65,67,69,73,75

Child Restraint Tether Anchors .............71,73

Child Safety Locks ........................ 32 Clean Air Gasoline

....................... 369

Cleaning Wheels ............................. 454

Windshield Wiper Blades ................. 437

Climate Control ......................... 285

Clock ........................ 236,240,255,267

Coin Holder ........................... 183

Cold Weather Operation ................... 309

Compact Disc (CD) Maintenance ............. 284

Compact Spare Tire ...................... 349

Compass .............................. 227

Compass Calibration .................. 219,228

Compass Variance .................... 219,229

Computer, Trip/Travel .................... 226

Connector UCI ................................ 278

Universal Consumer Interface (UCI) ......... 278

Conserving Fuel ........................ 226

Console, Floor .......................... 183

INDEX 499

10