oil light DODGE JOURNEY 2009 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2009, Model line: JOURNEY, Model: DODGE JOURNEY 2009 1.GPages: 523

Page 82 of 523

Whenever a change is noticed in the sound of the exhaust

system, when exhaust fumes can be detected inside the

vehicle, or when the underside or rear of the vehicle is

damaged, have a competent mechanic inspect the com-

plete exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

Safety Checks You Should Make Inside The

Vehicle

Seat Belts

Inspect the seat belt system periodically, checking for

cuts, frays, and loose parts. Damaged parts must be

replaced immediately. Do not disassemble or modify the

system.Front seat belt assemblies must be replaced after a

collision. Rear seat belt assemblies must be replaced after

a collision if they have been damaged (i.e., bent retractor,

torn webbing, etc.). If there is any question regarding belt

or retractor condition, replace the seat belt.

Airbag Warning Light

The light should turn on and remain on for four to six

seconds as a bulb check when the ignition switch is first

turned ON. If the light is not lit during starting, or if the

light stays on, flickers, or turns on while driving, have the

system checked by an authorized dealer.

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield. See your

authorized dealer for service if your defroster is inoper-

able.

80 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 83 of 523

Periodic Safety Checks You Should Make Outside

The Vehicle

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread. Inspect the tread and sidewall for

cuts and cracks. Check the wheel nuts for tightness.

Check the tires (including spare) for proper pressure.

Lights

Have someone observe the operation of exterior lights

while you work the controls. Check Turn Signal and High

Beam Indicator Lights on the instrument panel.

Door Latches

Check for positive closing, latching, and locking.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

engine coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel, power steering fluid, or

brake fluid leaks are suspected, the cause should be

located and corrected immediately.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 81

2

Page 209 of 523

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, refer to Section 7 and follow the

warnings under the Cooling System Pressure Cap

paragraph.

5. Front Fog Light Indicator Light — If Equipped This light shows when the fog lights are ON. (See

page 148 for more information.)

6. Low Fuel Warning Light This indicator lights when the fuel level drops to

approximately one-eighth tank. (See page 372 for

more information.) 7. Turn Signal Indicator Light

The left or right arrow will flash in unison with the

corresponding front and rear turn signal lights when

the turn signal switch is operated. (See page 149 for more

information.)

NOTE: A chime will sound if the vehicle is driven more

than 1 mi (1.6 km) with either turn signal on.

NOTE: Check for an inoperative outside light bulb if

either indicator flashes at a rapid rate.

8. High Beam Indicator Light This light shows that the headlights are on high

beam. Pull the multifunction lever on the left side

of the steering column toward you to switch to low beam.

(See page 150 for more information.)

9. Speedometer

Shows the vehicle speed.

UNDERSTANDING YOUR INSTRUMENT PANEL 207

4

Page 213 of 523

16. Electronic Throttle Control (ETC) Warning Light —

If EquippedThis light will turn on briefly as a bulb check

when the ignition switch is turned ON. This

light will also turn on while the engine is

running if there is a problem with the Elec-

tronic Throttle Control (ETC) system.

If the light turns on while the engine is running, safely

bring the vehicle to a complete stop as soon as possible,

place the shift lever in PARK, and cycle the ignition key.

The light should turn off. If the light remains lit with the

engine running, your vehicle will usually be drivable.

However, see your authorized dealer for service as soon

as possible.

If the light is flashing when the engine is running,

immediate service is required. In this case, you may

experience reduced performance, an elevated/rough idle

or engine stall, and your vehicle may require towing. Also, have the system checked by an authorized dealer if

the light does not turn on during starting.

17. Oil Pressure Warning Light

This light shows low engine oil pressure. The light

will turn on and remain on when the ignition

switch is turned from the LOCK or ACC position to the

ON position. The light will turn off after the engine is

started.

If the light does not turn on during starting, have the

system checked by an authorized dealer.

If the light turns on and remains on while driving, safely

bring the vehicle to a stop and shut off the engine. DO

NOT OPERATE THE VEHICLE UNTIL THE CAUSE IS

CORRECTED. This light does not show the quantity of

oil in the engine. The engine oil level must be checked

using the proper procedure. (See page 424 for more

information.)

UNDERSTANDING YOUR INSTRUMENT PANEL 211

4

Page 227 of 523

•Coolant Low

•Key in Ignition

•Lights On

Oil Change Required

Your vehicle is equipped with an engine oil change

indicator system. The “Oil Change Required” message

will display in the EVIC for approximately 5 seconds

after a single chime has sounded to indicate the next

scheduled oil change interval. The engine oil change

indicator system is duty cycle based, which means the

engine oil change interval may fluctuate dependent upon

your personal driving style.

Unless reset, this message will continue to display each

time you turn the ignition switch to the ON position. To

turn off the message temporarily, press and release theMENU button. To reset the oil change indicator system

(after performing the scheduled maintenance) perform

the following procedure:

1. Turn the ignition switch to the ON position (Do not

start the engine).

2. Fully depress the accelerator pedal slowly three times

within 10 seconds.

3. Turn the ignition switch to the LOCK position.

NOTE:

If the indicator message illuminates when you

start the vehicle, the oil change indicator system did not

reset. If necessary, repeat this procedure.

UNDERSTANDING YOUR INSTRUMENT PANEL 225

4

Page 354 of 523

These indicators are molded into the bottom of the tread

grooves. They will appear as bands when the tread depth

becomes 1/16 in (2 mm). When the tread is worn to the

tread wear indicators, the tire should be replaced.

Many states have laws requiring tire replacement at this

point.

Life of Tire

The service life of a tire is dependent upon varying

factors including, but not limited to:

•Driving style

•Tire pressure

•Distance driven

WARNING!

Tires and the spare tire should be replaced after six

years, regardless of the remaining tread. Failure to

follow this warning can result in sudden tire failure.

You could lose control and have an accident resulting

in serious injury or death.

Keep dismounted tires in a cool, dry place with as little

exposure to light as possible. Protect tires from contact

with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for

wear and correct cold tire inflation pressure. The manu-

facturer strongly recommends that you use tires equiva-

lent to the originals in size, quality and performance

when replacement is needed. (Refer to the paragraph on

352 STARTING AND OPERATING

Page 449 of 523

Ensure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:

•Often, fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations

to ease the assembly of hoses to couplings. Therefore,

oil wetness at the hose-coupling area is not necessarily

an indication of leakage. Actual dripping of hot fluid

when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

•Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replacedimmediately. Eventual deterioration of the hose can

take place, resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder - Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the Brake System Warning Light indicates system

failure.

Check the fluid level in the master cylinder when per-

forming underhood services.

MAINTAINING YOUR VEHICLE 447

7

Page 469 of 523

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

4. Install the bulb and connector assembly into the

headlight housing and rotate it

1�4turn clockwise to lock

it in place.

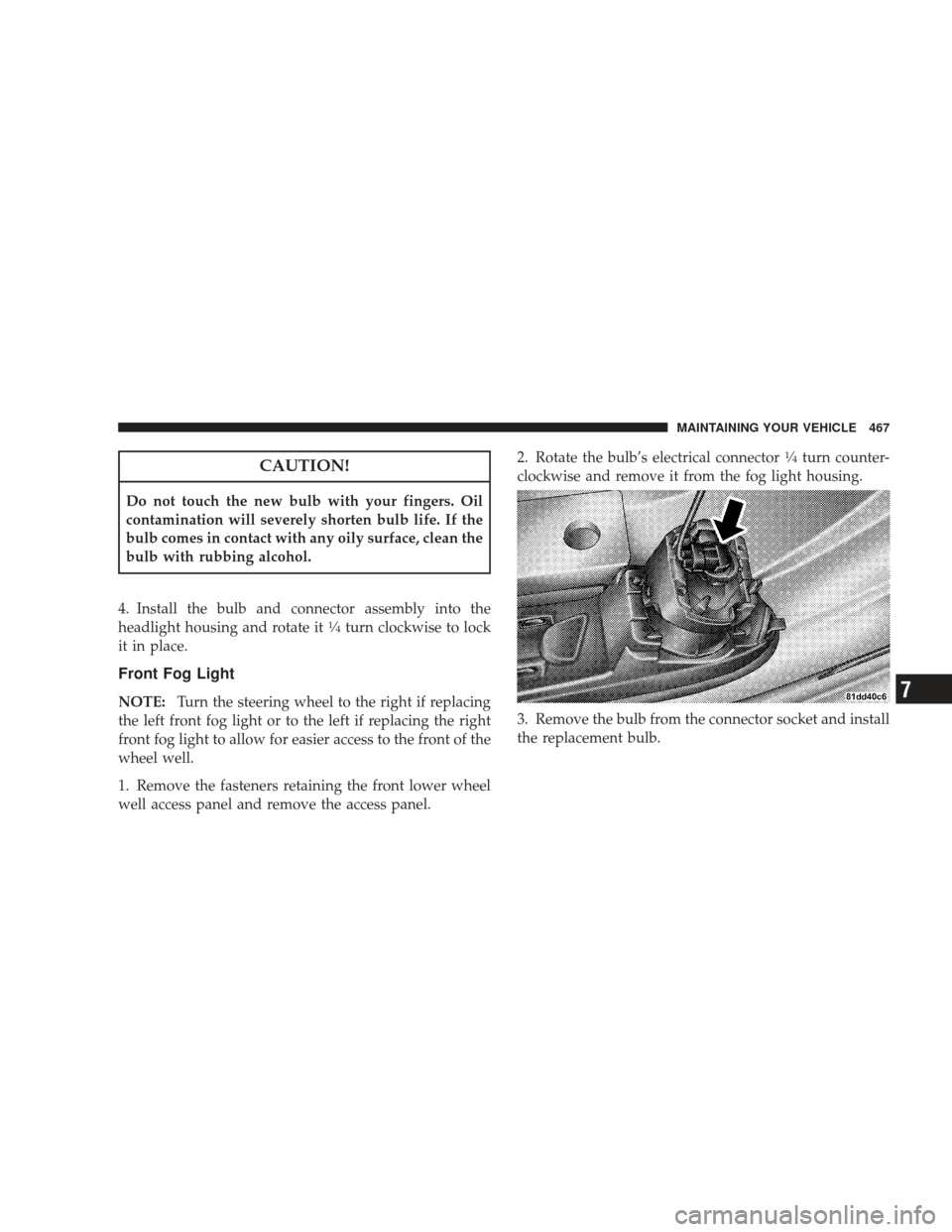

Front Fog Light

NOTE: Turn the steering wheel to the right if replacing

the left front fog light or to the left if replacing the right

front fog light to allow for easier access to the front of the

wheel well.

1. Remove the fasteners retaining the front lower wheel

well access panel and remove the access panel. 2. Rotate the bulb’s electrical connector

1�4turn counter-

clockwise and remove it from the fog light housing.

3. Remove the bulb from the connector socket and install

the replacement bulb.

MAINTAINING YOUR VEHICLE 467

7

Page 470 of 523

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

4. Install the bulb and connector assembly into the fog

light housing and rotate the connector

1�4turn clockwise

to lock it in place.

5. Reinstall the front lower wheel well access panel and

fasteners.

Tail/Stop Light, Rear Turn Signal Light, Tail Light,

Backup Light

The taillights are a two-piece design. The tail/stop lights

and rear turn signal lights are located in the rear corner

body panels. The tail and backup lights are located in the

liftgate.

Changing the Tail/Stop Light or Rear Turn Signal

Light

1. Open the liftgate.

2. Remove the two fasteners from the inboard side of the

taillight housing.

3. Carefully insert a trim stick (plastic flat-blade tool)

between the body panel and the outboard side of the

taillight housing with one hand and grasp the flange on

the inboard side of the taillight housing with the other

hand. Use the trim stick and hand pressure together to

disengage the taillight housing from the vehicle.

468 MAINTAINING YOUR VEHICLE

Page 482 of 523

At Each Stop for Fuel

•Check the engine oil level. Refer to “Engine Oil” under

“Maintenance Procedures” in Section 7.

•Check the windshield washer solvent and add if

required.

Once a Month

•Check tire pressure and look for unusual wear or

damage.

•Inspect the battery, and clean and tighten the terminals

as required.

•Check the fluid levels of coolant reservoir, brake

master cylinder, power steering, and transaxle, and

add as needed.

•Check all lights and other electrical items for correct

operation. At Each Oil Change

•Change the engine oil filter.

•Inspect the brake hoses and lines.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

480 MAINTENANCE SCHEDULES

8

M

A I

N T

E

N A

N CE

S

C

H E

D

U L

E

S