flat tire DODGE JOURNEY 2014 1.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2014, Model line: JOURNEY, Model: DODGE JOURNEY 2014 1.GPages: 124, PDF Size: 3.37 MB

Page 76 of 124

- Air Bag Warning Light

This light will turn on for four to eight seconds as a bulb check when the ignition switch is

first turned to the ON/RUN position. If the light is either not on during starting, stays on, or

turns on while driving, have the system inspected at an authorized dealer as soon as

possible. Refer to “Occupant Restraints” in “Things To Know Before Starting Your Vehicle” of

your Owner’s Manual for further information.

NOTE:

The Air Bag System is designed to be maintenance free.

- Electronic Throttle Control (ETC) Light

This light informs you of a problem with the Electronic Throttle Control (ETC) system.

If a problem is detected, the light will come on while the engine is running. Cycle the ignition

when the vehicle has completely stopped and the shift lever is placed in the PARK position;

the light should turn off.

If the light remains lit with the engine running, your vehicle will usually be drivable; however,

see an authorized service center immediately. If the light is flashing when the engine is

running, immediate service is required and you may experience reduced performance, an

elevated/rough idle or engine stall and your vehicle may require towing.

- Tire Pressure Monitoring System (TPMS) Light

Each tire, including the spare (if provided), should be checked monthly, when cold and

inflated to the inflation pressure recommended by the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. (If your vehicle has tires of a different size than the

size indicated on the vehicle placard or tire inflation pressure label, you should determine

the proper tire inflation pressure for those tires.)

As an added safety feature, your vehicle has been equipped with a Tire Pressure Monitoring

System (TPMS) which display in the Electronic Vehicle Information Center (EVIC) when one

or more of your tires is significantly under-inflated. Accordingly, when the low tire pressure

EVIC display illuminates, you should stop and check your tires as soon as possible, and

inflate them to the proper pressure. Driving on a significantly under-inflated tire causes the

tire to overheat and can lead to tire failure. Under-inflation also reduces fuel efficiency and

tire tread life, and may affect the vehicle’s handling and stopping ability.

IF THE LIGHT STARTS FLASHING INDICATING A LOW TIRE PRESSURE, ADJUST THE AIR

PRESSURE IN THE LOW TIRE TO THE AIR PRESSURE SHOWN ON THE VEHICLE PLACARD

OR TIRE INFLATION PRESSURE LABEL LOCATED ON THE DRIVER'S DOOR.

NOTE:

After inflation, the vehicle may need to be driven for 20 minutes before the flashing light

will turn off.

WHAT TO DO IN EMERGENCIES

74

Page 77 of 124

Please note that the TPMS is not a substitute for proper tire maintenance, and it is the

driver’s responsibility to maintain correct tire pressure, even if under-inflation has not

reached the level to trigger illumination of the TPMS low EVIC display.

Your vehicle has also been equipped with a TPMS malfunction indicator to indicate when

the system is not operating properly. The TPMS malfunction indicator is combined with the

low tire pressure telltale. When the system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously illuminated. This sequence will

continue each time the vehicle is restarted as long as the malfunction exists.

When the malfunction indicator is illuminated, the system may not be able to detect or

signal low tire pressure as intended. TPMS malfunctions may occur for a variety of reasons,

including the installation of replacement or alternate tires or wheels on the vehicle that

prevent the TPMS from functioning properly. Always check the TPMS malfunction telltale

after replacing one or more tires or wheels on your vehicle, to ensure that the replacement

or alternate tires and wheels allow the TPMS to continue to function properly.

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air temperature

change. Keep this in mind when checking tire pressure inside a garage, especially in the

Winter. Example: If garage temperature is 68°F (20°C) and the outside temperature is 32°F

(0°C), then the cold tire inflation pressure should be increased by 3 psi (21 kPa), which equals

1 psi (7 kPa) for every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or balance beads if your vehicle is

equipped with a TPMS, as damage to the sensors may result.

- Engine Temperature Warning Light

This light warns of an overheated engine condition.

If the light turns on and a warning chime sounds while driving, safely pull over and stop the

vehicle. If the A/C system is on, turn it off. Also, shift the transmission into NEUTRAL and idle the

vehicle. If the temperature reading does not return to normal, turn the engine off immediately.

We recommend that you do not operate the vehicle or engine damage will occur. Have the

vehicle serviced immediately.

WARNING!

A hot engine cooling system is dangerous. You or others could be badly burned by steam

or boiling coolant.

WHAT TO DO IN EMERGENCIES

75

Page 83 of 124

5. Turn OFF the ignition.

6. Block both the front and rear of the wheel diagonally opposite of the jacking position.For example, if changing the right front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Spare Tire Removal

NOTE:

On seven-passenger models, fold the third-row passenger seats flat. This will provide more

space when accessing the jacking tools and when operating the winch mechanism.

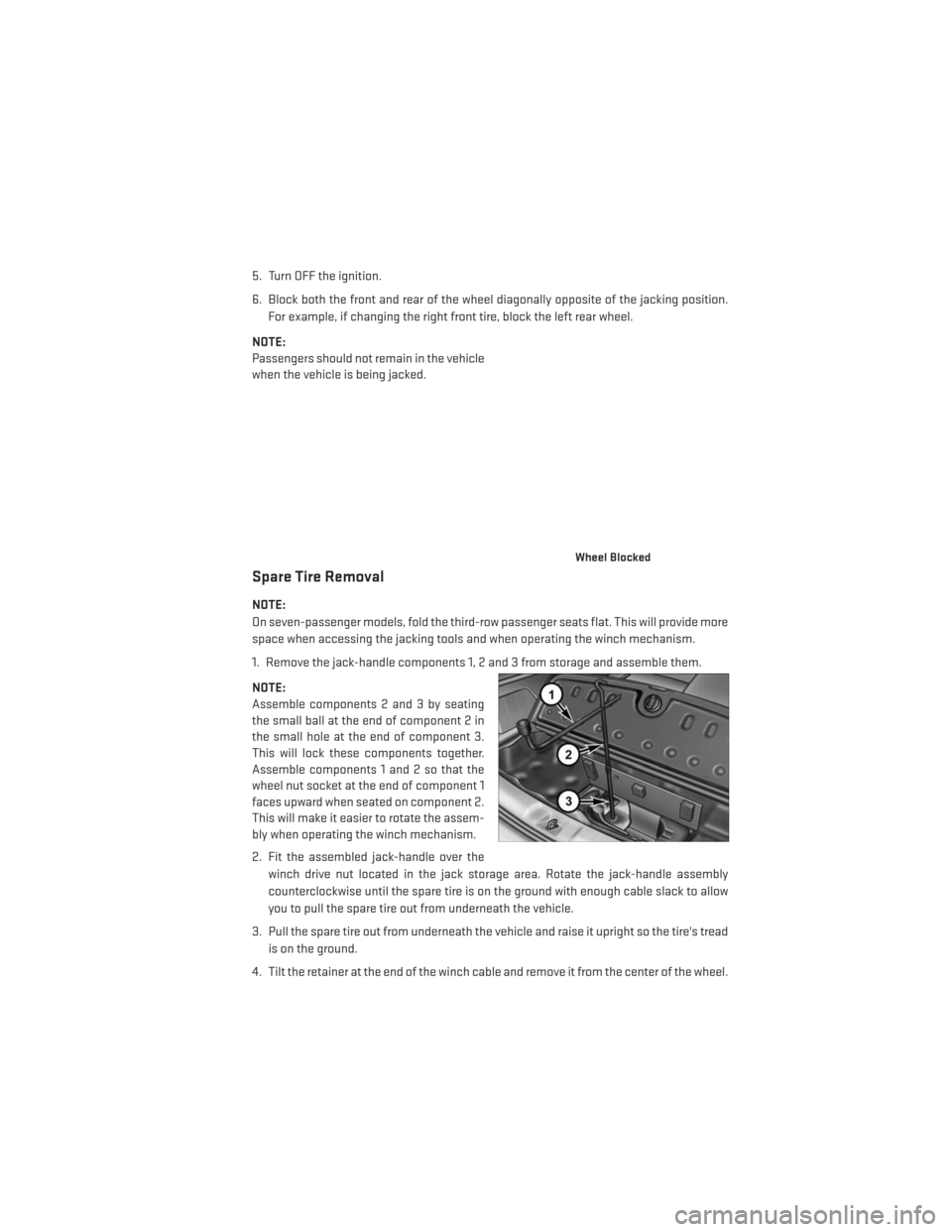

1. Remove the jack-handle components 1, 2 and 3 from storage and assemble them.

NOTE:

Assemble components 2 and 3 by seating

the small ball at the end of component 2 in

the small hole at the end of component 3.

This will lock these components together.

Assemble components 1 and 2 so that the

wheel nut socket at the end of component 1

faces upward when seated on component 2.

This will make it easier to rotate the assem-

bly when operating the winch mechanism.

2. Fit the assembled jack-handle over the winch drive nut located in the jack storage area. Rotate the jack-handle assembly

counterclockwise until the spare tire is on the ground with enough cable slack to allow

you to pull the spare tire out from underneath the vehicle.

3. Pull the spare tire out from underneath the vehicle and raise it upright so the tire's tread is on the ground.

4. Tilt the retainer at the end of the winch cable and remove it from the center of the wheel.

Wheel Blocked

WHAT TO DO IN EMERGENCIES

81

Page 84 of 124

Spare Tire Stowage

NOTE:

Refer to “Spare Tire Removal” for information on assembling the winch tools.

1.

Place the spare tire near to the winch cable. Hold the spare upright so that the tire's tread is on

the ground and the valve stem is at the top of the wheel facing away from the rear of the

vehicle.

2. Tilt the retainer at the end of the winch cable and drop it through the center of the wheel. Then place the spare tire with the cable and retainer underneath the vehicle.

3.

Fit the assembled jack-handle over the winch drive nut. Rotate the jack-handle assembly

clockwise to raise the spare tire into the storage area. Continue to rotate the jack-handle

assembly until you hear the winch mechanism click three times. It cannot be over tightened.

Push against the tire several times to be sure it is held securely in place.

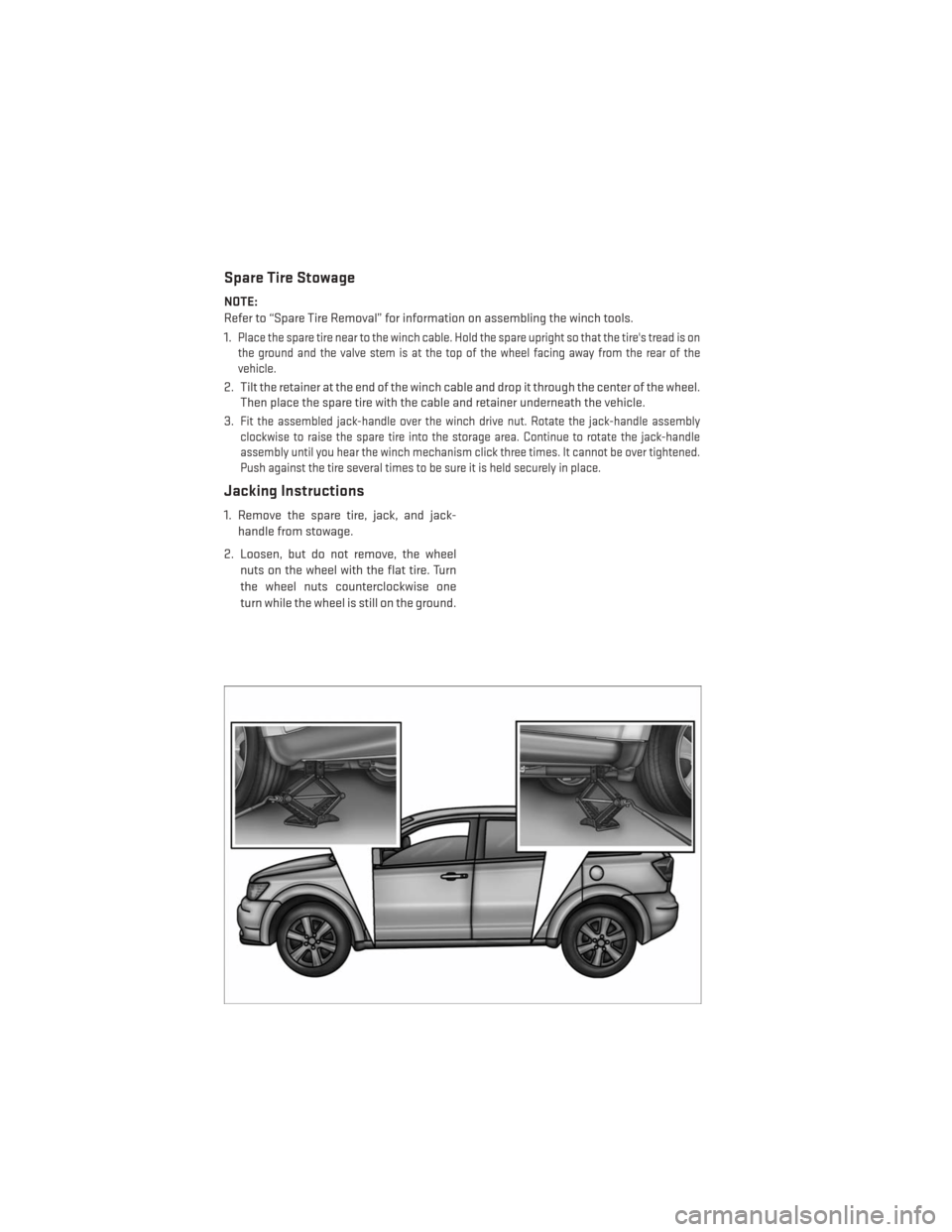

Jacking Instructions

1. Remove the spare tire, jack, and jack-

handle from stowage.

2. Loosen, but do not remove, the wheel nuts on the wheel with the flat tire. Turn

the wheel nuts counterclockwise one

turn while the wheel is still on the ground.

WHAT TO DO IN EMERGENCIES

82

Page 85 of 124

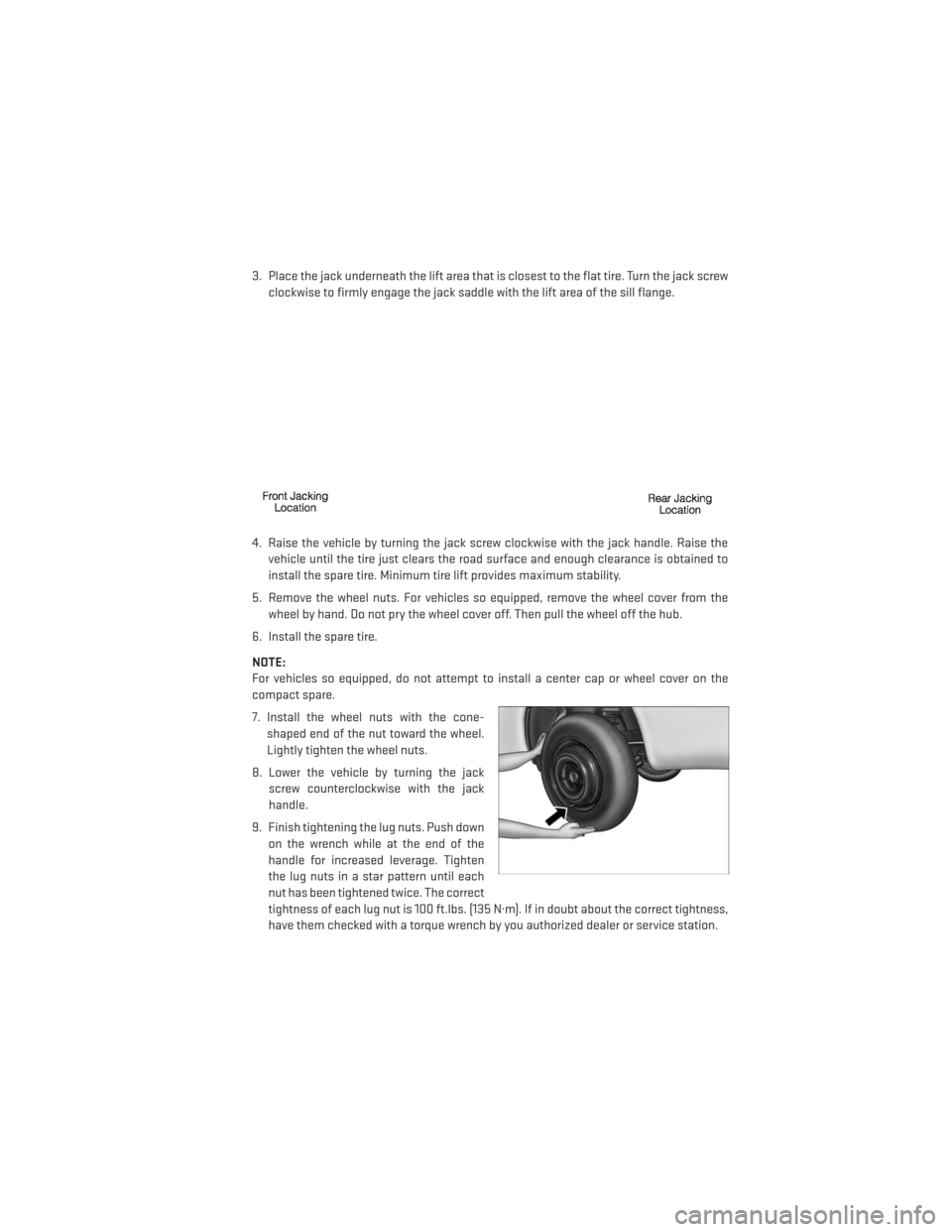

3. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screwclockwise to firmly engage the jack saddle with the lift area of the sill flange.

4. Raise the vehicle by turning the jack screw clockwise with the jack handle. Raise the vehicle until the tire just clears the road surface and enough clearance is obtained to

install the spare tire. Minimum tire lift provides maximum stability.

5. Remove the wheel nuts. For vehicles so equipped, remove the wheel cover from the wheel by hand. Do not pry the wheel cover off. Then pull the wheel off the hub.

6. Install the spare tire.

NOTE:

For vehicles so equipped, do not attempt to install a center cap or wheel cover on the

compact spare.

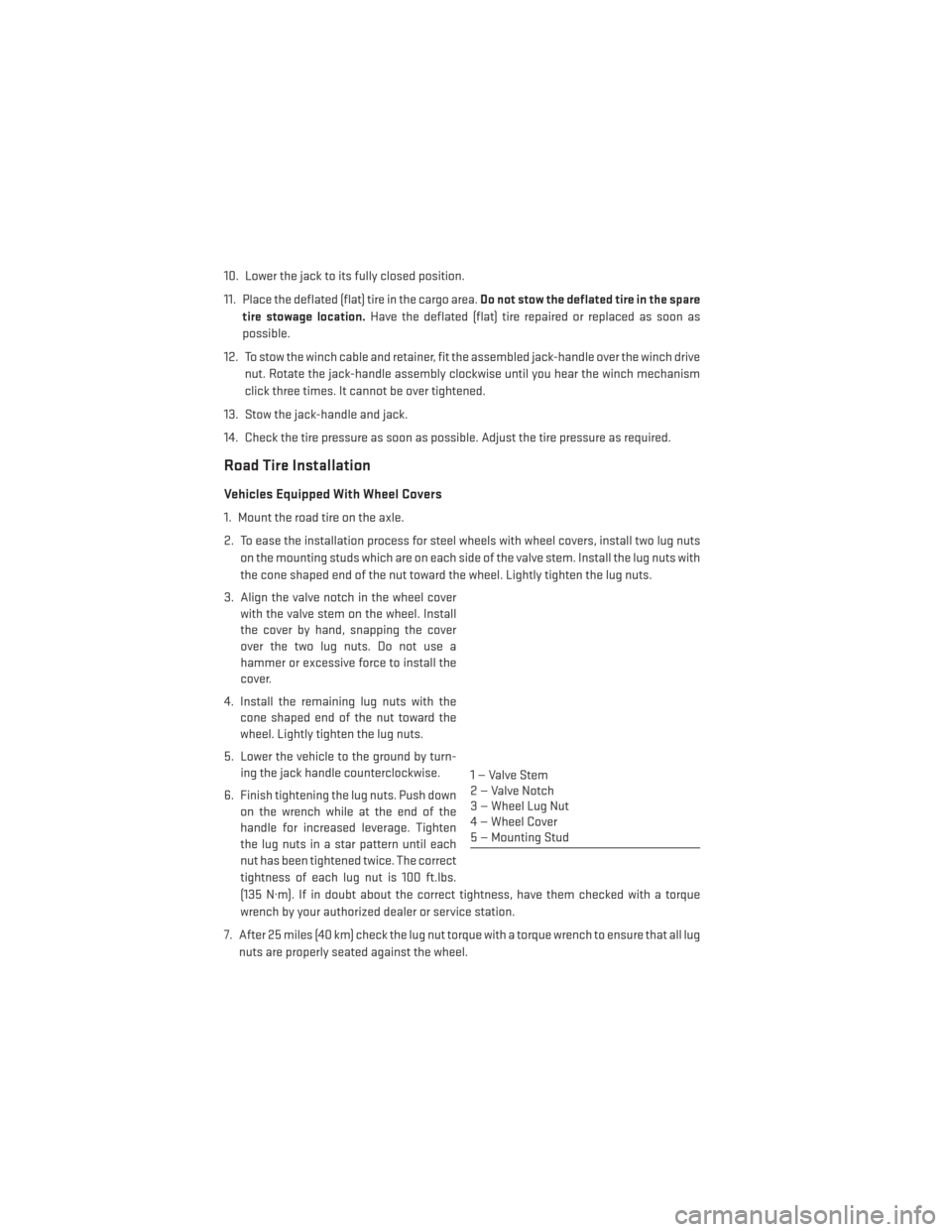

7. Install the wheel nuts with the cone- shaped end of the nut toward the wheel.

Lightly tighten the wheel nuts.

8. Lower the vehicle by turning the jack screw counterclockwise with the jack

handle.

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten

the lug nuts in a star pattern until each

nut has been tightened twice. The correct

tightness of each lug nut is 100 ft.lbs. (135 N·m). If in doubt about the correct tightness,

have them checked with a torque wrench by you authorized dealer or service station.

WHAT TO DO IN EMERGENCIES

83

Page 86 of 124

10. Lower the jack to its fully closed position.

11. Place the deflated (flat) tire in the cargo area.Do not stow the deflated tire in the spare

tire stowage location. Have the deflated (flat) tire repaired or replaced as soon as

possible.

12. To stow the winch cable and retainer, fit the assembled jack-handle over the winch drive nut. Rotate the jack-handle assembly clockwise until you hear the winch mechanism

click three times. It cannot be over tightened.

13. Stow the jack-handle and jack.

14. Check the tire pressure as soon as possible. Adjust the tire pressure as required.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts on the mounting studs which are on each side of the valve stem. Install the lug nuts with

the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two lug nuts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

5. Lower the vehicle to the ground by turn- ing the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten

the lug nuts in a star pattern until each

nut has been tightened twice. The correct

tightness of each lug nut is 100 ft.lbs.

(135 N·m). If in doubt about the correct tightness, have them checked with a torque

wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

1 — Valve Stem

2 — Valve Notch

3 — Wheel Lug Nut

4 — Wheel Cover

5 — Mounting Stud

WHAT TO DO IN EMERGENCIES

84

Page 88 of 124

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pullfar enough off the road to avoid the danger of being hit when operating the jack or

changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the jack and

fall on you. You could be crushed. Never put any part of your body under a vehicle that

is on a jack. If you need to get under a raised vehicle, take it to an authorized service

center where it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack should not

be used to lift the vehicle for service purposes. The vehicle should be jacked on a firm

level surface only. Avoid ice or slippery areas.

• Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible

before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire

change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

• Raising the vehicle higher than necessary can make the vehicle less stable. It could

slip off the jack and hurt someone near it. Raise the vehicle only enough to remove

the tire.

• To avoid possible personal injury, handle the wheel covers with care to avoid contact

with any sharp edges.

• To avoid the risk of forcing the vehicle off the jack, do not tighten the wheel nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

personal injury.

• A loose tire or jack, thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired or replaced immediately.

WHAT TO DO IN EMERGENCIES

86

Page 107 of 124

Cavity Cartridge Fuse Mini-FuseDescription

F166 20 Amp YellowSpare

F167 30 Amp Green Powertrain Shutdown

F168 10 Amp Red Air Conditioner Clutch

F169 40 Amp Green Emissions – Partial Zero Emissions

Vehicle Motor

F170 15 Amp BlueEmissions – Partial Zero Emissions

Vehicle Actuators

F172 20 Amp YellowSpare

F173 25 Amp Natural Anti Lock Brake Valves

F174 20 Amp Yellow Siren – If Equipped

F175 30 Amp GreenSpare

F176 10 Amp Red Powertrain Control Modules

F177 20 Amp YellowAll Wheel Drive Module –

If Equipped

F178 25 Amp Natural Sunroof – If Equipped

F179 10 Amp RedBattery Sensor

F181 100 Amp Blue Electrohydraulic Steering (EHPS) –

If Equipped

F182 50 Amp Red Cabin Heater #3 – If Equipped

F184 30 Amp Pink Front Wiper Motor

TIRE PRESSURES

Check the inflation pressure of each tire, including the spare tire, at least monthly and

inflate to the recommended pressure for your vehicle.

The tire pressures recommended for your vehicle are found on the “Tire and Loading

Information” label located on the driver’s side door opening.

NOTE:

Refer to the Owner's Manual on the DVD for

more information regarding tire warnings

and instructions.

Tire And Loading Information Location

(Example)

MAINTAINING YOUR VEHICLE

105

Page 108 of 124

WARNING!

• Overloading of your tires is dangerous. Overloading can cause tire failure, affectvehicle handling, and increase your stopping distance. Use tires of the recom-

mended load capacity for your vehicle. Never overload them.

• Improperly inflated tires are dangerous and can cause collisions. Under-inflation is

the leading cause of tire failure and may result in severe cracking, component

separation, or “blow out”. Over-inflation reduces a tire’s ability to cushion shock.

Objects on the road and chuck holes can cause damage that results in tire failure.

Unequal tire pressures can cause steering problems. You could lose control of your

vehicle. Over-inflated or under-inflated tires can affect vehicle handling and can fail

suddenly, resulting in loss of vehicle control.

WHEEL AND WHEEL TRIM CARE

All wheels and wheel trim, especially aluminum and chrome plated wheels, should be

cleaned regularly with a mild soap and water to prevent corrosion.

To remove heavy soil and/or excessive brake dust, use MOPAR® Wheel Cleaner or equiva-

lent or select a non-abrasive, non-acidic cleaner.

CAUTION!

Do not use scouring pads, steel wool, a bristle brush, or metal polishes. Do not use oven

cleaner. These products may damage the wheel's protective finish. Avoid automatic car

washes that use acidic solutions or harsh brushes that may damage the wheel's protec-

tive finish. Only MOPAR® Wheel Cleaner or equivalent is recommended.

MAINTAINING YOUR VEHICLE

106

Page 113 of 124

FREQUENTLY ASKED QUESTIONS

GETTING STARTED

• How do I install my LATCH Equipped Child Seat? pg. 16

• How do I move my rear seats? pg. 23

ELECTRONICS

• How do I know which radio I have?• Uconnect® 4.3 & 4.3S pg. 41

• Uconnect® 8.4 & 8.4N pg. 42

• How do I select the AUX music source? pg. 54

• How do I set the clock on my radio?

• Uconnect® 4.3 & 4.3S pg. 41

• Uconnect® 8.4 & 8.4N pg. 42

• How do I use the Navigation feature? pg. 50

• How do I pair my cell phone via Bluetooth® with the Uconnect® Hands-Free Voice Activation System? pg. 55

• How do I hear the audio from my iPod® through the USB port using the radio?

• Uconnect® 4.3 & 4.3S pg. 54

• Uconnect® 8.4, 8.4N pg. 54

• How do I configure my Universal Garage Door Opener (HomeLink®)? pg. 66

UTILITY

• How do I know how much I can tow with my Dodge Journey? pg. 71

WHAT TO DO IN EMERGENCIES

• What do I do if my TPMS warning light is blinking? pg. 74

• How do I change a flat tire? pg. 80

• How do I Jump-Start my vehicle? pg. 87

MAINTAINING YOUR VEHICLE

• Where is my Fuse Block located?

• Interior Fuses pg. 103

• Underhood Fuses pg. 104

• What type of oil do I use? pg. 96

• How often should I change my engine’s oil? pg. 98

• What should my tire pressure be set at? pg. 105

FREQUENTLY ASKED QUESTIONS

111