light DODGE JOURNEY 2019 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2019, Model line: JOURNEY, Model: DODGE JOURNEY 2019Pages: 524, PDF Size: 5.29 MB

Page 265 of 524

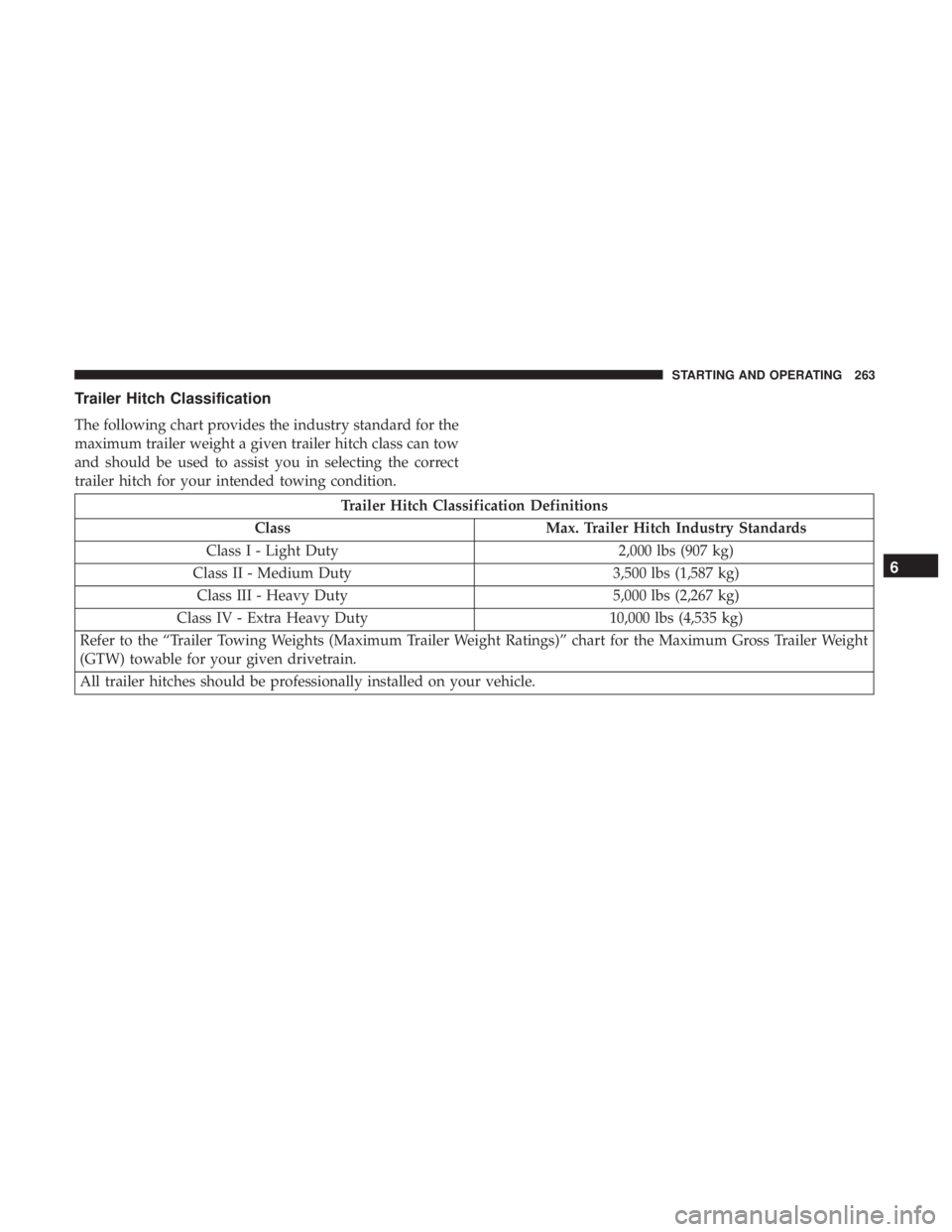

Trailer Hitch Classification

The following chart provides the industry standard for the

maximum trailer weight a given trailer hitch class can tow

and should be used to assist you in selecting the correct

trailer hitch for your intended towing condition.

Trailer Hitch Classification Definitions

Class Max. Trailer Hitch Industry Standards

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium Duty 3,500 lbs (1,587 kg)

Class III - Heavy Duty 5,000 lbs (2,267 kg)

Class IV - Extra Heavy Duty 10,000 lbs (4,535 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” chart for the Maximum Gross Trailer Weight

(GTW) towable for your given drivetrain.

All trailer hitches should be professionally installed on your vehicle.

6

STARTING AND OPERATING 263

Page 270 of 524

•When replacing tires, refer to “Tires” in “Servicing And

Maintenance” for the proper tire replacement proce-

dures. Replacing tires with a higher load carrying capac-

ity will not increase the vehicle’s GVWR and GAWR

limits.

Towing Requirements — Trailer Brakes

• Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible per-

sonal injury.

• An electronically actuated trailer brake controller is

required when towing a trailer with electronically actu-

ated brakes. When towing a trailer equipped with a

hydraulic surge actuated brake system, an electronic

brake controller is not required.

• Trailer brakes are recommended for trailers over

1,000 lbs (453 kg) and required for trailers in excess of

2,000 lbs (907 kg).

WARNING!

• Do not connect trailer brakes to your vehicle’s hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

• Towing any trailer will increase your stopping dis-

tance. When towing, you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lbs (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

268 STARTING AND OPERATING

Page 273 of 524

Speed Control — If Equipped

•Do not use on hilly terrain or with heavy loads.

• When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

• Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

AutoStick

• When using the AutoStick shift control, select the high-

est gear that allows for adequate performance and

avoids frequent downshifts. For example, choose “4” if

the desired speed can be maintained. Choose “3” or “2”

if needed to maintain the desired speed.

• To prevent excess heat generation, avoid continuous

driving at high RPM. Reduce vehicle speed as necessary

to avoid extended driving at high RPM. Return to a

higher gear or vehicle speed when grade and road

conditions allow.

Cooling System

To reduce potential for engine and transmission overheat-

ing, take the following actions:

City Driving

• In city traffic — while stopped, place the transmission in

NEUTRAL, but do not increase engine idle speed.

Highway Driving

• Reduce speed.

• Temporarily turn off air conditioning.

6

STARTING AND OPERATING 271

Page 276 of 524

•Maintain sufficient distance between your vehicle and

the vehicle in front of you to avoid a collision in a

sudden stop.

Driving Through Water

Driving through water more than a few inches/centimeters

deep will require extra caution to ensure safety and pre-

vent damage to your vehicle.

Flowing/Rising Water

WARNING!

Do not drive on or across a road or path where water is

flowing and/or rising (as in storm run-off). Flowing

water can wear away the road or path’s surface and

cause your vehicle to sink into deeper water. Further-

more, flowing and/or rising water can carry your ve-

hicle away swiftly. Failure to follow this warning may

result in injuries that are serious or fatal to you, your

passengers, and others around you.

Shallow Standing Water

Although your vehicle is capable of driving through shal-

low standing water, consider the following Cautions and

Warnings before doing so.

WARNING!

• Driving through standing water limits your vehicle’s

traction capabilities. Do not exceed 5 mph (8 km/h)

when driving through standing water.

• Driving through standing water limits your vehicle’s

braking capabilities, which increases stopping dis-

tances. Therefore, after driving through standing

water, drive slowly and lightly press on the brake

pedal several times to dry the brakes.

• Failure to follow these warnings may result in inju-

ries that are serious or fatal to you, your passengers,

and others around you.

274 STARTING AND OPERATING

Page 280 of 524

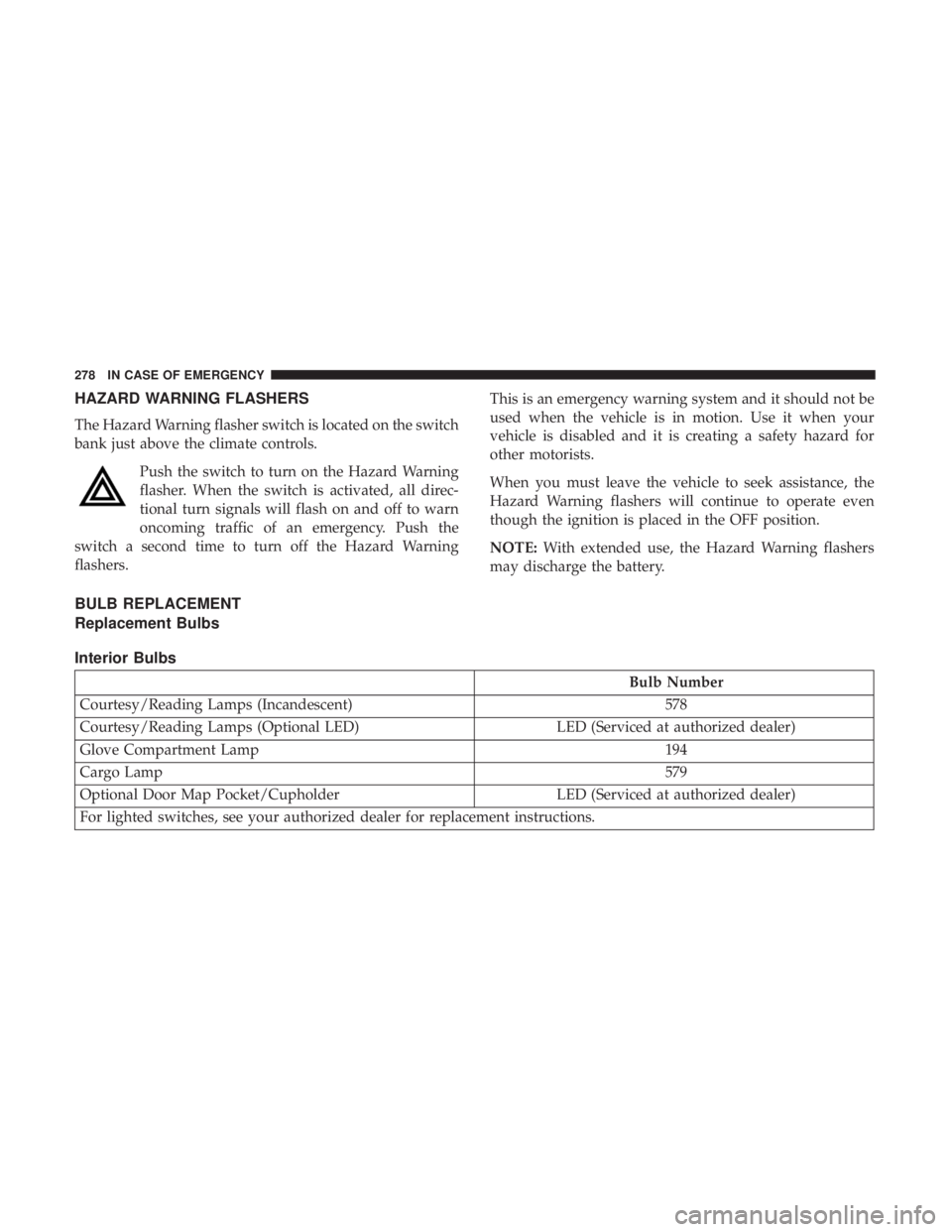

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located on the switch

bank just above the climate controls.Push the switch to turn on the Hazard Warning

flasher. When the switch is activated, all direc-

tional turn signals will flash on and off to warn

oncoming traffic of an emergency. Push the

switch a second time to turn off the Hazard Warning

flashers. This is an emergency warning system and it should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and it is creating a safety hazard for

other motorists.

When you must leave the vehicle to seek assistance, the

Hazard Warning flashers will continue to operate even

though the ignition is placed in the OFF position.

NOTE:

With extended use, the Hazard Warning flashers

may discharge the battery.

BULB REPLACEMENT

Replacement Bulbs

Interior Bulbs

Bulb Number

Courtesy/Reading Lamps (Incandescent) 578

Courtesy/Reading Lamps (Optional LED) LED (Serviced at authorized dealer)

Glove Compartment Lamp 194

Cargo Lamp 579

Optional Door Map Pocket/Cupholder LED (Serviced at authorized dealer)

For lighted switches, see your authorized dealer for replacement instructions.

278 IN CASE OF EMERGENCY

Page 286 of 524

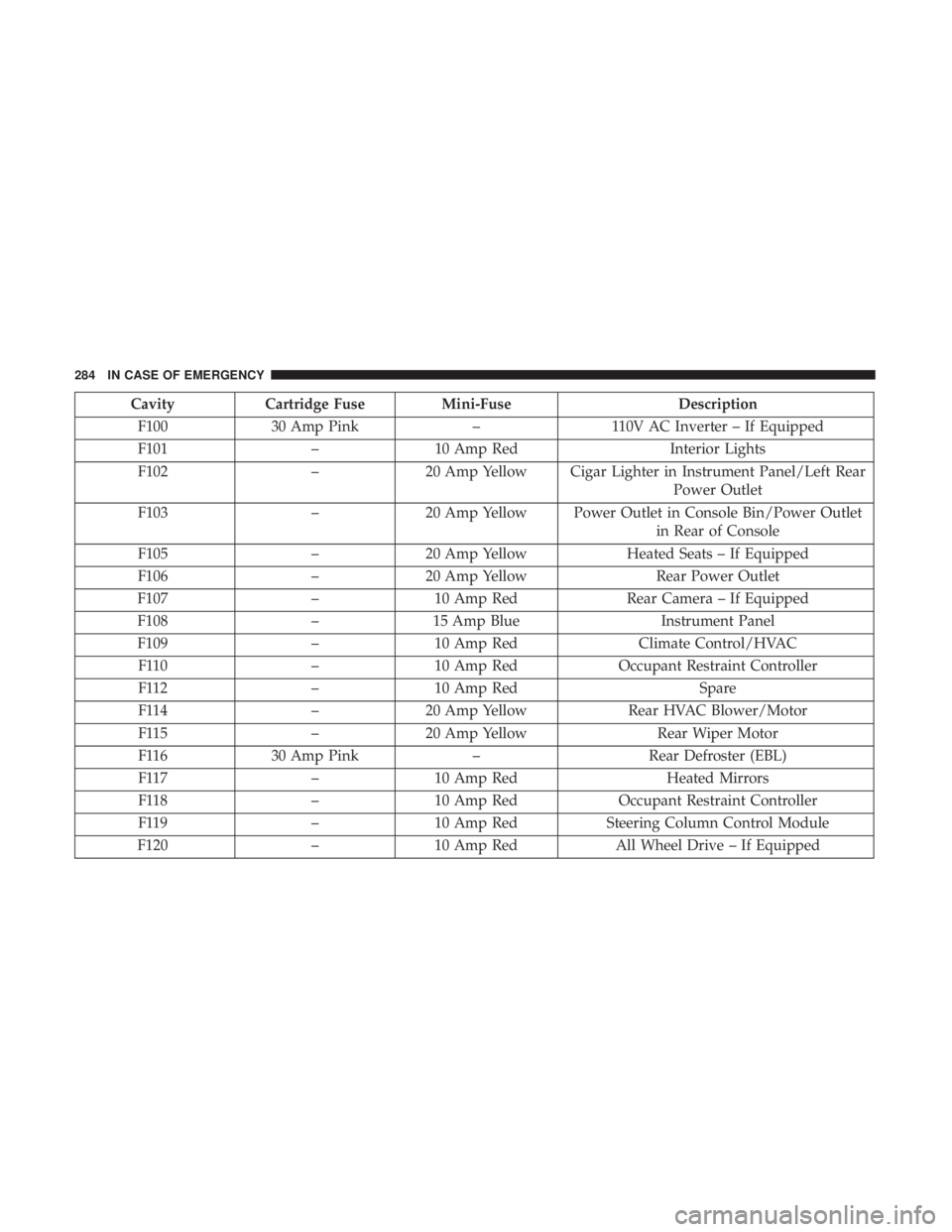

CavityCartridge Fuse Mini-Fuse Description

F100 30 Amp Pink –110V AC Inverter – If Equipped

F101 –10 Amp Red Interior Lights

F102 –20 Amp Yellow Cigar Lighter in Instrument Panel/Left Rear

Power Outlet

F103 –20 Amp Yellow Power Outlet in Console Bin/Power Outlet

in Rear of Console

F105 –20 Amp Yellow Heated Seats – If Equipped

F106 –20 Amp Yellow Rear Power Outlet

F107 –10 Amp Red Rear Camera – If Equipped

F108 –15 Amp Blue Instrument Panel

F109 –10 Amp Red Climate Control/HVAC

F110 –10 Amp Red Occupant Restraint Controller

F112 –10 Amp Red Spare

F114 –20 Amp Yellow Rear HVAC Blower/Motor

F115 –20 Amp Yellow Rear Wiper Motor

F116 30 Amp Pink –Rear Defroster (EBL)

F117 –10 Amp Red Heated Mirrors

F118 –10 Amp Red Occupant Restraint Controller

F119 –10 Amp Red Steering Column Control Module

F120 –10 Amp Red All Wheel Drive – If Equipped

284 IN CASE OF EMERGENCY

Page 289 of 524

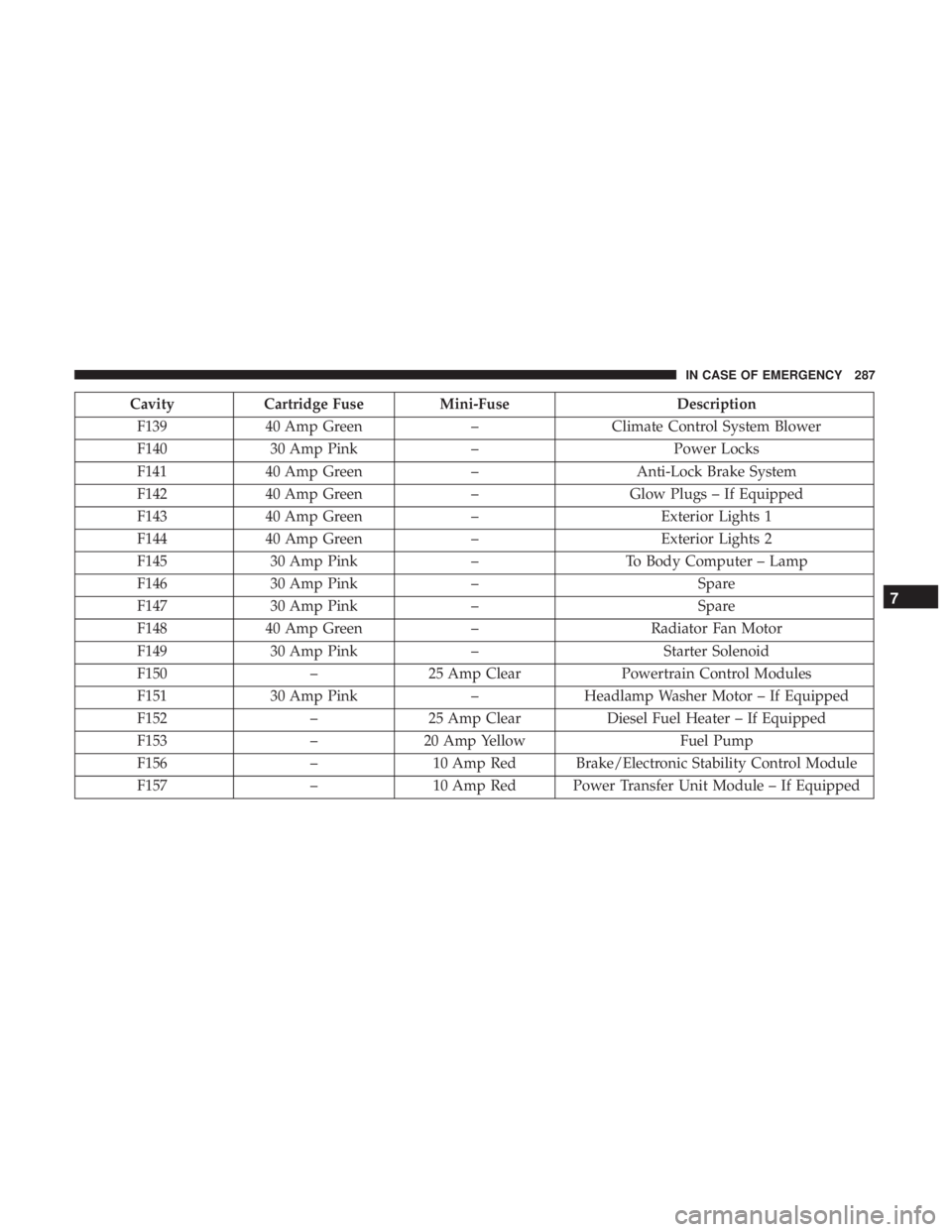

CavityCartridge Fuse Mini-Fuse Description

F139 40 Amp Green –Climate Control System Blower

F140 30 Amp Pink – Power Locks

F141 40 Amp Green –Anti-Lock Brake System

F142 40 Amp Green –Glow Plugs – If Equipped

F143 40 Amp Green –Exterior Lights 1

F144 40 Amp Green –Exterior Lights 2

F145 30 Amp Pink –To Body Computer – Lamp

F146 30 Amp Pink – Spare

F147 30 Amp Pink – Spare

F148 40 Amp Green –Radiator Fan Motor

F149 30 Amp Pink –Starter Solenoid

F150 –25 Amp Clear Powertrain Control Modules

F151 30 Amp Pink –Headlamp Washer Motor – If Equipped

F152 –25 Amp Clear Diesel Fuel Heater – If Equipped

F153 –20 Amp Yellow Fuel Pump

F156 –10 Amp Red Brake/Electronic Stability Control Module

F157 –10 Amp Red Power Transfer Unit Module – If Equipped

7

IN CASE OF EMERGENCY 287

Page 290 of 524

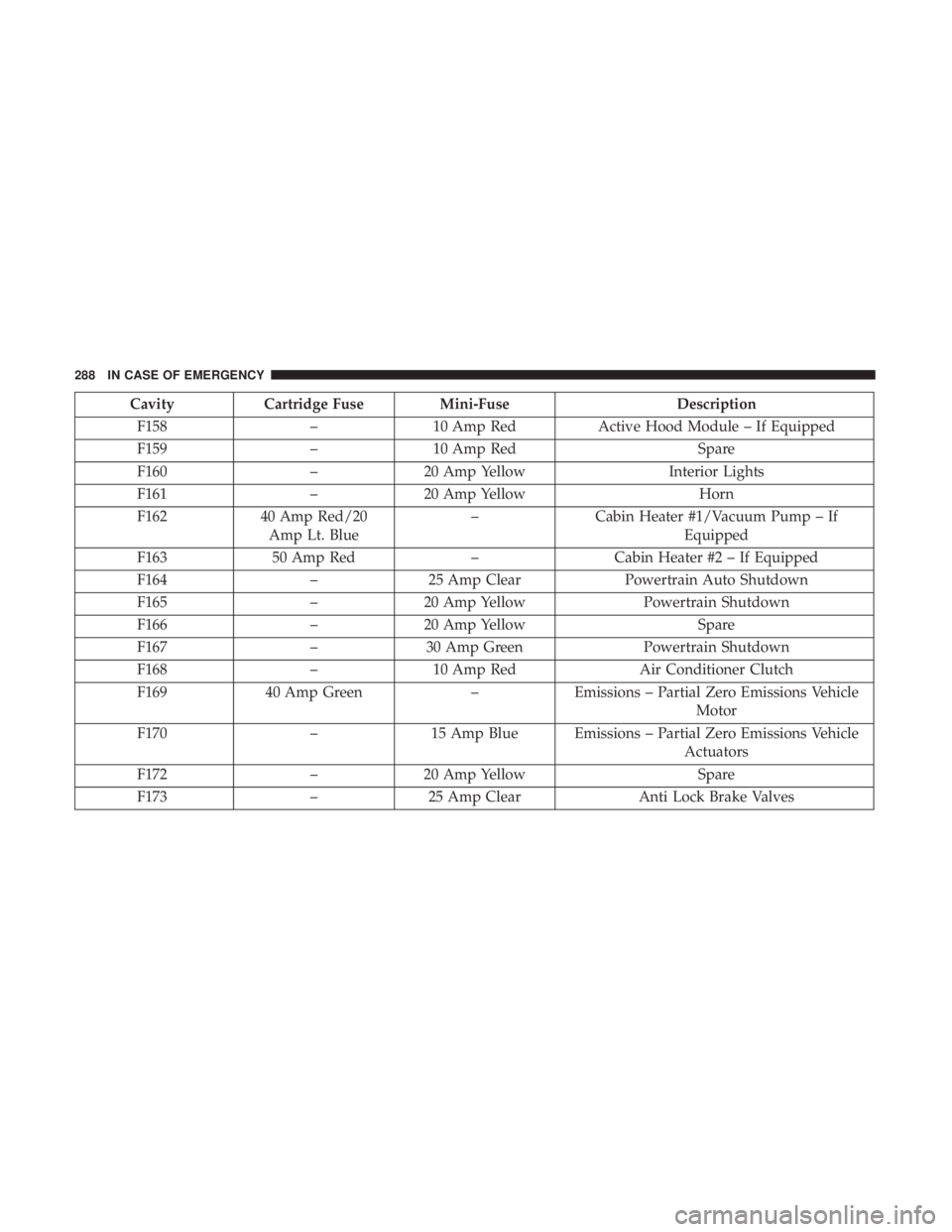

CavityCartridge Fuse Mini-Fuse Description

F158 –10 Amp Red Active Hood Module – If Equipped

F159 –10 Amp Red Spare

F160 –20 Amp Yellow Interior Lights

F161 –20 Amp Yellow Horn

F162 40 Amp Red/20

Amp Lt. Blue –

Cabin Heater #1/Vacuum Pump – If

Equipped

F163 50 Amp Red –Cabin Heater #2 – If Equipped

F164 –25 Amp Clear Powertrain Auto Shutdown

F165 –20 Amp Yellow Powertrain Shutdown

F166 –20 Amp Yellow Spare

F167 –30 Amp Green Powertrain Shutdown

F168 –10 Amp Red Air Conditioner Clutch

F169 40 Amp Green –Emissions – Partial Zero Emissions Vehicle

Motor

F170 –15 Amp Blue Emissions – Partial Zero Emissions Vehicle

Actuators

F172 –20 Amp Yellow Spare

F173 –25 Amp Clear Anti Lock Brake Valves

288 IN CASE OF EMERGENCY

Page 299 of 524

NOTE:•For vehicles so equipped, do not attempt to install a

center cap or wheel cover on the compact spare.

• Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires” in “Servicing And Maintenance”

for additional warnings, cautions, and information

about the spare tire, its use, and operation.

7. Install the wheel nuts with the cone-shaped end of the nut toward the wheel. Lightly tighten the wheel nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

8. Lower the vehicle by turning the jack screw counter- clockwise with the jack handle.

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each nut has been tightened twice. For the correct lug nut

torque, refer to “Torque Specifications” in “Technical

Specifications”. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

10. Lower the jack to its fully closed position.

11. Place the deflated (flat) tire in the cargo area. Do not

stow the deflated tire in the spare tire stowage

location. Have the deflated (flat) tire repaired or re-

placed as soon as possible.

12. To stow the winch cable and retainer, fit the assembled jack-handle over the winch drive nut. Rotate the jack-

handle assembly clockwise until you hear the winch

mechanism click three times. It cannot be over tight-

ened.

13. Stow the jack-handle and jack. Remove the wheel blocks from the vehicle and release the park brake.

14. Check the tire pressure as soon as possible. Adjust the tire pressure as required.

7

IN CASE OF EMERGENCY 297

Page 300 of 524

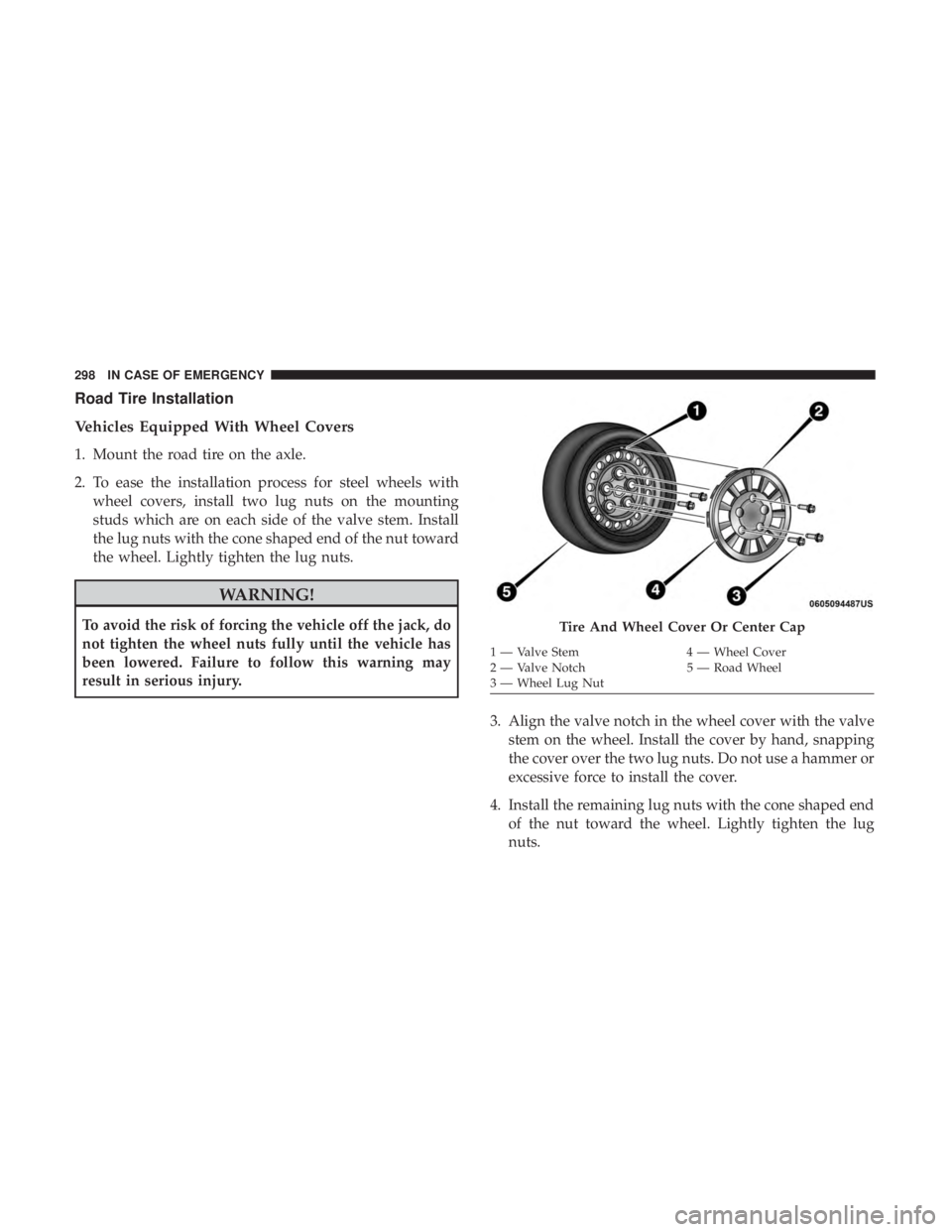

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels withwheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut toward

the wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

3. Align the valve notch in the wheel cover with the valvestem on the wheel. Install the cover by hand, snapping

the cover over the two lug nuts. Do not use a hammer or

excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug

nuts.Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel Lug Nut

298 IN CASE OF EMERGENCY