ECU DODGE MAGNUM 2005 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: MAGNUM, Model: DODGE MAGNUM 2005 1.GPages: 368

Page 210 of 368

A reset feature is available to allow the vehicle to be

driven to a dealer for service. To reset the transmission,

use the following procedure:

1. Stop the vehicle.

2. Move the selector lever to the PARK position.

3. Turn off the engine.

4. Wait approximately 10 seconds.

5. Restart the engine.

6. Move the shift lever to the desired range. If the

problem is no longer detected, the transmission will

return to normal operation.

NOTE:Even if the transmission can be reset, we

recommend that you visit a dealer at your earliest

possible convenience. Your dealer has diagnostic equip-

ment to determine if the problem could recur.Have the transmission checked at your authorized dealer

as soon as possible.

If the problem has been momentary, the transmission can

be reset to regain all forward gears.

Permanent Transmission Limp Home Mode

Permanent Limp Home Mode will be activated if the

transmission enters temporary Limp Home Mode three

times. Follow the reset procedure described in the previ-

ous section. In Permanent Limp Home Mode, PARK(P),

REVERSE(R) and NEUTRAL(N) will continue to operate.

SECOND gear will operate in the DRIVE(D) shifter

position. The malfunction indicator lamp may illuminate.

210 STARTING AND OPERATING

Page 248 of 368

NOTE:

•

Tighten the gas cap until you hear a“clicking”sound.

This is an indication that the gas cap is properly

tightened. If the gas cap is not secured properly the

Malfunction Indicator Light in the instrument cluster

will turn on. Make sure that the gas cap is tightened

each time the vehicle is refueled.

•When the fuel nozzle“clicks”or shuts off, the fuel

tank is full.

WARNING!

•Remove the fuel tank filler tube cap (gas cap)

slowly to prevent fuel spray from the filler neck

which may cause injury.

•The volatility of some gasolines may cause a

buildup of pressure in the fuel tank that may

increase while you drive. This pressure can result

in a spray of gasoline and/or vapors when the cap

is removed from a hot vehicle. Removing the cap

slowly allows the pressure to vent and prevents

fuel spray.

•Never have any smoking materials lit in or near

the vehicle when the gas cap is removed or the

tank filled.

•Never add fuel to the vehicle when the engine is

running.

•A fire may result if gasoline is pumped into a

portable container that is inside of a vehicle. You

could be burned. Always place gas containers on

the ground while filling.

248 STARTING AND OPERATING

Page 250 of 368

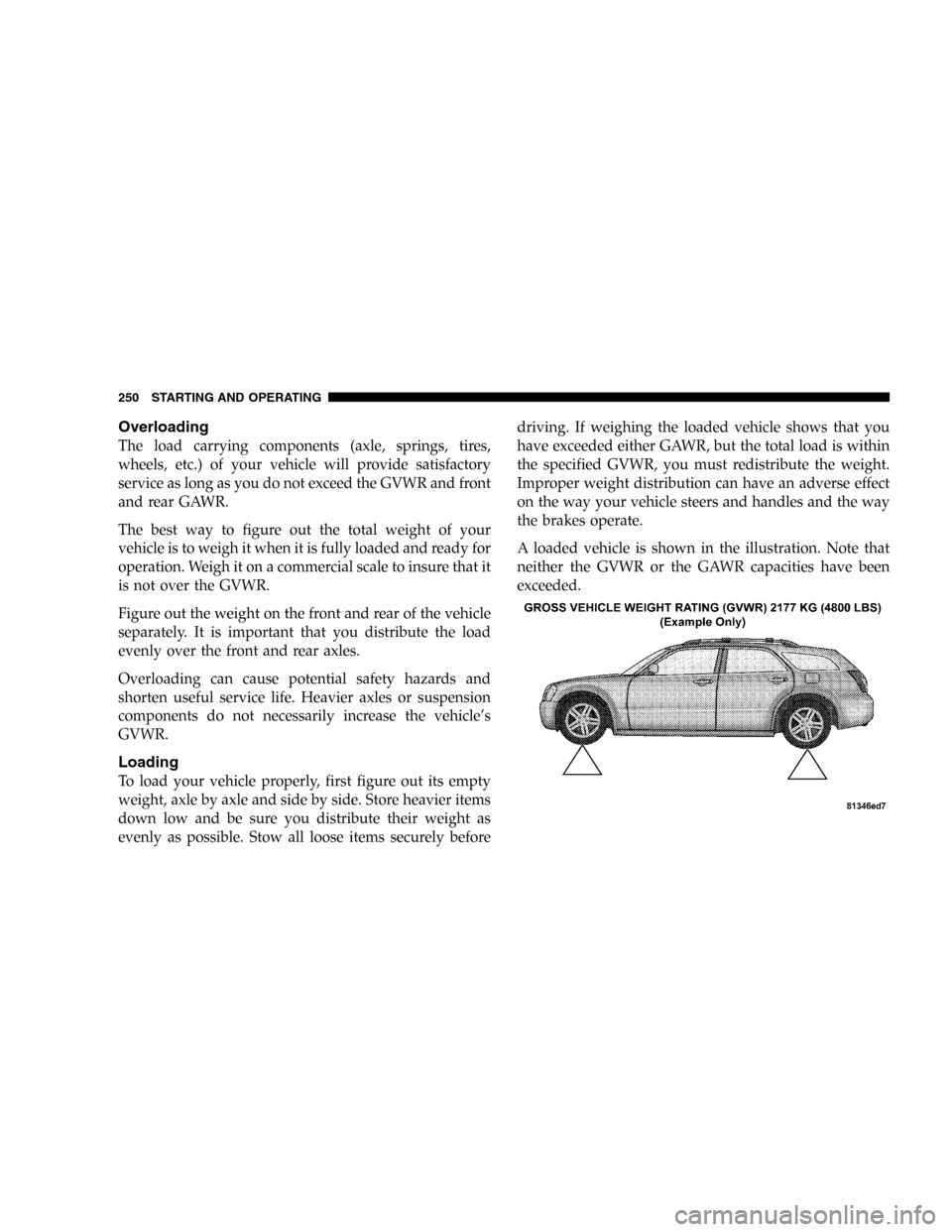

Overloading

The load carrying components (axle, springs, tires,

wheels, etc.) of your vehicle will provide satisfactory

service as long as you do not exceed the GVWR and front

and rear GAWR.

The best way to figure out the total weight of your

vehicle is to weigh it when it is fully loaded and ready for

operation. Weigh it on a commercial scale to insure that it

is not over the GVWR.

Figure out the weight on the front and rear of the vehicle

separately. It is important that you distribute the load

evenly over the front and rear axles.

Overloading can cause potential safety hazards and

shorten useful service life. Heavier axles or suspension

components do not necessarily increase the vehicle’s

GVWR.

Loading

To load your vehicle properly, first figure out its empty

weight, axle by axle and side by side. Store heavier items

down low and be sure you distribute their weight as

evenly as possible. Stow all loose items securely beforedriving. If weighing the loaded vehicle shows that you

have exceeded either GAWR, but the total load is within

the specified GVWR, you must redistribute the weight.

Improper weight distribution can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.

A loaded vehicle is shown in the illustration. Note that

neither the GVWR or the GAWR capacities have been

exceeded.

250 STARTING AND OPERATING

Page 260 of 368

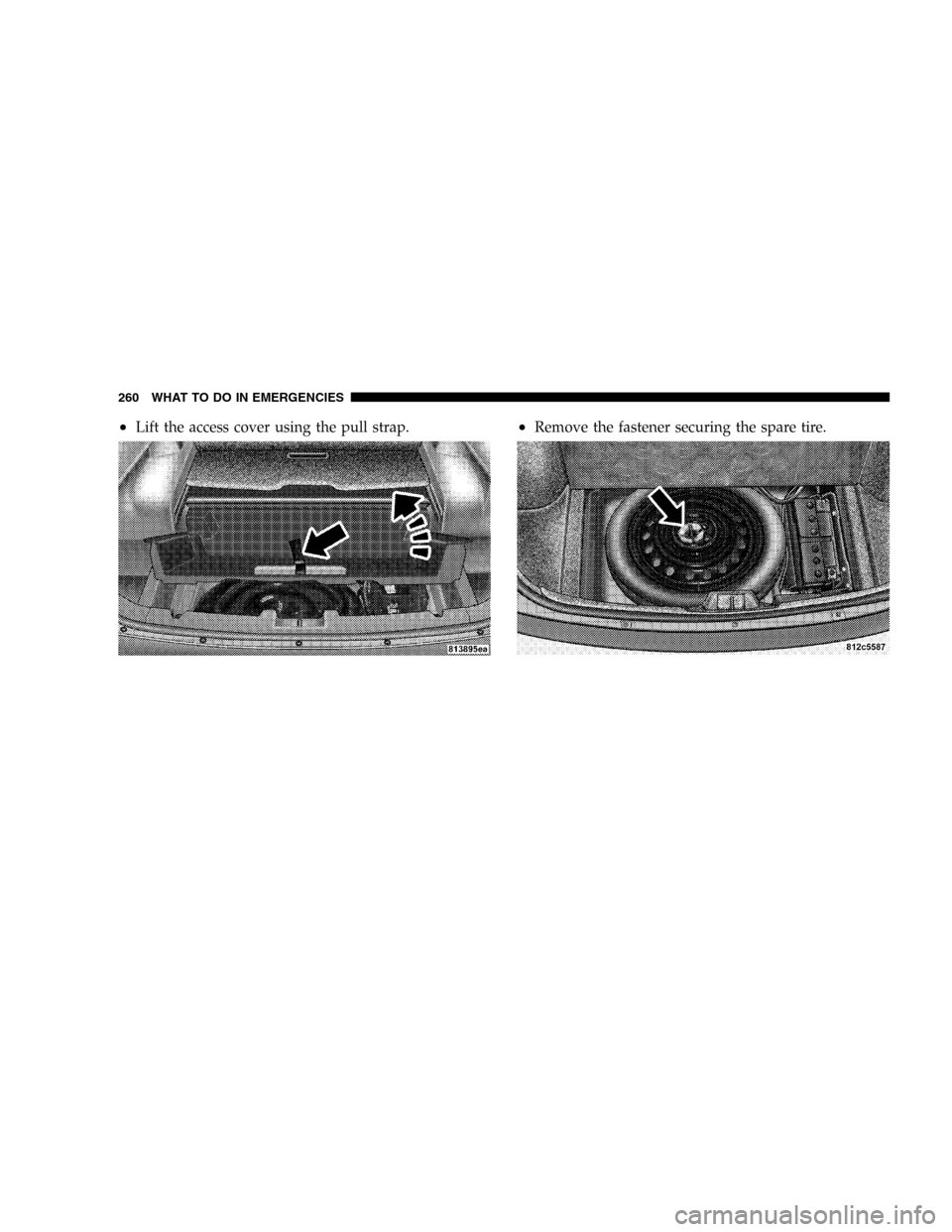

•Lift the access cover using the pull strap.•Remove the fastener securing the spare tire.

260 WHAT TO DO IN EMERGENCIES

Page 261 of 368

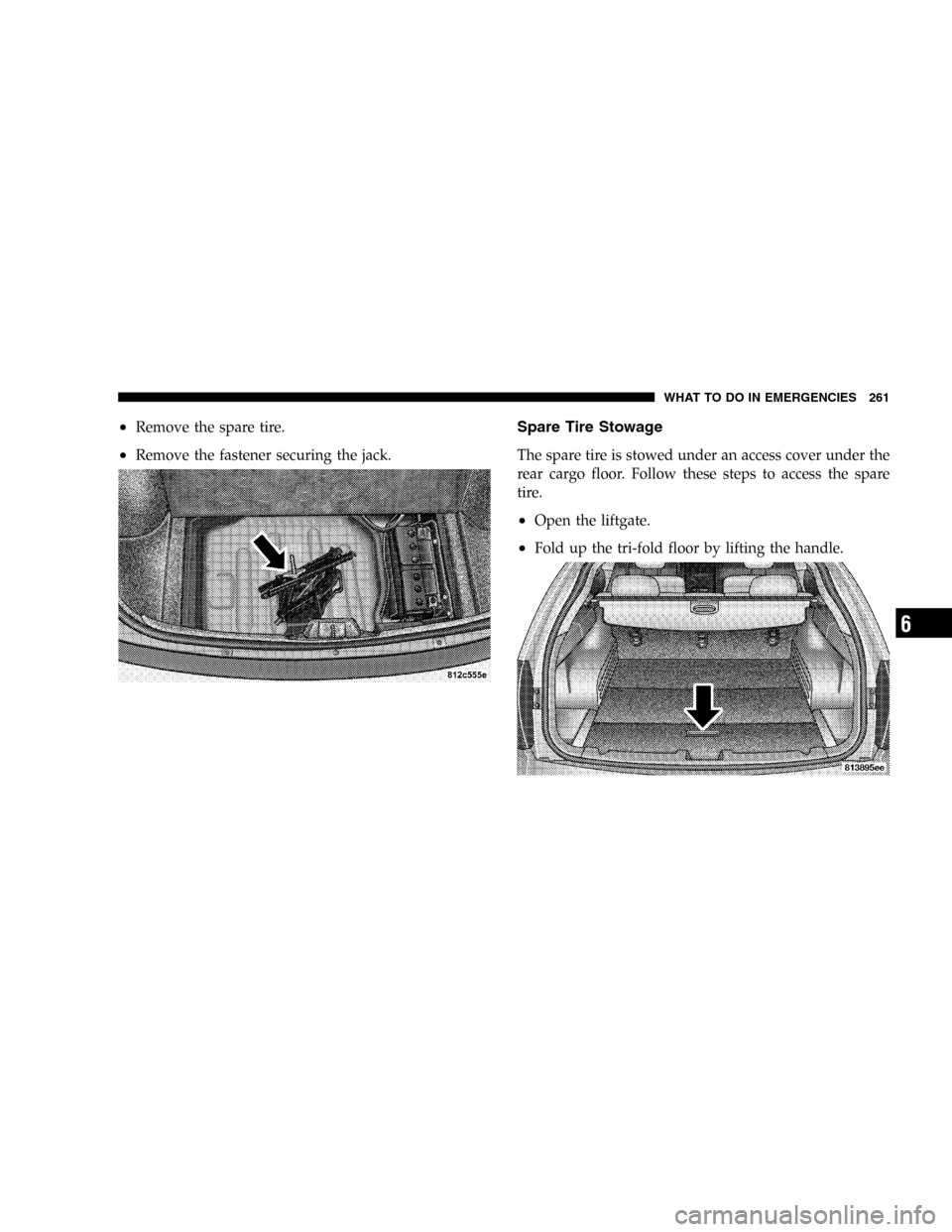

•Remove the spare tire.

•Remove the fastener securing the jack.

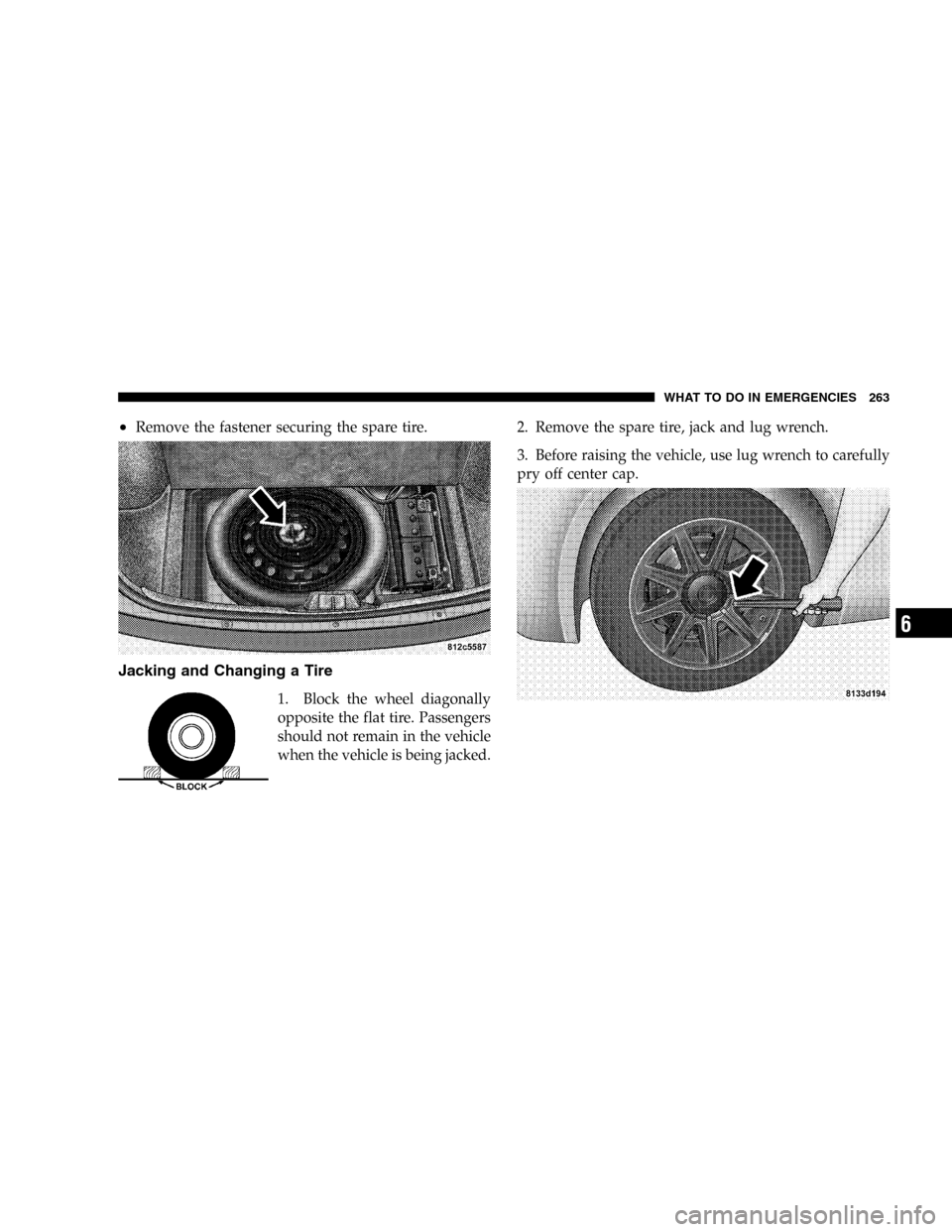

Spare Tire Stowage

The spare tire is stowed under an access cover under the

rear cargo floor. Follow these steps to access the spare

tire.

•Open the liftgate.

•Fold up the tri-fold floor by lifting the handle.

WHAT TO DO IN EMERGENCIES 261

6

Page 263 of 368

•Remove the fastener securing the spare tire.

Jacking and Changing a Tire

1. Block the wheel diagonally

opposite the flat tire. Passengers

should not remain in the vehicle

when the vehicle is being jacked.2. Remove the spare tire, jack and lug wrench.

3. Before raising the vehicle, use lug wrench to carefully

pry off center cap.

WHAT TO DO IN EMERGENCIES 263

6

Page 298 of 368

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

•Do not overfill the coolant bottle.

•Check coolant freeze point in the system.

•If frequent coolant additions are required, the cooling

system should be pressure tested for leaks.

•Maintain coolant concentration at 50% ethylene glycol

antifreeze (minimum) in water for proper corrosion

protection of your engine which contains aluminum

components.

•Make sure that the radiator and coolant bottle hoses

are not kinked or obstructed.

•Keep the front of the radiator and the front of the A/C

condenser clean.

•Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory cooling performance.

•Increasing engine speed at idle does not reduce cool-

ant temperature! Put transmission in NEUTRAL and

let engine idle at normal engine idle speed.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not come in contact with any

heat source or moving component which may cause heat

damage or mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of wear or damage that could cause failure.

298 MAINTAINING YOUR VEHICLE

Page 299 of 368

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Schedules section of this manual.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn’t have your full

braking capacity in an emergency.

Brake And Power Steering Hoses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, tears, cuts, abrasion, and excessive swelling

indicate deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:Often, fluid such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to facilitate the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation), should be noted before a hose is

replaced based on leakage.

NOTE:Inspection of brake hoses should be performed

whenever the brake system is serviced and at every

engine oil change. Inspect hydraulic brake hoses for

surface cracking, scuffing, or worn spots. If there is any

evidence of cracking, scuffing, or worn spots, the hose

should be replaced immediately! Eventual deterioration

of the hose can take place resulting in a possibility of a

burst failure.

MAINTAINING YOUR VEHICLE 299

7

Page 318 of 368

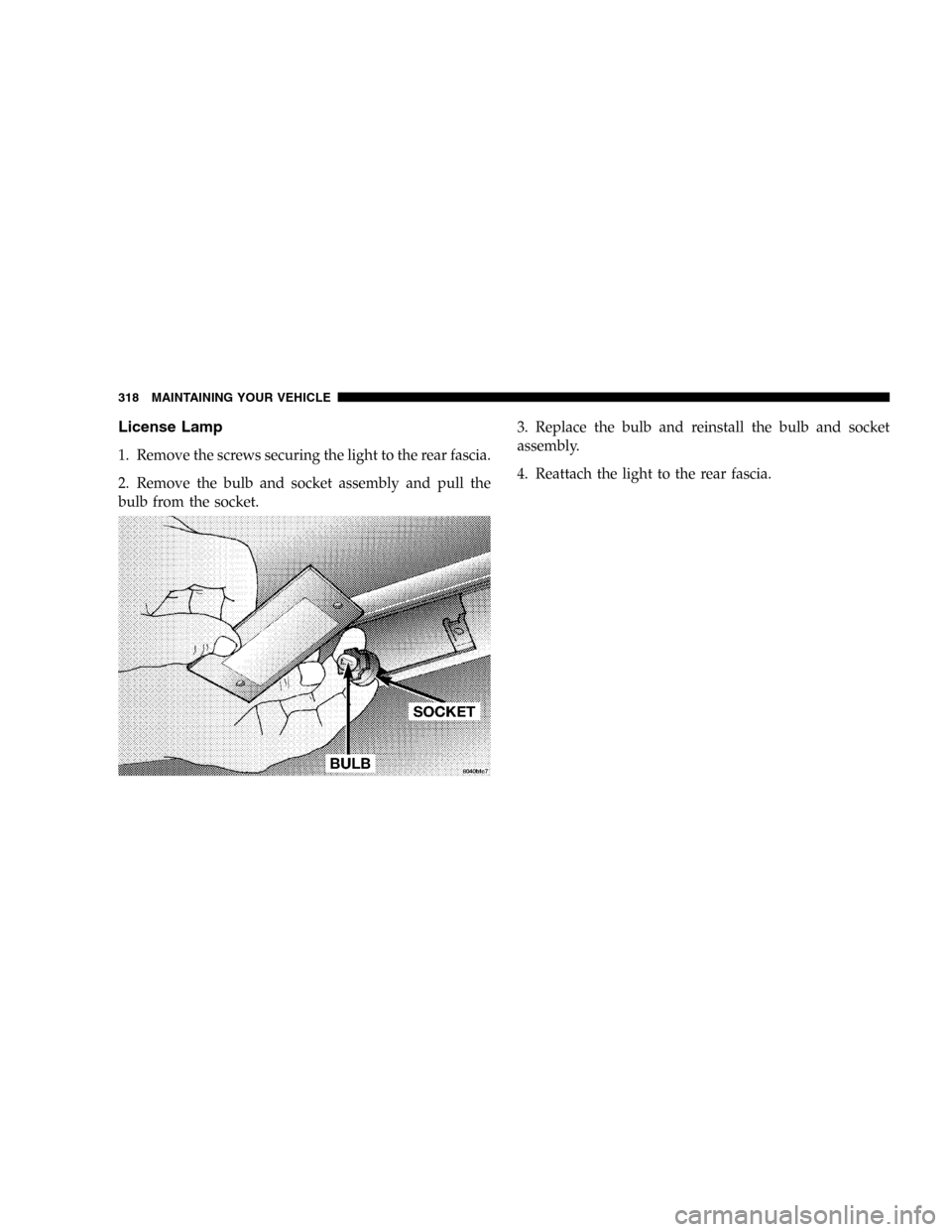

License Lamp

1. Remove the screws securing the light to the rear fascia.

2. Remove the bulb and socket assembly and pull the

bulb from the socket.3. Replace the bulb and reinstall the bulb and socket

assembly.

4. Reattach the light to the rear fascia.

318 MAINTAINING YOUR VEHICLE

Page 350 of 368

Adding Fuel.......................... 247

Adding Washer Fluid..................97,293

Additives, Fuel........................ 245

Adjustable Pedals....................... 88

Air Conditioner Maintenance.............. 290

Air Conditioning....................... 185

Air Conditioning Filter................194,291

Air Conditioning, Operating Tips........... 195

Air Conditioning Refrigerant.............. 291

Air Conditioning System................. 185

Air Pressure, Tires...................... 229

Airbag................................ 36

Airbag Deployment....................40,41

Airbag Light....................40,47,58,135

Airbag Maintenance...................... 43

Airbag, Side........................... 42

Airbag, Window......................37,42

Alarm System.......................... 24

Alignment and Balance.................. 235

All Wheel Drive.....................235,302

Alterations/Modifications, Vehicle............ 7

Antenna, Satellite Radio.................. 180

Antifreeze Disposal..................... 297Antifreeze (Engine Coolant).........295,296,319

Anti-Lock Brake System.................. 216

Anti-Lock Warning Light................. 140

Anti-Theft Security Alarm................. 24

Appearance Care....................... 303

Auto Down Power Windows............... 28

Automatic Dimming Mirror................ 62

Automatic Door Locks..................17,18

Automatic Temperature Control............ 188

Automatic Transaxle..................... 301

Adding Fluid........................ 321

Selection Of Lubricant................. 321

Automatic Transmission............201,206,302

Adding Fluid........................ 302

Fluid and Filter Changes................ 302

Fluid Change........................ 302

Fluid Level Check..................... 301

Gear Ranges......................... 202

Torque Converter..................... 204

Automatic Transmission Limp Home Mode . . . 205

Autostick..........................208,213

Ball Joints............................ 292

350 INDEX