maintenance schedule DODGE MAGNUM 2008 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: MAGNUM, Model: DODGE MAGNUM 2008 1.GPages: 482, PDF Size: 6.94 MB

Page 1 of 482

TABLE OF CONTENTSSECTIONPAGE

1INTRODUCTION.............................................................3

2THINGS TO KNOW BEFORE STARTING YOUR VEHICLE...............................9

3UNDERSTANDING THE FEATURES OF YOUR VEHICLE...............................81

4UNDERSTANDING YOUR INSTRUMENT PANEL................................... 167

5STARTING AND OPERATING................................................. 263

6WHAT TO DO IN EMERGENCIES...............................................359

7MAINTAINING YOUR VEHICLE............................................... 381

8MAINTENANCE SCHEDULES.................................................. 441

9IF YOU NEED CONSUMER ASSISTANCE..........................................449

10INDEX....................................................................459

1

2

3

4

5

6

7

8

9

10

Page 180 of 482

next scheduled oil change interval. The engine oil change

indicator system is duty cycle based, which means the

engine oil change interval may fluctuate dependent upon

your personal driving style.

Unless reset, this message will continue to display each

time you turn the ignition switch to the ªONº position.

To turn off the message temporarily, press and release the

Trip Odometer button on the instrument cluster. To reset

the oil change indicator system (after performing the

scheduled maintenance) perform the following proce-

dure:

1. Turn the ignition switch to the ON position (Do not

start the engine).

2. Fully depress the accelerator pedal slowly three

times within 10 seconds.

3. Turn the ignition switch to the LOCK position.NOTE:If the indicator message illuminates when you

start the vehicle, the oil change indicator system did not

reset. If necessary, repeat this procedure.

20. Brake System Warning Light

This light monitors various brake functions,

including brake fluid level and parking brake

application. If the brake light turns on, it may

indicate that the parking brake is applied, that

the brake fluid level is low, or that there is a problem with

the anti-lock brake system (if equipped).

The dual brake system provides a reserve braking capac-

ity to a portion of the hydraulic system in the event of a

failure. Failure of either half of the dual brake system is

indicated by the Brake Warning Light, which will turn on

when the brake fluid level in the master cylinder drops

below a specified level.

The light will remain on until the cause is corrected.

180 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 188 of 482

²Check Gascap (refer to ªAdding Fuelº in Section 5 of

this manual for more details)

²Oil Change Required (with a single chime)

Oil Change Required

Your vehicle is equipped with an engine oil change

indicator system. The ªOil Change Requiredº message

will flash in the EVIC display for approximately 10

seconds after a single chime has sounded to indicate the

next scheduled oil change interval. The engine oil change

indicator system is duty cycle based, which means the

engine oil change interval may fluctuate dependent upon

your personal driving style.

Unless reset, this message will continue to display each

time you turn the ignition switch to the ON position. To

turn off the message temporarily, press and release the

Menu button. To reset the oil change indicator system

(after performing the scheduled maintenance) perform

the following procedure:1. Turn the ignition switch to the ON position (Do not

start the engine).

2. Fully depress the accelerator pedal slowly three times

within 10 seconds.

3. Turn the ignition switch to the LOCK position.

NOTE:If the indicator message illuminates when you

start the vehicle, the oil change indicator system did not

reset. If necessary, repeat this procedure.

Trip Functions

Press and release the MENU button until one of the

following Trip Functions displays in the EVIC:

²Average Fuel Economy / Fuel Saver Mode

²Distance To Empty

²Trip A

²Trip B

188 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 321 of 482

NOTE:In order to avoid damage to tires, chains, and

your vehicle do not drive for a prolonged period of time

on dry pavement. Observe the tire chain manufacturer's

instructions on method of installation, operating speed,

and conditions for usage.

Always use the lower suggested operating speed if both

the chain manufacturer and vehicle manufacture suggest

a maximum speed. This notice applies to all chain

traction devices, including link and cable (radial) chains.

SNOW TIRES

Some areas of the country require the use of snow tires

during winter. Standard tires are of the all season type

and satisfy this requirement as indicated by the M+S

designation on the tire sidewall.

If you need snow tires, select tires equivalent in size and

type to the original equipment tires. Use snow tires only

in sets of 4, failure to do so may adversely affect the

safety and handling of your vehicle.Snow tires generally have lower speed ratings than what

was originally equipped with your vehicle and should

not be operated at sustained speeds over 75 mph (120

km/h).

TIRE ROTATION RECOMMENDATIONS

Tires on the front and rear axles of vehicles operate at

different loads and perform different steering, driving,

and braking functions. For these reasons, they wear at

unequal rates, and tend to develop irregular wear pat-

terns.

These effects can be reduced by timely rotation of tires.

The benefits of rotation are especially worthwhile with

aggressive tread designs such as those on all season type

tires. Rotation will increase tread life, help to maintain

mud, snow, and wet traction levels, and contribute to a

smooth, quiet ride.

Follow the ªMaintenance Scheduleº in Section 8 of this

manual for the recommended tire rotation frequency.

STARTING AND OPERATING 321

5

Page 355 of 482

Towing Tips

Before setting out on a trip, practice turning, stopping,

and backing the trailer in an area located away from

heavy traffic.

Towing Tips Ð Automatic Transmission

The ªDº range can be selected when towing. However, if

frequent shifting occurs while in this range, the ª3º range

should be selected.

NOTE:Using the ª3º range while operating the vehicle

under heavy operating conditions will improve perfor-

mance and extend transmission life by reducing exces-

sive shifting and heat build up. This action will also

provide better engine braking.

If you REGULARLY tow a trailer for more than 45

minutes of continuous operation, then change the auto-

matic transamission fluid and filter according to the

interval specified for ªpolice, taxi, fleet, or frequent trailer

towingº in the ªMaintenance Scheduleº in this manual.

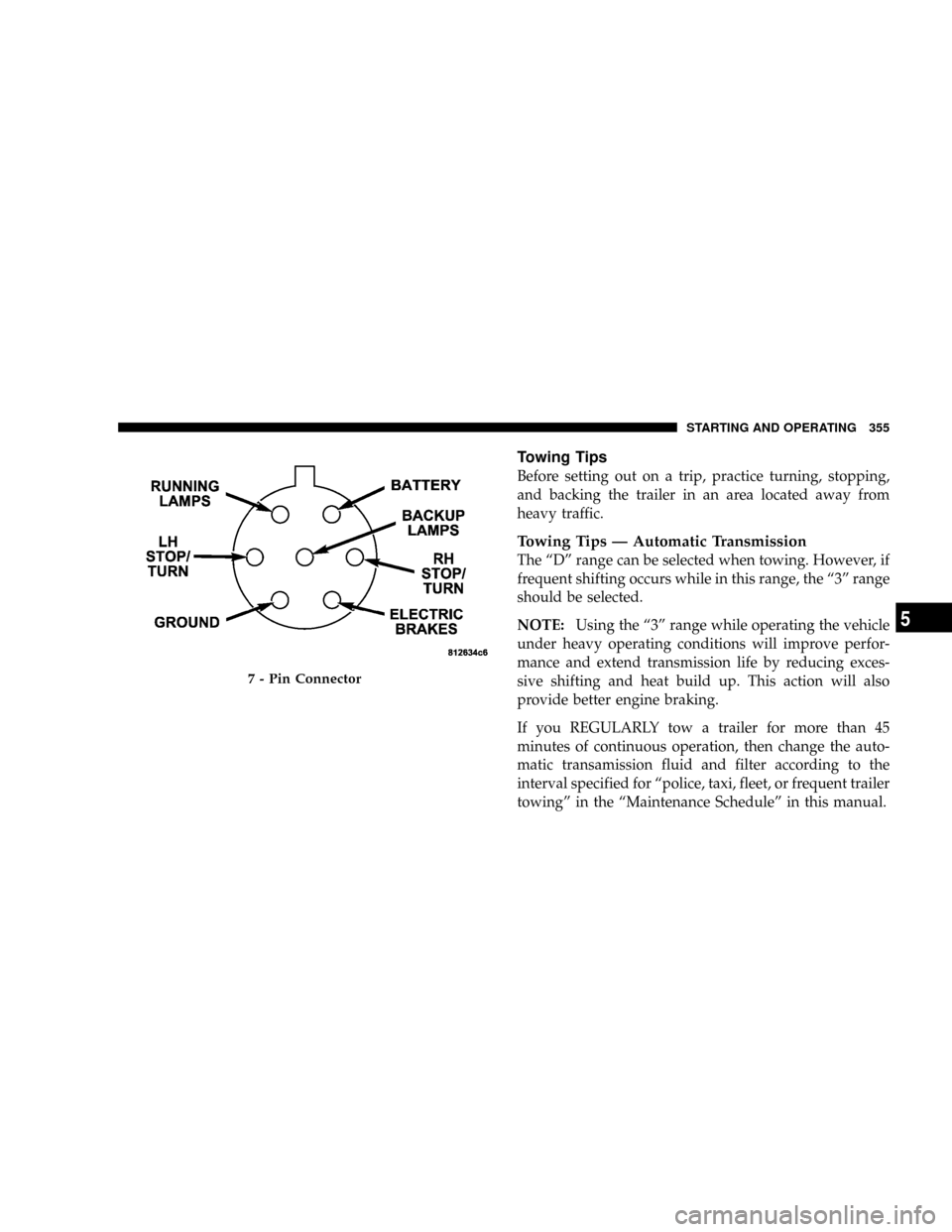

7 - Pin Connector

STARTING AND OPERATING 355

5

Page 389 of 482

5. Approximately 15 seconds later, one of two things will

happen:

a. The MIL will flash for about 10 seconds and then

return to being fully illuminated until you turn off the

ignition key or start the engine. This means that your

vehicle's OBD system isnot readyand you shouldnot

proceed to the I/M station.

b. The MIL will not flash at all and will remain fully

illuminated until you turn off the ignition key or start

the engine. This means that your vehicle's OBD system

isreadyand you can proceed to the I/M station.

If your OBD system isnot ready,you should see your

authorized dealer or repair facility. If your vehicle was

recently serviced or had a battery failure or replacement,

you may need to do nothing more than drive your

vehicle as you normally would in order for your OBD

system to update. A recheck with the above test routine

may then indicate that the system is now ready.Regardless of whether your vehicle's OBD system is

ready or not ready, if the MIL symbol is illuminated

during normal vehicle operation, you should have your

vehicle serviced before going to the I/M station. The I/M

station can fail your vehicle because the MIL symbol is on

with the engine running.

REPLACEMENT PARTS

Use of genuine Mopartparts for normal/scheduled

maintenance and repairs is highly recommended to in-

sure the designed performance. Damage or failures

caused by the use of non-Mopartparts for maintenance

and repairs will not be covered by the manufacturer's

warranty.

MAINTAINING YOUR VEHICLE 389

7

Page 393 of 482

Change Engine Oil

The oil change indicator system will remind you that it is

time to take your vehicle in for scheduled maintenance.

Refer to ªMaintenance Scheduleº in Section 8 of this

manual for information on this system.

NOTE: Under no circumstances should oil change

intervals exceed 6,000 miles (10 000 km) or 6 months,

whichever occurs first.

Engine Oil Selection

For best performance and maximum protection under all

types of operating conditions, the manufacture only

recommends engine oils that are API certified and meet

the requirements of DaimlerChrysler Material Standard

MS-6395.

American Petroleum Institute (API) Engine Oil

Identification Symbol

This symbol means that the oil has

been certified by the American

Petroleum Institute (API). The

manufacture only recommends

API Certified engine oils.

Engine Oil Viscosity (SAE Grade) Ð 2.7L and 5.7L

Engines

SAE 5W-20 engine oil is recommended for all operating

temperatures. This engine oil improves low temperature

starting and vehicle fuel economy.

MAINTAINING YOUR VEHICLE 393

7

Page 396 of 482

Spark Plugs

Spark plugs must fire properly to assure engine perfor-

mance and emission control. New plugs should be in-

stalled at the specified mileage. The entire set should be

replaced if there is any malfunction due to a faulty spark

plug. Malfunctioning spark plugs can damage the cata-

lytic converter. Refer to ªFluids, Lubricants, and Genuine

Partsº in this section for the proper type of spark plug for

use in your vehicle.

Engine Air Cleaner Filter

Refer to the ªMaintenance Scheduleº in Section 8 of this

manual for engine air cleaner filter maintenance inter-

vals.

NOTE:Be sure to follow the ªdusty or off-road condi-

tionsº maintenance interval if applicable.

WARNING!

The air induction system (air cleaner, hoses, etc) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner,

hoses, etc) removed. Failure to do so can result in

serious personal injury.

Fuel Filter

A plugged fuel filter can cause stalling, limit the speed at

which a vehicle can be driven or cause hard starting.

Should an excessive amount of dirt accumulate in the

fuel tank, filter replacement may be necessary. See your

authorized dealer for service.

396 MAINTAINING YOUR VEHICLE

Page 402 of 482

Install new filter with arrows pointing in the direction of

airflow, which is toward the rear of the vehicle (text and

arrows on the filter indicate this).

Refer to the ªMaintenance Scheduleº in Section 8 of

this manual for the recommended air conditioning

filter replacement intervals.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturer's recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to ªFluids, Lubricants, and Genuine

Partsº in this section for the correct fluid type.

Front & Rear Suspension Ball Joints

The suspension ball joints should be inspected for exter-

nal leakage or damage when other maintenance is per-

formed.

402 MAINTAINING YOUR VEHICLE

Page 406 of 482

Coolant Checks

Check engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty or rusty in appearance, the

system should be drained, flushed, and refilled with

fresh coolant. Check the front of the A/C condenser for

any accumulation of bugs, leaves, etc. If dirty, clean by

gently spraying water from a garden hose vertically

down the face of the condenser.

Check the coolant recovery bottle tubing for brittle rub-

ber, cracking, tears, cuts, and tightness of the connection

at the bottle and radiator. Inspect the entire system for

leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

coolant from the radiator drain cock. If the cap is sealing

properly, the engine coolant (antifreeze) will begin todrain from the coolant recovery bottle. DO NOT RE-

MOVE THE COOLANT PRESSURE CAP WHEN THE

COOLING SYSTEM IS HOT.

Cooling System Ð Drain, Flush, and Refill

The system should be drained, flushed, and refilled at the

intervals shown in the ªMaintenance Scheduleº in Sec-

tion 8 of this manual.

If the solution is dirty or contains a considerable amount

of sediment, clean and flush with a reliable cooling

system cleaner. Follow with a thorough rinsing to remove

all deposits and chemicals. Properly dispose of old

antifreeze solution.

Selection of Coolant

Use only the manufacturer's recommended coolant. Re-

fer to ªFluids, Lubricants, and Genuine Partsº for the

correct coolant type.

406 MAINTAINING YOUR VEHICLE