check engine light DODGE NEON 1997 1.G Wiring Diagrams Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1997, Model line: NEON, Model: DODGE NEON 1997 1.GPages: 256, PDF Size: 2.99 MB

Page 3 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-01 GENERAL INFORMATION

INDEX

page page

DESCRIPTION AND OPERATION

CIRCUIT IDENTIFICATION................. 3

CONNECTOR/GROUND LOCATIONS......... 1

CONNECTORS.......................... 3

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES.................... 5

FASTENERS............................ 5

HOW TO USE THIS GROUP................ 1

NOTES, CAUTIONS, and WARNINGS......... 2

POSITIVE TEMPERATURE COEFFICIENT..... 5

SECTION IDENTIFICATION................. 1

SPLICE LOCATIONS...................... 1

SYMBOLS.............................. 3

TAKE OUTS............................ 3

WIRE CODE IDENTIFICATION.............. 2

DIAGNOSIS AND TESTING

CHECKING FOR TERMINAL SPREADING...... 6INTERMITTENT AND POOR CONNECTIONS . . . 6

TROUBLESHOOTING TESTS............... 6

TROUBLESHOOTING TOOLS............... 5

TROUBLESHOOTING WIRING PROBLEMS.... 7

SERVICE PROCEDURES

CONNECTOR AND TERMINAL

REPLACEMENT........................ 9

CONNECTOR REPLACEMENT.............. 9

DIODE REPLACEMENT................... 11

FUSIBLE LINK REPLACEMENT............. 8

TERMINAL REPLACEMENT............... 10

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS........................ 8

WIRING REPAIR......................... 7

SPECIAL TOOLS

WIRING/TERMINAL...................... 11

DESCRIPTION AND OPERATION

HOW TO USE THIS GROUP

The purpose of this group is to show the electrical

circuits in a clear, simple fashion and to make trou-

bleshooting easier. Components that work together

are shown together. All electrical components used in

a specific system are shown on one diagram. The feed

for a system is shown at the top of the page. All

wires, connectors, splices, and components are shown

in the flow of current to the bottom of the page. Wir-

ing which is not part of the circuit represented is ref-

erenced to another page/section, where the complete

circuit is shown. In addition, all switches, compo-

nents, and modules are shown in theat rest posi-

tion with the doors closed and the key removed

from the ignition.

If a component is part of several different circuits,

it is shown in the diagram for each. For example, the

headlamp switch is the main part of the exterior

lighting, but it also affects the interior lighting and

the chime warning system.It is important to real-

ize that no attempt is made on the diagrams to

represent components and wiring as they

appear on the vehicle. For example, a short

piece of wire is treated the same as a long one.

In addition, switches and other components are

shown as simply as possible, with regard to

function only.

SECTION IDENTIFICATION

Sections in Group 8W are organized by sub-sys-

tems. The sections contain circuit operation descrip-

tions, helpful information, and system diagrams. The

intention is to organize information by system, con-

sistently from year to year.

CONNECTOR/GROUND LOCATIONS

Section 8W-90 contains connector/ground location

illustrations. The illustrations contain the connector

name (or number)/ground number and component

identification. Connector/ground location charts in

Section 8W-90 reference the illustration number for

components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the Dia-

gram pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

PL8W - 01 GENERAL INFORMATION 8W - 01 - 1

Page 9 of 256

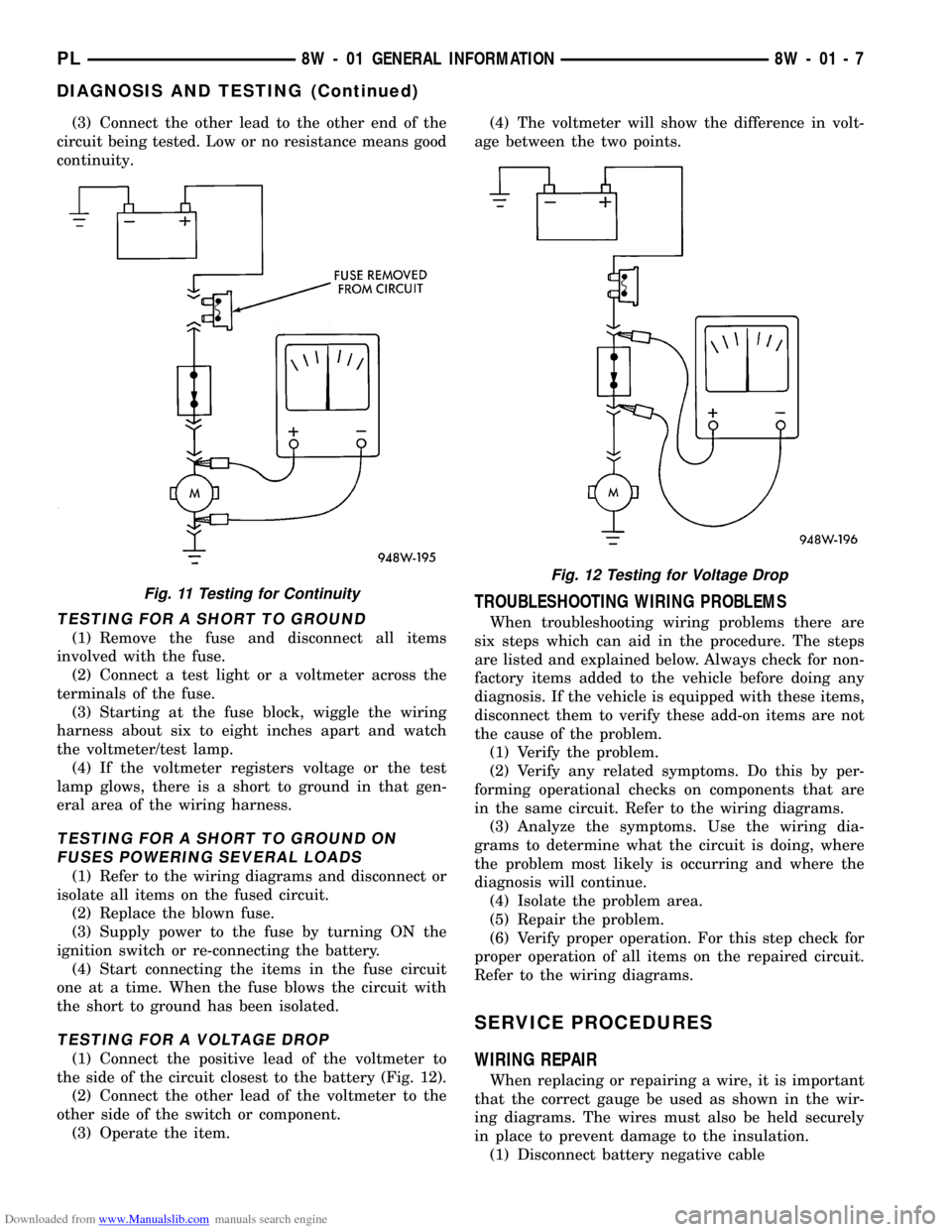

Downloaded from www.Manualslib.com manuals search engine (3) Connect the other lead to the other end of the

circuit being tested. Low or no resistance means good

continuity.

TESTING FOR A SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

TESTING FOR A SHORT TO GROUND ON

FUSES POWERING SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the fused circuit.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting the items in the fuse circuit

one at a time. When the fuse blows the circuit with

the short to ground has been isolated.

TESTING FOR A VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 12).

(2) Connect the other lead of the voltmeter to the

other side of the switch or component.

(3) Operate the item.(4) The voltmeter will show the difference in volt-

age between the two points.

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the repaired circuit.

Refer to the wiring diagrams.

SERVICE PROCEDURES

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gauge be used as shown in the wir-

ing diagrams. The wires must also be held securely

in place to prevent damage to the insulation.

(1) Disconnect battery negative cable

Fig. 11 Testing for Continuity

Fig. 12 Testing for Voltage Drop

PL8W - 01 GENERAL INFORMATION 8W - 01 - 7

DIAGNOSIS AND TESTING (Continued)

Page 15 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-02 COMPONENT INDEX

INDEX

page

SCHEMATICS AND DIAGRAMS........................................................... 1

DESCRIPTION AND OPERATION.......................................................... 3

Component Page

A/C Compressor Clutch.................8W-42

A/C Compressor Clutch Relay............8W-42

A/C Cycling Switch....................8W-42

A/C Heater Blower Motor................8W-42

A/C Heater Control Switch...............8W-42

A/C High Pressure Switch...............8W-42

A/C Low Pressure Switch................8W-42

ABS Hydraulic Modulator...............8W-35

ABS Pump Motor......................8W-35

ABS Pump Motor Relay.................8W-35

ABS Relay Box........................8W-35

ABS System Relay.....................8W-35

ABS Warning Lamp....................8W-35

Airbag Control Module..................8W-43

Airbag Impact Sensors..................8W-43

Airbag Warning Lamp..................8W-40

Antenna.............................8W-47

Anti-Lock Warning Lamp................8W-40

Ash Receiver Lamp....................8W-44

Automatic Shut Down Relay.............8W-30

Back-Up Lamp Switch..................8W-51

Back-Up Lamps.......................8W-51

Battery..............................8W-20

Battery Temperature Sensor.............8W-30

Blower Motor Resistor Block.............8W-42

Brake Warning Lamp...................8W-40

Brake Warning Lamp Switch.............8W-40

Camshaft Position (CMP) Sensor..........8W-30

Capacitor.........................8W-10, 20

Charge Indicator Lamp.................8W-40

Check Engine Lamp....................8W-40

Cigar Lighter Relay....................8W-41

Cigar Lighter/Power Outlet..............8W-41

Circuit Breaker.....................8W-11,62

Circuit Breaker (FB)...................8W-11

Clockspring..........................8W-41

Cluster Illumination Lamps..............8W-40

Clutch Pedal Position Switch..........8W-10, 21

Combination Flasher...................8W-52

Controller Anti-Lock Brake..............8W-35

Crankshaft Position (CKP) Sensor.........8W-30

Data Link Connector...................8W-30

Diode............................8W-15, 42

Dome Lamp..........................8W-44Component Page

Door Ajar Switches.....................8W-44

Door Jamb Switches....................8W-40

Door Lock Motors......................8W-61

Door Lock Switches....................8W-61

Door Speakers........................8W-47

Driver Side Airbag.....................8W-43

Duty Cycle Evap/Purge Solenoid..........8W-30

EGR Transducer Solenoid...............8W-30

Engine Coolant Temperature (ECT) Sensor . . 8W-30

Engine Coolant Temperature Gauge.......8W-40

Engine Oil Pressure Switch..............8W-40

Engine Starter Motor...................8W-21

Engine Starter Motor Relay..............8W-21

Fog Lamp Relay....................8W-50, 51

Fog Lamps........................8W-50, 51

Front Fog Lamp Switch.................8W-50

Fuel Gauge...........................8W-40

Fuel Injectors.........................8W-30

Fuel Pump Module.....................8W-30

Fuel Pump Relay......................8W-30

Fuse Block...........................8W-11

Fuses (FB)...........................8W-11

Fuses (PDC)..........................8W-10

Fusible Link.......................8W-20, 21

Generator............................8W-20

Glove Box Lamp And Switch.............8W-44

Ground Distribution....................8W-15

Headlamp Dimmer And Optical

Horn Switch........................8W-50

Headlamp Leveling Motors..............8W-50

Headlamp Leveling Switch...............8W-50

Headlamp Switch......................8W-50

Headlamps...........................8W-50

Heated Oxygen Sensors.................8W-30

High Beam Indicator Lamp..............8W-40

Horn Relay...........................8W-41

Horn Switches........................8W-41

Horns...............................8W-41

IAT/MAP Sensor......................8W-30

Idle Air Control (IAC) Motor.............8W-30

Ignition Coil Pack.....................8W-30

Ignition Switch........................8W-10

Immobilizer Engine Sensor..............8W-30

Immobilizer Sensor....................8W-30

PL8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 106 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-41 HORNS/CIGAR LIGHTER

DESCRIPTION AND OPERATION

HORNS

The horn system is powered by a 15 amp fuse

located in the Power Distribution Center (PDC)

which is HOT at all times on circuit F31. This circuit

supplies voltage to the coil and contact side of the

horn relay.

When the operator presses the horn switch, a

ground path is completed on the coil side of the horn

relay through the switch. The horn relay, located in

the PDC, then CLOSES the relay contacts. Voltage is

passed through the CLOSED relay contacts on circuit

X2 to the horn. Grounding for the horn is on the Z1

circuit to the left headlamp ground which is located

on the left side of the radiator closure panel.

HELPFUL INFORMATION

²Check the 15 amp fuse in the PDC.²Press the horn switch and listen for the horn

relay to click. A clicking relay indicates voltage is

present up to the switch.

²Check for a good ground at the left headlamp

ground.

CIGAR LIGHTER

The cigar lighter in this vehicle uses a cigar lighter

relay and a cigar lighter element. Power for the cigar

lighter relay is supplied by two sources.

Power for the coil side of the relay is supplied by

circuit F13. This circuit is protected by a 20 amp fuse

located in the fuse block. Power for the contact side

of the relay is supplied on circuit F38. The F38 cir-

cuit is protected by a 15 amp fuse.

Ground for the cigar lighter element and relay is

supplied on circuit Z1.

8W - 41 - 4 8W - 41 HORNS/CIGAR LIGHTERPL

Page 126 of 256

Downloaded from www.Manualslib.com manuals search engine The second ground path is through the headlamp

switch. Circuit M23 is spliced in with the time out

relay. When the operator turns the headlamp switch

to the dome lamp ON position, a ground path is pro-

vided through the switch on the Z1 circuit. This

ground terminates at the instrument panel left cen-

ter support.

On vehicles equipped with Remote Keyless Entry

(RKE) the M23 circuit is spliced to the RKE module.

This allows the lamp to be turned ON when a valid

signal is reveived by the RKE module from the trans-

mitter.

MAP/READING LAMPS

The map/reading lamps are powered by the M1 cir-

cuit from the Power Distribution Center (PDC). This

circuit is the Ignition-Off Draw circuit and protected

by a 10 amp fuse. The M1 circuit is spliced and pro-

vides power for the visor/vanity lamps, radio, power

mirrors, dome lamp, time delay relay, and other inte-

rior lamps.

Ground for the lamps is provided from two sources.

One is the Z3 circuit which is spliced in with the

glove box lamp and terminates at the instrument

panel left center support. The second ground is pro-

vided on circuit M23. This circuit is spliced in with

the time out relay so the lamps will turn ON when

any door is OPENED.

On vehicles equipped with Remote Keyless Entry

(RKE) the M23 circuit, which is the ground circuit

when a door is OPENED, is connected to the RKE

module. The module will provide a ground path for

the lamps with a valid signal from the transmitter.

GLOVE BOX LAMP

The glove box lamp receives power on the M1 cir-

cuit from the 10 amp fuse located in the Power Dis-

tribution Center (PDC). A switch, wired in series

after the lamp, CLOSES when the glove box door is

opened, and completes a path to ground on the Z3

circuit.

The Z3 circuit is spliced in with the ash receiver

lamp, PRNDL lamp, and the time delay relay. The Z3

circuit terminates at the instrument panel left center

support.

ASH RECEIVER LAMP

The ash receiver lamp receives power on the E2

circuit from the 4 amp fuse located in the fuse block

in cavity 12. The fuse receives power from the head-

lamp switch. Circuit E2, which is HOT at all times,

also powers the Transmission Range Indicator

(PRNDL) lamp.

When the headlamp switch is moved to the PARK

or ON position, current flows through the fuse to the

ash receiver lamp. The ground for the lamp is sup-

plied on the Z3 circuit, and terminates at the instru-

ment panel left center support. This circuit is also

spliced in with the PRNDL lamp, the ignition switch

lamp, and the glove box lamp.

UNDERHOOD LAMP

Power for the underhood lamp is supplied on cir-

cuit M1. This is the Ignition-Off Draw (IOD) circuit

and is protected by a 10 amp fuse located in the

Power Distribution Center (PDC).

When the hood is raised a ground path is com-

pleted through the mercury switch to a case ground

illuminating the lamp.

TRUNK LAMP

The trunk lamp uses a case-grounded switch

located on the trunk latch. The switch is normally

OPEN. When the deck lid is opened, the switch

CLOSES, completing a path to ground on circuit M4.

The M1 circuit provides power to the lamp, and is

HOT at all times.

HELPFUL INFORMATION

²Check the 10 amp fuse located in the Power Dis-

tribution Center (PDC) for the trunk lamp, under-

hood lamp, visor/vanity lamps, dome lamp, time

delay relay, and the glove box lamp.

²Check for a good ground at the instrument panel

left center support.

²Check the door switches for a good ground.

²Check the 4 amp fuse in the fuse block, cavity

12.

8W - 44 - 6 8W - 44 INTERIOR LIGHTINGPL

DESCRIPTION AND OPERATION (Continued)

Page 143 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-50 FRONT LIGHTING

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 7

DESCRIPTION AND OPERATION

FOG LAMPS (FRONT).................... 8HEADLAMP LEVELING MOTORS............ 8

HEADLAMPS........................... 7

PARKING LAMPS........................ 7

GENERAL INFORMATION

INTRODUCTION

The headlamp switch has 3 positions, ON, PARK

(parking lights) and OFF. Two circuits, L2 and L20

connect the headlamp switch to the headlamp dim-

mer/optical horn switch located in the multi-function

switch. The multi-function switch feeds the low and

high beams of the headlamps.

DESCRIPTION AND OPERATION

PARKING LAMPS

Circuit A3 in the Power Distribution Center (PDC)

connects to a bus bar in the fuse block. One of the

four circuits powered by the bus bar is circuit F33.

Circuit F33 connects to the headlamp switch. A 40

amp fuse in the PDC protects the A3 circuit. A 15

amp fuse, in cavity 2 of the fuse block, protects the

F33 circuit.

The headlamp switch has 3 positions, ON, PARK

(tail lamps) and OFF, plus a dimmer switch. When

the headlamp switch is in the PARK or ON position,

the switch connects circuit F33 to circuit L7. From

the headlamp switch, circuit L7 branches to power

the front parking lamps and rear tail lamps, lavalier

lamps, side marker lamps, and rear license plate

lamp.

GROUND CIRCUIT

Circuit Z1 provides ground for the parking lamps,

headlamps, lavalier lamps, tail lamps, side marker

lamps and rear license plate lamp although different

grounding points are used. Circuit Z1 also provides

the ground path for the headlamps and turn signals.

HELPFUL INFORMATION

²Check for a blown 40 amp fuse in the PDC.

²Check for a blown fuse in cavity 2 of the fuse

block.

²For the left front parking lamp, turn signal, side

marker lamp and left headlamp, the Z1 circuitgrounding point is the left side of the radiator closure

panel.

²For the right front parking lamp, turn signal,

side marker lamp and right headlamp, the Z1 circuit

grounding point is in the right fender side shield.

²Circuit L7 also feeds the radio, if equipped.

²When the headlamp switch is in the PARK or

ON position, the dimmer circuit, F33, also connects

to circuit E1. Circuit E1 powers the ash receiver

lamp, transmission range indicator lamp, instrument

panel cluster illumination lamps, HVAC control

lamp, heated rear window lamp, and radio lamp. A 4

amp fuse, in cavity 12 of the fuse block, protects cir-

cuit E1.

HEADLAMPS

The headlamp switch has 3 positions, ON, PARK

(parking lights) and OFF. Two circuits, L2 and L20

connect the headlamp switch to the headlamp dim-

mer/optical horn switch located in the multi-function

switch. The multi-function switch feeds the low and

high beams of the headlamps.

HEADLAMP SWITCH IN OFF OR PARKING

LAMP POSITION

Circuit A3 originates in the Power Distribution

Center (PDC) and supplies battery voltage for the

headlamp switch. A 40 amp fuse protects the A3 cir-

cuit. The headlamp switch has an internal 24 amp

circuit breaker that connects circuit A3 to either the

L2 or L20 circuits, depending on switch position.

In the OFF and PARK positions the headlamp

switch feeds the L20 circuit that connects to the

multi-function switch. Circuit L20 powers the high

beam circuit when the operator flashes the head-

lamps with the turn signal stalk of the multi-func-

tion switch. When the operator flashes the

headlamps with the stalk, the multi-function switch

connects the L20 circuit to the L3 circuit. The L3 cir-

cuit feeds the high beam of the headlamps.

HEADLAMP SWITCH IN ON POSITION

When the headlamp switch is in the ON position,

it connects the A3 circuit from the PDC to circuit L2.

PL8W - 50 FRONT LIGHTING 8W - 50 - 7

Page 144 of 256

Downloaded from www.Manualslib.com manuals search engine Circuit L2 connects to the multi- function switch and

feeds the L4 circuit (for low beam operation). The L4

circuit connects to a bus bar in the fuse block. Cir-

cuits L43 and L44 connect to the bus bar in fuse

block and power the low beam headlamps. Circuit

L43 supplies voltage to the left headlamp. Circuit

L44 supplies voltage to the right headlamp. Both the

L43 and L44 circuits have separate 10 amp fuses

located in fuse block. Fuse 17 protects circuit L43,

and fuse 18 protects circuit L44.

When the operator selects high beam operation

with the turn signal stalk of the multi-function

switch, circuit L2 connects to the L3 Circuit L3 pow-

ers high beam operation.

HEADLAMP GROUND

Although circuit Z1 provides ground for the right

and left headlamps it has different termination

points for both. For the right headlamp the Z1 circuit

terminates at the right inner fender shield. For the

left headlamp the Z1 circuit terminates at the left

side of the radiator closure panel.

HELPFUL INFORMATION

²Check for a blown fuse in cavity 17 for L43 and

cavity 18 for L44.

²Check the 40 amp fuse located in the PDC.

²The headlamp switch has a 24 amp internal cir-

cuit breaker.

²For the left front parking lamp, turn signal, side

marker lamp and left headlamp, the Z1 circuit

grounding point is the left side of the radiator closure

panel.

²For the right front parking lamp, turn signal,

side marker lamp and right headlamp, the Z1 circuit

grounding point is in the right fender side shield.

HEADLAMP LEVELING MOTORS

The headlamp leveling system used in this vehicle

uses a variable position switch located in the instru-

ment panel along with headlamp leveling motors

located at the headlamps.

Power for the switch and the leveling motors is

supplied on circuit L43. This circuit is HOT when the

headlamp switch is in the ON position and the oper-

ator has selected LOW beam operation. In addition,circuit L43 is protected by a 10 amp fuse located in

the fuse block and is the feed for the left LOW beam

headlamp.

Ground for the switch is supplied on circuit Z1.

When the operator moves the switch, power is sup-

plied on circuit L13 from the switch to the headlamp

leveling motors. Ground for the leveling motors is

supplied on circuit Z1 and has the same termination

point as the respective headlamps.

The headlamp leveling switch also has a lamp

located in it for night illumination. Power for the

lamp is supplied on circuit E2. The E2 circuit is HOT

when the operator has turned the headlamp switch

to the PARK or ON position. The E2 circuit is pro-

tected by a 4 amp fuse located in the fuse block.

FOG LAMPS (FRONT)

The fog lamp system in this vehicle uses a switch

located in the instrument panel along with a relay

located in the Power Distribution Center (PDC).

Power for the switch is supplied on circuit L7. This

circuit is the feed for the front and rear parking

lamps and is HOT when the headlamp switch is in

the PARK position.

Power for the contact side of the relay is supplied

on circuit F61. This circuit is HOT at all times and

protected by a 20 amp fuse in the PDC. Ground for

the coil side of the relay is supplied in circuit Z1.

When the operator turns the lamps ON by closing

the switch, power flows on circuit L7 through the

switch to circuit L35. Circuit L35 connects from the

switch to the coil side of the fog lamp relay. With this

input the contacts in the fog lamp relay CLOSE con-

necting circuits F61 and L39.

Circuit L39 connects from the relay to the fog

lamps. Ground for the lamps is supplied on circuit

Z1.

HELPFUL INFORMATION

²Check the 20 amp fuse located in the PDC for

the fog lamps

²Check the lamp filament

²Check the grounding points for the lamps,

switch and relay

8W - 50 - 8 8W - 50 FRONT LIGHTINGPL

DESCRIPTION AND OPERATION (Continued)

Page 153 of 256

Downloaded from www.Manualslib.com manuals search engine 8W-51 REAR LIGHTING

INDEX

page page

DESCRIPTION AND OPERATION

BACK-UP LAMPS....................... 10

FOG LAMPS (REAR)...................... 9STOP LAMPS.......................... 10

TAIL LAMPS AND LICENSE LAMPS.......... 9

DESCRIPTION AND OPERATION

TAIL LAMPS AND LICENSE LAMPS

Circuit A3 in the Power Distribution Center (PDC)

connects to a bus bar in the fuse block. One of the

four circuits powered by the bus bar is circuit F33. A

40 amp fuse in the PDC protects the A3 circuit. A 15

amp fuse, in cavity number 2 of the fuse block, pro-

tects the F33 circuit.

The headlamp switch has 3 positions, ON, PARK

(tail lamps) and OFF, plus a dimmer switch. When

the headlamp switch is in the PARK or ON position,

it connects circuit F33 to circuit L7. From the head-

lamp switch, circuit L7 branches to power the front

parking lamps, rear tail lamps, side marker lamps,

and rear license plate lamp.

GROUND CIRCUIT

Circuit Z1 provides ground for the tail lamps, park-

ing lamps, headlamps, side marker lamps, lamps and

rear license plate lamps although different grounding

points are used. Circuit Z1 also provides the ground

path for the headlamps, stop lamps and turn signals.

HELPFUL INFORMATION

²Check for a blown 40 amp fuse in the PDC.

²Check for a blown fuse in cavity 2 of the fuse

block

²For the left rear parking lamp, turn signal, side

marker lamp, and the rear license plate the Z1 cir-

cuit grounding point is in the left rear wheel well.

²For the right rear parking lamp, turn signal and

side marker lamp, the Z1 circuit grounding point is

in the right rear wheel well.

²Circuit L7 also feeds the radio, if equipped.

²When the headlamp switch is in the PARK or

ON position, the dimmer circuit, F33, connects to cir-

cuit E1. Circuit E1 powers the ash receiver lamp,

transmission range indicator lamp, instrument panel

cluster illumination lamps, HVAC control lamp,

heated rear window lamp, and radio lamp. A 4 amp

fuse, in cavity 12 of the fuse block, protects circuit

E1.

FOG LAMPS (REAR)

The rear fog lamps will operate only when the

headlamp switch is in the ON position.

Circuit A3 from the Power Distribution Center sup-

plies (PDC) voltage to a bus bar in the fuse block.

Circuit F61 is one of four circuits that the bus bar

feeds and is protected by a 20 amp fuse in cavity 4.

Circuit F61 connects to the rear fog lamp switch and

the front fog lamp relay.

The fog lamp switch contains a relay that supplies

voltage to the fog lamps. Circuit L2 from the multi-

function switch supplies voltage to the coil side of the

relay (only when the headlamps operate on LOW

beam). Circuit F61 supplies voltage to the contact

side of the relay. During LOW beam headlamp oper-

ation when the fog lamp switch contacts CLOSE, cir-

cuit F61 connects to circuit L38.

Circuit L38 feeds right and left fog lamp. Circuit

L38 also feeds the green L.E.D. in the switch that

illuminates during fog lamps operation.

When the headlamp switch is in the PARK or ON

position, circuit E1 from the headlamp switch sup-

plies voltage for circuit E2. Circuit E2 contains a 4

amp fuse in cavity 12 of the fuse block, and powers

the bulb in the fog lamp switch.

GROUND CIRCUIT

Although circuit Z1 provides the ground path for

the fog lamps, the circuit has different grounding

points for each lamp.

Circuit Z3 supplies the ground path for the fog

lamp switch. The grounding point for the headlamp

switch is the instrument panel left center support.

HELPFUL INFORMATION

²Circuit Z1 also supplies ground for side marker

lamps, turn signals, parking lamps and headlamps.

²Circuit A3 from the PDC supplies voltage to the

headlamp switch for circuit L2.

²Circuit F33 from the fuse block supplies voltage

to the headlamp switch for circuit E1. Circuit A3

from the PDC supplies voltage to a bus bar in the

fuse block that feeds the F33 circuit. Fuse 2, in the

fuse block, protects the F33 circuit.

PL8W - 51 REAR LIGHTING 8W - 51 - 9

Page 154 of 256

Downloaded from www.Manualslib.com manuals search engine STOP LAMPS

Circuit F32 in the Power Distribution Center

(PDC) feeds the stop lamps. Circuit F32 connects to

the stop lamp switch. A 15 amp fuse in the PDC pro-

tects circuit F32.

When the operator presses the brake pedal, the

stop lamp switch CLOSES and connects circuit F32

to circuit L50. Circuit L50 connects to the stop

lamps. Circuit L50 also splices to power the CHMSL

lamp.

GROUND CIRCUIT

Circuit Z1 provides ground for the stop lamps,

CHMSL lamp, and the stop lamp switch. The Z1 cir-

cuit has more than one grounding point. It also sup-

plies ground path for the tail lamps, parking lamps,

headlamps, side marker lamps, rear license plate

lamp, back-up lamps and turn signals.

HELPFUL INFORMATION

²Check for blown fuses in circuit F32 (in PDC).

²Check for continuity across the stop lamp switch

when it is CLOSED.

²For rear lighting on the left side of the vehicle,

the Z1 circuit grounding point is in the left rear

wheel well.

²For rear lighting on the right side of the vehicle,

the Z1 circuit grounding point is in the right rear

wheel well.

²For the stop lamp switch, the Z1 circuit ground-

ing point is in the left front inner fender shield.

BACK-UP LAMPS

In the RUN position, the ignition switch connects

circuit A2 from the Power Distribution Center (PDC)to circuit A22. Circuit A22 feeds a bus bar in the fuse

block. A 40 amp fuse in the PDC protects the A2 and

A22 circuits.

Circuit F20 is one of four circuits that connects to

the fuse block bus bar fed by circuit A22. Circuit F20

supplies power to the back-up lamp switch. On 3±spd

automatic transaxle vehicles, the back-up lamp

switch is part of an assembly that includes the park/

neutral position switch.

When the operator puts the transmission in

REVERSE, the back-up lamp switch connects circuit

F20 to circuit L1. Circuit L1 feeds the back-up lamps.

A 10 amp fuse, in cavity 8 of the fuse block, protects

F20 and L1 circuits.

GROUND CIRCUIT

Circuit Z1 provides ground for the back-up lamps.

The Z1 circuit has more than one grounding point. It

also supplies ground path for the tail lamps, parking

lamps, headlamps, side marker lamps, rear license

plate lamp, stop lamps and turn signals.

HELPFUL INFORMATION

²Check for blown fuses in circuits A2 and F20.

²Check for continuity across the stop lamp switch

when it is CLOSED.

²For rear lighting on the left side of the vehicle,

the Z1 circuit grounding point is in the left rear

wheel well.

²For rear lighting on the right side of the vehicle,

the Z1 circuit grounding point is in the right rear

wheel well.

²Circuit F20 feeds the heated rear window switch

and A/C clutch cycling switch.

8W - 51 - 10 8W - 51 REAR LIGHTINGPL

DESCRIPTION AND OPERATION (Continued)