service indicator DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 283 of 1200

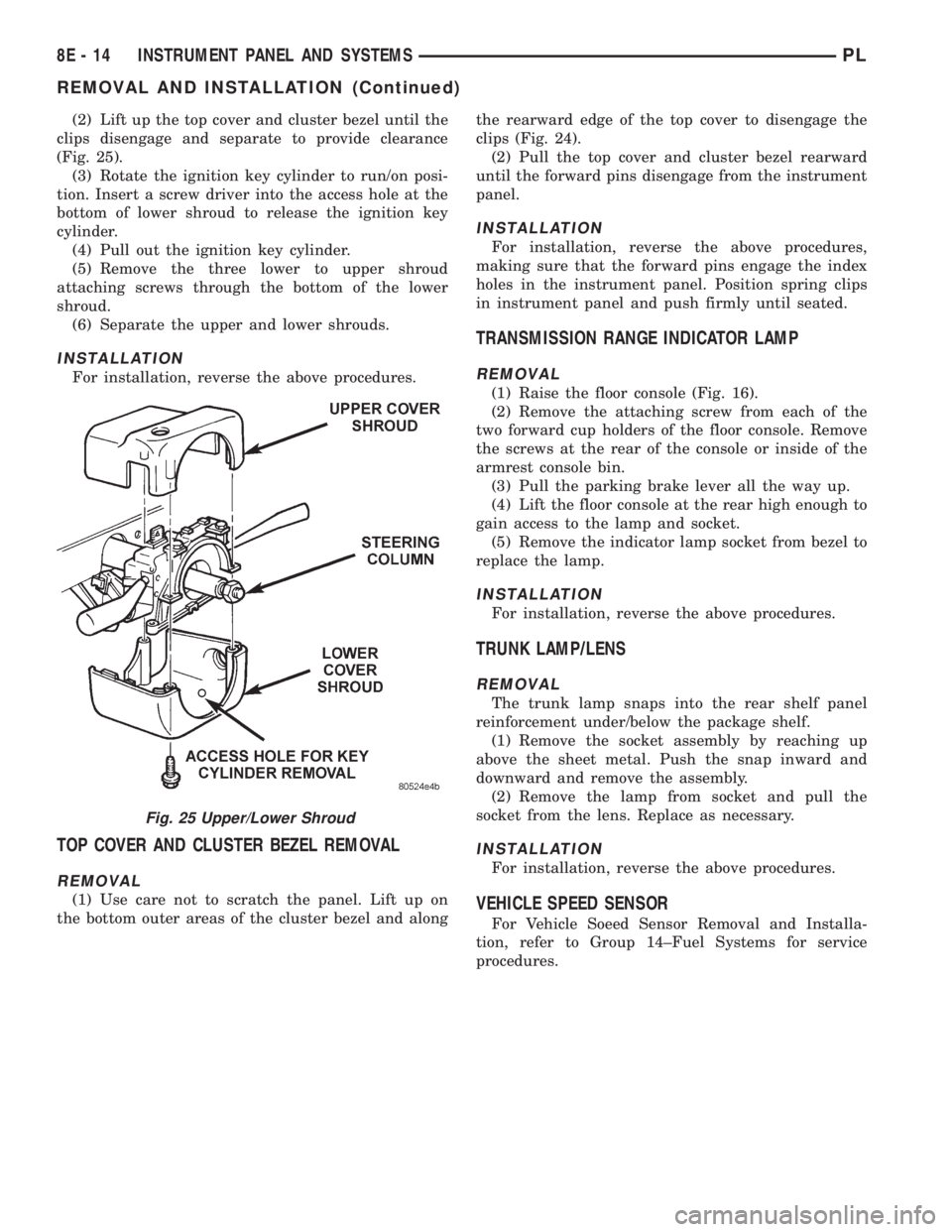

(2) Lift up the top cover and cluster bezel until the

clips disengage and separate to provide clearance

(Fig. 25).

(3) Rotate the ignition key cylinder to run/on posi-

tion. Insert a screw driver into the access hole at the

bottom of lower shroud to release the ignition key

cylinder.

(4) Pull out the ignition key cylinder.

(5) Remove the three lower to upper shroud

attaching screws through the bottom of the lower

shroud.

(6) Separate the upper and lower shrouds.

INSTALLATION

For installation, reverse the above procedures.

TOP COVER AND CLUSTER BEZEL REMOVAL

REMOVAL

(1) Use care not to scratch the panel. Lift up on

the bottom outer areas of the cluster bezel and alongthe rearward edge of the top cover to disengage the

clips (Fig. 24).

(2) Pull the top cover and cluster bezel rearward

until the forward pins disengage from the instrument

panel.

INSTALLATION

For installation, reverse the above procedures,

making sure that the forward pins engage the index

holes in the instrument panel. Position spring clips

in instrument panel and push firmly until seated.

TRANSMISSION RANGE INDICATOR LAMP

REMOVAL

(1) Raise the floor console (Fig. 16).

(2) Remove the attaching screw from each of the

two forward cup holders of the floor console. Remove

the screws at the rear of the console or inside of the

armrest console bin.

(3) Pull the parking brake lever all the way up.

(4) Lift the floor console at the rear high enough to

gain access to the lamp and socket.

(5) Remove the indicator lamp socket from bezel to

replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

TRUNK LAMP/LENS

REMOVAL

The trunk lamp snaps into the rear shelf panel

reinforcement under/below the package shelf.

(1) Remove the socket assembly by reaching up

above the sheet metal. Push the snap inward and

downward and remove the assembly.

(2) Remove the lamp from socket and pull the

socket from the lens. Replace as necessary.

INSTALLATION

For installation, reverse the above procedures.

VEHICLE SPEED SENSOR

For Vehicle Soeed Sensor Removal and Installa-

tion, refer to Group 14±Fuel Systems for service

procedures.

Fig. 25 Upper/Lower Shroud

8E - 14 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 333 of 1200

HEADLAMP ALIGNMENT

INDEX

page page

GENERAL INFORMATION

HEADLAMP ALIGNMENT................... 4

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION....... 4ADJUSTMENTS

FOG LAMP ALIGNMENT................... 4

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN.............................. 4

GENERAL INFORMATION

HEADLAMP ALIGNMENT

Headlamps can be aligned using the screen method

provided in this section.

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens (Fig. 1).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall.

(3) From the floor up 1.27 meters (5 ft.), tape a

line on the wall at the center line of the vehicle.

Sight along the center line of the vehicle (from rear

of vehicle forward) to verify accuracy of the line

placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

(7) Measure distance from the center line of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle center line. Use these lines for left/

right adjustment reference.

HEADLAMP ADJUSTMENT

A properly aimed low beam headlamp will project

the center of the low beam hot spot on the alignment

screen from 178 mm (7 in.) below the headlamp cen-

ter line. The side- to-side left edge of low beam hot

spot should be 127 mm (5 in.) to the right of head-

lamp center line (Fig. 1). The high beams on a vehi-

cle with aero headlamps cannot be aligned. The high

beam pattern should be correct when the low beams

are aligned properly.

To adjust headlamp alignment, rotate alignment

screws to achieve the specified low beam hot spot

pattern.

FOG LAMP ALIGNMENT

Prepare an alignment screen. Refer to Alignment

Screen Preparation paragraph in this section. Disen-

gage the wire connectors from the back of the head-

lamp bulbs to disable the headlamps. This will allow

a more accurate projection reading of the fog lamps.

Turn on the headlamp switch and actuate the fog

lamp switch. A properly aligned fog lamp will project

a pattern on the alignment screen 100 mm (4 in.)

below the fog lamp centerline and straight ahead

(Fig. 2).

8L - 4 LAMPSPL

Page 351 of 1200

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 8

SPECIFICATIONS

EXTERIOR LAMPS........................ 8INTERIOR LAMPS........................ 8

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up...............................P21W

Center High Mounted Stop..................921

Front Fog Lamp..........................H-3

Headlamp...............................H-4

License Plate...........................W5W

Front Turn Signal.....................P21/5W

Tail/Stop.............................P21/5W

Rear Turn Signal.......................P21W

Rear Fog Lamp.........................P21W

Citylight...............................T4W

Side Repeater...........................T4W

INTERIOR LAMPS

LAMP BULB

ABS.................................PC194

Airbag...............................PC194

AshTray................................161

Brake Warning System Indicator...........PC194

Cigar Lighter............................203

Climate Controls.........................203

Console Gear Selector......................161

Dome Light..............................578

Glove Box...............................194

High Beam Indicator....................PC194

Ignition Key.............................161

Instrument Cluster.....................PC194

Rear Cargo..............................912

Seat Belt Indicator.......................PC74

Service Engine Soon....................PC194

Turn Signal Indicator....................PC194

Underhood..............................105

Visor Vanity.........................6501966

Volts Indicator..........................PC74

8L - 8 LAMPSPL

Page 364 of 1200

ELECTRICALLY HEATED SYSTEMS

CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION......................... 1

REAR WINDOW DEFOGGER SWITCH........ 1

DIAGNOSIS AND TESTING

DEFOGGER SYSTEM..................... 1GRID LINES............................ 2

REAR WINDOW DEFOGGER SWITCH........ 2

SERVICE PROCEDURES

GRID LINE AND TERMINAL REPAIR......... 3

DESCRIPTION AND OPERATION

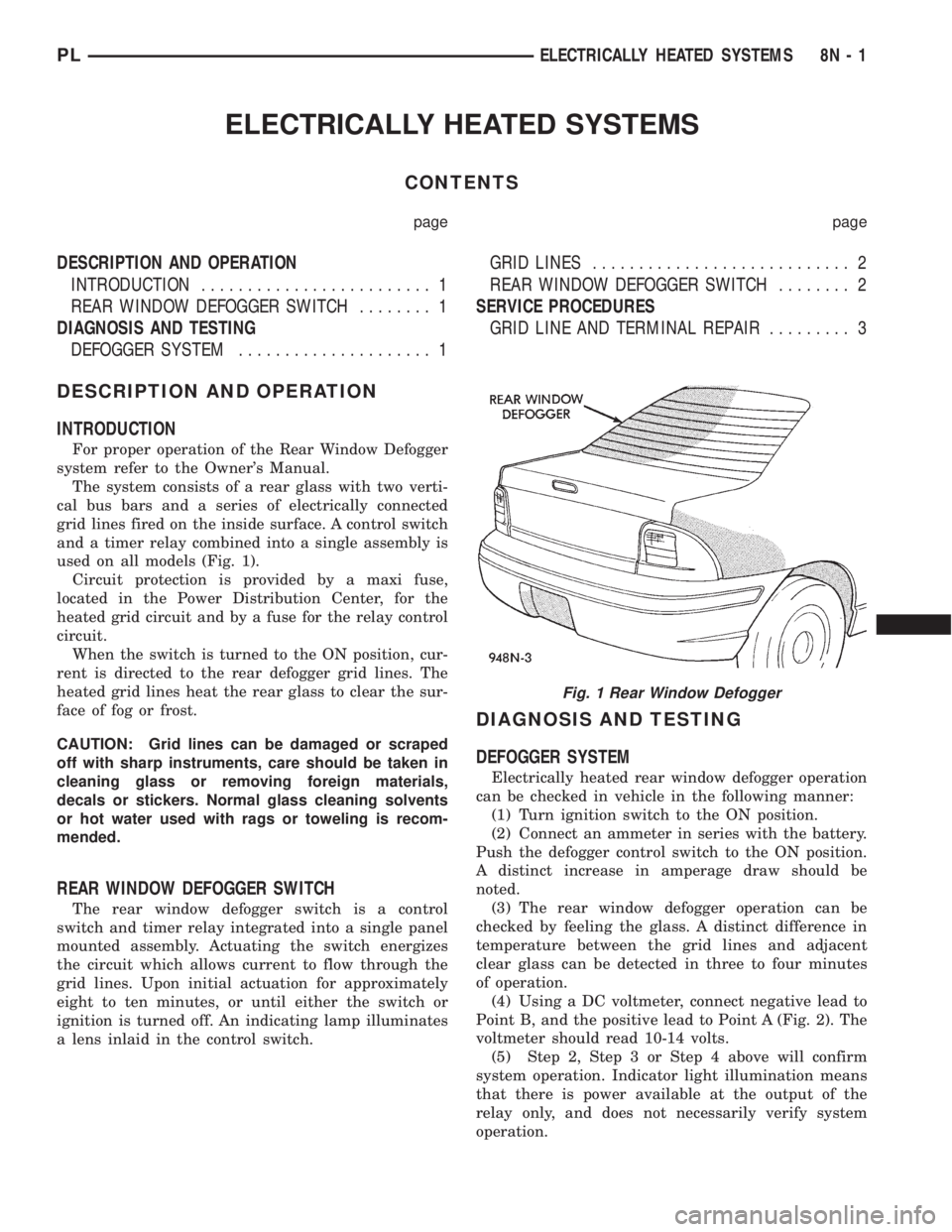

INTRODUCTION

For proper operation of the Rear Window Defogger

system refer to the Owner's Manual.

The system consists of a rear glass with two verti-

cal bus bars and a series of electrically connected

grid lines fired on the inside surface. A control switch

and a timer relay combined into a single assembly is

used on all models (Fig. 1).

Circuit protection is provided by a maxi fuse,

located in the Power Distribution Center, for the

heated grid circuit and by a fuse for the relay control

circuit.

When the switch is turned to the ON position, cur-

rent is directed to the rear defogger grid lines. The

heated grid lines heat the rear glass to clear the sur-

face of fog or frost.

CAUTION: Grid lines can be damaged or scraped

off with sharp instruments, care should be taken in

cleaning glass or removing foreign materials,

decals or stickers. Normal glass cleaning solvents

or hot water used with rags or toweling is recom-

mended.

REAR WINDOW DEFOGGER SWITCH

The rear window defogger switch is a control

switch and timer relay integrated into a single panel

mounted assembly. Actuating the switch energizes

the circuit which allows current to flow through the

grid lines. Upon initial actuation for approximately

eight to ten minutes, or until either the switch or

ignition is turned off. An indicating lamp illuminates

a lens inlaid in the control switch.

DIAGNOSIS AND TESTING

DEFOGGER SYSTEM

Electrically heated rear window defogger operation

can be checked in vehicle in the following manner:

(1) Turn ignition switch to the ON position.

(2) Connect an ammeter in series with the battery.

Push the defogger control switch to the ON position.

A distinct increase in amperage draw should be

noted.

(3) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected in three to four minutes

of operation.

(4) Using a DC voltmeter, connect negative lead to

Point B, and the positive lead to Point A (Fig. 2). The

voltmeter should read 10-14 volts.

(5) Step 2, Step 3 or Step 4 above will confirm

system operation. Indicator light illumination means

that there is power available at the output of the

relay only, and does not necessarily verify system

operation.

Fig. 1 Rear Window Defogger

PLELECTRICALLY HEATED SYSTEMS 8N - 1

Page 366 of 1200

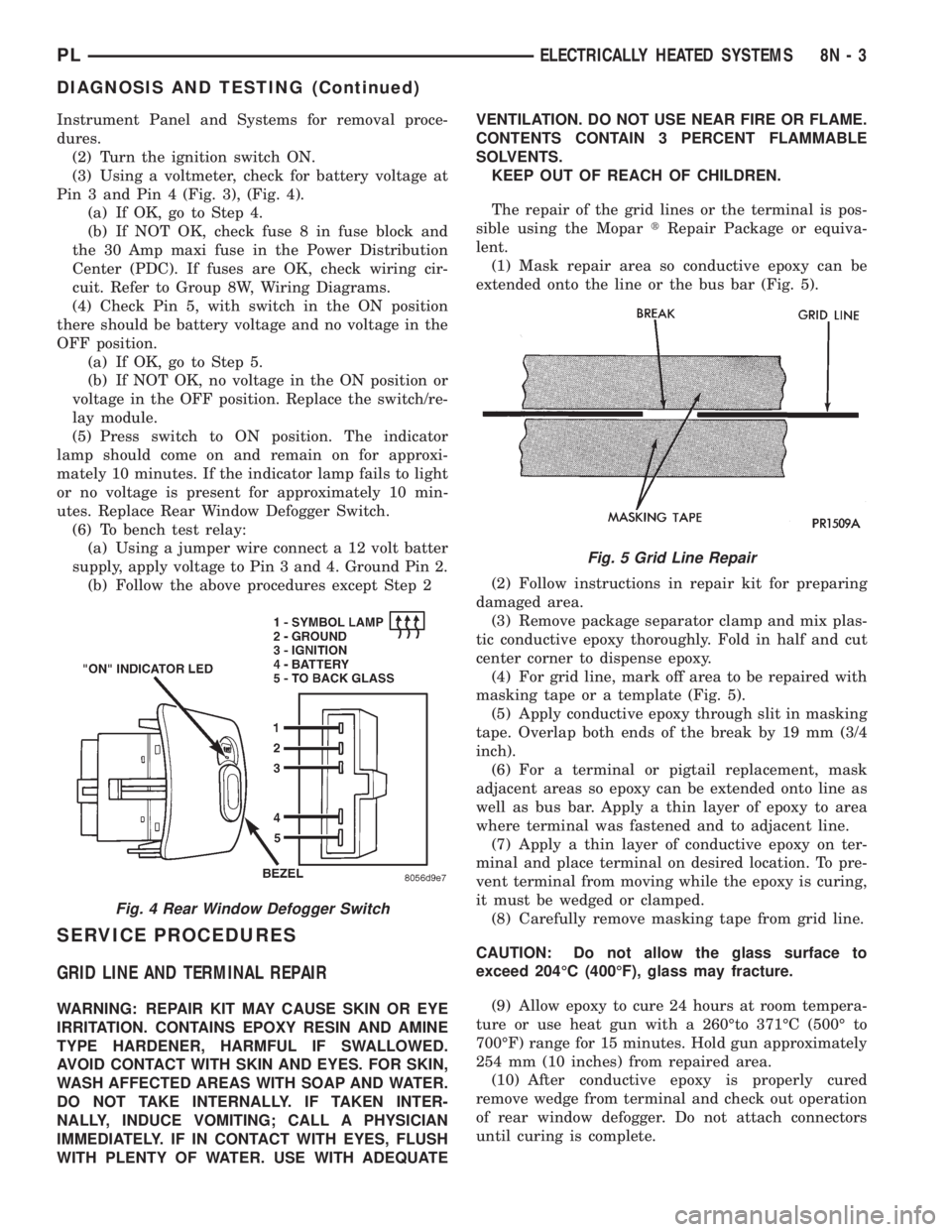

Instrument Panel and Systems for removal proce-

dures.

(2) Turn the ignition switch ON.

(3) Using a voltmeter, check for battery voltage at

Pin 3 and Pin 4 (Fig. 3), (Fig. 4).

(a) If OK, go to Step 4.

(b) If NOT OK, check fuse 8 in fuse block and

the 30 Amp maxi fuse in the Power Distribution

Center (PDC). If fuses are OK, check wiring cir-

cuit. Refer to Group 8W, Wiring Diagrams.

(4) Check Pin 5, with switch in the ON position

there should be battery voltage and no voltage in the

OFF position.

(a) If OK, go to Step 5.

(b) If NOT OK, no voltage in the ON position or

voltage in the OFF position. Replace the switch/re-

lay module.

(5) Press switch to ON position. The indicator

lamp should come on and remain on for approxi-

mately 10 minutes. If the indicator lamp fails to light

or no voltage is present for approximately 10 min-

utes. Replace Rear Window Defogger Switch.

(6) To bench test relay:

(a) Using a jumper wire connect a 12 volt batter

supply, apply voltage to Pin 3 and 4. Ground Pin 2.

(b) Follow the above procedures except Step 2

SERVICE PROCEDURES

GRID LINE AND TERMINAL REPAIR

WARNING: REPAIR KIT MAY CAUSE SKIN OR EYE

IRRITATION. CONTAINS EPOXY RESIN AND AMINE

TYPE HARDENER, HARMFUL IF SWALLOWED.

AVOID CONTACT WITH SKIN AND EYES. FOR SKIN,

WASH AFFECTED AREAS WITH SOAP AND WATER.

DO NOT TAKE INTERNALLY. IF TAKEN INTER-

NALLY, INDUCE VOMITING; CALL A PHYSICIAN

IMMEDIATELY. IF IN CONTACT WITH EYES, FLUSH

WITH PLENTY OF WATER. USE WITH ADEQUATEVENTILATION. DO NOT USE NEAR FIRE OR FLAME.

CONTENTS CONTAIN 3 PERCENT FLAMMABLE

SOLVENTS.

KEEP OUT OF REACH OF CHILDREN.

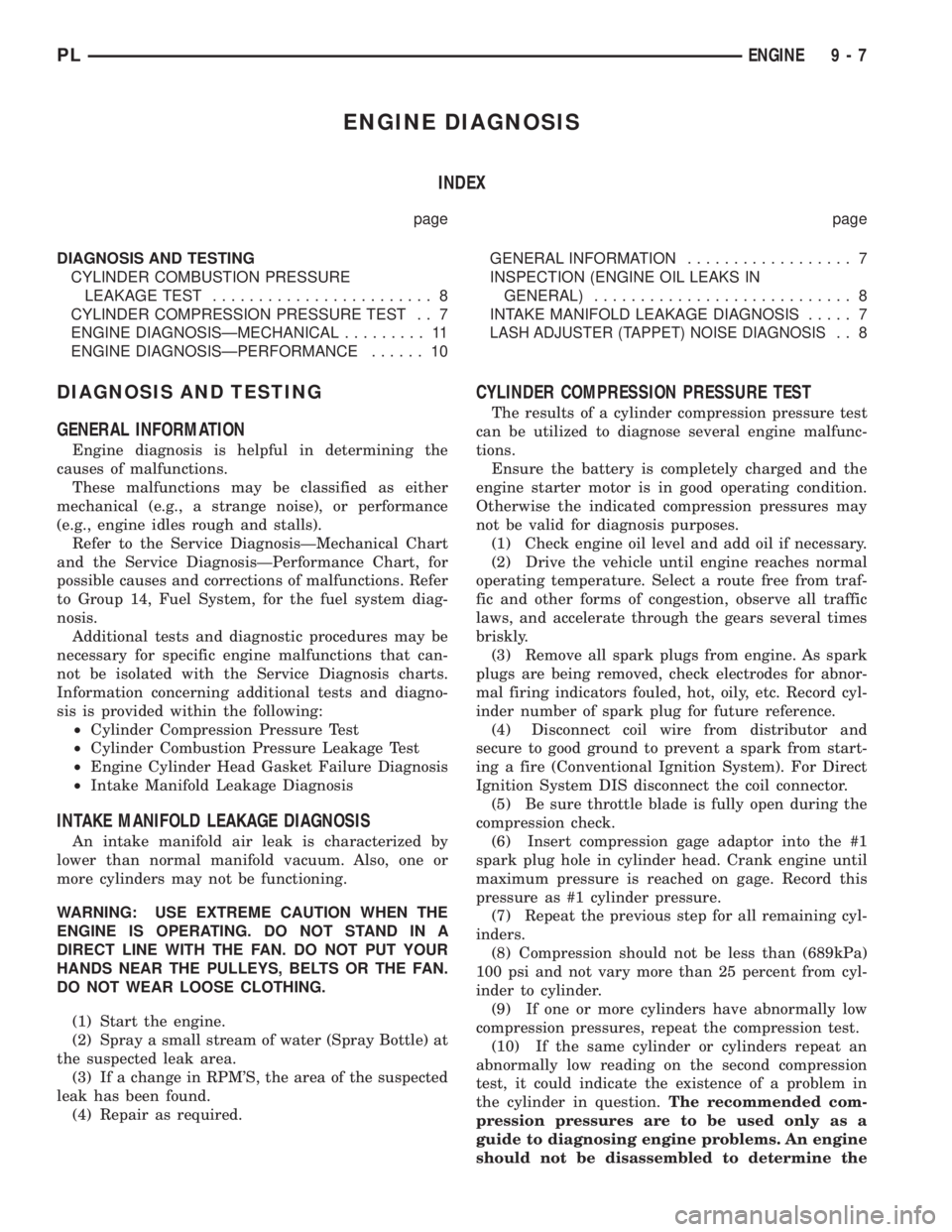

The repair of the grid lines or the terminal is pos-

sible using the MopartRepair Package or equiva-

lent.

(1) Mask repair area so conductive epoxy can be

extended onto the line or the bus bar (Fig. 5).

(2) Follow instructions in repair kit for preparing

damaged area.

(3) Remove package separator clamp and mix plas-

tic conductive epoxy thoroughly. Fold in half and cut

center corner to dispense epoxy.

(4) For grid line, mark off area to be repaired with

masking tape or a template (Fig. 5).

(5) Apply conductive epoxy through slit in masking

tape. Overlap both ends of the break by 19 mm (3/4

inch).

(6) For a terminal or pigtail replacement, mask

adjacent areas so epoxy can be extended onto line as

well as bus bar. Apply a thin layer of epoxy to area

where terminal was fastened and to adjacent line.

(7) Apply a thin layer of conductive epoxy on ter-

minal and place terminal on desired location. To pre-

vent terminal from moving while the epoxy is curing,

it must be wedged or clamped.

(8) Carefully remove masking tape from grid line.

CAUTION: Do not allow the glass surface to

exceed 204ÉC (400ÉF), glass may fracture.

(9) Allow epoxy to cure 24 hours at room tempera-

ture or use heat gun with a 260Éto 371ÉC (500É to

700ÉF) range for 15 minutes. Hold gun approximately

254 mm (10 inches) from repaired area.

(10) After conductive epoxy is properly cured

remove wedge from terminal and check out operation

of rear window defogger. Do not attach connectors

until curing is complete.

Fig. 4 Rear Window Defogger Switch

Fig. 5 Grid Line Repair

PLELECTRICALLY HEATED SYSTEMS 8N - 3

DIAGNOSIS AND TESTING (Continued)

Page 720 of 1200

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST........................ 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 11

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION (ENGINE OIL LEAKS IN

GENERAL)............................ 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS.. 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

PLENGINE 9 - 7

Page 729 of 1200

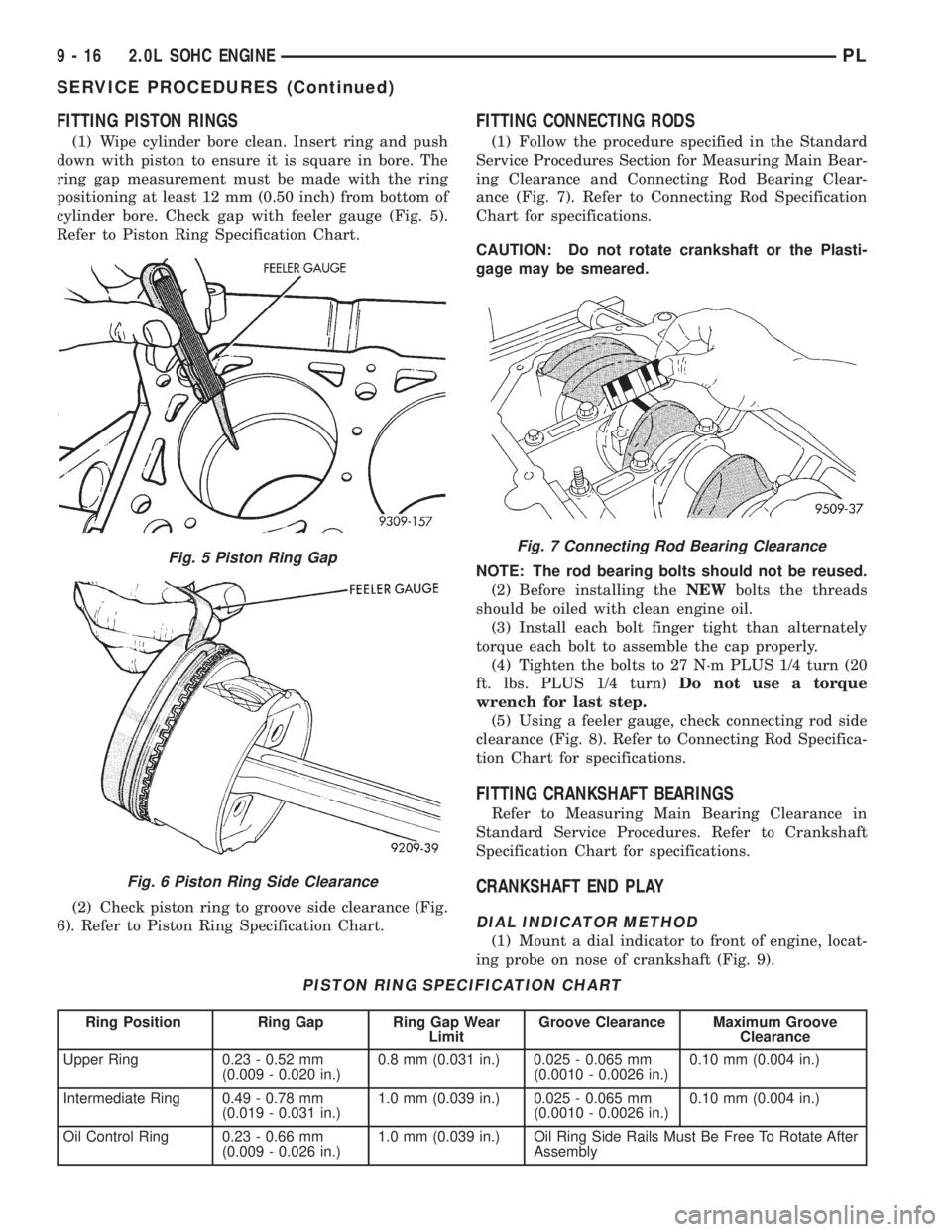

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 inch) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 5).

Refer to Piston Ring Specification Chart.

(2) Check piston ring to groove side clearance (Fig.

6). Refer to Piston Ring Specification Chart.

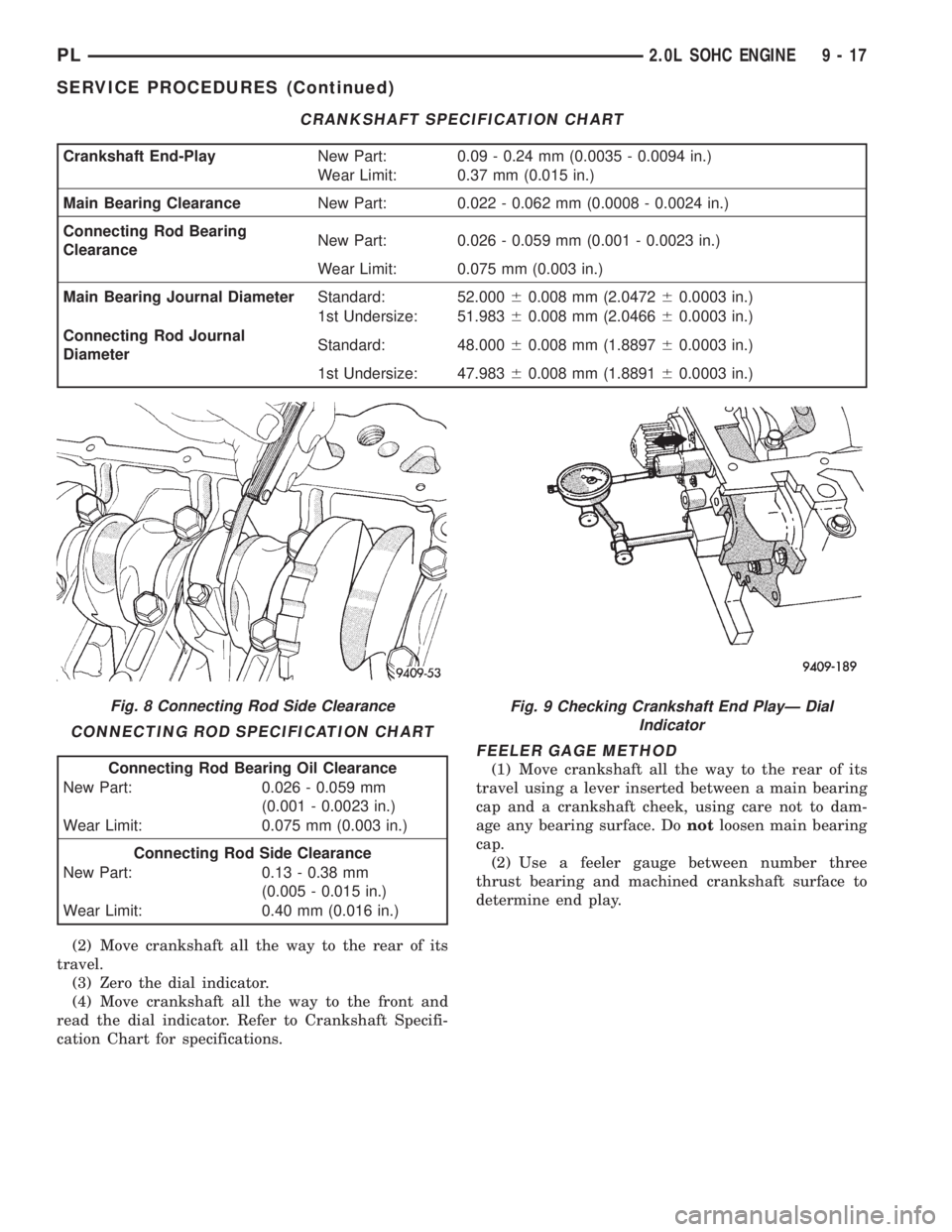

FITTING CONNECTING RODS

(1) Follow the procedure specified in the Standard

Service Procedures Section for Measuring Main Bear-

ing Clearance and Connecting Rod Bearing Clear-

ance (Fig. 7). Refer to Connecting Rod Specification

Chart for specifications.

CAUTION: Do not rotate crankshaft or the Plasti-

gage may be smeared.

NOTE: The rod bearing bolts should not be reused.

(2) Before installing theNEWbolts the threads

should be oiled with clean engine oil.

(3) Install each bolt finger tight than alternately

torque each bolt to assemble the cap properly.

(4) Tighten the bolts to 27 N´m PLUS 1/4 turn (20

ft. lbs. PLUS 1/4 turn)Do not use a torque

wrench for last step.

(5) Using a feeler gauge, check connecting rod side

clearance (Fig. 8). Refer to Connecting Rod Specifica-

tion Chart for specifications.

FITTING CRANKSHAFT BEARINGS

Refer to Measuring Main Bearing Clearance in

Standard Service Procedures. Refer to Crankshaft

Specification Chart for specifications.

CRANKSHAFT END PLAY

DIAL INDICATOR METHOD

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 9).

Fig. 5 Piston Ring Gap

Fig. 6 Piston Ring Side Clearance

PISTON RING SPECIFICATION CHART

Ring Position Ring Gap Ring Gap Wear

LimitGroove Clearance Maximum Groove

Clearance

Upper Ring 0.23 - 0.52 mm

(0.009 - 0.020 in.)0.8 mm (0.031 in.) 0.025 - 0.065 mm

(0.0010 - 0.0026 in.)0.10 mm (0.004 in.)

Intermediate Ring 0.49 - 0.78 mm

(0.019 - 0.031 in.)1.0 mm (0.039 in.) 0.025 - 0.065 mm

(0.0010 - 0.0026 in.)0.10 mm (0.004 in.)

Oil Control Ring 0.23 - 0.66 mm

(0.009 - 0.026 in.)1.0 mm (0.039 in.) Oil Ring Side Rails Must Be Free To Rotate After

Assembly

Fig. 7 Connecting Rod Bearing Clearance

9 - 16 2.0L SOHC ENGINEPL

SERVICE PROCEDURES (Continued)

Page 730 of 1200

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Crankshaft Specifi-

cation Chart for specifications.

FEELER GAGE METHOD

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

cap and a crankshaft cheek, using care not to dam-

age any bearing surface. Donotloosen main bearing

cap.

(2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

CRANKSHAFT SPECIFICATION CHART

Crankshaft End-PlayNew Part: 0.09 - 0.24 mm (0.0035 - 0.0094 in.)

Wear Limit: 0.37 mm (0.015 in.)

Main Bearing ClearanceNew Part: 0.022 - 0.062 mm (0.0008 - 0.0024 in.)

Connecting Rod Bearing

ClearanceNew Part: 0.026 - 0.059 mm (0.001 - 0.0023 in.)

Wear Limit: 0.075 mm (0.003 in.)

Main Bearing Journal DiameterStandard: 52.00060.008 mm (2.047260.0003 in.)

1st Undersize: 51.98360.008 mm (2.046660.0003 in.)

Connecting Rod Journal

DiameterStandard: 48.00060.008 mm (1.889760.0003 in.)

1st Undersize: 47.98360.008 mm (1.889160.0003 in.)

Fig. 8 Connecting Rod Side Clearance

CONNECTING ROD SPECIFICATION CHART

Connecting Rod Bearing Oil Clearance

New Part: 0.026 - 0.059 mm

(0.001 - 0.0023 in.)

Wear Limit: 0.075 mm (0.003 in.)

Connecting Rod Side Clearance

New Part: 0.13 - 0.38 mm

(0.005 - 0.015 in.)

Wear Limit: 0.40 mm (0.016 in.)

Fig. 9 Checking Crankshaft End PlayÐ Dial

Indicator

PL2.0L SOHC ENGINE 9 - 17

SERVICE PROCEDURES (Continued)

Page 761 of 1200

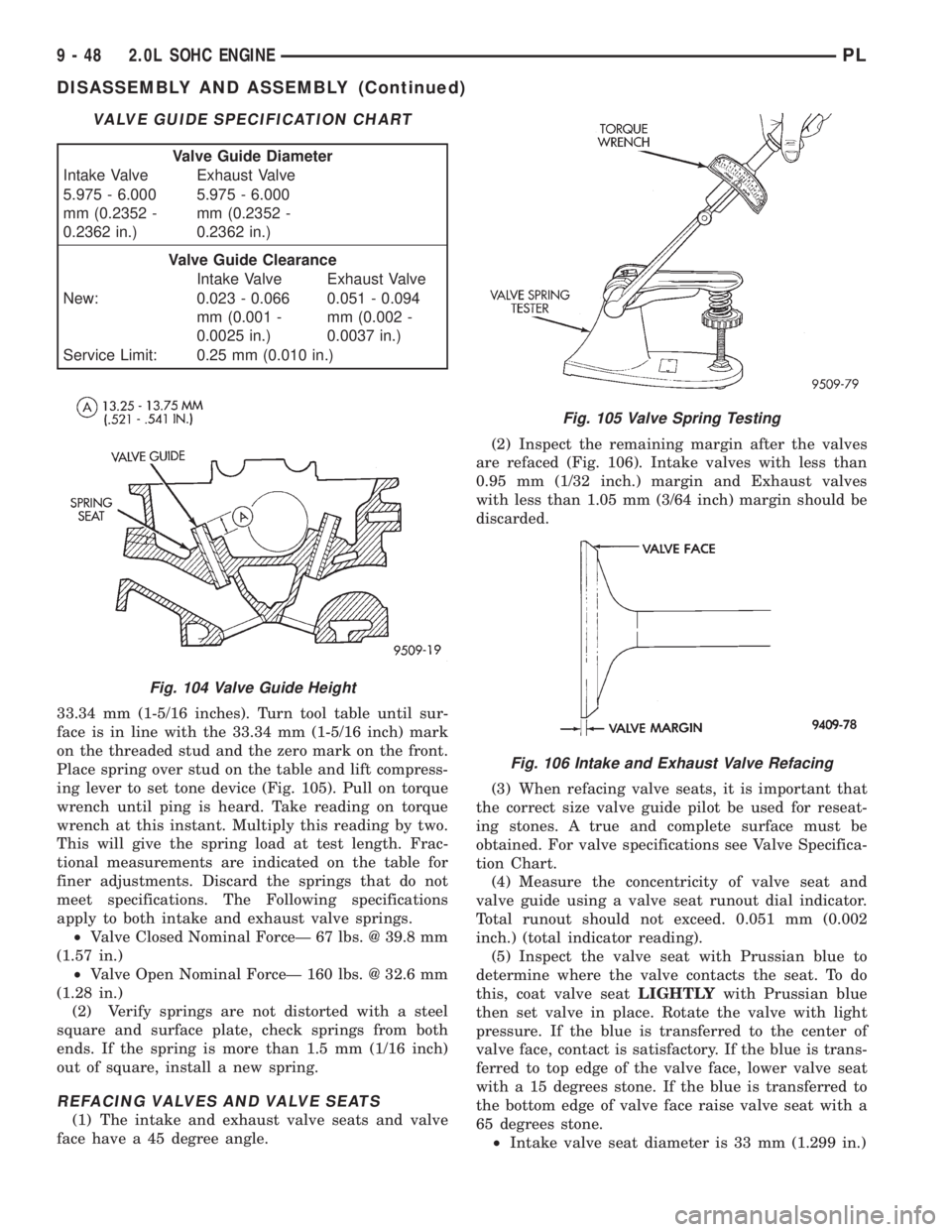

33.34 mm (1-5/16 inches). Turn tool table until sur-

face is in line with the 33.34 mm (1-5/16 inch) mark

on the threaded stud and the zero mark on the front.

Place spring over stud on the table and lift compress-

ing lever to set tone device (Fig. 105). Pull on torque

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The Following specifications

apply to both intake and exhaust valve springs.

²Valve Closed Nominal ForceÐ 67 lbs. @ 39.8 mm

(1.57 in.)

²Valve Open Nominal ForceÐ 160 lbs. @ 32.6 mm

(1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.(2) Inspect the remaining margin after the valves

are refaced (Fig. 106). Intake valves with less than

0.95 mm (1/32 inch.) margin and Exhaust valves

with less than 1.05 mm (3/64 inch) margin should be

discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For valve specifications see Valve Specifica-

tion Chart.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

²Intake valve seat diameter is 33 mm (1.299 in.)

VALVE GUIDE SPECIFICATION CHART

Valve Guide Diameter

Intake Valve Exhaust Valve

5.975 - 6.000

mm (0.2352 -

0.2362 in.)5.975 - 6.000

mm (0.2352 -

0.2362 in.)

Valve Guide Clearance

Intake Valve Exhaust Valve

New: 0.023 - 0.066

mm (0.001 -

0.0025 in.)0.051 - 0.094

mm (0.002 -

0.0037 in.)

Service Limit: 0.25 mm (0.010 in.)

Fig. 104 Valve Guide Height

Fig. 105 Valve Spring Testing

Fig. 106 Intake and Exhaust Valve Refacing

9 - 48 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 776 of 1200

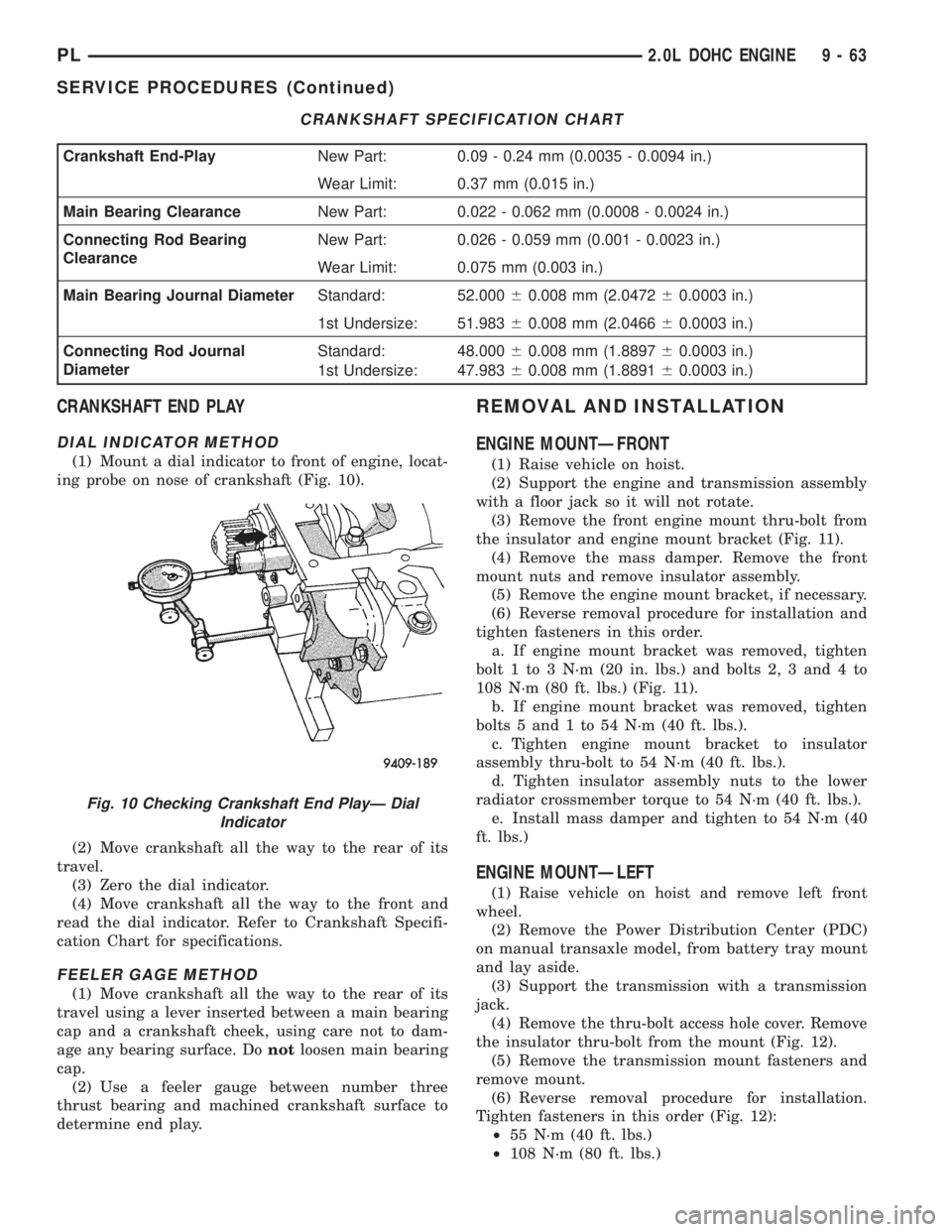

CRANKSHAFT END PLAY

DIAL INDICATOR METHOD

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 10).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Crankshaft Specifi-

cation Chart for specifications.

FEELER GAGE METHOD

(1) Move crankshaft all the way to the rear of its

travel using a lever inserted between a main bearing

cap and a crankshaft cheek, using care not to dam-

age any bearing surface. Donotloosen main bearing

cap.

(2) Use a feeler gauge between number three

thrust bearing and machined crankshaft surface to

determine end play.

REMOVAL AND INSTALLATION

ENGINE MOUNTÐFRONT

(1) Raise vehicle on hoist.

(2) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(3) Remove the front engine mount thru-bolt from

the insulator and engine mount bracket (Fig. 11).

(4) Remove the mass damper. Remove the front

mount nuts and remove insulator assembly.

(5) Remove the engine mount bracket, if necessary.

(6) Reverse removal procedure for installation and

tighten fasteners in this order.

a. If engine mount bracket was removed, tighten

bolt 1 to 3 N´m (20 in. lbs.) and bolts 2, 3 and 4 to

108 N´m (80 ft. lbs.) (Fig. 11).

b. If engine mount bracket was removed, tighten

bolts 5 and 1 to 54 N´m (40 ft. lbs.).

c. Tighten engine mount bracket to insulator

assembly thru-bolt to 54 N´m (40 ft. lbs.).

d. Tighten insulator assembly nuts to the lower

radiator crossmember torque to 54 N´m (40 ft. lbs.).

e. Install mass damper and tighten to 54 N´m (40

ft. lbs.)

ENGINE MOUNTÐLEFT

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Remove the Power Distribution Center (PDC)

on manual transaxle model, from battery tray mount

and lay aside.

(3) Support the transmission with a transmission

jack.

(4) Remove the thru-bolt access hole cover. Remove

the insulator thru-bolt from the mount (Fig. 12).

(5) Remove the transmission mount fasteners and

remove mount.

(6) Reverse removal procedure for installation.

Tighten fasteners in this order (Fig. 12):

²55 N´m (40 ft. lbs.)

²108 N´m (80 ft. lbs.)

CRANKSHAFT SPECIFICATION CHART

Crankshaft End-PlayNew Part: 0.09 - 0.24 mm (0.0035 - 0.0094 in.)

Wear Limit: 0.37 mm (0.015 in.)

Main Bearing ClearanceNew Part: 0.022 - 0.062 mm (0.0008 - 0.0024 in.)

Connecting Rod Bearing

ClearanceNew Part: 0.026 - 0.059 mm (0.001 - 0.0023 in.)

Wear Limit: 0.075 mm (0.003 in.)

Main Bearing Journal DiameterStandard: 52.00060.008 mm (2.047260.0003 in.)

1st Undersize: 51.98360.008 mm (2.046660.0003 in.)

Connecting Rod Journal

DiameterStandard: 48.00060.008 mm (1.889760.0003 in.)

1st Undersize: 47.98360.008 mm (1.889160.0003 in.)

Fig. 10 Checking Crankshaft End PlayÐ Dial

Indicator

PL2.0L DOHC ENGINE 9 - 63

SERVICE PROCEDURES (Continued)