coolant DODGE NEON 1999 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 606 of 1200

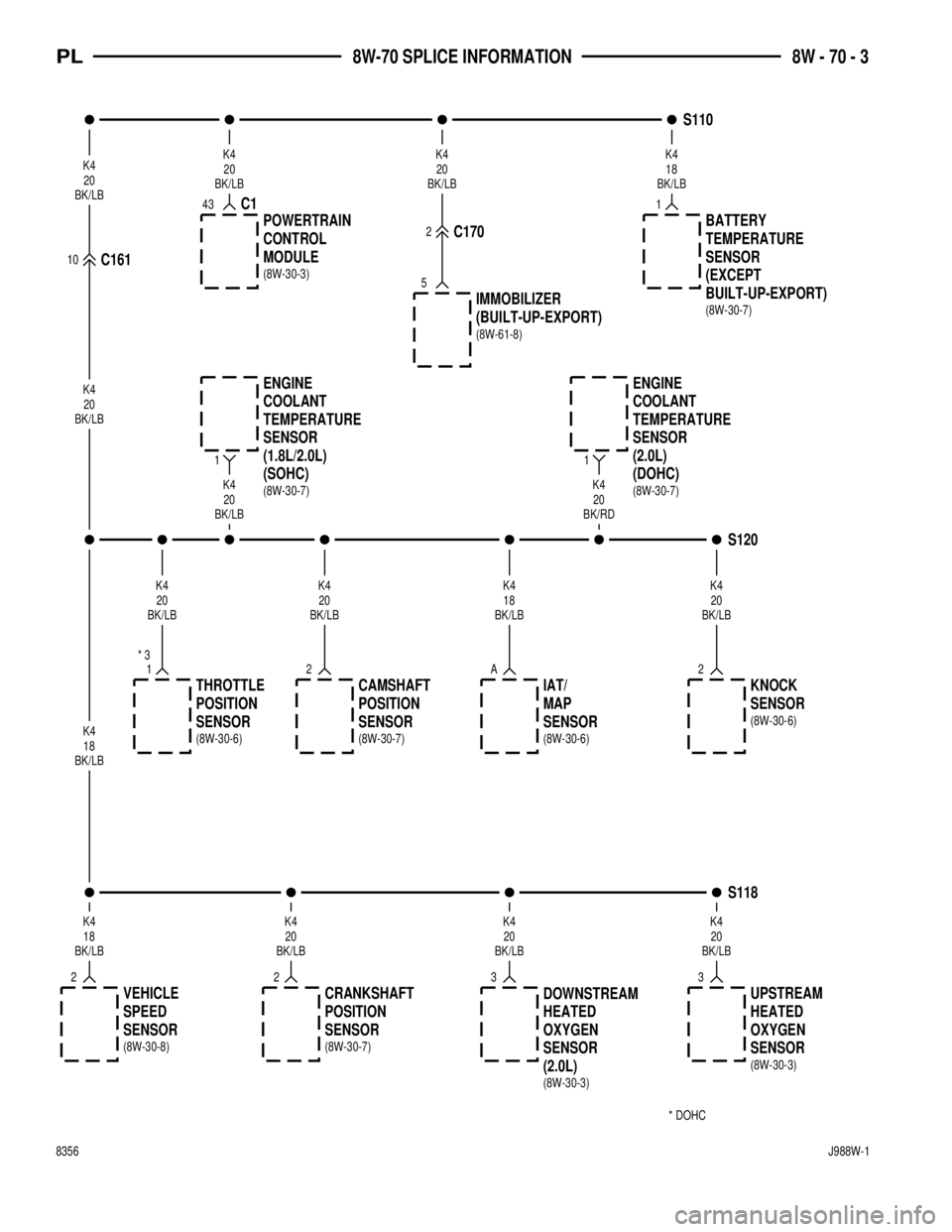

1

K4

20

BK/LBK4

20

BK/LBK4

18

BK/LB

10C161

K4

20

BK/LB

POWERTRAIN

CONTROL

MODULE

43C1

1

SENSOR POSITION

THROTTLE

BK/LB20 K4

K4

20

BK/LB

CAMSHAFT

POSITION

SENSOR

2A

BK/LB18 K4

K4

20

BK/LB

2

SENSOR KNOCK

K4

20

BK/LB

11

BK/RD20 K4

S110

S120

S118

3

BK/LB20 K4

K4

20

BK/LB

3 2

SENSOR POSITION

CRANKSHAFT

BK/LB20 K4

K4

18

BK/LB

VEHICLE

SPEED

SENSOR

2

UPSTREAM

HEATED

OXYGEN

SENSOR

K4

18

BK/LBSENSOR MAP

IAT/

* 3

* DOHC 5

BK/LB20 K4

BUILT-UP-EXPORT) (EXCEPT

SENSOR

TEMPERATURE

BATTERY

(2.0L) SENSOR

OXYGEN

HEATED

DOWNSTREAM (SOHC) (1.8L/2.0L)

SENSOR

TEMPERATURE

COOLANT

ENGINE ENGINE

COOLANT

TEMPERATURE

SENSOR

(2.0L)

(DOHC)

2C170

(BUILT-UP-EXPORT) IMMOBILIZER

(8W-30-6)

(8W-30-3) (8W-30-8) (8W-30-7)(8W-30-6)

(8W-30-7) (8W-30-6)(8W-30-3)

(8W-30-7)

(8W-30-3) (8W-30-7) (8W-30-7)(8W-61-8)

PL8W-70 SPLICE INFORMATION 8W - 70 - 3

8356J988W-1

Page 610 of 1200

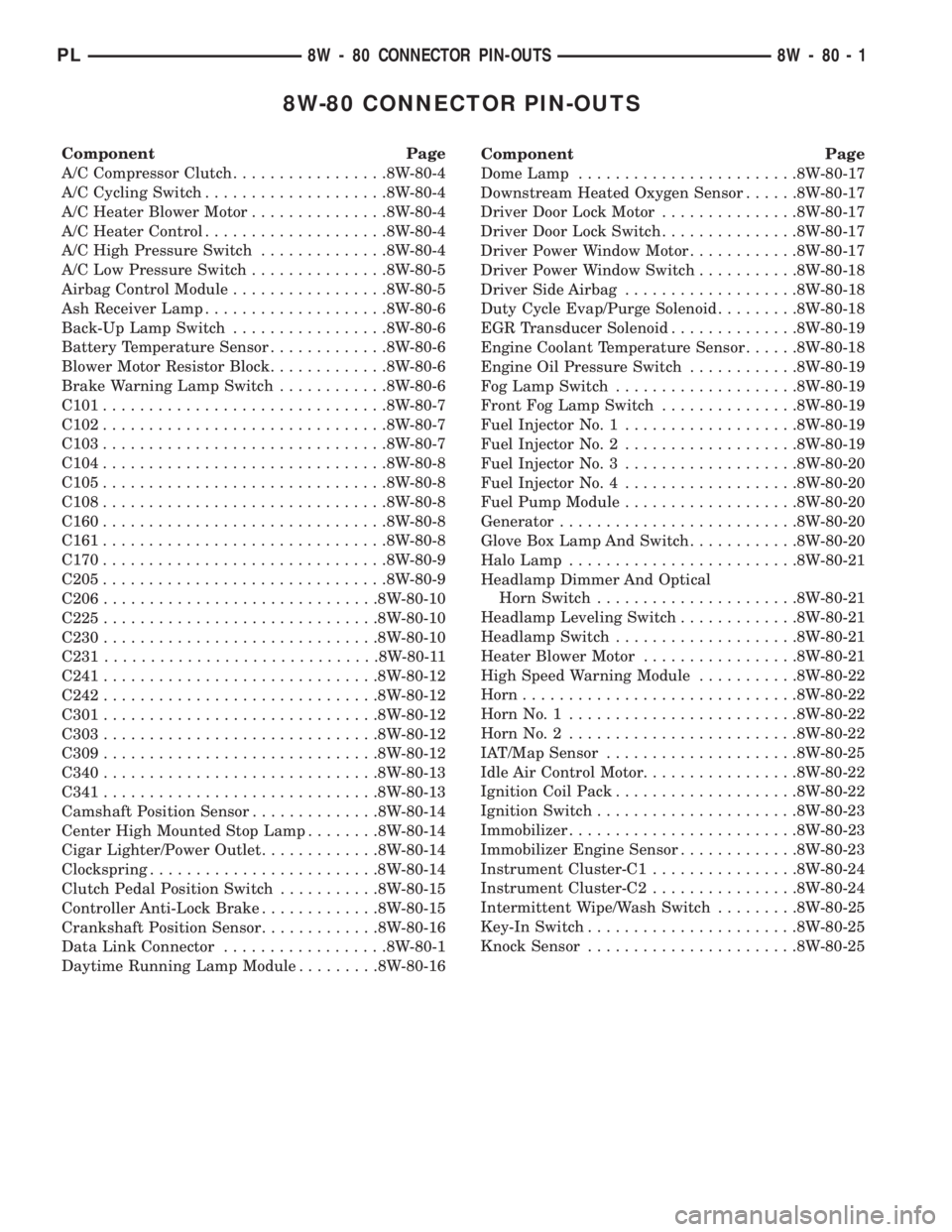

8W-80 CONNECTOR PIN-OUTS

Component Page

A/C Compressor Clutch.................8W-80-4

A/C Cycling Switch....................8W-80-4

A/C Heater Blower Motor...............8W-80-4

A/C Heater Control....................8W-80-4

A/C High Pressure Switch..............8W-80-4

A/C Low Pressure Switch...............8W-80-5

Airbag Control Module.................8W-80-5

Ash Receiver Lamp....................8W-80-6

Back-Up Lamp Switch.................8W-80-6

Battery Temperature Sensor.............8W-80-6

Blower Motor Resistor Block.............8W-80-6

Brake Warning Lamp Switch............8W-80-6

C101...............................8W-80-7

C102...............................8W-80-7

C103...............................8W-80-7

C104...............................8W-80-8

C105...............................8W-80-8

C108...............................8W-80-8

C160...............................8W-80-8

C161...............................8W-80-8

C170...............................8W-80-9

C205...............................8W-80-9

C206..............................8W-80-10

C225..............................8W-80-10

C230..............................8W-80-10

C231..............................8W-80-11

C241..............................8W-80-12

C242..............................8W-80-12

C301..............................8W-80-12

C303..............................8W-80-12

C309..............................8W-80-12

C340..............................8W-80-13

C341..............................8W-80-13

Camshaft Position Sensor..............8W-80-14

Center High Mounted Stop Lamp........8W-80-14

Cigar Lighter/Power Outlet.............8W-80-14

Clockspring.........................8W-80-14

Clutch Pedal Position Switch...........8W-80-15

Controller Anti-Lock Brake.............8W-80-15

Crankshaft Position Sensor.............8W-80-16

Data Link Connector..................8W-80-1

Daytime Running Lamp Module.........8W-80-16Component Page

Dome Lamp........................8W-80-17

Downstream Heated Oxygen Sensor......8W-80-17

Driver Door Lock Motor...............8W-80-17

Driver Door Lock Switch...............8W-80-17

Driver Power Window Motor............8W-80-17

Driver Power Window Switch...........8W-80-18

Driver Side Airbag...................8W-80-18

Duty Cycle Evap/Purge Solenoid.........8W-80-18

EGR Transducer Solenoid..............8W-80-19

Engine Coolant Temperature Sensor......8W-80-18

Engine Oil Pressure Switch............8W-80-19

Fog Lamp Switch....................8W-80-19

Front Fog Lamp Switch...............8W-80-19

Fuel Injector No. 1...................8W-80-19

Fuel Injector No. 2...................8W-80-19

Fuel Injector No. 3...................8W-80-20

Fuel Injector No. 4...................8W-80-20

Fuel Pump Module...................8W-80-20

Generator..........................8W-80-20

Glove Box Lamp And Switch............8W-80-20

Halo Lamp.........................8W-80-21

Headlamp Dimmer And Optical

Horn Switch......................8W-80-21

Headlamp Leveling Switch.............8W-80-21

Headlamp Switch....................8W-80-21

Heater Blower Motor.................8W-80-21

High Speed Warning Module...........8W-80-22

Horn..............................8W-80-22

Horn No. 1.........................8W-80-22

Horn No. 2.........................8W-80-22

IAT/Map Sensor.....................8W-80-25

Idle Air Control Motor.................8W-80-22

Ignition Coil Pack....................8W-80-22

Ignition Switch......................8W-80-23

Immobilizer.........................8W-80-23

Immobilizer Engine Sensor.............8W-80-23

Instrument Cluster-C1................8W-80-24

Instrument Cluster-C2................8W-80-24

Intermittent Wipe/Wash Switch.........8W-80-25

Key-In Switch.......................8W-80-25

Knock Sensor.......................8W-80-25

PL8W - 80 CONNECTOR PIN-OUTS 8W - 80 - 1

Page 627 of 1200

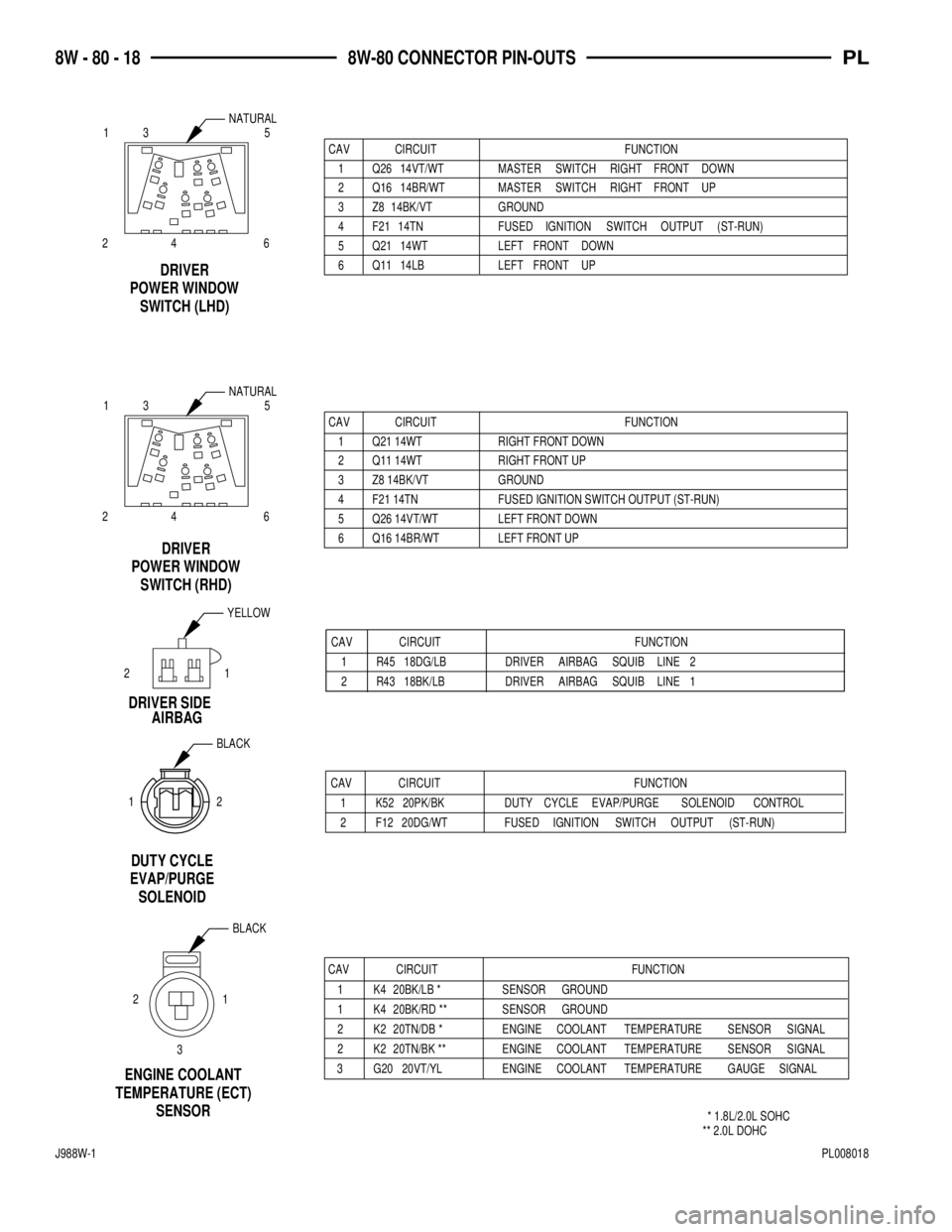

CAV CIRCUIT FUNCTION

1 K52 20PK/BK DUTY CYCLE EVAP/PURGE SOLENOID CONTROL

2 F12 20DG/WT FUSED IGNITION SWITCH OUTPUT (ST-RUN)

CAV CIRCUIT FUNCTION

1 K4 20BK/LB * SENSOR GROUND

1 K4 20BK/RD ** SENSOR GROUND

2 K2 20TN/DB * ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

2 K2 20TN/BK ** ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

3 G20 20VT/YL ENGINE COOLANT TEMPERATURE GAUGE SIGNAL

BLACK

2 1

3

* 1.8L/2.0L SOHC

** 2.0L DOHC

1

BLACK

2

6 4 25 3 1

NATURAL

UP FRONT LEFT 14LB Q11 6DOWN FRONT LEFT 14WT Q21 5

(ST-RUN) OUTPUT SWITCH IGNITION FUSED 14TN F21 4

GROUND 14BK/VT Z8 3

UP FRONT RIGHT SWITCH MASTER 14BR/WT Q16 2

DOWN FRONT RIGHT SWITCH MASTER 14VT/WT Q26 1

FUNCTION CIRCUIT CAV

CAV CIRCUIT FUNCTION

1 Q21 14WT RIGHT FRONT DOWN

2 Q11 14WT RIGHT FRONT UP

3 Z8 14BK/VT GROUND

4 F21 14TN FUSED IGNITION SWITCH OUTPUT (ST-RUN)

5 Q26 14VT/WT LEFT FRONT DOWN

6 Q16 14BR/WT LEFT FRONT UP

NATURAL1 3 5

24 6

DRIVER

POWER WINDOW

SWITCH (RHD) SWITCH (LHD) POWER WINDOWDRIVER

DUTY CYCLE

EVAP/PURGE

SOLENOID

ENGINE COOLANT

TEMPERATURE (ECT)

SENSOR

1 2

AIRBAG DRIVER SIDE

YELLOW

1 LINE SQUIB AIRBAG DRIVER 18BK/LB R43 22 LINE SQUIB AIRBAG DRIVER 18DG/LB R45 1

FUNCTION CIRCUIT CAV

8W - 80 - 18 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008018

Page 643 of 1200

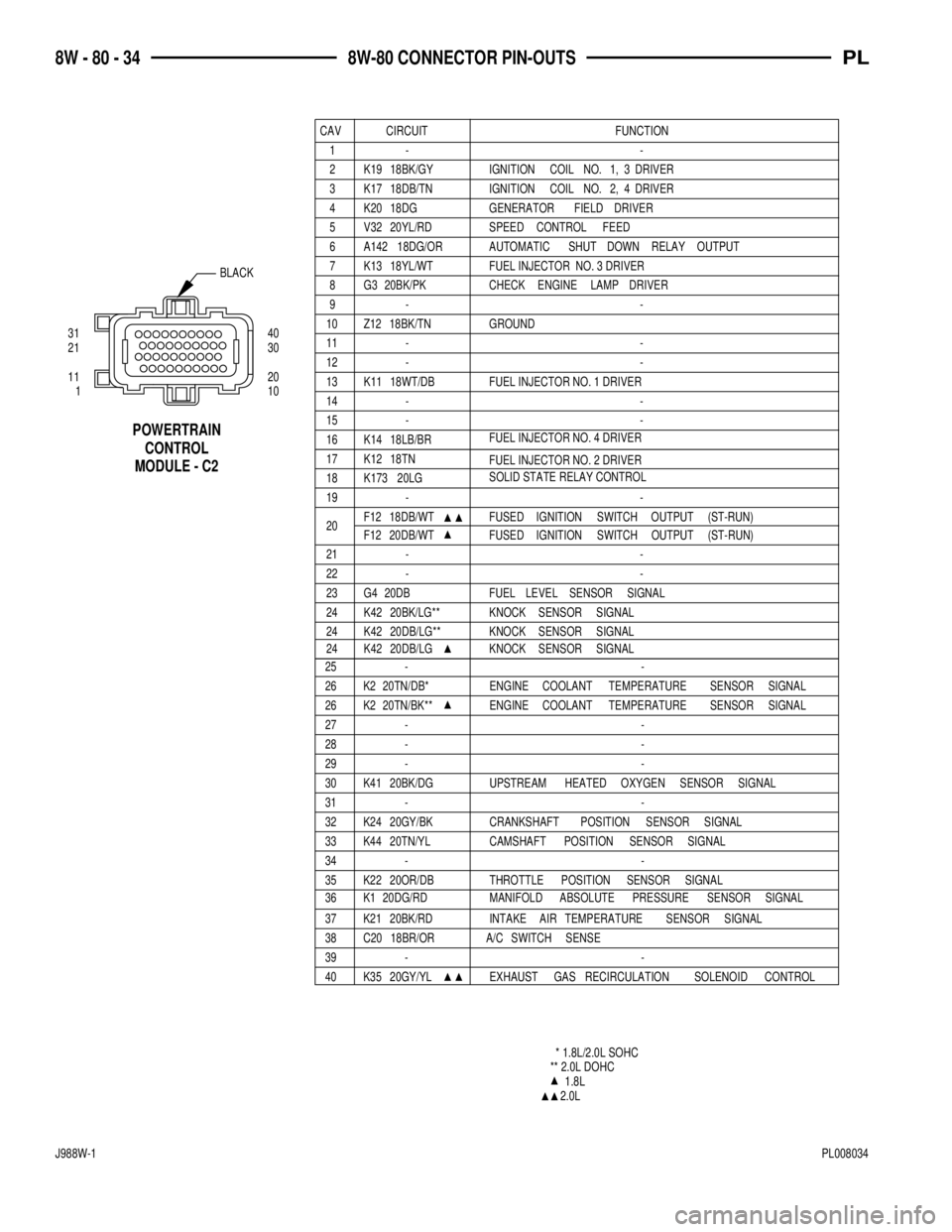

CAV CIRCUIT FUNCTION

1- -

2 K19 18BK/GY IGNITION COIL NO. 1, 3 DRIVER

3 K17 18DB/TN IGNITION COIL NO. 2, 4 DRIVER

4 K20 18DG GENERATOR FIELD DRIVER

5 V32 20YL/RD SPEED CONTROL FEED

6 A142 18DG/OR AUTOMATIC SHUT DOWN RELAY OUTPUT

7 K13 18YL/WT FUEL INJECTOR NO. 3 DRIVER

8 G3 20BK/PK CHECK ENGINE LAMP DRIVER

9- -

10 Z12 18BK/TN GROUND

11 - -

12 - -

13 K11 18WT/DB FUEL INJECTOR NO. 1 DRIVER

14 - -

15 - -

16 K14 18LB/BR

17 K12 18TN

18 K173 20LG

19 - -

20F12 18DB/WT FUSED IGNITION SWITCH OUTPUT (ST-RUN)

21 - -

22 - -

23 G4 20DB FUEL LEVEL SENSOR SIGNAL

24 K42 20BK/LG** KNOCK SENSOR SIGNAL

24 K42 20DB/LG** KNOCK SENSOR SIGNAL

31 40

21 30

11 20

110

BLACK

CONTROL SOLENOID RECIRCULATION GAS EXHAUST 20GY/YL K35 40- - 39

SENSE SWITCH A/C 18BR/OR C20 38

SIGNAL SENSOR POSITION THROTTLE 20OR/DB K22 35

- - 34

SIGNAL SENSOR POSITION CAMSHAFT 20TN/YL K44 33

SIGNAL SENSOR POSITION CRANKSHAFT 20GY/BK K24 32

- - 31

SIGNAL SENSOR OXYGEN HEATED UPSTREAM 20BK/DG K41 30

- - 29

- - 28

- - 27

SIGNAL SENSOR TEMPERATURE COOLANT ENGINE 20TN/BK** K2 26

SIGNAL SENSOR TEMPERATURE COOLANT ENGINE 20TN/DB* K2 26

- - 25

POWERTRAIN

CONTROL

MODULE - C2

20DB/WT F12 (ST-RUN)OUTPUT SWITCH IGNITION FUSED

24K42 20DB/LG KNOCK SENSOR SIGNAL

* 1.8L/2.0L SOHC

** 2.0L DOHC

1.8L

2.0L 36 K1 20DG/RD MANIFOLD ABSOLUTE PRESSURE SENSOR SIGNAL

37 K21 20BK/RD INTAKE AIR TEMPERATURE SENSOR SIGNAL

FUEL INJECTOR NO. 4 DRIVER

FUEL INJECTOR NO. 2 DRIVER

SOLID STATE RELAY CONTROL

8W - 80 - 34 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008034

Page 655 of 1200

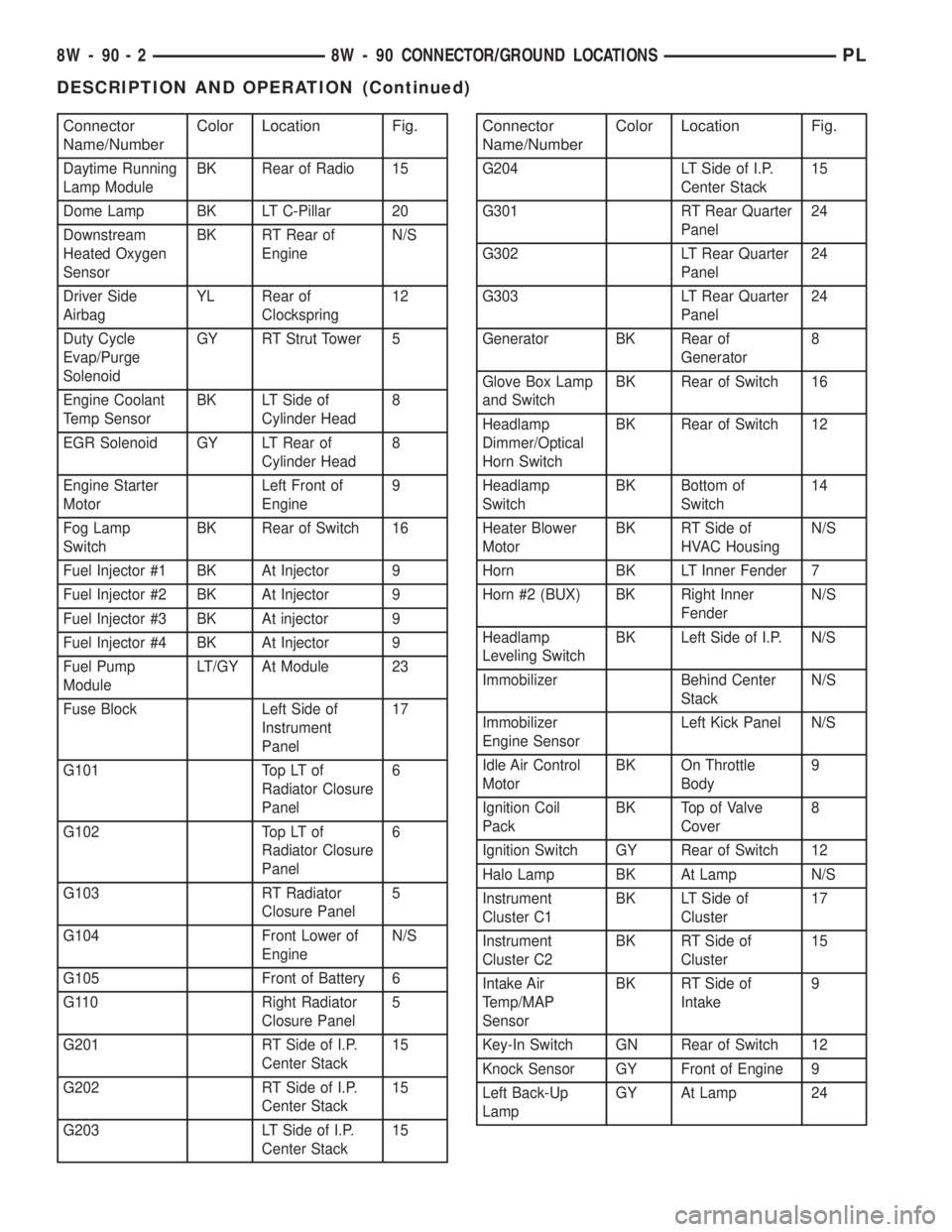

Connector

Name/NumberColor Location Fig.

Daytime Running

Lamp ModuleBK Rear of Radio 15

Dome Lamp BK LT C-Pillar 20

Downstream

Heated Oxygen

SensorBK RT Rear of

EngineN/S

Driver Side

AirbagYL Rear of

Clockspring12

Duty Cycle

Evap/Purge

SolenoidGY RT Strut Tower 5

Engine Coolant

Temp SensorBK LT Side of

Cylinder Head8

EGR Solenoid GY LT Rear of

Cylinder Head8

Engine Starter

MotorLeft Front of

Engine9

Fog Lamp

SwitchBK Rear of Switch 16

Fuel Injector #1 BK At Injector 9

Fuel Injector #2 BK At Injector 9

Fuel Injector #3 BK At injector 9

Fuel Injector #4 BK At Injector 9

Fuel Pump

ModuleLT/GY At Module 23

Fuse Block Left Side of

Instrument

Panel17

G101 Top LT of

Radiator Closure

Panel6

G102 Top LT of

Radiator Closure

Panel6

G103 RT Radiator

Closure Panel5

G104 Front Lower of

EngineN/S

G105 Front of Battery 6

G110 Right Radiator

Closure Panel5

G201 RT Side of I.P.

Center Stack15

G202 RT Side of I.P.

Center Stack15

G203 LT Side of I.P.

Center Stack15

Connector

Name/NumberColor Location Fig.

G204 LT Side of I.P.

Center Stack15

G301 RT Rear Quarter

Panel24

G302 LT Rear Quarter

Panel24

G303 LT Rear Quarter

Panel24

Generator BK Rear of

Generator8

Glove Box Lamp

and SwitchBK Rear of Switch 16

Headlamp

Dimmer/Optical

Horn SwitchBK Rear of Switch 12

Headlamp

SwitchBK Bottom of

Switch14

Heater Blower

MotorBK RT Side of

HVAC HousingN/S

Horn BK LT Inner Fender 7

Horn #2 (BUX) BK Right Inner

FenderN/S

Headlamp

Leveling SwitchBK Left Side of I.P. N/S

Immobilizer Behind Center

StackN/S

Immobilizer

Engine SensorLeft Kick Panel N/S

Idle Air Control

MotorBK On Throttle

Body9

Ignition Coil

PackBK Top of Valve

Cover8

Ignition Switch GY Rear of Switch 12

Halo Lamp BK At Lamp N/S

Instrument

Cluster C1BK LT Side of

Cluster17

Instrument

Cluster C2BK RT Side of

Cluster15

Intake Air

Temp/MAP

SensorBK RT Side of

Intake9

Key-In Switch GN Rear of Switch 12

Knock Sensor GY Front of Engine 9

Left Back-Up

LampGY At Lamp 24

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

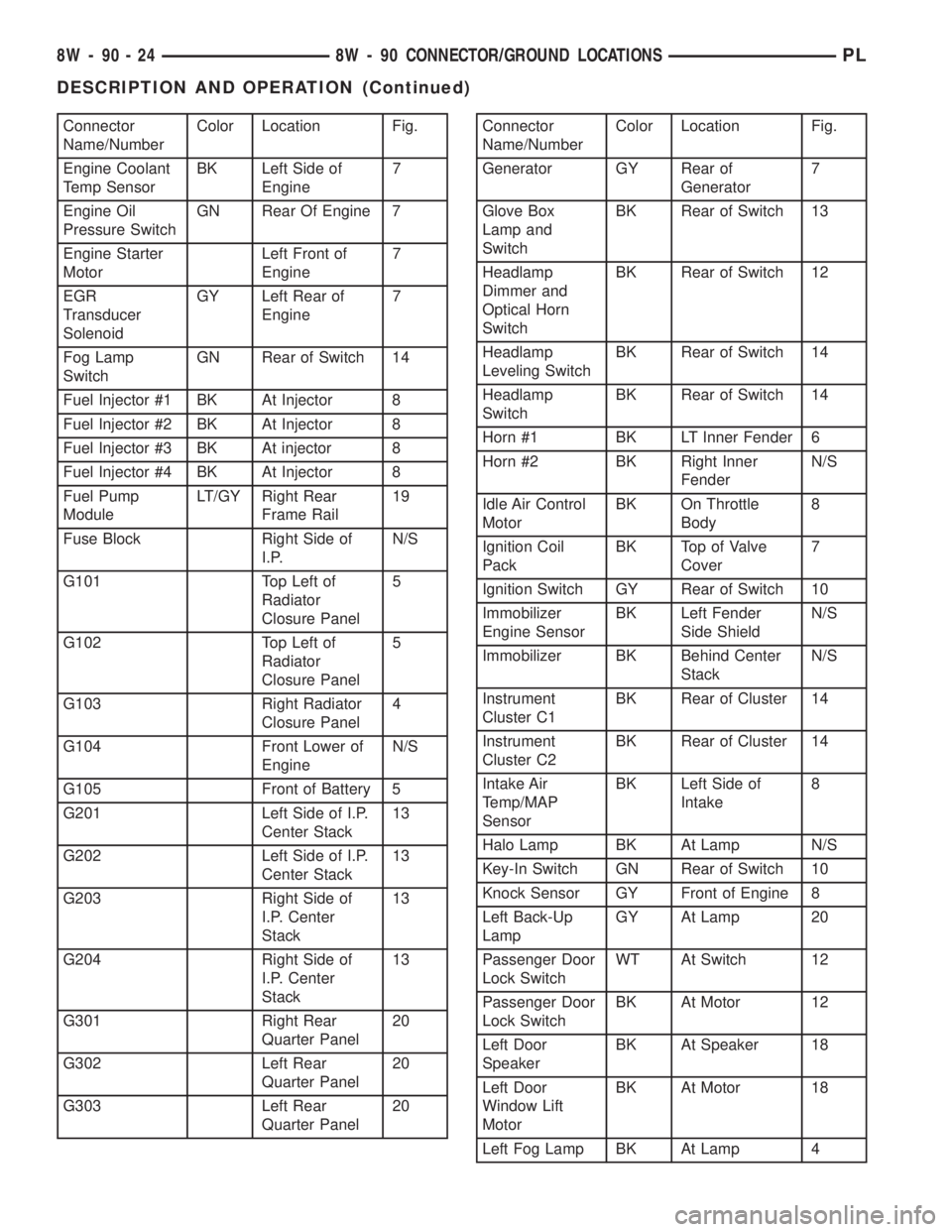

Page 677 of 1200

Connector

Name/NumberColor Location Fig.

Engine Coolant

Temp SensorBK Left Side of

Engine7

Engine Oil

Pressure SwitchGN Rear Of Engine 7

Engine Starter

MotorLeft Front of

Engine7

EGR

Transducer

SolenoidGY Left Rear of

Engine7

Fog Lamp

SwitchGN Rear of Switch 14

Fuel Injector #1 BK At Injector 8

Fuel Injector #2 BK At Injector 8

Fuel Injector #3 BK At injector 8

Fuel Injector #4 BK At Injector 8

Fuel Pump

ModuleLT/GY Right Rear

Frame Rail19

Fuse Block Right Side of

I.P.N/S

G101 Top Left of

Radiator

Closure Panel5

G102 Top Left of

Radiator

Closure Panel5

G103 Right Radiator

Closure Panel4

G104 Front Lower of

EngineN/S

G105 Front of Battery 5

G201 Left Side of I.P.

Center Stack13

G202 Left Side of I.P.

Center Stack13

G203 Right Side of

I.P. Center

Stack13

G204 Right Side of

I.P. Center

Stack13

G301 Right Rear

Quarter Panel20

G302 Left Rear

Quarter Panel20

G303 Left Rear

Quarter Panel20Connector

Name/NumberColor Location Fig.

Generator GY Rear of

Generator7

Glove Box

Lamp and

SwitchBK Rear of Switch 13

Headlamp

Dimmer and

Optical Horn

SwitchBK Rear of Switch 12

Headlamp

Leveling SwitchBK Rear of Switch 14

Headlamp

SwitchBK Rear of Switch 14

Horn #1 BK LT Inner Fender 6

Horn #2 BK Right Inner

FenderN/S

Idle Air Control

MotorBK On Throttle

Body8

Ignition Coil

PackBK Top of Valve

Cover7

Ignition Switch GY Rear of Switch 10

Immobilizer

Engine SensorBK Left Fender

Side ShieldN/S

Immobilizer BK Behind Center

StackN/S

Instrument

Cluster C1BK Rear of Cluster 14

Instrument

Cluster C2BK Rear of Cluster 14

Intake Air

Temp/MAP

SensorBK Left Side of

Intake8

Halo Lamp BK At Lamp N/S

Key-In Switch GN Rear of Switch 10

Knock Sensor GY Front of Engine 8

Left Back-Up

LampGY At Lamp 20

Passenger Door

Lock SwitchWT At Switch 12

Passenger Door

Lock SwitchBK At Motor 12

Left Door

SpeakerBK At Speaker 18

Left Door

Window Lift

MotorBK At Motor 18

Left Fog Lamp BK At Lamp 4

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 721 of 1200

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary

and adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance,.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

9 - 8 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 824 of 1200

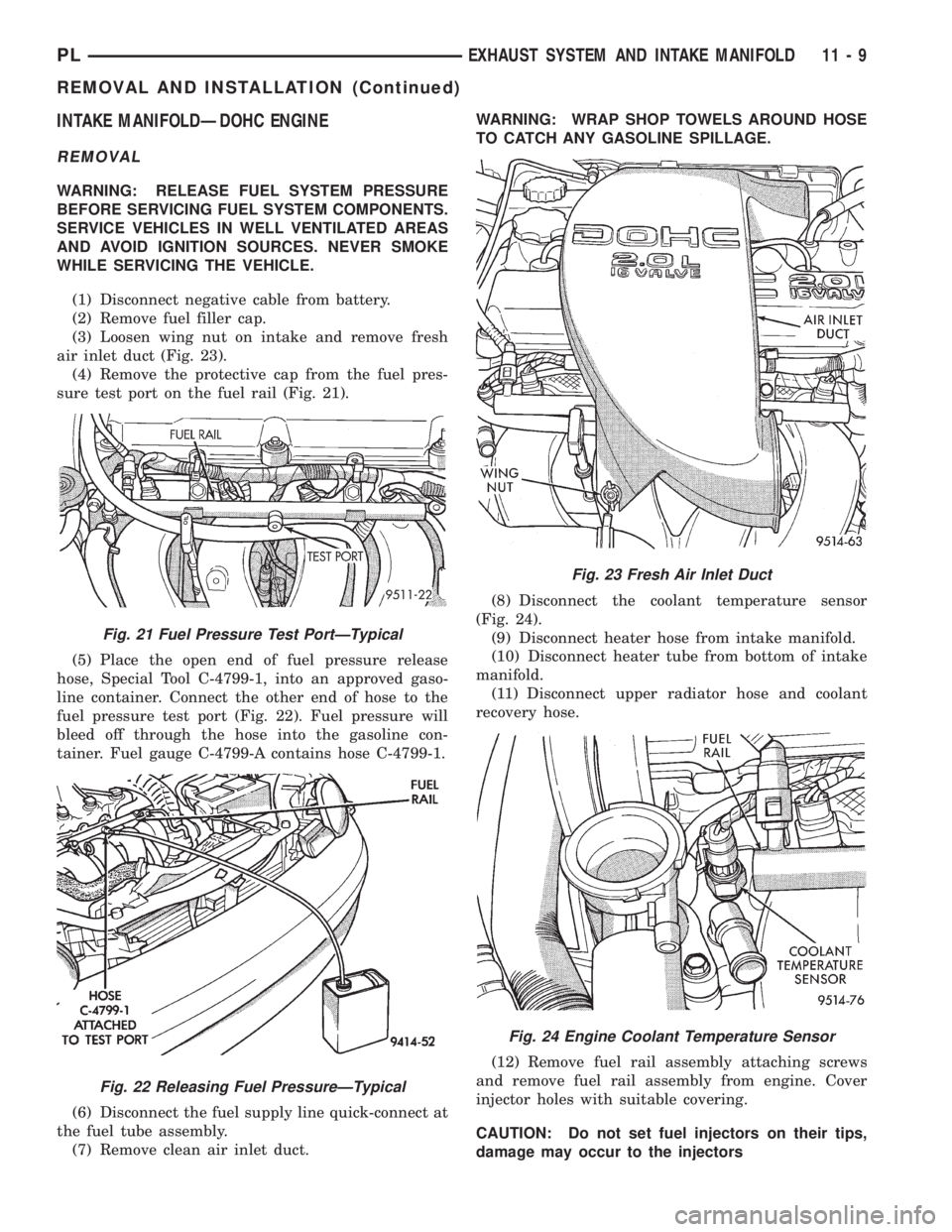

INTAKE MANIFOLDÐDOHC ENGINE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Loosen wing nut on intake and remove fresh

air inlet duct (Fig. 23).

(4) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 21).

(5) Place the open end of fuel pressure release

hose, Special Tool C-4799-1, into an approved gaso-

line container. Connect the other end of hose to the

fuel pressure test port (Fig. 22). Fuel pressure will

bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1.

(6) Disconnect the fuel supply line quick-connect at

the fuel tube assembly.

(7) Remove clean air inlet duct.WARNING: WRAP SHOP TOWELS AROUND HOSE

TO CATCH ANY GASOLINE SPILLAGE.

(8) Disconnect the coolant temperature sensor

(Fig. 24).

(9) Disconnect heater hose from intake manifold.

(10) Disconnect heater tube from bottom of intake

manifold.

(11) Disconnect upper radiator hose and coolant

recovery hose.

(12) Remove fuel rail assembly attaching screws

and remove fuel rail assembly from engine. Cover

injector holes with suitable covering.

CAUTION: Do not set fuel injectors on their tips,

damage may occur to the injectors

Fig. 21 Fuel Pressure Test PortÐTypical

Fig. 22 Releasing Fuel PressureÐTypical

Fig. 23 Fresh Air Inlet Duct

Fig. 24 Engine Coolant Temperature Sensor

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 9

REMOVAL AND INSTALLATION (Continued)

Page 826 of 1200

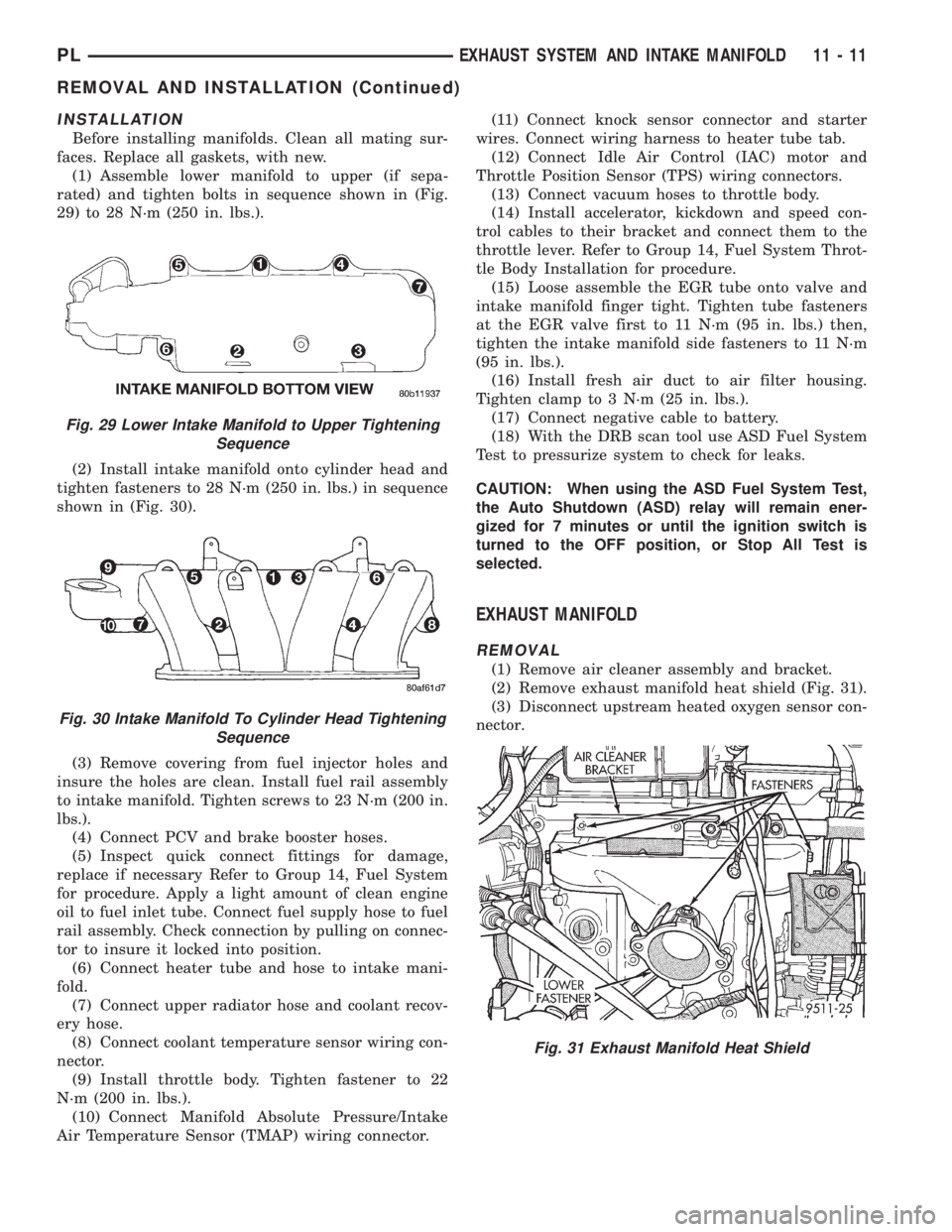

INSTALLATION

Before installing manifolds. Clean all mating sur-

faces. Replace all gaskets, with new.

(1) Assemble lower manifold to upper (if sepa-

rated) and tighten bolts in sequence shown in (Fig.

29) to 28 N´m (250 in. lbs.).

(2) Install intake manifold onto cylinder head and

tighten fasteners to 28 N´m (250 in. lbs.) in sequence

shown in (Fig. 30).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Connect heater tube and hose to intake mani-

fold.

(7) Connect upper radiator hose and coolant recov-

ery hose.

(8) Connect coolant temperature sensor wiring con-

nector.

(9) Install throttle body. Tighten fastener to 22

N´m (200 in. lbs.).

(10) Connect Manifold Absolute Pressure/Intake

Air Temperature Sensor (TMAP) wiring connector.(11) Connect knock sensor connector and starter

wires. Connect wiring harness to heater tube tab.

(12) Connect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors.

(13) Connect vacuum hoses to throttle body.

(14) Install accelerator, kickdown and speed con-

trol cables to their bracket and connect them to the

throttle lever. Refer to Group 14, Fuel System Throt-

tle Body Installation for procedure.

(15) Loose assemble the EGR tube onto valve and

intake manifold finger tight. Tighten tube fasteners

at the EGR valve first to 11 N´m (95 in. lbs.) then,

tighten the intake manifold side fasteners to 11 N´m

(95 in. lbs.).

(16) Install fresh air duct to air filter housing.

Tighten clamp to 3 N´m (25 in. lbs.).

(17) Connect negative cable to battery.

(18) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

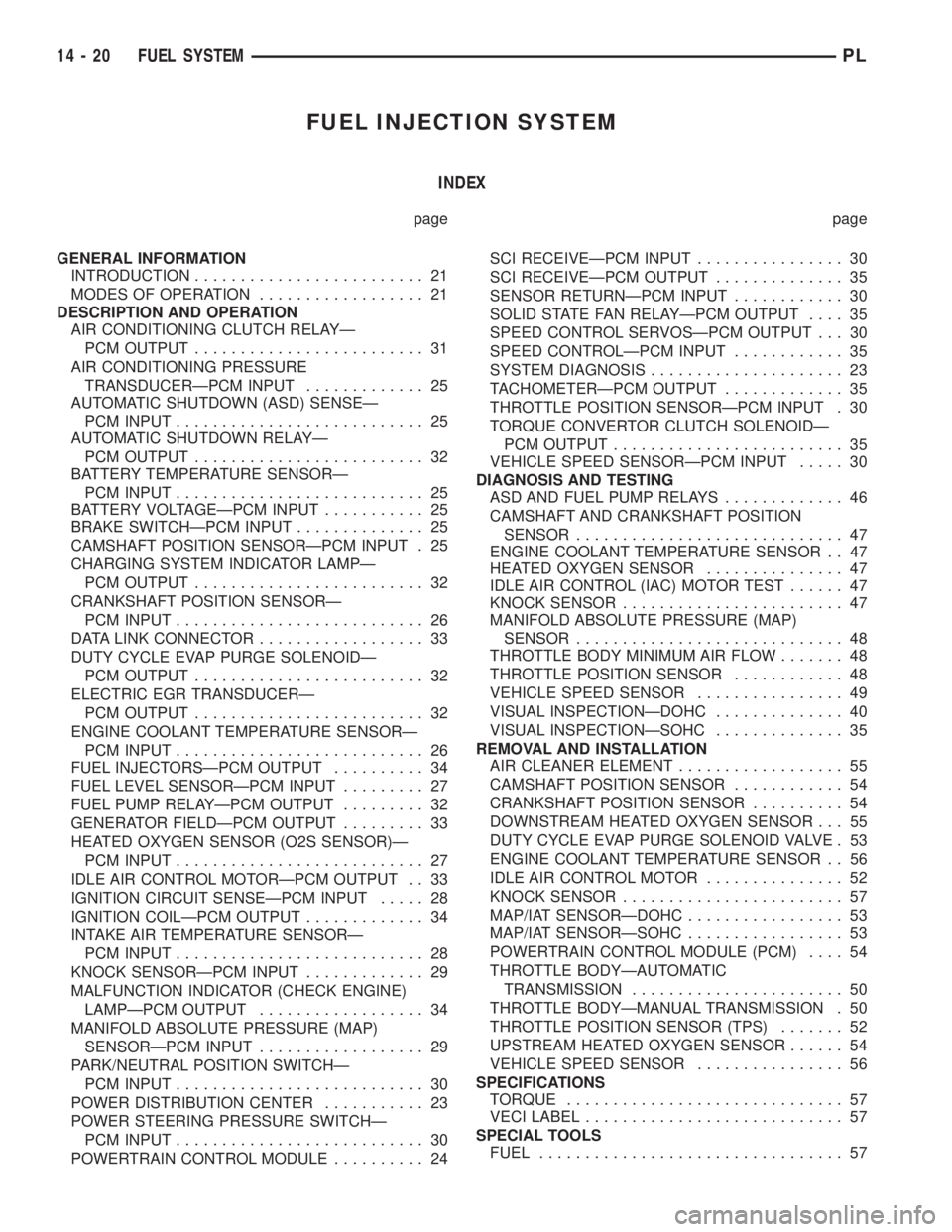

EXHAUST MANIFOLD

REMOVAL

(1) Remove air cleaner assembly and bracket.

(2) Remove exhaust manifold heat shield (Fig. 31).

(3) Disconnect upstream heated oxygen sensor con-

nector.

Fig. 29 Lower Intake Manifold to Upper Tightening

Sequence

Fig. 30 Intake Manifold To Cylinder Head Tightening

Sequence

Fig. 31 Exhaust Manifold Heat Shield

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 11

REMOVAL AND INSTALLATION (Continued)

Page 861 of 1200

FUEL INJECTION SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 21

MODES OF OPERATION.................. 21

DESCRIPTION AND OPERATION

AIR CONDITIONING CLUTCH RELAYÐ

PCM OUTPUT......................... 31

AIR CONDITIONING PRESSURE

TRANSDUCERÐPCM INPUT............. 25

AUTOMATIC SHUTDOWN (ASD) SENSEÐ

PCM INPUT........................... 25

AUTOMATIC SHUTDOWN RELAYÐ

PCM OUTPUT......................... 32

BATTERY TEMPERATURE SENSORÐ

PCM INPUT........................... 25

BATTERY VOLTAGEÐPCM INPUT........... 25

BRAKE SWITCHÐPCM INPUT.............. 25

CAMSHAFT POSITION SENSORÐPCM INPUT . 25

CHARGING SYSTEM INDICATOR LAMPÐ

PCM OUTPUT......................... 32

CRANKSHAFT POSITION SENSORÐ

PCM INPUT........................... 26

DATA LINK CONNECTOR.................. 33

DUTY CYCLE EVAP PURGE SOLENOIDÐ

PCM OUTPUT......................... 32

ELECTRIC EGR TRANSDUCERÐ

PCM OUTPUT......................... 32

ENGINE COOLANT TEMPERATURE SENSORÐ

PCM INPUT........................... 26

FUEL INJECTORSÐPCM OUTPUT.......... 34

FUEL LEVEL SENSORÐPCM INPUT......... 27

FUEL PUMP RELAYÐPCM OUTPUT......... 32

GENERATOR FIELDÐPCM OUTPUT......... 33

HEATED OXYGEN SENSOR (O2S SENSOR)Ð

PCM INPUT........................... 27

IDLE AIR CONTROL MOTORÐPCM OUTPUT . . 33

IGNITION CIRCUIT SENSEÐPCM INPUT..... 28

IGNITION COILÐPCM OUTPUT............. 34

INTAKE AIR TEMPERATURE SENSORÐ

PCM INPUT........................... 28

KNOCK SENSORÐPCM INPUT............. 29

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT.................. 34

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT.................. 29

PARK/NEUTRAL POSITION SWITCHÐ

PCM INPUT........................... 30

POWER DISTRIBUTION CENTER........... 23

POWER STEERING PRESSURE SWITCHÐ

PCM INPUT........................... 30

POWERTRAIN CONTROL MODULE.......... 24SCI RECEIVEÐPCM INPUT................ 30

SCI RECEIVEÐPCM OUTPUT.............. 35

SENSOR RETURNÐPCM INPUT............ 30

SOLID STATE FAN RELAYÐPCM OUTPUT.... 35

SPEED CONTROL SERVOSÐPCM OUTPUT . . . 30

SPEED CONTROLÐPCM INPUT............ 35

SYSTEM DIAGNOSIS..................... 23

TACHOMETERÐPCM OUTPUT............. 35

THROTTLE POSITION SENSORÐPCM INPUT . 30

TORQUE CONVERTOR CLUTCH SOLENOIDÐ

PCM OUTPUT......................... 35

VEHICLE SPEED SENSORÐPCM INPUT..... 30

DIAGNOSIS AND TESTING

ASD AND FUEL PUMP RELAYS............. 46

CAMSHAFT AND CRANKSHAFT POSITION

SENSOR............................. 47

ENGINE COOLANT TEMPERATURE SENSOR . . 47

HEATED OXYGEN SENSOR............... 47

IDLE AIR CONTROL (IAC) MOTOR TEST...... 47

KNOCK SENSOR........................ 47

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR............................. 48

THROTTLE BODY MINIMUM AIR FLOW....... 48

THROTTLE POSITION SENSOR............ 48

VEHICLE SPEED SENSOR................ 49

VISUAL INSPECTIONÐDOHC.............. 40

VISUAL INSPECTIONÐSOHC.............. 35

REMOVAL AND INSTALLATION

AIR CLEANER ELEMENT.................. 55

CAMSHAFT POSITION SENSOR............ 54

CRANKSHAFT POSITION SENSOR.......... 54

DOWNSTREAM HEATED OXYGEN SENSOR . . . 55

DUTY CYCLE EVAP PURGE SOLENOID VALVE . 53

ENGINE COOLANT TEMPERATURE SENSOR . . 56

IDLE AIR CONTROL MOTOR............... 52

KNOCK SENSOR........................ 57

MAP/IAT SENSORÐDOHC................. 53

MAP/IAT SENSORÐSOHC................. 53

POWERTRAIN CONTROL MODULE (PCM).... 54

THROTTLE BODYÐAUTOMATIC

TRANSMISSION....................... 50

THROTTLE BODYÐMANUAL TRANSMISSION . 50

THROTTLE POSITION SENSOR (TPS)....... 52

UPSTREAM HEATED OXYGEN SENSOR...... 54

VEHICLE SPEED SENSOR................ 56

SPECIFICATIONS

TORQUE.............................. 57

VECI LABEL............................ 57

SPECIAL TOOLS

FUEL................................. 57

14 - 20 FUEL SYSTEMPL