brake sensor DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 874 of 1200

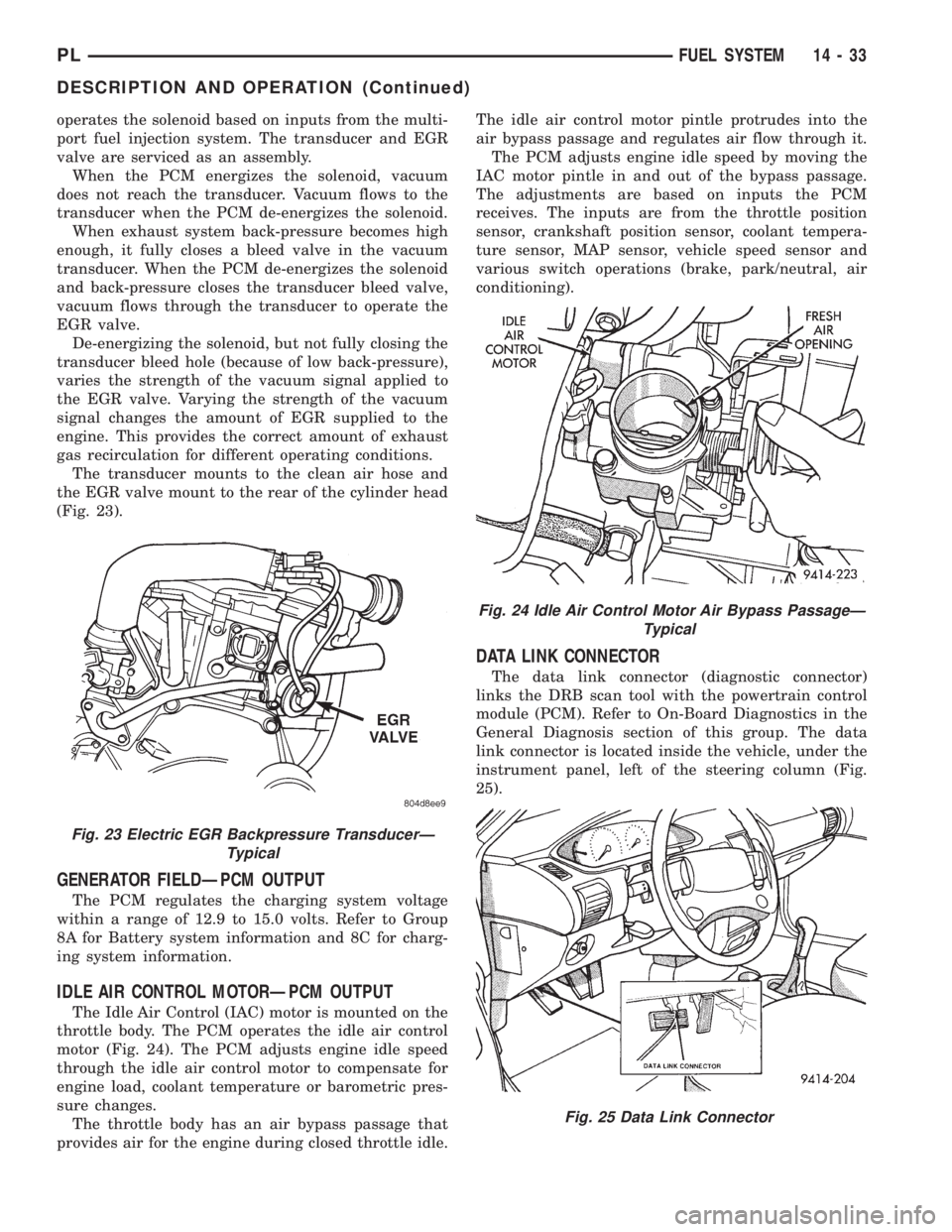

operates the solenoid based on inputs from the multi-

port fuel injection system. The transducer and EGR

valve are serviced as an assembly.

When the PCM energizes the solenoid, vacuum

does not reach the transducer. Vacuum flows to the

transducer when the PCM de-energizes the solenoid.

When exhaust system back-pressure becomes high

enough, it fully closes a bleed valve in the vacuum

transducer. When the PCM de-energizes the solenoid

and back-pressure closes the transducer bleed valve,

vacuum flows through the transducer to operate the

EGR valve.

De-energizing the solenoid, but not fully closing the

transducer bleed hole (because of low back-pressure),

varies the strength of the vacuum signal applied to

the EGR valve. Varying the strength of the vacuum

signal changes the amount of EGR supplied to the

engine. This provides the correct amount of exhaust

gas recirculation for different operating conditions.

The transducer mounts to the clean air hose and

the EGR valve mount to the rear of the cylinder head

(Fig. 23).

GENERATOR FIELDÐPCM OUTPUT

The PCM regulates the charging system voltage

within a range of 12.9 to 15.0 volts. Refer to Group

8A for Battery system information and 8C for charg-

ing system information.

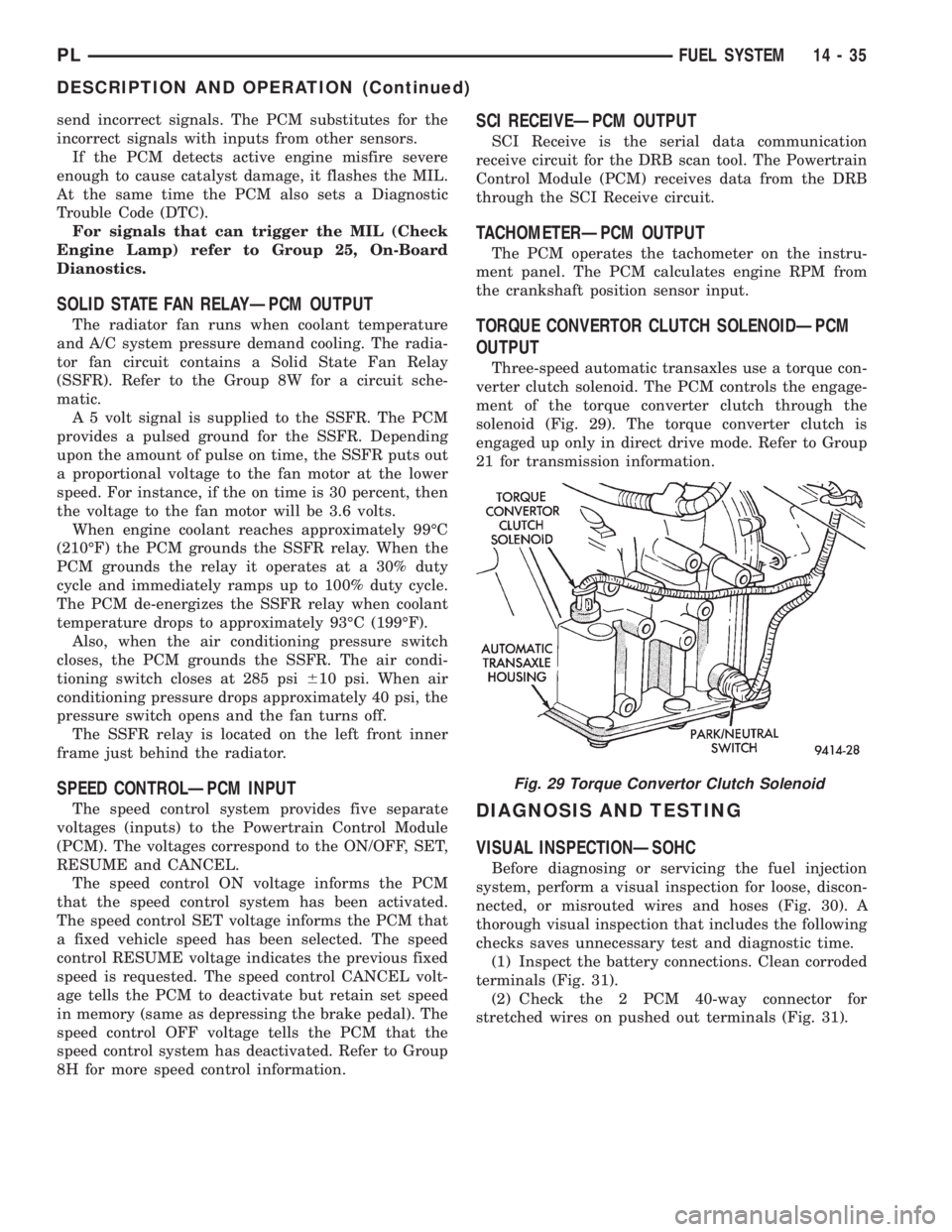

IDLE AIR CONTROL MOTORÐPCM OUTPUT

The Idle Air Control (IAC) motor is mounted on the

throttle body. The PCM operates the idle air control

motor (Fig. 24). The PCM adjusts engine idle speed

through the idle air control motor to compensate for

engine load, coolant temperature or barometric pres-

sure changes.

The throttle body has an air bypass passage that

provides air for the engine during closed throttle idle.The idle air control motor pintle protrudes into the

air bypass passage and regulates air flow through it.

The PCM adjusts engine idle speed by moving the

IAC motor pintle in and out of the bypass passage.

The adjustments are based on inputs the PCM

receives. The inputs are from the throttle position

sensor, crankshaft position sensor, coolant tempera-

ture sensor, MAP sensor, vehicle speed sensor and

various switch operations (brake, park/neutral, air

conditioning).

DATA LINK CONNECTOR

The data link connector (diagnostic connector)

links the DRB scan tool with the powertrain control

module (PCM). Refer to On-Board Diagnostics in the

General Diagnosis section of this group. The data

link connector is located inside the vehicle, under the

instrument panel, left of the steering column (Fig.

25).

Fig. 23 Electric EGR Backpressure TransducerÐ

Typical

Fig. 24 Idle Air Control Motor Air Bypass PassageÐ

Typical

Fig. 25 Data Link Connector

PLFUEL SYSTEM 14 - 33

DESCRIPTION AND OPERATION (Continued)

Page 876 of 1200

send incorrect signals. The PCM substitutes for the

incorrect signals with inputs from other sensors.

If the PCM detects active engine misfire severe

enough to cause catalyst damage, it flashes the MIL.

At the same time the PCM also sets a Diagnostic

Trouble Code (DTC).

For signals that can trigger the MIL (Check

Engine Lamp) refer to Group 25, On-Board

Dianostics.

SOLID STATE FAN RELAYÐPCM OUTPUT

The radiator fan runs when coolant temperature

and A/C system pressure demand cooling. The radia-

tor fan circuit contains a Solid State Fan Relay

(SSFR). Refer to the Group 8W for a circuit sche-

matic.

A 5 volt signal is supplied to the SSFR. The PCM

provides a pulsed ground for the SSFR. Depending

upon the amount of pulse on time, the SSFR puts out

a proportional voltage to the fan motor at the lower

speed. For instance, if the on time is 30 percent, then

the voltage to the fan motor will be 3.6 volts.

When engine coolant reaches approximately 99ÉC

(210ÉF) the PCM grounds the SSFR relay. When the

PCM grounds the relay it operates at a 30% duty

cycle and immediately ramps up to 100% duty cycle.

The PCM de-energizes the SSFR relay when coolant

temperature drops to approximately 93ÉC (199ÉF).

Also, when the air conditioning pressure switch

closes, the PCM grounds the SSFR. The air condi-

tioning switch closes at 285 psi610 psi. When air

conditioning pressure drops approximately 40 psi, the

pressure switch opens and the fan turns off.

The SSFR relay is located on the left front inner

frame just behind the radiator.

SPEED CONTROLÐPCM INPUT

The speed control system provides five separate

voltages (inputs) to the Powertrain Control Module

(PCM). The voltages correspond to the ON/OFF, SET,

RESUME and CANCEL.

The speed control ON voltage informs the PCM

that the speed control system has been activated.

The speed control SET voltage informs the PCM that

a fixed vehicle speed has been selected. The speed

control RESUME voltage indicates the previous fixed

speed is requested. The speed control CANCEL volt-

age tells the PCM to deactivate but retain set speed

in memory (same as depressing the brake pedal). The

speed control OFF voltage tells the PCM that the

speed control system has deactivated. Refer to Group

8H for more speed control information.

SCI RECEIVEÐPCM OUTPUT

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Control Module (PCM) receives data from the DRB

through the SCI Receive circuit.

TACHOMETERÐPCM OUTPUT

The PCM operates the tachometer on the instru-

ment panel. The PCM calculates engine RPM from

the crankshaft position sensor input.

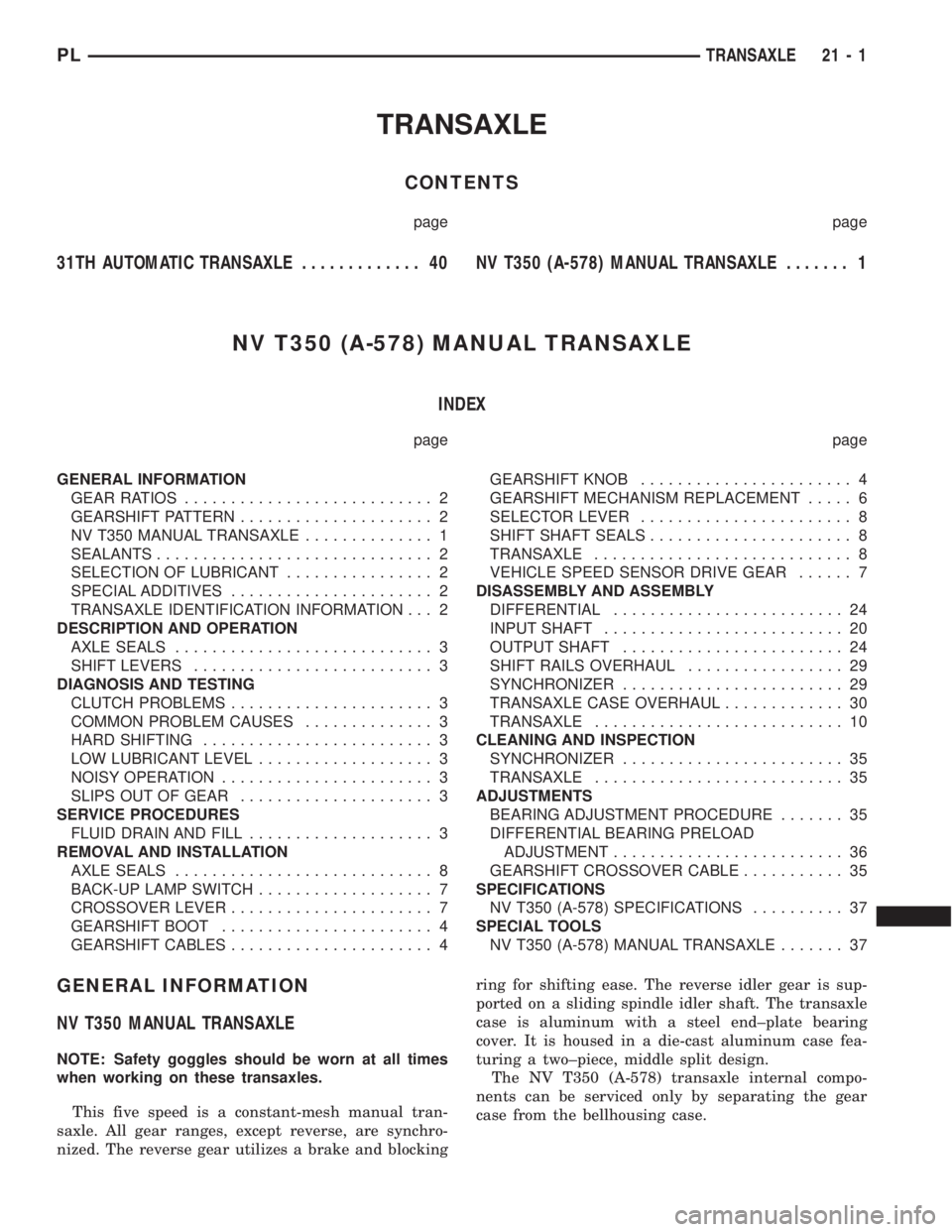

TORQUE CONVERTOR CLUTCH SOLENOIDÐPCM

OUTPUT

Three-speed automatic transaxles use a torque con-

verter clutch solenoid. The PCM controls the engage-

ment of the torque converter clutch through the

solenoid (Fig. 29). The torque converter clutch is

engaged up only in direct drive mode. Refer to Group

21 for transmission information.

DIAGNOSIS AND TESTING

VISUAL INSPECTIONÐSOHC

Before diagnosing or servicing the fuel injection

system, perform a visual inspection for loose, discon-

nected, or misrouted wires and hoses (Fig. 30). A

thorough visual inspection that includes the following

checks saves unnecessary test and diagnostic time.

(1) Inspect the battery connections. Clean corroded

terminals (Fig. 31).

(2) Check the 2 PCM 40-way connector for

stretched wires on pushed out terminals (Fig. 31).

Fig. 29 Torque Convertor Clutch Solenoid

PLFUEL SYSTEM 14 - 35

DESCRIPTION AND OPERATION (Continued)

Page 944 of 1200

TRANSAXLE

CONTENTS

page page

31TH AUTOMATIC TRANSAXLE............. 40 NVT350 (A-578) MANUAL TRANSAXLE....... 1

NV T350 (A-578) MANUAL TRANSAXLE

INDEX

page page

GENERAL INFORMATION

GEAR RATIOS........................... 2

GEARSHIFT PATTERN..................... 2

NV T350 MANUAL TRANSAXLE.............. 1

SEALANTS.............................. 2

SELECTION OF LUBRICANT................ 2

SPECIAL ADDITIVES...................... 2

TRANSAXLE IDENTIFICATION INFORMATION . . . 2

DESCRIPTION AND OPERATION

AXLE SEALS............................ 3

SHIFT LEVERS.......................... 3

DIAGNOSIS AND TESTING

CLUTCH PROBLEMS...................... 3

COMMON PROBLEM CAUSES.............. 3

HARD SHIFTING......................... 3

LOW LUBRICANT LEVEL................... 3

NOISY OPERATION....................... 3

SLIPS OUT OF GEAR..................... 3

SERVICE PROCEDURES

FLUID DRAIN AND FILL.................... 3

REMOVAL AND INSTALLATION

AXLE SEALS............................ 8

BACK-UP LAMP SWITCH................... 7

CROSSOVER LEVER...................... 7

GEARSHIFT BOOT....................... 4

GEARSHIFT CABLES...................... 4GEARSHIFT KNOB....................... 4

GEARSHIFT MECHANISM REPLACEMENT..... 6

SELECTOR LEVER....................... 8

SHIFT SHAFT SEALS...................... 8

TRANSAXLE............................ 8

VEHICLE SPEED SENSOR DRIVE GEAR...... 7

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL......................... 24

INPUT SHAFT.......................... 20

OUTPUT SHAFT........................ 24

SHIFT RAILS OVERHAUL................. 29

SYNCHRONIZER........................ 29

TRANSAXLE CASE OVERHAUL............. 30

TRANSAXLE........................... 10

CLEANING AND INSPECTION

SYNCHRONIZER........................ 35

TRANSAXLE........................... 35

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURE....... 35

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT......................... 36

GEARSHIFT CROSSOVER CABLE........... 35

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS.......... 37

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE....... 37

GENERAL INFORMATION

NV T350 MANUAL TRANSAXLE

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This five speed is a constant-mesh manual tran-

saxle. All gear ranges, except reverse, are synchro-

nized. The reverse gear utilizes a brake and blockingring for shifting ease. The reverse idler gear is sup-

ported on a sliding spindle idler shaft. The transaxle

case is aluminum with a steel end±plate bearing

cover. It is housed in a die-cast aluminum case fea-

turing a two±piece, middle split design.

The NV T350 (A-578) transaxle internal compo-

nents can be serviced only by separating the gear

case from the bellhousing case.

PLTRANSAXLE 21 - 1

Page 1169 of 1200

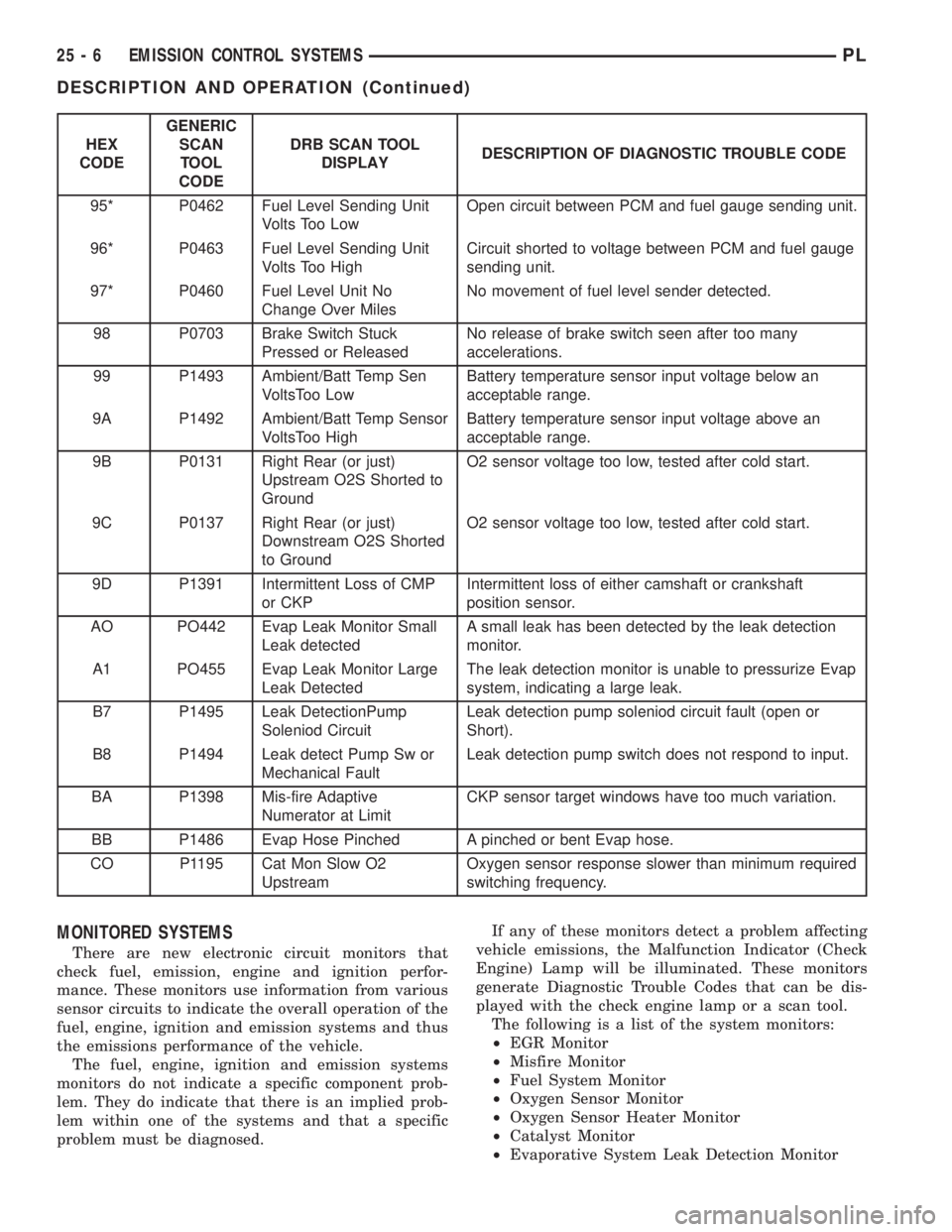

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC TROUBLE CODE

95* P0462 Fuel Level Sending Unit

Volts Too LowOpen circuit between PCM and fuel gauge sending unit.

96* P0463 Fuel Level Sending Unit

Volts Too HighCircuit shorted to voltage between PCM and fuel gauge

sending unit.

97* P0460 Fuel Level Unit No

Change Over MilesNo movement of fuel level sender detected.

98 P0703 Brake Switch Stuck

Pressed or ReleasedNo release of brake switch seen after too many

accelerations.

99 P1493 Ambient/Batt Temp Sen

VoltsToo LowBattery temperature sensor input voltage below an

acceptable range.

9A P1492 Ambient/Batt Temp Sensor

VoltsToo HighBattery temperature sensor input voltage above an

acceptable range.

9B P0131 Right Rear (or just)

Upstream O2S Shorted to

GroundO2 sensor voltage too low, tested after cold start.

9C P0137 Right Rear (or just)

Downstream O2S Shorted

to GroundO2 sensor voltage too low, tested after cold start.

9D P1391 Intermittent Loss of CMP

or CKPIntermittent loss of either camshaft or crankshaft

position sensor.

AO PO442 Evap Leak Monitor Small

Leak detectedA small leak has been detected by the leak detection

monitor.

A1 PO455 Evap Leak Monitor Large

Leak DetectedThe leak detection monitor is unable to pressurize Evap

system, indicating a large leak.

B7 P1495 Leak DetectionPump

Soleniod CircuitLeak detection pump soleniod circuit fault (open or

Short).

B8 P1494 Leak detect Pump Sw or

Mechanical FaultLeak detection pump switch does not respond to input.

BA P1398 Mis-fire Adaptive

Numerator at LimitCKP sensor target windows have too much variation.

BB P1486 Evap Hose Pinched A pinched or bent Evap hose.

CO P1195 Cat Mon Slow O2

UpstreamOxygen sensor response slower than minimum required

switching frequency.

MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the system monitors:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor

25 - 6 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1182 of 1200

DIAGNOSIS AND TESTING

EGR SYSTEM ON-BOARD DIAGNOSTICS

The PCM performs an on-board diagnostic check of

the EGR system. The diagnostic system uses the

electronic EGR transducer for the system tests.

The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in

the heated oxygen sensor signal. If the air-fuel mix-

ture goes lean, the PCM will attempt to enrichen the

mixture. The PCM registers a Diagnostic Trouble

Code (DTC) if the EGR system is not operating cor-

rectly. After registering a DTC, the PCM turns on the

malfunction indicator (Check Engine) lamp after 2

consecutive trips. There are 2 types of failures sensed

by the PCM. The first is a short or open in the elec-

trical solenoid circuit. the second is a mechhanical

failure or loss of vacuum. The Malfunction Indicator

Lamp (MIL) indicates the need for service.

If a problem is indicated by the MIL and a DTC for

the EGR system is set, check for proper operation of

the EGR system. Use the System Test, EGR Gas

Flow Test. If the EGR system tests properly, check

the system using the DRB scan tool. Refer to

On-Board Diagnosis sections in this Group. Also,

refer to the DRB scan tool and the appropriate Pow-

ertrain Diagnostics Procedure manual.

EGR SYSTEM TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE TESTING THE EGR SYS-

TEM.

(1) Check the condition of all EGR system hoses

and tubes for leaks, blockages, cracks, kinks and

hardening of rubber hoses. Repair and correct these

conditions before performing any tests.

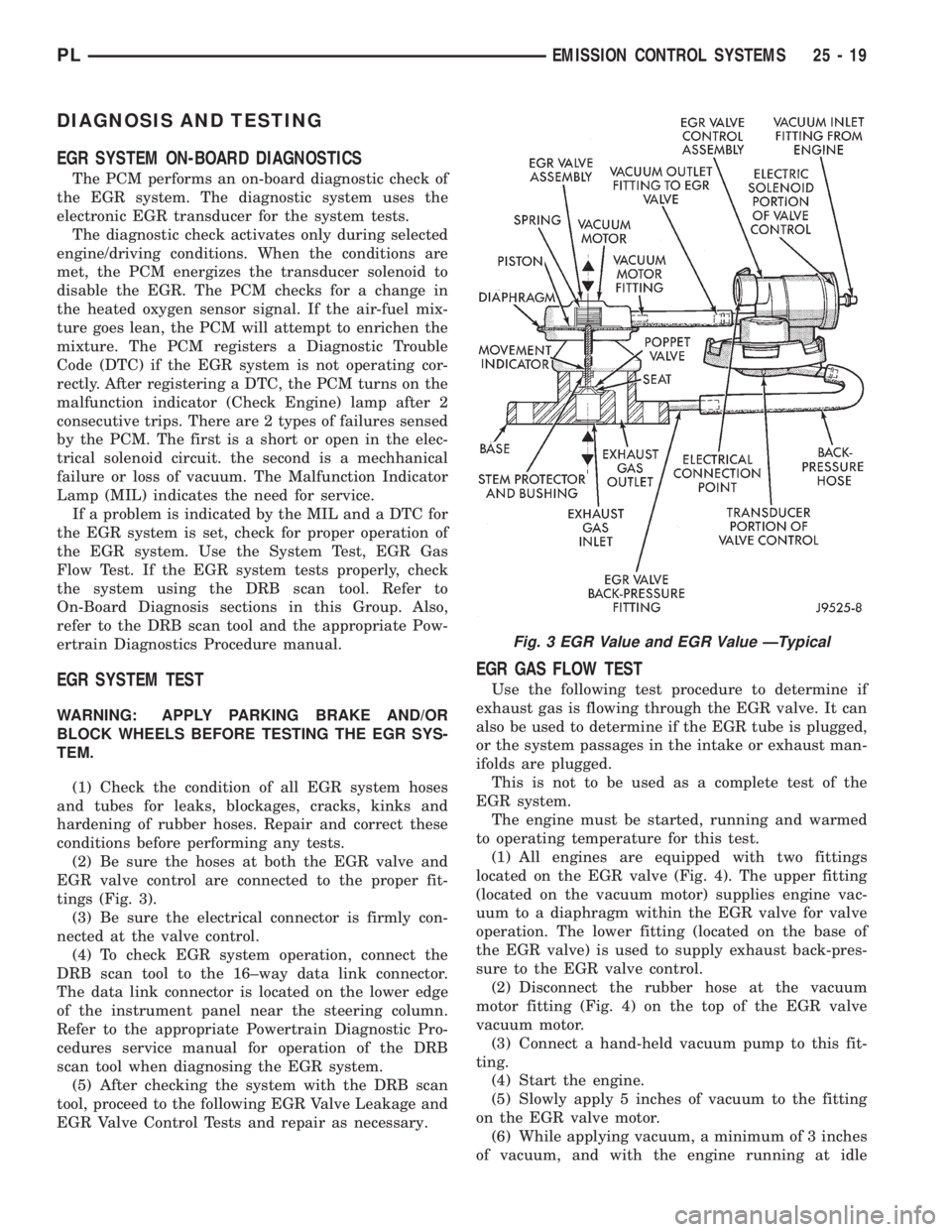

(2) Be sure the hoses at both the EGR valve and

EGR valve control are connected to the proper fit-

tings (Fig. 3).

(3) Be sure the electrical connector is firmly con-

nected at the valve control.

(4) To check EGR system operation, connect the

DRB scan tool to the 16±way data link connector.

The data link connector is located on the lower edge

of the instrument panel near the steering column.

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool when diagnosing the EGR system.

(5) After checking the system with the DRB scan

tool, proceed to the following EGR Valve Leakage and

EGR Valve Control Tests and repair as necessary.

EGR GAS FLOW TEST

Use the following test procedure to determine if

exhaust gas is flowing through the EGR valve. It can

also be used to determine if the EGR tube is plugged,

or the system passages in the intake or exhaust man-

ifolds are plugged.

This is not to be used as a complete test of the

EGR system.

The engine must be started, running and warmed

to operating temperature for this test.

(1) All engines are equipped with two fittings

located on the EGR valve (Fig. 4). The upper fitting

(located on the vacuum motor) supplies engine vac-

uum to a diaphragm within the EGR valve for valve

operation. The lower fitting (located on the base of

the EGR valve) is used to supply exhaust back-pres-

sure to the EGR valve control.

(2) Disconnect the rubber hose at the vacuum

motor fitting (Fig. 4) on the top of the EGR valve

vacuum motor.

(3) Connect a hand-held vacuum pump to this fit-

ting.

(4) Start the engine.

(5) Slowly apply 5 inches of vacuum to the fitting

on the EGR valve motor.

(6) While applying vacuum, a minimum of 3 inches

of vacuum, and with the engine running at idle

Fig. 3 EGR Value and EGR Value ÐTypical

PLEMISSION CONTROL SYSTEMS 25 - 19