hood release DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 218 of 1200

BATTERY

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)........ 1

CHARGING TIME REQUIRED............... 1

DIAGNOSIS AND TESTING

BATTERY BUILT-IN TEST INDICATOR........ 2

BATTERY IGNITION OFF DRAW (IOD)........ 3

BATTERY LOAD TEST..................... 5

BATTERY OPEN CIRCUIT VOLTAGE TEST..... 6

BATTERY TEMPERATURE SENSOR.......... 6

SERVICE PROCEDURES

BATTERY CHARGING..................... 6CHARGING COMPLETELY DISCHARGED

BATTERY............................. 7

VISUAL INSPECTION..................... 7

REMOVAL AND INSTALLATION

BATTERY TRAY.......................... 9

BATTERY............................... 8

FRESH AIR INLET TUBE REMOVAL.......... 9

SPECIFICATIONS

BATTERY SPECIFICATIONS............... 10

TORQUE.............................. 10

GENERAL INFORMATION

INTRODUCTION

The battery stores, stabilizes, and delivers electri-

cal current to operate various electrical systems in

the vehicle. The determination of whether a battery

is good or bad is made by its ability to accept a

charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The original equipment (OE)

battery is equipped with a hydrometer (test indica-

tor) built into the battery cover. The specific gravity

indicates the battery's state-of-charge. The OE bat-

tery is sealed and water cannot be added.

The battery is vented to release gases that are cre-

ated when the battery is being charged and dis-

charged. The battery top, posts, and terminals should

be cleaned when other under hood maintenance is

performed.

When the electrolyte level is below the top of the

plates, Yellow/Clear in the test Indicator, the battery

must be replaced. The battery must be completely

charged, and the battery top, posts, and cable clampsmust be cleaned before diagnostic procedures are per-

formed.DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)

A completely normal vehicle will have a small

amount of current drain on the battery with the key

out of the ignition. It can range from 4 to 10 milli-

amperes after all the modules time out. If a vehicle

will not be operated for approximately a 20 days, the

IOD fuse should be disconnected to minimize the

vehicle electrical drain on the battery. The IOD fuse

is located in the Power Distribution Center (PDC).

Refer to the PDC to locate the cover proper fuse.

CHARGING TIME REQUIRED

WARNING: NEVER EXCEED 20 AMPS WHEN

CHARGING A COLD -1ÉC (30ÉF) BATTERY. PER-

SONAL INJURY MAY RESULT.

The time required to charge a battery will vary

depending upon the following factors.

SIZE OF BATTERY

A completely discharged large heavy-duty battery

may require more recharging time than a completely

discharged small capacity battery. Refer to Battery

Charging Timetable for proper charging times.

PLBATTERY 8A - 1

Page 321 of 1200

WINDSHIELD WASHER SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

WASHER NOZZLE........................ 8

DIAGNOSIS AND TESTING

WINDSHIELD WASHERS................... 8REMOVAL AND INSTALLATION

WASHER NOZZLE........................ 9

WASHER RESERVOIR PUMP.............. 10

WASHER RESERVOIR..................... 9

DESCRIPTION AND OPERATION

WASHER NOZZLE

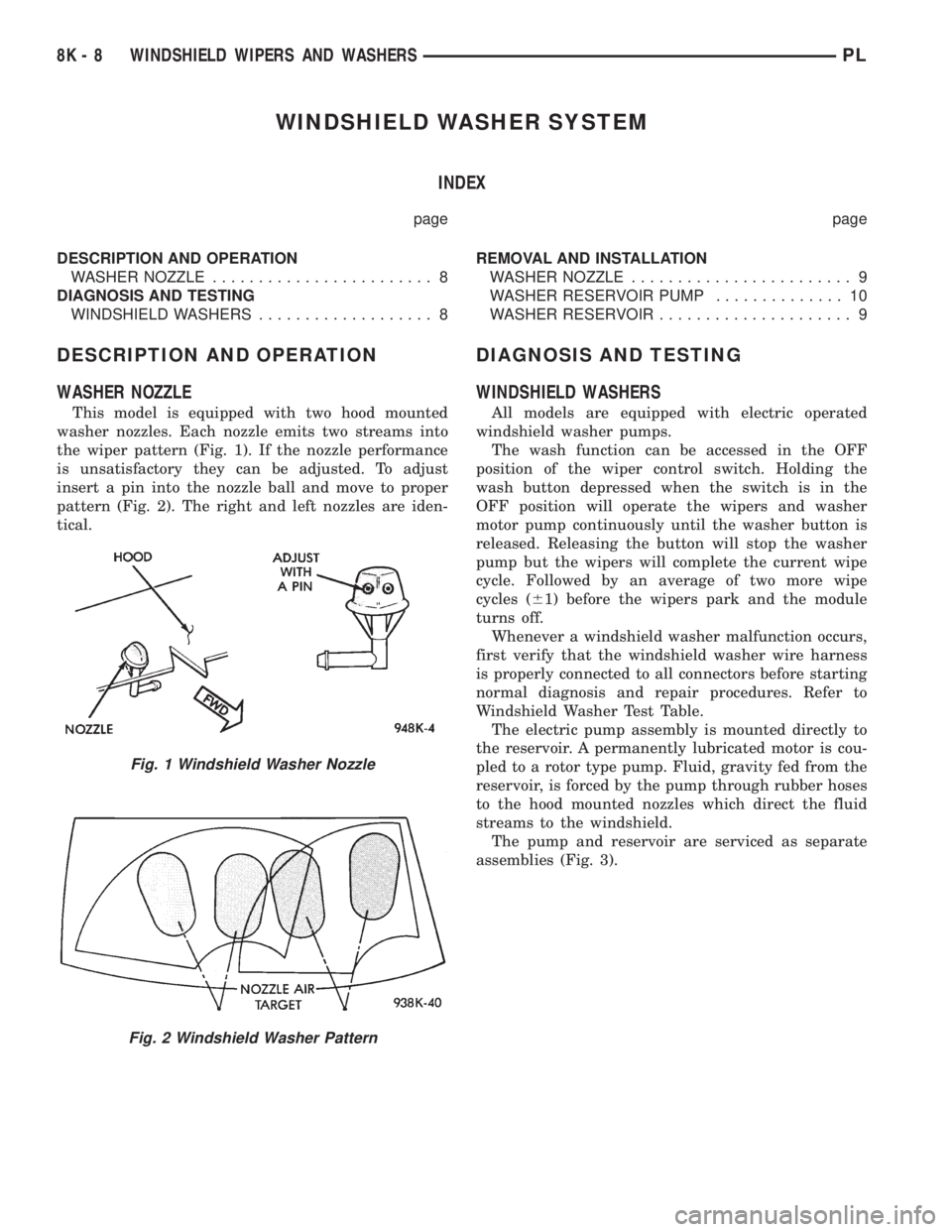

This model is equipped with two hood mounted

washer nozzles. Each nozzle emits two streams into

the wiper pattern (Fig. 1). If the nozzle performance

is unsatisfactory they can be adjusted. To adjust

insert a pin into the nozzle ball and move to proper

pattern (Fig. 2). The right and left nozzles are iden-

tical.

DIAGNOSIS AND TESTING

WINDSHIELD WASHERS

All models are equipped with electric operated

windshield washer pumps.

The wash function can be accessed in the OFF

position of the wiper control switch. Holding the

wash button depressed when the switch is in the

OFF position will operate the wipers and washer

motor pump continuously until the washer button is

released. Releasing the button will stop the washer

pump but the wipers will complete the current wipe

cycle. Followed by an average of two more wipe

cycles (61) before the wipers park and the module

turns off.

Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harness

is properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer Test Table.

The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated motor is cou-

pled to a rotor type pump. Fluid, gravity fed from the

reservoir, is forced by the pump through rubber hoses

to the hood mounted nozzles which direct the fluid

streams to the windshield.

The pump and reservoir are serviced as separate

assemblies (Fig. 3).

Fig. 1 Windshield Washer Nozzle

Fig. 2 Windshield Washer Pattern

8K - 8 WINDSHIELD WIPERS AND WASHERSPL

Page 335 of 1200

LAMP BULB SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP BULB . . . 7

DOME LAMP BULB....................... 8

FOG LAMP BULB......................... 6

FRONT SIDE MARKER LAMP BULB.......... 7

HEADLAMP BULB........................ 6

LICENSE PLATE LAMP BULB............... 8PARK AND TURN SIGNAL LAMP BULB........ 6

REAR CARGO LAMP BULB................. 8

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULB........................... 7

UNDERHOOD LAMP BULB................. 8

VISOR VANITY LAMP BULB................. 8

REMOVAL AND INSTALLATION

HEADLAMP BULB

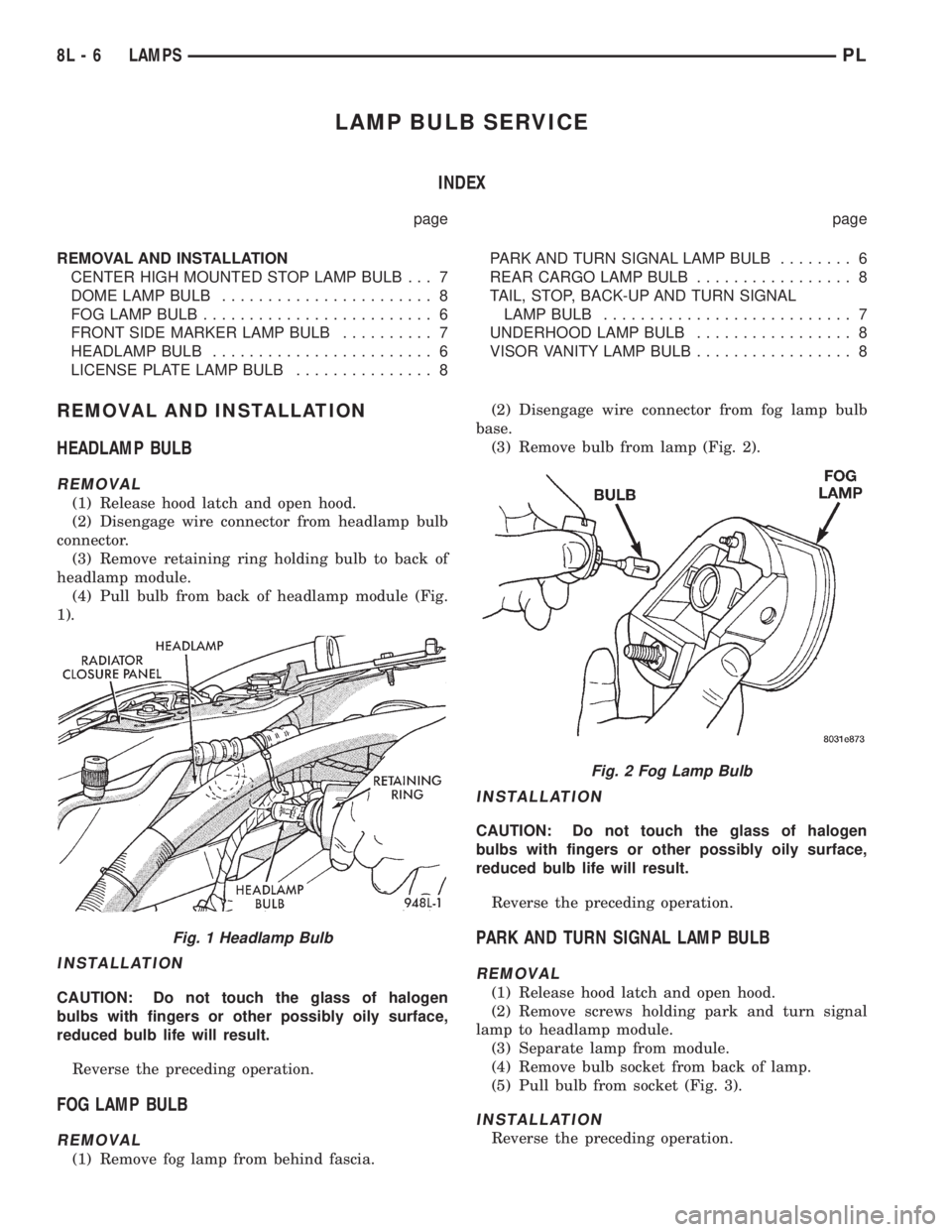

REMOVAL

(1) Release hood latch and open hood.

(2) Disengage wire connector from headlamp bulb

connector.

(3) Remove retaining ring holding bulb to back of

headlamp module.

(4) Pull bulb from back of headlamp module (Fig.

1).

INSTALLATION

CAUTION: Do not touch the glass of halogen

bulbs with fingers or other possibly oily surface,

reduced bulb life will result.

Reverse the preceding operation.

FOG LAMP BULB

REMOVAL

(1) Remove fog lamp from behind fascia.(2) Disengage wire connector from fog lamp bulb

base.

(3) Remove bulb from lamp (Fig. 2).

INSTALLATION

CAUTION: Do not touch the glass of halogen

bulbs with fingers or other possibly oily surface,

reduced bulb life will result.

Reverse the preceding operation.

PARK AND TURN SIGNAL LAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws holding park and turn signal

lamp to headlamp module.

(3) Separate lamp from module.

(4) Remove bulb socket from back of lamp.

(5) Pull bulb from socket (Fig. 3).

INSTALLATION

Reverse the preceding operation.

Fig. 1 Headlamp Bulb

Fig. 2 Fog Lamp Bulb

8L - 6 LAMPSPL

Page 338 of 1200

LAMP SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)............................. 10

DOME LAMP........................... 11

FOG LAMP.............................. 9

FRONT SIDE MARKER LAMP.............. 10

HEADLAMP MODULE..................... 9LICENSE PLATE LAMP................... 11

PARK AND TURN SIGNAL LAMP............. 9

REAR CARGO LAMP..................... 11

TAIL, STOP AND TURN SIGNAL LAMP........ 10

UNDERHOOD LAMP..................... 11

VISOR VANITY LAMP..................... 11

REMOVAL AND INSTALLATION

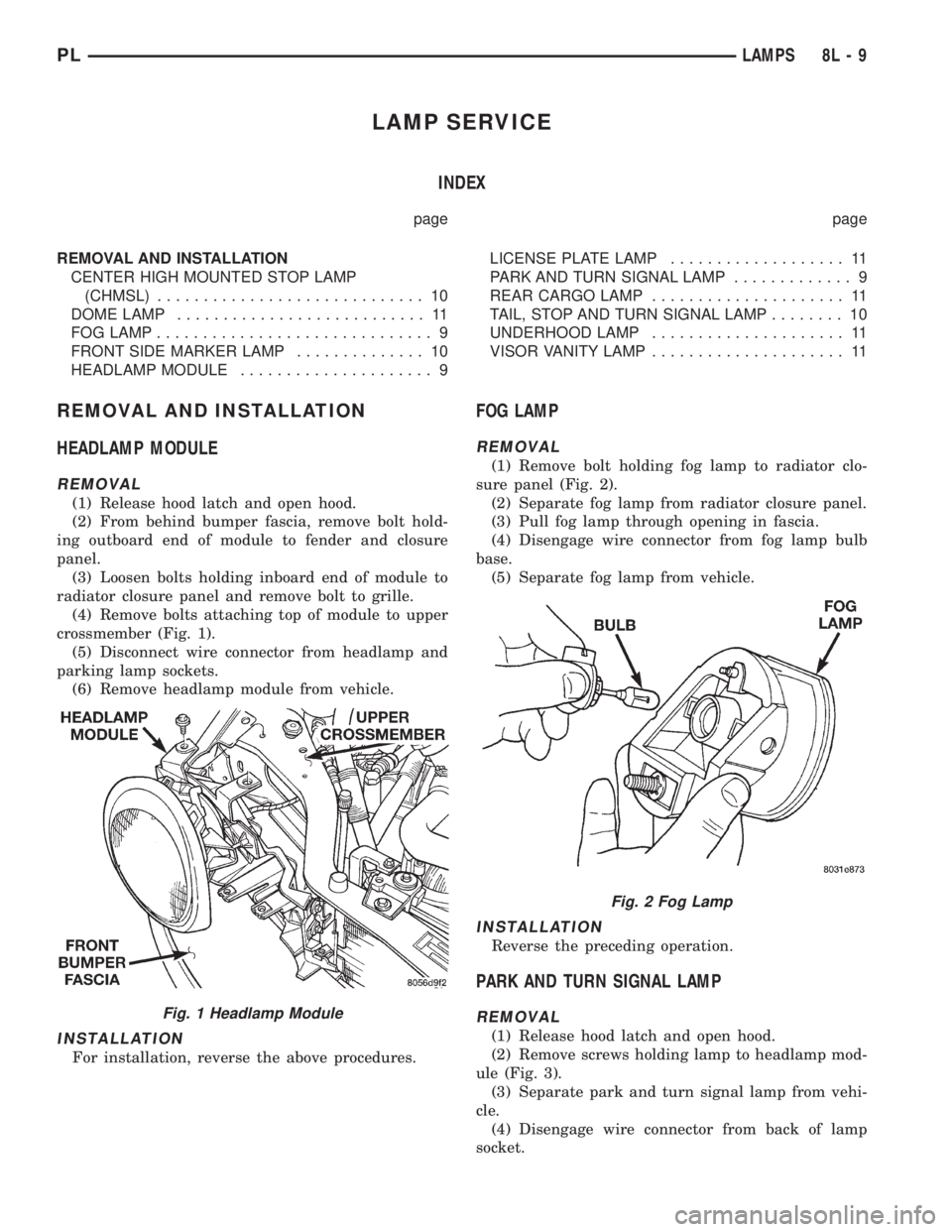

HEADLAMP MODULE

REMOVAL

(1) Release hood latch and open hood.

(2) From behind bumper fascia, remove bolt hold-

ing outboard end of module to fender and closure

panel.

(3) Loosen bolts holding inboard end of module to

radiator closure panel and remove bolt to grille.

(4) Remove bolts attaching top of module to upper

crossmember (Fig. 1).

(5) Disconnect wire connector from headlamp and

parking lamp sockets.

(6) Remove headlamp module from vehicle.

INSTALLATION

For installation, reverse the above procedures.

FOG LAMP

REMOVAL

(1) Remove bolt holding fog lamp to radiator clo-

sure panel (Fig. 2).

(2) Separate fog lamp from radiator closure panel.

(3) Pull fog lamp through opening in fascia.

(4) Disengage wire connector from fog lamp bulb

base.

(5) Separate fog lamp from vehicle.

INSTALLATION

Reverse the preceding operation.

PARK AND TURN SIGNAL LAMP

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws holding lamp to headlamp mod-

ule (Fig. 3).

(3) Separate park and turn signal lamp from vehi-

cle.

(4) Disengage wire connector from back of lamp

socket.

Fig. 1 Headlamp Module

Fig. 2 Fog Lamp

PLLAMPS 8L - 9

Page 345 of 1200

LAMP BULB SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CITYLIGHT LAMP BULB.................... 3

FOG LAMP BULB......................... 3FRONT TURN SIGNAL LAMP BULB........... 2

HEADLAMP BULB........................ 2

SIDE REPEATER LAMP BULB............... 4

REMOVAL AND INSTALLATION

HEADLAMP BULB

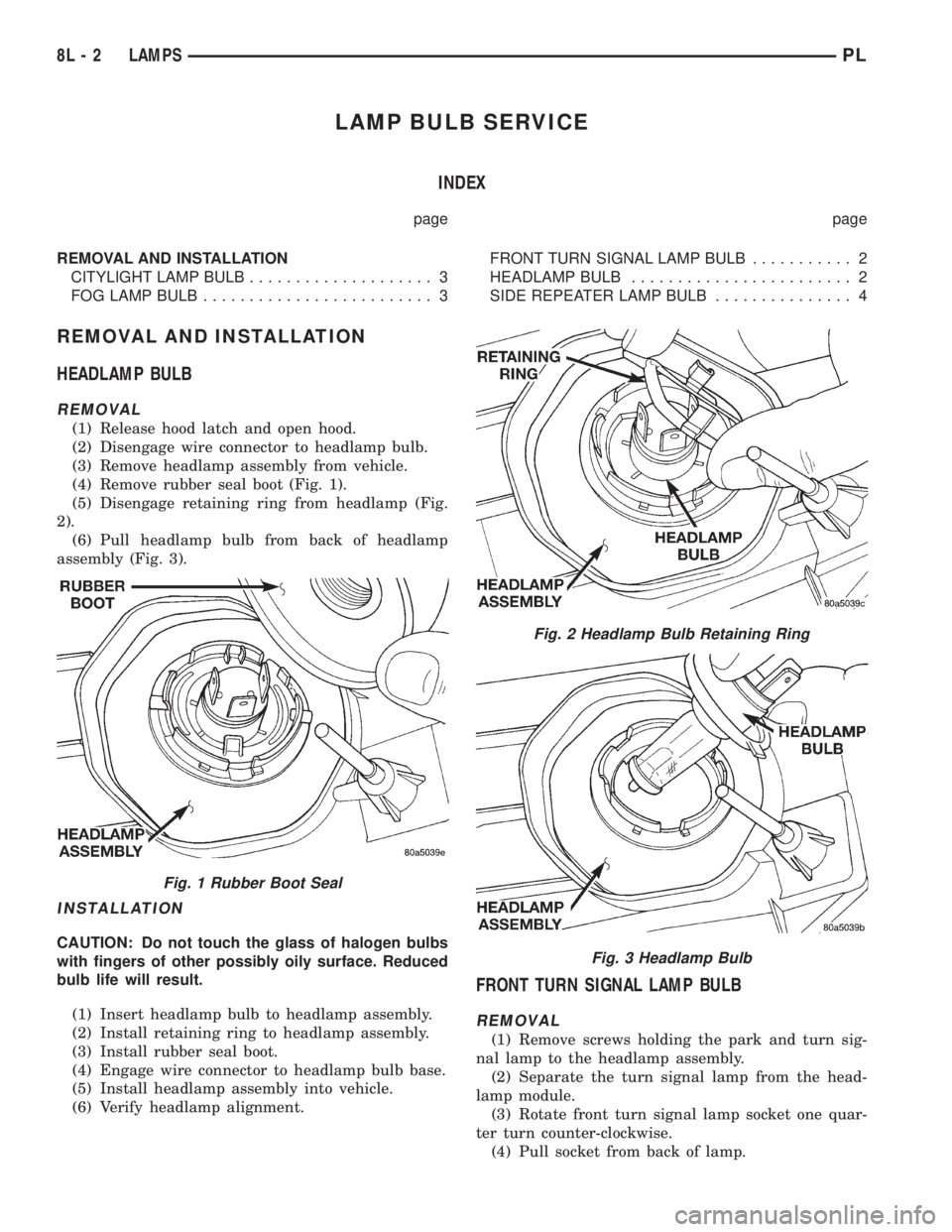

REMOVAL

(1) Release hood latch and open hood.

(2) Disengage wire connector to headlamp bulb.

(3) Remove headlamp assembly from vehicle.

(4) Remove rubber seal boot (Fig. 1).

(5) Disengage retaining ring from headlamp (Fig.

2).

(6) Pull headlamp bulb from back of headlamp

assembly (Fig. 3).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers of other possibly oily surface. Reduced

bulb life will result.

(1) Insert headlamp bulb to headlamp assembly.

(2) Install retaining ring to headlamp assembly.

(3) Install rubber seal boot.

(4) Engage wire connector to headlamp bulb base.

(5) Install headlamp assembly into vehicle.

(6) Verify headlamp alignment.

FRONT TURN SIGNAL LAMP BULB

REMOVAL

(1) Remove screws holding the park and turn sig-

nal lamp to the headlamp assembly.

(2) Separate the turn signal lamp from the head-

lamp module.

(3) Rotate front turn signal lamp socket one quar-

ter turn counter-clockwise.

(4) Pull socket from back of lamp.

Fig. 1 Rubber Boot Seal

Fig. 2 Headlamp Bulb Retaining Ring

Fig. 3 Headlamp Bulb

8L - 2 LAMPSPL

Page 348 of 1200

LAMP SERVICE

INDEX

page page

GENERAL INFORMATION

HEADLAMP DIMMER SWITCH............... 5

HEADLAMP SWITCH...................... 5

REMOVAL AND INSTALLATION

FOG LAMP.............................. 6HEADLAMP ASSEMBLY.................... 5

HEADLAMP LEVELING MOTOR.............. 6

SIDE REPEATER LAMP.................... 6

GENERAL INFORMATION

HEADLAMP SWITCH

Service procedures for the headlamp switch can be

found in Group 8E, Instrument Panel and Gauges.

More information can be found in Group 8W, Wiring

Diagrams.

HEADLAMP DIMMER SWITCH

The headlamp dimmer switch is incorporated into

the multi-function (turn signal) switch. Proper proce-

dures can be found in Group 8J, Turn Signal and

Flashers. More information can be found in Group

8W, Wiring Diagrams.

REMOVAL AND INSTALLATION

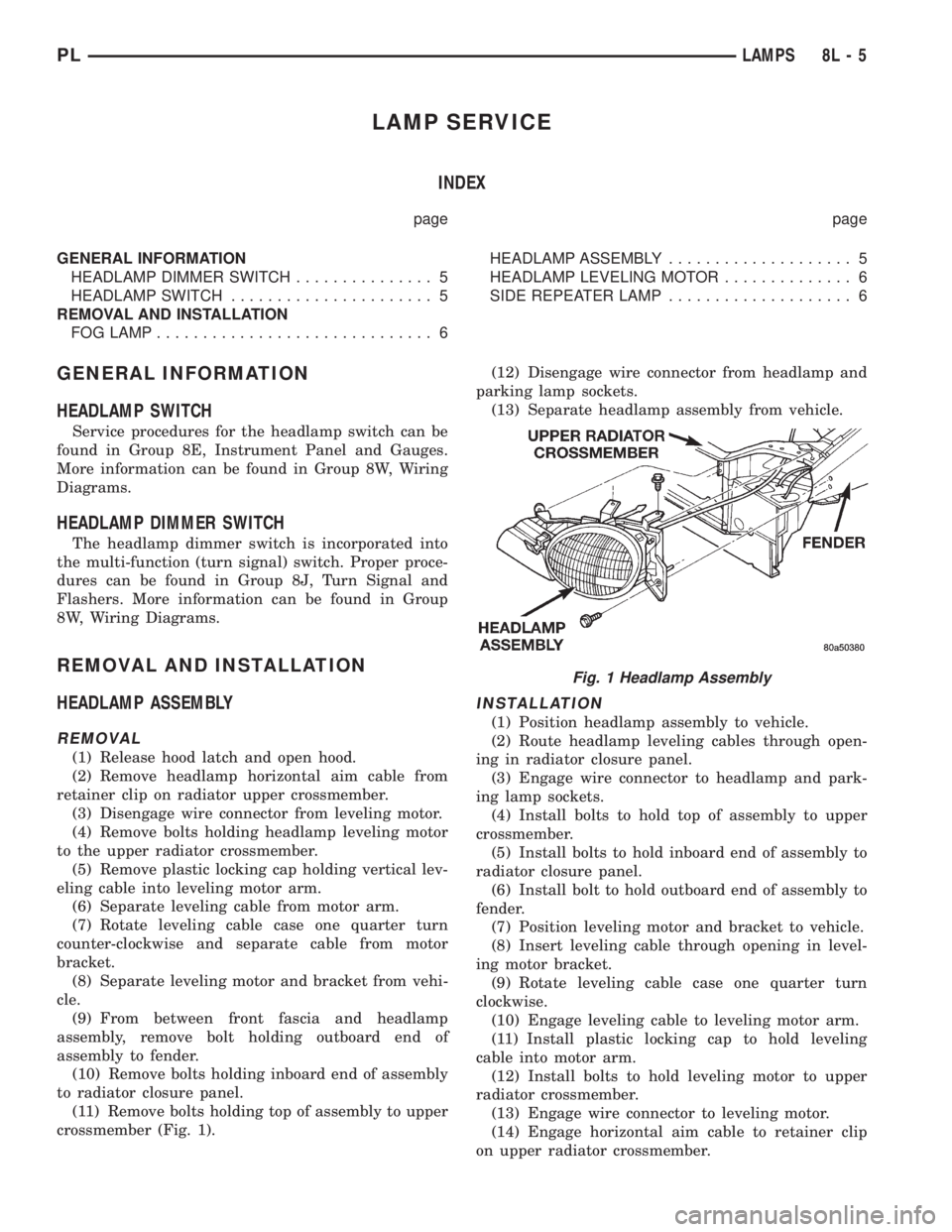

HEADLAMP ASSEMBLY

REMOVAL

(1) Release hood latch and open hood.

(2) Remove headlamp horizontal aim cable from

retainer clip on radiator upper crossmember.

(3) Disengage wire connector from leveling motor.

(4) Remove bolts holding headlamp leveling motor

to the upper radiator crossmember.

(5) Remove plastic locking cap holding vertical lev-

eling cable into leveling motor arm.

(6) Separate leveling cable from motor arm.

(7) Rotate leveling cable case one quarter turn

counter-clockwise and separate cable from motor

bracket.

(8) Separate leveling motor and bracket from vehi-

cle.

(9) From between front fascia and headlamp

assembly, remove bolt holding outboard end of

assembly to fender.

(10) Remove bolts holding inboard end of assembly

to radiator closure panel.

(11) Remove bolts holding top of assembly to upper

crossmember (Fig. 1).(12) Disengage wire connector from headlamp and

parking lamp sockets.

(13) Separate headlamp assembly from vehicle.

INSTALLATION

(1) Position headlamp assembly to vehicle.

(2) Route headlamp leveling cables through open-

ing in radiator closure panel.

(3) Engage wire connector to headlamp and park-

ing lamp sockets.

(4) Install bolts to hold top of assembly to upper

crossmember.

(5) Install bolts to hold inboard end of assembly to

radiator closure panel.

(6) Install bolt to hold outboard end of assembly to

fender.

(7) Position leveling motor and bracket to vehicle.

(8) Insert leveling cable through opening in level-

ing motor bracket.

(9) Rotate leveling cable case one quarter turn

clockwise.

(10) Engage leveling cable to leveling motor arm.

(11) Install plastic locking cap to hold leveling

cable into motor arm.

(12) Install bolts to hold leveling motor to upper

radiator crossmember.

(13) Engage wire connector to leveling motor.

(14) Engage horizontal aim cable to retainer clip

on upper radiator crossmember.

Fig. 1 Headlamp Assembly

PLLAMPS 8L - 5

Page 1083 of 1200

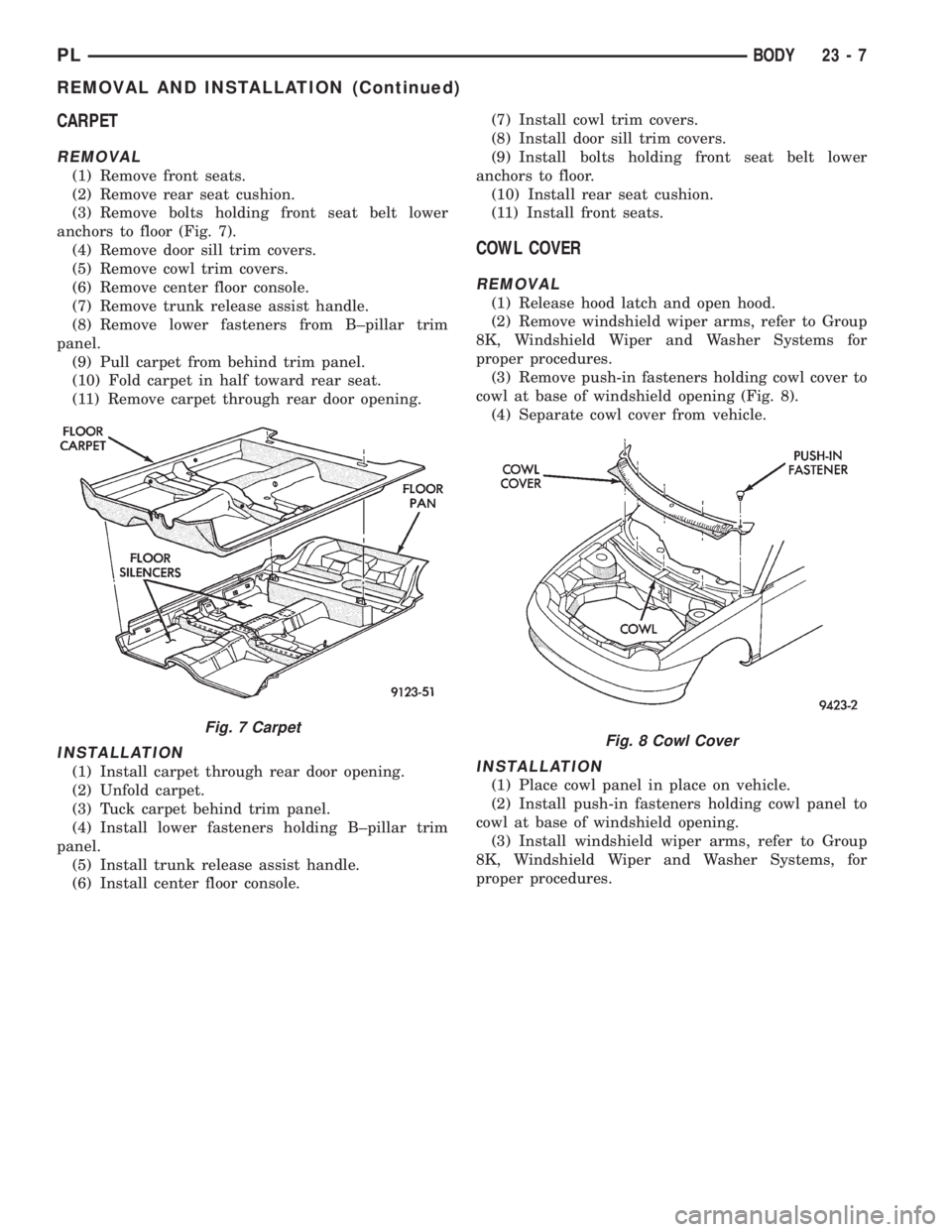

BODY COMPONENTS

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 3

WIND NOISE............................ 4

SERVICE PROCEDURES

HEAT STAKING.......................... 4

REMOVAL AND INSTALLATION

WINDOW REGULATORÐ4 DOOR........... 36

A-PILLAR TRIM.......................... 4

B-PILLAR APPLIQUEÐ2 DOOR.............. 5

B-PILLAR APPLIQUEÐ4 DOOR.............. 5

B-PILLAR TRIMÐ4 DOOR.................. 6

B-PILLAR WEATHERSTRIP CHANNEL......... 6

BODY VENT............................. 6

CARPET............................... 7

CHILD RESTRAINT SEAT BACK............. 8

CHILD SEAT MODULE..................... 8

COWL COVER........................... 7

DOOR HINGE........................... 9

DOOR LOCK CYLINDER.................. 10

DOOR OPENING TRIM WELT.............. 10

DOOR SILL TRIM........................ 10

DOOR................................. 9

FLOOR CONSOLE LATCH................. 11

FLOOR CONSOLE....................... 11

FRONT DOOR CHECK STOP............... 11

FRONT DOOR GLASSÐ2 DOOR............ 12

FRONT DOOR GLASSÐ4 DOOR............ 13

FRONT DOOR INNER BELT WEATHERSTRIP . . 13

FRONT DOOR LATCH STRIKER............ 14

FRONT DOOR LATCH.................... 13

FRONT DOOR OUTER BELT WEATHERSTRIP . 14

FRONT DOOR OUTSIDE HANDLE........... 14

FRONT DOOR TRIM PANEL................ 14

FRONT DOOR WATER SHIELD............. 16

FRONT DOOR WEATHERSTRIP............ 16

FRONT OUTBOARD SEAT BELT............ 17

FRONT SEAT BELT BUCKLE............... 18

FRONT SEAT BELT RETRACTOR........... 18

FRONT SEAT........................... 17

FRONT SHOULDER BELT ADJUSTER........ 18

FRONT VERTICAL GUIDE BAR............. 18

GRILLE............................... 19

HEADLINING........................... 19

HOOD HINGE.......................... 20

HOOD LATCH.......................... 21

HOOD RELEASE CABLE.................. 21

HOOD................................ 20

LOCK BUTTON BELL-CRANK.............. 21

LOWER QUARTER TRIMÐ4 DOOR.......... 22PARCEL SHELF TRIM.................... 22

QUARTER TRIM PANELÐ2 DOOR........... 22

REAR DOOR GLASS..................... 23

REAR DOOR INNER BELT WEATHERSTRIP . . . 23

REAR DOOR INTERLOCK LATCH STRIKER . . . 24

REAR DOOR LATCH STRIKER............. 24

REAR DOOR LATCH..................... 24

REAR DOOR LOCK BELL CRANK........... 24

REAR DOOR OUTER BELT WEATHERSTRIP . . 25

REAR DOOR TRIM....................... 25

REAR DOOR WINDOW REGULATOR........ 25

REAR SEAT BACK....................... 26

REAR SEAT BELT BUCKLE................ 26

REAR SEAT BELT RETRACTOR............ 26

REAR SEAT CUSHION.................... 26

REAR SPOILER......................... 27

REAR VERTICAL GUIDE BAR.............. 27

ROOF APERTURE (RAP) MOLDING.......... 28

ROOF RACK CROSS RAILS............... 28

ROOF RACK........................... 28

ROOF RAIL WEATHER-STRIP FOUR DOOR . . . 29

ROOF RAIL WEATHER-STRIP ± TWO DOOR . . . 29

SIDE COWL TRIM....................... 30

SIDE VIEW MIRROR STANCHION........... 31

SIDE VIEW MIRROR TRIM COVER.......... 31

SIDE VIEW MIRROR..................... 30

SUN VISOR SUPPORT................... 31

SUN VISOR............................ 31

TRUNK CARPET........................ 31

TRUNK LATCH STRIKER.................. 32

TRUNK LATCH.......................... 32

TRUNK LID LIFT SPRINGS................ 33

TRUNK LID............................ 32

TRUNK LOCK CYLINDER................. 33

TRUNK TRIM PANEL..................... 34

TRUNK WEATHERSTRIP.................. 34

UPPER QUARTER TRIMÐ4 DOOR.......... 34

WINDOW INNERBELT STABILIZER.......... 34

WINDOW REGULATORÐ2 DOOR........... 35

ADJUSTMENTS

FRONT DOOR GLASS ADJUSTMENT........ 37

FRONT DOOR LATCH ADJUSTMENT........ 38

REAR DOOR GLASS ADJUSTMENT......... 38

REAR DOOR LATCH ADJUSTMENT.......... 39

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS....... 39

SPECIAL TOOLS

BODY................................. 40

23 - 2 BODYPL

Page 1088 of 1200

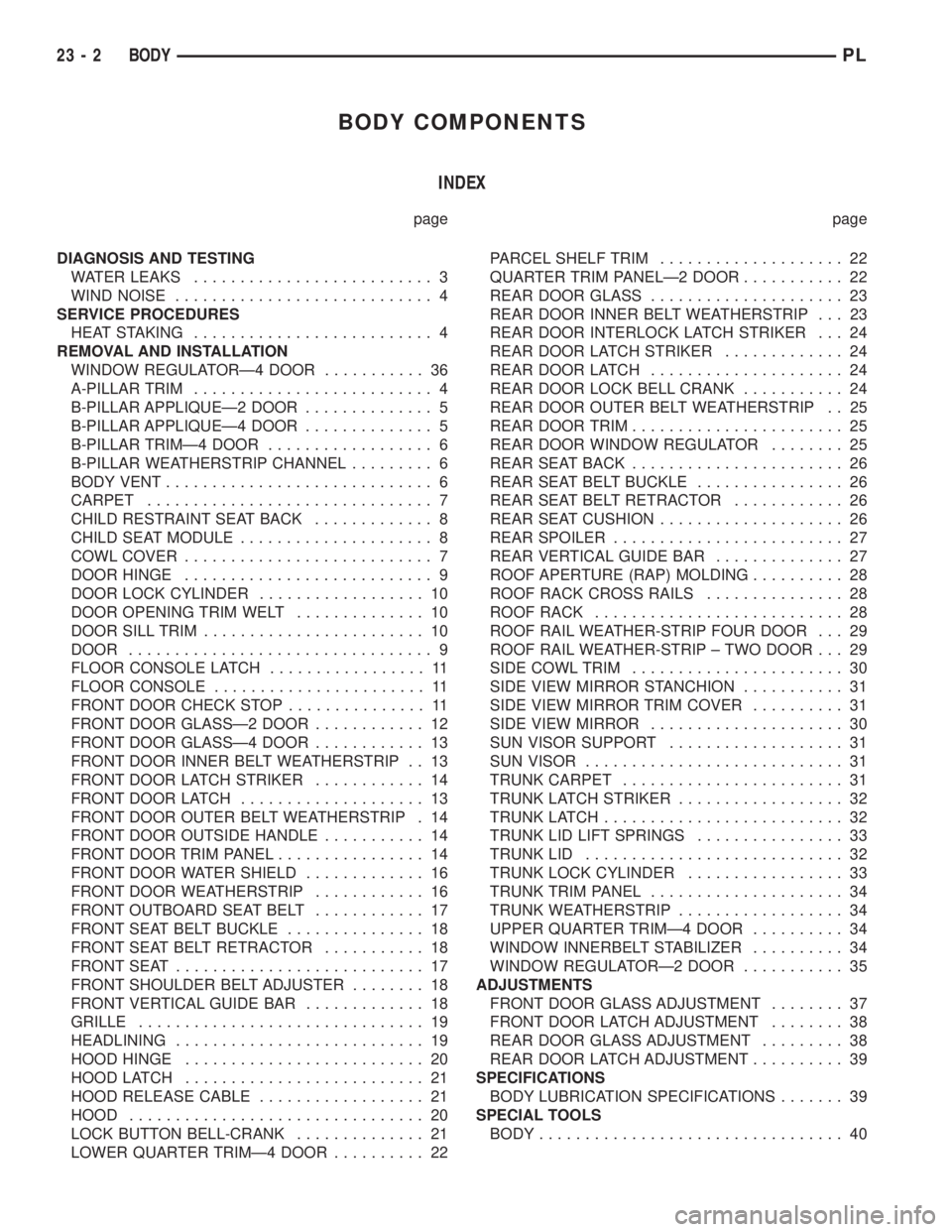

CARPET

REMOVAL

(1) Remove front seats.

(2) Remove rear seat cushion.

(3) Remove bolts holding front seat belt lower

anchors to floor (Fig. 7).

(4) Remove door sill trim covers.

(5) Remove cowl trim covers.

(6) Remove center floor console.

(7) Remove trunk release assist handle.

(8) Remove lower fasteners from B±pillar trim

panel.

(9) Pull carpet from behind trim panel.

(10) Fold carpet in half toward rear seat.

(11) Remove carpet through rear door opening.

INSTALLATION

(1) Install carpet through rear door opening.

(2) Unfold carpet.

(3) Tuck carpet behind trim panel.

(4) Install lower fasteners holding B±pillar trim

panel.

(5) Install trunk release assist handle.

(6) Install center floor console.(7) Install cowl trim covers.

(8) Install door sill trim covers.

(9) Install bolts holding front seat belt lower

anchors to floor.

(10) Install rear seat cushion.

(11) Install front seats.

COWL COVER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems for

proper procedures.

(3) Remove push-in fasteners holding cowl cover to

cowl at base of windshield opening (Fig. 8).

(4) Separate cowl cover from vehicle.

INSTALLATION

(1) Place cowl panel in place on vehicle.

(2) Install push-in fasteners holding cowl panel to

cowl at base of windshield opening.

(3) Install windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems, for

proper procedures.

Fig. 7 CarpetFig. 8 Cowl Cover

PLBODY 23 - 7

REMOVAL AND INSTALLATION (Continued)

Page 1100 of 1200

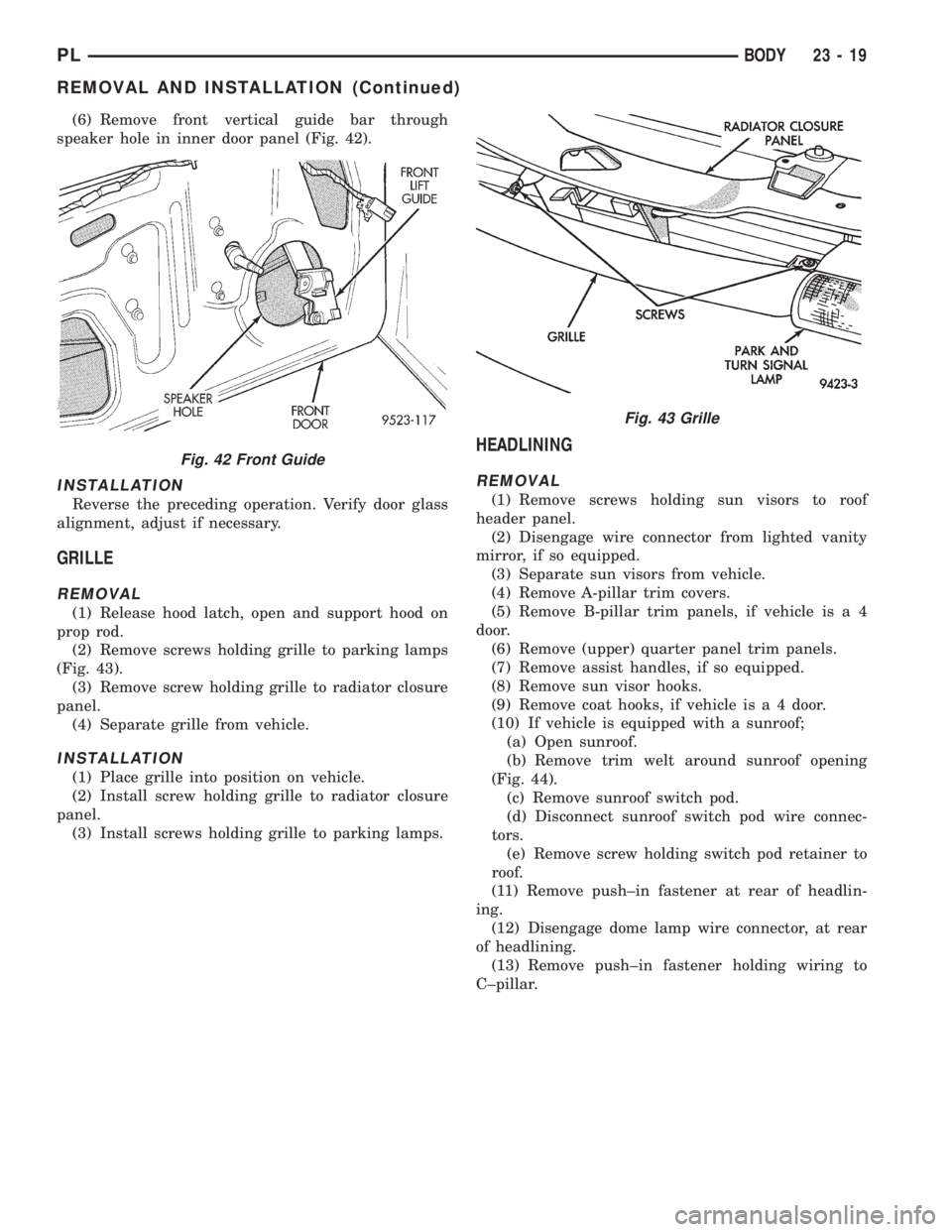

(6) Remove front vertical guide bar through

speaker hole in inner door panel (Fig. 42).

INSTALLATION

Reverse the preceding operation. Verify door glass

alignment, adjust if necessary.

GRILLE

REMOVAL

(1) Release hood latch, open and support hood on

prop rod.

(2) Remove screws holding grille to parking lamps

(Fig. 43).

(3) Remove screw holding grille to radiator closure

panel.

(4) Separate grille from vehicle.

INSTALLATION

(1) Place grille into position on vehicle.

(2) Install screw holding grille to radiator closure

panel.

(3) Install screws holding grille to parking lamps.

HEADLINING

REMOVAL

(1) Remove screws holding sun visors to roof

header panel.

(2) Disengage wire connector from lighted vanity

mirror, if so equipped.

(3) Separate sun visors from vehicle.

(4) Remove A-pillar trim covers.

(5) Remove B-pillar trim panels, if vehicle is a 4

door.

(6) Remove (upper) quarter panel trim panels.

(7) Remove assist handles, if so equipped.

(8) Remove sun visor hooks.

(9) Remove coat hooks, if vehicle is a 4 door.

(10) If vehicle is equipped with a sunroof;

(a) Open sunroof.

(b) Remove trim welt around sunroof opening

(Fig. 44).

(c) Remove sunroof switch pod.

(d) Disconnect sunroof switch pod wire connec-

tors.

(e) Remove screw holding switch pod retainer to

roof.

(11) Remove push±in fastener at rear of headlin-

ing.

(12) Disengage dome lamp wire connector, at rear

of headlining.

(13) Remove push±in fastener holding wiring to

C±pillar.

Fig. 42 Front Guide

Fig. 43 Grille

PLBODY 23 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1102 of 1200

(4) Remove bolts holding hood hinge to front

fender flange and separate hinge from vehicle. If nec-

essary, paint new hinge before installation.

INSTALLATION

(1) If necessary, paint new hinge before installa-

tion.

(2) Place hinge in position on vehicle.

(3) Install bolts to hold hood hinge to front fender

flange.

(4) Install bolts to hold hood to hinge.

(5) Align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers. Shims can be added or removed under hood

hinge to achieve proper hood height.

(6) Remove support from under hood and verify

hood operation.

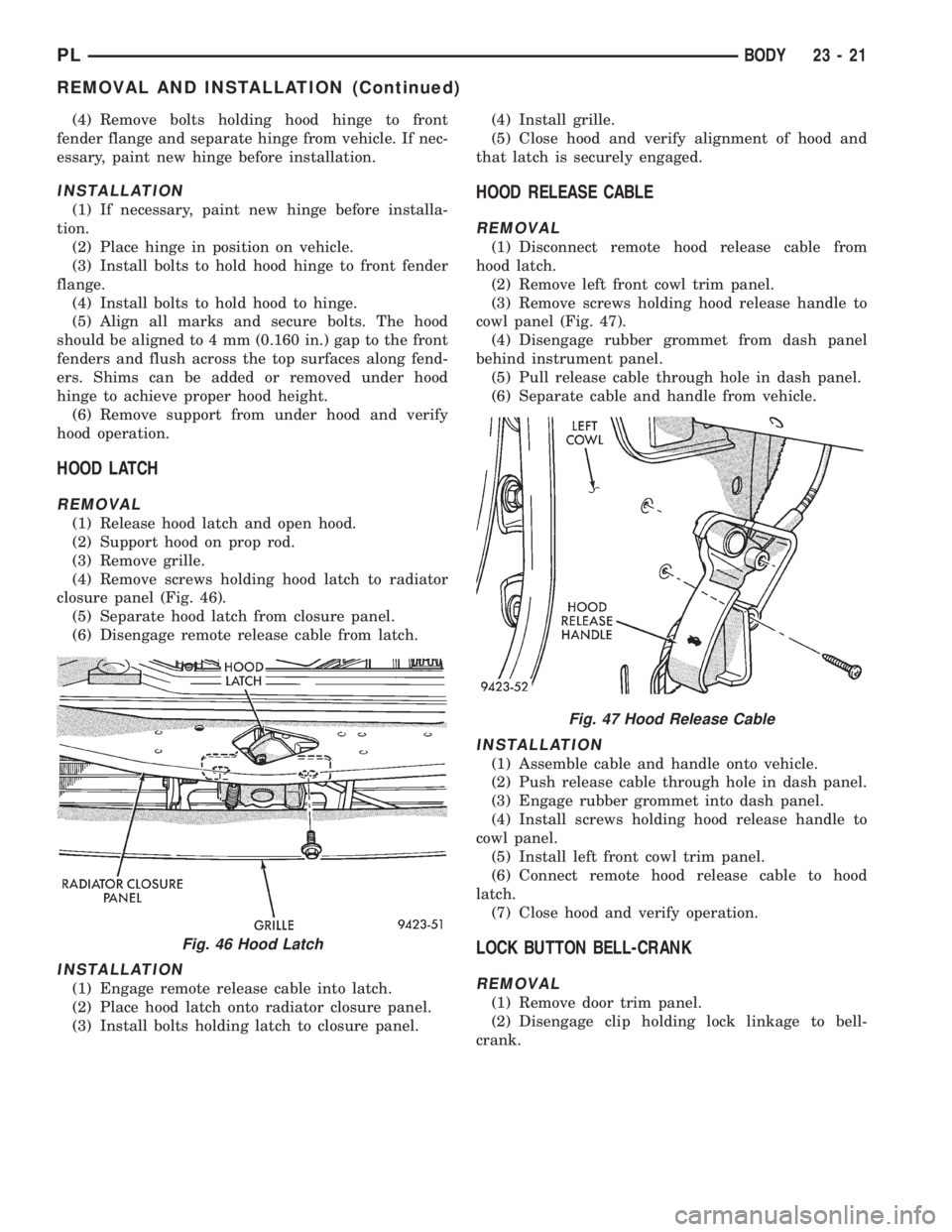

HOOD LATCH

REMOVAL

(1) Release hood latch and open hood.

(2) Support hood on prop rod.

(3) Remove grille.

(4) Remove screws holding hood latch to radiator

closure panel (Fig. 46).

(5) Separate hood latch from closure panel.

(6) Disengage remote release cable from latch.

INSTALLATION

(1) Engage remote release cable into latch.

(2) Place hood latch onto radiator closure panel.

(3) Install bolts holding latch to closure panel.(4) Install grille.

(5) Close hood and verify alignment of hood and

that latch is securely engaged.

HOOD RELEASE CABLE

REMOVAL

(1) Disconnect remote hood release cable from

hood latch.

(2) Remove left front cowl trim panel.

(3) Remove screws holding hood release handle to

cowl panel (Fig. 47).

(4) Disengage rubber grommet from dash panel

behind instrument panel.

(5) Pull release cable through hole in dash panel.

(6) Separate cable and handle from vehicle.

INSTALLATION

(1) Assemble cable and handle onto vehicle.

(2) Push release cable through hole in dash panel.

(3) Engage rubber grommet into dash panel.

(4) Install screws holding hood release handle to

cowl panel.

(5) Install left front cowl trim panel.

(6) Connect remote hood release cable to hood

latch.

(7) Close hood and verify operation.

LOCK BUTTON BELL-CRANK

REMOVAL

(1) Remove door trim panel.

(2) Disengage clip holding lock linkage to bell-

crank.

Fig. 46 Hood Latch

Fig. 47 Hood Release Cable

PLBODY 23 - 21

REMOVAL AND INSTALLATION (Continued)