air condition DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 148 of 1285

AMBER ABS WARNING LAMP

The amber ABS warning lamp is located in the

instrument cluster. The purpose of the warning lamp

is discussed in detail below.

When the ignition key is turned to the ON posi-

tion, the amber ABS warning lamp is lit until the

CAB completes its self-tests and turns off the lamp

(approximately 4 seconds). The amber ABS warning

lamp will illuminate when the CAB detects a condi-

tion that results in the shutdown of ABS function.

The CAB sends a message to the mechanical instu-

ment cluster (MIC) instructing it to turn on the

amber ABS warning lamp.

Under most conditions, when the amber ABS warn-

ing lamp is on, only the ABS function of the brake

system is affected; The electronic brake distribution

(EBD), the base brake system and the ability to stop

the vehicle are not affected.

WHEEL SPEED SENSOR (WSS)

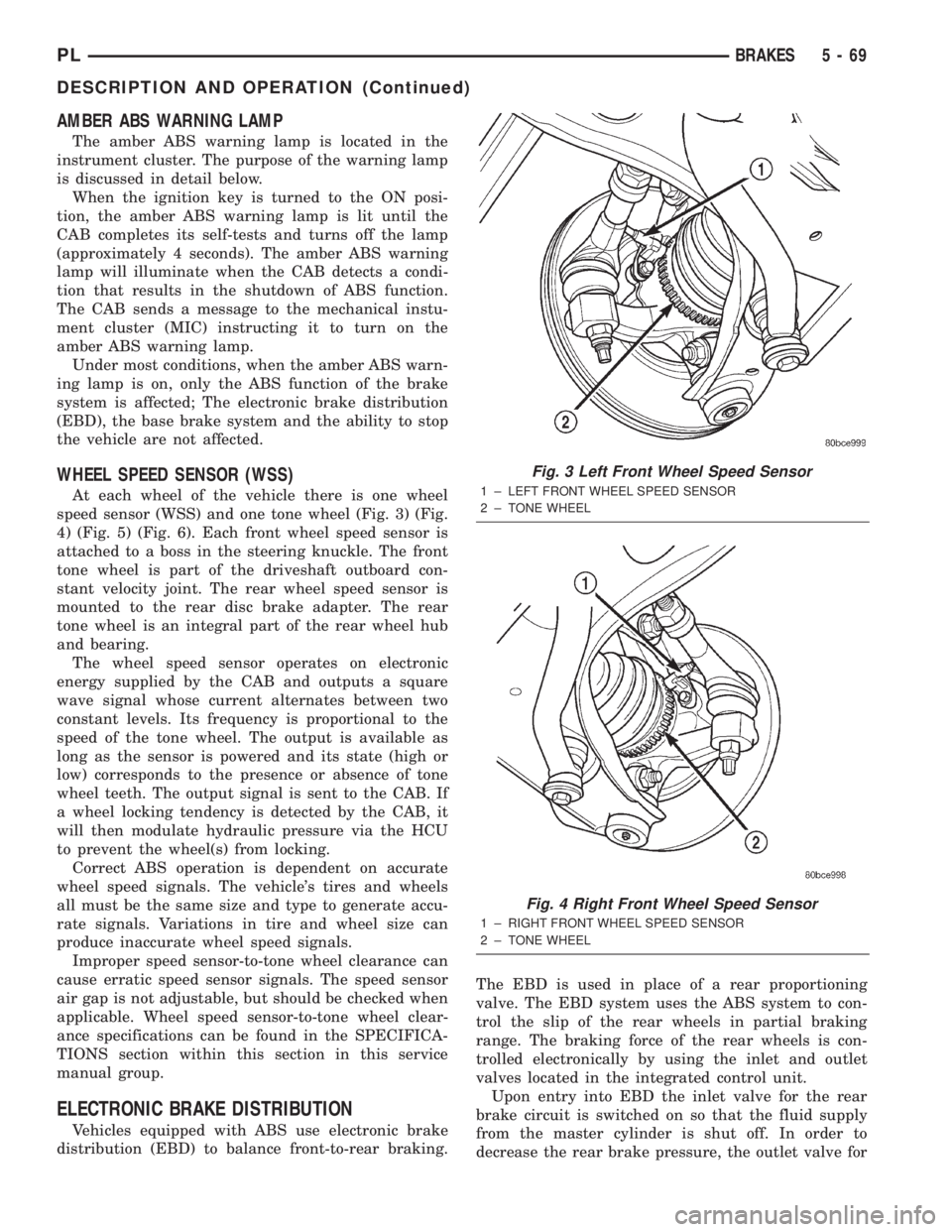

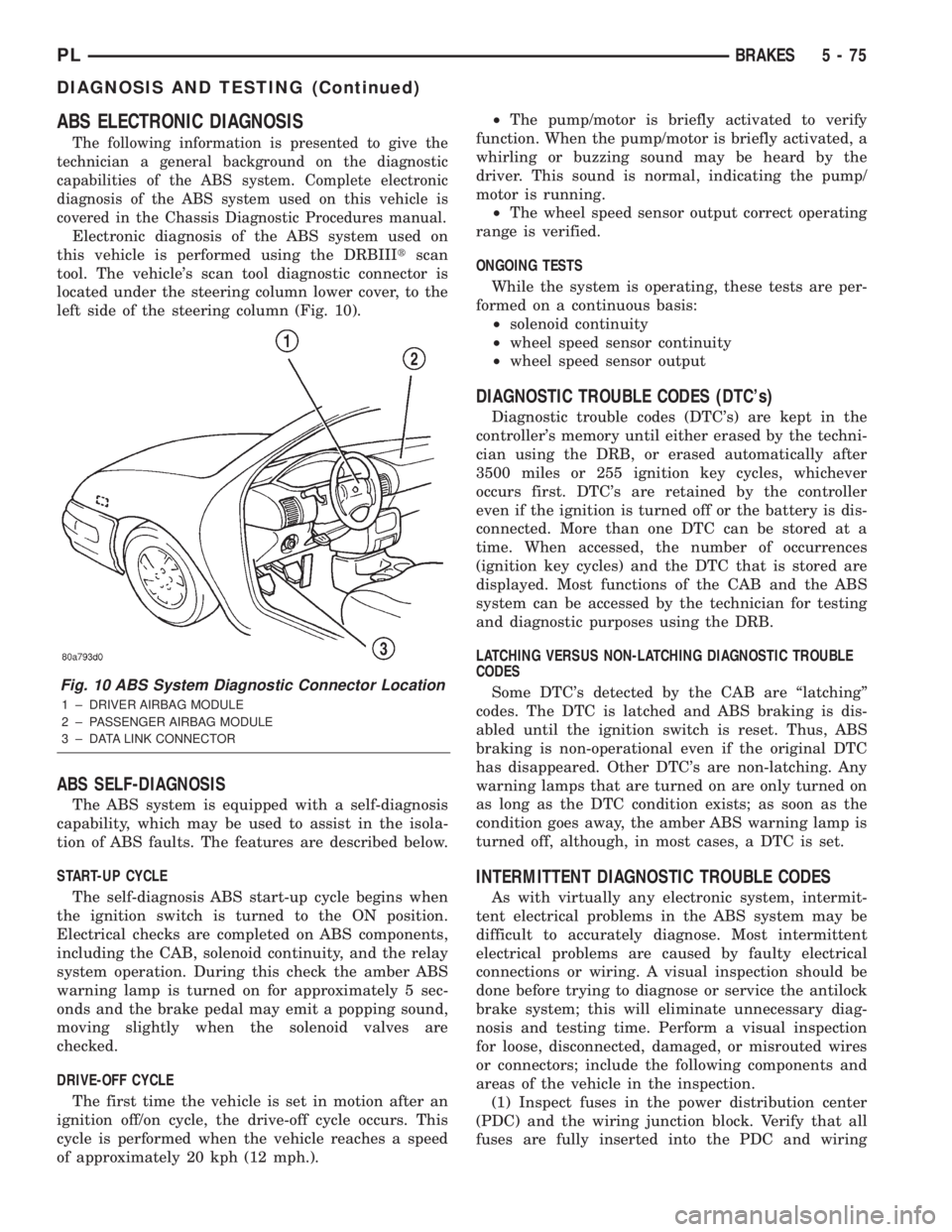

At each wheel of the vehicle there is one wheel

speed sensor (WSS) and one tone wheel (Fig. 3) (Fig.

4) (Fig. 5) (Fig. 6). Each front wheel speed sensor is

attached to a boss in the steering knuckle. The front

tone wheel is part of the driveshaft outboard con-

stant velocity joint. The rear wheel speed sensor is

mounted to the rear disc brake adapter. The rear

tone wheel is an integral part of the rear wheel hub

and bearing.

The wheel speed sensor operates on electronic

energy supplied by the CAB and outputs a square

wave signal whose current alternates between two

constant levels. Its frequency is proportional to the

speed of the tone wheel. The output is available as

long as the sensor is powered and its state (high or

low) corresponds to the presence or absence of tone

wheel teeth. The output signal is sent to the CAB. If

a wheel locking tendency is detected by the CAB, it

will then modulate hydraulic pressure via the HCU

to prevent the wheel(s) from locking.

Correct ABS operation is dependent on accurate

wheel speed signals. The vehicle's tires and wheels

all must be the same size and type to generate accu-

rate signals. Variations in tire and wheel size can

produce inaccurate wheel speed signals.

Improper speed sensor-to-tone wheel clearance can

cause erratic speed sensor signals. The speed sensor

air gap is not adjustable, but should be checked when

applicable. Wheel speed sensor-to-tone wheel clear-

ance specifications can be found in the SPECIFICA-

TIONS section within this section in this service

manual group.

ELECTRONIC BRAKE DISTRIBUTION

Vehicles equipped with ABS use electronic brake

distribution (EBD) to balance front-to-rear braking.The EBD is used in place of a rear proportioning

valve. The EBD system uses the ABS system to con-

trol the slip of the rear wheels in partial braking

range. The braking force of the rear wheels is con-

trolled electronically by using the inlet and outlet

valves located in the integrated control unit.

Upon entry into EBD the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

Fig. 3 Left Front Wheel Speed Sensor

1 ± LEFT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

Fig. 4 Right Front Wheel Speed Sensor

1 ± RIGHT FRONT WHEEL SPEED SENSOR

2 ± TONE WHEEL

PLBRAKES 5 - 69

DESCRIPTION AND OPERATION (Continued)

Page 154 of 1285

ABS ELECTRONIC DIAGNOSIS

The following information is presented to give the

technician a general background on the diagnostic

capabilities of the ABS system. Complete electronic

diagnosis of the ABS system used on this vehicle is

covered in the Chassis Diagnostic Procedures manual.

Electronic diagnosis of the ABS system used on

this vehicle is performed using the DRBIIItscan

tool. The vehicle's scan tool diagnostic connector is

located under the steering column lower cover, to the

left side of the steering column (Fig. 10).

ABS SELF-DIAGNOSIS

The ABS system is equipped with a self-diagnosis

capability, which may be used to assist in the isola-

tion of ABS faults. The features are described below.

START-UP CYCLE

The self-diagnosis ABS start-up cycle begins when

the ignition switch is turned to the ON position.

Electrical checks are completed on ABS components,

including the CAB, solenoid continuity, and the relay

system operation. During this check the amber ABS

warning lamp is turned on for approximately 5 sec-

onds and the brake pedal may emit a popping sound,

moving slightly when the solenoid valves are

checked.

DRIVE-OFF CYCLE

The first time the vehicle is set in motion after an

ignition off/on cycle, the drive-off cycle occurs. This

cycle is performed when the vehicle reaches a speed

of approximately 20 kph (12 mph.).²The pump/motor is briefly activated to verify

function. When the pump/motor is briefly activated, a

whirling or buzzing sound may be heard by the

driver. This sound is normal, indicating the pump/

motor is running.

²The wheel speed sensor output correct operating

range is verified.

ONGOING TESTS

While the system is operating, these tests are per-

formed on a continuous basis:

²solenoid continuity

²wheel speed sensor continuity

²wheel speed sensor output

DIAGNOSTIC TROUBLE CODES (DTC's)

Diagnostic trouble codes (DTC's) are kept in the

controller's memory until either erased by the techni-

cian using the DRB, or erased automatically after

3500 miles or 255 ignition key cycles, whichever

occurs first. DTC's are retained by the controller

even if the ignition is turned off or the battery is dis-

connected. More than one DTC can be stored at a

time. When accessed, the number of occurrences

(ignition key cycles) and the DTC that is stored are

displayed. Most functions of the CAB and the ABS

system can be accessed by the technician for testing

and diagnostic purposes using the DRB.

LATCHING VERSUS NON-LATCHING DIAGNOSTIC TROUBLE

CODES

Some DTC's detected by the CAB are ªlatchingº

codes. The DTC is latched and ABS braking is dis-

abled until the ignition switch is reset. Thus, ABS

braking is non-operational even if the original DTC

has disappeared. Other DTC's are non-latching. Any

warning lamps that are turned on are only turned on

as long as the DTC condition exists; as soon as the

condition goes away, the amber ABS warning lamp is

turned off, although, in most cases, a DTC is set.

INTERMITTENT DIAGNOSTIC TROUBLE CODES

As with virtually any electronic system, intermit-

tent electrical problems in the ABS system may be

difficult to accurately diagnose. Most intermittent

electrical problems are caused by faulty electrical

connections or wiring. A visual inspection should be

done before trying to diagnose or service the antilock

brake system; this will eliminate unnecessary diag-

nosis and testing time. Perform a visual inspection

for loose, disconnected, damaged, or misrouted wires

or connectors; include the following components and

areas of the vehicle in the inspection.

(1) Inspect fuses in the power distribution center

(PDC) and the wiring junction block. Verify that all

fuses are fully inserted into the PDC and wiring

Fig. 10 ABS System Diagnostic Connector Location

1 ± DRIVER AIRBAG MODULE

2 ± PASSENGER AIRBAG MODULE

3 ± DATA LINK CONNECTOR

PLBRAKES 5 - 75

DIAGNOSIS AND TESTING (Continued)

Page 172 of 1285

SERVICE DIAGNOSIS±CLUTCH INTERLOCK/UPSTOP SWITCH

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE STARTER

WON'T CRANK

WHEN CLUTCH

PEDAL IS

PRESSED TO THE

FLOORClutch interlock switch does not have

continuity when plunger is depressed 1.25

mm (1.30 in.)Defective switch or open wiring circuit.

Replace switch if necessary.

Interlock switch plunger is not depressed

when clutch pedal is pushed to the floorFloor mat interferes with clutch pedal

movement or clutch pedal bracket is bent.

Problem is related to other components in

the starting circuit.Check other components in the starting

circuit. Refer to Battery/Starting/Charging

System in Group 8.

SPEED CONTROL

DOES NOT

TERMINATE WHEN

CLUTCH PEDAL IS

DEPRESSED BY AT

LEAST 33 mm (1.30

in.)Upstop switch circuit is closed when clutch

pedal is depressed, or harness is shorted.Refer to Upstop Switch Electrical Test in

this group. Repair wiring or replace switch

assembly as necessary.

Other speed control system failure. Refer to Group 8H, Speed Control for

further diagnosis and testing procedures.

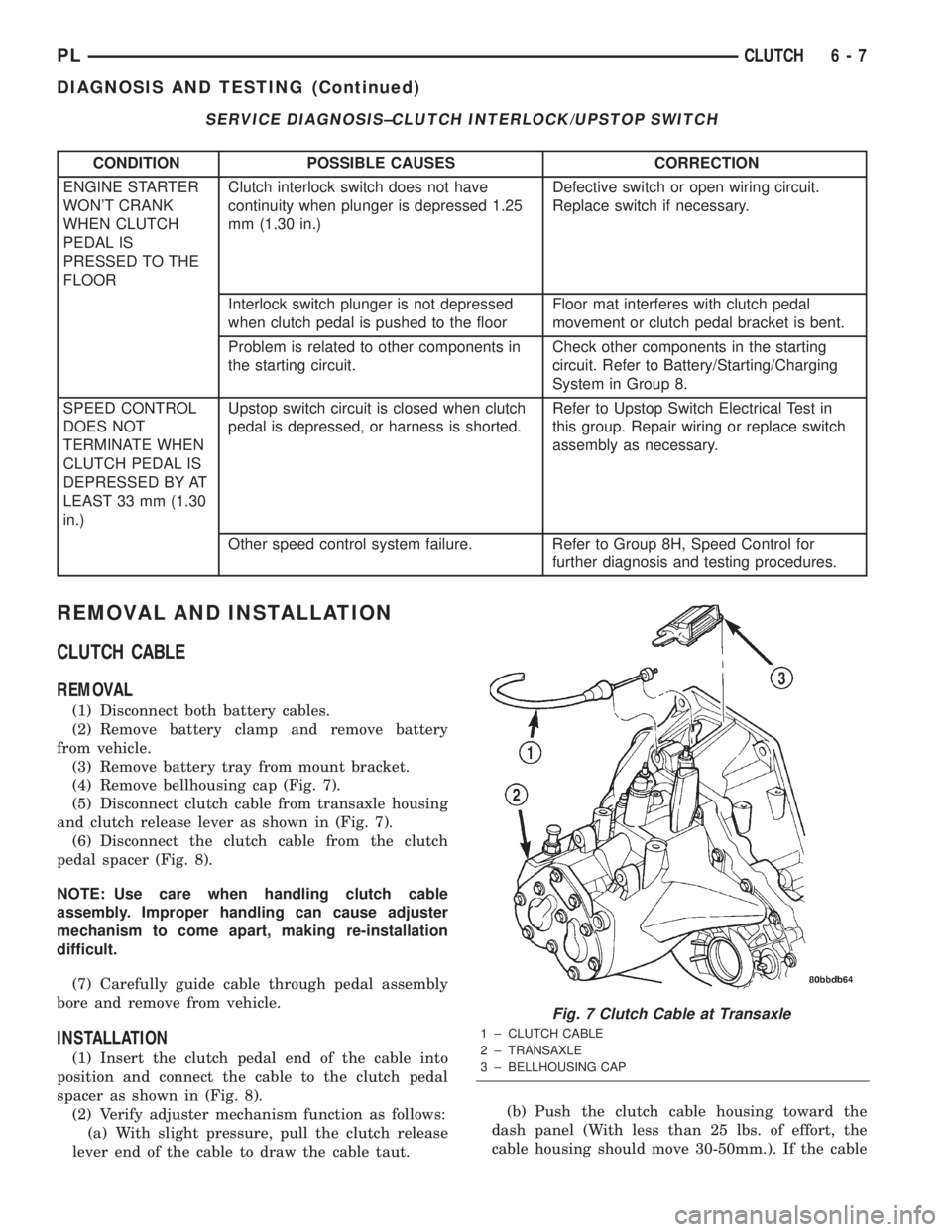

REMOVAL AND INSTALLATION

CLUTCH CABLE

REMOVAL

(1) Disconnect both battery cables.

(2) Remove battery clamp and remove battery

from vehicle.

(3) Remove battery tray from mount bracket.

(4) Remove bellhousing cap (Fig. 7).

(5) Disconnect clutch cable from transaxle housing

and clutch release lever as shown in (Fig. 7).

(6) Disconnect the clutch cable from the clutch

pedal spacer (Fig. 8).

NOTE: Use care when handling clutch cable

assembly. Improper handling can cause adjuster

mechanism to come apart, making re-installation

difficult.

(7) Carefully guide cable through pedal assembly

bore and remove from vehicle.

INSTALLATION

(1) Insert the clutch pedal end of the cable into

position and connect the cable to the clutch pedal

spacer as shown in (Fig. 8).

(2) Verify adjuster mechanism function as follows:

(a) With slight pressure, pull the clutch release

lever end of the cable to draw the cable taut.(b) Push the clutch cable housing toward the

dash panel (With less than 25 lbs. of effort, the

cable housing should move 30-50mm.). If the cable

Fig. 7 Clutch Cable at Transaxle

1 ± CLUTCH CABLE

2 ± TRANSAXLE

3 ± BELLHOUSING CAP

PLCLUTCH 6 - 7

DIAGNOSIS AND TESTING (Continued)

Page 180 of 1285

COOLING SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

COOLING SYSTEM........................1

COOLANT...............................2

COOLANT PERFORMANCE..................2

COOLANT RECOVERY SYSTEM..............3

ENGINE THERMOSTAT.....................3

RADIATOR..............................3

RADIATOR COOLING FAN MODULE...........3

COOLING SYSTEM PRESSURE CAP..........4

RADIATOR HOSES AND CLAMPS............5

WATER PUMP...........................5

AUTOMATIC TRANSMISSION OIL COOLER.....6

ACCESSORY DRIVE BELTS.................6

ENGINE BLOCK HEATER...................6

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS..............7

ENGINE THERMOSTAT TESTING............14

ACCESSORY DRIVE BELT DIAGNOSIS........14

WATER PUMP DIAGNOSIS................15

COOLING SYSTEM FLOW CHECK...........15

ELECTRIC FAN MOTOR TEST...............15

COOLANT CONCENTRATION TESTING........15

TESTING COOLING SYSTEM FOR LEAKS.....15

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK...............16

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP.......................16

LOW COOLANT LEVEL AERATION...........17

DEAERATION...........................17

TEMPERATURE GAUGE INDICATION.........17

ENGINE BLOCK HEATER..................17

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE.........17COOLANTÐADDING ADDITIONAL...........18

COOLANT LEVELÐSERVICING.............18

COOLING SYSTEMÐDRAINING.............19

COOLING SYSTEMÐREFILLING............19

REMOVAL AND INSTALLATION

WATER PUMP..........................19

WATER PUMP INLET TUBE................20

ENGINE THERMOSTAT....................20

RADIATOR.............................21

RADIATOR DRAINCOCK...................22

COOLING FAN MODULE...................22

COOLANT RECOVERY CONTAINER..........23

ENGINE BLOCK HEATER..................24

ACCESSORY DRIVE BELTS................24

AUTOMATIC BELT TENSIONER & PULLEY....26

DISASSEMBLY AND ASSEMBLY

COOLING FAN MODULE...................26

CLEANING AND INSPECTION

WATER PUMP..........................28

ACCESSORY DRIVE BELT INSPECTION.......28

COOLING SYSTEM CAP...................28

COOLING SYSTEM CLEANING..............28

RADIATOR FLUSHING....................28

REVERSE FLUSHING.....................29

CHEMICAL CLEANING....................29

ADJUSTMENTS

BELT TENSION..........................29

SPECIFICATIONS

COOLING SYSTEM CAPACITY..............30

TORQUE SPECIFICATIONS.................30

SPECIAL TOOLS

COOLING..............................30

DESCRIPTION AND OPERATION

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, and a water pump to

circulate the coolant. The engine cooling module may

consist of a radiator, electric fan motor, fan, shroud,

coolant reserve system, transmission oil cooler, hoses,clamps, air conditioning condenser and transmission

oil lines.

²When the Engine is cold: The thermostat is

closed and the cooling system has no flow through

the radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open

and the cooling system has flow through the radiator,

engine, heater system, and bypass.

PLCOOLING SYSTEM 7 - 1

Page 182 of 1285

protection. MopartAntifreeze or the equivalent is

recommended for best engine cooling without corro-

sion. When mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it looses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

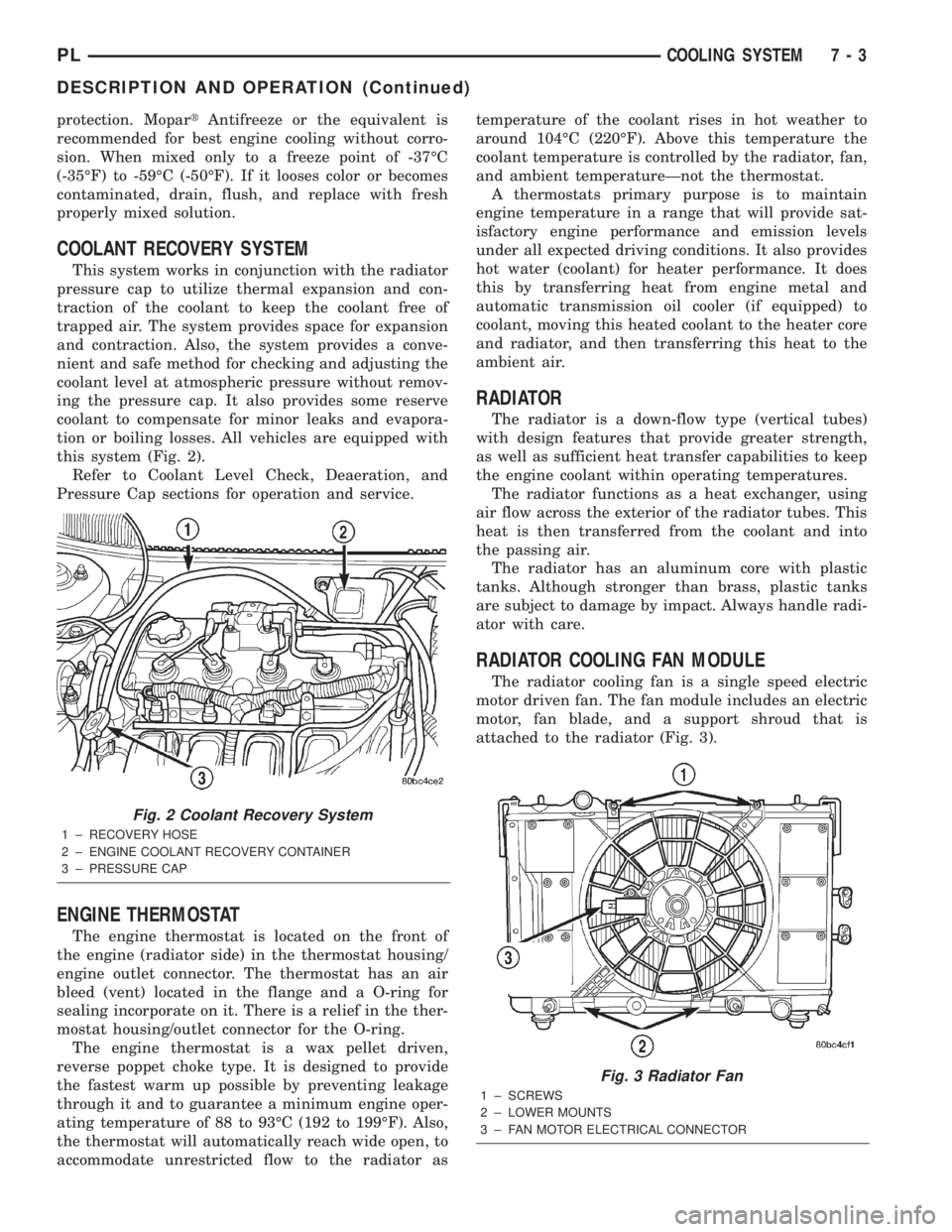

COOLANT RECOVERY SYSTEM

This system works in conjunction with the radiator

pressure cap to utilize thermal expansion and con-

traction of the coolant to keep the coolant free of

trapped air. The system provides space for expansion

and contraction. Also, the system provides a conve-

nient and safe method for checking and adjusting the

coolant level at atmospheric pressure without remov-

ing the pressure cap. It also provides some reserve

coolant to compensate for minor leaks and evapora-

tion or boiling losses. All vehicles are equipped with

this system (Fig. 2).

Refer to Coolant Level Check, Deaeration, and

Pressure Cap sections for operation and service.

ENGINE THERMOSTAT

The engine thermostat is located on the front of

the engine (radiator side) in the thermostat housing/

engine outlet connector. The thermostat has an air

bleed (vent) located in the flange and a O-ring for

sealing incorporate on it. There is a relief in the ther-

mostat housing/outlet connector for the O-ring.

The engine thermostat is a wax pellet driven,

reverse poppet choke type. It is designed to provide

the fastest warm up possible by preventing leakage

through it and to guarantee a minimum engine oper-

ating temperature of 88 to 93ÉC (192 to 199ÉF). Also,

the thermostat will automatically reach wide open, to

accommodate unrestricted flow to the radiator astemperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the radiator, fan,

and ambient temperatureÐnot the thermostat.

A thermostats primary purpose is to maintain

engine temperature in a range that will provide sat-

isfactory engine performance and emission levels

under all expected driving conditions. It also provides

hot water (coolant) for heater performance. It does

this by transferring heat from engine metal and

automatic transmission oil cooler (if equipped) to

coolant, moving this heated coolant to the heater core

and radiator, and then transferring this heat to the

ambient air.

RADIATOR

The radiator is a down-flow type (vertical tubes)

with design features that provide greater strength,

as well as sufficient heat transfer capabilities to keep

the engine coolant within operating temperatures.

The radiator functions as a heat exchanger, using

air flow across the exterior of the radiator tubes. This

heat is then transferred from the coolant and into

the passing air.

The radiator has an aluminum core with plastic

tanks. Although stronger than brass, plastic tanks

are subject to damage by impact. Always handle radi-

ator with care.

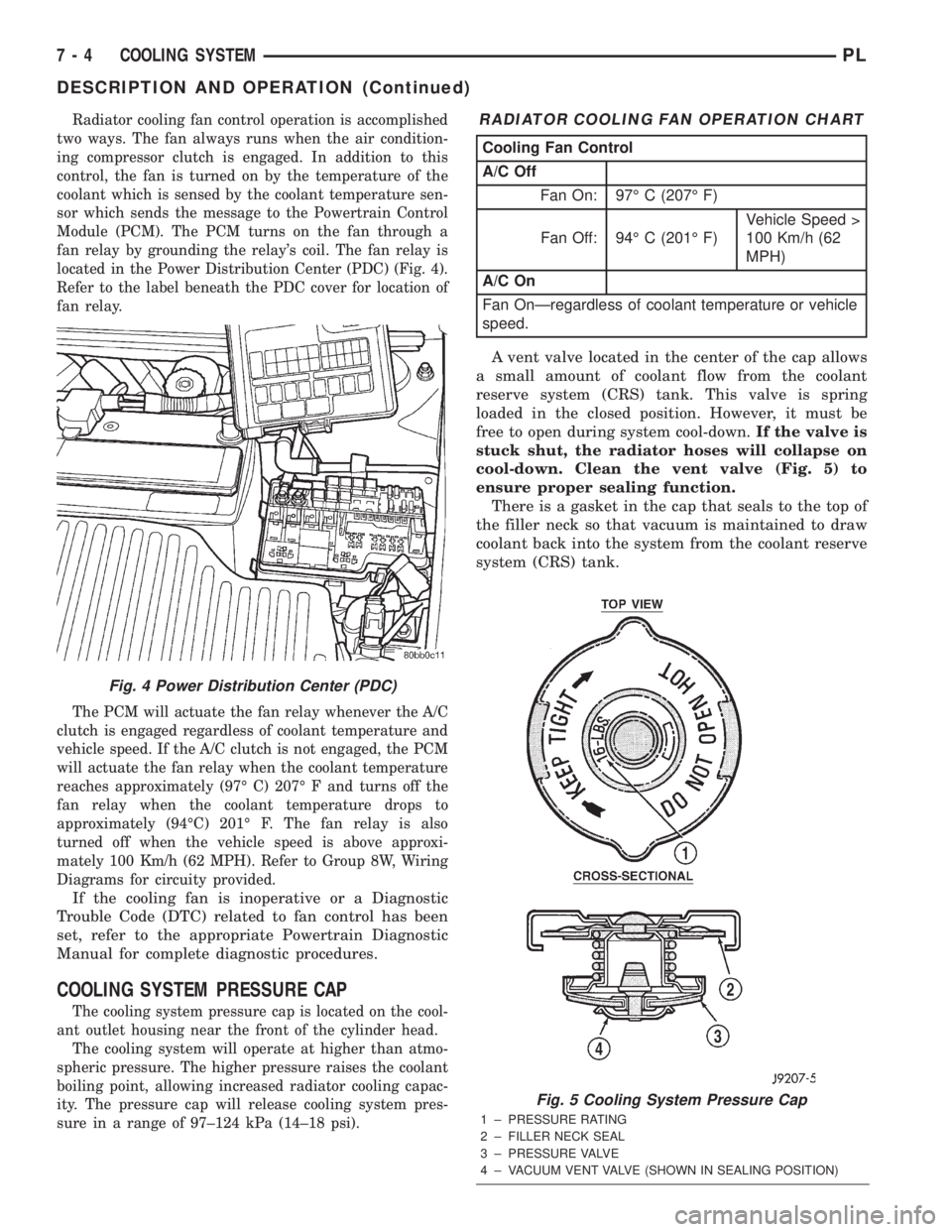

RADIATOR COOLING FAN MODULE

The radiator cooling fan is a single speed electric

motor driven fan. The fan module includes an electric

motor, fan blade, and a support shroud that is

attached to the radiator (Fig. 3).

Fig. 2 Coolant Recovery System

1 ± RECOVERY HOSE

2 ± ENGINE COOLANT RECOVERY CONTAINER

3 ± PRESSURE CAP

Fig. 3 Radiator Fan

1 ± SCREWS

2 ± LOWER MOUNTS

3 ± FAN MOTOR ELECTRICAL CONNECTOR

PLCOOLING SYSTEM 7 - 3

DESCRIPTION AND OPERATION (Continued)

Page 183 of 1285

Radiator cooling fan control operation is accomplished

two ways. The fan always runs when the air condition-

ing compressor clutch is engaged. In addition to this

control, the fan is turned on by the temperature of the

coolant which is sensed by the coolant temperature sen-

sor which sends the message to the Powertrain Control

Module (PCM). The PCM turns on the fan through a

fan relay by grounding the relay's coil. The fan relay is

located in the Power Distribution Center (PDC) (Fig. 4).

Refer to the label beneath the PDC cover for location of

fan relay.

The PCM will actuate the fan relay whenever the A/C

clutch is engaged regardless of coolant temperature and

vehicle speed. If the A/C clutch is not engaged, the PCM

will actuate the fan relay when the coolant temperature

reaches approximately (97É C) 207É F and turns off the

fan relay when the coolant temperature drops to

approximately (94ÉC) 201É F. The fan relay is also

turned off when the vehicle speed is above approxi-

mately 100 Km/h (62 MPH). Refer to Group 8W, Wiring

Diagrams for circuity provided.

If the cooling fan is inoperative or a Diagnostic

Trouble Code (DTC) related to fan control has been

set, refer to the appropriate Powertrain Diagnostic

Manual for complete diagnostic procedures.

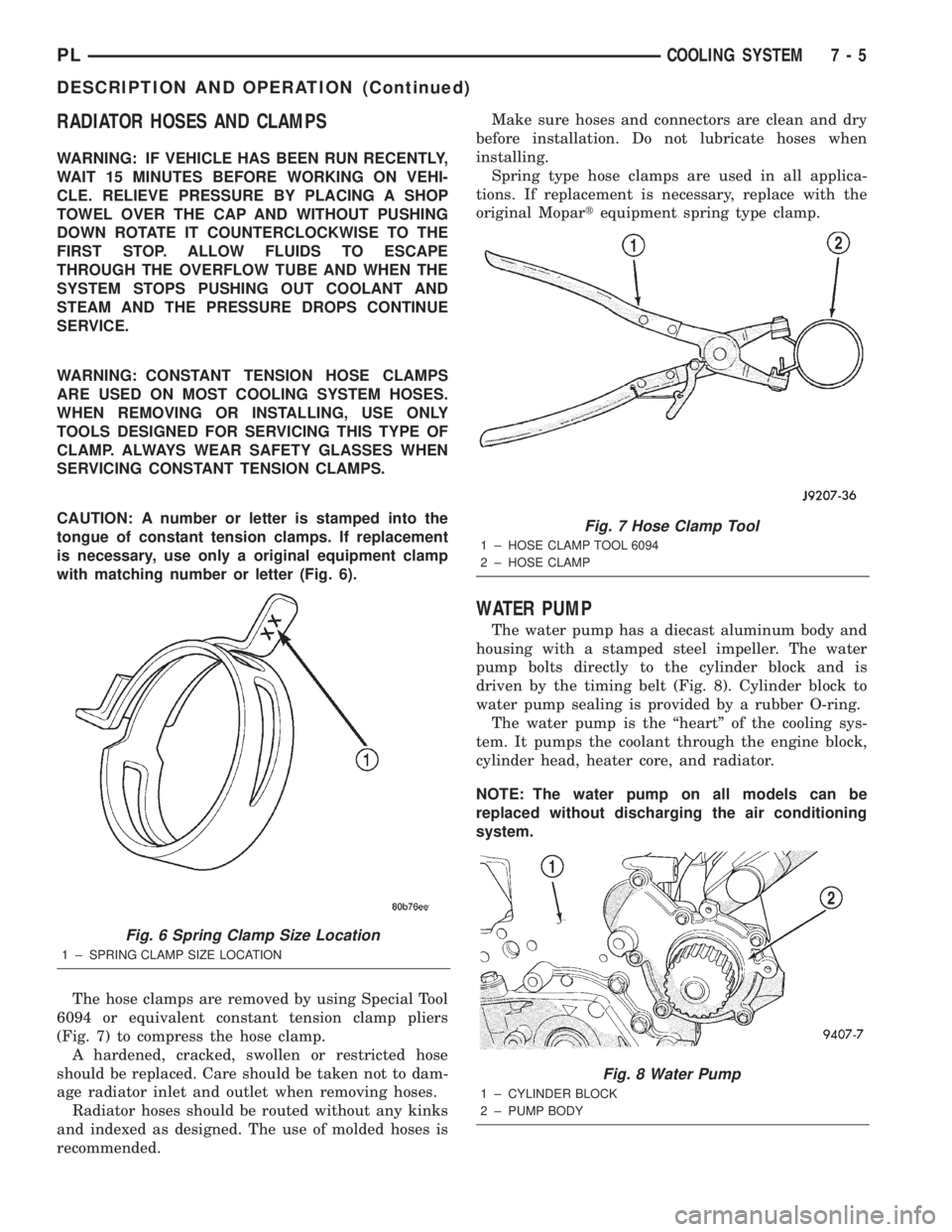

COOLING SYSTEM PRESSURE CAP

The cooling system pressure cap is located on the cool-

ant outlet housing near the front of the cylinder head.

The cooling system will operate at higher than atmo-

spheric pressure. The higher pressure raises the coolant

boiling point, allowing increased radiator cooling capac-

ity. The pressure cap will release cooling system pres-

sure in a range of 97±124 kPa (14±18 psi).

A vent valve located in the center of the cap allows

a small amount of coolant flow from the coolant

reserve system (CRS) tank. This valve is spring

loaded in the closed position. However, it must be

free to open during system cool-down.If the valve is

stuck shut, the radiator hoses will collapse on

cool-down. Clean the vent valve (Fig. 5) to

ensure proper sealing function.

There is a gasket in the cap that seals to the top of

the filler neck so that vacuum is maintained to draw

coolant back into the system from the coolant reserve

system (CRS) tank.

Fig. 4 Power Distribution Center (PDC)

RADIATOR COOLING FAN OPERATION CHART

Cooling Fan Control

A/C Off

Fan On: 97É C (207É F)

Fan Off: 94É C (201É F)Vehicle Speed >

100 Km/h (62

MPH)

A/C On

Fan OnÐregardless of coolant temperature or vehicle

speed.

Fig. 5 Cooling System Pressure Cap

1 ± PRESSURE RATING

2 ± FILLER NECK SEAL

3 ± PRESSURE VALVE

4 ± VACUUM VENT VALVE (SHOWN IN SEALING POSITION)

7 - 4 COOLING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 184 of 1285

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE WORKING ON VEHI-

CLE. RELIEVE PRESSURE BY PLACING A SHOP

TOWEL OVER THE CAP AND WITHOUT PUSHING

DOWN ROTATE IT COUNTERCLOCKWISE TO THE

FIRST STOP. ALLOW FLUIDS TO ESCAPE

THROUGH THE OVERFLOW TUBE AND WHEN THE

SYSTEM STOPS PUSHING OUT COOLANT AND

STEAM AND THE PRESSURE DROPS CONTINUE

SERVICE.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 6).

The hose clamps are removed by using Special Tool

6094 or equivalent constant tension clamp pliers

(Fig. 7) to compress the hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Care should be taken not to dam-

age radiator inlet and outlet when removing hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.Make sure hoses and connectors are clean and dry

before installation. Do not lubricate hoses when

installing.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary, replace with the

original Mopartequipment spring type clamp.

WATER PUMP

The water pump has a diecast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the cylinder block and is

driven by the timing belt (Fig. 8). Cylinder block to

water pump sealing is provided by a rubber O-ring.

The water pump is the ªheartº of the cooling sys-

tem. It pumps the coolant through the engine block,

cylinder head, heater core, and radiator.

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

Fig. 6 Spring Clamp Size Location

1 ± SPRING CLAMP SIZE LOCATION

Fig. 7 Hose Clamp Tool

1 ± HOSE CLAMP TOOL 6094

2 ± HOSE CLAMP

Fig. 8 Water Pump

1 ± CYLINDER BLOCK

2 ± PUMP BODY

PLCOOLING SYSTEM 7 - 5

DESCRIPTION AND OPERATION (Continued)

Page 185 of 1285

AUTOMATIC TRANSMISSION OIL COOLER

Oil coolers are internal oil to coolant type, mounted

in the radiator lower tank (Fig. 9). Rubber oil lines

feed the oil cooler and the automatic transmission.

Use only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended. Tighten Oil Cooler Hose Clamps

to 2 N´m (18 in. lbs.).

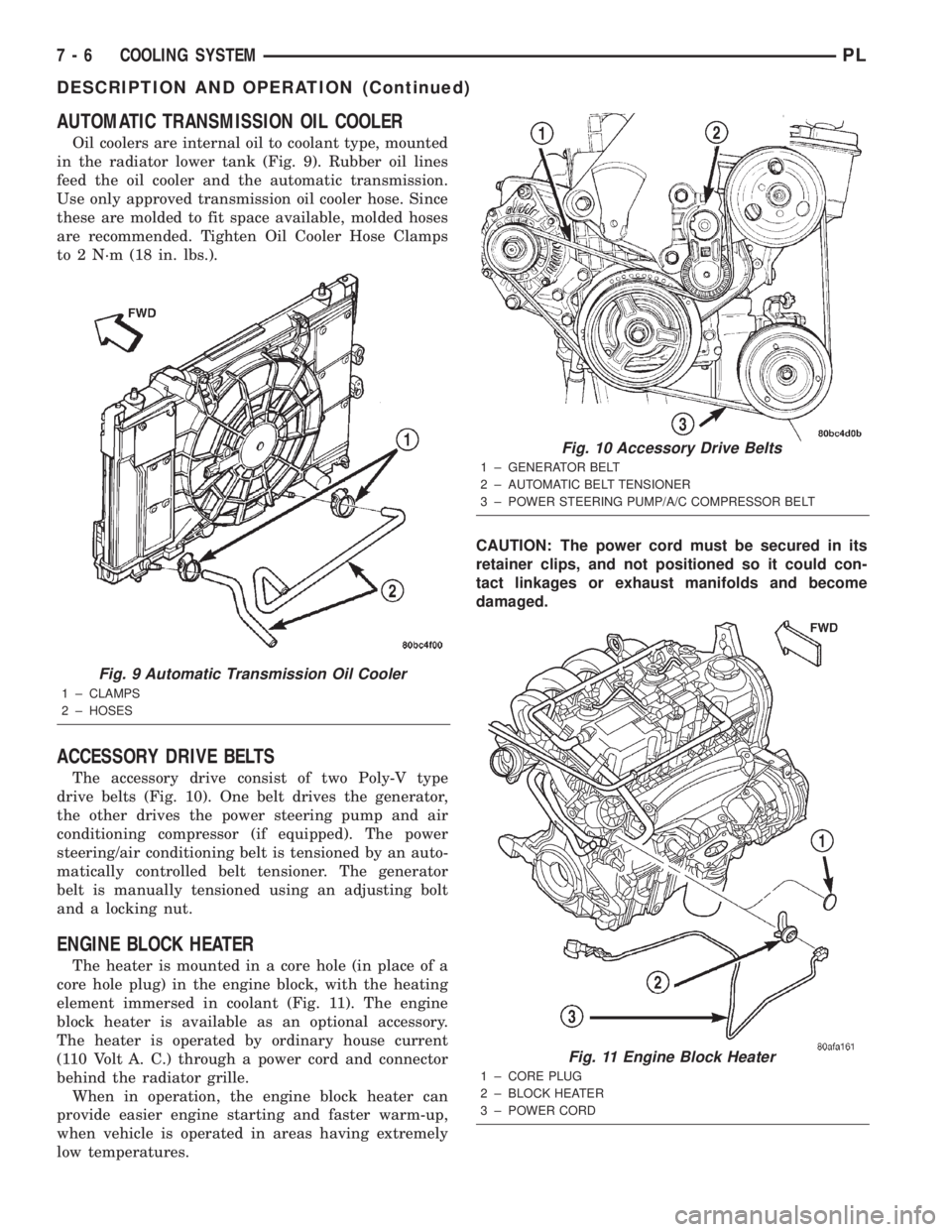

ACCESSORY DRIVE BELTS

The accessory drive consist of two Poly-V type

drive belts (Fig. 10). One belt drives the generator,

the other drives the power steering pump and air

conditioning compressor (if equipped). The power

steering/air conditioning belt is tensioned by an auto-

matically controlled belt tensioner. The generator

belt is manually tensioned using an adjusting bolt

and a locking nut.

ENGINE BLOCK HEATER

The heater is mounted in a core hole (in place of a

core hole plug) in the engine block, with the heating

element immersed in coolant (Fig. 11). The engine

block heater is available as an optional accessory.

The heater is operated by ordinary house current

(110 Volt A. C.) through a power cord and connector

behind the radiator grille.

When in operation, the engine block heater can

provide easier engine starting and faster warm-up,

when vehicle is operated in areas having extremely

low temperatures.CAUTION: The power cord must be secured in its

retainer clips, and not positioned so it could con-

tact linkages or exhaust manifolds and become

damaged.

Fig. 9 Automatic Transmission Oil Cooler

1 ± CLAMPS

2 ± HOSES

Fig. 10 Accessory Drive Belts

1 ± GENERATOR BELT

2 ± AUTOMATIC BELT TENSIONER

3 ± POWER STEERING PUMP/A/C COMPRESSOR BELT

Fig. 11 Engine Block Heater

1 ± CORE PLUG

2 ± BLOCK HEATER

3 ± POWER CORD

7 - 6 COOLING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 186 of 1285

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS

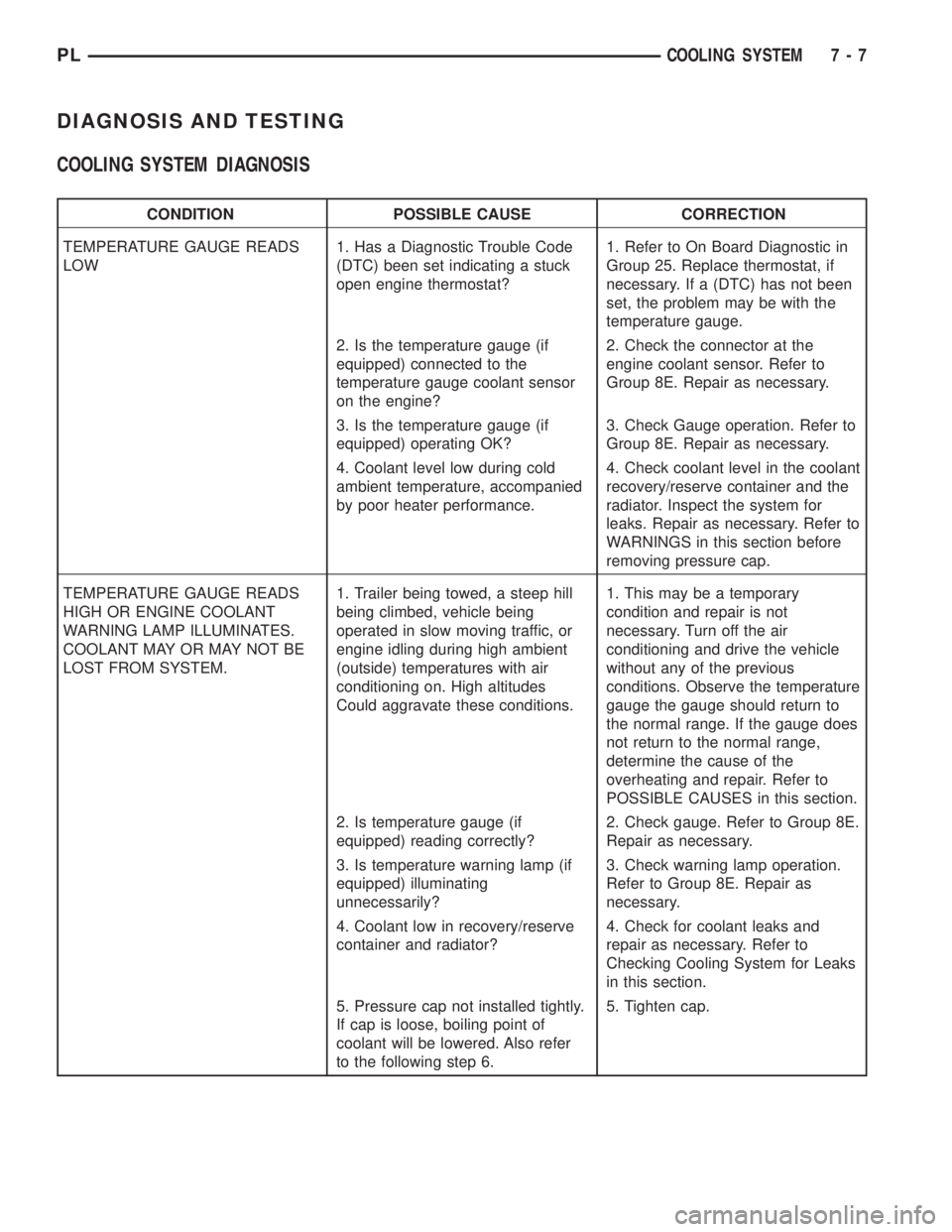

CONDITION POSSIBLE CAUSE CORRECTION

TEMPERATURE GAUGE READS

LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open engine thermostat?1. Refer to On Board Diagnostic in

Group 25. Replace thermostat, if

necessary. If a (DTC) has not been

set, the problem may be with the

temperature gauge.

2. Is the temperature gauge (if

equipped) connected to the

temperature gauge coolant sensor

on the engine?2. Check the connector at the

engine coolant sensor. Refer to

Group 8E. Repair as necessary.

3. Is the temperature gauge (if

equipped) operating OK?3. Check Gauge operation. Refer to

Group 8E. Repair as necessary.

4. Coolant level low during cold

ambient temperature, accompanied

by poor heater performance.4. Check coolant level in the coolant

recovery/reserve container and the

radiator. Inspect the system for

leaks. Repair as necessary. Refer to

WARNINGS in this section before

removing pressure cap.

TEMPERATURE GAUGE READS

HIGH OR ENGINE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST FROM SYSTEM.1. Trailer being towed, a steep hill

being climbed, vehicle being

operated in slow moving traffic, or

engine idling during high ambient

(outside) temperatures with air

conditioning on. High altitudes

Could aggravate these conditions.1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and drive the vehicle

without any of the previous

conditions. Observe the temperature

gauge the gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause of the

overheating and repair. Refer to

POSSIBLE CAUSES in this section.

2. Is temperature gauge (if

equipped) reading correctly?2. Check gauge. Refer to Group 8E.

Repair as necessary.

3. Is temperature warning lamp (if

equipped) illuminating

unnecessarily?3. Check warning lamp operation.

Refer to Group 8E. Repair as

necessary.

4. Coolant low in recovery/reserve

container and radiator?4. Check for coolant leaks and

repair as necessary. Refer to

Checking Cooling System for Leaks

in this section.

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following step 6.5. Tighten cap.

PLCOOLING SYSTEM 7 - 7

Page 187 of 1285

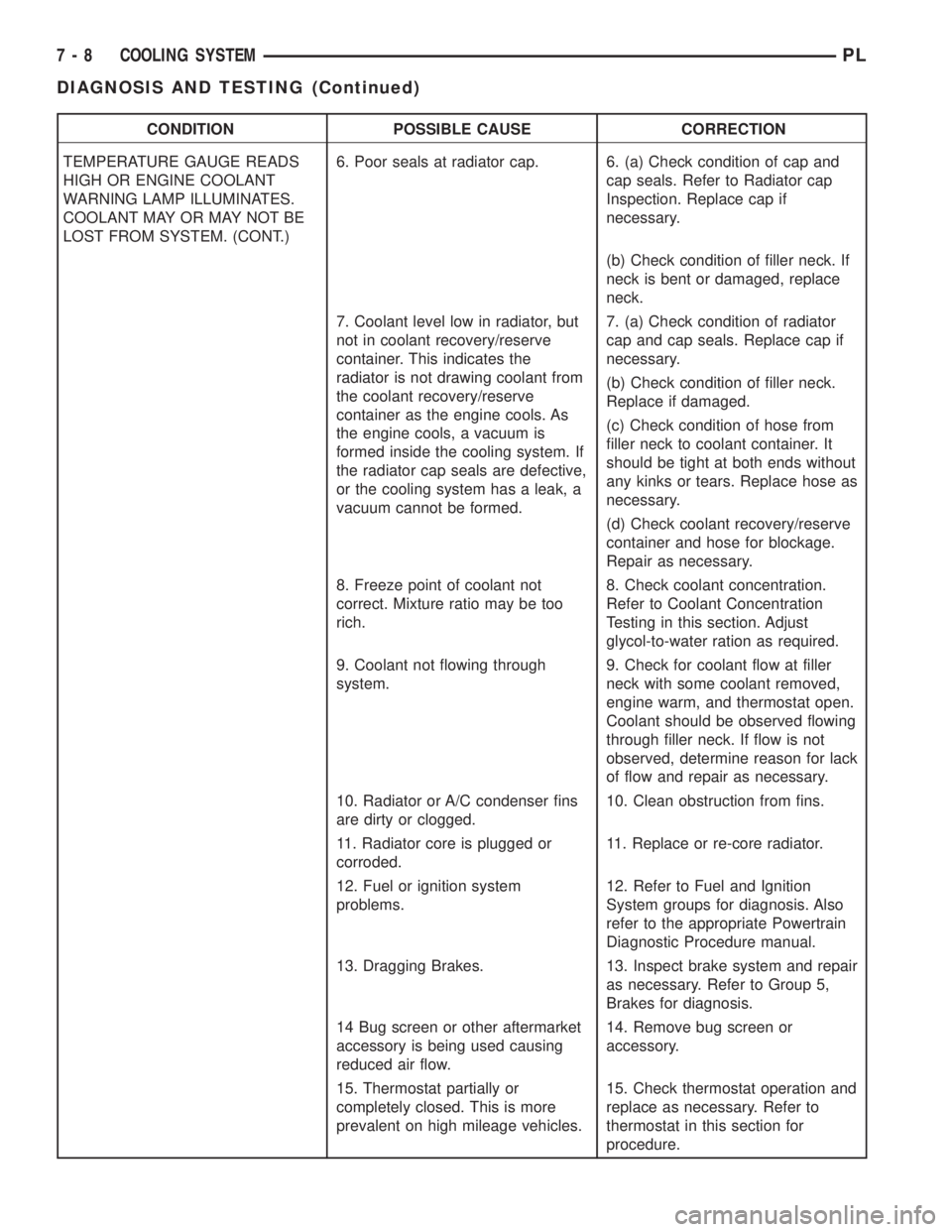

CONDITION POSSIBLE CAUSE CORRECTION

TEMPERATURE GAUGE READS

HIGH OR ENGINE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST FROM SYSTEM. (CONT.)6. Poor seals at radiator cap. 6. (a) Check condition of cap and

cap seals. Refer to Radiator cap

Inspection. Replace cap if

necessary.

(b) Check condition of filler neck. If

neck is bent or damaged, replace

neck.

7. Coolant level low in radiator, but

not in coolant recovery/reserve

container. This indicates the

radiator is not drawing coolant from

the coolant recovery/reserve

container as the engine cools. As

the engine cools, a vacuum is

formed inside the cooling system. If

the radiator cap seals are defective,

or the cooling system has a leak, a

vacuum cannot be formed.7. (a) Check condition of radiator

cap and cap seals. Replace cap if

necessary.

(b) Check condition of filler neck.

Replace if damaged.

(c) Check condition of hose from

filler neck to coolant container. It

should be tight at both ends without

any kinks or tears. Replace hose as

necessary.

(d) Check coolant recovery/reserve

container and hose for blockage.

Repair as necessary.

8. Freeze point of coolant not

correct. Mixture ratio may be too

rich.8. Check coolant concentration.

Refer to Coolant Concentration

Testing in this section. Adjust

glycol-to-water ration as required.

9. Coolant not flowing through

system.9. Check for coolant flow at filler

neck with some coolant removed,

engine warm, and thermostat open.

Coolant should be observed flowing

through filler neck. If flow is not

observed, determine reason for lack

of flow and repair as necessary.

10. Radiator or A/C condenser fins

are dirty or clogged.10. Clean obstruction from fins.

11. Radiator core is plugged or

corroded.11. Replace or re-core radiator.

12. Fuel or ignition system

problems.12. Refer to Fuel and Ignition

System groups for diagnosis. Also

refer to the appropriate Powertrain

Diagnostic Procedure manual.

13. Dragging Brakes. 13. Inspect brake system and repair

as necessary. Refer to Group 5,

Brakes for diagnosis.

14 Bug screen or other aftermarket

accessory is being used causing

reduced air flow.14. Remove bug screen or

accessory.

15. Thermostat partially or

completely closed. This is more

prevalent on high mileage vehicles.15. Check thermostat operation and

replace as necessary. Refer to

thermostat in this section for

procedure.

7 - 8 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)