air conditioning DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 204 of 1285

GENERATOR BELT

REMOVAL

(1) Remove power steering pump/air conditioning

compressor drive belt.

(2) Loosen pivot bolt, then locking nut and adjust-

ing bolt (Fig. 36).

(3) Remove generator belt.

NOTE: When installing drive belt onto pulleys,

make sure that belt is properly routed and all

V-grooves make proper contact with pulley grooves.

INSTALLATION

(1) Install belt and/or adjust belt tension by tight-

ening adjusting bolt. Adjust belt to specification

shown in Belt Tension Chart.

NOTE: Due to space limitations, the use of a belt

tension gauge is limited. Therefore, measure the

belt deflection at the center span of the generator

belt. Refer to Belt Tension Chart for specifications.

(2) Tighten pivot bolt to 54 N´m (40 ft. lbs.) and

locking nut to 54 N´m (40 ft. lbs.) (Fig. 36).

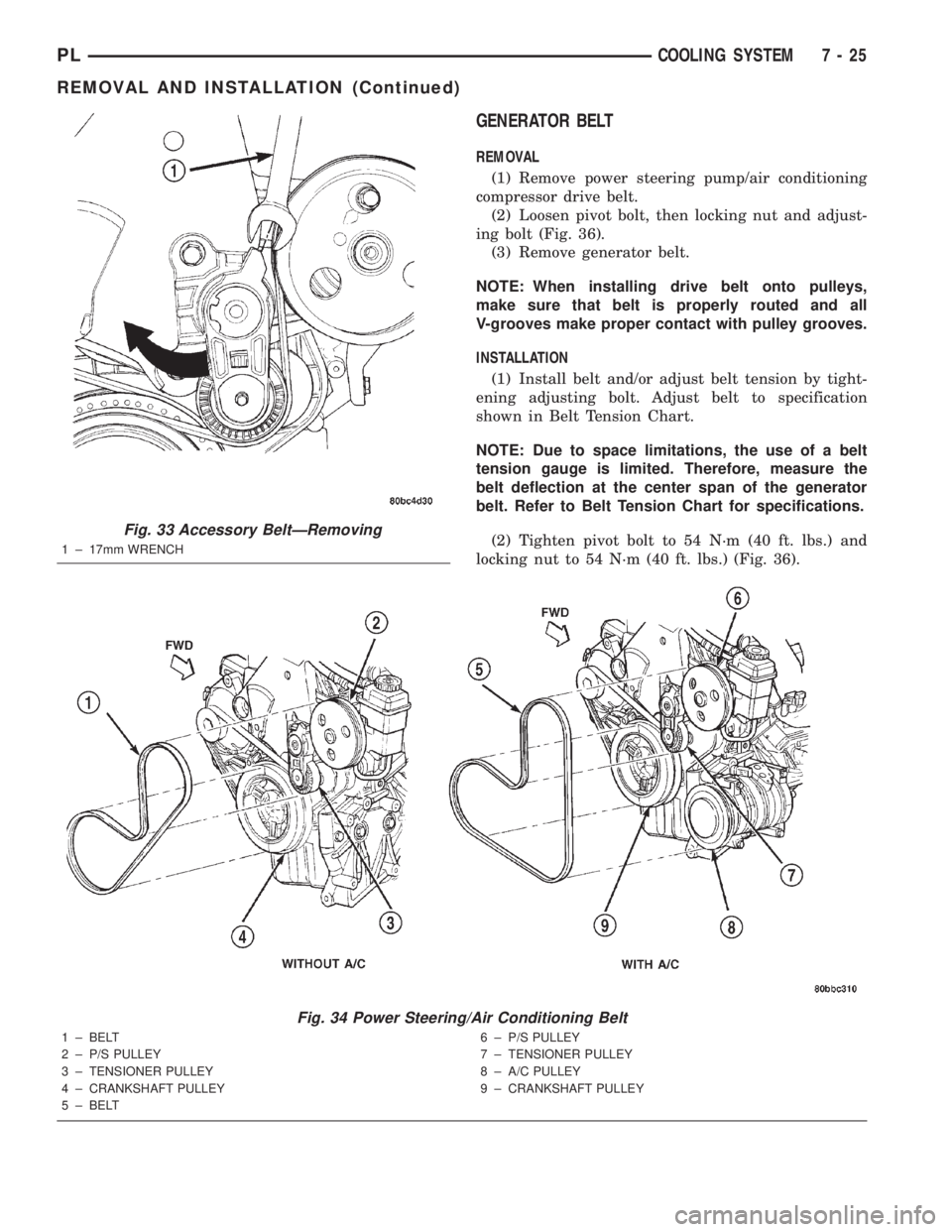

Fig. 33 Accessory BeltÐRemoving

1 ± 17mm WRENCH

Fig. 34 Power Steering/Air Conditioning Belt

1 ± BELT

2 ± P/S PULLEY

3 ± TENSIONER PULLEY

4 ± CRANKSHAFT PULLEY

5 ± BELT6 ± P/S PULLEY

7 ± TENSIONER PULLEY

8 ± A/C PULLEY

9 ± CRANKSHAFT PULLEY

PLCOOLING SYSTEM 7 - 25

REMOVAL AND INSTALLATION (Continued)

Page 392 of 1285

WIRING DIAGRAMS

TABLE OF CONTENTS

page page

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

ANTI-LOCK BRAKES.................. 8W-35-1

AUDIO SYSTEM..................... 8W-47-1

CHARGING SYSTEM.................. 8W-20-1

COMPONENT INDEX.................. 8W-02-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND LOCATIONS...... 8W-90-1

FRONT LIGHTING.................... 8W-50-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

FUSE BLOCK........................ 8W-11-1

GENERAL INFORMATION.............. 8W-01-1

GROUND DISTRIBUTION.............. 8W-15-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

INSTRUMENT CLUSTER............... 8W-40-1INTERIOR LIGHTING.................. 8W-44-1

POWER DISTRIBUTION............... 8W-10-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SUNROOF................... 8W-64-1

POWER WINDOWS................... 8W-60-1

REAR LIGHTING..................... 8W-51-1

REAR WINDOW DEFOGGER............ 8W-48-1

SPLICE INFORMATION................ 8W-70-1

SPLICE LOCATIONS.................. 8W-95-1

STARTING SYSTEM.................. 8W-21-1

TURN SIGNALS...................... 8W-52-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

WIPERS............................ 8W-53-1

PLWIRING DIAGRAMS 8W - 1

Page 526 of 1285

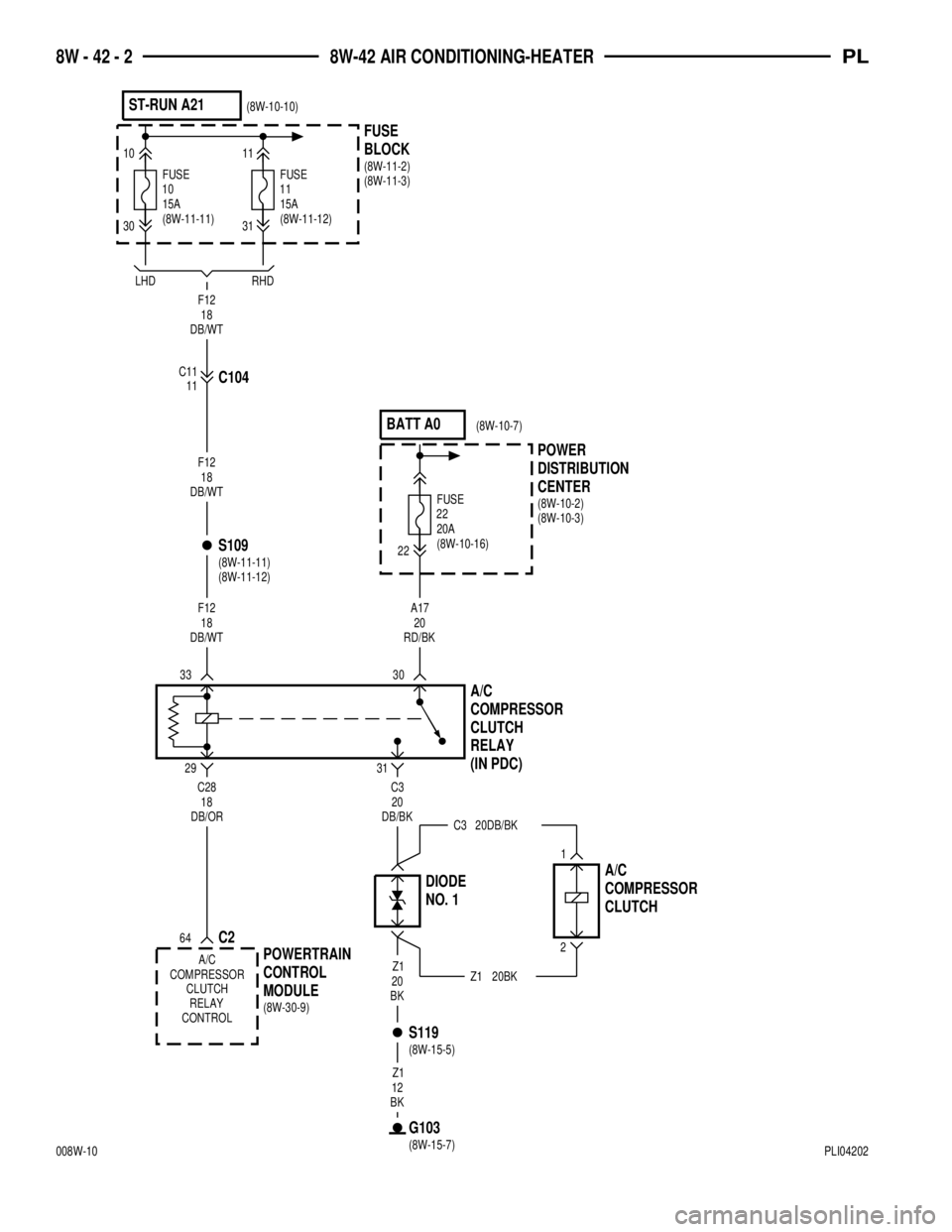

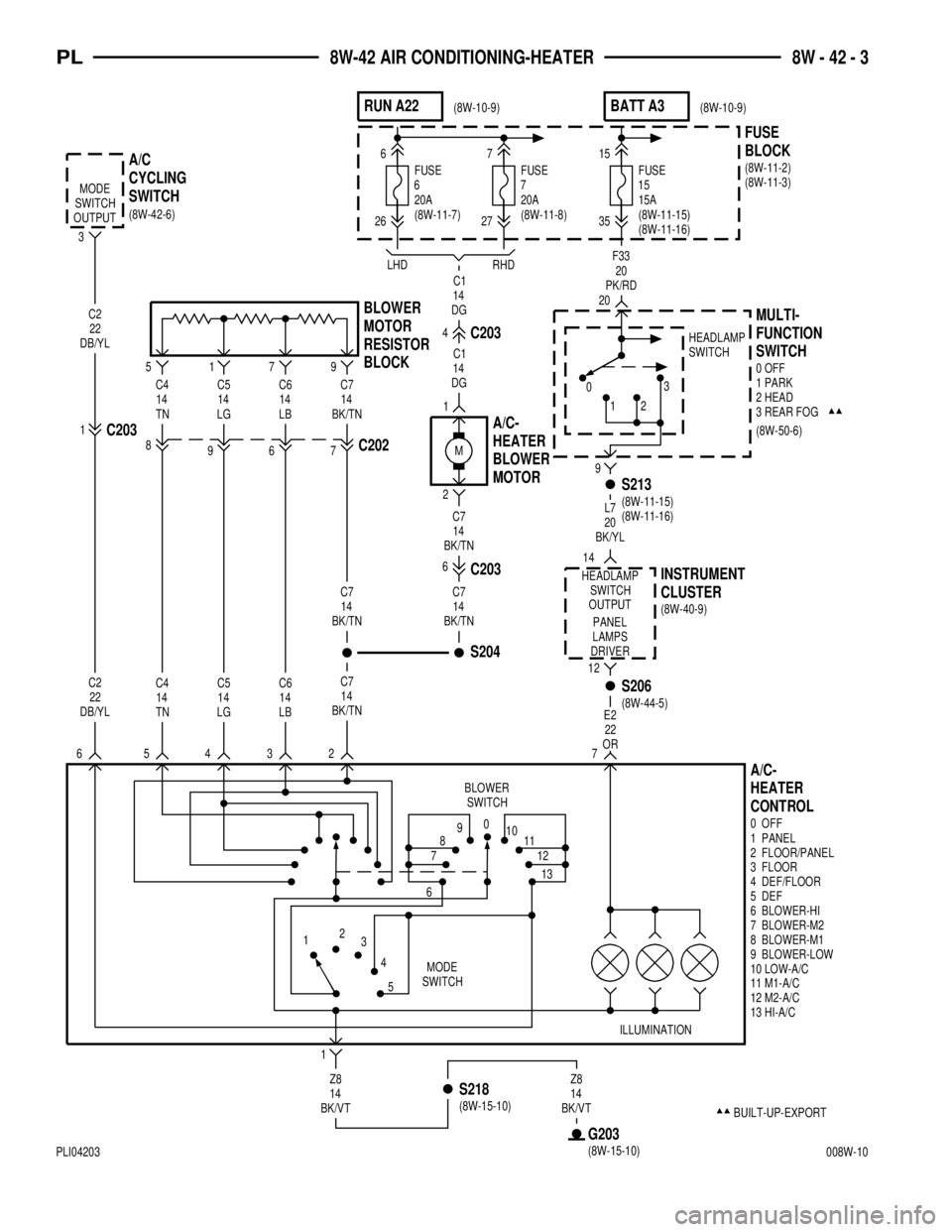

8W-42 AIR CONDITIONING-HEATER

Component Page

A/C Compressor Clutch................8W-42-2

A/C Compressor Clutch Relay...........8W-42-2

A/C Cycling Switch...............8W-42-3, 5, 6

A/C High Pressure Switch.............8W-42-5

A/C Low Pressure Switch............8W-42-5, 6

A/C Heater Blower Motor............8W-42-3, 4

A/C Heater Control...............8W-42-3, 4, 6

Blower Motor Resistor Block..........8W-42-3, 4

Diode No. 1.........................8W-42-2

Fuse 6 (FB).....................8W-42-3, 4, 6

Fuse 6 (PDC).......................8W-42-5

Fuse 7 (FB).....................8W-42-3, 4, 6

Fuse 10 (FB)......................8W-42-2, 5Component Page

Fuse 11 (FB)......................8W-42-2, 5

Fuse 15 (FB)......................8W-42-3, 4

Fuse 22 (PDC)......................8W-42-2

Fuse Block..................8W-42-2, 3, 4, 5, 6

G103............................8W-42-2, 5

G203............................8W-42-3, 4

Instrument Cluster.................8W-42-3, 4

Multi-Function Switch..............8W-42-3, 4

Power Distribution Center...........8W-42-2, 5

Powertrain Control Module...........8W-42-2, 5

Radiator Fan Motor..................8W-42-5

Radiator Fan Relay...................8W-42-5

PL8W - 42 AIR CONDITIONING-HEATER 8W - 42 - 1

Page 527 of 1285

22

29 31

3033

POWER

DISTRIBUTION

CENTER

15A

FUSE

10

10

30BLOCK FUSE

F12

18

DB/WT

F12

18

DB/WT

F12

18

DB/WT

Z1

20

BK

G103CLUTCH COMPRESSOR

A/C

C2

64

POWERTRAIN

CONTROL

MODULE S109

C28

18

DB/OR

A/C

COMPRESSOR

CLUTCH

RELAY

CONTROL

ST-RUN A21

20A

FUSE

22

1

2

DIODE

C3 20DB/BK

20BK Z1

DB/BK20 C3

NO. 1

11C104

Z1

12

BK

S119

31 11

11FUSE15A

LHD RHD

A/C

COMPRESSOR

CLUTCH

RELAY

(IN PDC)

A17

20

RD/BK

C11

BATT A0

(8W-10-2)

(8W-10-3) (8W-11-11)(8W-11-2)

(8W-11-3)

(8W-15-7) (8W-30-9) (8W-11-11)

(8W-11-12)(8W-10-16) (8W-10-10)

(8W-15-5) (8W-11-12)

(8W-10-7)

8W - 42 - 2 8W-42 AIR CONDITIONING-HEATERPL

008W-10PLI04202

Page 528 of 1285

C4

14

TNC5

14

LGC6

14

LBC7

14

BK/TN

BLOCK RESISTOR

MOTOR

BLOWER

C2

22

DB/YL

C2

22

DB/YL1

C203

S204

6

26

20A

FUSE

6

BLOCK FUSE

C1

14

DG

C7

14

BK/TN 4

C203

6C203

1

2

5179

SWITCH

OUTPUT

MOTOR BLOWER

HEATER

A/C-

M

F33

20

PK/RD

13 HI-A/C 12 M2-A/C

11 M1-A/C

10 LOW-A/C

9 BLOWER-LOW

8 BLOWER-M1

7 BLOWER-M2

6 BLOWER-HI

5 DEF

4 DEF/FLOOR 1 PANEL 0 OFF

2 FLOOR/PANEL

3 FLOOR

ILLUMINATION

A/C-

HEATER

CONTROL

9

60

10

11

12

13

12

3

4

5MODE

SWITCH

SWITCH BLOWER

73 4 5

1

26

3MODE

15FUSE15A

35 15

RUN A22BATT A3

20

9

C2027698

C5

14

LG

SWITCH CYCLING

A/C

C4

14

TNC6

14

LBC7

14

BK/TN

12 14

CLUSTER INSTRUMENT

L7

20

BK/YL

E2

22

OR

S206

C7

14

BK/TNC7

14

BK/TN

Z8

14

BK/VTZ8

14

BK/VTS218

DG14C1

G203

HEADLAMP

SWITCH

OUTPUT

PANEL

LAMPS

DRIVER

S213

7FUSE20A

277

RHD LHD

8

7

MULTI-

FUNCTION

SWITCH

HEADLAMP

SWITCH

3

2 1 0

3 REAR FOG 2 HEAD

1 PARK

0 OFF

BUILT-UP-EXPORT

(8W-11-2)

(8W-11-3)

(8W-11-7) (8W-11-15)

(8W-11-16) (8W-10-9) (8W-10-9)

(8W-42-6)

(8W-40-9)

(8W-44-5)

(8W-15-10)

(8W-15-10)

(8W-11-15)

(8W-11-16) (8W-11-8)

(8W-50-6)

PL8W-42 AIR CONDITIONING-HEATER 8W - 42 - 3

PLI04203008W-10

Page 529 of 1285

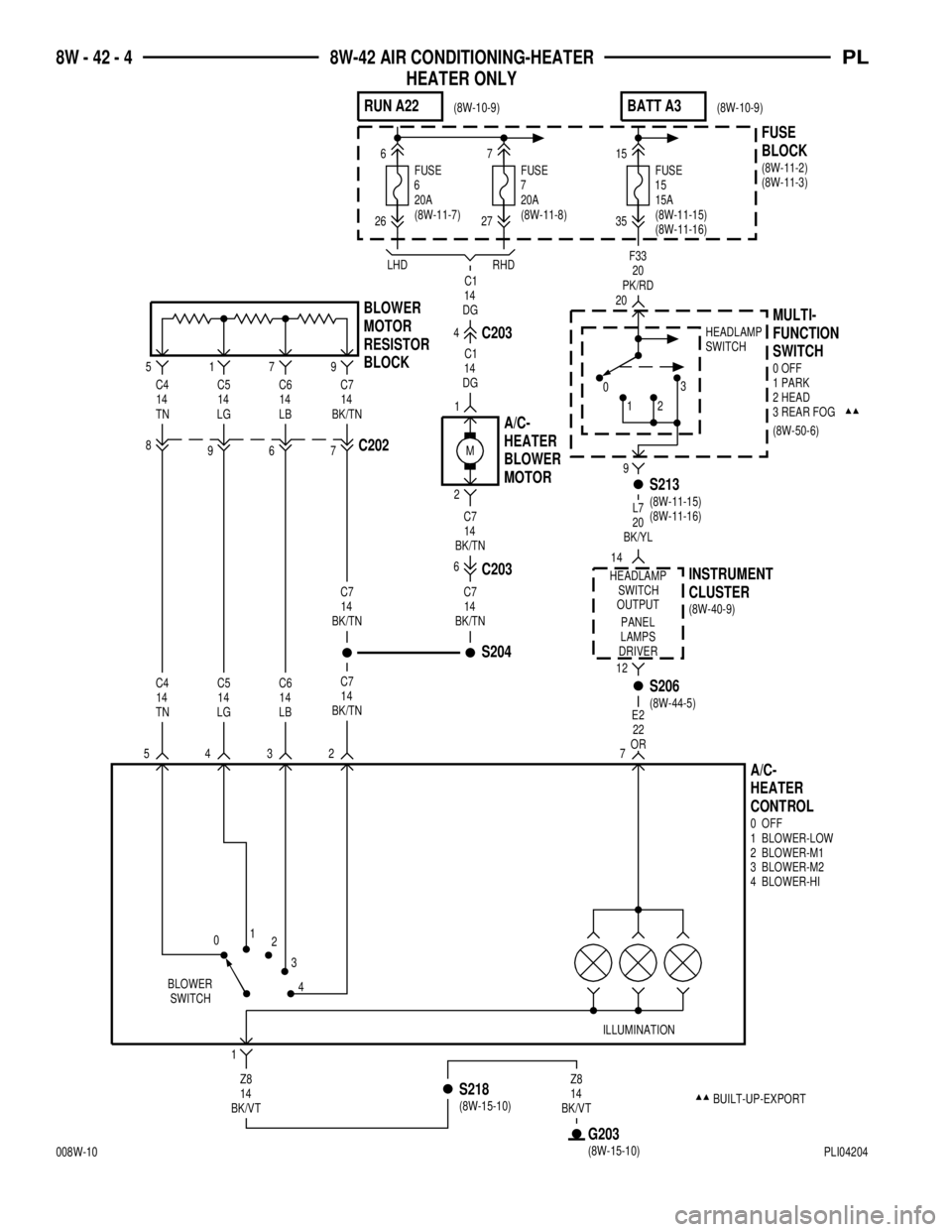

C4

14

TNC5

14

LGC6

14

LBC7

14

BK/TN

BLOCK RESISTOR

MOTOR

BLOWER

S204

6

26

20A

FUSE

6

BLOCK FUSE

C1

14

DG

C7

14

BK/TN 4

C203

6C203

1

2

5179

MOTOR BLOWER

HEATER

A/C-

M

4 BLOWER-HI 1 BLOWER-LOW 0 OFF

2 BLOWER-M1

3 BLOWER-M2

ILLUMINATION

A/C-

HEATER

CONTROL

01

2

3

4

SWITCH BLOWER

3 4 5

1

2

15FUSE15A

35 15

RUN A22BATT A3

C2027698

C5

14

LGC4

14

TNC6

14

LBC7

14

BK/TN

C7

14

BK/TNC7

14

BK/TN

Z8

14

BK/VTZ8

14

BK/VTS218

DG14C1

G203

7FUSE20A

277

RHD LHD

0 OFF

1 PARK

2 HEAD

3 REAR FOG

0

123

SWITCH HEADLAMPSWITCH

FUNCTION

MULTI-

S213

DRIVERLAMPSPANEL OUTPUTSWITCH HEADLAMP

S206

OR22 E2

BK/YL20 L7

INSTRUMENT

CLUSTER

14

12

9 20

7PK/RD20 F33

BUILT-UP-EXPORT

(8W-11-2)

(8W-11-3)

(8W-11-7) (8W-11-15)

(8W-11-16) (8W-10-9) (8W-10-9)

(8W-15-10)

(8W-15-10)

(8W-11-8)

(8W-50-6)

(8W-11-15)

(8W-11-16)

(8W-44-5)(8W-40-9)

8W - 42 - 4 8W-42 AIR CONDITIONING-HEATER

HEATER ONLYPL

008W-10PLI04204

Page 530 of 1285

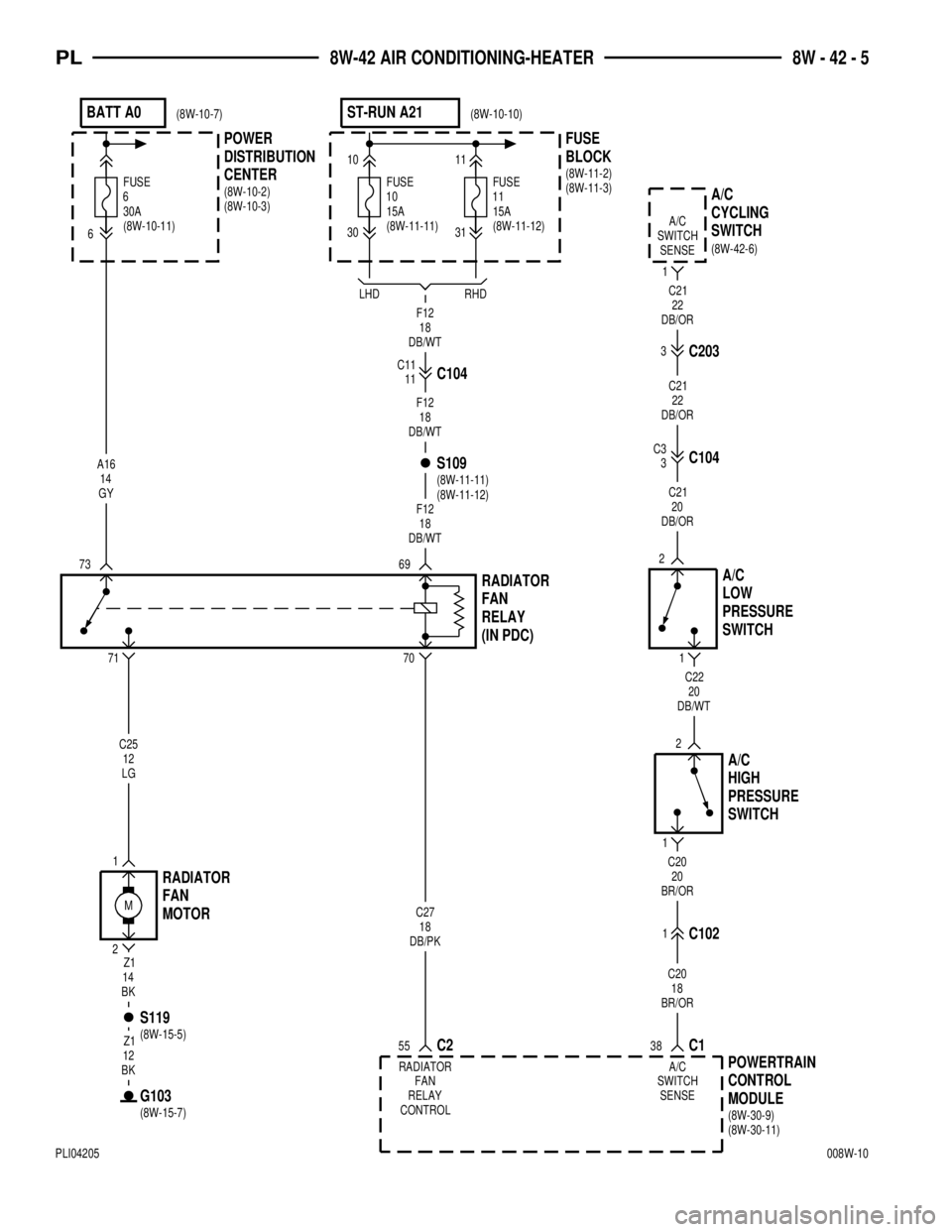

BATT A0

30A

FUSE

6

70

71

6973

6

1

2

M

G103

S119

Z1

12

BK

Z1

14

BK

POWER

DISTRIBUTION

CENTER

10

30

15A

FUSE

10

BLOCK FUSE

C10411

S109

(IN PDC) RELAY

FAN

RADIATOR

5538C2 C1

2

1

SWITCH PRESSURE

HIGH

A/C

1 2

A/C

LOW

PRESSURE

SWITCH

1

A/C

SWITCH

SENSESWITCH CYCLING

A/C

1C102

C1043

C2033

C20

18

BR/OR

C20

20

BR/OR

C22

20

DB/WT

C21

20

DB/OR

C21

22

DB/OR

C21

22

DB/OR

C27

18

DB/PK

F12

18

DB/WT

F12

18

DB/WT

F12

18

DB/WT

A16

14

GY

POWERTRAIN

CONTROL

MODULERADIATOR

FAN

RELAY

CONTROLA/C

SWITCH

SENSE

MOTOR FAN

RADIATOR

C11

C3 11FUSE

15A

31 11

RHD LHD

ST-RUN A21

LG12 C25(8W-10-7)

(8W-10-11)

(8W-15-7) (8W-15-5)(8W-10-2)

(8W-10-3)

(8W-11-11)(8W-11-2)

(8W-11-3)

(8W-11-11)

(8W-11-12)(8W-42-6)

(8W-30-9)

(8W-30-11) (8W-11-12) (8W-10-10)

PL8W-42 AIR CONDITIONING-HEATER 8W - 42 - 5

PLI04205008W-10

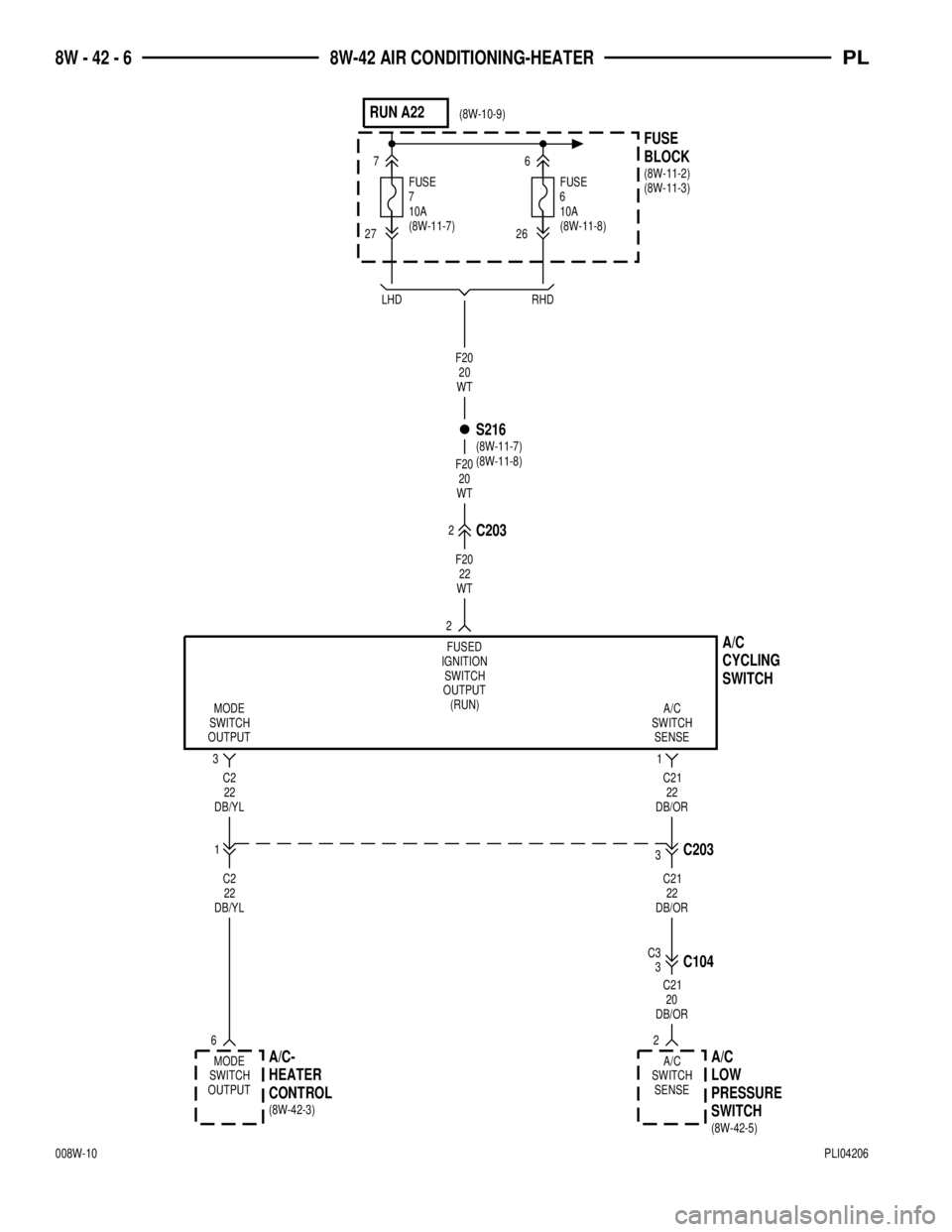

Page 531 of 1285

10A

FUSE

7 7

27

RUN A22

266

6FUSE

10A

FUSE

BLOCK

321

2

6

2C203

1C2033

C1043

MODE

SWITCH

OUTPUTA/C

SWITCH

SENSE

S216

OUTPUTSWITCHMODE

SENSE SWITCHA/C FUSED

IGNITION

SWITCH

OUTPUT

(RUN) LHD RHD

F20

20

WT

F20

20

WT

F20

22

WT

C2

22

DB/YL

C2

22

DB/YL

C21

22

DB/OR

C21

22

DB/OR

C21

20

DB/OR

A/C-

HEATER

CONTROL

SWITCH PRESSURE

LOW

A/CSWITCH CYCLING

A/C

C3 (8W-11-7)(8W-10-9)

(8W-11-8)(8W-11-2)

(8W-11-3)

(8W-11-7)

(8W-11-8)

(8W-42-3)

(8W-42-5)

8W - 42 - 6 8W-42 AIR CONDITIONING-HEATERPL

008W-10PLI04206

Page 747 of 1285

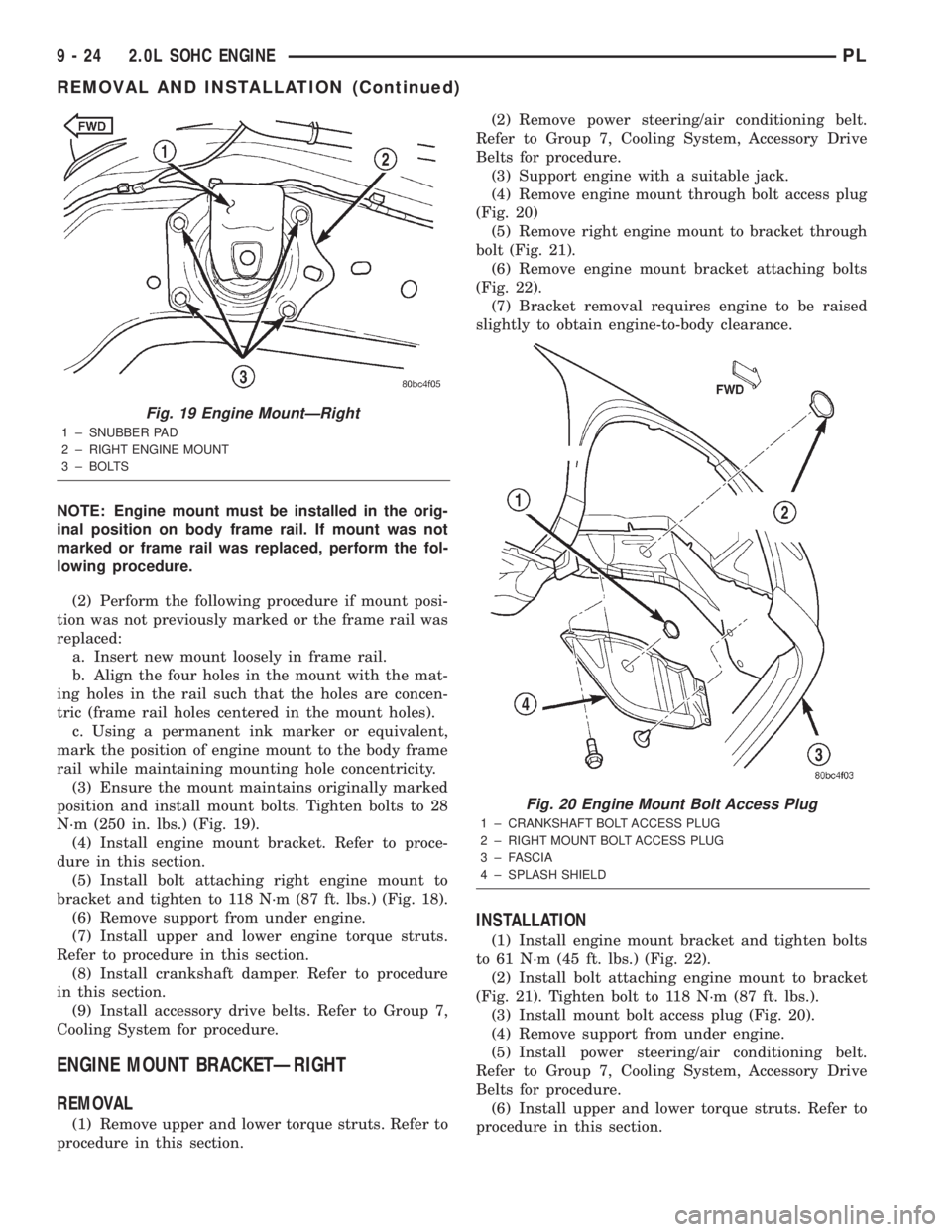

NOTE: Engine mount must be installed in the orig-

inal position on body frame rail. If mount was not

marked or frame rail was replaced, perform the fol-

lowing procedure.

(2) Perform the following procedure if mount posi-

tion was not previously marked or the frame rail was

replaced:

a. Insert new mount loosely in frame rail.

b. Align the four holes in the mount with the mat-

ing holes in the rail such that the holes are concen-

tric (frame rail holes centered in the mount holes).

c. Using a permanent ink marker or equivalent,

mark the position of engine mount to the body frame

rail while maintaining mounting hole concentricity.

(3) Ensure the mount maintains originally marked

position and install mount bolts. Tighten bolts to 28

N´m (250 in. lbs.) (Fig. 19).

(4) Install engine mount bracket. Refer to proce-

dure in this section.

(5) Install bolt attaching right engine mount to

bracket and tighten to 118 N´m (87 ft. lbs.) (Fig. 18).

(6) Remove support from under engine.

(7) Install upper and lower engine torque struts.

Refer to procedure in this section.

(8) Install crankshaft damper. Refer to procedure

in this section.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System for procedure.

ENGINE MOUNT BRACKETÐRIGHT

REMOVAL

(1) Remove upper and lower torque struts. Refer to

procedure in this section.(2) Remove power steering/air conditioning belt.

Refer to Group 7, Cooling System, Accessory Drive

Belts for procedure.

(3) Support engine with a suitable jack.

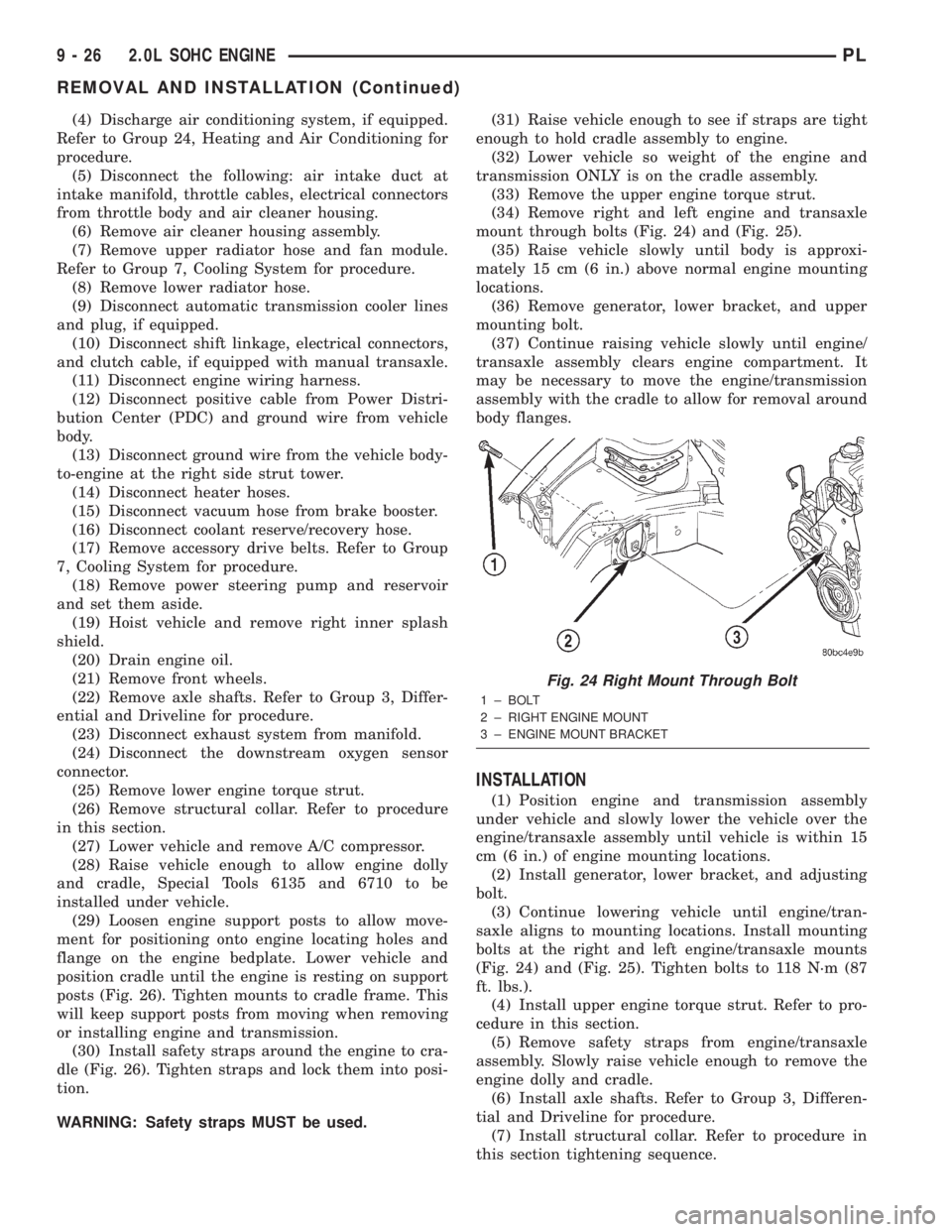

(4) Remove engine mount through bolt access plug

(Fig. 20)

(5) Remove right engine mount to bracket through

bolt (Fig. 21).

(6) Remove engine mount bracket attaching bolts

(Fig. 22).

(7) Bracket removal requires engine to be raised

slightly to obtain engine-to-body clearance.

INSTALLATION

(1) Install engine mount bracket and tighten bolts

to 61 N´m (45 ft. lbs.) (Fig. 22).

(2) Install bolt attaching engine mount to bracket

(Fig. 21). Tighten bolt to 118 N´m (87 ft. lbs.).

(3) Install mount bolt access plug (Fig. 20).

(4) Remove support from under engine.

(5) Install power steering/air conditioning belt.

Refer to Group 7, Cooling System, Accessory Drive

Belts for procedure.

(6) Install upper and lower torque struts. Refer to

procedure in this section.

Fig. 19 Engine MountÐRight

1 ± SNUBBER PAD

2 ± RIGHT ENGINE MOUNT

3 ± BOLTS

Fig. 20 Engine Mount Bolt Access Plug

1 ± CRANKSHAFT BOLT ACCESS PLUG

2 ± RIGHT MOUNT BOLT ACCESS PLUG

3 ± FASCIA

4 ± SPLASH SHIELD

9 - 24 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 749 of 1285

(4) Discharge air conditioning system, if equipped.

Refer to Group 24, Heating and Air Conditioning for

procedure.

(5) Disconnect the following: air intake duct at

intake manifold, throttle cables, electrical connectors

from throttle body and air cleaner housing.

(6) Remove air cleaner housing assembly.

(7) Remove upper radiator hose and fan module.

Refer to Group 7, Cooling System for procedure.

(8) Remove lower radiator hose.

(9) Disconnect automatic transmission cooler lines

and plug, if equipped.

(10) Disconnect shift linkage, electrical connectors,

and clutch cable, if equipped with manual transaxle.

(11) Disconnect engine wiring harness.

(12) Disconnect positive cable from Power Distri-

bution Center (PDC) and ground wire from vehicle

body.

(13) Disconnect ground wire from the vehicle body-

to-engine at the right side strut tower.

(14) Disconnect heater hoses.

(15) Disconnect vacuum hose from brake booster.

(16) Disconnect coolant reserve/recovery hose.

(17) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(18) Remove power steering pump and reservoir

and set them aside.

(19) Hoist vehicle and remove right inner splash

shield.

(20) Drain engine oil.

(21) Remove front wheels.

(22) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(23) Disconnect exhaust system from manifold.

(24) Disconnect the downstream oxygen sensor

connector.

(25) Remove lower engine torque strut.

(26) Remove structural collar. Refer to procedure

in this section.

(27) Lower vehicle and remove A/C compressor.

(28) Raise vehicle enough to allow engine dolly

and cradle, Special Tools 6135 and 6710 to be

installed under vehicle.

(29) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 26). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(30) Install safety straps around the engine to cra-

dle (Fig. 26). Tighten straps and lock them into posi-

tion.

WARNING: Safety straps MUST be used.(31) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(32) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(33) Remove the upper engine torque strut.

(34) Remove right and left engine and transaxle

mount through bolts (Fig. 24) and (Fig. 25).

(35) Raise vehicle slowly until body is approxi-

mately 15 cm (6 in.) above normal engine mounting

locations.

(36) Remove generator, lower bracket, and upper

mounting bolt.

(37) Continue raising vehicle slowly until engine/

transaxle assembly clears engine compartment. It

may be necessary to move the engine/transmission

assembly with the cradle to allow for removal around

body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine/transaxle assembly until vehicle is within 15

cm (6 in.) of engine mounting locations.

(2) Install generator, lower bracket, and adjusting

bolt.

(3) Continue lowering vehicle until engine/tran-

saxle aligns to mounting locations. Install mounting

bolts at the right and left engine/transaxle mounts

(Fig. 24) and (Fig. 25). Tighten bolts to 118 N´m (87

ft. lbs.).

(4) Install upper engine torque strut. Refer to pro-

cedure in this section.

(5) Remove safety straps from engine/transaxle

assembly. Slowly raise vehicle enough to remove the

engine dolly and cradle.

(6) Install axle shafts. Refer to Group 3, Differen-

tial and Driveline for procedure.

(7) Install structural collar. Refer to procedure in

this section tightening sequence.

Fig. 24 Right Mount Through Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

9 - 26 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)