ECO mode DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1115 of 1285

The check valves are one-way valves. The first

check valve is used to draw outside air into the lower

chamber of the LDP (the space that is below the

pump diaphragm). The second check valve is used to

vent this outside air, which has become pressurized

from the fall of the pump diaphragm, into the evap-

orative system.

The spring loaded vent seal valve, inside the LDP

is used to seal off the evaporative system. When the

pump diaphragm is in the ªupº position the spring

pushes the vent seal valve closed. The vent seal valve

opens only when the pump diaphragm is in its ªfull

downº position. When the pump assembly is in its

pump mode the pump diaphragm is not allowed to

descend (fall) so far as to allow the vent seal valve to

open. This allows the leak detection pump to develop

the required pressure within the evaporative system

for system leak testing.

A pressure build up within the evaporative system

may cause pressure on the lower side of the LDP dia-

phragm. This will cause the LDP diaphragm to

remain in its ªupº position (stuck in the up position).

This condition can occur even when the solenoid

valve is deenergized. This condition can be caused by

previous cycling (pumping) of the LDP by the techni-

cian (dealer test). Another way that this condition is

created is immediately following the running of the

vehicle evaporative system monitor. In this case, the

PCM has not yet opened the proportional purge sole-

noid in order to vent the pressure that has been built

up in the evaporative system to the engine combus-

tion system. The technician will need to vent the

evaporative system pressure via the vehicle fuel filler

cap and its fuel filler secondary seal (if so equipped

in the fuel filler neck). This will allow the technician

to cycle the LDP and to watch switch state changes.

After passing the leak detection phase of the test,

system pressure is maintained until the purge sys-

tem is activated, in effect creating a leak. If the dia-

phragm falls (as is expected), causing the reed switch

to change state, then the diagnostic test is completed.

When of the evaporative system leak monitor

begins its various tests, a test is performed to deter-

mine that no part of the evaporative system is

blocked. In this test, the LDP is cycled (pumped) a

calibrated (few) number of times. Pressure should not

build up in the evaporative system. If pressure is

present, then LDP diaphragm is forced to stay in its

ªupº position. The reed switch now stays open and

the PCM senses this open (incorrect) state. The evap-

orative system monitor will fail the test because of a

detected obstruction within the system.

Possible causes:

²Open or shorted LDP switch sense circuit

²Leak Detection Pump switch failure²Open fused ignition switch output

²Restricted, disconnected, or blocked manifold

vacuum source

²Obstruction of hoses or lines

²PCM failure

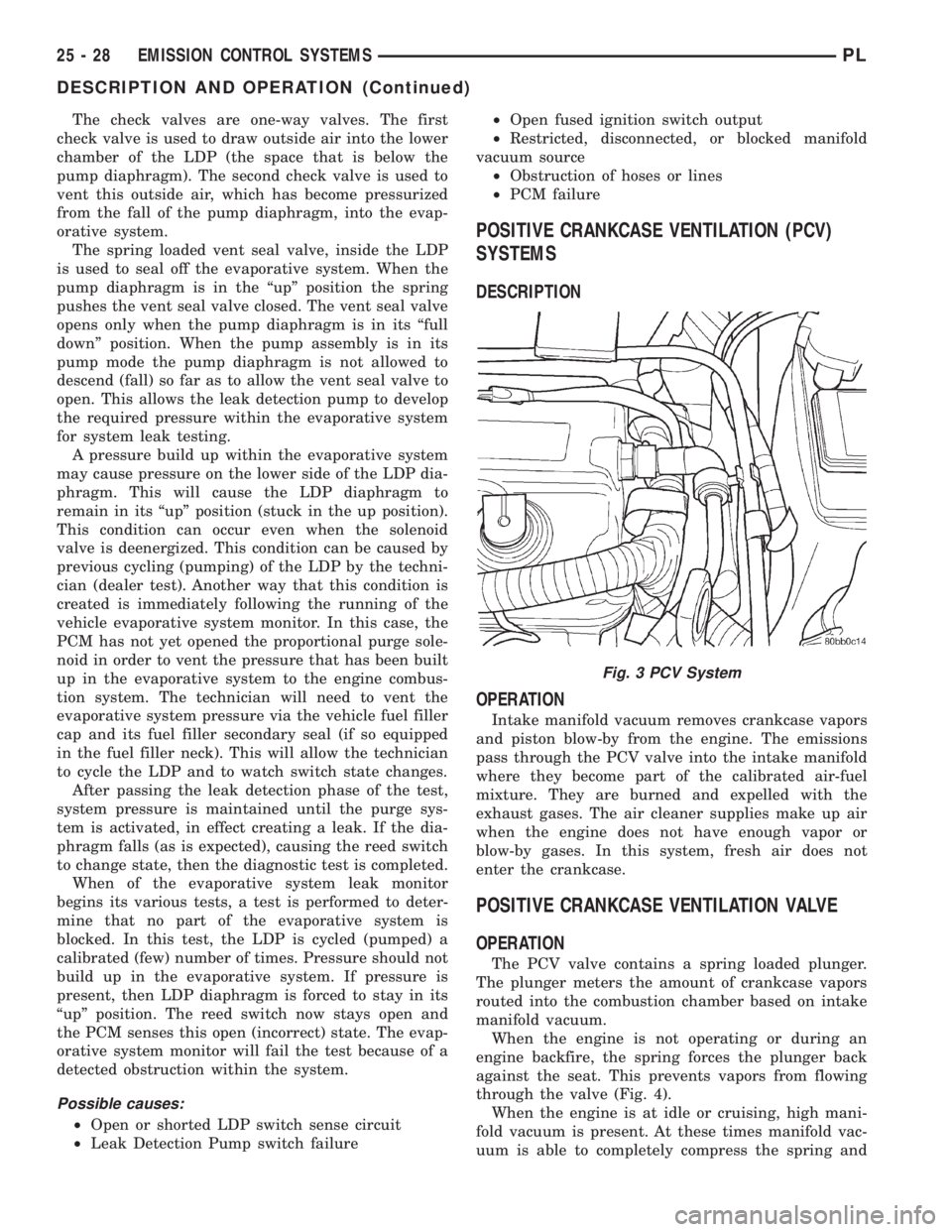

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS

DESCRIPTION

OPERATION

Intake manifold vacuum removes crankcase vapors

and piston blow-by from the engine. The emissions

pass through the PCV valve into the intake manifold

where they become part of the calibrated air-fuel

mixture. They are burned and expelled with the

exhaust gases. The air cleaner supplies make up air

when the engine does not have enough vapor or

blow-by gases. In this system, fresh air does not

enter the crankcase.

POSITIVE CRANKCASE VENTILATION VALVE

OPERATION

The PCV valve contains a spring loaded plunger.

The plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

When the engine is not operating or during an

engine backfire, the spring forces the plunger back

against the seat. This prevents vapors from flowing

through the valve (Fig. 4).

When the engine is at idle or cruising, high mani-

fold vacuum is present. At these times manifold vac-

uum is able to completely compress the spring and

Fig. 3 PCV System

25 - 28 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1245 of 1285

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT

HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

NOTE: The maximum amount of R-134a refrigerant

that the air conditioning system holds is 765 grams

(27 oz. or 1.69 lbs.)

It is recommended to use the gauges or reclaim/re-

cycle equipment.

(1) Use a manifold gauge and check the liquid line

pressure.

(2) Attach a clamp-on thermocouple (P. S. E.

66-324-0014 or 80PK-1A) or equivalent to the liquid

line near the filter/drier.

(3) The vehicle must be in the following modes:

²Automatic transaxle in park or manual tran-

saxle in neutral.

²Engine at idle

²A/C controls set to outside air

²Panel mode

²A/C ON full cool

²Blower motor ON high speed

²Vehicle windows closed

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Observe filter/drier pressure and Liquid line

temperature. Using the Charge Determination Chart

(Fig. 14) determine where the system is currently

operating. If the system is not in the proper range,

reclaim all the refrigerant and recharge per A/C

label.

24 - 14 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)

Page 1247 of 1285

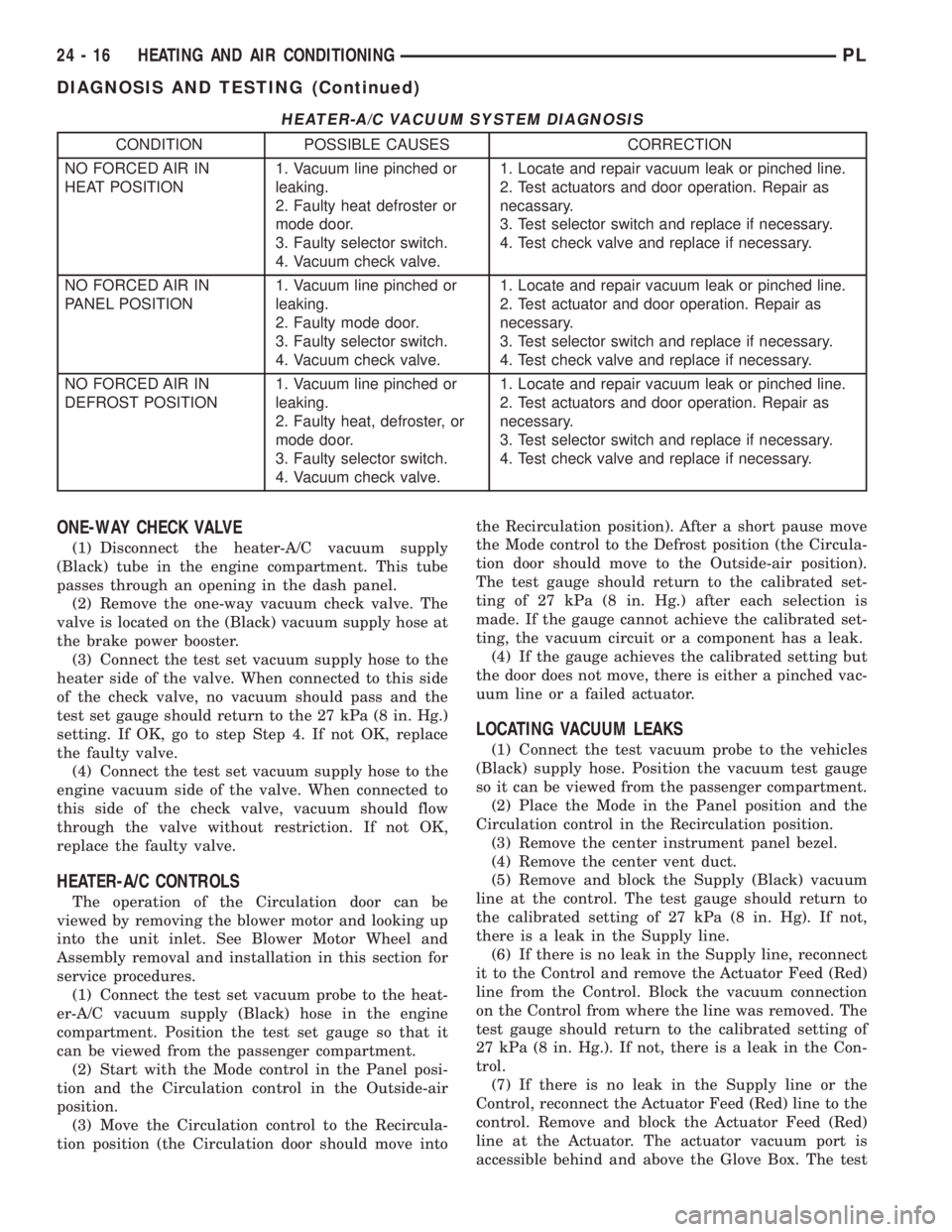

HEATER-A/C VACUUM SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO FORCED AIR IN

HEAT POSITION1. Vacuum line pinched or

leaking.

2. Faulty heat defroster or

mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuators and door operation. Repair as

necassary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

NO FORCED AIR IN

PANEL POSITION1. Vacuum line pinched or

leaking.

2. Faulty mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuator and door operation. Repair as

necessary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

NO FORCED AIR IN

DEFROST POSITION1. Vacuum line pinched or

leaking.

2. Faulty heat, defroster, or

mode door.

3. Faulty selector switch.

4. Vacuum check valve.1. Locate and repair vacuum leak or pinched line.

2. Test actuators and door operation. Repair as

necessary.

3. Test selector switch and replace if necessary.

4. Test check valve and replace if necessary.

ONE-WAY CHECK VALVE

(1) Disconnect the heater-A/C vacuum supply

(Black) tube in the engine compartment. This tube

passes through an opening in the dash panel.

(2) Remove the one-way vacuum check valve. The

valve is located on the (Black) vacuum supply hose at

the brake power booster.

(3) Connect the test set vacuum supply hose to the

heater side of the valve. When connected to this side

of the check valve, no vacuum should pass and the

test set gauge should return to the 27 kPa (8 in. Hg.)

setting. If OK, go to step Step 4. If not OK, replace

the faulty valve.

(4) Connect the test set vacuum supply hose to the

engine vacuum side of the valve. When connected to

this side of the check valve, vacuum should flow

through the valve without restriction. If not OK,

replace the faulty valve.

HEATER-A/C CONTROLS

The operation of the Circulation door can be

viewed by removing the blower motor and looking up

into the unit inlet. See Blower Motor Wheel and

Assembly removal and installation in this section for

service procedures.

(1) Connect the test set vacuum probe to the heat-

er-A/C vacuum supply (Black) hose in the engine

compartment. Position the test set gauge so that it

can be viewed from the passenger compartment.

(2) Start with the Mode control in the Panel posi-

tion and the Circulation control in the Outside-air

position.

(3) Move the Circulation control to the Recircula-

tion position (the Circulation door should move intothe Recirculation position). After a short pause move

the Mode control to the Defrost position (the Circula-

tion door should move to the Outside-air position).

The test gauge should return to the calibrated set-

ting of 27 kPa (8 in. Hg.) after each selection is

made. If the gauge cannot achieve the calibrated set-

ting, the vacuum circuit or a component has a leak.

(4) If the gauge achieves the calibrated setting but

the door does not move, there is either a pinched vac-

uum line or a failed actuator.

LOCATING VACUUM LEAKS

(1) Connect the test vacuum probe to the vehicles

(Black) supply hose. Position the vacuum test gauge

so it can be viewed from the passenger compartment.

(2) Place the Mode in the Panel position and the

Circulation control in the Recirculation position.

(3) Remove the center instrument panel bezel.

(4) Remove the center vent duct.

(5) Remove and block the Supply (Black) vacuum

line at the control. The test gauge should return to

the calibrated setting of 27 kPa (8 in. Hg). If not,

there is a leak in the Supply line.

(6) If there is no leak in the Supply line, reconnect

it to the Control and remove the Actuator Feed (Red)

line from the Control. Block the vacuum connection

on the Control from where the line was removed. The

test gauge should return to the calibrated setting of

27 kPa (8 in. Hg.). If not, there is a leak in the Con-

trol.

(7) If there is no leak in the Supply line or the

Control, reconnect the Actuator Feed (Red) line to the

control. Remove and block the Actuator Feed (Red)

line at the Actuator. The actuator vacuum port is

accessible behind and above the Glove Box. The test

24 - 16 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)

Page 1248 of 1285

gauge should return to the calibrated setting of 27

kPa (8 in. Hg.). If not there is a leak in the Actuator

Feed line.

(8) If there is no leak in the Supply line, Control,

or the Actuator Feed line, the leak must be in the

Actuator itself. Connect the Vacuum hose from the

Vacuum Test Gauge directly to the Actuator to verify

the leak.

LOCATING PINCHED VACUUM LINES

The operation of the Circulation door can be

viewed by removing the blower motor and looking up

into the unit inlet. See Blower Motor Wheel and

Assembly removal and installation in this section for

service procedures.

(1) Connect the test vacuum probe to the vehicles

(Black) supply hose. Position the vacuum test gauge

so it can be viewed from the passenger compartment.

(2) Place the Mode in the Panel position and the

Circulation control in the Recirculation position.

(3) Remove the center instrument panel bezel.

(4) Remove the center vent duct.

(5) Remove the Supply (Black) vacuum line at the

control. The test gauge should drop indicating free

flow through the Supply line. If not, there is a block-

age in the Supply line.

(6) If there is no blockage in the Supply line,

reconnect it to the Control. Remove the Actuator

Feed (Red) line from the Control. The test gauge

should drop indicating free flow through the Supply

line and Control. If not the vacuum switches on the

Control are not functioning.

(7) If there is no blockage in the Supply line or the

Control, reconnect the Actuator Feed (Red) line to the

control. Remove the Actuator Feed (Red) line at the

Actuator. The Actuator vacuum port is accessible

behind and above the Glove Box. The test gauge

should drop indicating free flow through the supply

line, Control, and the Actuator Feed line. If not,

there is a blockage in the Actuator Feed line.

(8) If there is no blockage in the Supply line, Con-

trol, or the Actuator Feed line, the Actuator must

have failed. Connect the Vacuum hose from the Vac-

uum Test Gauge directly to the Actuator to verify the

Actuator has failed.

SERVICE PROCEDURES

CHARGING A/C SYSTEM

PARTIAL CHARGE

This vehicle does not have a sight glass. It is not

possible to determine the amount of (R-134a) charge

in the system. Therefore it is necessary to completely

evacuate and recover the system, and then recharge

the system fully.

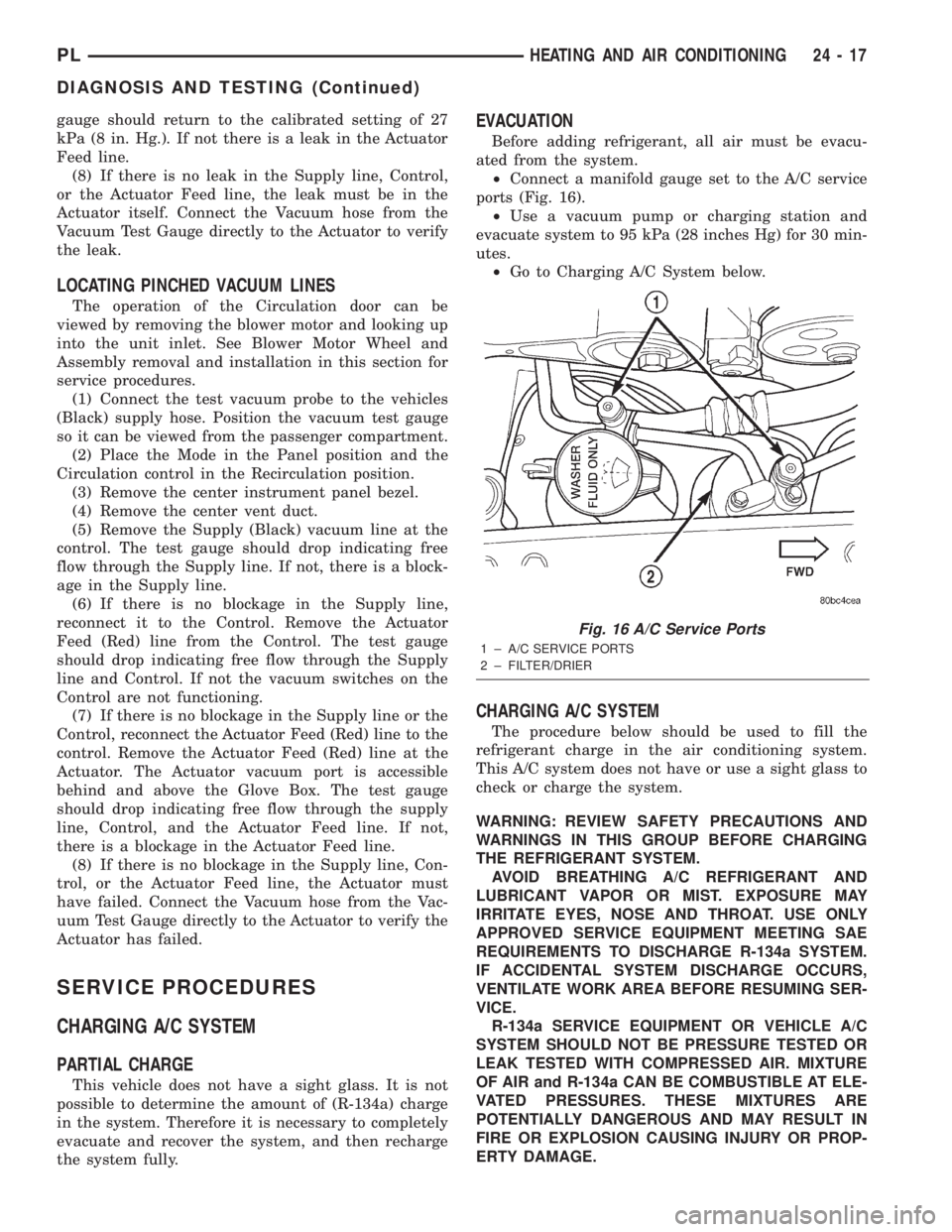

EVACUATION

Before adding refrigerant, all air must be evacu-

ated from the system.

²Connect a manifold gauge set to the A/C service

ports (Fig. 16).

²Use a vacuum pump or charging station and

evacuate system to 95 kPa (28 inches Hg) for 30 min-

utes.

²Go to Charging A/C System below.

CHARGING A/C SYSTEM

The procedure below should be used to fill the

refrigerant charge in the air conditioning system.

This A/C system does not have or use a sight glass to

check or charge the system.

WARNING: REVIEW SAFETY PRECAUTIONS AND

WARNINGS IN THIS GROUP BEFORE CHARGING

THE REFRIGERANT SYSTEM.

AVOID BREATHING A/C REFRIGERANT AND

LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

Fig. 16 A/C Service Ports

1 ± A/C SERVICE PORTS

2 ± FILTER/DRIER

PLHEATING AND AIR CONDITIONING 24 - 17

DIAGNOSIS AND TESTING (Continued)

Page 1249 of 1285

CAUTION: Do not overcharge refrigerant system,

as excessive compressor head pressure can cause

noise and system failure.

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports (Fig. 16).

NOTE: The air conditioning system in this vehicle

holds (27 oz. or 1.69 lbs.) of R-134a refrigerant.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transaxle in park or manual tran-

saxle in neutral

²Engine idling at 700 rpm

²A/C control set in 100 percent outside air

²Panel mode

²Blower motor ON high speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure. Refer to Group 8W, Wiring Diagrams.

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

EVACUATING REFRIGERANT SYSTEM

NOTE: Special effort must be used to prevent mois-

ture from entering the A/C system oil. Moisture in

the oil is very difficult to remove and will cause a

reliability problem with the compressor.If a compressor designed to use R-134a refrigerant

is left open to the atmosphere for an extended period

of time. It is recommended that the refrigerant oil be

drained and replaced with new oil or a new compres-

sor be used. This will eliminate the possibility of con-

taminating the refrigerant system.

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be filled. Moisture and air mixed with the refrig-

erant will raise the compressor head pressure above

acceptable operating levels. This will reduce the per-

formance of the air conditioner and damage the com-

pressor. Moisture will boil at near room temperature

when exposed to vacuum. To evacuate the refrigerant

system:

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

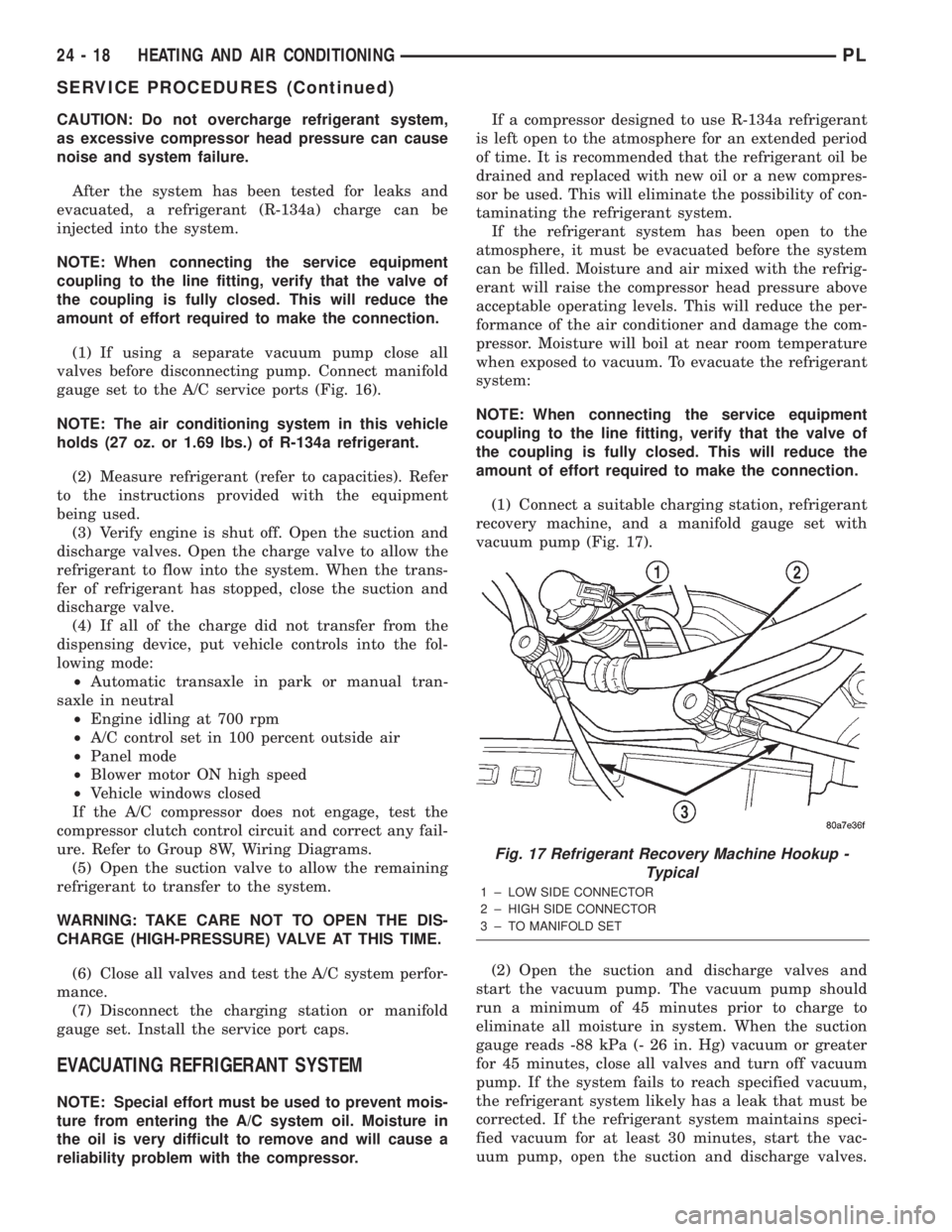

(1) Connect a suitable charging station, refrigerant

recovery machine, and a manifold gauge set with

vacuum pump (Fig. 17).

(2) Open the suction and discharge valves and

start the vacuum pump. The vacuum pump should

run a minimum of 45 minutes prior to charge to

eliminate all moisture in system. When the suction

gauge reads -88 kPa (- 26 in. Hg) vacuum or greater

for 45 minutes, close all valves and turn off vacuum

pump. If the system fails to reach specified vacuum,

the refrigerant system likely has a leak that must be

corrected. If the refrigerant system maintains speci-

fied vacuum for at least 30 minutes, start the vac-

uum pump, open the suction and discharge valves.

Fig. 17 Refrigerant Recovery Machine Hookup -

Typical

1 ± LOW SIDE CONNECTOR

2 ± HIGH SIDE CONNECTOR

3 ± TO MANIFOLD SET

24 - 18 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)

Page 1256 of 1285

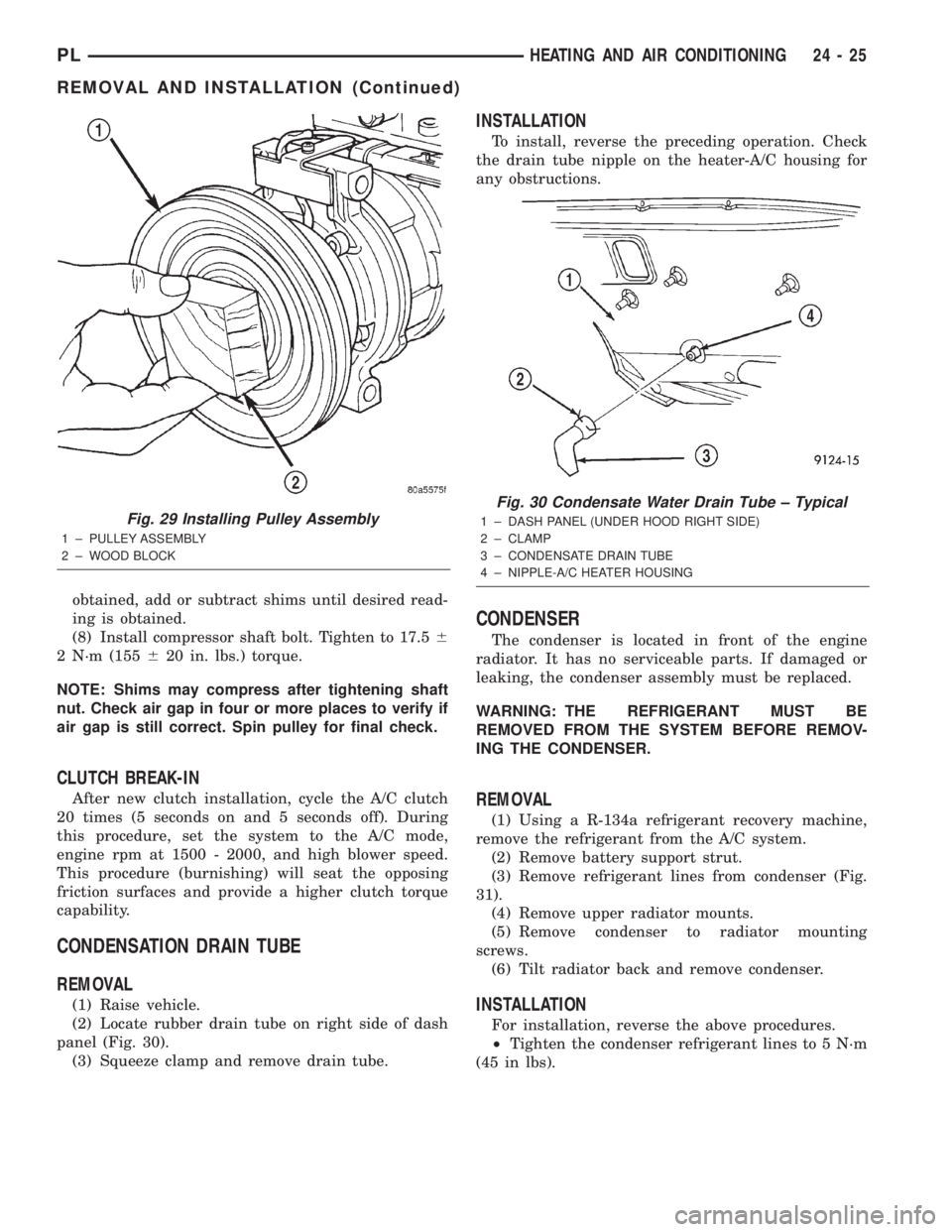

obtained, add or subtract shims until desired read-

ing is obtained.

(8) Install compressor shaft bolt. Tighten to 17.56

2 N´m (155620 in. lbs.) torque.

NOTE: Shims may compress after tightening shaft

nut. Check air gap in four or more places to verify if

air gap is still correct. Spin pulley for final check.

CLUTCH BREAK-IN

After new clutch installation, cycle the A/C clutch

20 times (5 seconds on and 5 seconds off). During

this procedure, set the system to the A/C mode,

engine rpm at 1500 - 2000, and high blower speed.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher clutch torque

capability.

CONDENSATION DRAIN TUBE

REMOVAL

(1) Raise vehicle.

(2) Locate rubber drain tube on right side of dash

panel (Fig. 30).

(3) Squeeze clamp and remove drain tube.

INSTALLATION

To install, reverse the preceding operation. Check

the drain tube nipple on the heater-A/C housing for

any obstructions.

CONDENSER

The condenser is located in front of the engine

radiator. It has no serviceable parts. If damaged or

leaking, the condenser assembly must be replaced.

WARNING: THE REFRIGERANT MUST BE

REMOVED FROM THE SYSTEM BEFORE REMOV-

ING THE CONDENSER.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from the A/C system.

(2) Remove battery support strut.

(3) Remove refrigerant lines from condenser (Fig.

31).

(4) Remove upper radiator mounts.

(5) Remove condenser to radiator mounting

screws.

(6) Tilt radiator back and remove condenser.

INSTALLATION

For installation, reverse the above procedures.

²Tighten the condenser refrigerant lines to 5 N´m

(45 in lbs).

Fig. 29 Installing Pulley Assembly

1 ± PULLEY ASSEMBLY

2 ± WOOD BLOCK

Fig. 30 Condensate Water Drain Tube ± Typical

1 ± DASH PANEL (UNDER HOOD RIGHT SIDE)

2 ± CLAMP

3 ± CONDENSATE DRAIN TUBE

4 ± NIPPLE-A/C HEATER HOUSING

PLHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1263 of 1285

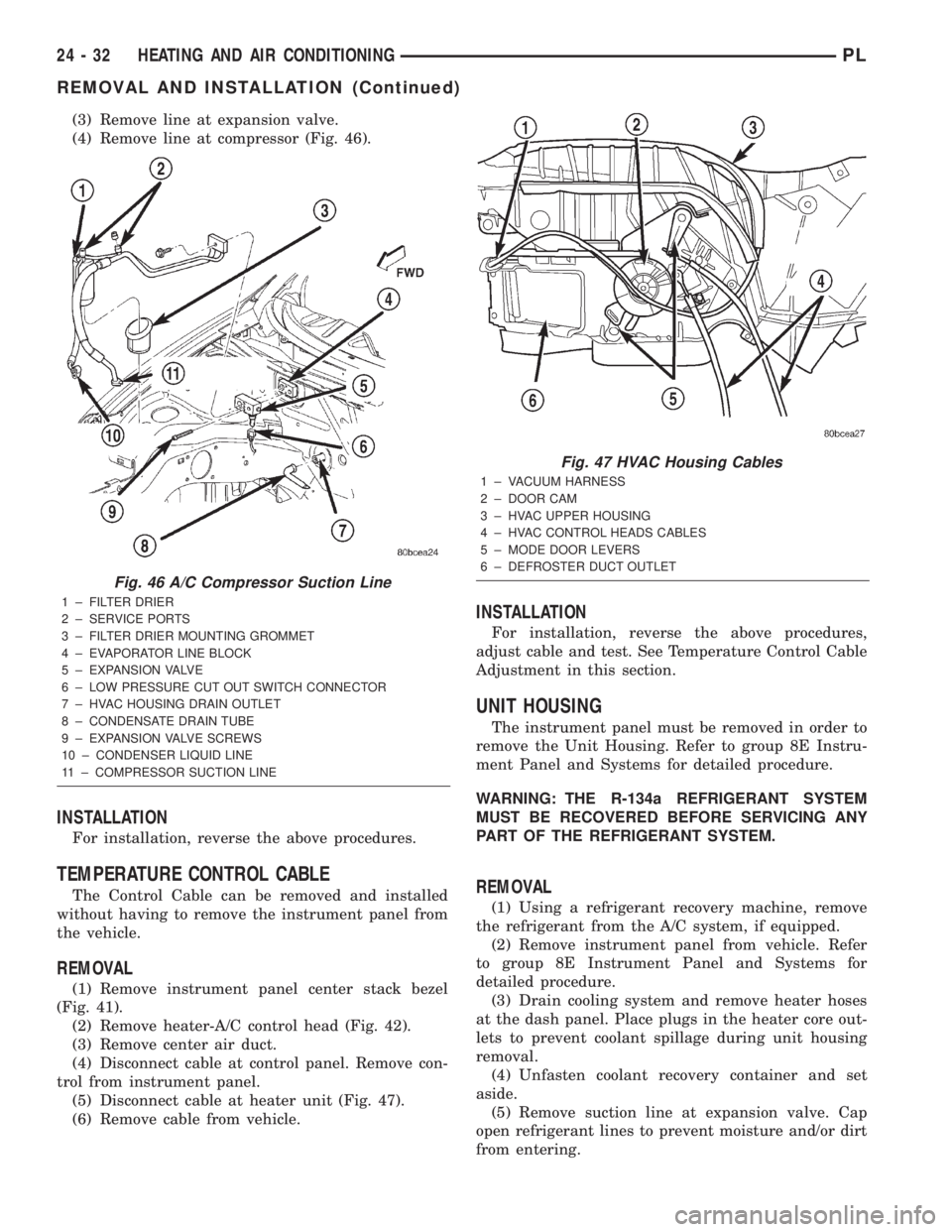

(3) Remove line at expansion valve.

(4) Remove line at compressor (Fig. 46).

INSTALLATION

For installation, reverse the above procedures.

TEMPERATURE CONTROL CABLE

The Control Cable can be removed and installed

without having to remove the instrument panel from

the vehicle.

REMOVAL

(1) Remove instrument panel center stack bezel

(Fig. 41).

(2) Remove heater-A/C control head (Fig. 42).

(3) Remove center air duct.

(4) Disconnect cable at control panel. Remove con-

trol from instrument panel.

(5) Disconnect cable at heater unit (Fig. 47).

(6) Remove cable from vehicle.

INSTALLATION

For installation, reverse the above procedures,

adjust cable and test. See Temperature Control Cable

Adjustment in this section.

UNIT HOUSING

The instrument panel must be removed in order to

remove the Unit Housing. Refer to group 8E Instru-

ment Panel and Systems for detailed procedure.

WARNING: THE R-134a REFRIGERANT SYSTEM

MUST BE RECOVERED BEFORE SERVICING ANY

PART OF THE REFRIGERANT SYSTEM.

REMOVAL

(1) Using a refrigerant recovery machine, remove

the refrigerant from the A/C system, if equipped.

(2) Remove instrument panel from vehicle. Refer

to group 8E Instrument Panel and Systems for

detailed procedure.

(3) Drain cooling system and remove heater hoses

at the dash panel. Place plugs in the heater core out-

lets to prevent coolant spillage during unit housing

removal.

(4) Unfasten coolant recovery container and set

aside.

(5) Remove suction line at expansion valve. Cap

open refrigerant lines to prevent moisture and/or dirt

from entering.

Fig. 46 A/C Compressor Suction Line

1 ± FILTER DRIER

2 ± SERVICE PORTS

3 ± FILTER DRIER MOUNTING GROMMET

4 ± EVAPORATOR LINE BLOCK

5 ± EXPANSION VALVE

6 ± LOW PRESSURE CUT OUT SWITCH CONNECTOR

7 ± HVAC HOUSING DRAIN OUTLET

8 ± CONDENSATE DRAIN TUBE

9 ± EXPANSION VALVE SCREWS

10 ± CONDENSER LIQUID LINE

11 ± COMPRESSOR SUCTION LINE

Fig. 47 HVAC Housing Cables

1 ± VACUUM HARNESS

2 ± DOOR CAM

3 ± HVAC UPPER HOUSING

4 ± HVAC CONTROL HEADS CABLES

5 ± MODE DOOR LEVERS

6 ± DEFROSTER DUCT OUTLET

24 - 32 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1275 of 1285

VIN CODE DECODING

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 1 = United states

2 MakeB = Dodge

P = Plymouth

3 Vehicle Type 3 = Passenger Car

4 Pass. Safety E = Restraint System, Active Driver & Passenger Airbags

5 Car Line S = Neon

6 Series2 = Low Line

4 = High Line

7 Body Style6 = 4 Door Sedan

8 Engine C = 2.0 L 4 Cyl. 16V

9 Check Digit See explanation in this section.

10 Model Year Y = 2000

11 Assembly Plant D = Belvidere

12 Thru 17 Vehicle Build Sequence 6 digit number assigned by assembly plant.

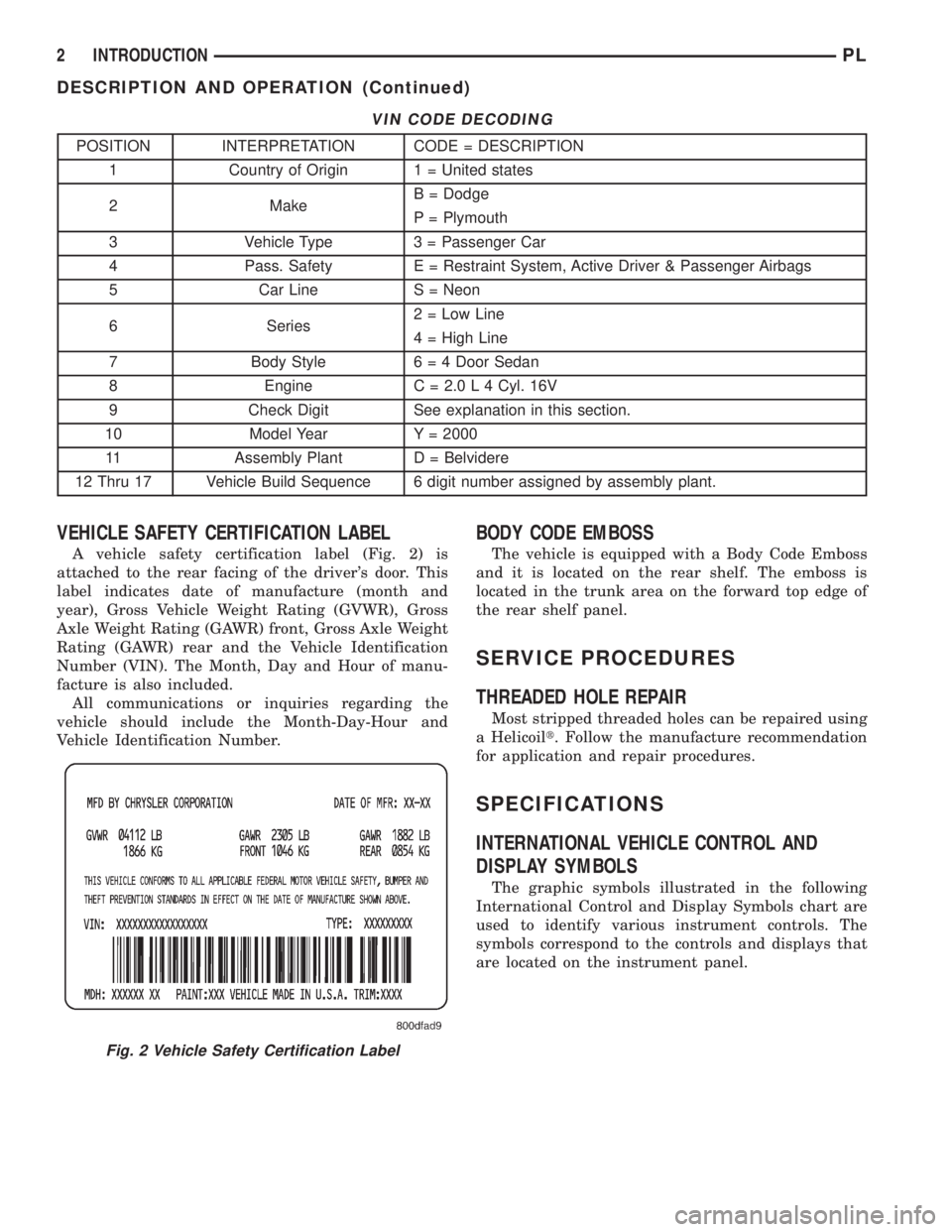

VEHICLE SAFETY CERTIFICATION LABEL

A vehicle safety certification label (Fig. 2) is

attached to the rear facing of the driver's door. This

label indicates date of manufacture (month and

year), Gross Vehicle Weight Rating (GVWR), Gross

Axle Weight Rating (GAWR) front, Gross Axle Weight

Rating (GAWR) rear and the Vehicle Identification

Number (VIN). The Month, Day and Hour of manu-

facture is also included.

All communications or inquiries regarding the

vehicle should include the Month-Day-Hour and

Vehicle Identification Number.

BODY CODE EMBOSS

The vehicle is equipped with a Body Code Emboss

and it is located on the rear shelf. The emboss is

located in the trunk area on the forward top edge of

the rear shelf panel.

SERVICE PROCEDURES

THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the manufacture recommendation

for application and repair procedures.

SPECIFICATIONS

INTERNATIONAL VEHICLE CONTROL AND

DISPLAY SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

Fig. 2 Vehicle Safety Certification Label

2 INTRODUCTIONPL

DESCRIPTION AND OPERATION (Continued)

Page 1283 of 1285

VIN DECODING INFORMATION

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of origin 1 = United States

2 Make C = Chrysler

3 Vehicle Type 3 = Passenger Car

4 Passenger Safety E = Active Restraints, Driver and Passenger Airbags

5 Car Line S = Neon BUX L. H. D.

V = Neon BUX R. H. D.

6 Series M = DD5 5-Speed Manual Transmission

A = 3-Speed Automatic Transmission

7 Body Style7 = 4 Door Pillared Hardtop

8 Engine C = 2.0L 4 Cyl. 16V SOHC

A = 1.8L 4 Cyl. 16V SOHC

9 Check Digit See explanation in this section.

10 Model Year Y = 2000

11 Assembly Plant D = Belvedere Assembly

12 Thru 17 Build Sequence 6 Digit number assigned by assembly plant

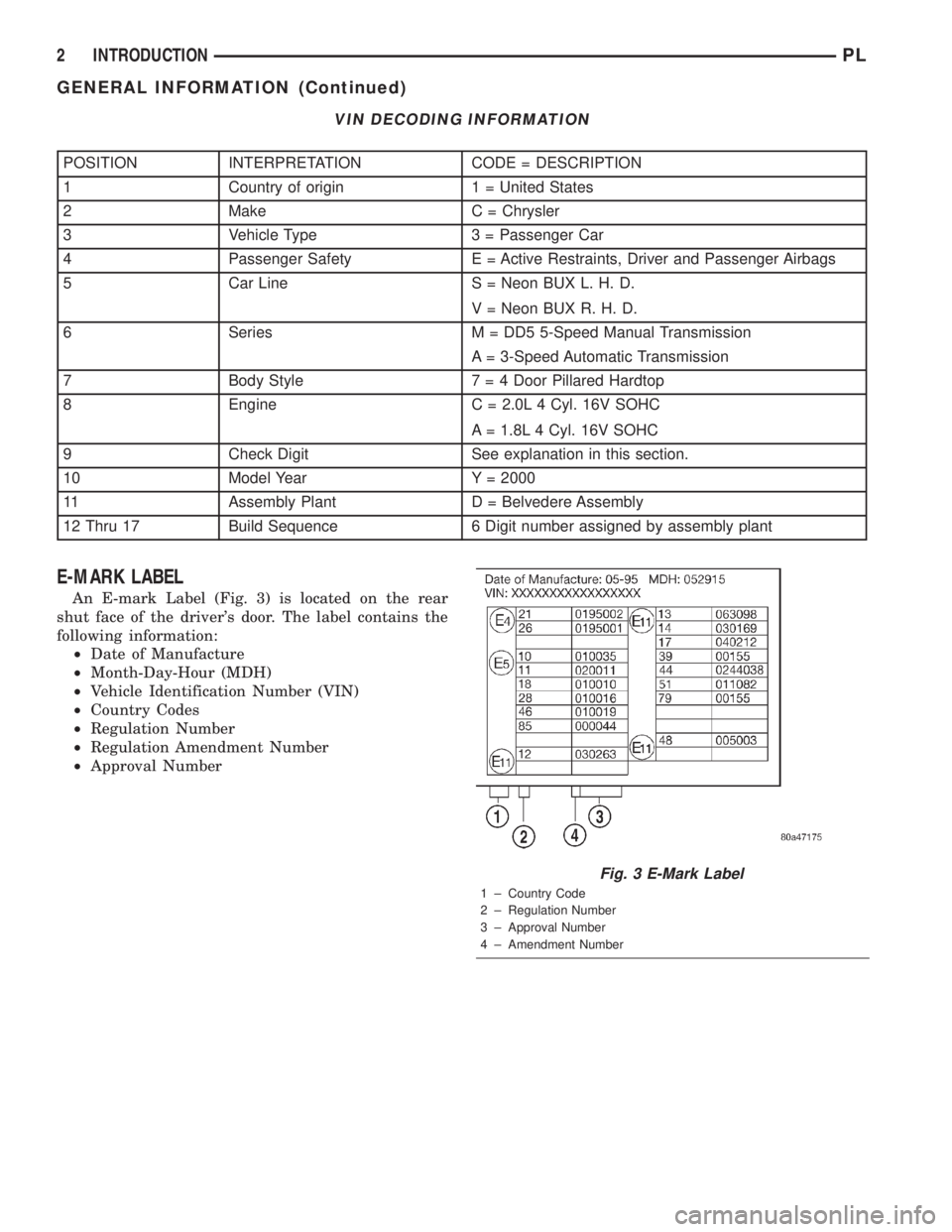

E-MARK LABEL

An E-mark Label (Fig. 3) is located on the rear

shut face of the driver's door. The label contains the

following information:

²Date of Manufacture

²Month-Day-Hour (MDH)

²Vehicle Identification Number (VIN)

²Country Codes

²Regulation Number

²Regulation Amendment Number

²Approval Number

Fig. 3 E-Mark Label

1 ± Country Code

2 ± Regulation Number

3 ± Approval Number

4 ± Amendment Number

2 INTRODUCTIONPL

GENERAL INFORMATION (Continued)