cooling DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 208 of 1285

(3) Remove engine thermostat and reinstall ther-

mostat housing. A gasket may be needed to seal thehousing to cylinder head because the seal is part of

thermostat.

(4) Install suitable flushing gun to thermostat

housing hose. Turn on water, and when engine is

filled, turn on air, but no higher than 138 kPa (20

psi) in short blasts. Allow engine to fill between

blasts of air. Continue this procedure until water

runs clean.

(5) Install thermostat and fill cooling system.

Refer to Cooling System Refilling in this section for

procedure.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system, using air

pressure in a direction opposite to that of the normal

flow of water. This is only necessary with dirty sys-

tems and evidence of partial plugging.

CHEMICAL CLEANING

One type of corrosion encountered with aluminum

cylinder heads is aluminum hydroxide deposits. Cor-

rosion products are carried to the radiator and depos-

ited when cooled off. They appear as dark grey when

wet and white when dry. This corrosion can be

removed with a two part cleaner (oxalic acid and

neutralizer) available in auto parts outlets. Follow

manufacturers directions for use.

ADJUSTMENTS

BELT TENSION

For belt tension adjustment procedure, refer to

Accessory Drive Belt Removal and Installation proce-

dure.

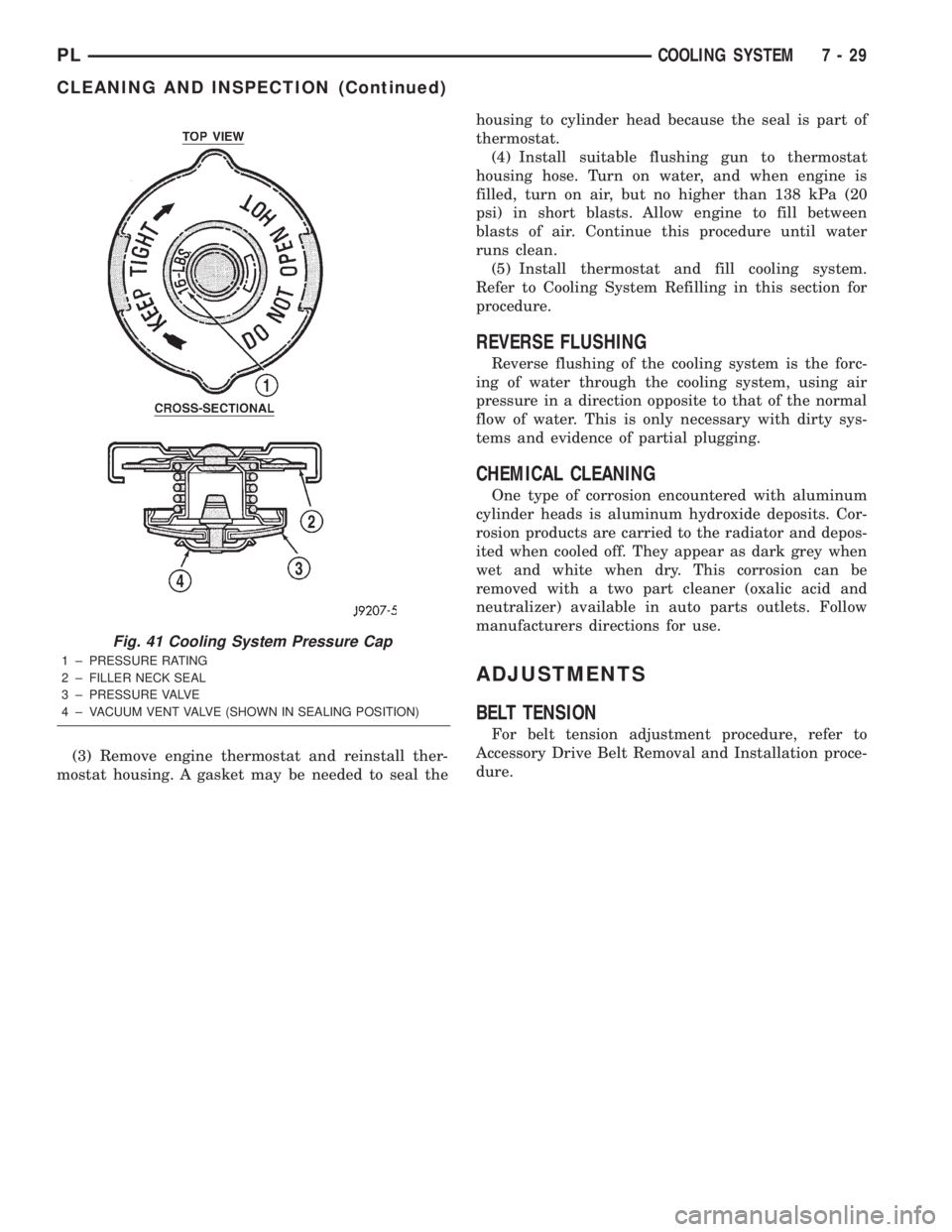

Fig. 41 Cooling System Pressure Cap

1 ± PRESSURE RATING

2 ± FILLER NECK SEAL

3 ± PRESSURE VALVE

4 ± VACUUM VENT VALVE (SHOWN IN SEALING POSITION)

PLCOOLING SYSTEM 7 - 29

CLEANING AND INSPECTION (Continued)

Page 209 of 1285

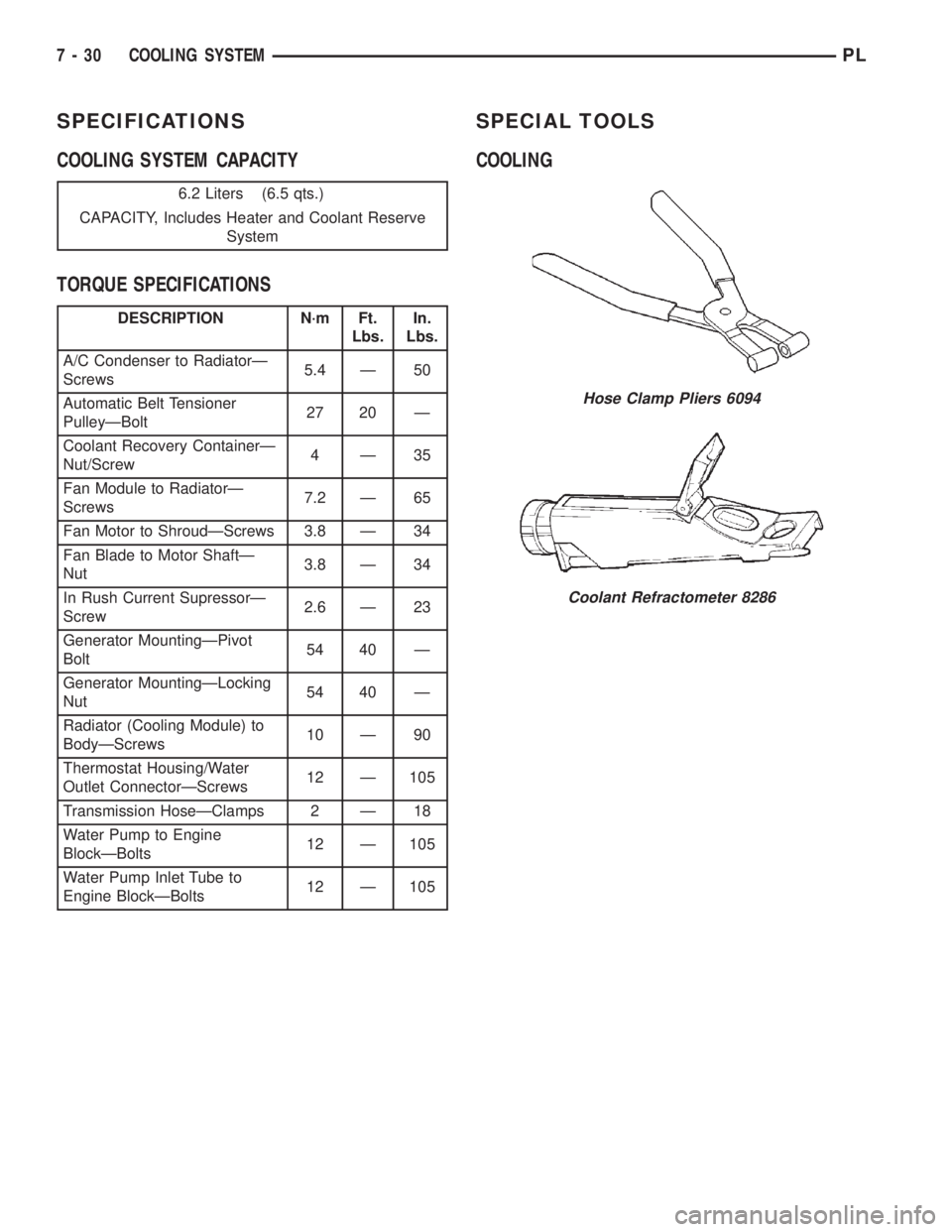

SPECIFICATIONS

COOLING SYSTEM CAPACITY

TORQUE SPECIFICATIONSSPECIAL TOOLS

COOLING

6.2 Liters (6.5 qts.)

CAPACITY, Includes Heater and Coolant Reserve

System

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

A/C Condenser to RadiatorÐ

Screws5.4 Ð 50

Automatic Belt Tensioner

PulleyÐBolt27 20 Ð

Coolant Recovery ContainerÐ

Nut/Screw4Ð35

Fan Module to RadiatorÐ

Screws7.2 Ð 65

Fan Motor to ShroudÐScrews 3.8 Ð 34

Fan Blade to Motor ShaftÐ

Nut3.8 Ð 34

In Rush Current SupressorÐ

Screw2.6 Ð 23

Generator MountingÐPivot

Bolt54 40 Ð

Generator MountingÐLocking

Nut54 40 Ð

Radiator (Cooling Module) to

BodyÐScrews10 Ð 90

Thermostat Housing/Water

Outlet ConnectorÐScrews12 Ð 105

Transmission HoseÐClamps 2 Ð 18

Water Pump to Engine

BlockÐBolts12 Ð 105

Water Pump Inlet Tube to

Engine BlockÐBolts12 Ð 105

Hose Clamp Pliers 6094

Coolant Refractometer 8286

7 - 30 COOLING SYSTEMPL

Page 726 of 1285

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly clean all debris/rust from inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with MopartStud and Bearing Mount Adhesive.

Make certain the new plug is cleaned of all oil or

grease. Using a proper driver, drive plug into hole so

that the sharp edge of the plug is at least 0.5 mm

(0.020 inch.) inside the lead in chamfer (Fig. 3).

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to it's

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-ing to these standards, refer to Engine Diagnosis in

this section. The following procedures can assist in

achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system. Refer to

Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.HONING CYLINDER BORES

(1) Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped

with 220 grit stones, is the best tool for this honing

procedure. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

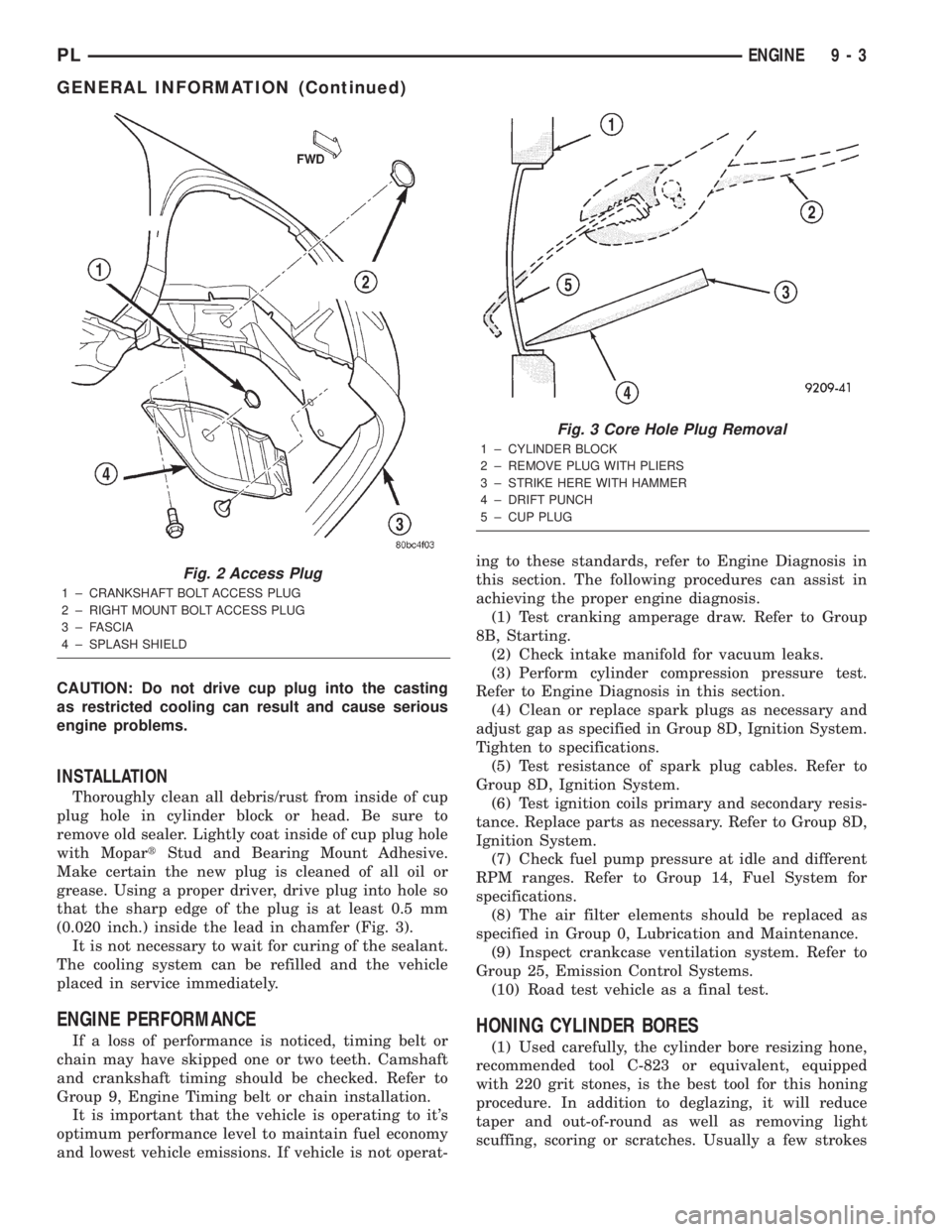

Fig. 2 Access Plug

1 ± CRANKSHAFT BOLT ACCESS PLUG

2 ± RIGHT MOUNT BOLT ACCESS PLUG

3 ± FASCIA

4 ± SPLASH SHIELD

Fig. 3 Core Hole Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

PLENGINE 9 - 3

GENERAL INFORMATION (Continued)

Page 729 of 1285

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.).

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter.

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

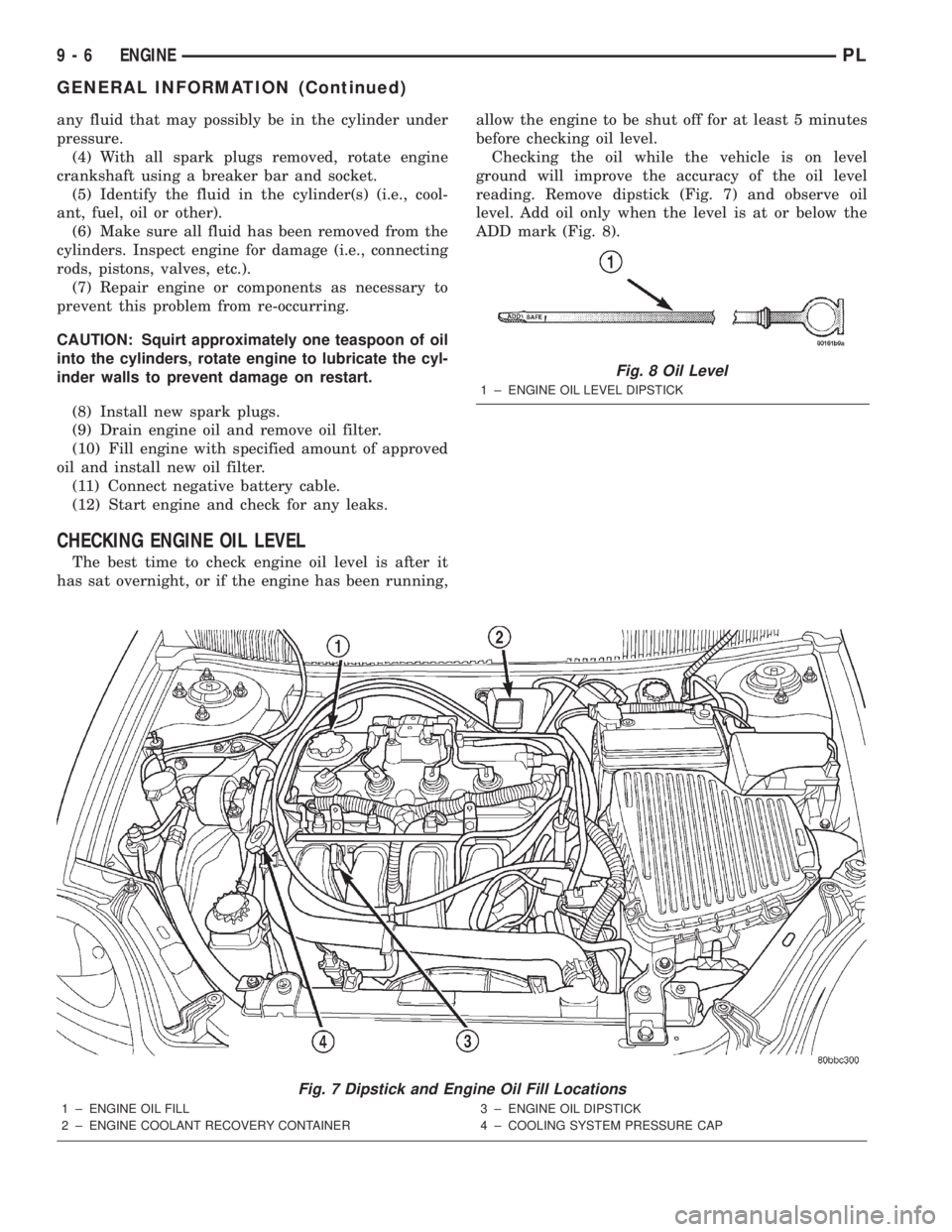

CHECKING ENGINE OIL LEVEL

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick (Fig. 7) and observe oil

level. Add oil only when the level is at or below the

ADD mark (Fig. 8).

Fig. 7 Dipstick and Engine Oil Fill Locations

1 ± ENGINE OIL FILL

2 ± ENGINE COOLANT RECOVERY CONTAINER3 ± ENGINE OIL DIPSTICK

4 ± COOLING SYSTEM PRESSURE CAP

Fig. 8 Oil Level

1 ± ENGINE OIL LEVEL DIPSTICK

9 - 6 ENGINEPL

GENERAL INFORMATION (Continued)

Page 732 of 1285

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

PLENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 738 of 1285

2.0L SOHC ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION..................15

ENGINE COMPONENTS...................15

ENGINE LUBRICATION SYSTEM.............17

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE..........18

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING........18

FITTING PISTON RINGS...................19

FITTING CONNECTING RODS...............19

FITTING CRANKSHAFT BEARINGS...........19

CRANKSHAFT END PLAY..................20

REMOVAL AND INSTALLATION

TORQUE STRUTS........................20

ENGINE MOUNTÐLEFT...................21

ENGINE MOUNTÐRIGHT..................23

ENGINE MOUNT BRACKETÐRIGHT..........24

STRUCTURAL COLLAR....................25

ENGINE ASSEMBLY.......................25

INTAKE MANIFOLD.......................28

EXHAUST MANIFOLD.....................30

CYLINDER HEAD COVER..................31

SPARK PLUG TUBE SEALS.................32

SPARK PLUG TUBE.......................33

CAMSHAFT.............................33

ROCKER ARM/HYDRAULIC LASH ADJUSTER . . . 34

VALVE SEALS AND SPRINGSÐIN VEHICLE....36

CYLINDER HEAD.........................37

CRANKSHAFT DAMPER...................40

TIMING BELT COVERS....................41TIMING BELT............................43

TIMING BELT TENSIONER..................46

CAMSHAFT OIL SEAL.....................46

OILPAN................................47

CRANKSHAFT OIL SEALÐFRONT............48

CRANKSHAFT OIL SEALÐREAR.............50

DRIVE PLATE...........................51

CRANKSHAFT...........................52

OIL FILTER ADAPTER.....................55

OILFILTER .............................55

OIL PUMP..............................55

PISTON AND CONNECTING ROD............57

DISASSEMBLY AND ASSEMBLY

OIL PUMP..............................60

VALVE SERVICE WITH THE CYLINDER HEAD

REMOVED............................60

CLEANING AND INSPECTION

INTAKE MANIFOLD.......................63

EXHAUST MANIFOLD.....................63

CYLINDER HEAD AND CAMSHAFT

JOURNALS............................63

OIL PUMP..............................64

CYLINDER BLOCK AND BORE..............65

ADJUSTMENTS

ENGINE TORQUE STRUT ADJUSTMENT......66

SPECIFICATIONS

2.0L SOHC ENGINE.......................68

TORQUE...............................71

SPECIAL TOOLS

2.0L SOHC ENGINE.......................72

DESCRIPTION AND OPERATION

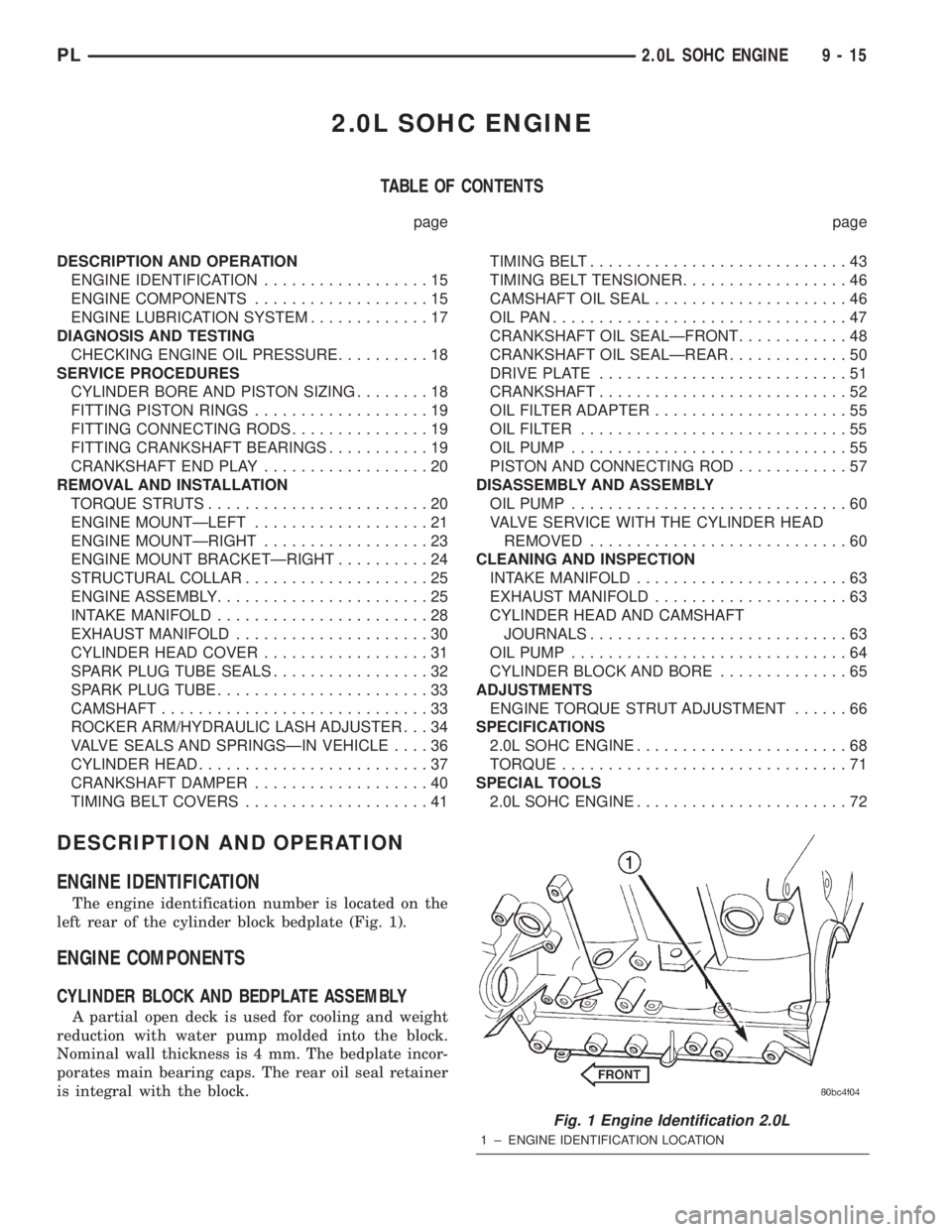

ENGINE IDENTIFICATION

The engine identification number is located on the

left rear of the cylinder block bedplate (Fig. 1).

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEMBLY

A partial open deck is used for cooling and weight

reduction with water pump molded into the block.

Nominal wall thickness is 4 mm. The bedplate incor-

porates main bearing caps. The rear oil seal retainer

is integral with the block.

Fig. 1 Engine Identification 2.0L

1 ± ENGINE IDENTIFICATION LOCATION

PL2.0L SOHC ENGINE 9 - 15

Page 746 of 1285

(9) Install air cleaner assembly (Fig. 13).

(10) Lower vehicle.

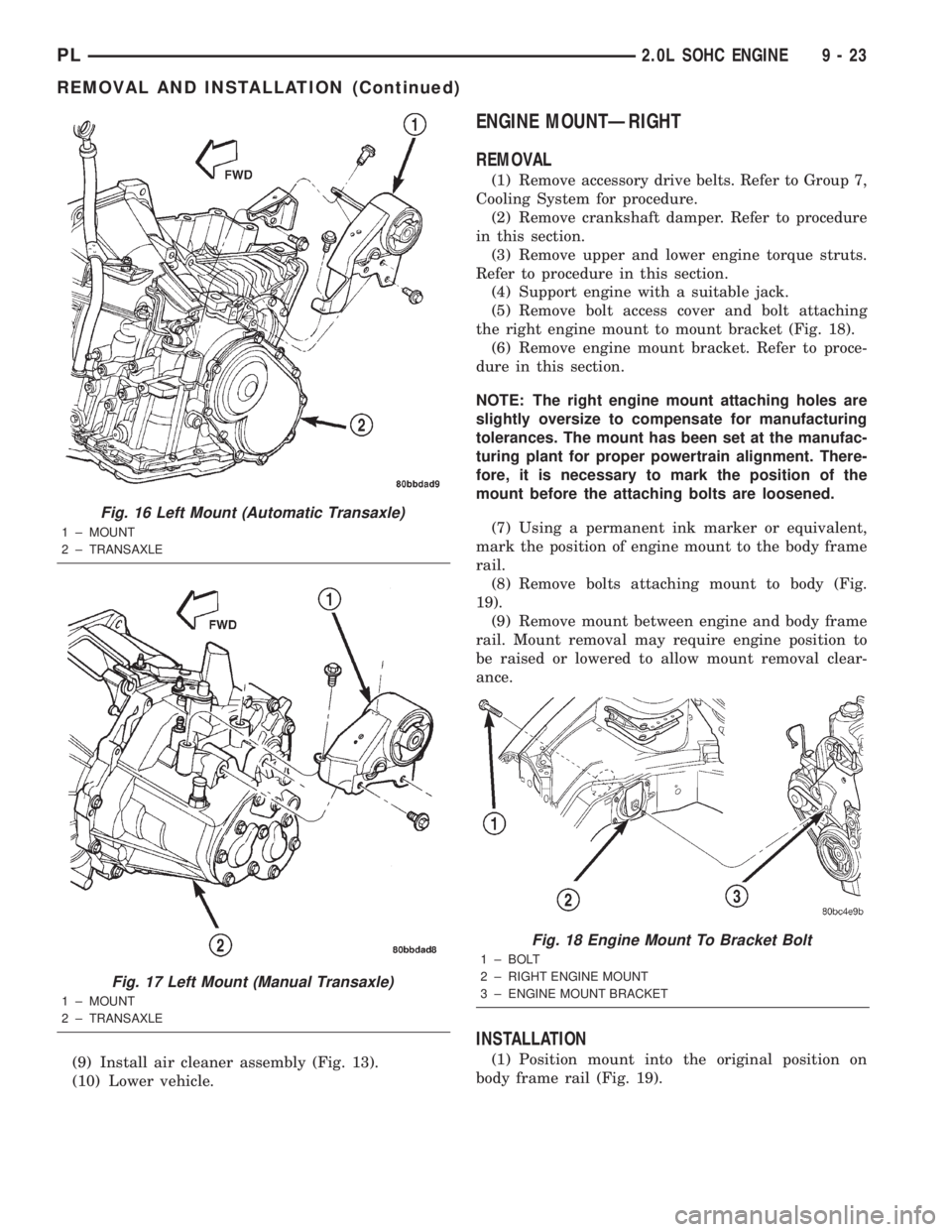

ENGINE MOUNTÐRIGHT

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(2) Remove crankshaft damper. Refer to procedure

in this section.

(3) Remove upper and lower engine torque struts.

Refer to procedure in this section.

(4) Support engine with a suitable jack.

(5) Remove bolt access cover and bolt attaching

the right engine mount to mount bracket (Fig. 18).

(6) Remove engine mount bracket. Refer to proce-

dure in this section.

NOTE: The right engine mount attaching holes are

slightly oversize to compensate for manufacturing

tolerances. The mount has been set at the manufac-

turing plant for proper powertrain alignment. There-

fore, it is necessary to mark the position of the

mount before the attaching bolts are loosened.

(7) Using a permanent ink marker or equivalent,

mark the position of engine mount to the body frame

rail.

(8) Remove bolts attaching mount to body (Fig.

19).

(9) Remove mount between engine and body frame

rail. Mount removal may require engine position to

be raised or lowered to allow mount removal clear-

ance.

INSTALLATION

(1) Position mount into the original position on

body frame rail (Fig. 19).

Fig. 16 Left Mount (Automatic Transaxle)

1 ± MOUNT

2 ± TRANSAXLE

Fig. 17 Left Mount (Manual Transaxle)

1 ± MOUNT

2 ± TRANSAXLE

Fig. 18 Engine Mount To Bracket Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

PL2.0L SOHC ENGINE 9 - 23

REMOVAL AND INSTALLATION (Continued)

Page 747 of 1285

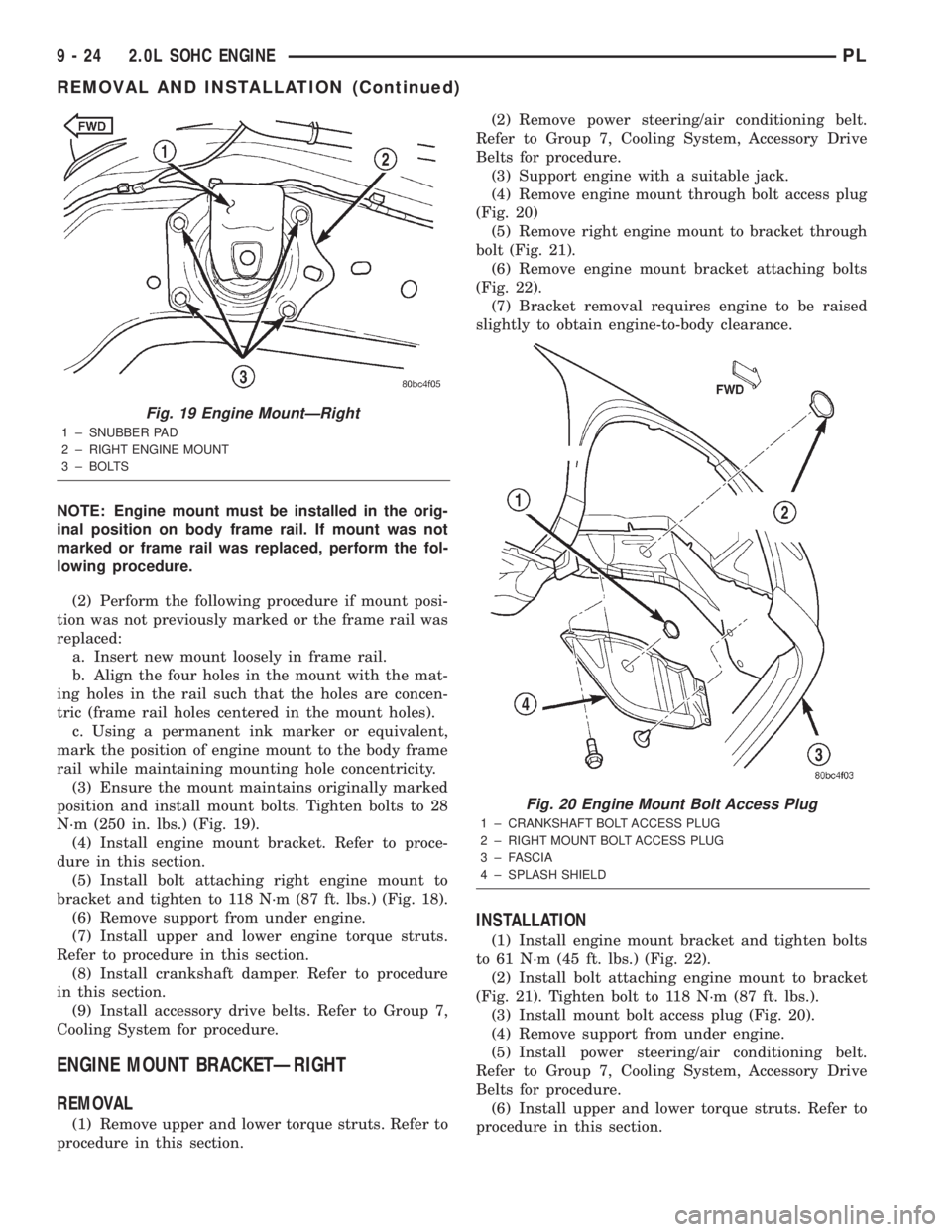

NOTE: Engine mount must be installed in the orig-

inal position on body frame rail. If mount was not

marked or frame rail was replaced, perform the fol-

lowing procedure.

(2) Perform the following procedure if mount posi-

tion was not previously marked or the frame rail was

replaced:

a. Insert new mount loosely in frame rail.

b. Align the four holes in the mount with the mat-

ing holes in the rail such that the holes are concen-

tric (frame rail holes centered in the mount holes).

c. Using a permanent ink marker or equivalent,

mark the position of engine mount to the body frame

rail while maintaining mounting hole concentricity.

(3) Ensure the mount maintains originally marked

position and install mount bolts. Tighten bolts to 28

N´m (250 in. lbs.) (Fig. 19).

(4) Install engine mount bracket. Refer to proce-

dure in this section.

(5) Install bolt attaching right engine mount to

bracket and tighten to 118 N´m (87 ft. lbs.) (Fig. 18).

(6) Remove support from under engine.

(7) Install upper and lower engine torque struts.

Refer to procedure in this section.

(8) Install crankshaft damper. Refer to procedure

in this section.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System for procedure.

ENGINE MOUNT BRACKETÐRIGHT

REMOVAL

(1) Remove upper and lower torque struts. Refer to

procedure in this section.(2) Remove power steering/air conditioning belt.

Refer to Group 7, Cooling System, Accessory Drive

Belts for procedure.

(3) Support engine with a suitable jack.

(4) Remove engine mount through bolt access plug

(Fig. 20)

(5) Remove right engine mount to bracket through

bolt (Fig. 21).

(6) Remove engine mount bracket attaching bolts

(Fig. 22).

(7) Bracket removal requires engine to be raised

slightly to obtain engine-to-body clearance.

INSTALLATION

(1) Install engine mount bracket and tighten bolts

to 61 N´m (45 ft. lbs.) (Fig. 22).

(2) Install bolt attaching engine mount to bracket

(Fig. 21). Tighten bolt to 118 N´m (87 ft. lbs.).

(3) Install mount bolt access plug (Fig. 20).

(4) Remove support from under engine.

(5) Install power steering/air conditioning belt.

Refer to Group 7, Cooling System, Accessory Drive

Belts for procedure.

(6) Install upper and lower torque struts. Refer to

procedure in this section.

Fig. 19 Engine MountÐRight

1 ± SNUBBER PAD

2 ± RIGHT ENGINE MOUNT

3 ± BOLTS

Fig. 20 Engine Mount Bolt Access Plug

1 ± CRANKSHAFT BOLT ACCESS PLUG

2 ± RIGHT MOUNT BOLT ACCESS PLUG

3 ± FASCIA

4 ± SPLASH SHIELD

9 - 24 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 748 of 1285

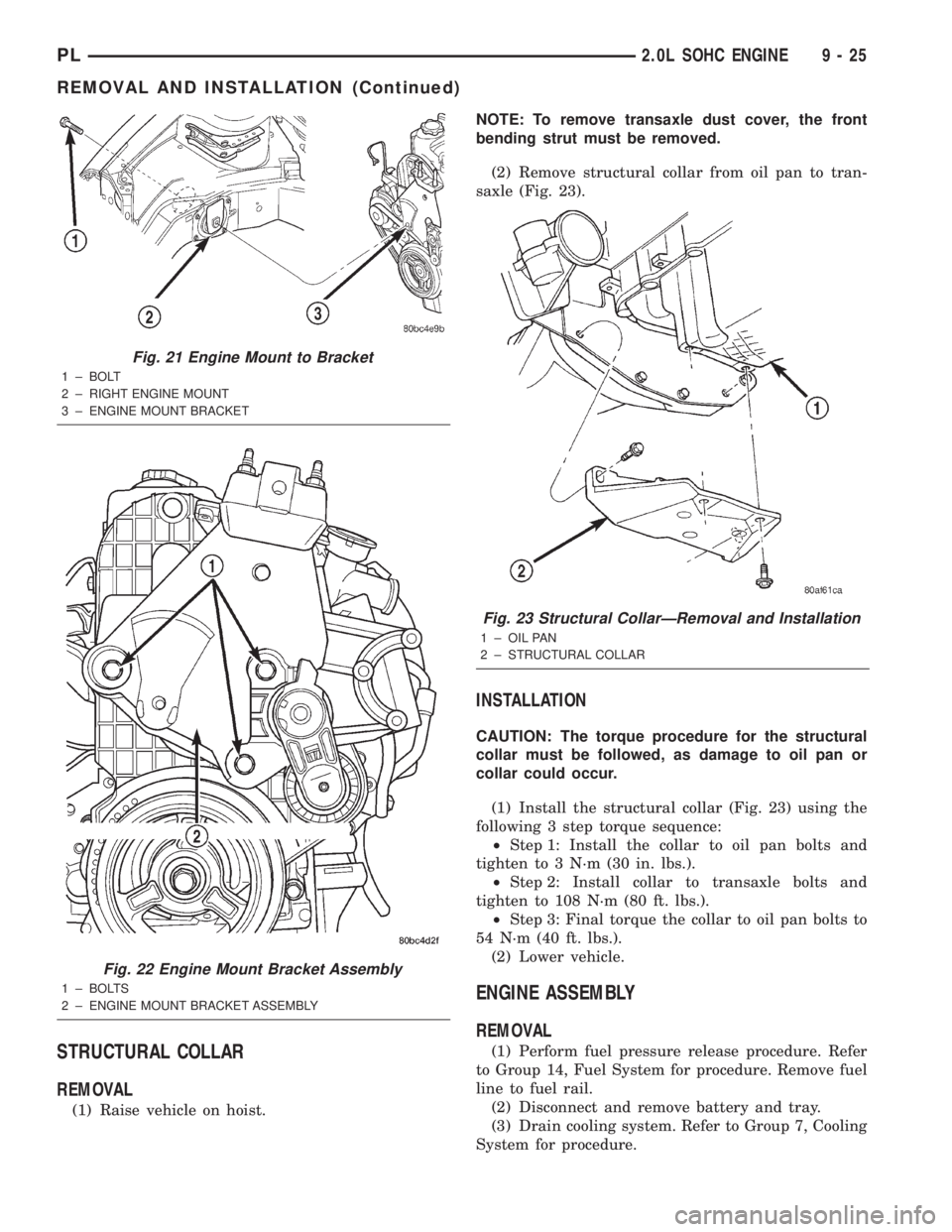

STRUCTURAL COLLAR

REMOVAL

(1) Raise vehicle on hoist.NOTE: To remove transaxle dust cover, the front

bending strut must be removed.

(2) Remove structural collar from oil pan to tran-

saxle (Fig. 23).

INSTALLATION

CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(1) Install the structural collar (Fig. 23) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(2) Lower vehicle.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect and remove battery and tray.

(3) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

Fig. 21 Engine Mount to Bracket

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

Fig. 22 Engine Mount Bracket Assembly

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET ASSEMBLY

Fig. 23 Structural CollarÐRemoval and Installation

1 ± OIL PAN

2 ± STRUCTURAL COLLAR

PL2.0L SOHC ENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)

Page 749 of 1285

(4) Discharge air conditioning system, if equipped.

Refer to Group 24, Heating and Air Conditioning for

procedure.

(5) Disconnect the following: air intake duct at

intake manifold, throttle cables, electrical connectors

from throttle body and air cleaner housing.

(6) Remove air cleaner housing assembly.

(7) Remove upper radiator hose and fan module.

Refer to Group 7, Cooling System for procedure.

(8) Remove lower radiator hose.

(9) Disconnect automatic transmission cooler lines

and plug, if equipped.

(10) Disconnect shift linkage, electrical connectors,

and clutch cable, if equipped with manual transaxle.

(11) Disconnect engine wiring harness.

(12) Disconnect positive cable from Power Distri-

bution Center (PDC) and ground wire from vehicle

body.

(13) Disconnect ground wire from the vehicle body-

to-engine at the right side strut tower.

(14) Disconnect heater hoses.

(15) Disconnect vacuum hose from brake booster.

(16) Disconnect coolant reserve/recovery hose.

(17) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(18) Remove power steering pump and reservoir

and set them aside.

(19) Hoist vehicle and remove right inner splash

shield.

(20) Drain engine oil.

(21) Remove front wheels.

(22) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(23) Disconnect exhaust system from manifold.

(24) Disconnect the downstream oxygen sensor

connector.

(25) Remove lower engine torque strut.

(26) Remove structural collar. Refer to procedure

in this section.

(27) Lower vehicle and remove A/C compressor.

(28) Raise vehicle enough to allow engine dolly

and cradle, Special Tools 6135 and 6710 to be

installed under vehicle.

(29) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 26). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(30) Install safety straps around the engine to cra-

dle (Fig. 26). Tighten straps and lock them into posi-

tion.

WARNING: Safety straps MUST be used.(31) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(32) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(33) Remove the upper engine torque strut.

(34) Remove right and left engine and transaxle

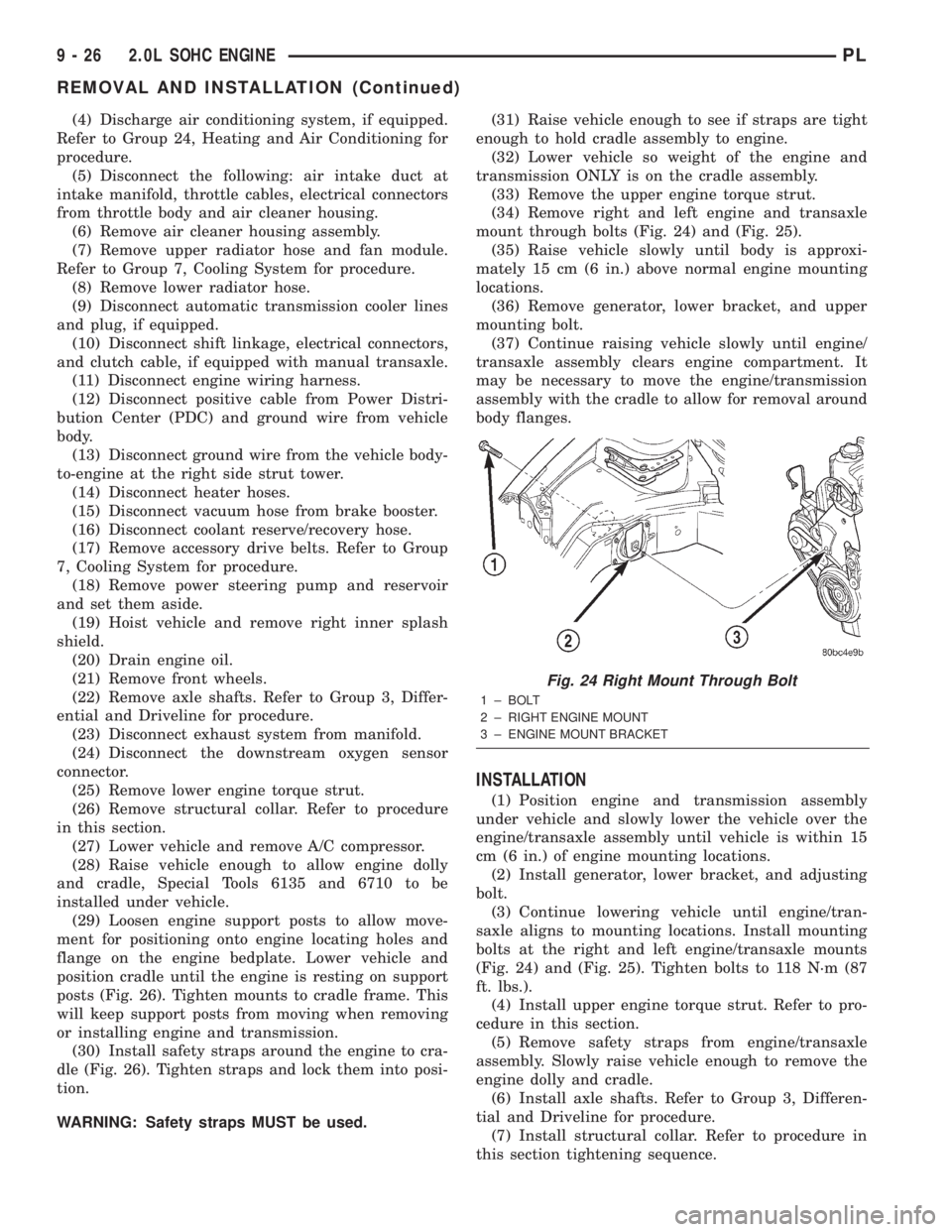

mount through bolts (Fig. 24) and (Fig. 25).

(35) Raise vehicle slowly until body is approxi-

mately 15 cm (6 in.) above normal engine mounting

locations.

(36) Remove generator, lower bracket, and upper

mounting bolt.

(37) Continue raising vehicle slowly until engine/

transaxle assembly clears engine compartment. It

may be necessary to move the engine/transmission

assembly with the cradle to allow for removal around

body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine/transaxle assembly until vehicle is within 15

cm (6 in.) of engine mounting locations.

(2) Install generator, lower bracket, and adjusting

bolt.

(3) Continue lowering vehicle until engine/tran-

saxle aligns to mounting locations. Install mounting

bolts at the right and left engine/transaxle mounts

(Fig. 24) and (Fig. 25). Tighten bolts to 118 N´m (87

ft. lbs.).

(4) Install upper engine torque strut. Refer to pro-

cedure in this section.

(5) Remove safety straps from engine/transaxle

assembly. Slowly raise vehicle enough to remove the

engine dolly and cradle.

(6) Install axle shafts. Refer to Group 3, Differen-

tial and Driveline for procedure.

(7) Install structural collar. Refer to procedure in

this section tightening sequence.

Fig. 24 Right Mount Through Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

9 - 26 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)