electrical DODGE NEON 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 261 of 1285

REMOVAL AND INSTALLATION

HEADLAMP LEVELING SWITCH

REMOVAL

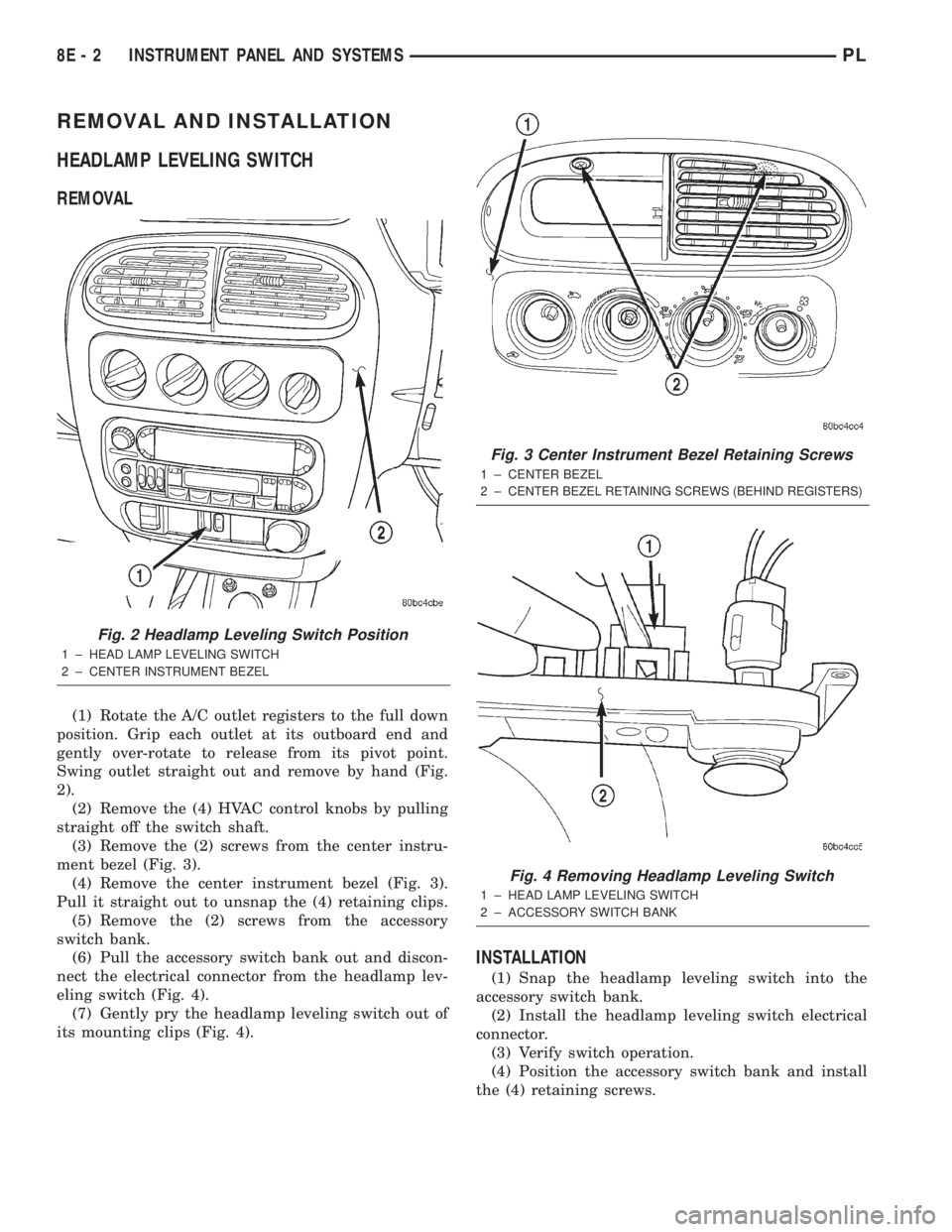

(1) Rotate the A/C outlet registers to the full down

position. Grip each outlet at its outboard end and

gently over-rotate to release from its pivot point.

Swing outlet straight out and remove by hand (Fig.

2).

(2) Remove the (4) HVAC control knobs by pulling

straight off the switch shaft.

(3) Remove the (2) screws from the center instru-

ment bezel (Fig. 3).

(4) Remove the center instrument bezel (Fig. 3).

Pull it straight out to unsnap the (4) retaining clips.

(5) Remove the (2) screws from the accessory

switch bank.

(6) Pull the accessory switch bank out and discon-

nect the electrical connector from the headlamp lev-

eling switch (Fig. 4).

(7) Gently pry the headlamp leveling switch out of

its mounting clips (Fig. 4).

INSTALLATION

(1) Snap the headlamp leveling switch into the

accessory switch bank.

(2) Install the headlamp leveling switch electrical

connector.

(3) Verify switch operation.

(4) Position the accessory switch bank and install

the (4) retaining screws.

Fig. 2 Headlamp Leveling Switch Position

1 ± HEAD LAMP LEVELING SWITCH

2 ± CENTER INSTRUMENT BEZEL

Fig. 3 Center Instrument Bezel Retaining Screws

1 ± CENTER BEZEL

2±

CENTER BEZEL RETAINING SCREWS (BEHIND REGISTERS)

Fig. 4 Removing Headlamp Leveling Switch

1 ± HEAD LAMP LEVELING SWITCH

2 ± ACCESSORY SWITCH BANK

8E - 2 INSTRUMENT PANEL AND SYSTEMSPL

Page 288 of 1285

On most vehicles another resistor has been added

to the at rest circuit causing the PCM to never see 5

volts. This was done for diagnostic purposes. If the

switch circuit should open (bad connection) then the

PCM will see the 5 volts and know the circuit is bad.

The PCM will then set an open circuit fault.

STOP LAMP SWITCH

DESCRIPTION

The switch is mounted on the brake pedal mount-

ing bracket under the instrument panel.

OPERATION

Vehicles equipped with the speed control option use

a dual function stop lamp switch. The PCM monitors

the state of the dual function stop lamp switch. Refer

to the Brake section for more information on stop

lamp switch service and adjustment procedures.

The brake switch is equipped with three sets of

contacts, one normally open and the other two nor-

mally closed (brakes disengaged). The PCM sends a

12 volt signal to one of the normally closed contacts

in the brake switch, which is connected to a ground.

With the contacts closed, the 12 volt signal is pulled

to ground causing the signal to go low. The low volt-

age signal, monitored by the PCM, indicates that the

brakes are not applied. When the brakes are applied,

the contacts open, causing the PCM's output voltage

to go high, disengaging the speed control also

grounding the dump solenoid.

The second set of normally closed contacts is sup-

plied battery voltage any time speed control is

selected. From the brake switch, current is routed to

the speed control servo solenoids. The speed control

solenoids (vacuum, vent and dump) are provided this

current any time the speed control is ON and the

brakes are disengaged. When the driver applies the

brakes, the contacts open and current is interrupted

to the solenoids. The normally open contacts are fed

battery voltage. When the brakes are applied, battery

voltage is supplied to the stop lamps.

SERVO CABLE

DESCRIPTION

The speed control servo cable is connected between

the speed control vacuum servo diaphragm and the

throttle body control linkage.

OPERATION

This cable causes the throttle control linkage to

open or close the throttle valve in response to move-

ment of the vacuum servo diaphragm.

VACUUM RESERVOIR

OPERATION

The reservoir stores engine vacuum in the reser-

voir. When engine vacuum drops, as in climbing a

grade while driving, the reservoir supplies the vac-

uum needed to maintain proper speed control opera-

tion. The vacuum reservoir cannot be repaired and

must be replaced if faulty.

VEHICLE SPEED SENSOR

The Vehicle Speed Sensor (VSS) is a pulse genera-

tor mounted to an adapter near the transmission out-

put shaft. The sensor is driven through the adapter

by a speedometer pinion gear. The VSS pulse signal

to the speedometer/odometer is monitored by the

PCM speed control circuitry to determine vehicle

speed and to maintain speed control set speed.

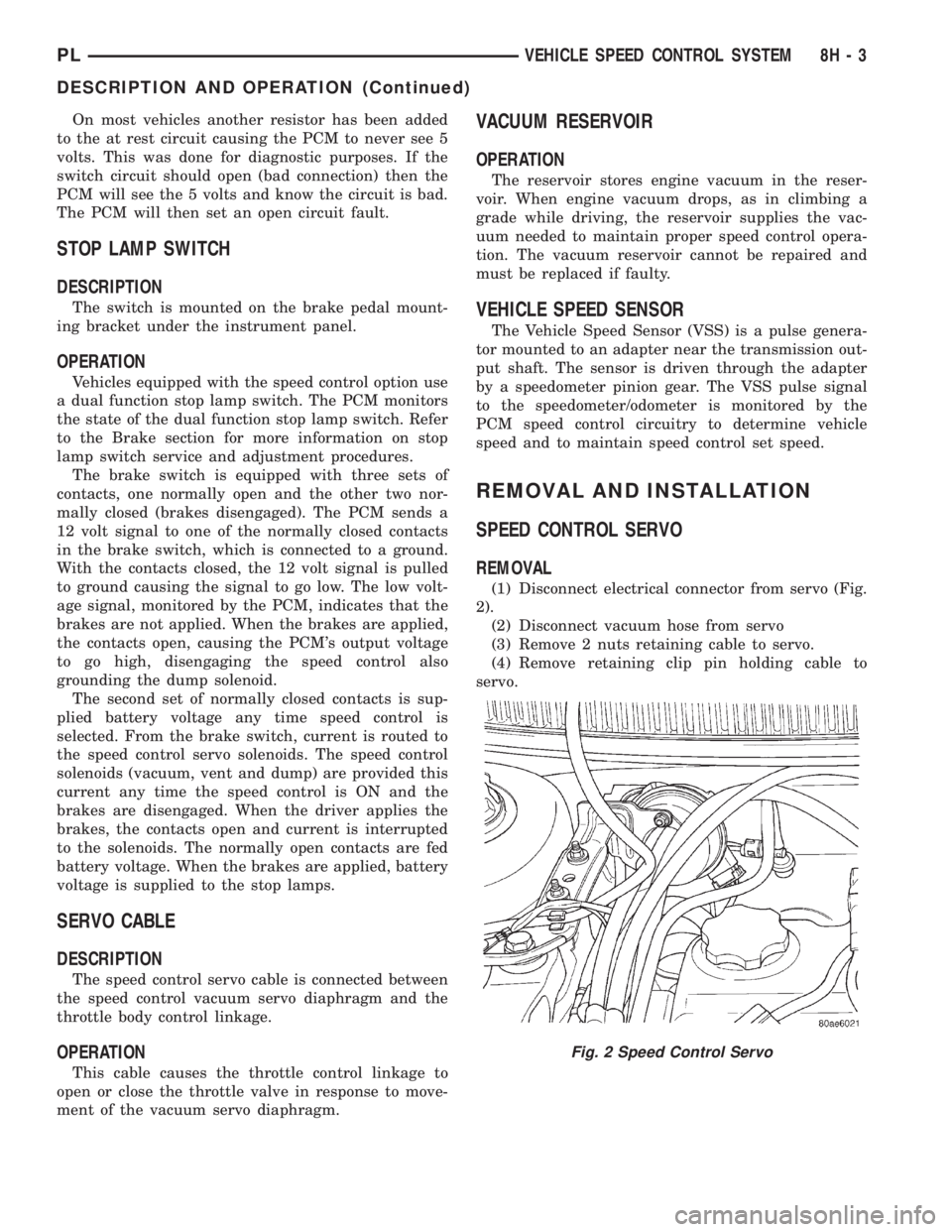

REMOVAL AND INSTALLATION

SPEED CONTROL SERVO

REMOVAL

(1) Disconnect electrical connector from servo (Fig.

2).

(2) Disconnect vacuum hose from servo

(3) Remove 2 nuts retaining cable to servo.

(4) Remove retaining clip pin holding cable to

servo.

Fig. 2 Speed Control Servo

PLVEHICLE SPEED CONTROL SYSTEM 8H - 3

DESCRIPTION AND OPERATION (Continued)

Page 289 of 1285

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(3) Connect electrical connector to servo.

(4) Connect vacuum hose to servo

SPEED CONTROL SWITCH

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module (Fig. 1).

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS.

REMOVAL

(1) Turn off ignition.

(2) Remove two screws from side of each switch.

(3) Rock switch away from airbag and steering

wheel.

(4) Disconnect two-way electrical connector.

(5) Repeat for the other switch.

INSTALLATION

(1) Install switches.

(2) Connect two-way electrical connector.

(3) Install two screws to the side of each switch.

(4) Install airbag, refer to the Restraint Systems

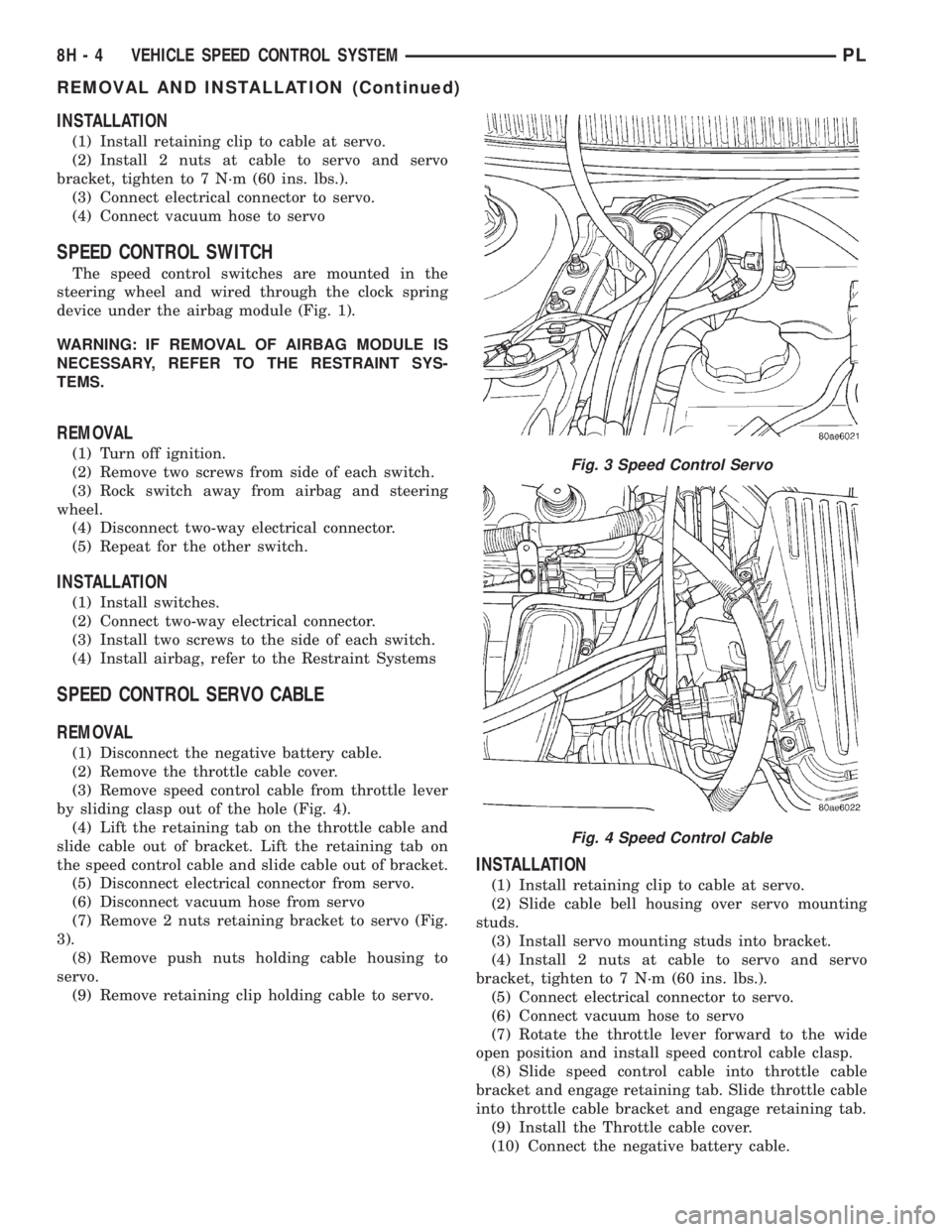

SPEED CONTROL SERVO CABLE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the throttle cable cover.

(3) Remove speed control cable from throttle lever

by sliding clasp out of the hole (Fig. 4).

(4) Lift the retaining tab on the throttle cable and

slide cable out of bracket. Lift the retaining tab on

the speed control cable and slide cable out of bracket.

(5) Disconnect electrical connector from servo.

(6) Disconnect vacuum hose from servo

(7) Remove 2 nuts retaining bracket to servo (Fig.

3).

(8) Remove push nuts holding cable housing to

servo.

(9) Remove retaining clip holding cable to servo.

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Slide cable bell housing over servo mounting

studs.

(3) Install servo mounting studs into bracket.

(4) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(5) Connect electrical connector to servo.

(6) Connect vacuum hose to servo

(7) Rotate the throttle lever forward to the wide

open position and install speed control cable clasp.

(8) Slide speed control cable into throttle cable

bracket and engage retaining tab. Slide throttle cable

into throttle cable bracket and engage retaining tab.

(9) Install the Throttle cable cover.

(10) Connect the negative battery cable.

Fig. 3 Speed Control Servo

Fig. 4 Speed Control Cable

8H - 4 VEHICLE SPEED CONTROL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 292 of 1285

TURN SIGNAL and HAZARD WARNING SYSTEMS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

HAZARD WARNING SYSTEM................2

HEADLAMP SWITCH......................2

COMBINATION FLASHER...................2DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH.................3

REMOVAL AND INSTALLATION

COMBINATION FLASHER...................5

MULTI-FUNCTION SWITCH.................5

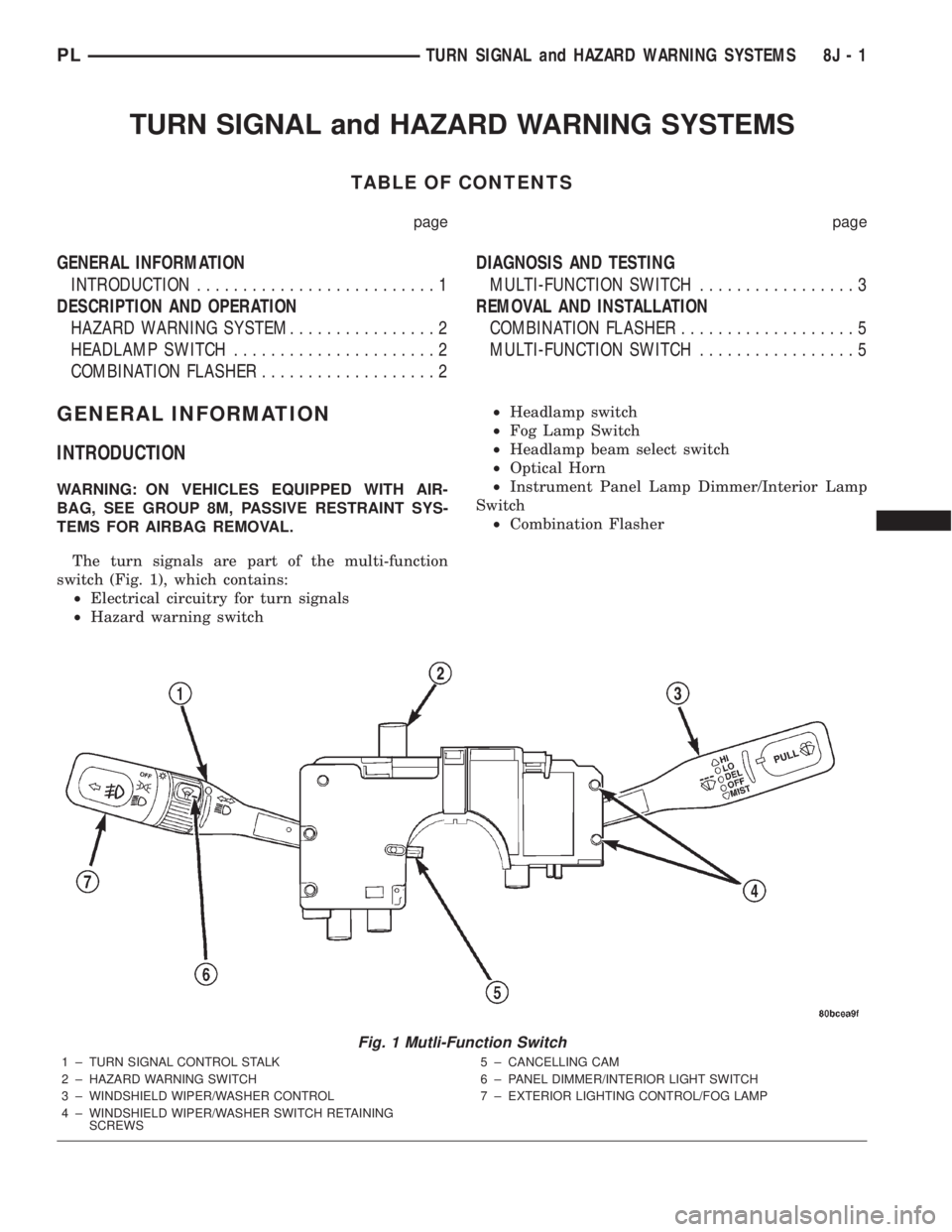

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, PASSIVE RESTRAINT SYS-

TEMS FOR AIRBAG REMOVAL.

The turn signals are part of the multi-function

switch (Fig. 1), which contains:

²Electrical circuitry for turn signals

²Hazard warning switch²Headlamp switch

²Fog Lamp Switch

²Headlamp beam select switch

²Optical Horn

²Instrument Panel Lamp Dimmer/Interior Lamp

Switch

²Combination Flasher

Fig. 1 Mutli-Function Switch

1 ± TURN SIGNAL CONTROL STALK

2 ± HAZARD WARNING SWITCH

3 ± WINDSHIELD WIPER/WASHER CONTROL

4 ± WINDSHIELD WIPER/WASHER SWITCH RETAINING

SCREWS5 ± CANCELLING CAM

6 ± PANEL DIMMER/INTERIOR LIGHT SWITCH

7 ± EXTERIOR LIGHTING CONTROL/FOG LAMP

PLTURN SIGNAL and HAZARD WARNING SYSTEMS 8J - 1

Page 305 of 1285

WINDSHIELD WASHER SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

WINDSHIELD WASHER NOZZLE(S)............8

WINDSHIELD WASHER SYSTEM.............8

DIAGNOSIS AND TESTING

WINDSHIELD WASHER SYSTEM.............9REMOVAL AND INSTALLATION

WINDSHIELD WASHER HOSE................9

WINDSHIELD WASHER NOZZLES.............9

WINDSHIELD WASHER RESERVOIR..........10

WINDSHIELD WASHER PUMP...............10

DESCRIPTION AND OPERATION

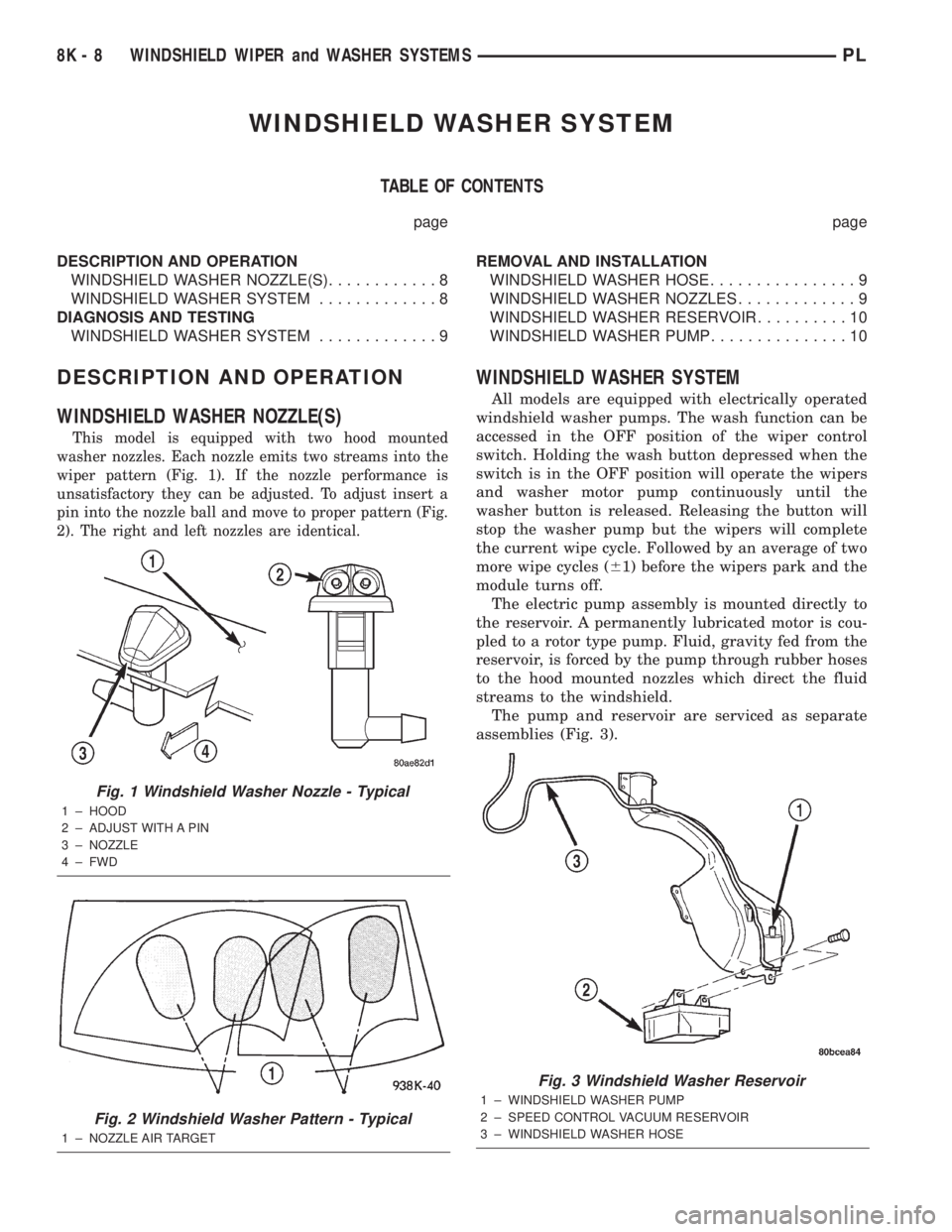

WINDSHIELD WASHER NOZZLE(S)

This model is equipped with two hood mounted

washer nozzles. Each nozzle emits two streams into the

wiper pattern (Fig. 1). If the nozzle performance is

unsatisfactory they can be adjusted. To adjust insert a

pin into the nozzle ball and move to proper pattern (Fig.

2). The right and left nozzles are identical.

WINDSHIELD WASHER SYSTEM

All models are equipped with electrically operated

windshield washer pumps. The wash function can be

accessed in the OFF position of the wiper control

switch. Holding the wash button depressed when the

switch is in the OFF position will operate the wipers

and washer motor pump continuously until the

washer button is released. Releasing the button will

stop the washer pump but the wipers will complete

the current wipe cycle. Followed by an average of two

more wipe cycles (61) before the wipers park and the

module turns off.

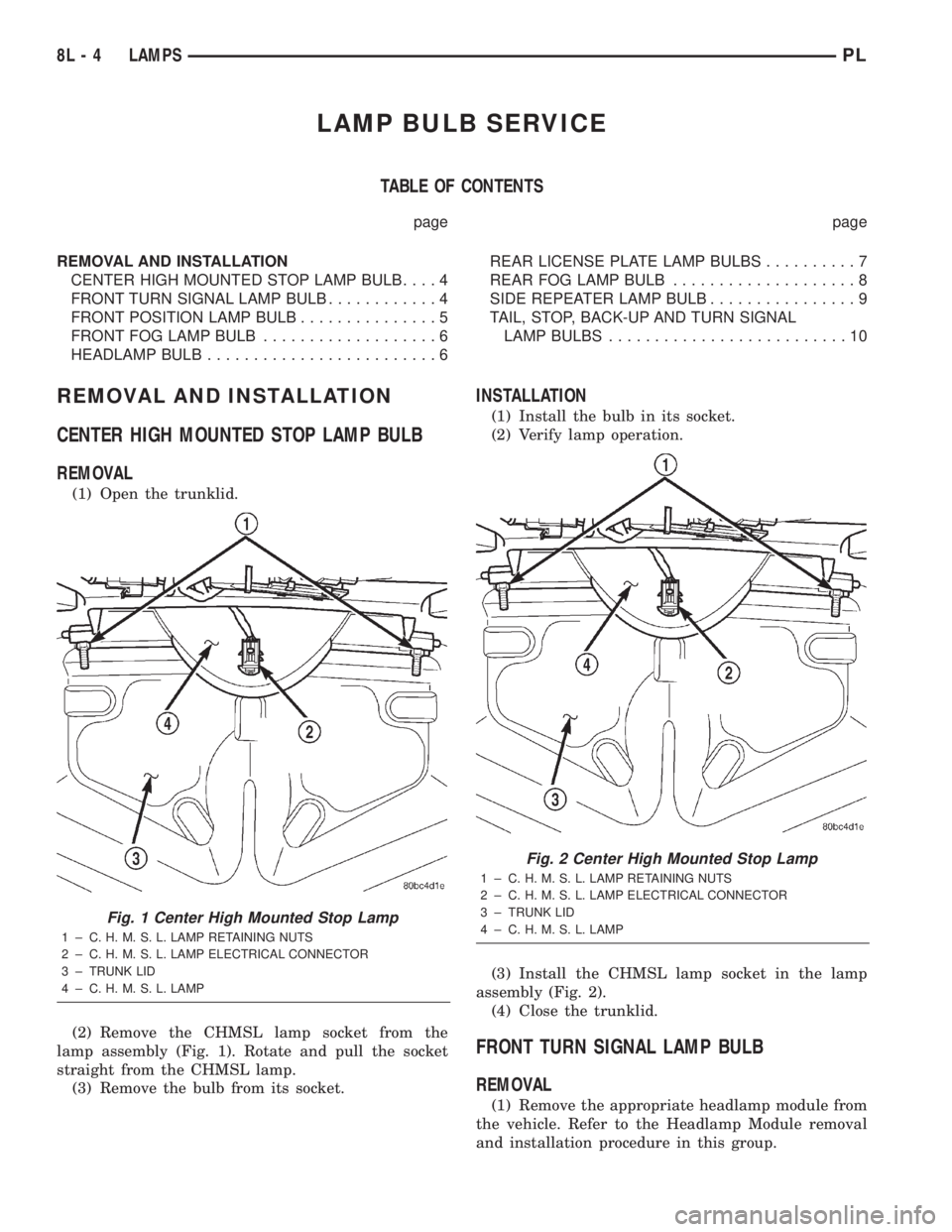

The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated motor is cou-

pled to a rotor type pump. Fluid, gravity fed from the

reservoir, is forced by the pump through rubber hoses

to the hood mounted nozzles which direct the fluid

streams to the windshield.

The pump and reservoir are serviced as separate

assemblies (Fig. 3).

Fig. 1 Windshield Washer Nozzle - Typical

1 ± HOOD

2 ± ADJUST WITH A PIN

3 ± NOZZLE

4 ± FWD

Fig. 2 Windshield Washer Pattern - Typical

1 ± NOZZLE AIR TARGET

Fig. 3 Windshield Washer Reservoir

1 ± WINDSHIELD WASHER PUMP

2 ± SPEED CONTROL VACUUM RESERVOIR

3 ± WINDSHIELD WASHER HOSE

8K - 8 WINDSHIELD WIPER and WASHER SYSTEMSPL

Page 329 of 1285

LAMP BULB SERVICE

TABLE OF CONTENTS

page page

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP BULB....4

FRONT TURN SIGNAL LAMP BULB............4

FRONT POSITION LAMP BULB...............5

FRONT FOG LAMP BULB...................6

HEADLAMP BULB.........................6REAR LICENSE PLATE LAMP BULBS..........7

REAR FOG LAMP BULB....................8

SIDE REPEATER LAMP BULB................9

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULBS..........................10

REMOVAL AND INSTALLATION

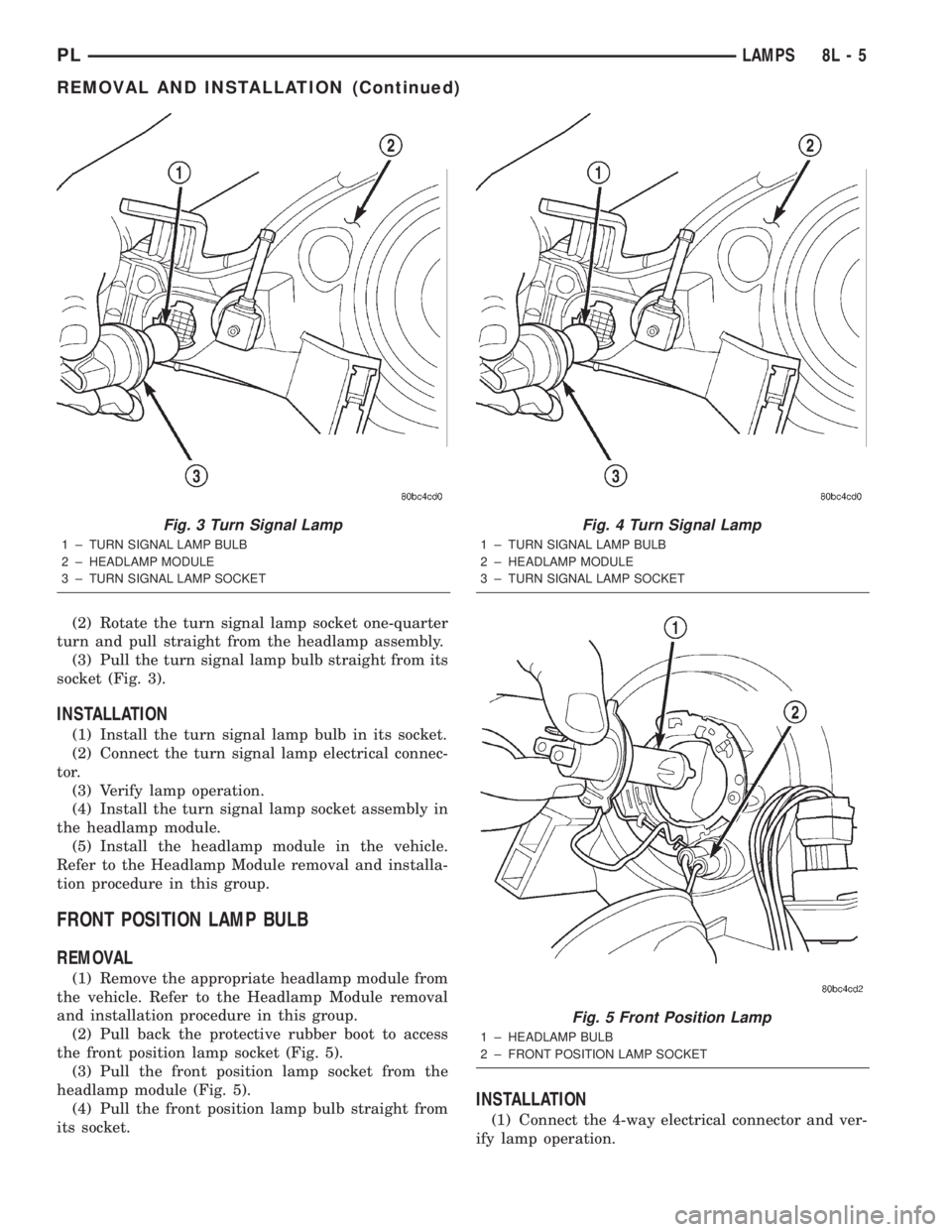

CENTER HIGH MOUNTED STOP LAMP BULB

REMOVAL

(1) Open the trunklid.

(2) Remove the CHMSL lamp socket from the

lamp assembly (Fig. 1). Rotate and pull the socket

straight from the CHMSL lamp.

(3) Remove the bulb from its socket.

INSTALLATION

(1) Install the bulb in its socket.

(2) Verify lamp operation.

(3) Install the CHMSL lamp socket in the lamp

assembly (Fig. 2).

(4) Close the trunklid.

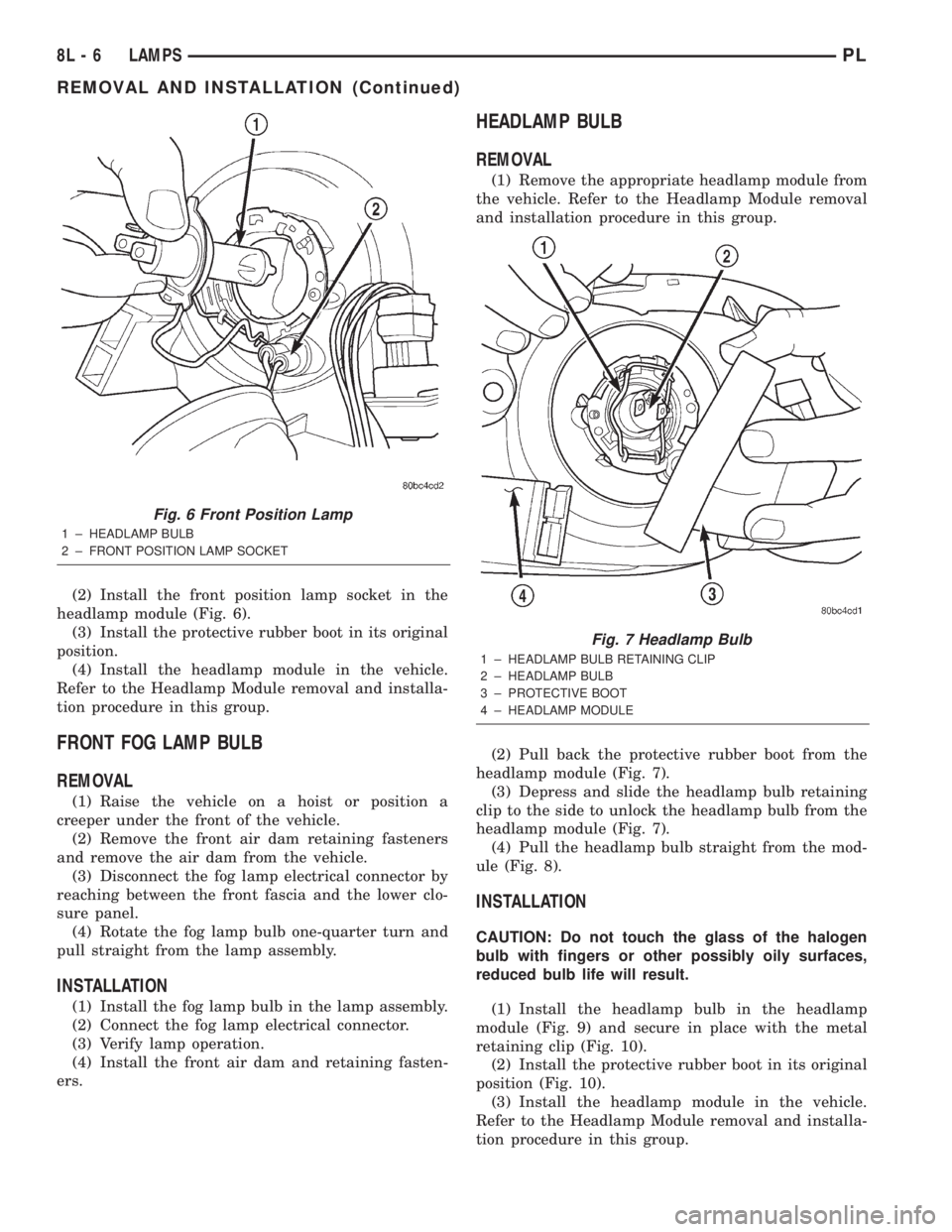

FRONT TURN SIGNAL LAMP BULB

REMOVAL

(1) Remove the appropriate headlamp module from

the vehicle. Refer to the Headlamp Module removal

and installation procedure in this group.

Fig. 1 Center High Mounted Stop Lamp

1 ± C. H. M. S. L. LAMP RETAINING NUTS

2 ± C. H. M. S. L. LAMP ELECTRICAL CONNECTOR

3 ± TRUNK LID

4 ± C. H. M. S. L. LAMP

Fig. 2 Center High Mounted Stop Lamp

1 ± C. H. M. S. L. LAMP RETAINING NUTS

2 ± C. H. M. S. L. LAMP ELECTRICAL CONNECTOR

3 ± TRUNK LID

4 ± C. H. M. S. L. LAMP

8L - 4 LAMPSPL

Page 330 of 1285

(2) Rotate the turn signal lamp socket one-quarter

turn and pull straight from the headlamp assembly.

(3) Pull the turn signal lamp bulb straight from its

socket (Fig. 3).

INSTALLATION

(1) Install the turn signal lamp bulb in its socket.

(2) Connect the turn signal lamp electrical connec-

tor.

(3) Verify lamp operation.

(4) Install the turn signal lamp socket assembly in

the headlamp module.

(5) Install the headlamp module in the vehicle.

Refer to the Headlamp Module removal and installa-

tion procedure in this group.

FRONT POSITION LAMP BULB

REMOVAL

(1) Remove the appropriate headlamp module from

the vehicle. Refer to the Headlamp Module removal

and installation procedure in this group.

(2) Pull back the protective rubber boot to access

the front position lamp socket (Fig. 5).

(3) Pull the front position lamp socket from the

headlamp module (Fig. 5).

(4) Pull the front position lamp bulb straight from

its socket.

INSTALLATION

(1) Connect the 4-way electrical connector and ver-

ify lamp operation.

Fig. 3 Turn Signal Lamp

1 ± TURN SIGNAL LAMP BULB

2 ± HEADLAMP MODULE

3 ± TURN SIGNAL LAMP SOCKET

Fig. 4 Turn Signal Lamp

1 ± TURN SIGNAL LAMP BULB

2 ± HEADLAMP MODULE

3 ± TURN SIGNAL LAMP SOCKET

Fig. 5 Front Position Lamp

1 ± HEADLAMP BULB

2 ± FRONT POSITION LAMP SOCKET

PLLAMPS 8L - 5

REMOVAL AND INSTALLATION (Continued)

Page 331 of 1285

(2) Install the front position lamp socket in the

headlamp module (Fig. 6).

(3) Install the protective rubber boot in its original

position.

(4) Install the headlamp module in the vehicle.

Refer to the Headlamp Module removal and installa-

tion procedure in this group.

FRONT FOG LAMP BULB

REMOVAL

(1) Raise the vehicle on a hoist or position a

creeper under the front of the vehicle.

(2) Remove the front air dam retaining fasteners

and remove the air dam from the vehicle.

(3) Disconnect the fog lamp electrical connector by

reaching between the front fascia and the lower clo-

sure panel.

(4) Rotate the fog lamp bulb one-quarter turn and

pull straight from the lamp assembly.

INSTALLATION

(1) Install the fog lamp bulb in the lamp assembly.

(2) Connect the fog lamp electrical connector.

(3) Verify lamp operation.

(4) Install the front air dam and retaining fasten-

ers.

HEADLAMP BULB

REMOVAL

(1) Remove the appropriate headlamp module from

the vehicle. Refer to the Headlamp Module removal

and installation procedure in this group.

(2) Pull back the protective rubber boot from the

headlamp module (Fig. 7).

(3) Depress and slide the headlamp bulb retaining

clip to the side to unlock the headlamp bulb from the

headlamp module (Fig. 7).

(4) Pull the headlamp bulb straight from the mod-

ule (Fig. 8).

INSTALLATION

CAUTION: Do not touch the glass of the halogen

bulb with fingers or other possibly oily surfaces,

reduced bulb life will result.

(1) Install the headlamp bulb in the headlamp

module (Fig. 9) and secure in place with the metal

retaining clip (Fig. 10).

(2) Install the protective rubber boot in its original

position (Fig. 10).

(3) Install the headlamp module in the vehicle.

Refer to the Headlamp Module removal and installa-

tion procedure in this group.

Fig. 6 Front Position Lamp

1 ± HEADLAMP BULB

2 ± FRONT POSITION LAMP SOCKET

Fig. 7 Headlamp Bulb

1 ± HEADLAMP BULB RETAINING CLIP

2 ± HEADLAMP BULB

3 ± PROTECTIVE BOOT

4 ± HEADLAMP MODULE

8L - 6 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 335 of 1285

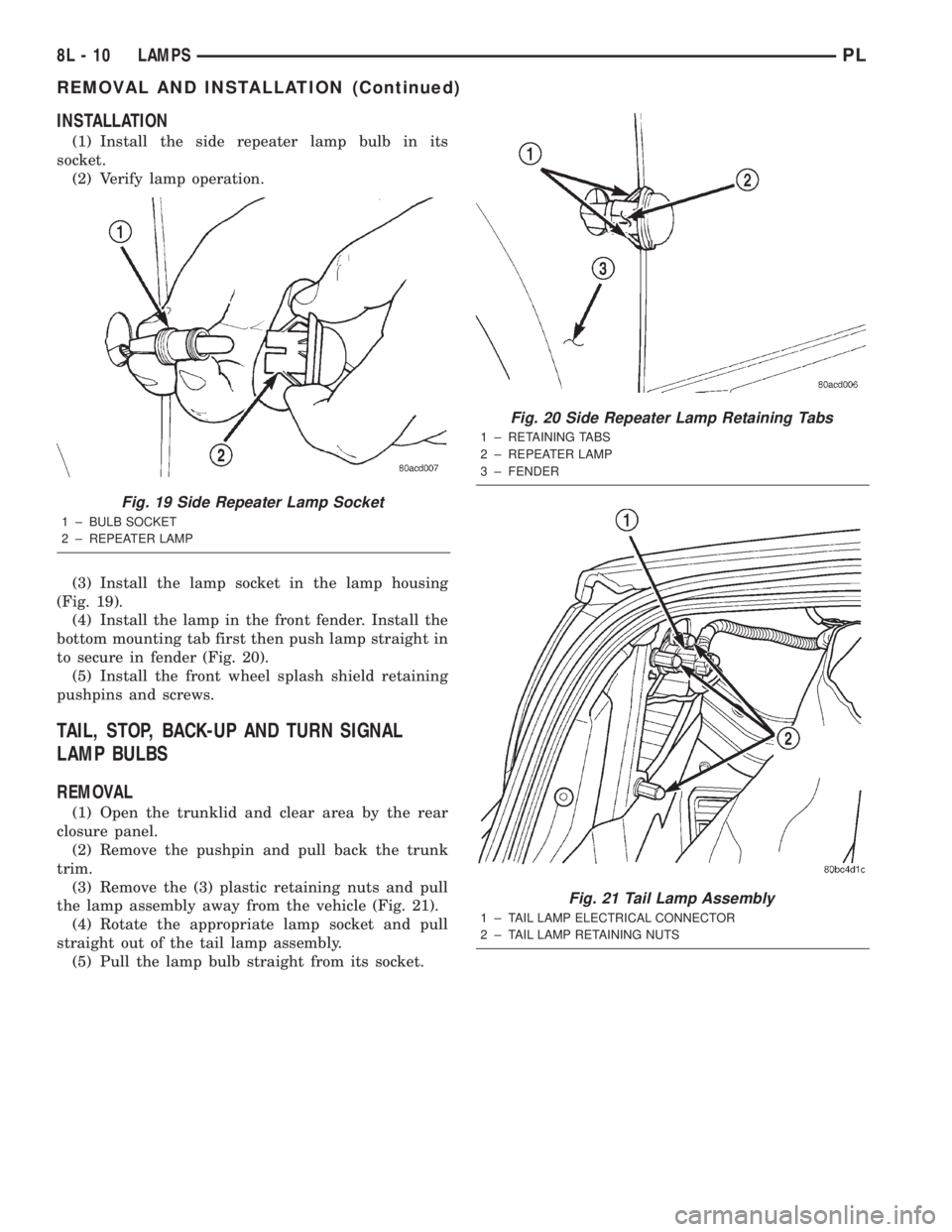

INSTALLATION

(1) Install the side repeater lamp bulb in its

socket.

(2) Verify lamp operation.

(3) Install the lamp socket in the lamp housing

(Fig. 19).

(4) Install the lamp in the front fender. Install the

bottom mounting tab first then push lamp straight in

to secure in fender (Fig. 20).

(5) Install the front wheel splash shield retaining

pushpins and screws.

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULBS

REMOVAL

(1) Open the trunklid and clear area by the rear

closure panel.

(2) Remove the pushpin and pull back the trunk

trim.

(3) Remove the (3) plastic retaining nuts and pull

the lamp assembly away from the vehicle (Fig. 21).

(4) Rotate the appropriate lamp socket and pull

straight out of the tail lamp assembly.

(5) Pull the lamp bulb straight from its socket.

Fig. 19 Side Repeater Lamp Socket

1 ± BULB SOCKET

2 ± REPEATER LAMP

Fig. 20 Side Repeater Lamp Retaining Tabs

1 ± RETAINING TABS

2 ± REPEATER LAMP

3 ± FENDER

Fig. 21 Tail Lamp Assembly

1 ± TAIL LAMP ELECTRICAL CONNECTOR

2 ± TAIL LAMP RETAINING NUTS

8L - 10 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 336 of 1285

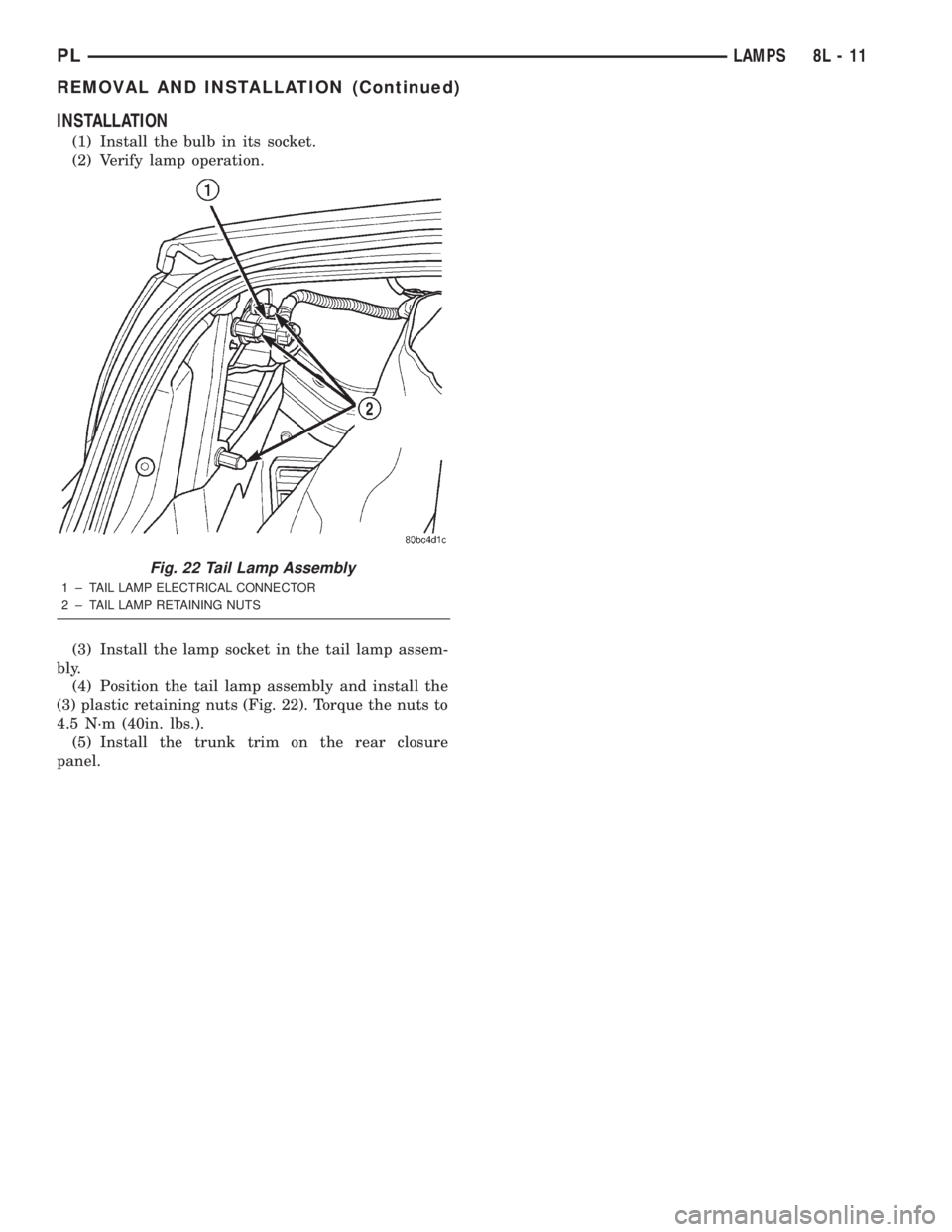

INSTALLATION

(1) Install the bulb in its socket.

(2) Verify lamp operation.

(3) Install the lamp socket in the tail lamp assem-

bly.

(4) Position the tail lamp assembly and install the

(3) plastic retaining nuts (Fig. 22). Torque the nuts to

4.5 N´m (40in. lbs.).

(5) Install the trunk trim on the rear closure

panel.

Fig. 22 Tail Lamp Assembly

1 ± TAIL LAMP ELECTRICAL CONNECTOR

2 ± TAIL LAMP RETAINING NUTS

PLLAMPS 8L - 11

REMOVAL AND INSTALLATION (Continued)