instrument panel DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 295 of 1285

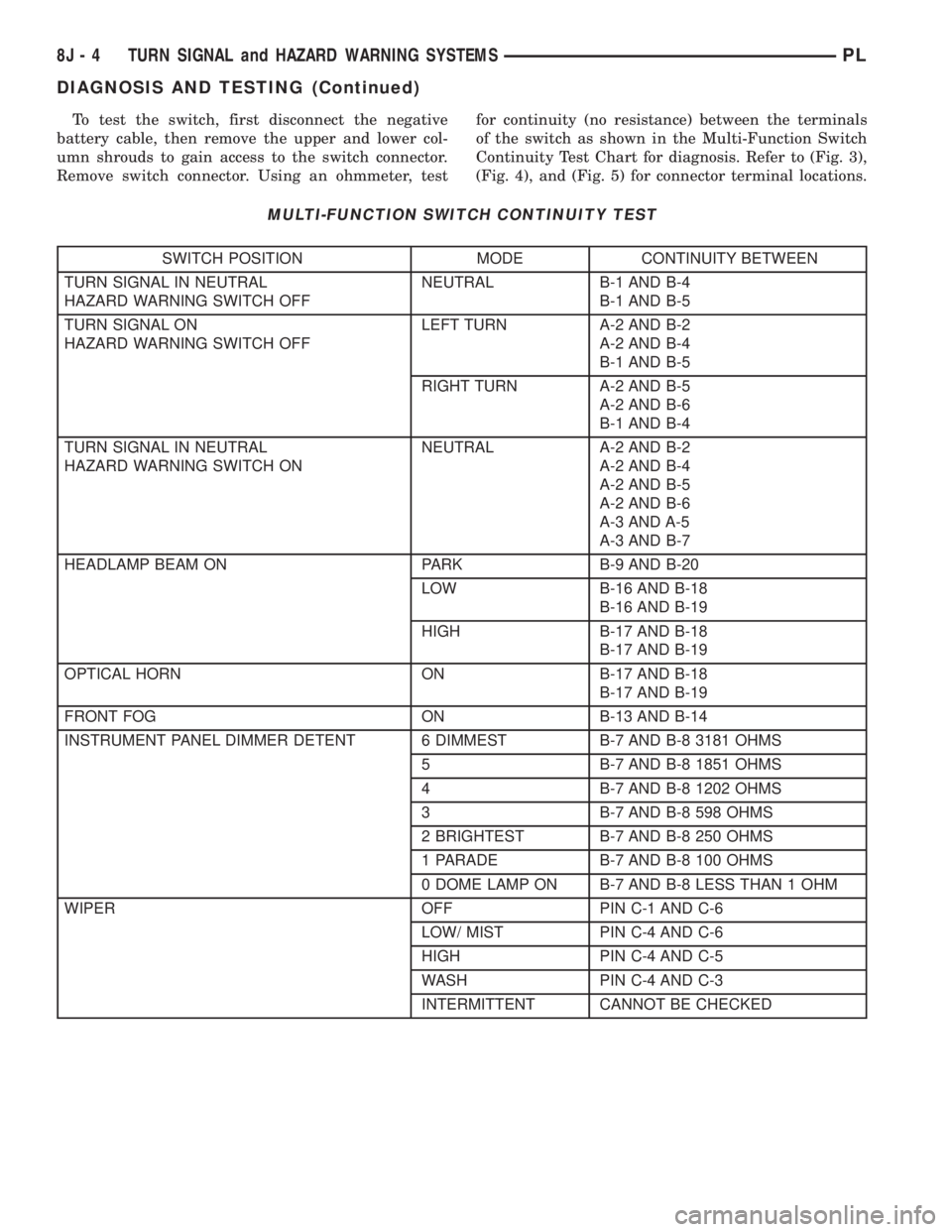

To test the switch, first disconnect the negative

battery cable, then remove the upper and lower col-

umn shrouds to gain access to the switch connector.

Remove switch connector. Using an ohmmeter, testfor continuity (no resistance) between the terminals

of the switch as shown in the Multi-Function Switch

Continuity Test Chart for diagnosis. Refer to (Fig. 3),

(Fig. 4), and (Fig. 5) for connector terminal locations.

MULTI-FUNCTION SWITCH CONTINUITY TEST

SWITCH POSITION MODE CONTINUITY BETWEEN

TURN SIGNAL IN NEUTRAL

HAZARD WARNING SWITCH OFFNEUTRAL B-1 AND B-4

B-1 AND B-5

TURN SIGNAL ON

HAZARD WARNING SWITCH OFFLEFT TURN A-2 AND B-2

A-2 AND B-4

B-1 AND B-5

RIGHT TURN A-2 AND B-5

A-2 AND B-6

B-1 AND B-4

TURN SIGNAL IN NEUTRAL

HAZARD WARNING SWITCH ONNEUTRAL A-2 AND B-2

A-2 AND B-4

A-2 AND B-5

A-2 AND B-6

A-3 AND A-5

A-3 AND B-7

HEADLAMP BEAM ON PARK B-9 AND B-20

LOW B-16 AND B-18

B-16 AND B-19

HIGH B-17 AND B-18

B-17 AND B-19

OPTICAL HORN ON B-17 AND B-18

B-17 AND B-19

FRONT FOG ON B-13 AND B-14

INSTRUMENT PANEL DIMMER DETENT 6 DIMMEST B-7 AND B-8 3181 OHMS

5 B-7 AND B-8 1851 OHMS

4 B-7 AND B-8 1202 OHMS

3 B-7 AND B-8 598 OHMS

2 BRIGHTEST B-7 AND B-8 250 OHMS

1 PARADE B-7 AND B-8 100 OHMS

0 DOME LAMP ON B-7 AND B-8 LESS THAN 1 OHM

WIPER OFF PIN C-1 AND C-6

LOW/ MIST PIN C-4 AND C-6

HIGH PIN C-4 AND C-5

WASH PIN C-4 AND C-3

INTERMITTENT CANNOT BE CHECKED

8J - 4 TURN SIGNAL and HAZARD WARNING SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 296 of 1285

REMOVAL AND INSTALLATION

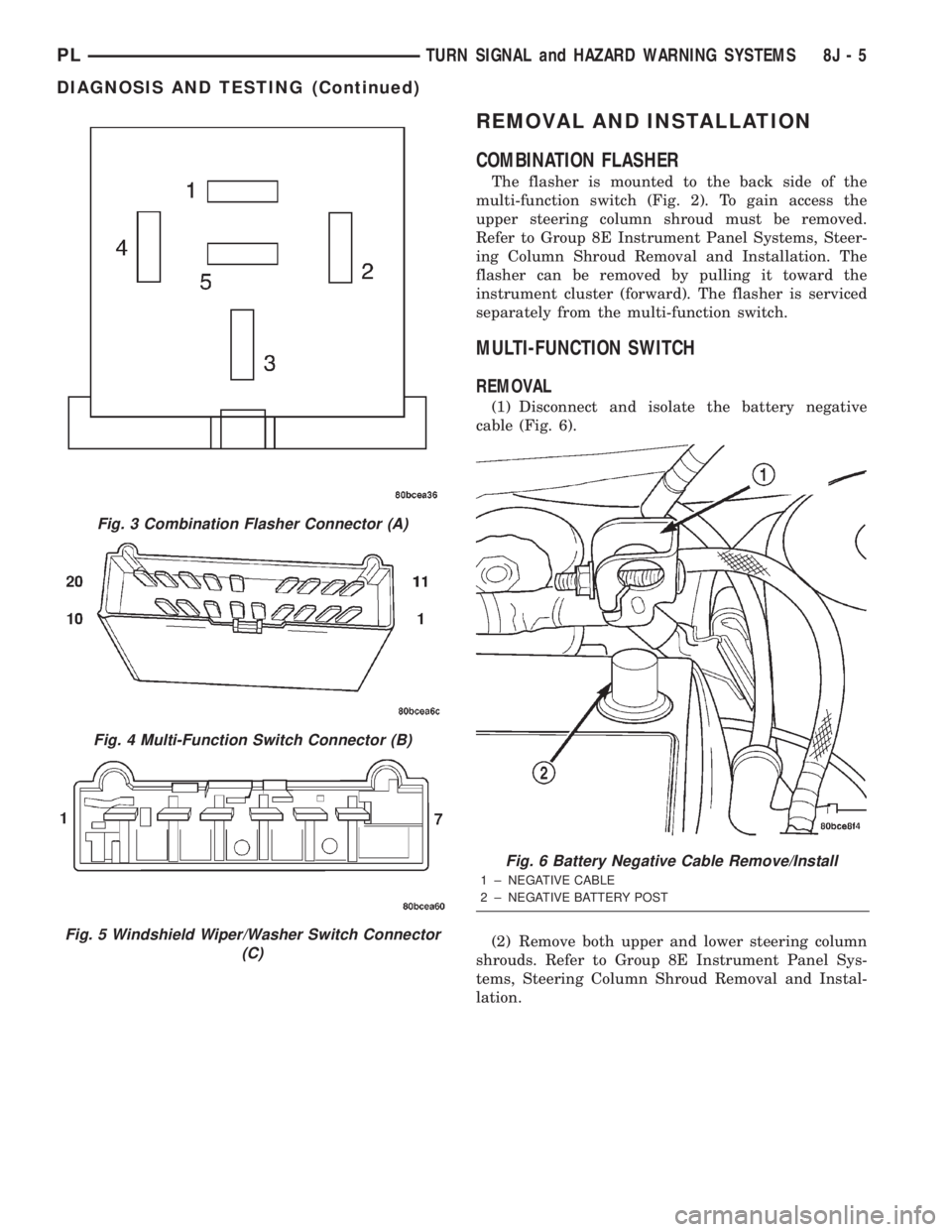

COMBINATION FLASHER

The flasher is mounted to the back side of the

multi-function switch (Fig. 2). To gain access the

upper steering column shroud must be removed.

Refer to Group 8E Instrument Panel Systems, Steer-

ing Column Shroud Removal and Installation. The

flasher can be removed by pulling it toward the

instrument cluster (forward). The flasher is serviced

separately from the multi-function switch.

MULTI-FUNCTION SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 6).

(2) Remove both upper and lower steering column

shrouds. Refer to Group 8E Instrument Panel Sys-

tems, Steering Column Shroud Removal and Instal-

lation.

Fig. 3 Combination Flasher Connector (A)

Fig. 4 Multi-Function Switch Connector (B)

Fig. 5 Windshield Wiper/Washer Switch Connector

(C)

Fig. 6 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

PLTURN SIGNAL and HAZARD WARNING SYSTEMS 8J - 5

DIAGNOSIS AND TESTING (Continued)

Page 318 of 1285

INSTALLATION

(1) Push bulb in socket and snap into place.

(2) Install floor console.

GLOVE BOX LAMP BULB

REMOVAL

(1) Open glove box door.

(2) Pull downward on lamp/switch assembly to dis-

engage tabs from instrument panel.

(3) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Place lamp/switch assembly into position.

(3) Push lamp/switch assembly to lock tabs.

(4) Check lamp operation, and close glove door.

FLOOR CONSOLE LAMP BULB

REMOVAL

(1) Using a flat bladed tool, slide it between the

lamp and instrument panel to disengage tabs.(2) Remove bulb from lamp socket.

INSTALLATION

(1) Install bulb into socket.

(2) Place lamp into position.

(3) Push lamp to lock tabs.

(4) Check lamp operation.

VISOR VANITY LAMP BULB

REMOVAL

(1) Lower visor.

(2) Insert a small flat bladed tool between the

lamp lens and lamp.

(3) Carefully pry lens outward.

(4) Remove bulb from socket.

INSTALLATION

(1) Position bulb in socket and snap into place.

(2) Position lens on lamp and snap into place.

PLLAMPS 8L - 11

REMOVAL AND INSTALLATION (Continued)

Page 322 of 1285

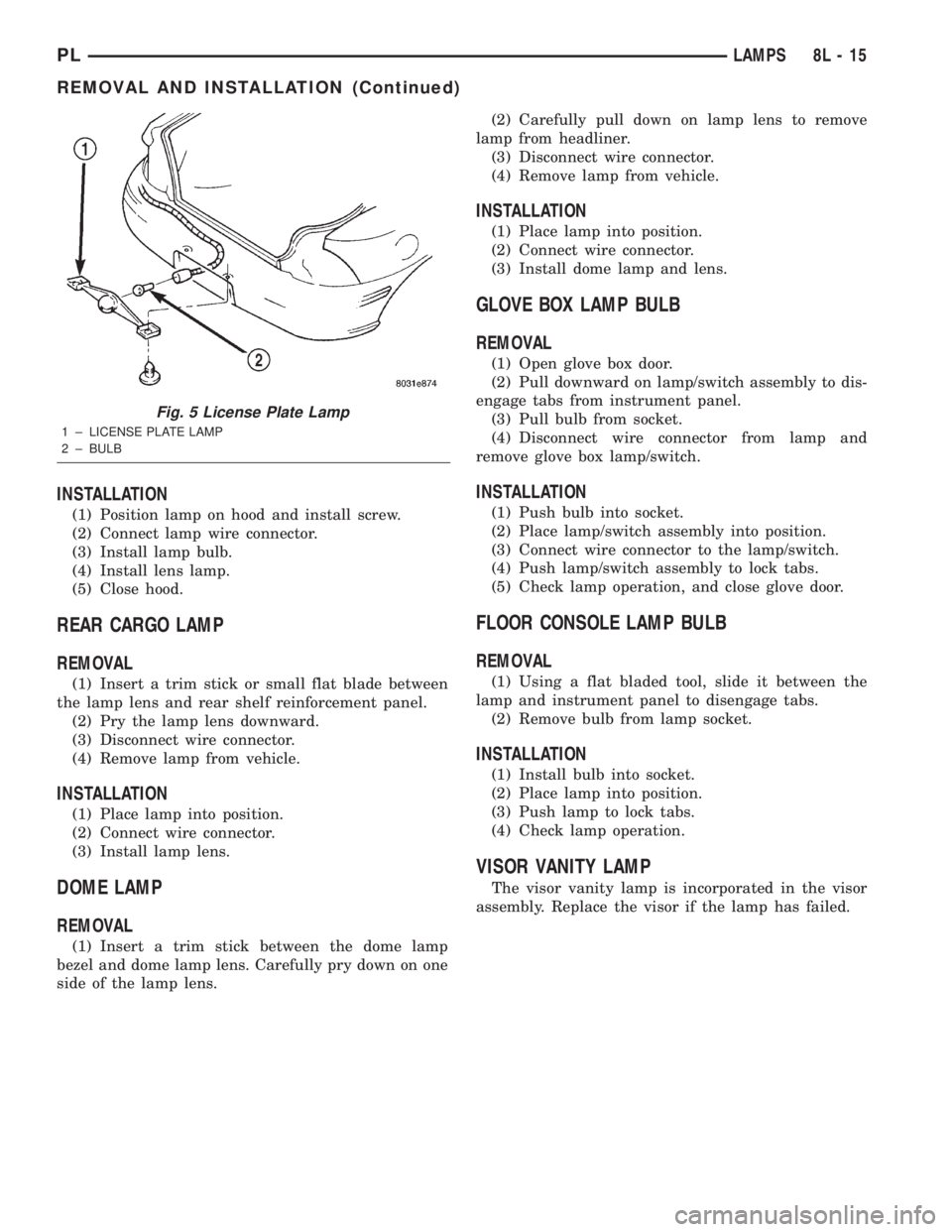

INSTALLATION

(1) Position lamp on hood and install screw.

(2) Connect lamp wire connector.

(3) Install lamp bulb.

(4) Install lens lamp.

(5) Close hood.

REAR CARGO LAMP

REMOVAL

(1) Insert a trim stick or small flat blade between

the lamp lens and rear shelf reinforcement panel.

(2) Pry the lamp lens downward.

(3) Disconnect wire connector.

(4) Remove lamp from vehicle.

INSTALLATION

(1) Place lamp into position.

(2) Connect wire connector.

(3) Install lamp lens.

DOME LAMP

REMOVAL

(1) Insert a trim stick between the dome lamp

bezel and dome lamp lens. Carefully pry down on one

side of the lamp lens.(2) Carefully pull down on lamp lens to remove

lamp from headliner.

(3) Disconnect wire connector.

(4) Remove lamp from vehicle.

INSTALLATION

(1) Place lamp into position.

(2) Connect wire connector.

(3) Install dome lamp and lens.

GLOVE BOX LAMP BULB

REMOVAL

(1) Open glove box door.

(2) Pull downward on lamp/switch assembly to dis-

engage tabs from instrument panel.

(3) Pull bulb from socket.

(4) Disconnect wire connector from lamp and

remove glove box lamp/switch.

INSTALLATION

(1) Push bulb into socket.

(2) Place lamp/switch assembly into position.

(3) Connect wire connector to the lamp/switch.

(4) Push lamp/switch assembly to lock tabs.

(5) Check lamp operation, and close glove door.

FLOOR CONSOLE LAMP BULB

REMOVAL

(1) Using a flat bladed tool, slide it between the

lamp and instrument panel to disengage tabs.

(2) Remove bulb from lamp socket.

INSTALLATION

(1) Install bulb into socket.

(2) Place lamp into position.

(3) Push lamp to lock tabs.

(4) Check lamp operation.

VISOR VANITY LAMP

The visor vanity lamp is incorporated in the visor

assembly. Replace the visor if the lamp has failed.

Fig. 5 License Plate Lamp

1 ± LICENSE PLATE LAMP

2 ± BULB

PLLAMPS 8L - 15

REMOVAL AND INSTALLATION (Continued)

Page 323 of 1285

LAMP SYSTEMS

DESCRIPTION AND OPERATION

DAYTIME RUNNING LAMP MODULE

PL vehicles built for use in Canada are equipped

with a Daytime Running Lamp (DRL) system. The

DRL function is provided by the cluster. The DRL

Module is an integral part of the instrument panel

cluster.

8L - 16 LAMPSPL

Page 324 of 1285

BULB APPLICATION

TABLE OF CONTENTS

page page

SPECIFICATIONS

EXTERIOR LAMPS........................17INTERIOR LAMPS........................17

SPECIFICATIONS

EXTERIOR LAMPS

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the chart below.

Damage to lamp can result. Do not touch halogen

bulbs with fingers or other oily surfaces. Bulb life

will be reduced.

LAMP BULB

Back Up Lamp................3157 ± P27/7W

Center High Mounted Stop Lamp

(CHMSL).........................W16W

Front Fog Lamp..................... GE881

Front Park/Turn Signal Lamp..........3157NA

Front Side Marker Lamp................. 168

Headlamp............................9007

License Plate Lamp..................... 168

Rear Tail/Stop/

Turn Signal Lamp............3157 ± P27/7W

INTERIOR LAMPS

Service procedures for most of the lamps in the

instrument panel, Instrument cluster and switches

are located in Group 8E, Instrument Panel and

Gauges.

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the chart below.

Damage to lamp can result.LAMP BULB

ABS Indicator......................... LED

Airbag Indicator....................... LED

Brake System Warning Indicator.......... LED

Climate Controls....................... LED

Console Gear Selector W/Auto...........PC194

Dome Lamp..........................T579

Floor Console Lamp..................... T37

Front Fog Lamp Indicator................ LED

Glove Compartment....................T194

High Beam Lamp Indicator.............PC194

Ignition Lock........................... 161

Instrument Cluster Illumination.........PC194

Low Fuel Indicator..................... LED

Low Oil Pressure Indicator............... LED

Rear Cargo...........................T906

Seat Belt Indicator..................... LED

Security Alarm Indicator................. LED

Malfunction Indicator Light.............. LED

TRAC OFF Indicator.................... LED

Turn Signal Indicator..................PC194

Underhood............................ 105

Visor Vanity........................6501966

Voltage Indicator....................... LED

All the inside bulbs brass or glass wedge base. Alu-

minum base bulbs are not approved and should not

be used for replacement.

PLLAMPS 8L - 17

Page 326 of 1285

LAMPS

TABLE OF CONTENTS

page page

LAMP DIAGNOSIS......................... 1

HEADLAMP ALIGNMENT.................... 2

LAMP BULB SERVICE...................... 4LAMP SERVICE........................... 12

BULB APPLICATION....................... 19

LAMP DIAGNOSIS

TABLE OF CONTENTS

page

GENERAL INFORMATION

HEADLAMP LEVELING MOTOR...............1

GENERAL INFORMATION

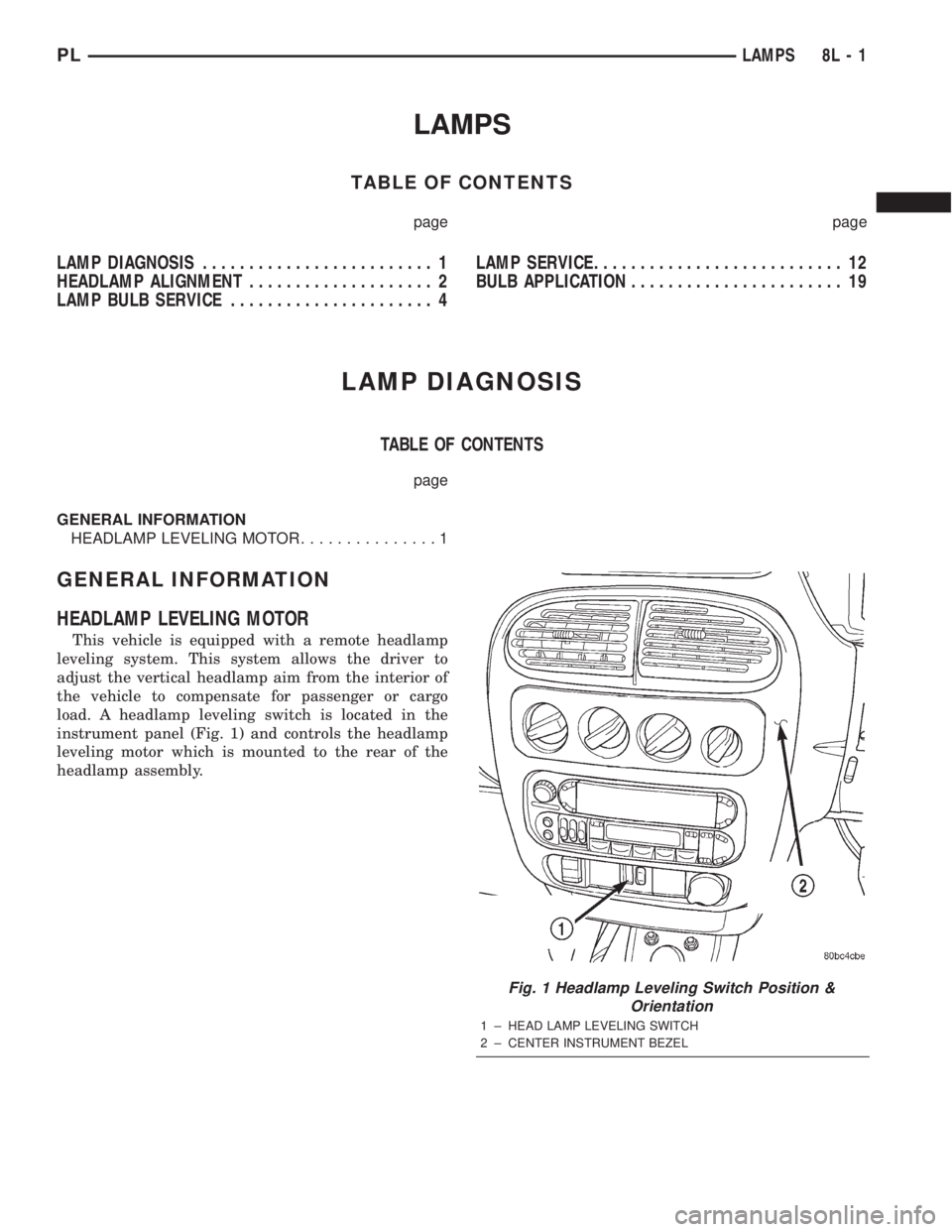

HEADLAMP LEVELING MOTOR

This vehicle is equipped with a remote headlamp

leveling system. This system allows the driver to

adjust the vertical headlamp aim from the interior of

the vehicle to compensate for passenger or cargo

load. A headlamp leveling switch is located in the

instrument panel (Fig. 1) and controls the headlamp

leveling motor which is mounted to the rear of the

headlamp assembly.

Fig. 1 Headlamp Leveling Switch Position &

Orientation

1 ± HEAD LAMP LEVELING SWITCH

2 ± CENTER INSTRUMENT BEZEL

PLLAMPS 8L - 1

Page 337 of 1285

LAMP SERVICE

TABLE OF CONTENTS

page page

GENERAL INFORMATION

HEADLAMP SWITCH......................12

HEADLAMP LEVELING SWITCH.............12

HEADLAMP DIMMER SWITCH...............12

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)..............................12HEADLAMP MODULE.....................12

HEADLAMP LEVELING MOTOR..............14

FRONT FOG LAMP.......................15

REAR LICENSE PLATE LAMPS..............15

REAR FOG LAMP........................15

SIDE REPEATER LAMP....................17

TAIL, STOP AND TURN SIGNAL LAMP........18

GENERAL INFORMATION

HEADLAMP SWITCH

Service procedures for the headlamp switch can be

found in Group 8E, Instrument Panel and Gauges.

More information can be found in Group 8W, Wiring

Diagrams.

HEADLAMP LEVELING SWITCH

Service procedures for the headlamp leveling

switch can be found in Group 8E, Instrument Panel

Systems. More information can be found in Group

8W, Wiring Diagrams.

HEADLAMP DIMMER SWITCH

The headlamp dimmer switch is incorporated into

the multi-function (turn signal) switch. Proper proce-

dures can be found in Group 8J, Turn Signal and

Flashers. More information can be found in Group

8W, Wiring Diagrams.

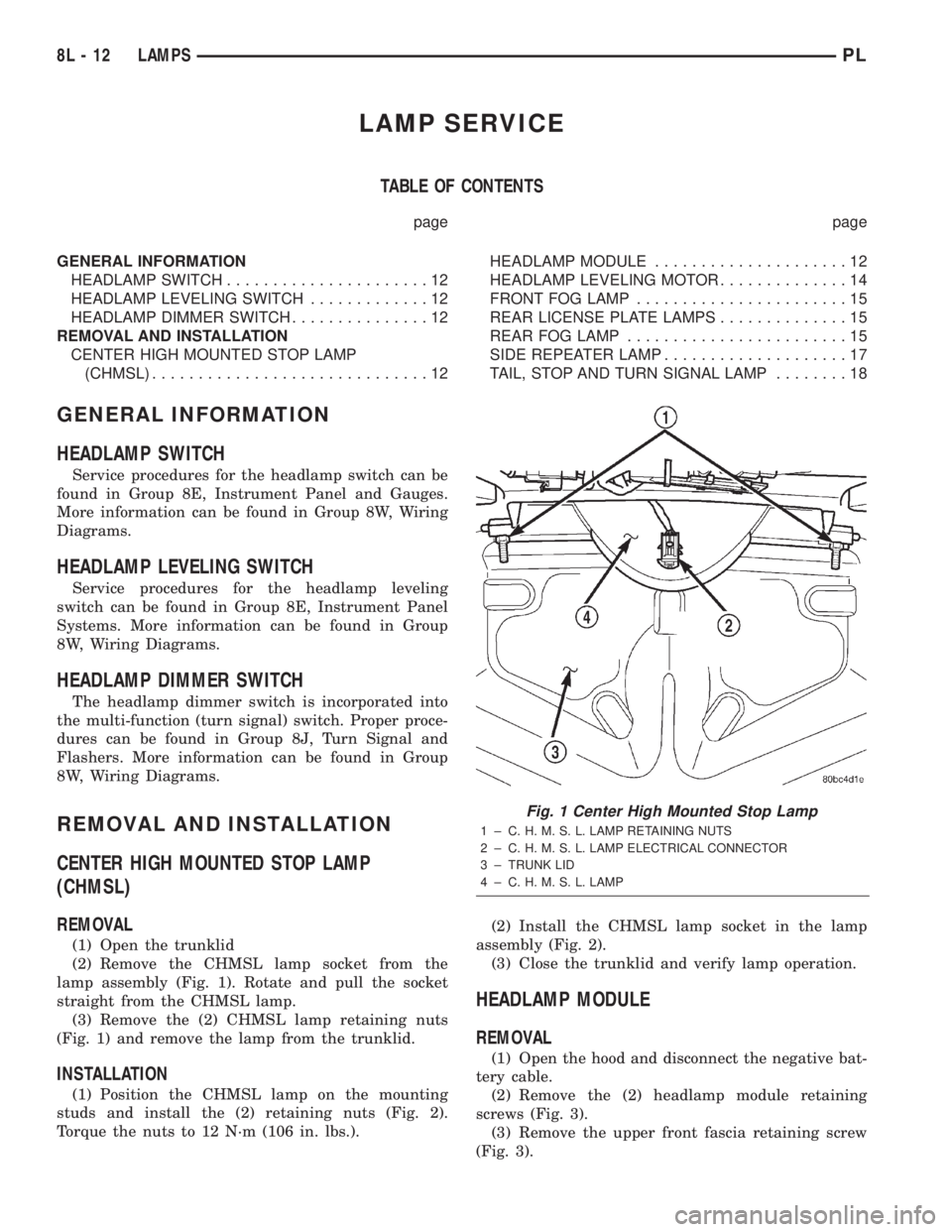

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)

REMOVAL

(1) Open the trunklid

(2) Remove the CHMSL lamp socket from the

lamp assembly (Fig. 1). Rotate and pull the socket

straight from the CHMSL lamp.

(3) Remove the (2) CHMSL lamp retaining nuts

(Fig. 1) and remove the lamp from the trunklid.

INSTALLATION

(1) Position the CHMSL lamp on the mounting

studs and install the (2) retaining nuts (Fig. 2).

Torque the nuts to 12 N´m (106 in. lbs.).(2) Install the CHMSL lamp socket in the lamp

assembly (Fig. 2).

(3) Close the trunklid and verify lamp operation.

HEADLAMP MODULE

REMOVAL

(1) Open the hood and disconnect the negative bat-

tery cable.

(2) Remove the (2) headlamp module retaining

screws (Fig. 3).

(3) Remove the upper front fascia retaining screw

(Fig. 3).

Fig. 1 Center High Mounted Stop Lamp

1 ± C. H. M. S. L. LAMP RETAINING NUTS

2 ± C. H. M. S. L. LAMP ELECTRICAL CONNECTOR

3 ± TRUNK LID

4 ± C. H. M. S. L. LAMP

8L - 12 LAMPSPL

Page 347 of 1285

lever (Fig. 1). The ACM monitors the system to deter-

mine the system readiness. The ACM contains

on-board diagnostics, and will illuminate the AIR-

BAG warning lamp in the cluster when a fault

occurs. The warning equipment is tested for six to

eight seconds every time the vehicle is started.

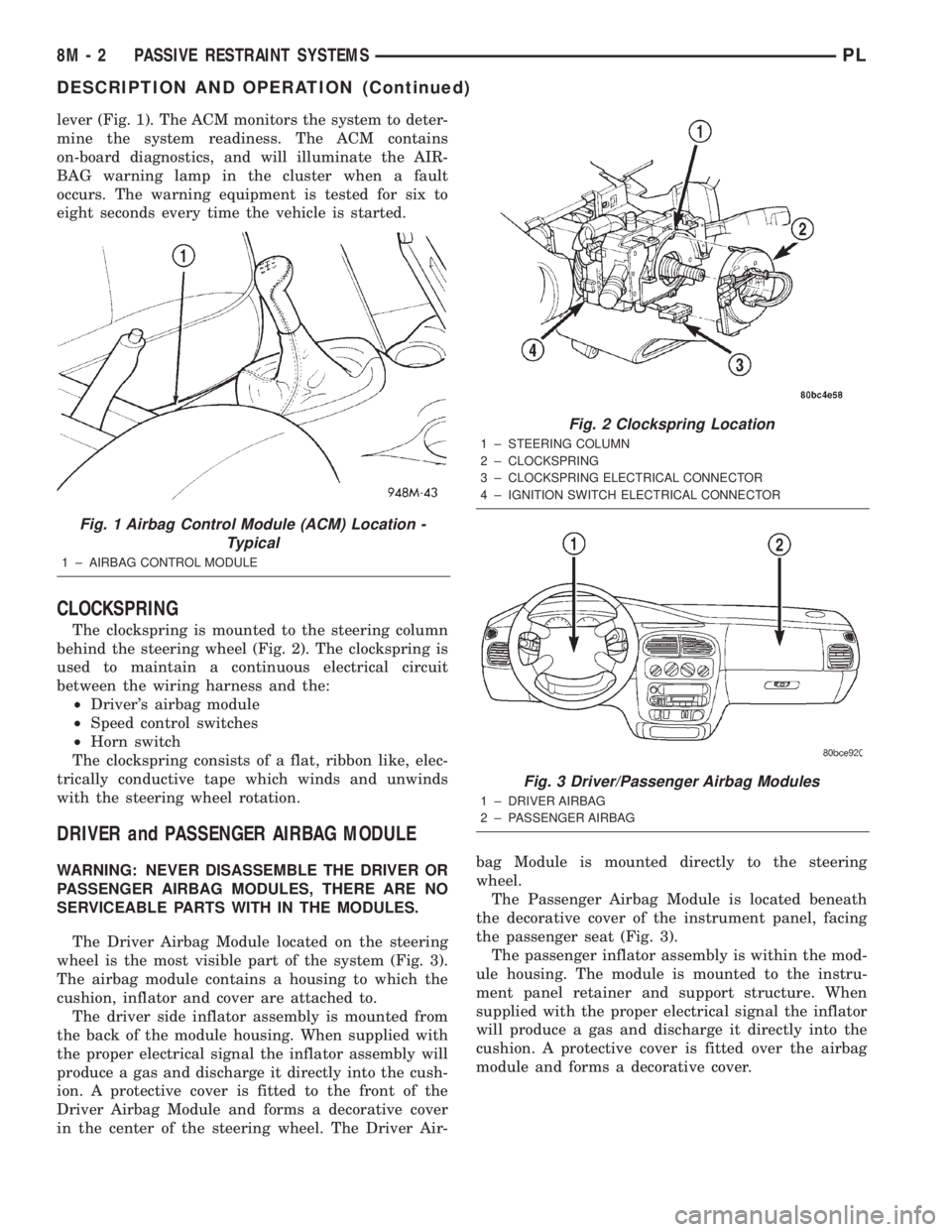

CLOCKSPRING

The clockspring is mounted to the steering column

behind the steering wheel (Fig. 2). The clockspring is

used to maintain a continuous electrical circuit

between the wiring harness and the:

²Driver's airbag module

²Speed control switches

²Horn switch

The clockspring consists of a flat, ribbon like, elec-

trically conductive tape which winds and unwinds

with the steering wheel rotation.

DRIVER and PASSENGER AIRBAG MODULE

WARNING: NEVER DISASSEMBLE THE DRIVER OR

PASSENGER AIRBAG MODULES, THERE ARE NO

SERVICEABLE PARTS WITH IN THE MODULES.

The Driver Airbag Module located on the steering

wheel is the most visible part of the system (Fig. 3).

The airbag module contains a housing to which the

cushion, inflator and cover are attached to.

The driver side inflator assembly is mounted from

the back of the module housing. When supplied with

the proper electrical signal the inflator assembly will

produce a gas and discharge it directly into the cush-

ion. A protective cover is fitted to the front of the

Driver Airbag Module and forms a decorative cover

in the center of the steering wheel. The Driver Air-bag Module is mounted directly to the steering

wheel.

The Passenger Airbag Module is located beneath

the decorative cover of the instrument panel, facing

the passenger seat (Fig. 3).

The passenger inflator assembly is within the mod-

ule housing. The module is mounted to the instru-

ment panel retainer and support structure. When

supplied with the proper electrical signal the inflator

will produce a gas and discharge it directly into the

cushion. A protective cover is fitted over the airbag

module and forms a decorative cover.

Fig. 1 Airbag Control Module (ACM) Location -

Typical

1 ± AIRBAG CONTROL MODULE

Fig. 2 Clockspring Location

1 ± STEERING COLUMN

2 ± CLOCKSPRING

3 ± CLOCKSPRING ELECTRICAL CONNECTOR

4 ± IGNITION SWITCH ELECTRICAL CONNECTOR

Fig. 3 Driver/Passenger Airbag Modules

1 ± DRIVER AIRBAG

2 ± PASSENGER AIRBAG

8M - 2 PASSIVE RESTRAINT SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 348 of 1285

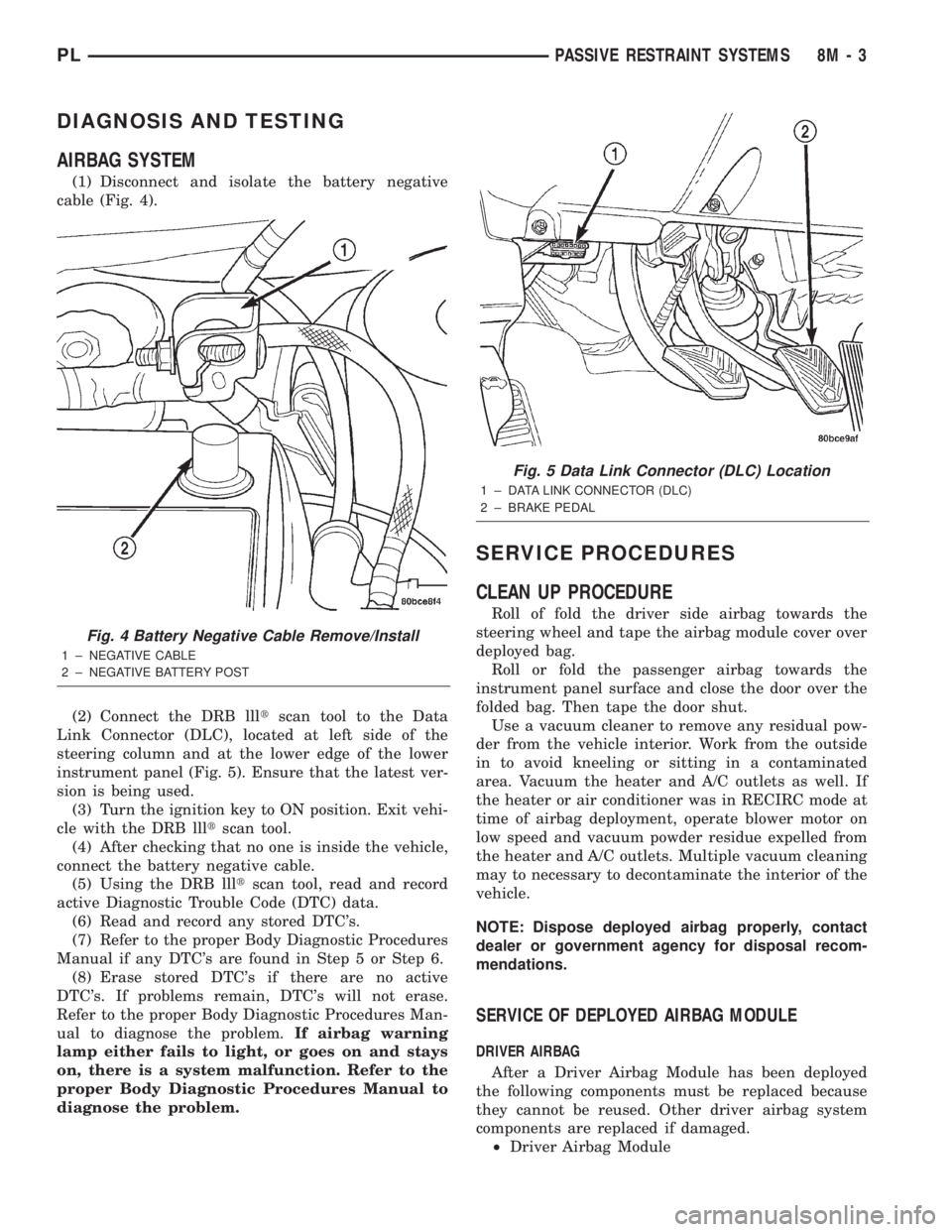

DIAGNOSIS AND TESTING

AIRBAG SYSTEM

(1) Disconnect and isolate the battery negative

cable (Fig. 4).

(2) Connect the DRB llltscan tool to the Data

Link Connector (DLC), located at left side of the

steering column and at the lower edge of the lower

instrument panel (Fig. 5). Ensure that the latest ver-

sion is being used.

(3) Turn the ignition key to ON position. Exit vehi-

cle with the DRB llltscan tool.

(4) After checking that no one is inside the vehicle,

connect the battery negative cable.

(5) Using the DRB llltscan tool, read and record

active Diagnostic Trouble Code (DTC) data.

(6) Read and record any stored DTC's.

(7) Refer to the proper Body Diagnostic Procedures

Manual if any DTC's are found in Step 5 or Step 6.

(8) Erase stored DTC's if there are no active

DTC's. If problems remain, DTC's will not erase.

Refer to the proper Body Diagnostic Procedures Man-

ual to diagnose the problem.If airbag warning

lamp either fails to light, or goes on and stays

on, there is a system malfunction. Refer to the

proper Body Diagnostic Procedures Manual to

diagnose the problem.

SERVICE PROCEDURES

CLEAN UP PROCEDURE

Roll of fold the driver side airbag towards the

steering wheel and tape the airbag module cover over

deployed bag.

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

the heater or air conditioner was in RECIRC mode at

time of airbag deployment, operate blower motor on

low speed and vacuum powder residue expelled from

the heater and A/C outlets. Multiple vacuum cleaning

may to necessary to decontaminate the interior of the

vehicle.

NOTE: Dispose deployed airbag properly, contact

dealer or government agency for disposal recom-

mendations.

SERVICE OF DEPLOYED AIRBAG MODULE

DRIVER AIRBAG

After a Driver Airbag Module has been deployed

the following components must be replaced because

they cannot be reused. Other driver airbag system

components are replaced if damaged.

²Driver Airbag Module

Fig. 4 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 5 Data Link Connector (DLC) Location

1 ± DATA LINK CONNECTOR (DLC)

2 ± BRAKE PEDAL

PLPASSIVE RESTRAINT SYSTEMS 8M - 3