oil pressure DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 726 of 1285

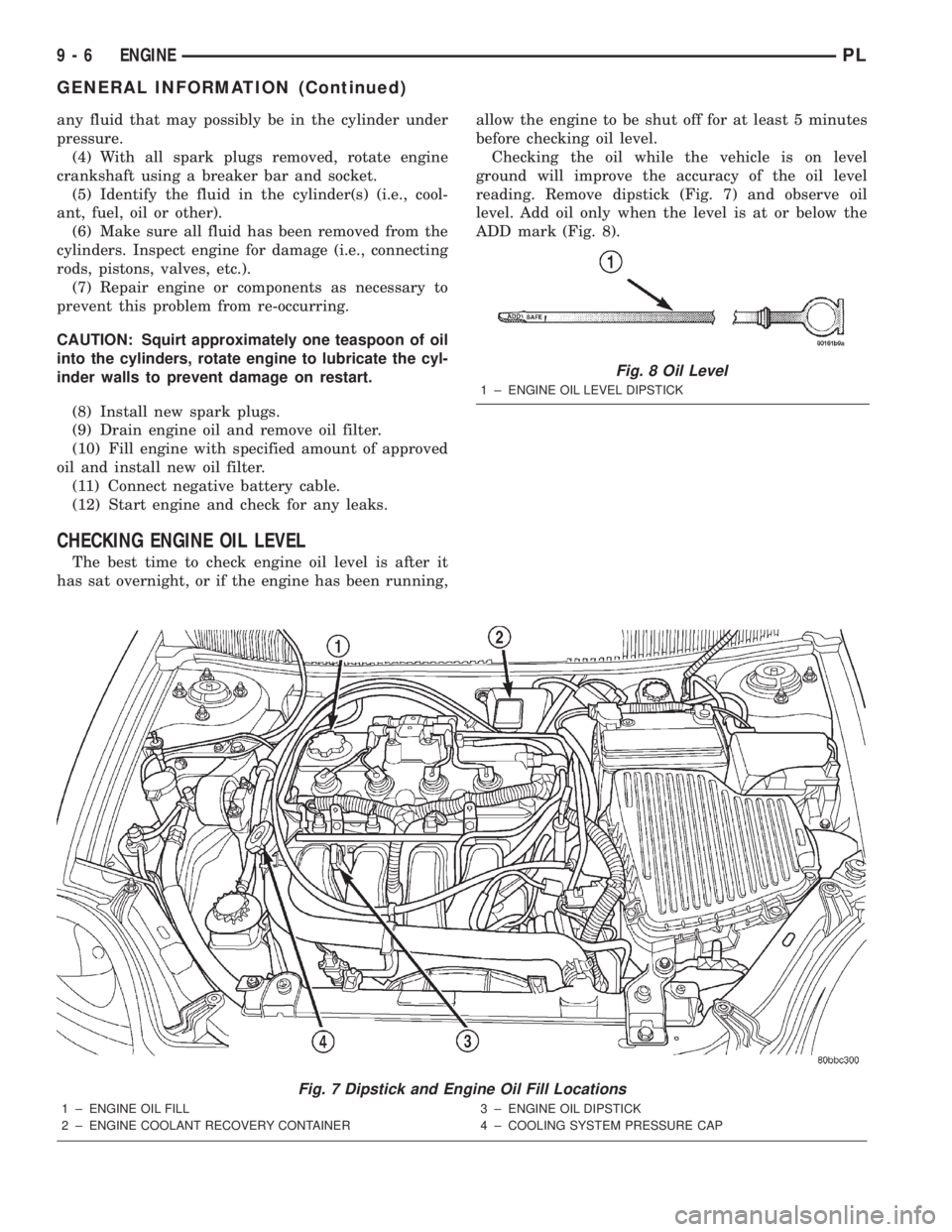

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly clean all debris/rust from inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with MopartStud and Bearing Mount Adhesive.

Make certain the new plug is cleaned of all oil or

grease. Using a proper driver, drive plug into hole so

that the sharp edge of the plug is at least 0.5 mm

(0.020 inch.) inside the lead in chamfer (Fig. 3).

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to it's

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-ing to these standards, refer to Engine Diagnosis in

this section. The following procedures can assist in

achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system. Refer to

Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.HONING CYLINDER BORES

(1) Used carefully, the cylinder bore resizing hone,

recommended tool C-823 or equivalent, equipped

with 220 grit stones, is the best tool for this honing

procedure. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

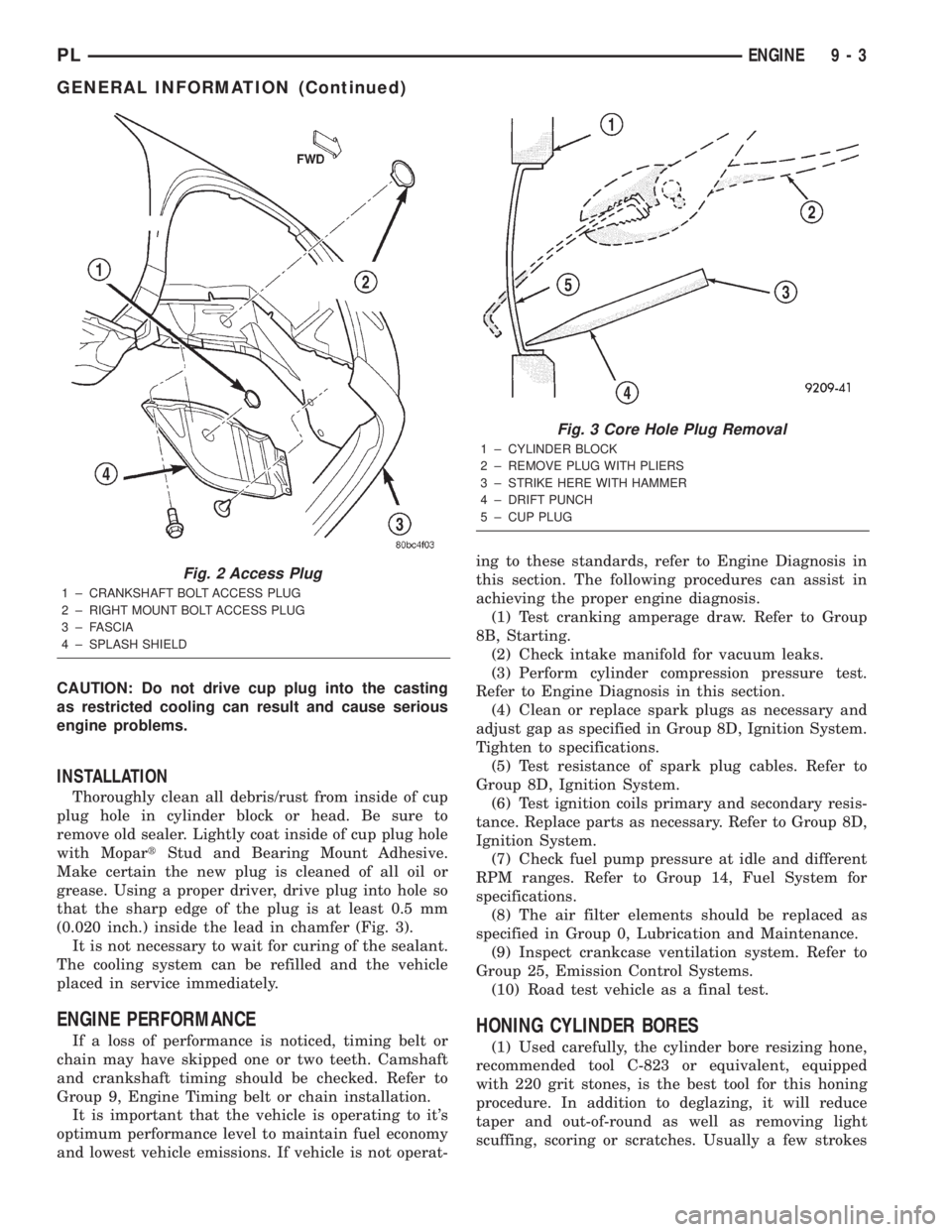

Fig. 2 Access Plug

1 ± CRANKSHAFT BOLT ACCESS PLUG

2 ± RIGHT MOUNT BOLT ACCESS PLUG

3 ± FASCIA

4 ± SPLASH SHIELD

Fig. 3 Core Hole Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

PLENGINE 9 - 3

GENERAL INFORMATION (Continued)

Page 729 of 1285

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.).

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter.

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

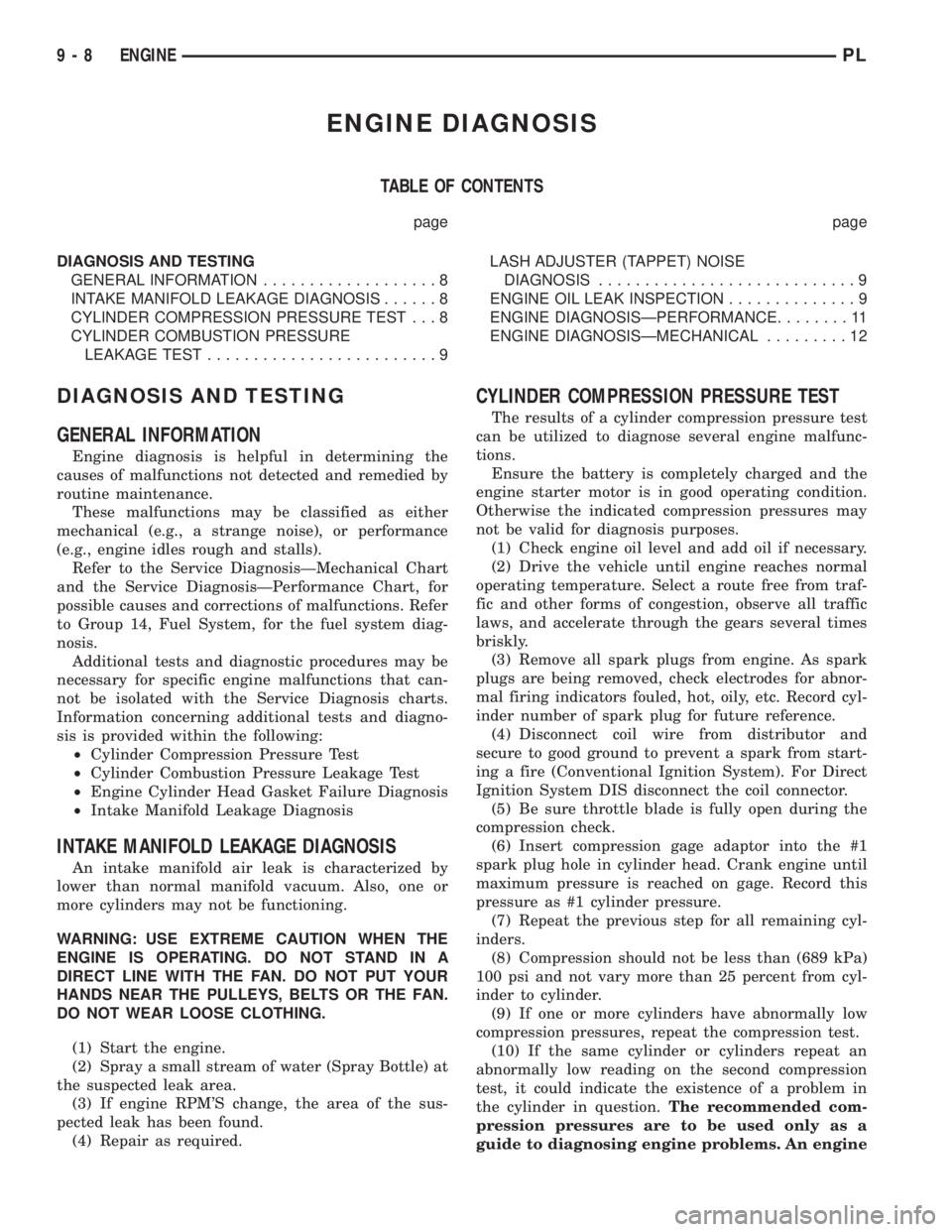

CHECKING ENGINE OIL LEVEL

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick (Fig. 7) and observe oil

level. Add oil only when the level is at or below the

ADD mark (Fig. 8).

Fig. 7 Dipstick and Engine Oil Fill Locations

1 ± ENGINE OIL FILL

2 ± ENGINE COOLANT RECOVERY CONTAINER3 ± ENGINE OIL DIPSTICK

4 ± COOLING SYSTEM PRESSURE CAP

Fig. 8 Oil Level

1 ± ENGINE OIL LEVEL DIPSTICK

9 - 6 ENGINEPL

GENERAL INFORMATION (Continued)

Page 731 of 1285

ENGINE DIAGNOSIS

TABLE OF CONTENTS

page page

DIAGNOSIS AND TESTING

GENERAL INFORMATION...................8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS......8

CYLINDER COMPRESSION PRESSURE TEST . . . 8

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.........................9LASH ADJUSTER (TAPPET) NOISE

DIAGNOSIS............................9

ENGINE OIL LEAK INSPECTION..............9

ENGINE DIAGNOSISÐPERFORMANCE........11

ENGINE DIAGNOSISÐMECHANICAL.........12

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689 kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

9 - 8 ENGINEPL

Page 732 of 1285

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

PLENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 733 of 1285

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (makeup air) at

the cylinder head cover and plug or cap the nipple on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and CCV hose. Proceed to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of theengine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil galley cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurized the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, refer to Crank-

shaft Oil SealÐRear for proper replacement proce-

dures.

9 - 10 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 735 of 1285

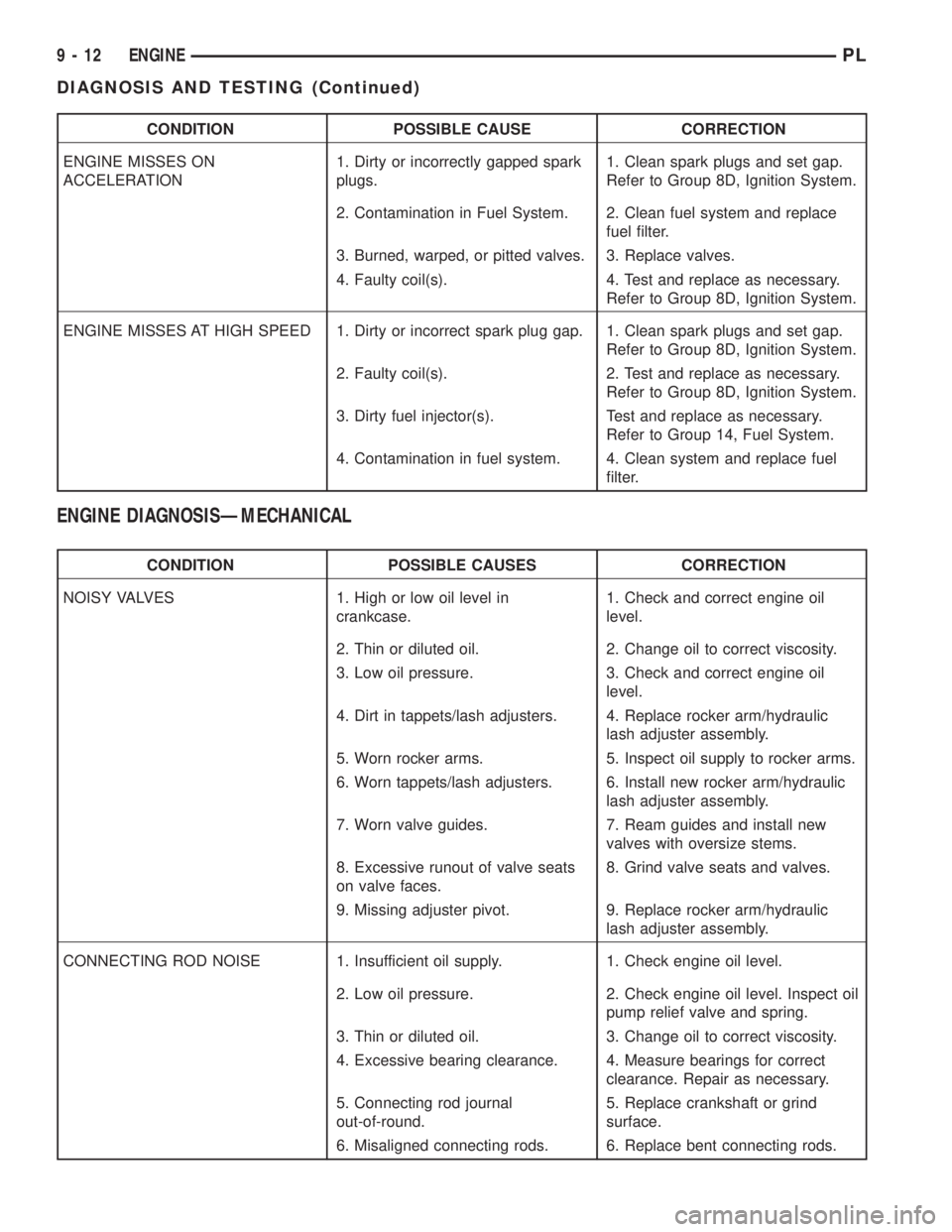

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE MISSES ON

ACCELERATION1. Dirty or incorrectly gapped spark

plugs.1. Clean spark plugs and set gap.

Refer to Group 8D, Ignition System.

2. Contamination in Fuel System. 2. Clean fuel system and replace

fuel filter.

3. Burned, warped, or pitted valves. 3. Replace valves.

4. Faulty coil(s). 4. Test and replace as necessary.

Refer to Group 8D, Ignition System.

ENGINE MISSES AT HIGH SPEED 1. Dirty or incorrect spark plug gap. 1. Clean spark plugs and set gap.

Refer to Group 8D, Ignition System.

2. Faulty coil(s). 2. Test and replace as necessary.

Refer to Group 8D, Ignition System.

3. Dirty fuel injector(s). Test and replace as necessary.

Refer to Group 14, Fuel System.

4. Contamination in fuel system. 4. Clean system and replace fuel

filter.

ENGINE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Low oil pressure. 3. Check and correct engine oil

level.

4. Dirt in tappets/lash adjusters. 4. Replace rocker arm/hydraulic

lash adjuster assembly.

5. Worn rocker arms. 5. Inspect oil supply to rocker arms.

6. Worn tappets/lash adjusters. 6. Install new rocker arm/hydraulic

lash adjuster assembly.

7. Worn valve guides. 7. Ream guides and install new

valves with oversize stems.

8. Excessive runout of valve seats

on valve faces.8. Grind valve seats and valves.

9. Missing adjuster pivot. 9. Replace rocker arm/hydraulic

lash adjuster assembly.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Connecting rod journal

out-of-round.5. Replace crankshaft or grind

surface.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

9 - 12 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 736 of 1285

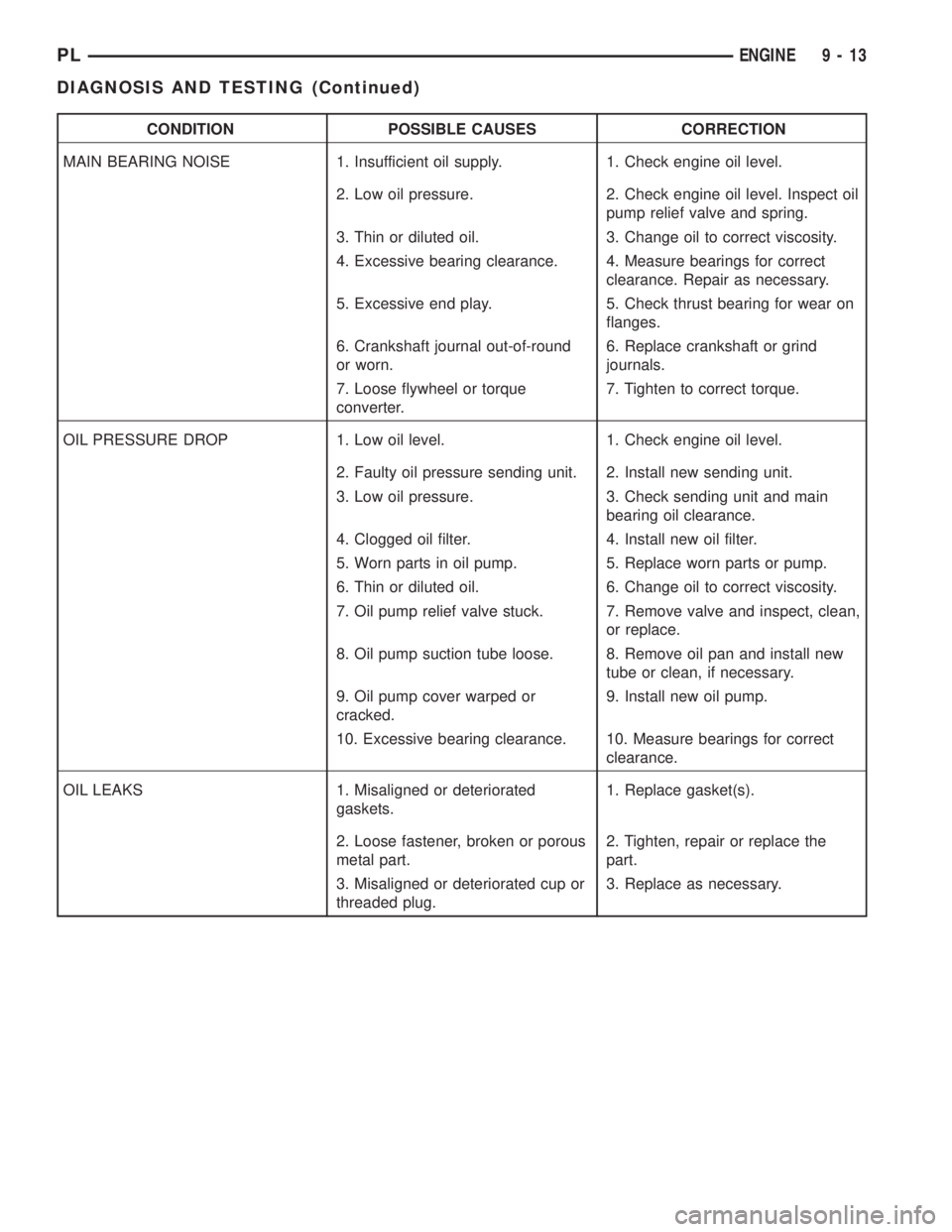

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on

flanges.

6. Crankshaft journal out-of-round

or worn.6. Replace crankshaft or grind

journals.

7. Loose flywheel or torque

converter.7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main

bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

PLENGINE 9 - 13

DIAGNOSIS AND TESTING (Continued)

Page 738 of 1285

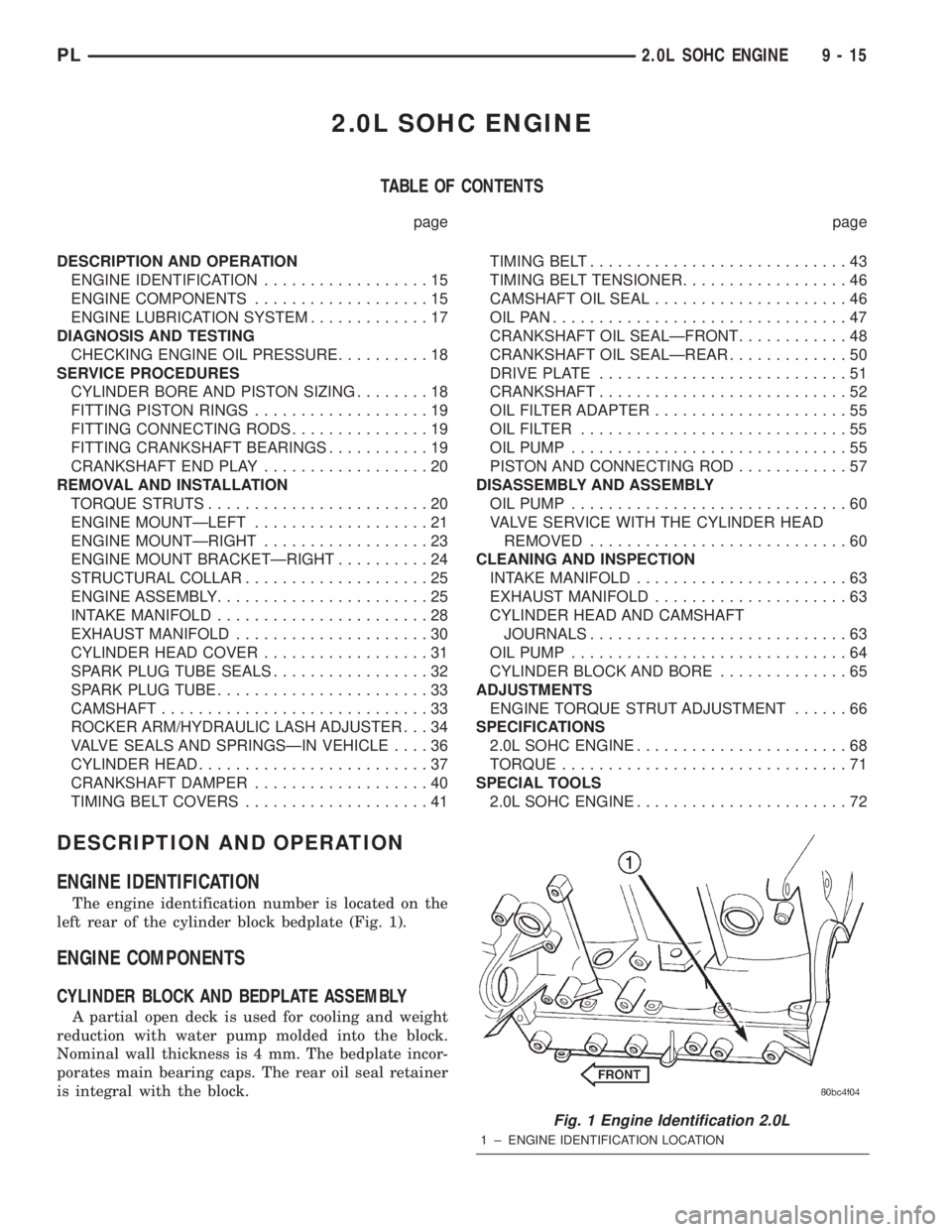

2.0L SOHC ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION..................15

ENGINE COMPONENTS...................15

ENGINE LUBRICATION SYSTEM.............17

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE..........18

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING........18

FITTING PISTON RINGS...................19

FITTING CONNECTING RODS...............19

FITTING CRANKSHAFT BEARINGS...........19

CRANKSHAFT END PLAY..................20

REMOVAL AND INSTALLATION

TORQUE STRUTS........................20

ENGINE MOUNTÐLEFT...................21

ENGINE MOUNTÐRIGHT..................23

ENGINE MOUNT BRACKETÐRIGHT..........24

STRUCTURAL COLLAR....................25

ENGINE ASSEMBLY.......................25

INTAKE MANIFOLD.......................28

EXHAUST MANIFOLD.....................30

CYLINDER HEAD COVER..................31

SPARK PLUG TUBE SEALS.................32

SPARK PLUG TUBE.......................33

CAMSHAFT.............................33

ROCKER ARM/HYDRAULIC LASH ADJUSTER . . . 34

VALVE SEALS AND SPRINGSÐIN VEHICLE....36

CYLINDER HEAD.........................37

CRANKSHAFT DAMPER...................40

TIMING BELT COVERS....................41TIMING BELT............................43

TIMING BELT TENSIONER..................46

CAMSHAFT OIL SEAL.....................46

OILPAN................................47

CRANKSHAFT OIL SEALÐFRONT............48

CRANKSHAFT OIL SEALÐREAR.............50

DRIVE PLATE...........................51

CRANKSHAFT...........................52

OIL FILTER ADAPTER.....................55

OILFILTER .............................55

OIL PUMP..............................55

PISTON AND CONNECTING ROD............57

DISASSEMBLY AND ASSEMBLY

OIL PUMP..............................60

VALVE SERVICE WITH THE CYLINDER HEAD

REMOVED............................60

CLEANING AND INSPECTION

INTAKE MANIFOLD.......................63

EXHAUST MANIFOLD.....................63

CYLINDER HEAD AND CAMSHAFT

JOURNALS............................63

OIL PUMP..............................64

CYLINDER BLOCK AND BORE..............65

ADJUSTMENTS

ENGINE TORQUE STRUT ADJUSTMENT......66

SPECIFICATIONS

2.0L SOHC ENGINE.......................68

TORQUE...............................71

SPECIAL TOOLS

2.0L SOHC ENGINE.......................72

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION

The engine identification number is located on the

left rear of the cylinder block bedplate (Fig. 1).

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEMBLY

A partial open deck is used for cooling and weight

reduction with water pump molded into the block.

Nominal wall thickness is 4 mm. The bedplate incor-

porates main bearing caps. The rear oil seal retainer

is integral with the block.

Fig. 1 Engine Identification 2.0L

1 ± ENGINE IDENTIFICATION LOCATION

PL2.0L SOHC ENGINE 9 - 15

Page 740 of 1285

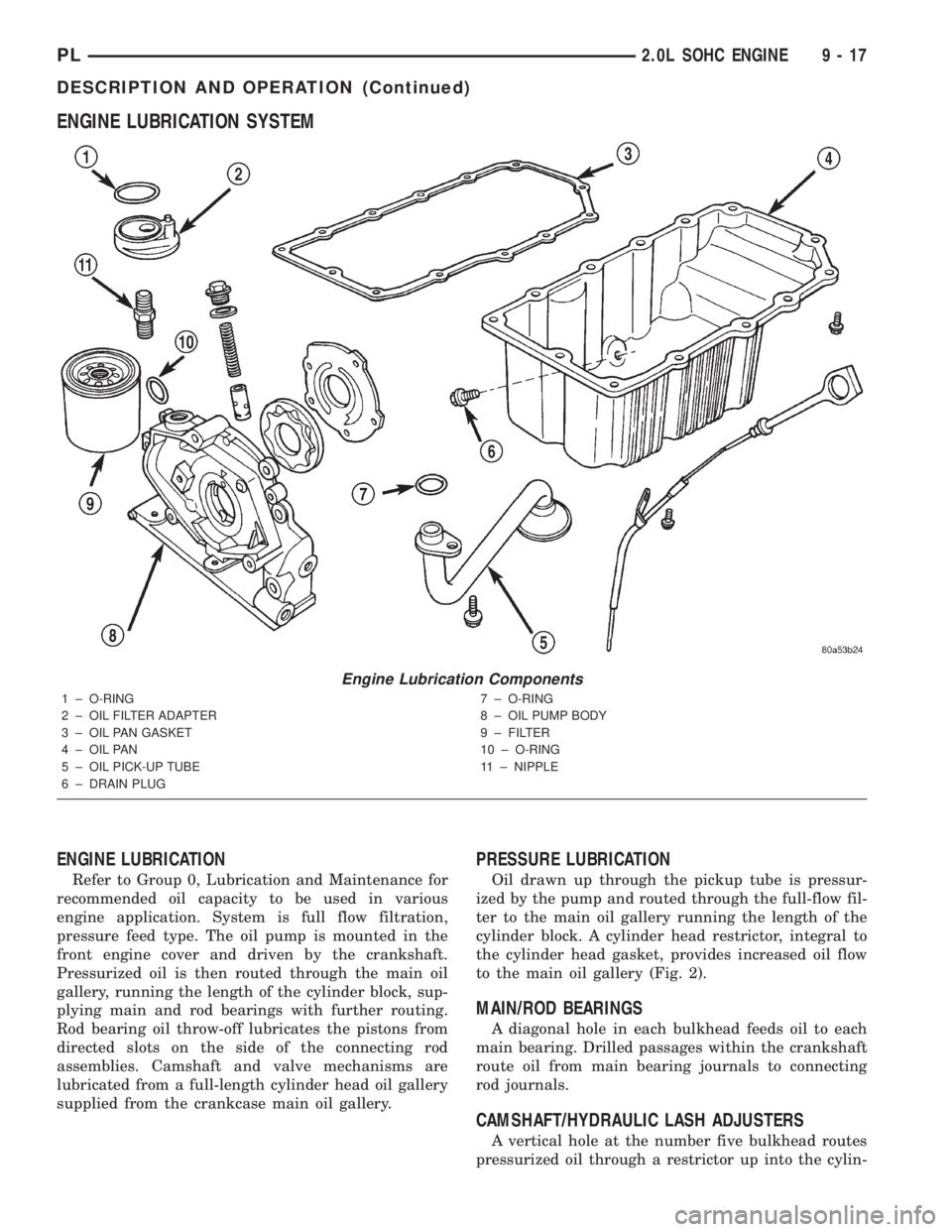

ENGINE LUBRICATION SYSTEM

ENGINE LUBRICATION

Refer to Group 0, Lubrication and Maintenance for

recommended oil capacity to be used in various

engine application. System is full flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

Pressurized oil is then routed through the main oil

gallery, running the length of the cylinder block, sup-

plying main and rod bearings with further routing.

Rod bearing oil throw-off lubricates the pistons from

directed slots on the side of the connecting rod

assemblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full-flow fil-

ter to the main oil gallery running the length of the

cylinder block. A cylinder head restrictor, integral to

the cylinder head gasket, provides increased oil flow

to the main oil gallery (Fig. 2).

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

Engine Lubrication Components

1 ± O-RING

2 ± OIL FILTER ADAPTER

3 ± OIL PAN GASKET

4 ± OIL PAN

5 ± OIL PICK-UP TUBE

6 ± DRAIN PLUG7 ± O-RING

8 ± OIL PUMP BODY

9 ± FILTER

10 ± O-RING

11 ± NIPPLE

PL2.0L SOHC ENGINE 9 - 17

DESCRIPTION AND OPERATION (Continued)

Page 741 of 1285

der head. The rocker shafts route oil to the rocker

arms/hydraulic lash adjuster assemblies.

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

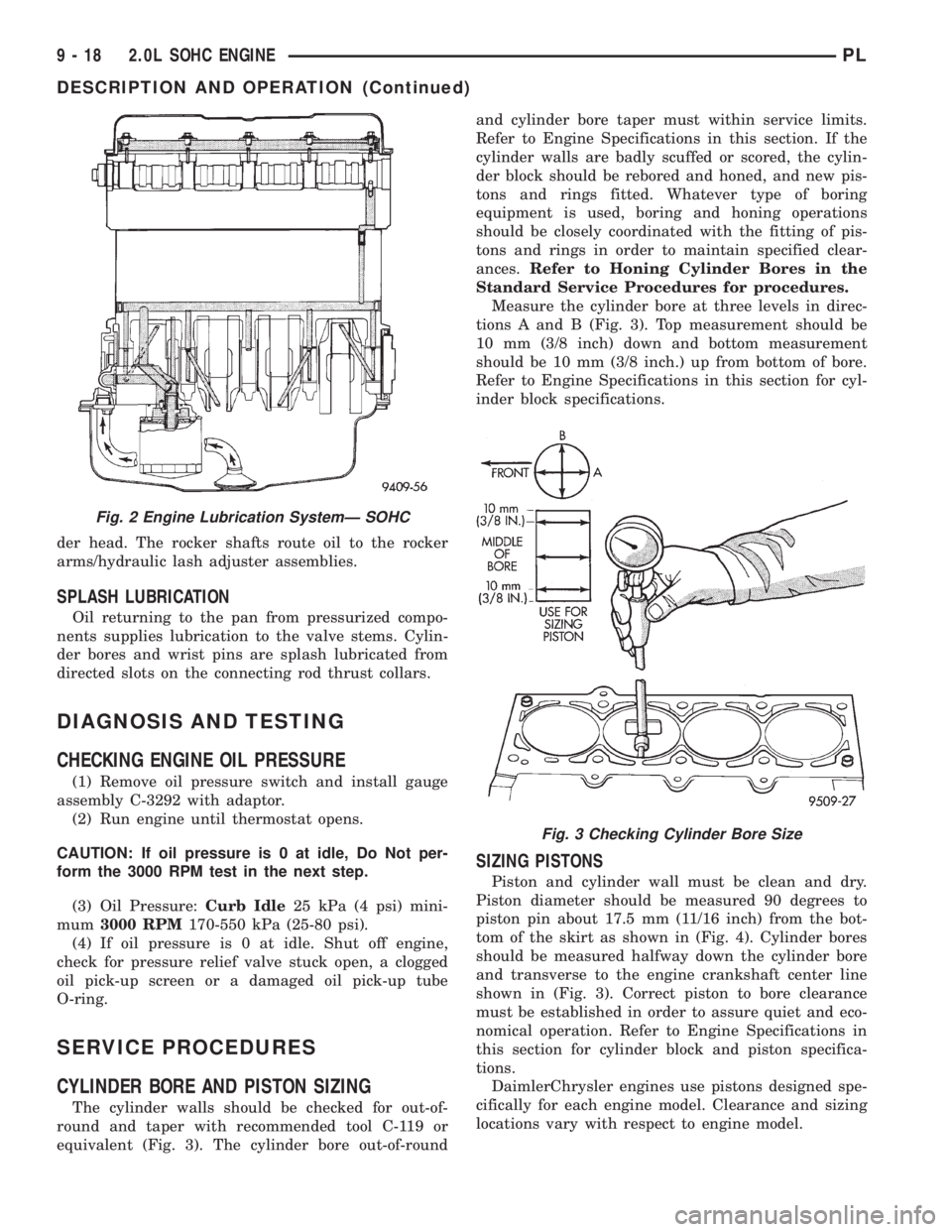

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with recommended tool C-119 or

equivalent (Fig. 3). The cylinder bore out-of-roundand cylinder bore taper must within service limits.

Refer to Engine Specifications in this section. If the

cylinder walls are badly scuffed or scored, the cylin-

der block should be rebored and honed, and new pis-

tons and rings fitted. Whatever type of boring

equipment is used, boring and honing operations

should be closely coordinated with the fitting of pis-

tons and rings in order to maintain specified clear-

ances.Refer to Honing Cylinder Bores in the

Standard Service Procedures for procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 3). Top measurement should be

10 mm (3/8 inch) down and bottom measurement

should be 10 mm (3/8 inch.) up from bottom of bore.

Refer to Engine Specifications in this section for cyl-

inder block specifications.

SIZING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin about 17.5 mm (11/16 inch) from the bot-

tom of the skirt as shown in (Fig. 4). Cylinder bores

should be measured halfway down the cylinder bore

and transverse to the engine crankshaft center line

shown in (Fig. 3). Correct piston to bore clearance

must be established in order to assure quiet and eco-

nomical operation. Refer to Engine Specifications in

this section for cylinder block and piston specifica-

tions.

DaimlerChrysler engines use pistons designed spe-

cifically for each engine model. Clearance and sizing

locations vary with respect to engine model.

Fig. 2 Engine Lubrication SystemÐ SOHC

Fig. 3 Checking Cylinder Bore Size

9 - 18 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)