alternator DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 229 of 1285

REMOVAL AND INSTALLATION

SAFETY SWITCHES

For Removal and Installation of:

²Clutch Interlock/Upstop Switch, refer to

Removal and Installation in Group 6-Clutch.

²Park/Neutral Starting and Back-Up Lamp

Switch, refer to Removal and Installation in Group

21-Transaxle.

STARTER MOTOR

REMOVAL

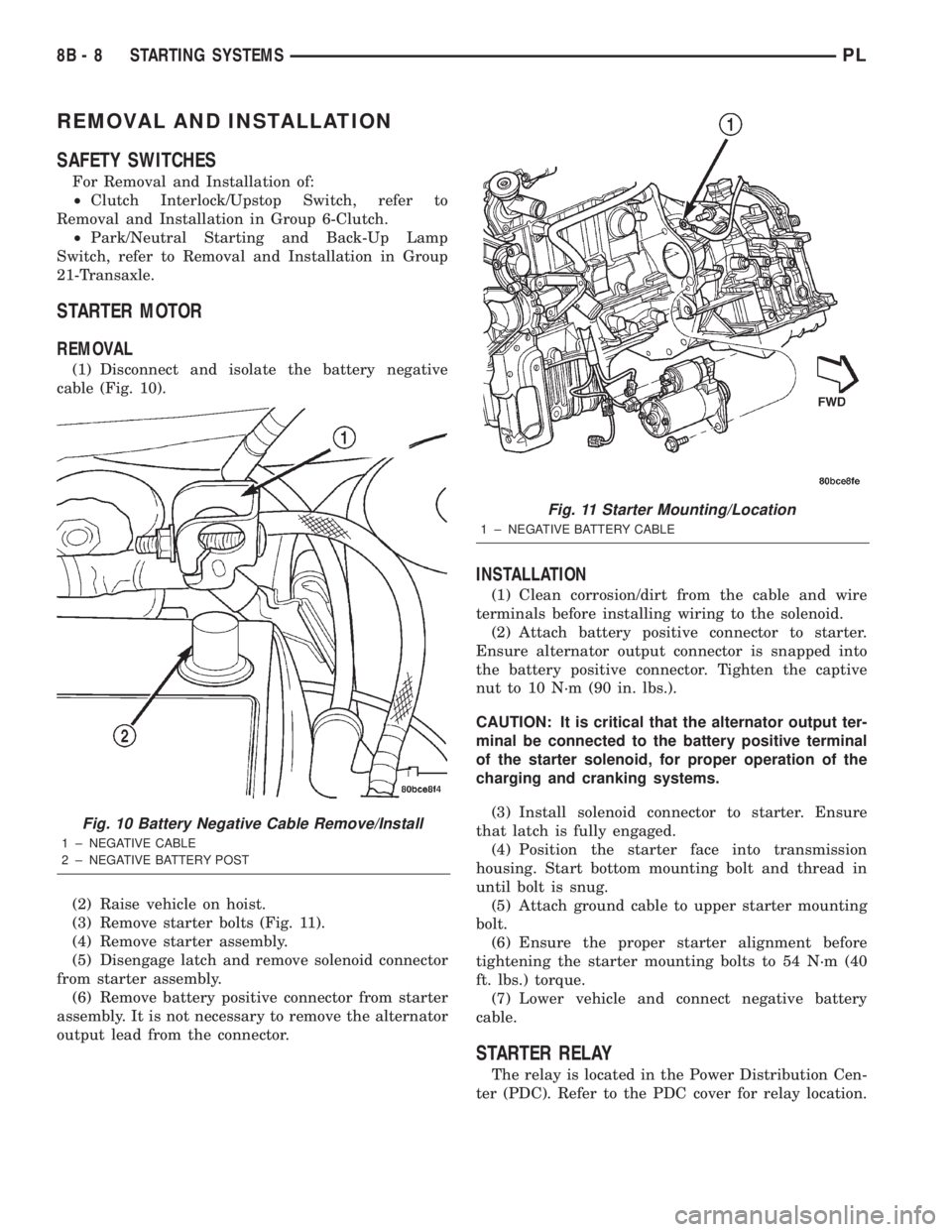

(1) Disconnect and isolate the battery negative

cable (Fig. 10).

(2) Raise vehicle on hoist.

(3) Remove starter bolts (Fig. 11).

(4) Remove starter assembly.

(5) Disengage latch and remove solenoid connector

from starter assembly.

(6) Remove battery positive connector from starter

assembly. It is not necessary to remove the alternator

output lead from the connector.

INSTALLATION

(1) Clean corrosion/dirt from the cable and wire

terminals before installing wiring to the solenoid.

(2) Attach battery positive connector to starter.

Ensure alternator output connector is snapped into

the battery positive connector. Tighten the captive

nut to 10 N´m (90 in. lbs.).

CAUTION: It is critical that the alternator output ter-

minal be connected to the battery positive terminal

of the starter solenoid, for proper operation of the

charging and cranking systems.

(3) Install solenoid connector to starter. Ensure

that latch is fully engaged.

(4) Position the starter face into transmission

housing. Start bottom mounting bolt and thread in

until bolt is snug.

(5) Attach ground cable to upper starter mounting

bolt.

(6) Ensure the proper starter alignment before

tightening the starter mounting bolts to 54 N´m (40

ft. lbs.) torque.

(7) Lower vehicle and connect negative battery

cable.

STARTER RELAY

The relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for relay location.

Fig. 10 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 11 Starter Mounting/Location

1 ± NEGATIVE BATTERY CABLE

8B - 8 STARTING SYSTEMSPL

Page 1253 of 1285

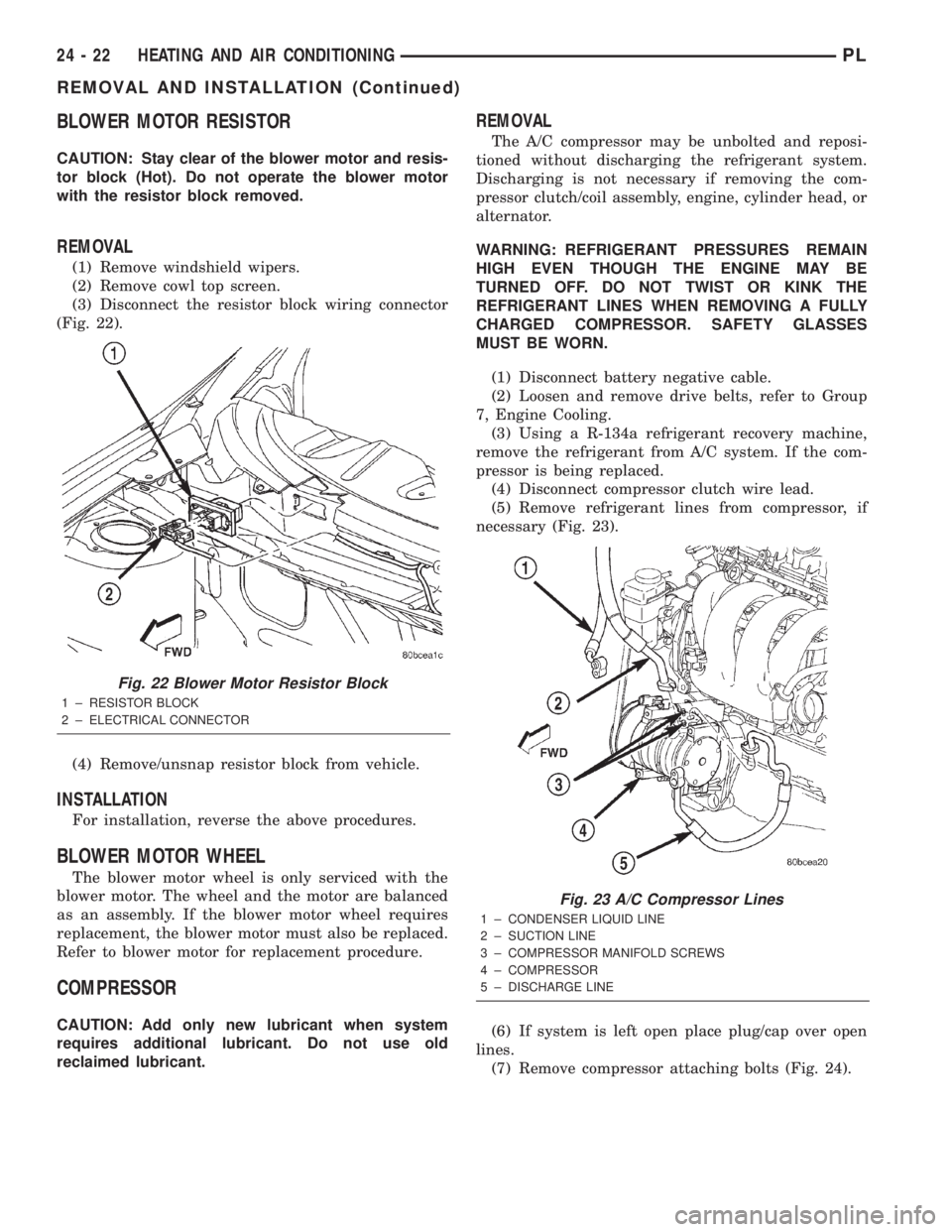

BLOWER MOTOR RESISTOR

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed.

REMOVAL

(1) Remove windshield wipers.

(2) Remove cowl top screen.

(3) Disconnect the resistor block wiring connector

(Fig. 22).

(4) Remove/unsnap resistor block from vehicle.

INSTALLATION

For installation, reverse the above procedures.

BLOWER MOTOR WHEEL

The blower motor wheel is only serviced with the

blower motor. The wheel and the motor are balanced

as an assembly. If the blower motor wheel requires

replacement, the blower motor must also be replaced.

Refer to blower motor for replacement procedure.

COMPRESSOR

CAUTION: Add only new lubricant when system

requires additional lubricant. Do not use old

reclaimed lubricant.

REMOVAL

The A/C compressor may be unbolted and reposi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the com-

pressor clutch/coil assembly, engine, cylinder head, or

alternator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. DO NOT TWIST OR KINK THE

REFRIGERANT LINES WHEN REMOVING A FULLY

CHARGED COMPRESSOR. SAFETY GLASSES

MUST BE WORN.

(1) Disconnect battery negative cable.

(2) Loosen and remove drive belts, refer to Group

7, Engine Cooling.

(3) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system. If the com-

pressor is being replaced.

(4) Disconnect compressor clutch wire lead.

(5) Remove refrigerant lines from compressor, if

necessary (Fig. 23).

(6) If system is left open place plug/cap over open

lines.

(7) Remove compressor attaching bolts (Fig. 24).

Fig. 22 Blower Motor Resistor Block

1 ± RESISTOR BLOCK

2 ± ELECTRICAL CONNECTOR

Fig. 23 A/C Compressor Lines

1 ± CONDENSER LIQUID LINE

2 ± SUCTION LINE

3 ± COMPRESSOR MANIFOLD SCREWS

4 ± COMPRESSOR

5 ± DISCHARGE LINE

24 - 22 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)