open hood DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 8 of 1285

JUMP STARTING, TOWING, AND HOISTING

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

JUMP STARTING PROCEDURE...............7

TOWING RECOMMENDATIONS...............7

HOISTING RECOMMENDATIONS.............7SERVICE PROCEDURES

JUMP STARTING PROCEDURE...............7

TOWING RECOMMENDATIONS...............8

HOISTING RECOMMENDATIONS.............9

DESCRIPTION AND OPERATION

JUMP STARTING PROCEDURE

Describes the procedure for starting a disable vehi-

cle.

TOWING RECOMMENDATIONS

Describes the recommended towing procedures.

HOISTING RECOMMENDATIONS

Describes the location of hoisting and jacking

points so that the vehicle can be lifted by a floor jack

or hoist.

SERVICE PROCEDURES

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

PLLUBRICATION AND MAINTENANCE 0 - 7

Page 26 of 1285

(6) Remove the two bolts attaching the strut to the

steering knuckle (Fig. 1).

(7) Lower the vehicle just enough to open the

hood, but without letting the tires touch the floor.

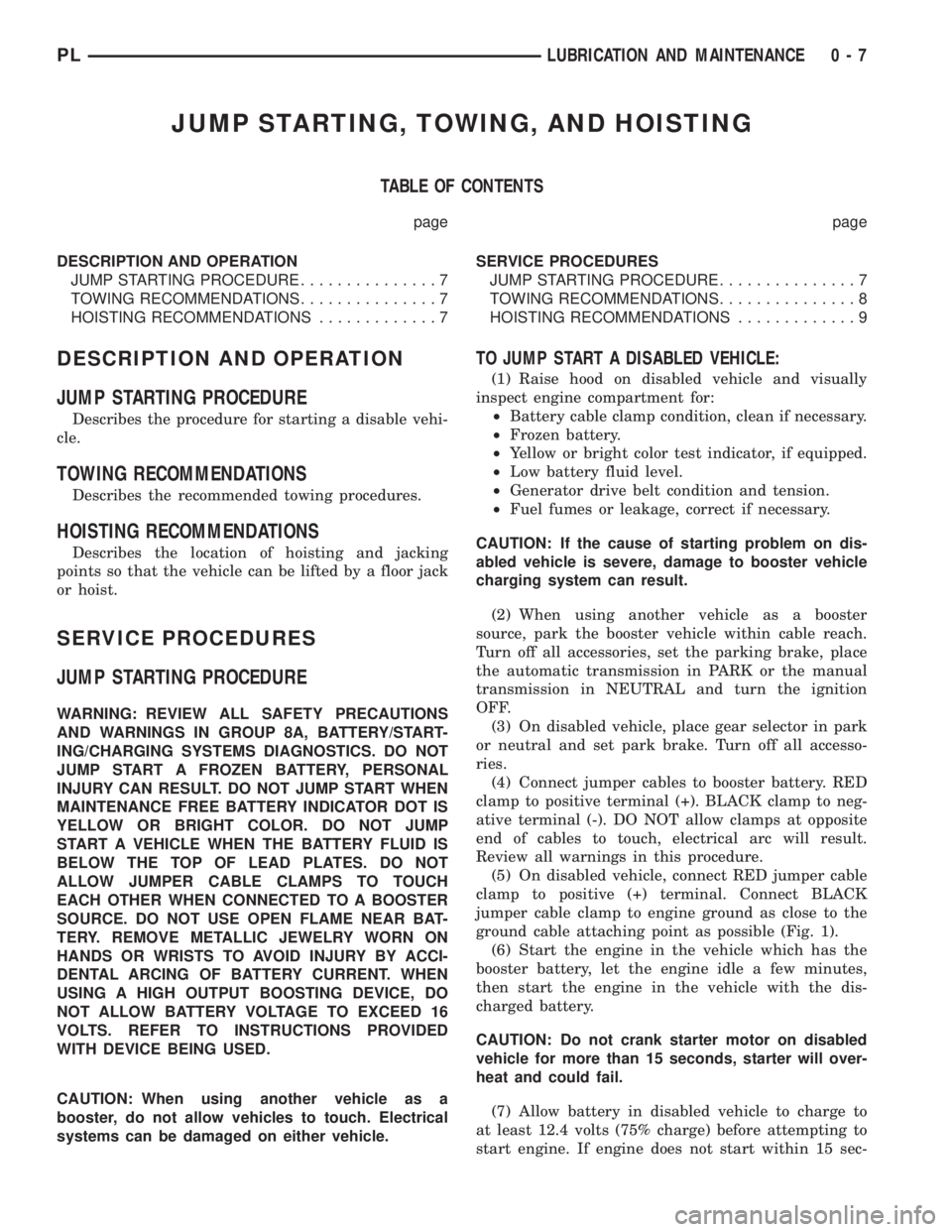

(8) Remove the three nuts attaching the upper

mount of the strut assembly to the vehicle's strut

tower (Fig. 6).

(9) Remove the strut assembly from the vehicle.

(10) For disassembly and assembly procedures,

refer to STRUT ASSEMBLY in the DISASSEMBLY

AND ASSEMBLY section in this section of this ser-

vice manual group.

INSTALLATION

(1) Install the strut assembly into the strut tower,

aligning the three studs on the strut upper mount

with the holes in strut tower. Install the three

mounting nuts on the studs (Fig. 6). Tighten the

three nuts to a torque of 34 N´m (300 in. lbs.).

(2) Close the hood of the vehicle.

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during installation. Install the nuts while holding the

bolts stationary in the steering knuckle.

(3) Position the lower end of the strut assembly in

line with the upper end of the steering knuckle and

align the mounting holes (Fig. 1). Install the two

attaching bolts. The bolts should be installed with so

that the nuts face towards the front of the vehicle

once installed. Install the nuts. Holding the bolts in

place tighten the nuts to a torque of 53 N´m (40 ft.

lbs.) plus an additional 90É turn after the specified

torque is met.(4) If the vehicle is equipped with Antilock brakes

(ABS), attach the ABS wheel speed sensor to the rear

of the strut (rearward ear) using its mounting screw

(Fig. 5). Tighten the mounting screw to a torque of

13 N´m (120 in. lbs.).

(5) Attach the ground strap to the rear of the strut

(forward ear) using its mounting screw (Fig. 5).

Tighten the mounting screw to a torque of 13 N´m

(120 in. lbs.).

(6) Install the tire and wheel assembly. Install and

tighten the wheel mounting nuts in proper sequence

until all nuts are torqued to half specification. Next,

repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

(7) Lower the vehicle.

STEERING KNUCKLE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Apply the brakes and hold in place.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(3) Remove the front tire and wheel assembly.

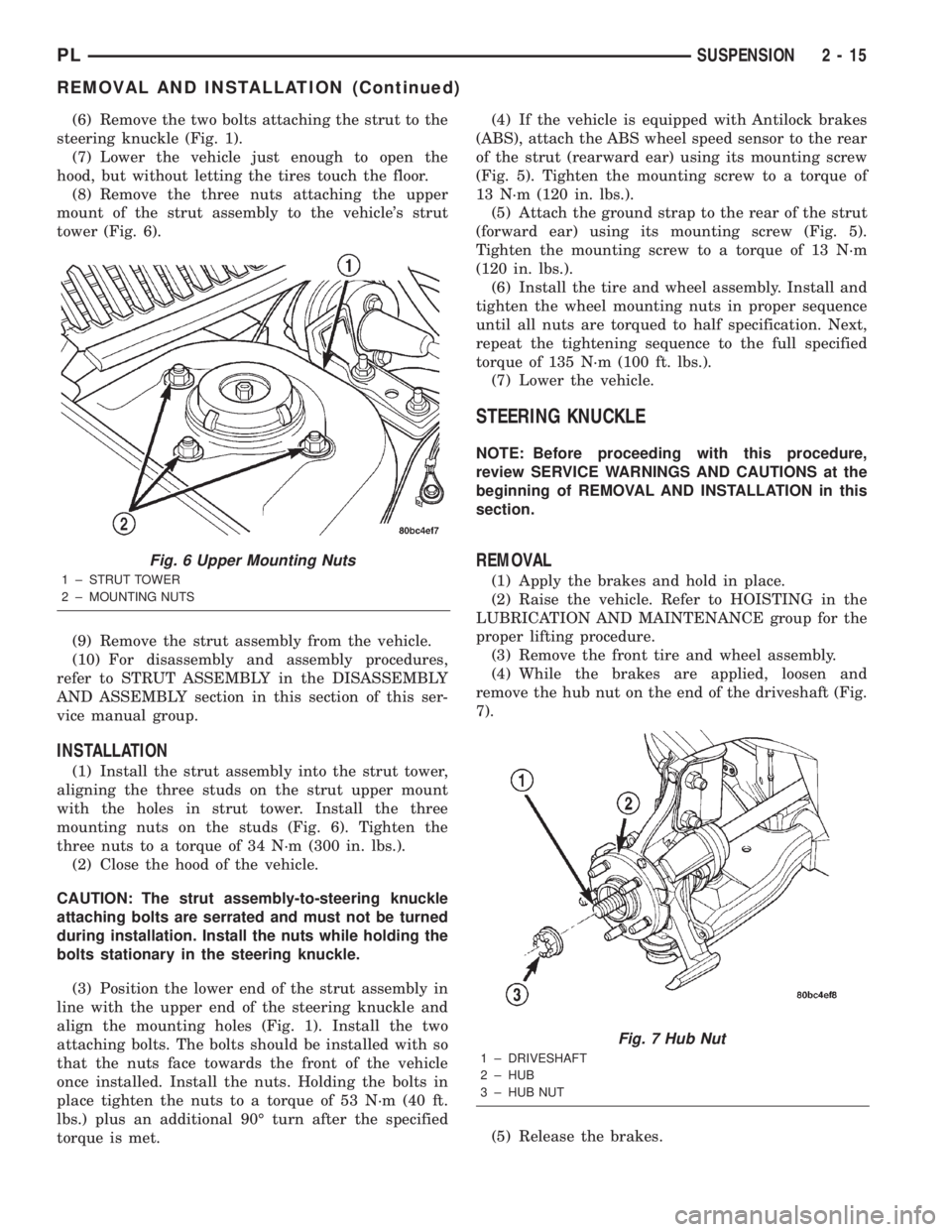

(4) While the brakes are applied, loosen and

remove the hub nut on the end of the driveshaft (Fig.

7).

(5) Release the brakes.

Fig. 6 Upper Mounting Nuts

1 ± STRUT TOWER

2 ± MOUNTING NUTS

Fig. 7 Hub Nut

1 ± DRIVESHAFT

2 ± HUB

3 ± HUB NUT

PLSUSPENSION 2 - 15

REMOVAL AND INSTALLATION (Continued)

Page 201 of 1285

(10) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.

INSTALLATION

(1) Slide radiator down into position behind radia-

tor support (yoke).

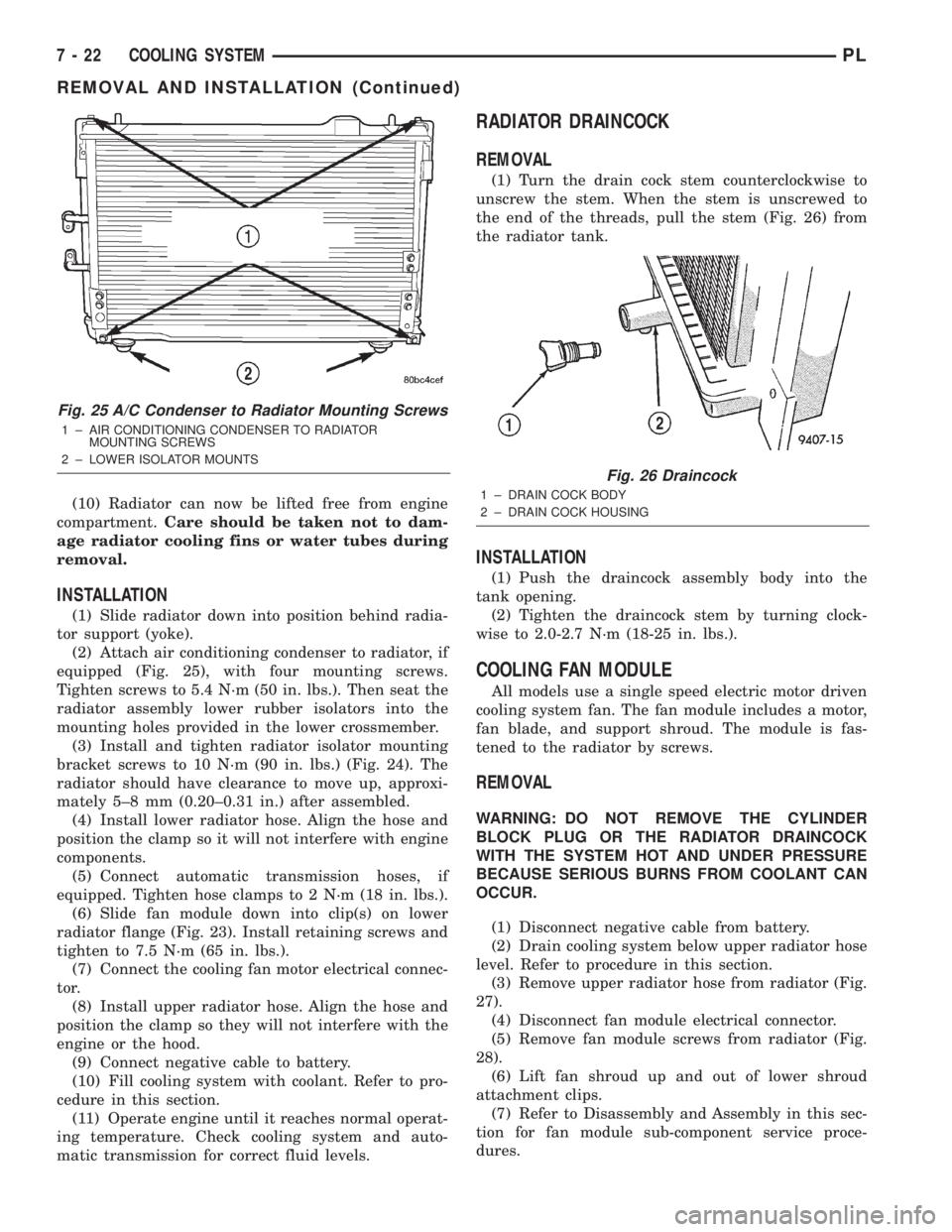

(2) Attach air conditioning condenser to radiator, if

equipped (Fig. 25), with four mounting screws.

Tighten screws to 5.4 N´m (50 in. lbs.). Then seat the

radiator assembly lower rubber isolators into the

mounting holes provided in the lower crossmember.

(3) Install and tighten radiator isolator mounting

bracket screws to 10 N´m (90 in. lbs.) (Fig. 24). The

radiator should have clearance to move up, approxi-

mately 5±8 mm (0.20±0.31 in.) after assembled.

(4) Install lower radiator hose. Align the hose and

position the clamp so it will not interfere with engine

components.

(5) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 2 N´m (18 in. lbs.).

(6) Slide fan module down into clip(s) on lower

radiator flange (Fig. 23). Install retaining screws and

tighten to 7.5 N´m (65 in. lbs.).

(7) Connect the cooling fan motor electrical connec-

tor.

(8) Install upper radiator hose. Align the hose and

position the clamp so they will not interfere with the

engine or the hood.

(9) Connect negative cable to battery.

(10) Fill cooling system with coolant. Refer to pro-

cedure in this section.

(11) Operate engine until it reaches normal operat-

ing temperature. Check cooling system and auto-

matic transmission for correct fluid levels.

RADIATOR DRAINCOCK

REMOVAL

(1) Turn the drain cock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

the end of the threads, pull the stem (Fig. 26) from

the radiator tank.

INSTALLATION

(1) Push the draincock assembly body into the

tank opening.

(2) Tighten the draincock stem by turning clock-

wise to 2.0-2.7 N´m (18-25 in. lbs.).

COOLING FAN MODULE

All models use a single speed electric motor driven

cooling system fan. The fan module includes a motor,

fan blade, and support shroud. The module is fas-

tened to the radiator by screws.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain cooling system below upper radiator hose

level. Refer to procedure in this section.

(3) Remove upper radiator hose from radiator (Fig.

27).

(4) Disconnect fan module electrical connector.

(5) Remove fan module screws from radiator (Fig.

28).

(6) Lift fan shroud up and out of lower shroud

attachment clips.

(7) Refer to Disassembly and Assembly in this sec-

tion for fan module sub-component service proce-

dures.

Fig. 25 A/C Condenser to Radiator Mounting Screws

1 ± AIR CONDITIONING CONDENSER TO RADIATOR

MOUNTING SCREWS

2 ± LOWER ISOLATOR MOUNTS

Fig. 26 Draincock

1 ± DRAIN COCK BODY

2 ± DRAIN COCK HOUSING

7 - 22 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 210 of 1285

BATTERY

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD).........2

CHARGING TIME REQUIRED................2

DIAGNOSIS AND TESTING

BATTERY BUILT-IN TEST INDICATOR.........3

BATTERY IGNITION OFF DRAW (IOD).........4

BATTERY LOAD TEST......................6

BATTERY OPEN CIRCUIT VOLTAGE...........7

SERVICE PROCEDURES

BATTERY CHARGING......................7CHARGING COMPLETELY DISCHARGED

BATTERY..............................8

VISUAL INSPECTION......................9

REMOVAL AND INSTALLATION

BATTERY...............................10

BATTERY THERMOWRAP..................10

BATTERY TRAY..........................11

SPECIFICATIONS

BATTERY SPECIFICATIONS................11

TORQUE...............................11

GENERAL INFORMATION

INTRODUCTION

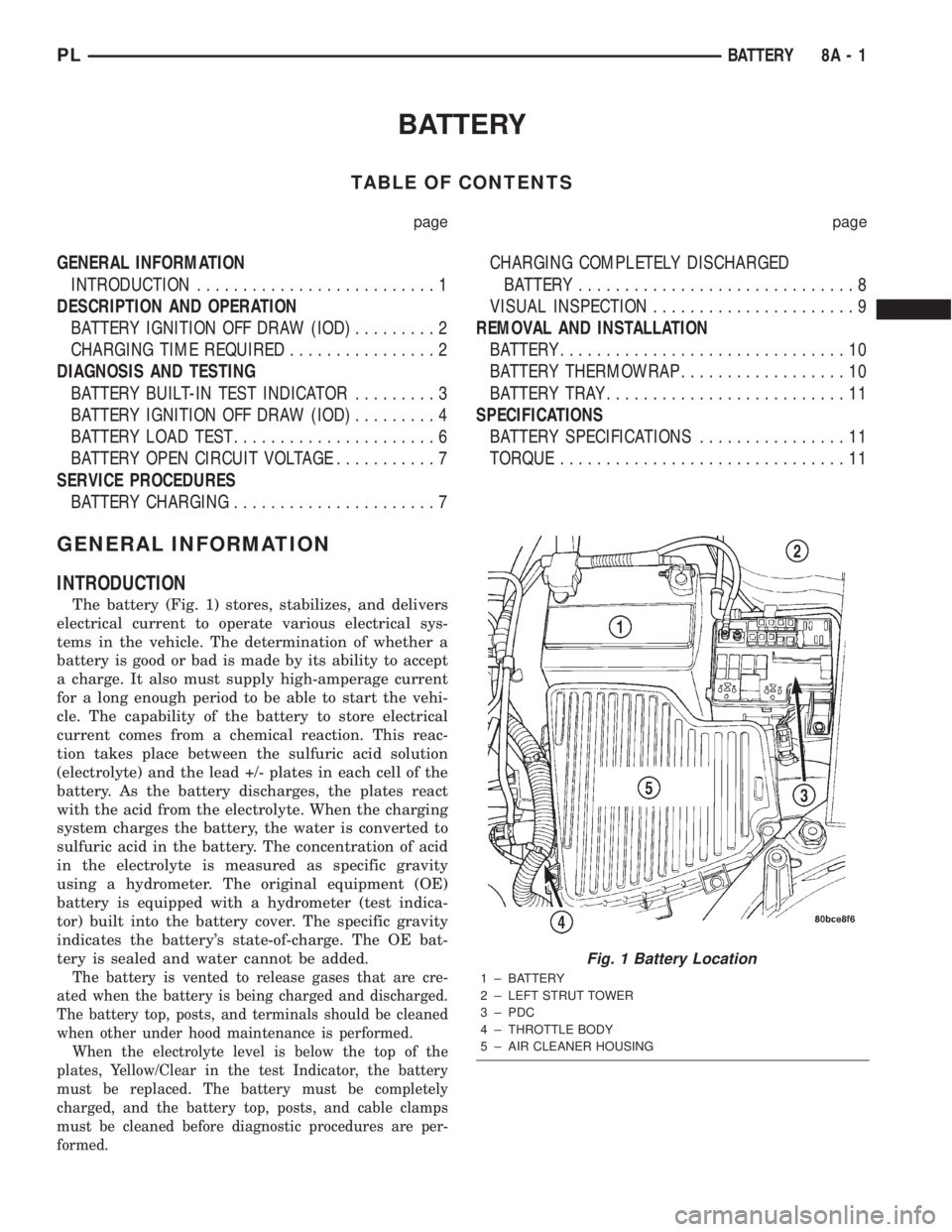

The battery (Fig. 1) stores, stabilizes, and delivers

electrical current to operate various electrical sys-

tems in the vehicle. The determination of whether a

battery is good or bad is made by its ability to accept

a charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The original equipment (OE)

battery is equipped with a hydrometer (test indica-

tor) built into the battery cover. The specific gravity

indicates the battery's state-of-charge. The OE bat-

tery is sealed and water cannot be added.

The battery is vented to release gases that are cre-

ated when the battery is being charged and discharged.

The battery top, posts, and terminals should be cleaned

when other under hood maintenance is performed.

When the electrolyte level is below the top of the

plates, Yellow/Clear in the test Indicator, the battery

must be replaced. The battery must be completely

charged, and the battery top, posts, and cable clamps

must be cleaned before diagnostic procedures are per-

formed.

Fig. 1 Battery Location

1 ± BATTERY

2 ± LEFT STRUT TOWER

3 ± PDC

4 ± THROTTLE BODY

5 ± AIR CLEANER HOUSING

PLBATTERY 8A - 1

Page 219 of 1285

REMOVAL AND INSTALLATION

BATTERY

REMOVAL

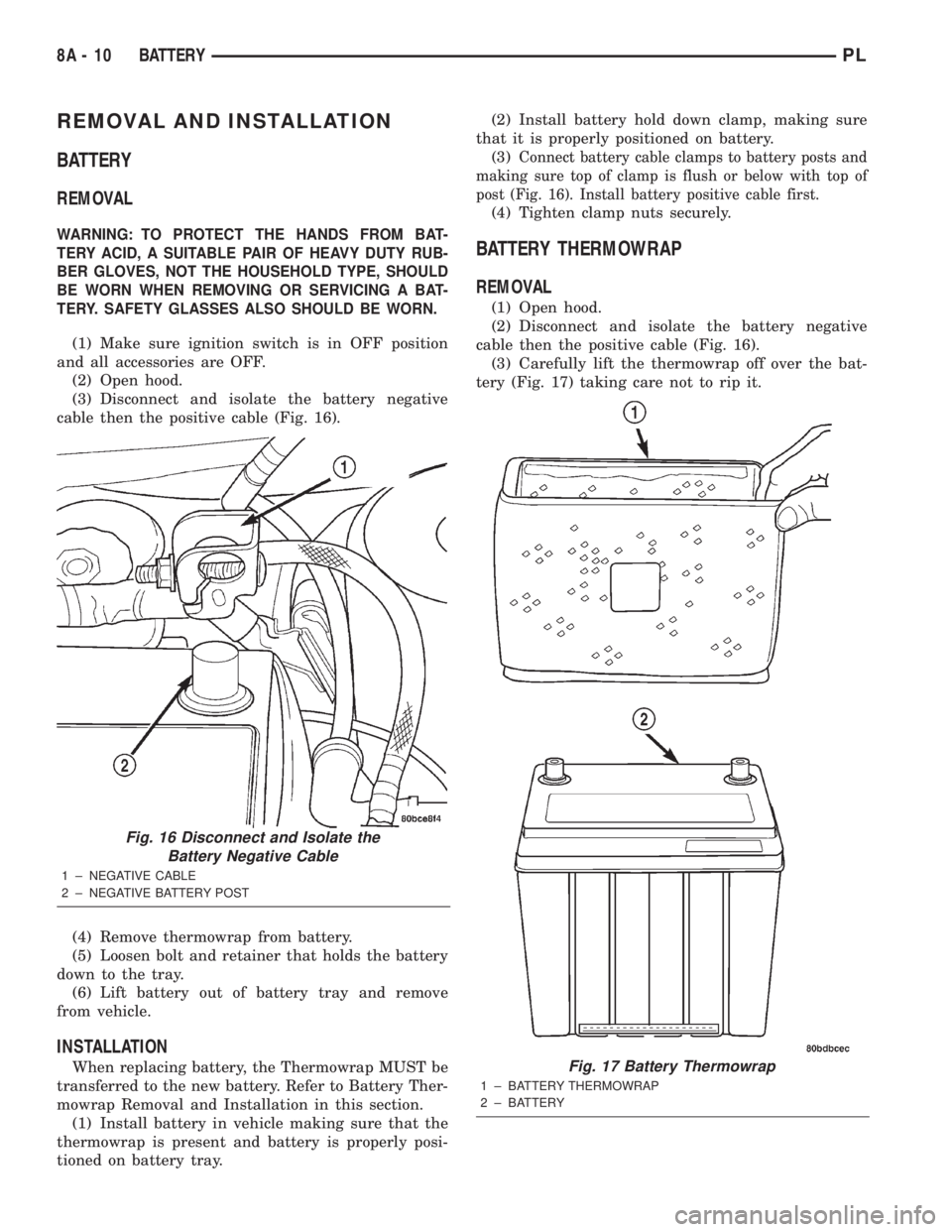

WARNING: TO PROTECT THE HANDS FROM BAT-

TERY ACID, A SUITABLE PAIR OF HEAVY DUTY RUB-

BER GLOVES, NOT THE HOUSEHOLD TYPE, SHOULD

BE WORN WHEN REMOVING OR SERVICING A BAT-

TERY. SAFETY GLASSES ALSO SHOULD BE WORN.

(1) Make sure ignition switch is in OFF position

and all accessories are OFF.

(2) Open hood.

(3) Disconnect and isolate the battery negative

cable then the positive cable (Fig. 16).

(4) Remove thermowrap from battery.

(5) Loosen bolt and retainer that holds the battery

down to the tray.

(6) Lift battery out of battery tray and remove

from vehicle.

INSTALLATION

When replacing battery, the Thermowrap MUST be

transferred to the new battery. Refer to Battery Ther-

mowrap Removal and Installation in this section.

(1) Install battery in vehicle making sure that the

thermowrap is present and battery is properly posi-

tioned on battery tray.(2) Install battery hold down clamp, making sure

that it is properly positioned on battery.

(3)

Connect battery cable clamps to battery posts and

making sure top of clamp is flush or below with top of

post (Fig. 16). Install battery positive cable first.

(4) Tighten clamp nuts securely.

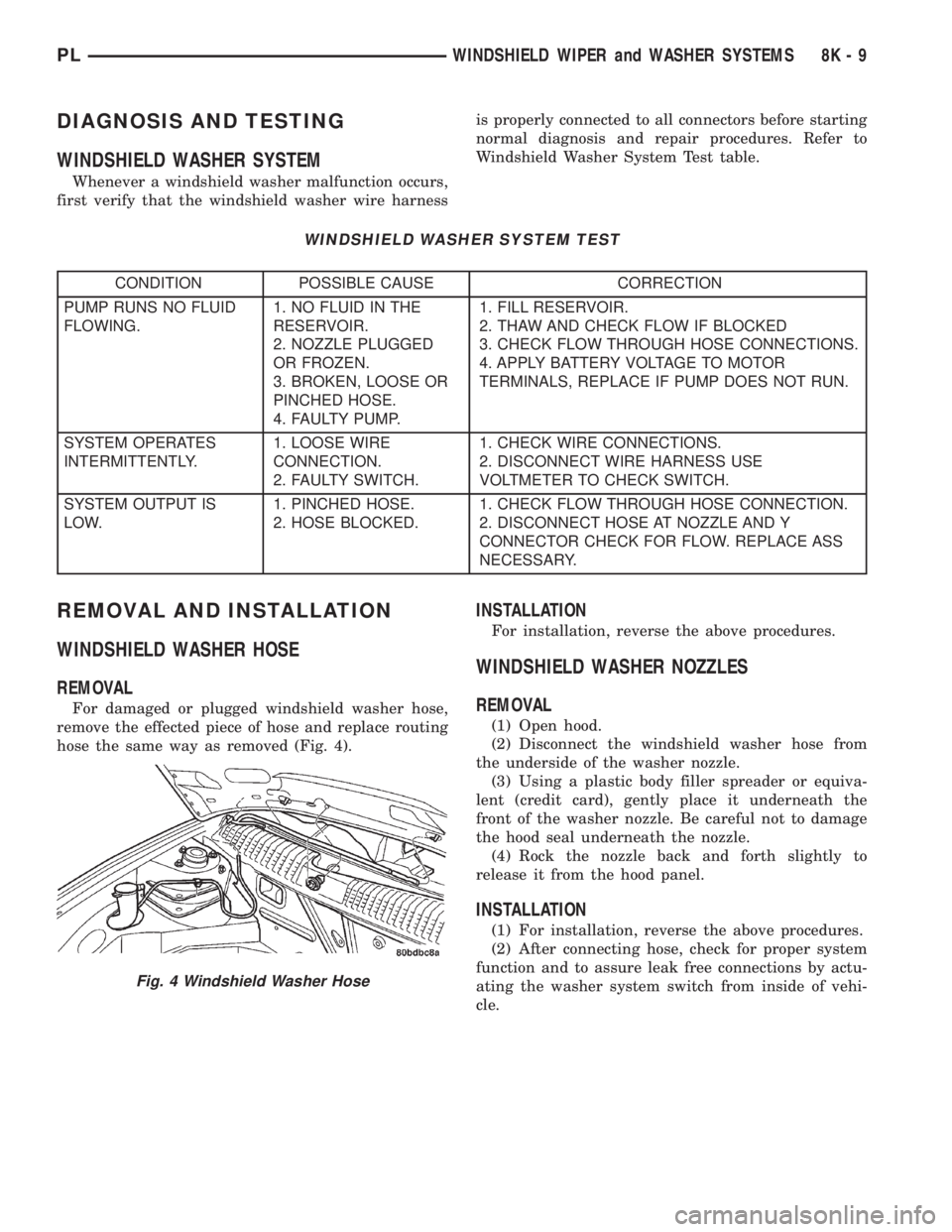

BATTERY THERMOWRAP

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable then the positive cable (Fig. 16).

(3) Carefully lift the thermowrap off over the bat-

tery (Fig. 17) taking care not to rip it.

Fig. 16 Disconnect and Isolate the

Battery Negative Cable

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 17 Battery Thermowrap

1 ± BATTERY THERMOWRAP

2 ± BATTERY

8A - 10 BATTERYPL

Page 306 of 1285

DIAGNOSIS AND TESTING

WINDSHIELD WASHER SYSTEM

Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harnessis properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer System Test table.

WINDSHIELD WASHER SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

PUMP RUNS NO FLUID

FLOWING.1. NO FLUID IN THE

RESERVOIR.

2. NOZZLE PLUGGED

OR FROZEN.

3. BROKEN, LOOSE OR

PINCHED HOSE.

4. FAULTY PUMP.1. FILL RESERVOIR.

2. THAW AND CHECK FLOW IF BLOCKED

3. CHECK FLOW THROUGH HOSE CONNECTIONS.

4. APPLY BATTERY VOLTAGE TO MOTOR

TERMINALS, REPLACE IF PUMP DOES NOT RUN.

SYSTEM OPERATES

INTERMITTENTLY.1. LOOSE WIRE

CONNECTION.

2. FAULTY SWITCH.1. CHECK WIRE CONNECTIONS.

2. DISCONNECT WIRE HARNESS USE

VOLTMETER TO CHECK SWITCH.

SYSTEM OUTPUT IS

LOW.1. PINCHED HOSE.

2. HOSE BLOCKED.1. CHECK FLOW THROUGH HOSE CONNECTION.

2. DISCONNECT HOSE AT NOZZLE AND Y

CONNECTOR CHECK FOR FLOW. REPLACE ASS

NECESSARY.

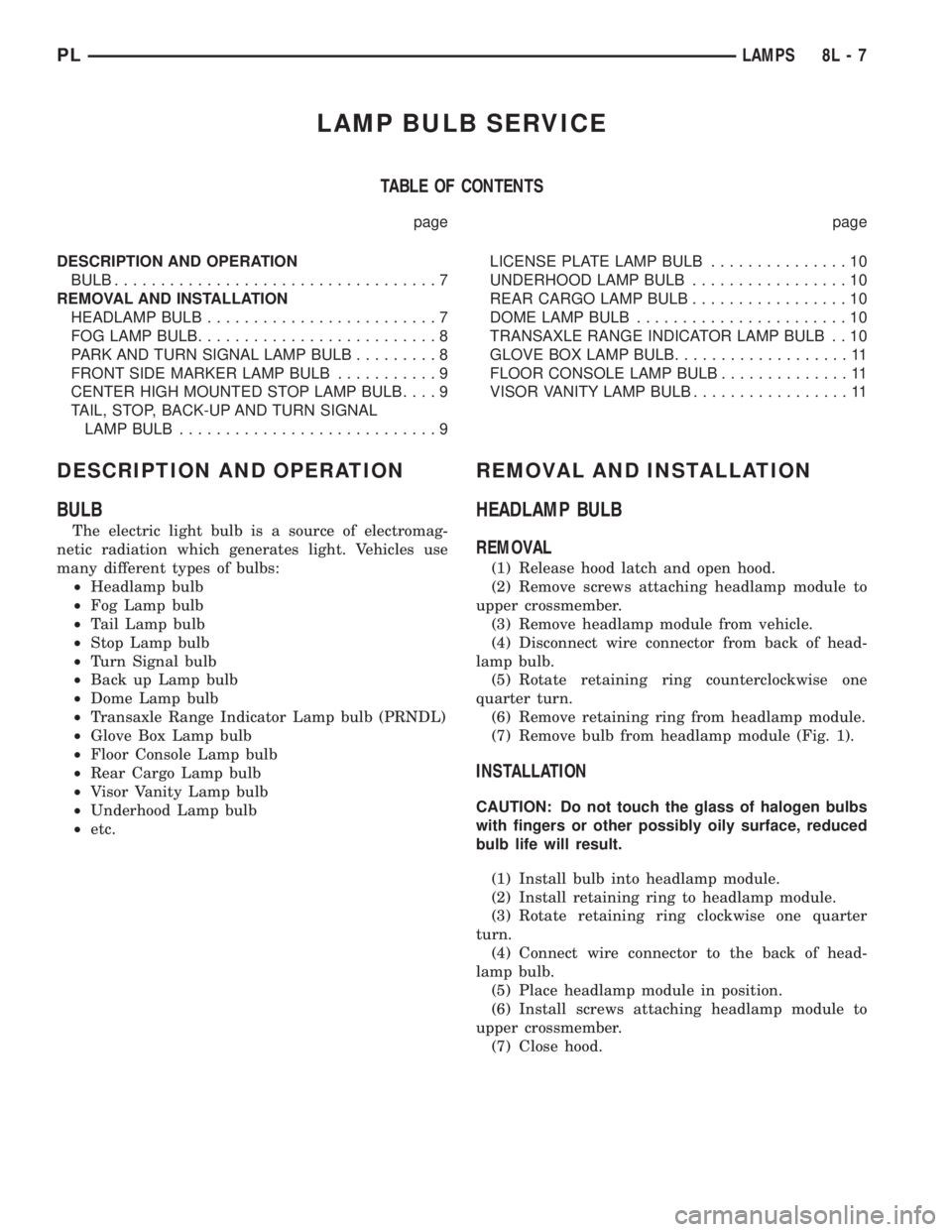

REMOVAL AND INSTALLATION

WINDSHIELD WASHER HOSE

REMOVAL

For damaged or plugged windshield washer hose,

remove the effected piece of hose and replace routing

hose the same way as removed (Fig. 4).

INSTALLATION

For installation, reverse the above procedures.

WINDSHIELD WASHER NOZZLES

REMOVAL

(1) Open hood.

(2) Disconnect the windshield washer hose from

the underside of the washer nozzle.

(3) Using a plastic body filler spreader or equiva-

lent (credit card), gently place it underneath the

front of the washer nozzle. Be careful not to damage

the hood seal underneath the nozzle.

(4) Rock the nozzle back and forth slightly to

release it from the hood panel.

INSTALLATION

(1) For installation, reverse the above procedures.

(2) After connecting hose, check for proper system

function and to assure leak free connections by actu-

ating the washer system switch from inside of vehi-

cle.

Fig. 4 Windshield Washer Hose

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 9

Page 314 of 1285

LAMP BULB SERVICE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

BULB...................................7

REMOVAL AND INSTALLATION

HEADLAMP BULB.........................7

FOG LAMP BULB..........................8

PARK AND TURN SIGNAL LAMP BULB.........8

FRONT SIDE MARKER LAMP BULB...........9

CENTER HIGH MOUNTED STOP LAMP BULB....9

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULB............................9LICENSE PLATE LAMP BULB...............10

UNDERHOOD LAMP BULB.................10

REAR CARGO LAMP BULB.................10

DOME LAMP BULB.......................10

TRANSAXLE RANGE INDICATOR LAMP BULB . . 10

GLOVE BOX LAMP BULB...................11

FLOOR CONSOLE LAMP BULB..............11

VISOR VANITY LAMP BULB.................11

DESCRIPTION AND OPERATION

BULB

The electric light bulb is a source of electromag-

netic radiation which generates light. Vehicles use

many different types of bulbs:

²Headlamp bulb

²Fog Lamp bulb

²Tail Lamp bulb

²Stop Lamp bulb

²Turn Signal bulb

²Back up Lamp bulb

²Dome Lamp bulb

²Transaxle Range Indicator Lamp bulb (PRNDL)

²Glove Box Lamp bulb

²Floor Console Lamp bulb

²Rear Cargo Lamp bulb

²Visor Vanity Lamp bulb

²Underhood Lamp bulb

²etc.

REMOVAL AND INSTALLATION

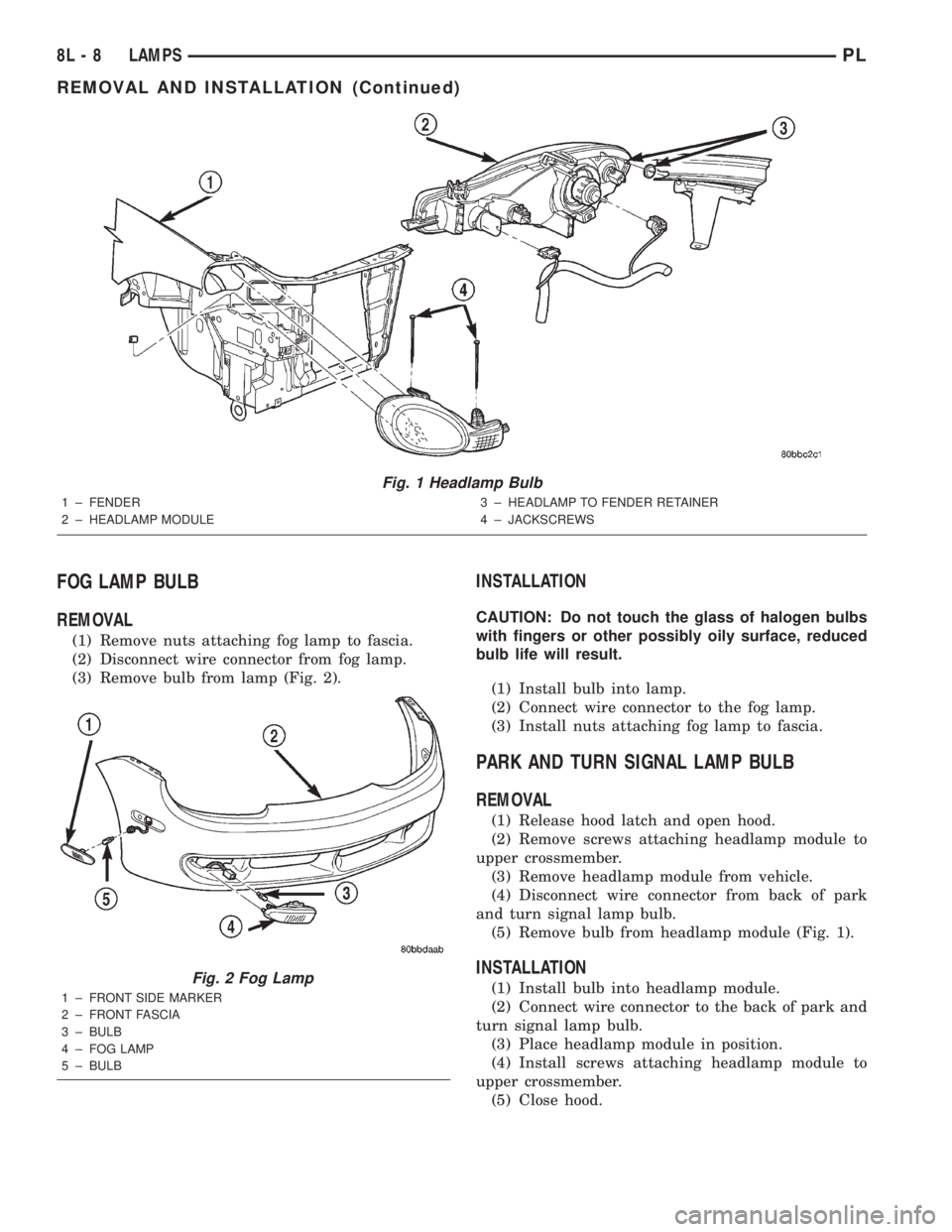

HEADLAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws attaching headlamp module to

upper crossmember.

(3) Remove headlamp module from vehicle.

(4) Disconnect wire connector from back of head-

lamp bulb.

(5) Rotate retaining ring counterclockwise one

quarter turn.

(6) Remove retaining ring from headlamp module.

(7) Remove bulb from headlamp module (Fig. 1).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Install bulb into headlamp module.

(2) Install retaining ring to headlamp module.

(3) Rotate retaining ring clockwise one quarter

turn.

(4) Connect wire connector to the back of head-

lamp bulb.

(5) Place headlamp module in position.

(6) Install screws attaching headlamp module to

upper crossmember.

(7) Close hood.

PLLAMPS 8L - 7

Page 315 of 1285

FOG LAMP BULB

REMOVAL

(1) Remove nuts attaching fog lamp to fascia.

(2) Disconnect wire connector from fog lamp.

(3) Remove bulb from lamp (Fig. 2).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Install bulb into lamp.

(2) Connect wire connector to the fog lamp.

(3) Install nuts attaching fog lamp to fascia.

PARK AND TURN SIGNAL LAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws attaching headlamp module to

upper crossmember.

(3) Remove headlamp module from vehicle.

(4) Disconnect wire connector from back of park

and turn signal lamp bulb.

(5) Remove bulb from headlamp module (Fig. 1).

INSTALLATION

(1) Install bulb into headlamp module.

(2) Connect wire connector to the back of park and

turn signal lamp bulb.

(3) Place headlamp module in position.

(4) Install screws attaching headlamp module to

upper crossmember.

(5) Close hood.

Fig. 1 Headlamp Bulb

1 ± FENDER

2 ± HEADLAMP MODULE3 ± HEADLAMP TO FENDER RETAINER

4 ± JACKSCREWS

Fig. 2 Fog Lamp

1 ± FRONT SIDE MARKER

2 ± FRONT FASCIA

3 ± BULB

4 ± FOG LAMP

5 ± BULB

8L - 8 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 317 of 1285

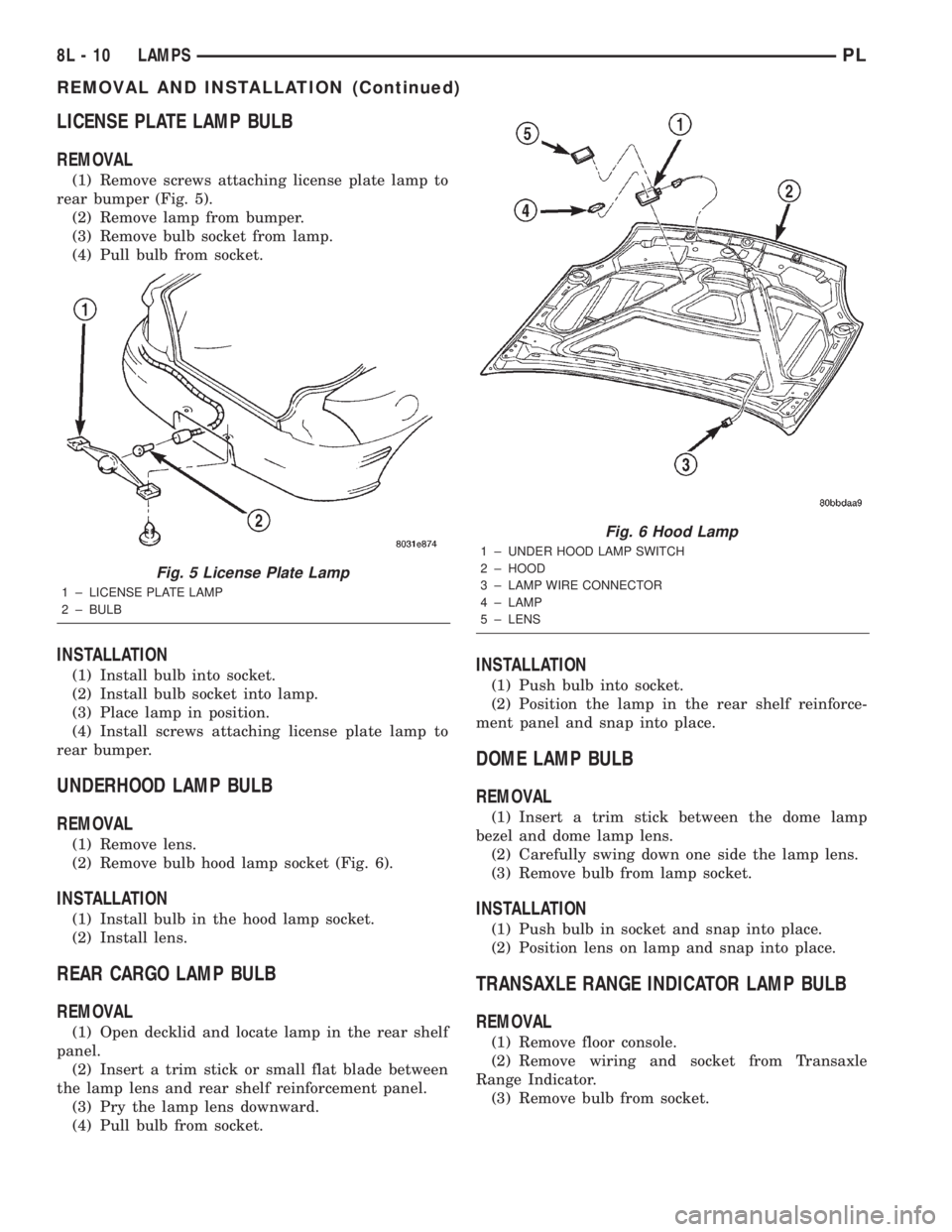

LICENSE PLATE LAMP BULB

REMOVAL

(1) Remove screws attaching license plate lamp to

rear bumper (Fig. 5).

(2) Remove lamp from bumper.

(3) Remove bulb socket from lamp.

(4) Pull bulb from socket.

INSTALLATION

(1) Install bulb into socket.

(2) Install bulb socket into lamp.

(3) Place lamp in position.

(4) Install screws attaching license plate lamp to

rear bumper.

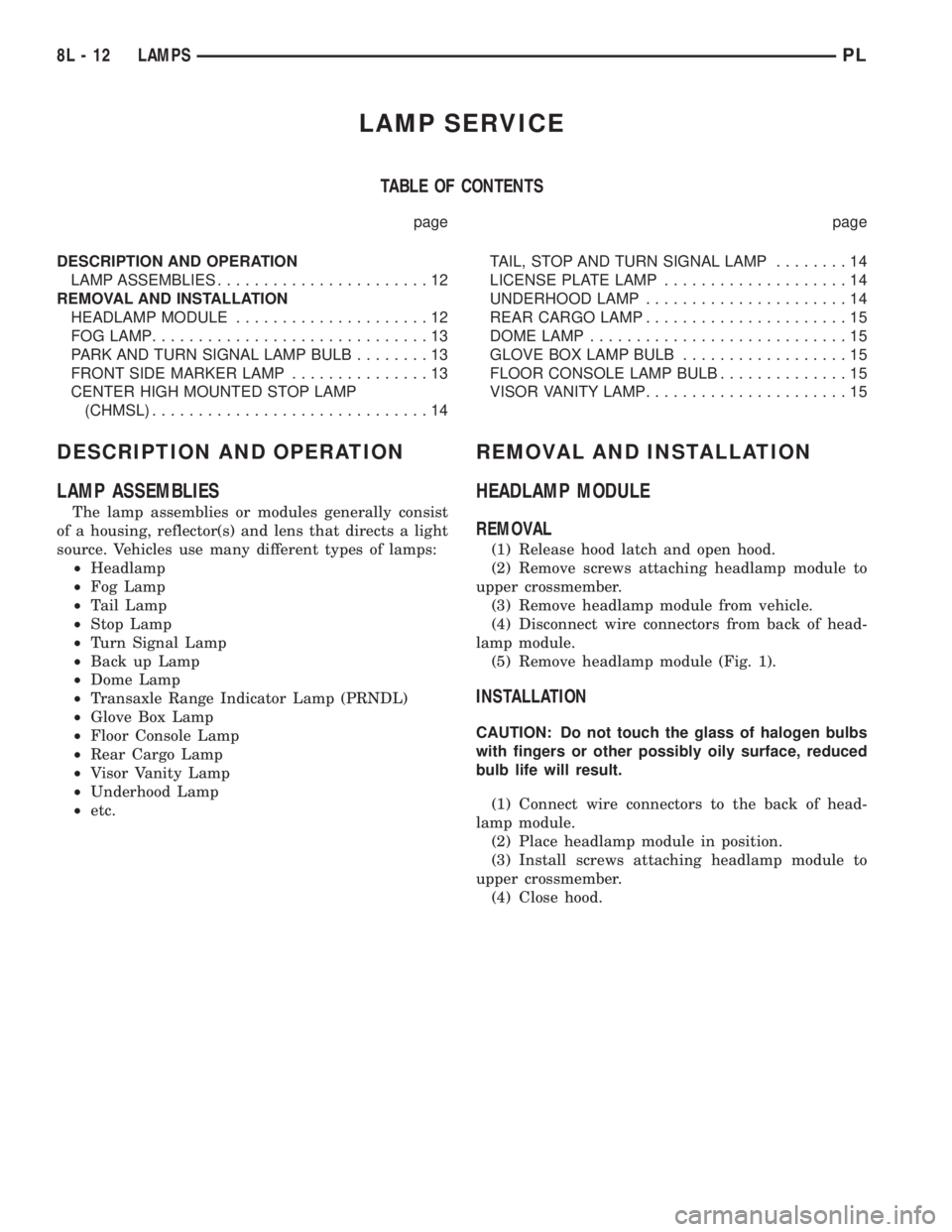

UNDERHOOD LAMP BULB

REMOVAL

(1) Remove lens.

(2) Remove bulb hood lamp socket (Fig. 6).

INSTALLATION

(1) Install bulb in the hood lamp socket.

(2) Install lens.

REAR CARGO LAMP BULB

REMOVAL

(1) Open decklid and locate lamp in the rear shelf

panel.

(2) Insert a trim stick or small flat blade between

the lamp lens and rear shelf reinforcement panel.

(3) Pry the lamp lens downward.

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Position the lamp in the rear shelf reinforce-

ment panel and snap into place.

DOME LAMP BULB

REMOVAL

(1) Insert a trim stick between the dome lamp

bezel and dome lamp lens.

(2) Carefully swing down one side the lamp lens.

(3) Remove bulb from lamp socket.

INSTALLATION

(1) Push bulb in socket and snap into place.

(2) Position lens on lamp and snap into place.

TRANSAXLE RANGE INDICATOR LAMP BULB

REMOVAL

(1) Remove floor console.

(2) Remove wiring and socket from Transaxle

Range Indicator.

(3) Remove bulb from socket.

Fig. 5 License Plate Lamp

1 ± LICENSE PLATE LAMP

2 ± BULB

Fig. 6 Hood Lamp

1 ± UNDER HOOD LAMP SWITCH

2 ± HOOD

3 ± LAMP WIRE CONNECTOR

4 ± LAMP

5 ± LENS

8L - 10 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 319 of 1285

LAMP SERVICE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

LAMP ASSEMBLIES.......................12

REMOVAL AND INSTALLATION

HEADLAMP MODULE.....................12

FOG LAMP..............................13

PARK AND TURN SIGNAL LAMP BULB........13

FRONT SIDE MARKER LAMP...............13

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)..............................14TAIL, STOP AND TURN SIGNAL LAMP........14

LICENSE PLATE LAMP....................14

UNDERHOOD LAMP......................14

REAR CARGO LAMP......................15

DOME LAMP............................15

GLOVE BOX LAMP BULB..................15

FLOOR CONSOLE LAMP BULB..............15

VISOR VANITY LAMP......................15

DESCRIPTION AND OPERATION

LAMP ASSEMBLIES

The lamp assemblies or modules generally consist

of a housing, reflector(s) and lens that directs a light

source. Vehicles use many different types of lamps:

²Headlamp

²Fog Lamp

²Tail Lamp

²Stop Lamp

²Turn Signal Lamp

²Back up Lamp

²Dome Lamp

²Transaxle Range Indicator Lamp (PRNDL)

²Glove Box Lamp

²Floor Console Lamp

²Rear Cargo Lamp

²Visor Vanity Lamp

²Underhood Lamp

²etc.

REMOVAL AND INSTALLATION

HEADLAMP MODULE

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws attaching headlamp module to

upper crossmember.

(3) Remove headlamp module from vehicle.

(4) Disconnect wire connectors from back of head-

lamp module.

(5) Remove headlamp module (Fig. 1).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

(1) Connect wire connectors to the back of head-

lamp module.

(2) Place headlamp module in position.

(3) Install screws attaching headlamp module to

upper crossmember.

(4) Close hood.

8L - 12 LAMPSPL