brake DODGE NEON 2004 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: NEON, Model: DODGE NEON 2004 2.GPages: 241, PDF Size: 3.75 MB

Page 164 of 241

NHoses And Vacuum/Vapor Harnesses.......184

NBrake System........................185

NAutomatic Transaxle...................187

NManual Transaxle.....................189

NAppearance Care And Protection From

Corrosion...........................190

mFuses...............................195

NUnderhood Fuses

(Power Distribution Center)..............195

NInterior Fuses........................195

mVehicle Storage........................196

mReplacement Bulbs.....................196

mBulb Replacement......................197

NHeadlight Bulb Replacement.............197

NFront Park/Turn Signal Lights............199

NFront Sidemarker Light.................199

NTail/Stop, Rear Turn Signals And Back-Up

Lights.............................199

NCenter High Mounted Stop Light..........199

mFluids And Capacities...................200

mRecommended Fluids, Lubricants And Genuine

Parts

...............................201

NEngine.............................201

NChassis............................201

164 MAINTAINING YOUR VEHICLE

Page 185 of 241

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could cause failure.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.

MAINTAINING YOUR VEHICLE 185

7

Page 186 of 241

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

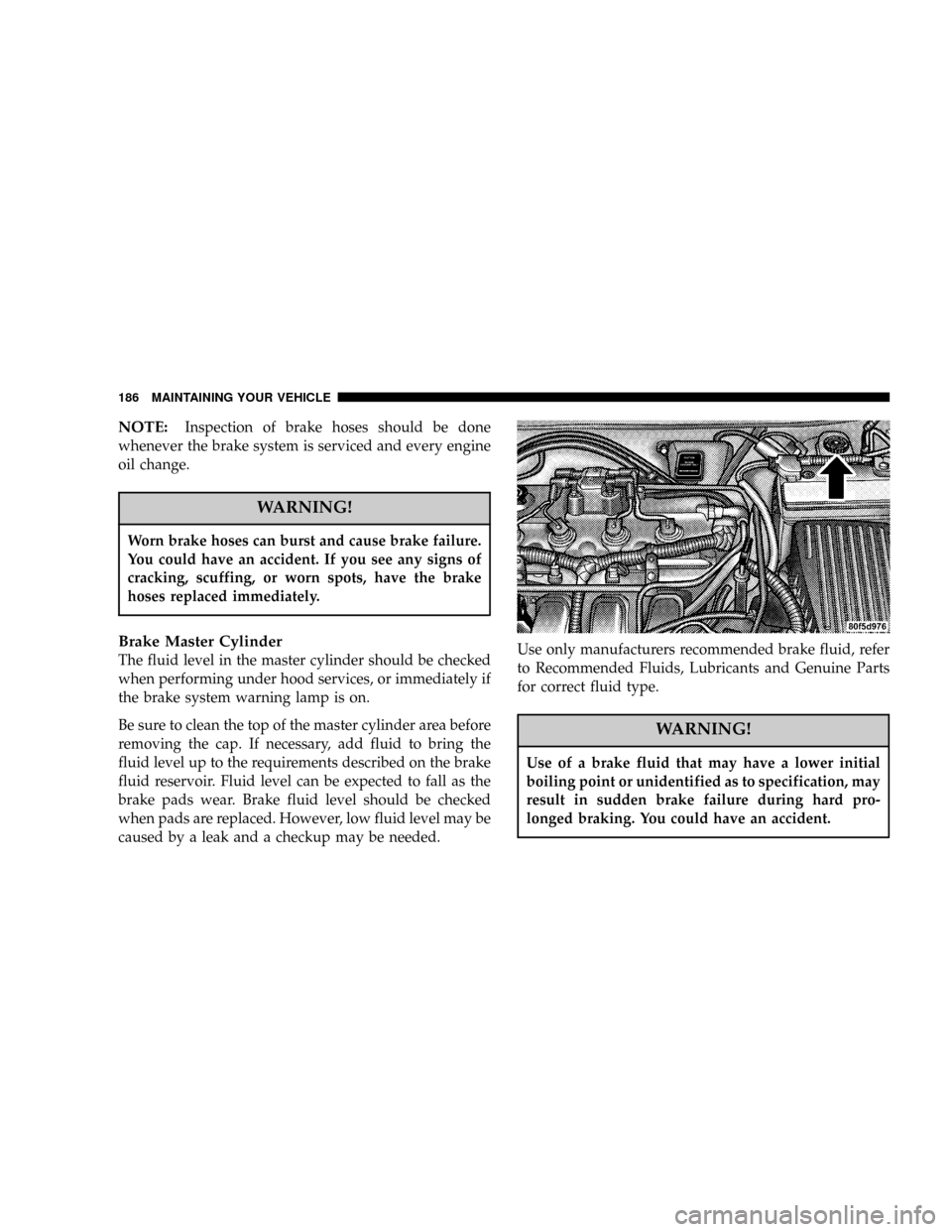

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. Fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.Use only manufacturers recommended brake fluid, refer

to Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

WARNING!

Use of a brake fluid that may have a lower initial

boiling point or unidentified as to specification, may

result in sudden brake failure during hard pro-

longed braking. You could have an accident.

186 MAINTAINING YOUR VEHICLE

Page 187 of 241

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter.

Do not allow petroleum based fluid to contaminate the

brake fluid as seal damage will result!

Automatic Transaxle

All front wheel drive vehicles have a transaxle and

differential assembly contained within a single housing.

Selection of Lubricant

It is important that the proper lubricant is used in the

transaxle to assure optimum transaxle performance. Use

only manufacturers recommended transmission fluid,

refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type. It is important that the

transmission fluid be maintained at the prescribed level

using the recommended fluid.

CAUTION!

Using a transmission fluid other than the manufac-

turers recommended fluid may cause deterioration

in transmission shift quality and/or torque converter

shudder. Using a transmission fluid other than the

manufacturers recommended fluid will result in

more frequent fluid and filter changes. Refer to

Recommended Fluids, Lubricants and Genuine Parts

for correct fluid type.

Fluid Level Check

The fluid level in the automatic transaxle should be

checked whenever the vehicle is serviced. Operation with

an improper fluid level will greatly reduce the life of the

transaxle and of the fluid.

Procedure for Checking Fluid Level

Check the fluid level while the transmission is at normal

operating temperature. This occurs after at least 15 miles

(25 km) of driving. At normal operating temperature,

which is approximately180ÉF ( 82ÉC), the fluid cannot be

held comfortably between the fingertips.

MAINTAINING YOUR VEHICLE 187

7

Page 188 of 241

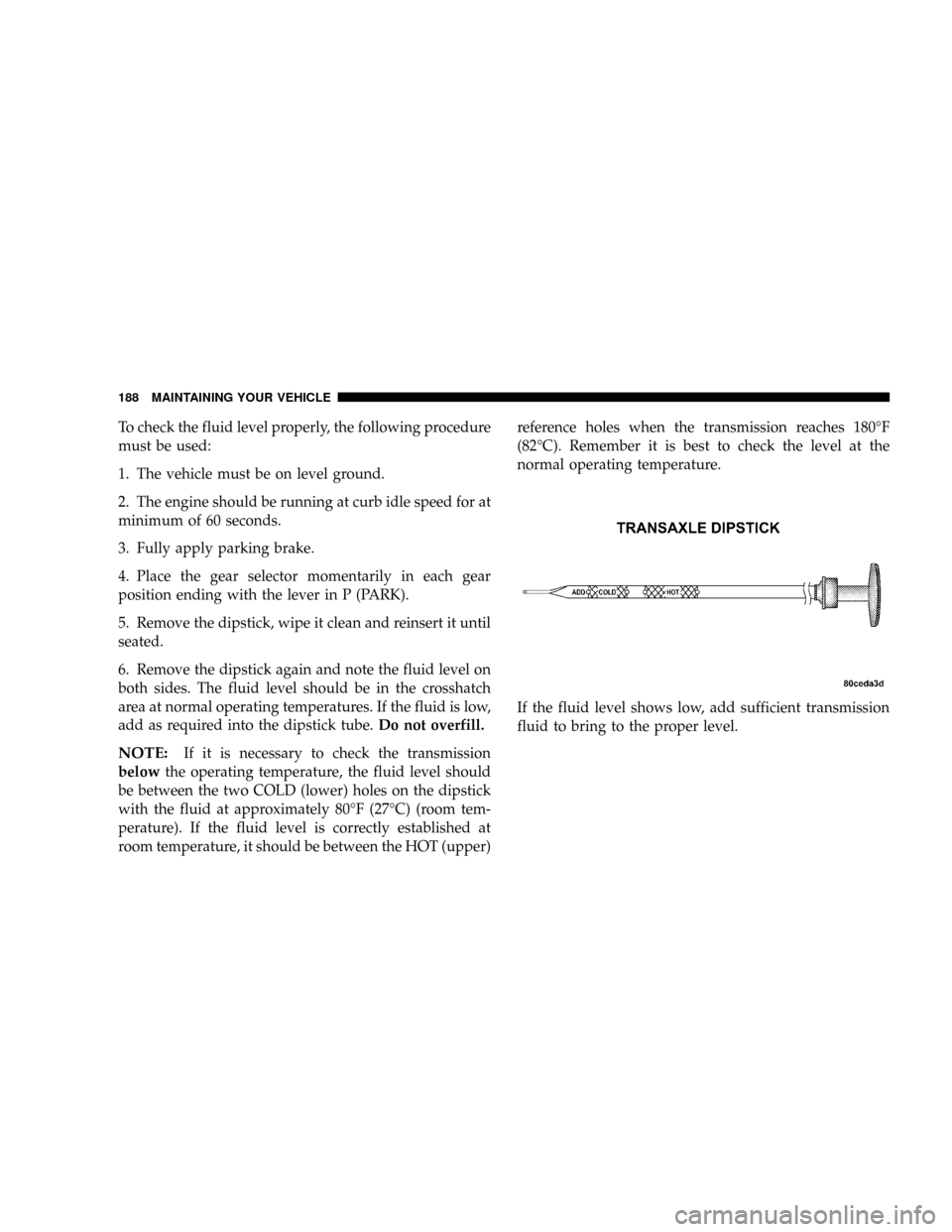

To check the fluid level properly, the following procedure

must be used:

1. The vehicle must be on level ground.

2. The engine should be running at curb idle speed for at

minimum of 60 seconds.

3. Fully apply parking brake.

4. Place the gear selector momentarily in each gear

position ending with the lever in P (PARK).

5. Remove the dipstick, wipe it clean and reinsert it until

seated.

6. Remove the dipstick again and note the fluid level on

both sides. The fluid level should be in the crosshatch

area at normal operating temperatures. If the fluid is low,

add as required into the dipstick tube.Do not overfill.

NOTE:If it is necessary to check the transmission

belowthe operating temperature, the fluid level should

be between the two COLD (lower) holes on the dipstick

with the fluid at approximately 80ÉF (27ÉC) (room tem-

perature). If the fluid level is correctly established at

room temperature, it should be between the HOT (upper)reference holes when the transmission reaches 180ÉF

(82ÉC). Remember it is best to check the level at the

normal operating temperature.

If the fluid level shows low, add sufficient transmission

fluid to bring to the proper level.

188 MAINTAINING YOUR VEHICLE

Page 196 of 241

CAUTION!

When replacing a blown fuse, it is important to use

only a fuse having the correct amperage rating. The

use of a fuse with a rating other than indicated may

result in a dangerous electrical system overload. If a

properly rated fuse continues to blow, it shows a

problem in the circuit that must be corrected.

VEHICLE STORAGE

If you will not be using your vehicle for more than 21

days you may want to take steps to preserve your battery.

You may:

²Disengage the mini fuse in the Power Distribution

Center labeled IOD (Ignition Off-Draw).

²Or, disconnect the negative cable from the battery.

REPLACEMENT BULBS

LIGHT BULBS Ð Inside Bulb No.

ABS Indicator.......................... LED

Airbag Indicator........................ LED

Brake System Warning Indicator............. LED

Climate Controls........................ LED

Console Gear Selector...................PC194

Dome Light............................T579

Front Fog Indicator...................... LED

High Beam Indicator....................PC194

Instrument Cluster Illumination............PC194

Low Fuel Indicator....................... LED

Low Oil Pressure Indicator................. LED

Rear Cargo............................T906

Seat Belt Indicator....................... LED

Security Alarm Indicator................... LED

Malfunction Indicator Light................ LED

Turn Signal Indicator....................PC194

Voltage Indicator........................ LED

All the inside bulbs are brass or glass wedge base.

Aluminum base bulbs are not approved and should not

be used for replacement.

196 MAINTAINING YOUR VEHICLE

Page 201 of 241

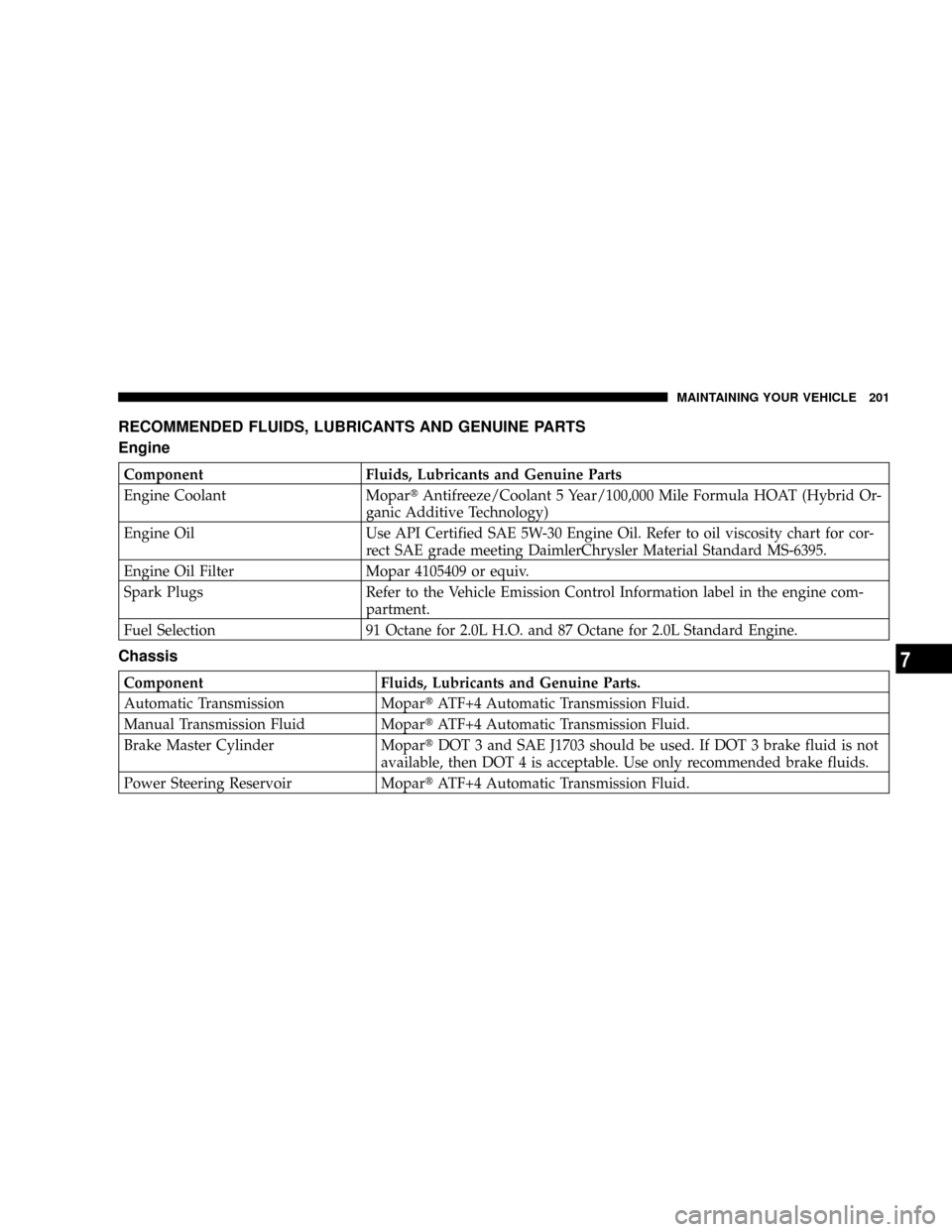

RECOMMENDED FLUIDS, LUBRICANTS AND GENUINE PARTS

Engine

Component Fluids, Lubricants and Genuine Parts

Engine Coolant MopartAntifreeze/Coolant 5 Year/100,000 Mile Formula HOAT (Hybrid Or-

ganic Additive Technology)

Engine Oil Use API Certified SAE 5W-30 Engine Oil. Refer to oil viscosity chart for cor-

rect SAE grade meeting DaimlerChrysler Material Standard MS-6395.

Engine Oil Filter Mopar 4105409 or equiv.

Spark Plugs Refer to the Vehicle Emission Control Information label in the engine com-

partment.

Fuel Selection 91 Octane for 2.0L H.O. and 87 Octane for 2.0L Standard Engine.

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transmission MopartATF+4 Automatic Transmission Fluid.

Manual Transmission Fluid MopartATF+4 Automatic Transmission Fluid.

Brake Master Cylinder MopartDOT 3 and SAE J1703 should be used. If DOT 3 brake fluid is not

available, then DOT 4 is acceptable. Use only recommended brake fluids.

Power Steering Reservoir MopartATF+4 Automatic Transmission Fluid.

MAINTAINING YOUR VEHICLE 201

7

Page 205 of 241

²If equipped for and operating with E-85 (ethanol)

fuel.

NOTE:IfANYof these apply to you then change your

engine oil every 3,000 miles (5 000 km) or 3 months,

whichever comes first and follow schedule ªBº of the

9Maintenance Schedules9section of this manual.

NOTE:Most vehicles are operated under the conditions

listed for Schedule9B9.

Second is ScheduleªAº. It is for vehicles that are not

operated under any of the conditions listed under Sched-

ule9B9.

Use the schedule that best describes your driving condi-

tions. Where time and mileage are listed, follow the

interval that occurs first.

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²

Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²

Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and add

as needed.

²Check all lights and all other electrical items for correct

operation.

MAINTENANCE SCHEDULES 205

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 206 of 241

²Check rubber seals on each side of the radiator for

proper fit.

At Each Oil Change

²

Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension compo-

nents.

²Check the automatic transaxle fluid level.

²Check the manual transaxle fluid level and fill plug

condition.

²Check the coolant level, hoses, and clamps.

²Rotate the tires at each oil change interval shown on

Schedule ªAº 6,000 miles (10 000 km) or every other

interval shown on Schedule ªBº 6,000 miles (10 000

km).

206 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 208 of 241

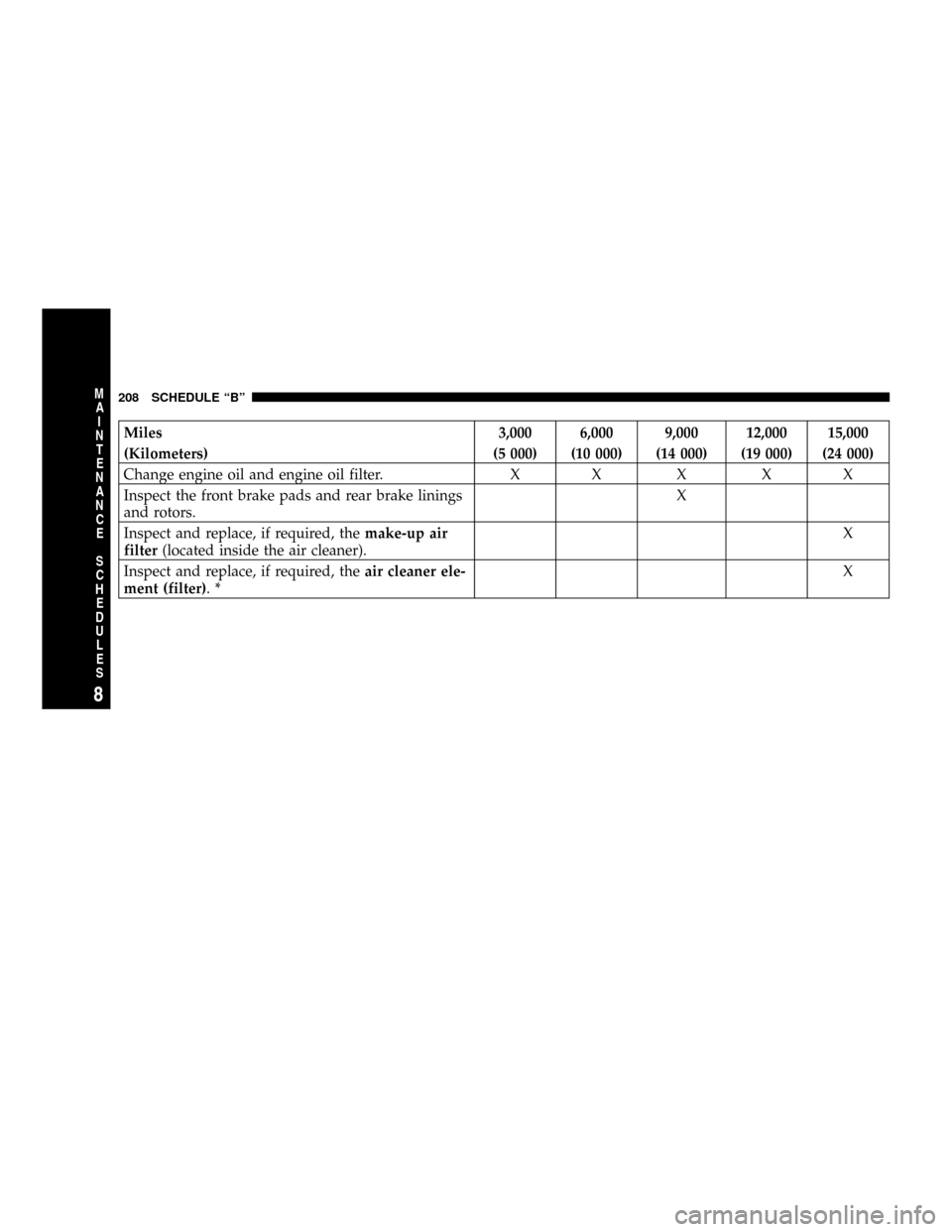

Miles 3,000 6,000 9,000 12,000 15,000

(Kilometers) (5 000) (10 000) (14 000) (19 000) (24 000)

Change engine oil and engine oil filter. X X X X X

Inspect the front brake pads and rear brake linings

and rotors.X

Inspect and replace, if required, themake-up air

filter(located inside the air cleaner).X

Inspect and replace, if required, theair cleaner ele-

ment (filter).*X

208 SCHEDULE ªBº

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S