ECU DODGE NEON 2005 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: NEON, Model: DODGE NEON 2005 2.GPages: 246, PDF Size: 3.69 MB

Page 59 of 246

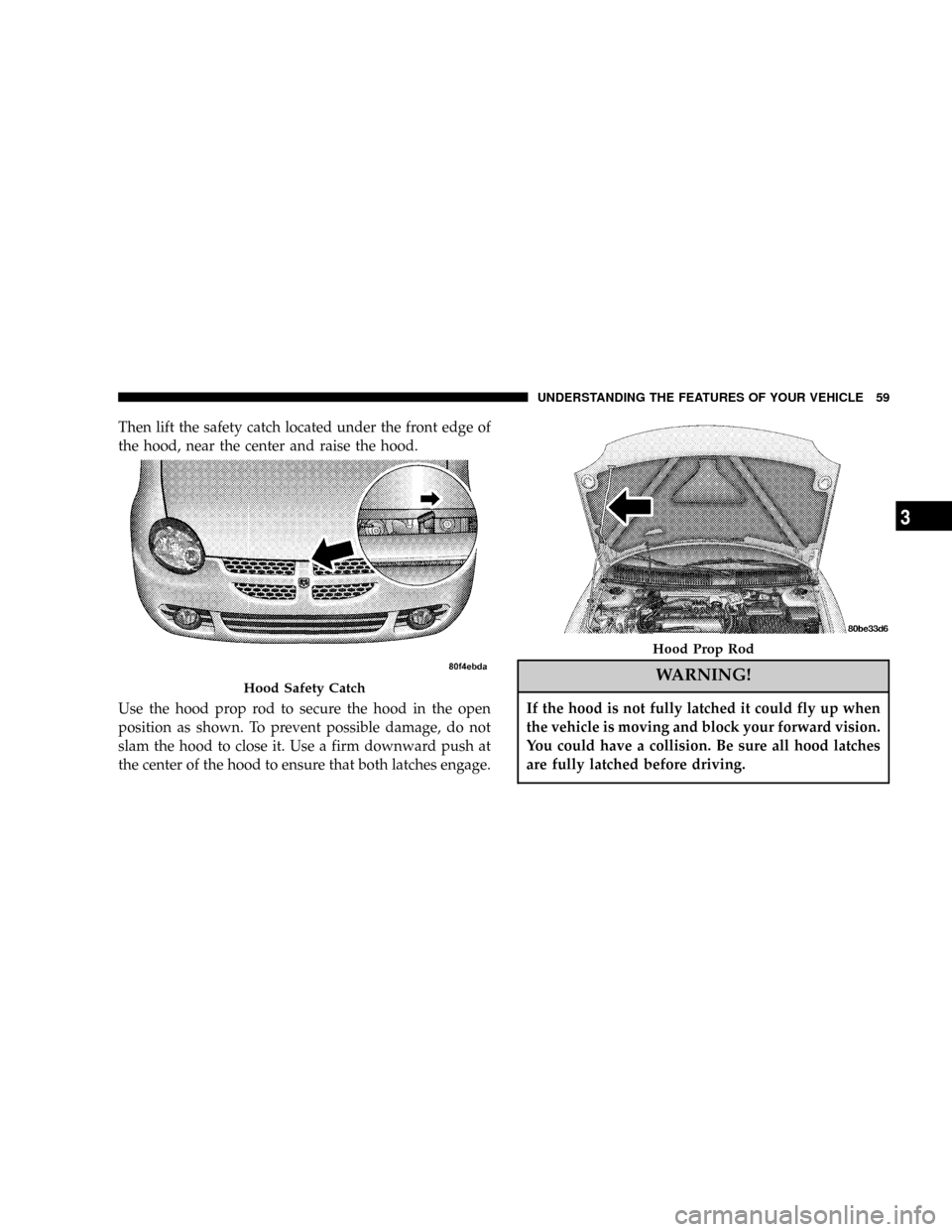

Then lift the safety catch located under the front edge of

the hood, near the center and raise the hood.

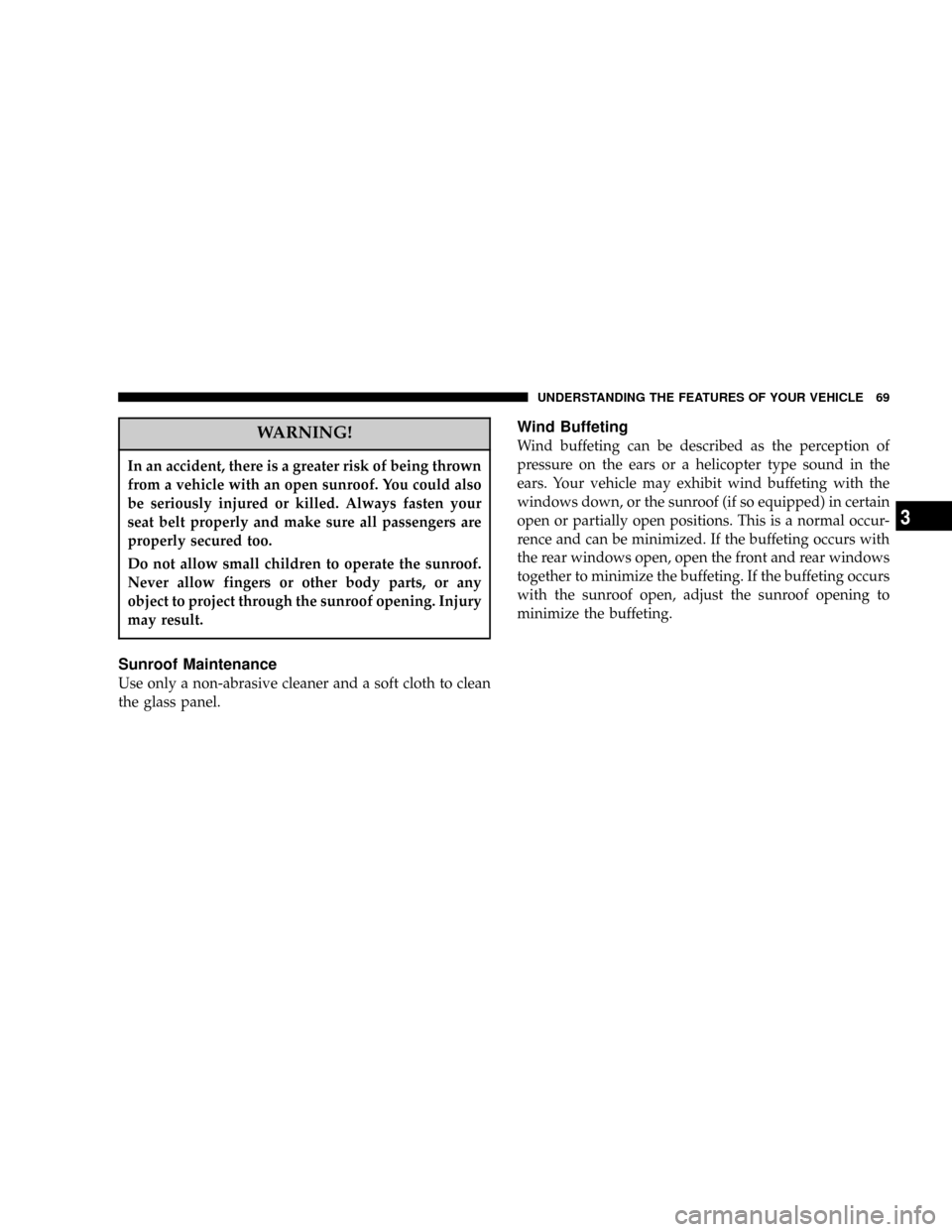

Use the hood prop rod to secure the hood in the open

position as shown. To prevent possible damage, do not

slam the hood to close it. Use a firm downward push at

the center of the hood to ensure that both latches engage.

WARNING!

If the hood is not fully latched it could fly up when

the vehicle is moving and block your forward vision.

You could have a collision. Be sure all hood latches

are fully latched before driving.

Hood Safety Catch

Hood Prop Rod

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 59

3

Page 69 of 246

WARNING!

In an accident, there is a greater risk of being thrown

from a vehicle with an open sunroof. You could also

be seriously injured or killed. Always fasten your

seat belt properly and make sure all passengers are

properly secured too.

Do not allow small children to operate the sunroof.

Never allow fingers or other body parts, or any

object to project through the sunroof opening. Injury

may result.

Sunroof Maintenance

Use only a non-abrasive cleaner and a soft cloth to clean

the glass panel.

Wind Buffeting

Wind buffeting can be described as the perception of

pressure on the ears or a helicopter type sound in the

ears. Your vehicle may exhibit wind buffeting with the

windows down, or the sunroof (if so equipped) in certain

open or partially open positions. This is a normal occur-

rence and can be minimized. If the buffeting occurs with

the rear windows open, open the front and rear windows

together to minimize the buffeting. If the buffeting occurs

with the sunroof open, adjust the sunroof opening to

minimize the buffeting.

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 69

3

Page 117 of 246

NOTE:If a malfunction occurs, the system will trap the

key in the ignition cylinder to warn you that this safety

feature is inoperable. The engine can be started and

stopped but the key cannot be removed until you obtain

service.

Four Speed Automatic Transaxle

The electronically controlled transaxle provides a precise

shift schedule. The transaxle electronics are self calibrat-

ing; therefore, the first few shifts on a new vehicle may be

somewhat abrupt. This is a normal condition, and preci-

sion shifts will develop within a few shift cycles.

Reset Mode

The transaxle is monitored electronically for abnormal

conditions. If a condition is detected that could cause

damage, the transaxle shifts automatically into second

gear. The transaxle remains in second gear despite the

forward gear selected. Park (P), Reverse (R), and Neutral

(N) will continue to operate. This second gear limp-in

feature allows the vehicle to be driven to a dealer for

service without damaging the transaxle.

In the event that the problem has been momentary, the

transaxle can be reset to regain all forward gears.Stop the vehicle and shift into Park (P).

Turn the Key to OFF then restart the engine.

Shift into D and resume driving.

NOTE:Even if the transaxle can be reset, it is recom-

mended that you visit a dealer at your earliest possible

convenience. Your dealer has diagnostic equipment to

determine if the problem could recur.

If the transaxle cannot be reset, dealer service is required.

Gear Ranges For Four Speed Automatic

Transaxle

DO NOT race the engine when shifting from PARK or

NEUTRAL positions into another gear range.

ªPº Park

Supplements the parking brake by locking the transmis-

sion. The engine can be started in this range. Never use P

(Park) while the vehicle is in motion. Apply the parking

brake when leaving the vehicle in this range. Always

apply the parking brake first, and then place the selector

in P (Park) position.

STARTING AND OPERATING 117

5

Page 118 of 246

WARNING!

Unintended movement of a vehicle could injure

those in and near the vehicle. As with all vehicles,

you should never exit a vehicle while the engine is

running. Before exiting a vehicle, you should always

shift the vehicle into P (Park), remove the key from

the ignition, and apply the parking brake. Once the

key is removed from the ignition, the transmission

shift lever is locked in the P (Park) position, securing

the vehicle against unwanted movement. Further-

more, you should never leave children unattended

inside a vehicle.

The following indicators should be used to ensure that

you have engaged the transmission shift lever into the P

(Park) position:

²When shifting into P (Park), depress the button on the

shift lever and firmly move the lever all the way

forward until it stops.

²Look at the shift indicator window on the console to

ensure it is in the P (Park) position.

²When engaged in P (Park), you will not be able to

move the shifter rearward without depressing the shift

lever button.

CAUTION!

Before moving the shift lever out of P (Park), you

must turn the ignition from LOCK to ON so the

steering wheel and shift lever are released. Other-

wise, damage to the steering column or shifter could

result.

ªRº Reverse

Shift into this range only after the vehicle has come to a

complete stop.

ªNº Neutral

Engine may be started in this range.

ªDº Overdrive

This range should be used for most city and highway

driving. It provides smoothest up shifts and down shifts

and best fuel economy.

118 STARTING AND OPERATING

Page 154 of 246

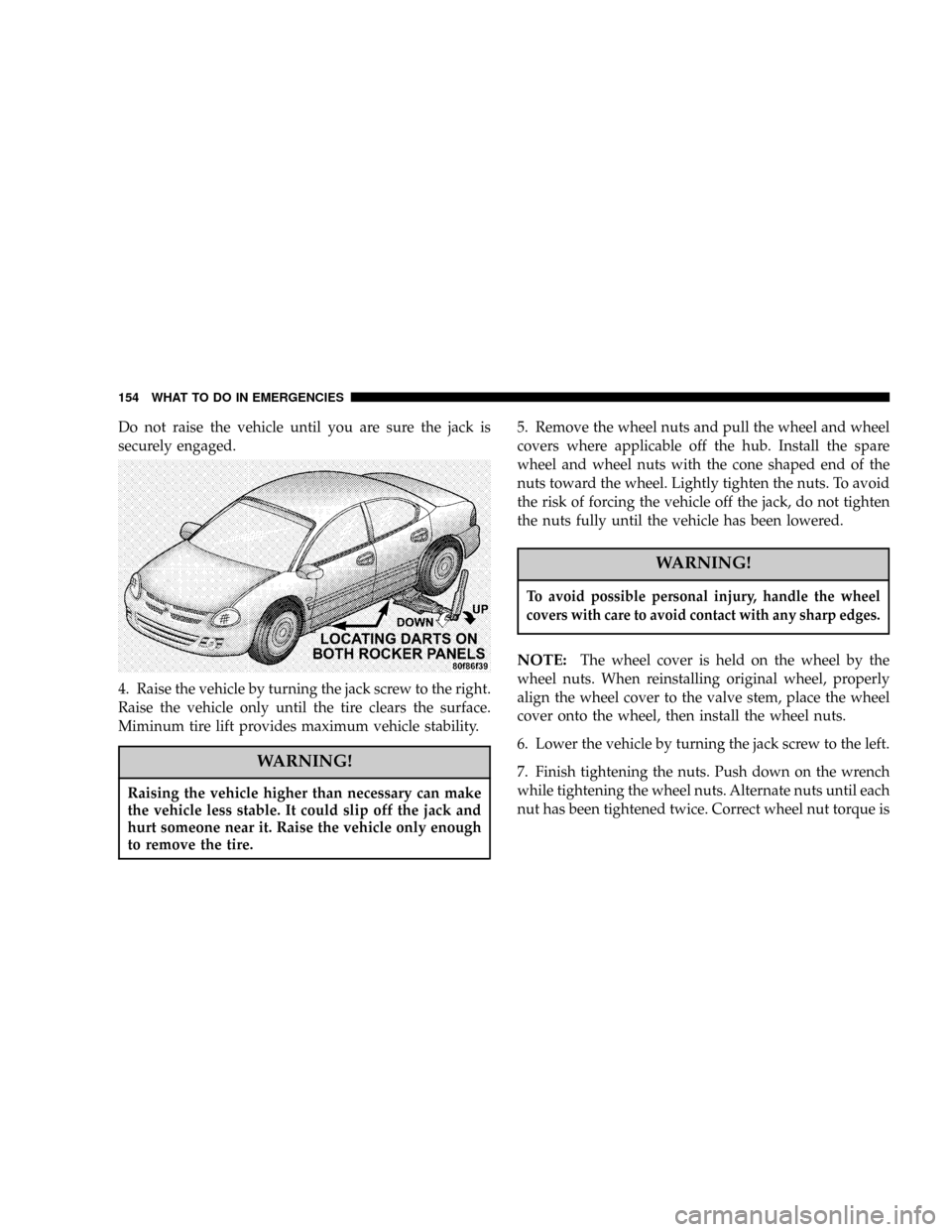

Do not raise the vehicle until you are sure the jack is

securely engaged.

4. Raise the vehicle by turning the jack screw to the right.

Raise the vehicle only until the tire clears the surface.

Miminum tire lift provides maximum vehicle stability.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

5. Remove the wheel nuts and pull the wheel and wheel

covers where applicable off the hub. Install the spare

wheel and wheel nuts with the cone shaped end of the

nuts toward the wheel. Lightly tighten the nuts. To avoid

the risk of forcing the vehicle off the jack, do not tighten

the nuts fully until the vehicle has been lowered.

WARNING!

To avoid possible personal injury, handle the wheel

covers with care to avoid contact with any sharp edges.

NOTE:The wheel cover is held on the wheel by the

wheel nuts. When reinstalling original wheel, properly

align the wheel cover to the valve stem, place the wheel

cover onto the wheel, then install the wheel nuts.

6. Lower the vehicle by turning the jack screw to the left.

7. Finish tightening the nuts. Push down on the wrench

while tightening the wheel nuts. Alternate nuts until each

nut has been tightened twice. Correct wheel nut torque is

154 WHAT TO DO IN EMERGENCIES

Page 155 of 246

100 ft. lbs. (135 N´m). If you are not sure about the

tightness, have them checked with a torque wrench by

your dealer or at a service station.

8. Remove the wheel blocks and lower the jack until it is

free. Stow the lug wrench, replaced tire, and jack. Secure

all parts using the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

9. Adjust the tire pressure as soon as possible.

NOTE:The spare tire well is designed to hold the

compact spare tire or a deflated (flat) tire. A fully inflated

tire will not fit in the spare tire well.

JUMP-STARTING PROCEDURES IF BATTERY IS

LOW

WARNING!

Take care to avoid the radiator cooling fan whenever

the hood is raised. It can start anytime the ignition

switch is on. You can be hurt by the fan.

WARNING!

Do not attempt to push or tow your vehicle to get it

started. Vehicles equipped with an automatic trans-

axle cannot be started this way. Unburned fuel could

enter the catalytic converter and once the engine has

started, ignite and damage the converter and vehicle.

If the vehicle has a discharged battery, booster cables

may be used to obtain a start from another vehicle.

This type of start can be dangerous if done improp-

erly, so follow this procedure carefully.

WHAT TO DO IN EMERGENCIES 155

6

Page 186 of 246

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could cause failure.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.

186 MAINTAINING YOUR VEHICLE

Page 199 of 246

LIGHT BULBS Ð Inside Bulb No.

Seat Belt Indicator....................... LED

Security Alarm Indicator................... LED

Malfunction Indicator Light................ LED

Turn Signal Indicator....................PC194

Voltage Indicator........................ LED

All the inside bulbs are brass or glass wedge base.

Aluminum base bulbs are not approved and should not

be used for replacement.

LIGHTS BULBS Ð Outside Bulb No.

Headlight.............................9007

Front Park/Turn Signal Light.............3457AK

Front Side Marker Light.................... 168

Front Fog Light.......................... 899

Center High Mounted Stop Light (CHMSL).....921±

W16W

Rear Tail/Stop/Turn Signal Light......3157±P27/7W

Backup Light......................921±W16W

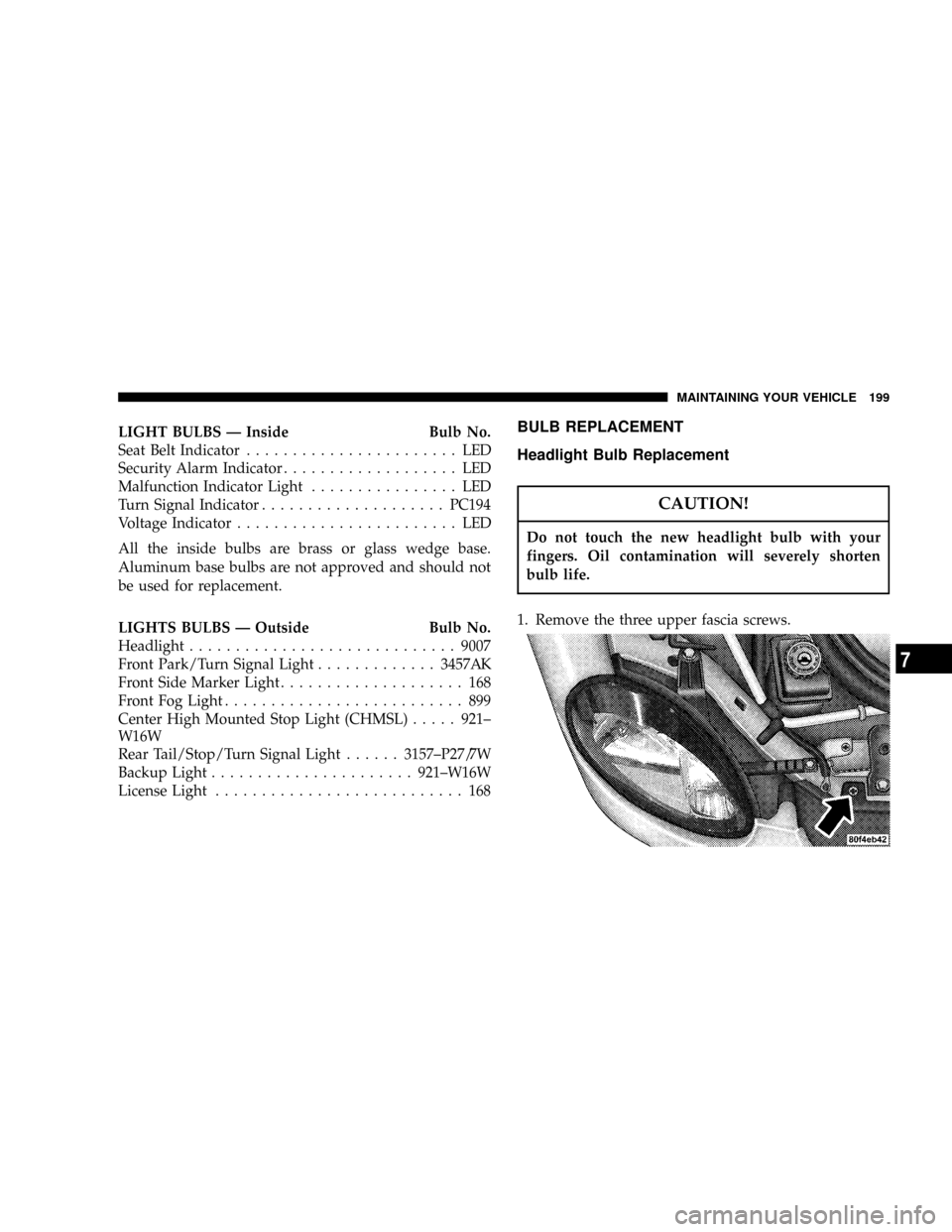

License Light........................... 168BULB REPLACEMENT

Headlight Bulb Replacement

CAUTION!

Do not touch the new headlight bulb with your

fingers. Oil contamination will severely shorten

bulb life.

1. Remove the three upper fascia screws.

MAINTAINING YOUR VEHICLE 199

7

Page 234 of 246

ABS (Anti-Lock Brake) System............. 123

Adding Engine Coolant (Antifreeze)......... 183

Adding Fuel.......................... 144

Air Cleaner, Engine (Engine Air Cleaner Filter) . 175

Air Conditioning....................103,177

Air Conditioning Controls................ 103

Air Conditioning Refrigerant.............. 177

Air Conditioning System................. 177

Air Pressure, Tires...................... 133

Airbag................................ 31

Airbag Deployment...................... 36

Airbag Light.......................39,47,79

Airbag Maintenance...................... 38

Airbag, Side........................... 37

Alarm, Panic........................... 20

Alarm System........................22,79

Alignment and Balance.................. 139

Alterations/Modifications, Vehicle............ 6

Antenna, Satellite Radio................... 96

Antifreeze (Engine Coolant).........182,202,203

Capacities........................... 202

Disposal............................ 184

Anti-Lock Brake System (ABS)............. 123Anti-Lock Warning Light.................. 77

Anti-Theft Security Alarm................. 22

Appearance Care....................... 191

Arming Theft System..................... 22

Ashtrays and Lighter..................... 70

Automatic Door Locks.................... 16

Automatic Transaxle........... 9,114,116,117,188

Fluid and Filter Changes................ 190

Fluid Level Check..................... 188

Interlock System....................14,116

Reset Mode.......................... 117

Selection Of Lubricant................. 188

Shifting............................. 117

Special Additives..................... 190

Ball Joints............................ 178

Battery............................... 176

Keyless Transmitter Replacement.......... 21

Belts, Drive........................... 173

Belts, Engine.......................... 174

Body Mechanism Lubrication.............. 178

B-Pillar Location....................... 128

Brake Fluid........................... 203

234 INDEX

Page 240 of 246

Rear Servicing....................... 201

Rear Tail............................ 201

Seat Belt Reminder..................... 79

Security Alarm........................ 22

Side Marker......................... 201

Theft Alarm.......................... 79

Turn Signal.....................62,78,201

Voltage.............................. 79

Warning (Instrument Cluster Description).... 77

Loading Vehicle........................ 146

Tires ............................... 128

Locks................................ 14

Child Protection....................... 17

Door............................... 14

Power Door.......................... 15

Steering Wheel........................ 13

Lubrication, Body....................... 178

Maintenance.......................169,206

Maintenance, Airbag..................... 38

Maintenance Free Battery................. 176

Maintenance Procedures.................. 169

Maintenance Schedule................... 206Schedule9A9......................... 218

Schedule9B9......................... 209

Maintenance, Sunroof.................... 69

Malfunction Indicator Light.............80,167

Manual, Service........................ 229

Manual Transaxle...............67,114,119,190

Downshifting........................ 120

Fluid Level Check..................... 190

Frequency of Fluid Change.............. 191

Lubricant Selection.................... 190

Map/Reading Lights..................... 60

Master Cylinder........................ 187

Mirrors............................... 51

Compass/Temperature.................. 51

Electric Remote....................... 55

Outside............................. 54

Rearview............................ 51

Modifications/Alterations, Vehicle............ 6

Mopar Parts........................168,229

Multi-Function Control Lever.............61,62

Occupant Restraints...................... 24

240 INDEX