ECU DODGE NEON SRT 2004 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: NEON SRT, Model: DODGE NEON SRT 2004 2.GPages: 200, PDF Size: 3.23 MB

Page 125 of 200

7. Finish tightening the nuts. Push down on the wrench

while tightening the wheel nuts. Alternate nuts until each

nut has been tightened twice. Correct wheel nut torque is

100 ft. lbs. (135 N´m.). If you are not sure about the

tightness, have them checked with a torgue wrench by

your dealer or at a service station.

8. Remove the wheel blocks and lower the jack until it is

free. Stow the lug wrench, replaced tire, and jack. Secure

all parts using the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

9. Adjust the tire pressure as soon as possible.

NOTE:The spare tire well is designed to hold the

compact spare tire or a deflated (flat) tire. A fully inflated

tire will not fit in the spare tire well.

JUMP-STARTING PROCEDURES DUE TO A LOW

BATTERY

WARNING!

Take care to avoid the radiator cooling fan whenever

the hood is raised. It can start anytime the ignition

switch is on. You can be hurt by the fan.

WARNING!

Do not attempt to push or tow your vehicle to get it

started. Unburned fuel could enter the catalytic

converter and once the engine has started, ignite and

damage the converter and vehicle. If the vehicle has

a discharged battery, booster cables may be used to

obtain a start from another vehicle. This type of start

can be dangerous if done improperly, so follow this

procedure carefully.

WHAT TO DO IN EMERGENCIES 125

6

Page 152 of 200

E. Make sure that the radiator and coolant bottle hoses

are not kinked or obstructed.

F. Keep the front of the radiator and air conditioning

condenser clean.

G. Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install ONLY

the correct type thermostat. Other designs may result in

unsatisfactory coolant performance, poor gas mileage,

and increased emissions.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, checking, tear, cuts, abrasions,

and excessive swelling indicate deterioration of the rub-

ber.Pay particular attention to the hoses nearest to high heat

sources such as the exhaust manifold. Inspect hose rout-

ing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could cause failure.

152 MAINTAINING YOUR VEHICLE

Page 153 of 200

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particularattention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and every engine

oil change.

MAINTAINING YOUR VEHICLE 153

7

Page 162 of 200

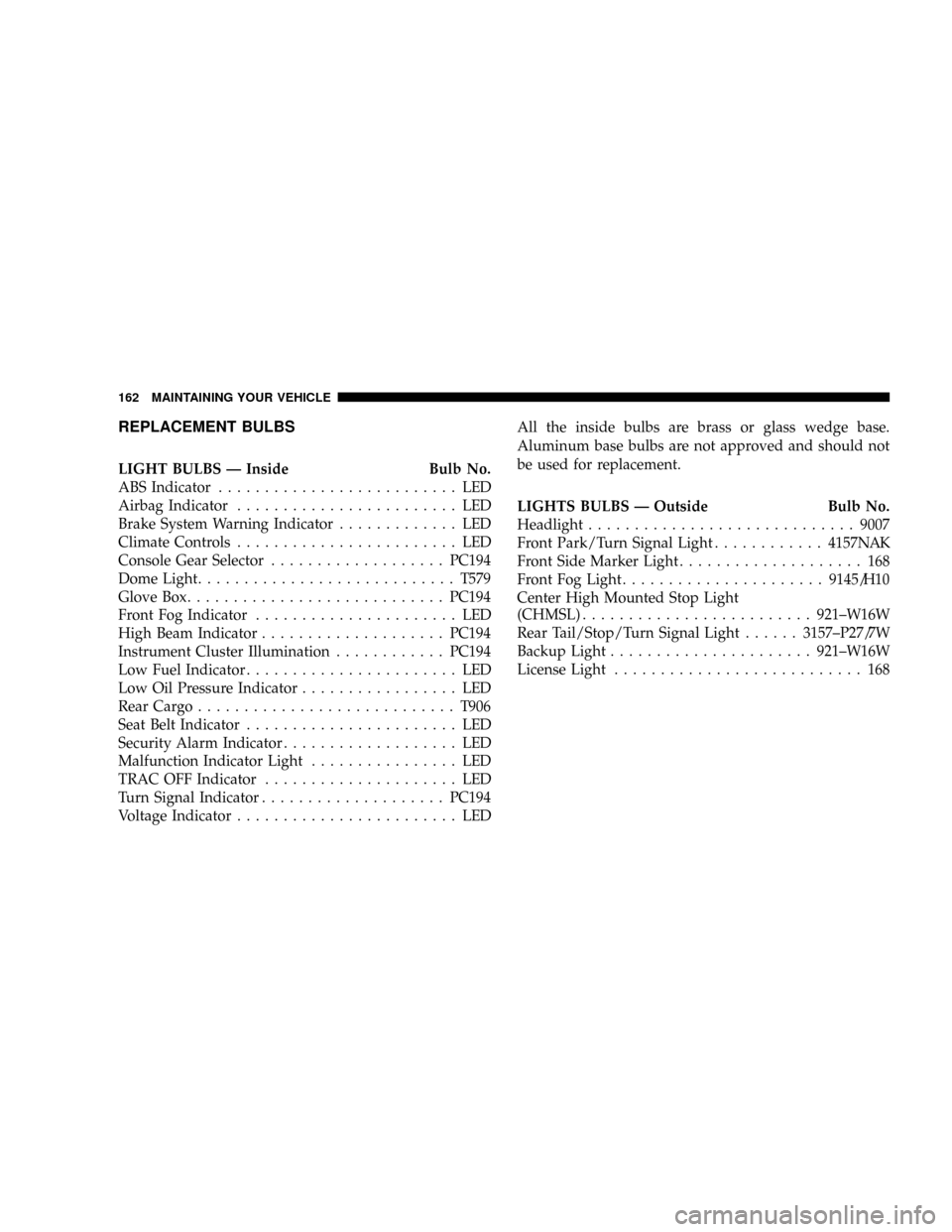

REPLACEMENT BULBS

LIGHT BULBS Ð Inside Bulb No.

ABS Indicator.......................... LED

Airbag Indicator........................ LED

Brake System Warning Indicator............. LED

Climate Controls........................ LED

Console Gear Selector...................PC194

Dome Light............................T579

Glove Box............................PC194

Front Fog Indicator...................... LED

High Beam Indicator....................PC194

Instrument Cluster Illumination............PC194

Low Fuel Indicator....................... LED

Low Oil Pressure Indicator................. LED

Rear Cargo............................T906

Seat Belt Indicator....................... LED

Security Alarm Indicator................... LED

Malfunction Indicator Light................ LED

TRAC OFF Indicator..................... LED

Turn Signal Indicator....................PC194

Voltage Indicator........................ LEDAll the inside bulbs are brass or glass wedge base.

Aluminum base bulbs are not approved and should not

be used for replacement.

LIGHTS BULBS Ð Outside Bulb No.

Headlight.............................9007

Front Park/Turn Signal Light............4157NAK

Front Side Marker Light.................... 168

Front Fog Light......................9145/H10

Center High Mounted Stop Light

(CHMSL).........................921±W16W

Rear Tail/Stop/Turn Signal Light......3157±P27/7W

Backup Light......................921±W16W

License Light........................... 168

162 MAINTAINING YOUR VEHICLE

Page 199 of 200

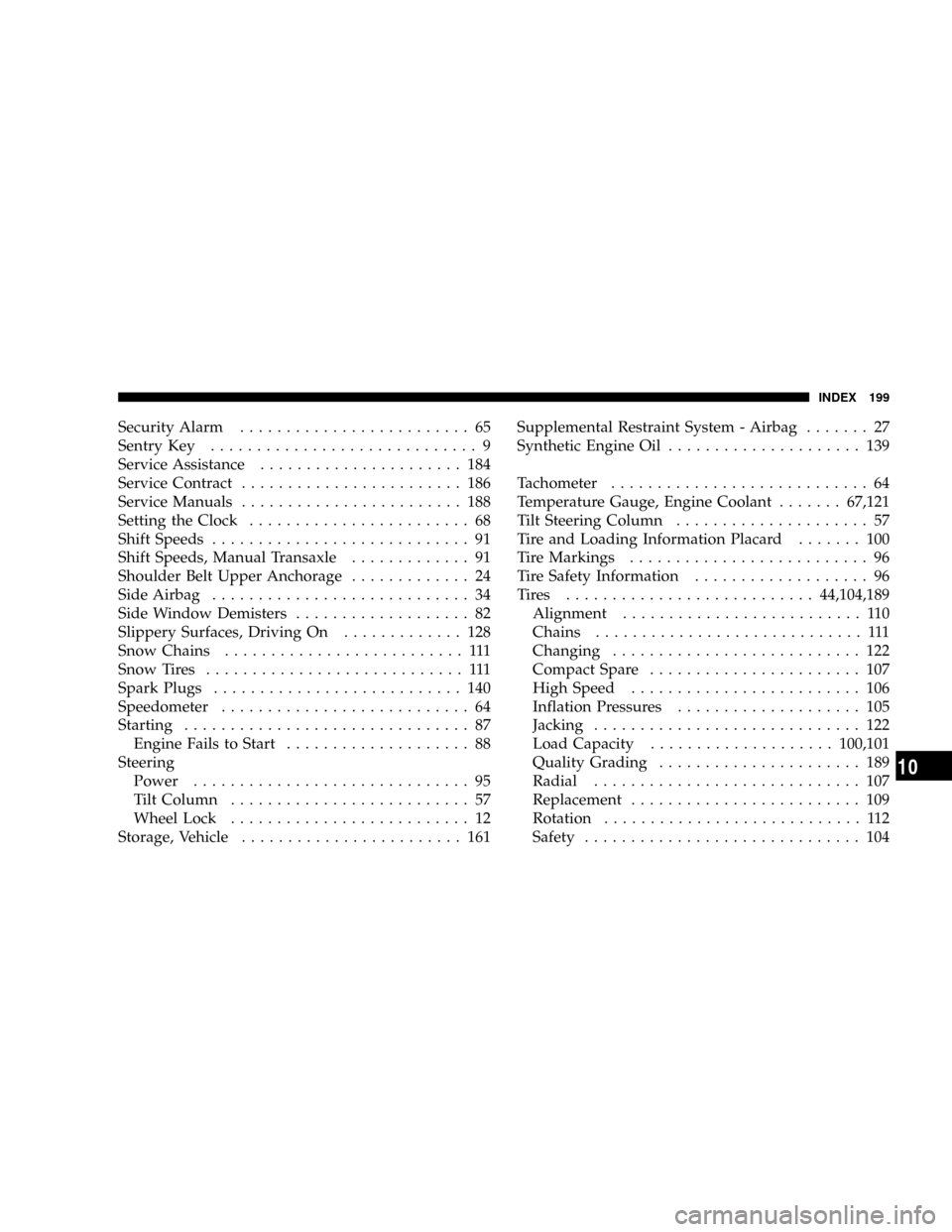

Security Alarm......................... 65

Sentry Key............................. 9

Service Assistance...................... 184

Service Contract........................ 186

Service Manuals........................ 188

Setting the Clock........................ 68

Shift Speeds............................ 91

Shift Speeds, Manual Transaxle............. 91

Shoulder Belt Upper Anchorage............. 24

Side Airbag............................ 34

Side Window Demisters................... 82

Slippery Surfaces, Driving On............. 128

Snow Chains.......................... 111

Snow Tires............................ 111

Spark Plugs........................... 140

Speedometer........................... 64

Starting............................... 87

Engine Fails to Start.................... 88

Steering

Power.............................. 95

Tilt Column.......................... 57

Wheel Lock.......................... 12

Storage, Vehicle........................ 161Supplemental Restraint System - Airbag....... 27

Synthetic Engine Oil..................... 139

Tachometer............................ 64

Temperature Gauge, Engine Coolant.......67,121

Tilt Steering Column..................... 57

Tire and Loading Information Placard....... 100

Tire Markings.......................... 96

Tire Safety Information................... 96

Tires ...........................44,104,189

Alignment.......................... 110

Chains............................. 111

Changing........................... 122

Compact Spare....................... 107

High Speed......................... 106

Inflation Pressures.................... 105

Jacking............................. 122

Load Capacity....................100,101

Quality Grading...................... 189

Radial............................. 107

Replacement......................... 109

Rotation............................ 112

Safety.............................. 104

INDEX 199

10