Intake removal DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1520 of 2627

(13) Install the cooling fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(14) Connect battery negative cables.

(15) Start engine and check for oil leaks.

INTAKE MANIFOLD

REMOVAL

(1) Disconnect the battery negative cables.

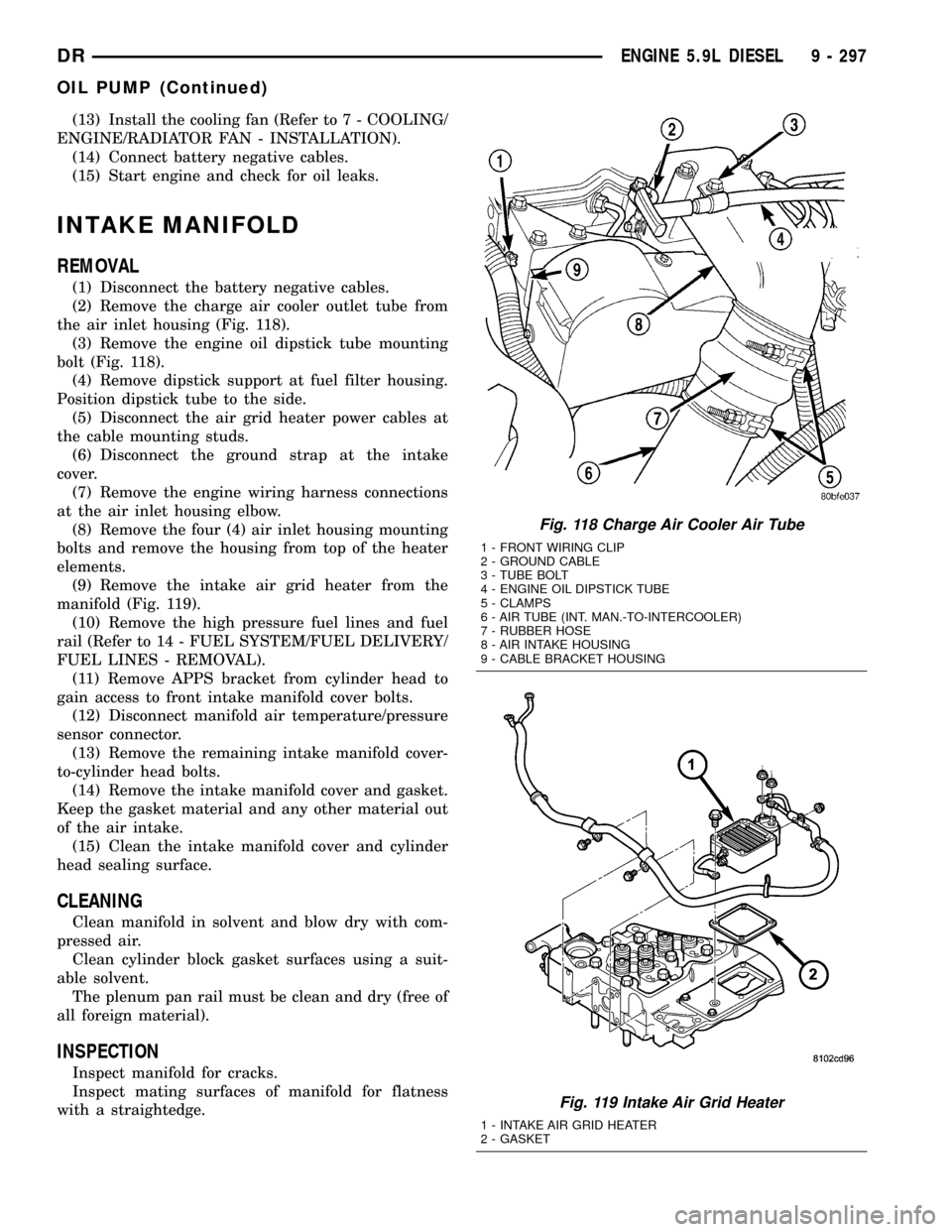

(2) Remove the charge air cooler outlet tube from

the air inlet housing (Fig. 118).

(3) Remove the engine oil dipstick tube mounting

bolt (Fig. 118).

(4) Remove dipstick support at fuel filter housing.

Position dipstick tube to the side.

(5) Disconnect the air grid heater power cables at

the cable mounting studs.

(6) Disconnect the ground strap at the intake

cover.

(7) Remove the engine wiring harness connections

at the air inlet housing elbow.

(8) Remove the four (4) air inlet housing mounting

bolts and remove the housing from top of the heater

elements.

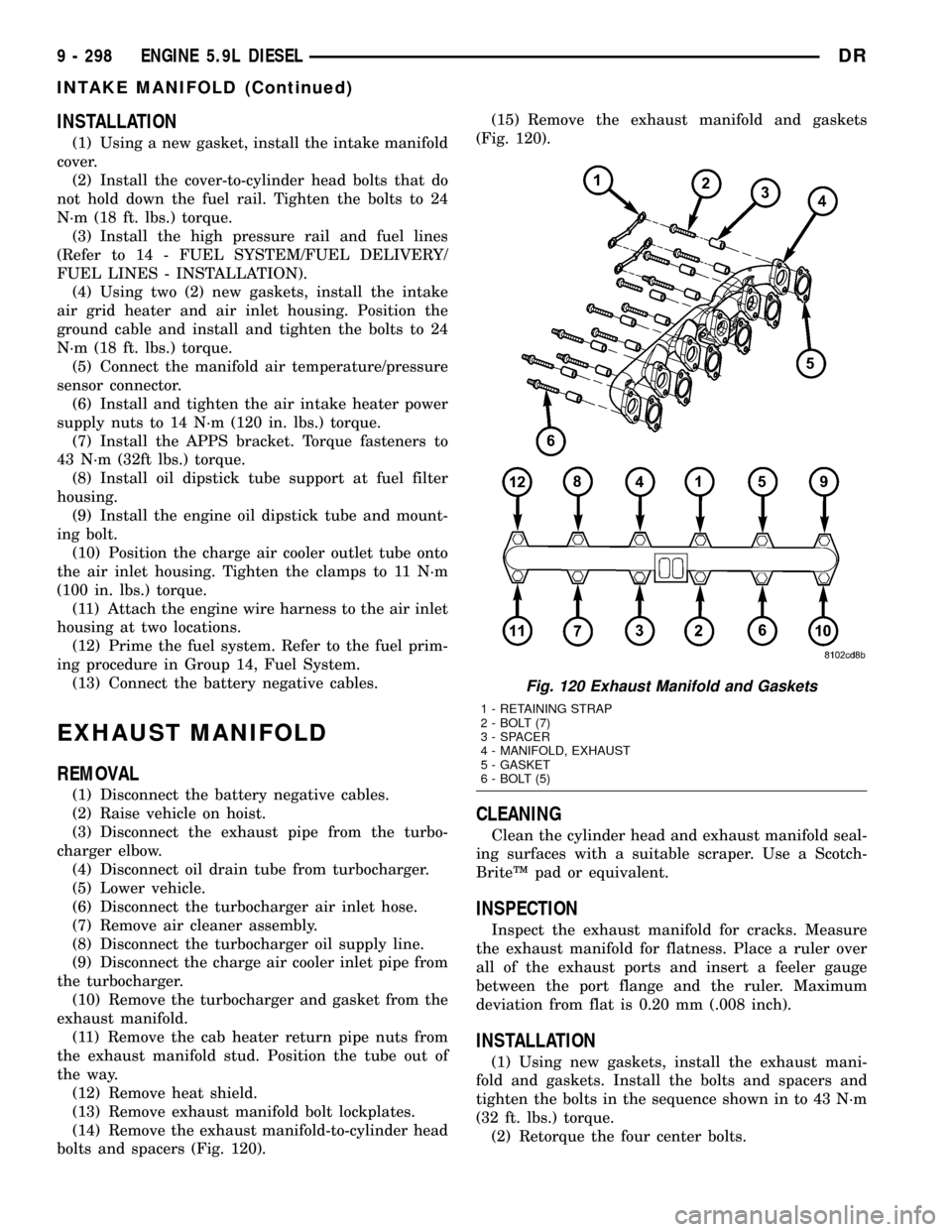

(9) Remove the intake air grid heater from the

manifold (Fig. 119).

(10) Remove the high pressure fuel lines and fuel

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - REMOVAL).

(11) Remove APPS bracket from cylinder head to

gain access to front intake manifold cover bolts.

(12) Disconnect manifold air temperature/pressure

sensor connector.

(13) Remove the remaining intake manifold cover-

to-cylinder head bolts.

(14) Remove the intake manifold cover and gasket.

Keep the gasket material and any other material out

of the air intake.

(15) Clean the intake manifold cover and cylinder

head sealing surface.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

Fig. 118 Charge Air Cooler Air Tube

1 - FRONT WIRING CLIP

2 - GROUND CABLE

3 - TUBE BOLT

4 - ENGINE OIL DIPSTICK TUBE

5 - CLAMPS

6 - AIR TUBE (INT. MAN.-TO-INTERCOOLER)

7 - RUBBER HOSE

8 - AIR INTAKE HOUSING

9 - CABLE BRACKET HOUSING

Fig. 119 Intake Air Grid Heater

1 - INTAKE AIR GRID HEATER

2 - GASKET

DRENGINE 5.9L DIESEL 9 - 297

OIL PUMP (Continued)

Page 1521 of 2627

INSTALLATION

(1) Using a new gasket, install the intake manifold

cover.

(2) Install the cover-to-cylinder head bolts that do

not hold down the fuel rail. Tighten the bolts to 24

N´m (18 ft. lbs.) torque.

(3) Install the high pressure rail and fuel lines

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - INSTALLATION).

(4) Using two (2) new gaskets, install the intake

air grid heater and air inlet housing. Position the

ground cable and install and tighten the bolts to 24

N´m (18 ft. lbs.) torque.

(5) Connect the manifold air temperature/pressure

sensor connector.

(6) Install and tighten the air intake heater power

supply nuts to 14 N´m (120 in. lbs.) torque.

(7) Install the APPS bracket. Torque fasteners to

43 N´m (32ft lbs.) torque.

(8) Install oil dipstick tube support at fuel filter

housing.

(9) Install the engine oil dipstick tube and mount-

ing bolt.

(10) Position the charge air cooler outlet tube onto

the air inlet housing. Tighten the clamps to 11 N´m

(100 in. lbs.) torque.

(11) Attach the engine wire harness to the air inlet

housing at two locations.

(12) Prime the fuel system. Refer to the fuel prim-

ing procedure in Group 14, Fuel System.

(13) Connect the battery negative cables.

EXHAUST MANIFOLD

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Disconnect the exhaust pipe from the turbo-

charger elbow.

(4) Disconnect oil drain tube from turbocharger.

(5) Lower vehicle.

(6) Disconnect the turbocharger air inlet hose.

(7) Remove air cleaner assembly.

(8) Disconnect the turbocharger oil supply line.

(9) Disconnect the charge air cooler inlet pipe from

the turbocharger.

(10) Remove the turbocharger and gasket from the

exhaust manifold.

(11) Remove the cab heater return pipe nuts from

the exhaust manifold stud. Position the tube out of

the way.

(12) Remove heat shield.

(13) Remove exhaust manifold bolt lockplates.

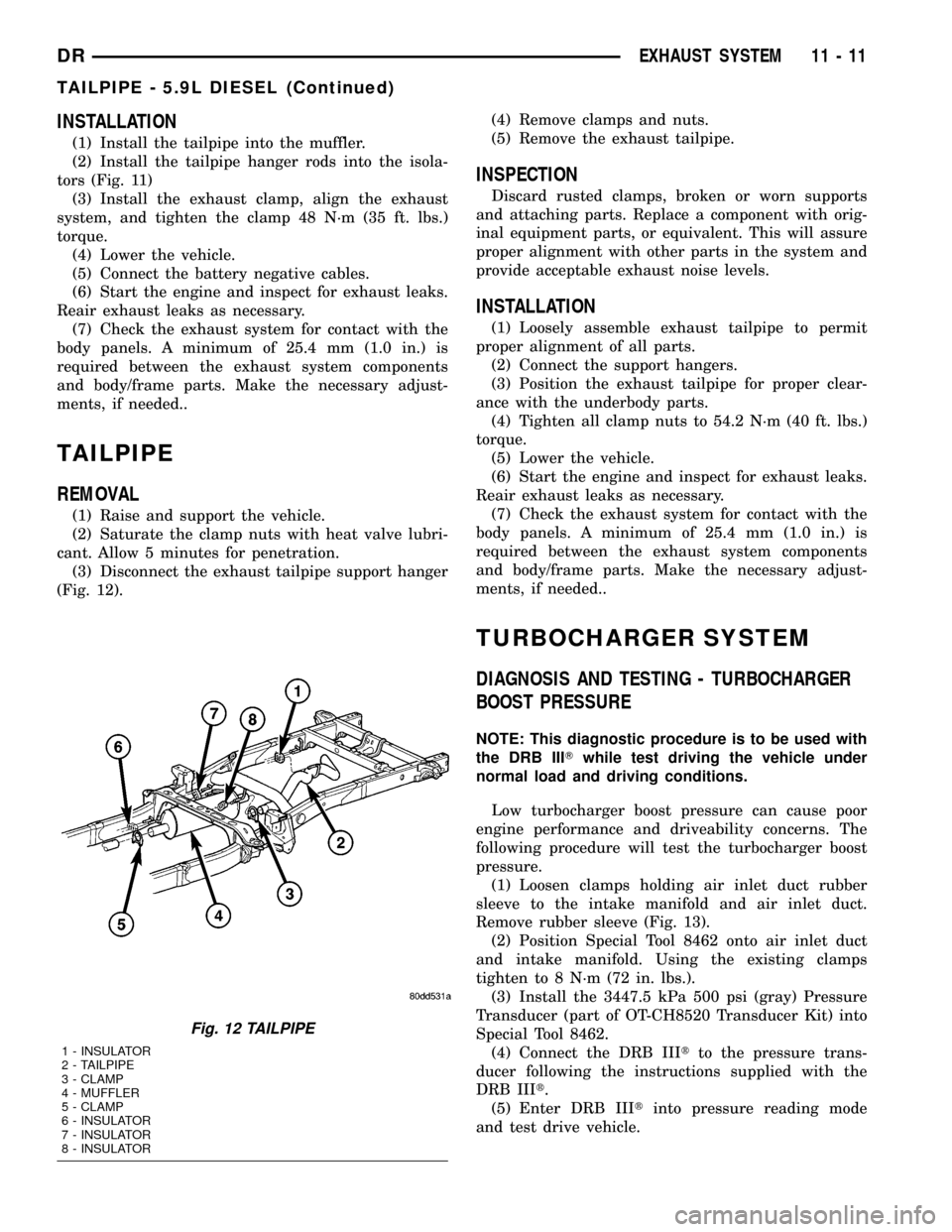

(14) Remove the exhaust manifold-to-cylinder head

bolts and spacers (Fig. 120).(15) Remove the exhaust manifold and gaskets

(Fig. 120).

CLEANING

Clean the cylinder head and exhaust manifold seal-

ing surfaces with a suitable scraper. Use a Scotch-

BriteŸ pad or equivalent.

INSPECTION

Inspect the exhaust manifold for cracks. Measure

the exhaust manifold for flatness. Place a ruler over

all of the exhaust ports and insert a feeler gauge

between the port flange and the ruler. Maximum

deviation from flat is 0.20 mm (.008 inch).

INSTALLATION

(1) Using new gaskets, install the exhaust mani-

fold and gaskets. Install the bolts and spacers and

tighten the bolts in the sequence shown in to 43 N´m

(32 ft. lbs.) torque.

(2) Retorque the four center bolts.

Fig. 120 Exhaust Manifold and Gaskets

1 - RETAINING STRAP

2 - BOLT (7)

3 - SPACER

4 - MANIFOLD, EXHAUST

5 - GASKET

6 - BOLT (5)

9 - 298 ENGINE 5.9L DIESELDR

INTAKE MANIFOLD (Continued)

Page 1536 of 2627

INSTALLATION

(1) Install the tailpipe into the muffler.

(2) Install the tailpipe hanger rods into the isola-

tors (Fig. 11)

(3) Install the exhaust clamp, align the exhaust

system, and tighten the clamp 48 N´m (35 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Connect the battery negative cables.

(6) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.

(7) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

TAILPIPE

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the clamp nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

(3) Disconnect the exhaust tailpipe support hanger

(Fig. 12).(4) Remove clamps and nuts.

(5) Remove the exhaust tailpipe.

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-

inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION

(1) Loosely assemble exhaust tailpipe to permit

proper alignment of all parts.

(2) Connect the support hangers.

(3) Position the exhaust tailpipe for proper clear-

ance with the underbody parts.

(4) Tighten all clamp nuts to 54.2 N´m (40 ft. lbs.)

torque.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.

(7) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING - TURBOCHARGER

BOOST PRESSURE

NOTE: This diagnostic procedure is to be used with

the DRB IIITwhile test driving the vehicle under

normal load and driving conditions.

Low turbocharger boost pressure can cause poor

engine performance and driveability concerns. The

following procedure will test the turbocharger boost

pressure.

(1) Loosen clamps holding air inlet duct rubber

sleeve to the intake manifold and air inlet duct.

Remove rubber sleeve (Fig. 13).

(2) Position Special Tool 8462 onto air inlet duct

and intake manifold. Using the existing clamps

tighten to 8 N´m (72 in. lbs.).

(3) Install the 3447.5 kPa 500 psi (gray) Pressure

Transducer (part of OT-CH8520 Transducer Kit) into

Special Tool 8462.

(4) Connect the DRB IIItto the pressure trans-

ducer following the instructions supplied with the

DRB IIIt.

(5) Enter DRB IIItinto pressure reading mode

and test drive vehicle.

Fig. 12 TAILPIPE

1 - INSULATOR

2 - TAILPIPE

3 - CLAMP

4 - MUFFLER

5 - CLAMP

6 - INSULATOR

7 - INSULATOR

8 - INSULATOR

DREXHAUST SYSTEM 11 - 11

TAILPIPE - 5.9L DIESEL (Continued)

Page 1542 of 2627

CAUTION: Do not apply more than 138 kPa (20 psi)

air pressure to the charge air cooler system, sever

damage to the charge air cooler system may occur.

(3) Connect a regulated air supply to air fitting on

Tool 9022 Adapter. Set air pressure to a Maximum of

138 kPa (20 psi).

(4) Using soapy water check the rubber sleeves,

charge air cooler and intake manifold for leaks.

REMOVAL

WARNING: IF THE ENGINE WAS JUST TURNED

OFF, THE AIR INTAKE SYSTEM TUBES MAY BE

HOT.

(1) Disconnect the battery negative cables.

(2) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (if A/C

equipped).

(3) Remove the transmission auxiliary cooler

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

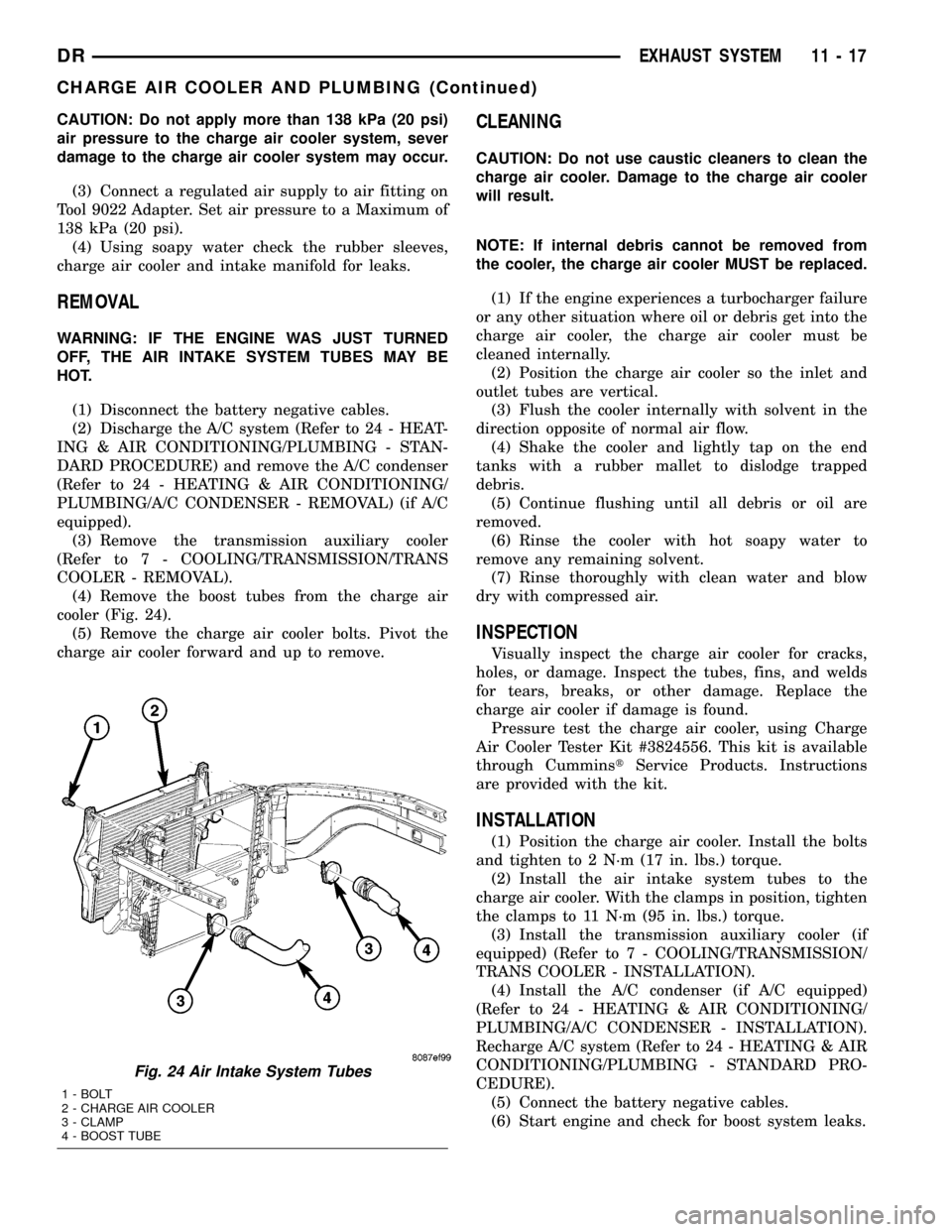

(4) Remove the boost tubes from the charge air

cooler (Fig. 24).

(5) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.

(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4) Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped

debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

(2) Install the air intake system tubes to the

charge air cooler. With the clamps in position, tighten

the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4) Install the A/C condenser (if A/C equipped)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - INSTALLATION).

Recharge A/C system (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(5) Connect the battery negative cables.

(6) Start engine and check for boost system leaks.

Fig. 24 Air Intake System Tubes

1 - BOLT

2 - CHARGE AIR COOLER

3 - CLAMP

4 - BOOST TUBE

DREXHAUST SYSTEM 11 - 17

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1554 of 2627

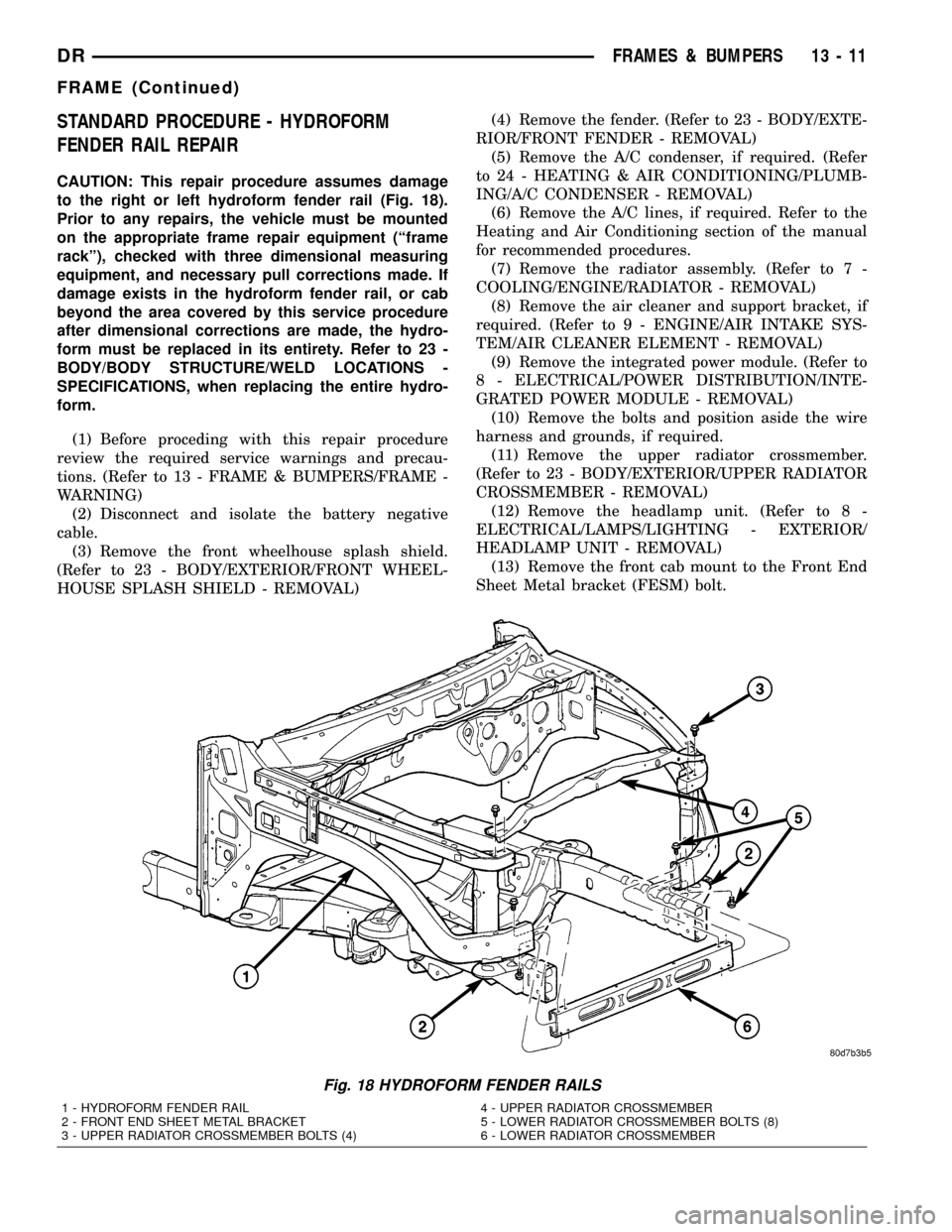

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR

CAUTION: This repair procedure assumes damage

to the right or left hydroform fender rail (Fig. 18).

Prior to any repairs, the vehicle must be mounted

on the appropriate frame repair equipment (ªframe

rackº), checked with three dimensional measuring

equipment, and necessary pull corrections made. If

damage exists in the hydroform fender rail, or cab

beyond the area covered by this service procedure

after dimensional corrections are made, the hydro-

form must be replaced in its entirety. Refer to 23 -

BODY/BODY STRUCTURE/WELD LOCATIONS -

SPECIFICATIONS, when replacing the entire hydro-

form.

(1) Before proceding with this repair procedure

review the required service warnings and precau-

tions. (Refer to 13 - FRAME & BUMPERS/FRAME -

WARNING)

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - REMOVAL)(4) Remove the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - REMOVAL)

(5) Remove the A/C condenser, if required. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - REMOVAL)

(6) Remove the A/C lines, if required. Refer to the

Heating and Air Conditioning section of the manual

for recommended procedures.

(7) Remove the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - REMOVAL)

(8) Remove the air cleaner and support bracket, if

required. (Refer to 9 - ENGINE/AIR INTAKE SYS-

TEM/AIR CLEANER ELEMENT - REMOVAL)

(9) Remove the integrated power module. (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - REMOVAL)

(10) Remove the bolts and position aside the wire

harness and grounds, if required.

(11) Remove the upper radiator crossmember.

(Refer to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - REMOVAL)

(12) Remove the headlamp unit. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

(13) Remove the front cab mount to the Front End

Sheet Metal bracket (FESM) bolt.

Fig. 18 HYDROFORM FENDER RAILS

1 - HYDROFORM FENDER RAIL

2 - FRONT END SHEET METAL BRACKET

3 - UPPER RADIATOR CROSSMEMBER BOLTS (4)4 - UPPER RADIATOR CROSSMEMBER

5 - LOWER RADIATOR CROSSMEMBER BOLTS (8)

6 - LOWER RADIATOR CROSSMEMBER

DRFRAMES & BUMPERS 13 - 11

FRAME (Continued)

Page 1584 of 2627

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove flex tube (air cleaner housing to

engine).

(5) Remove air resonator box at throttle body.

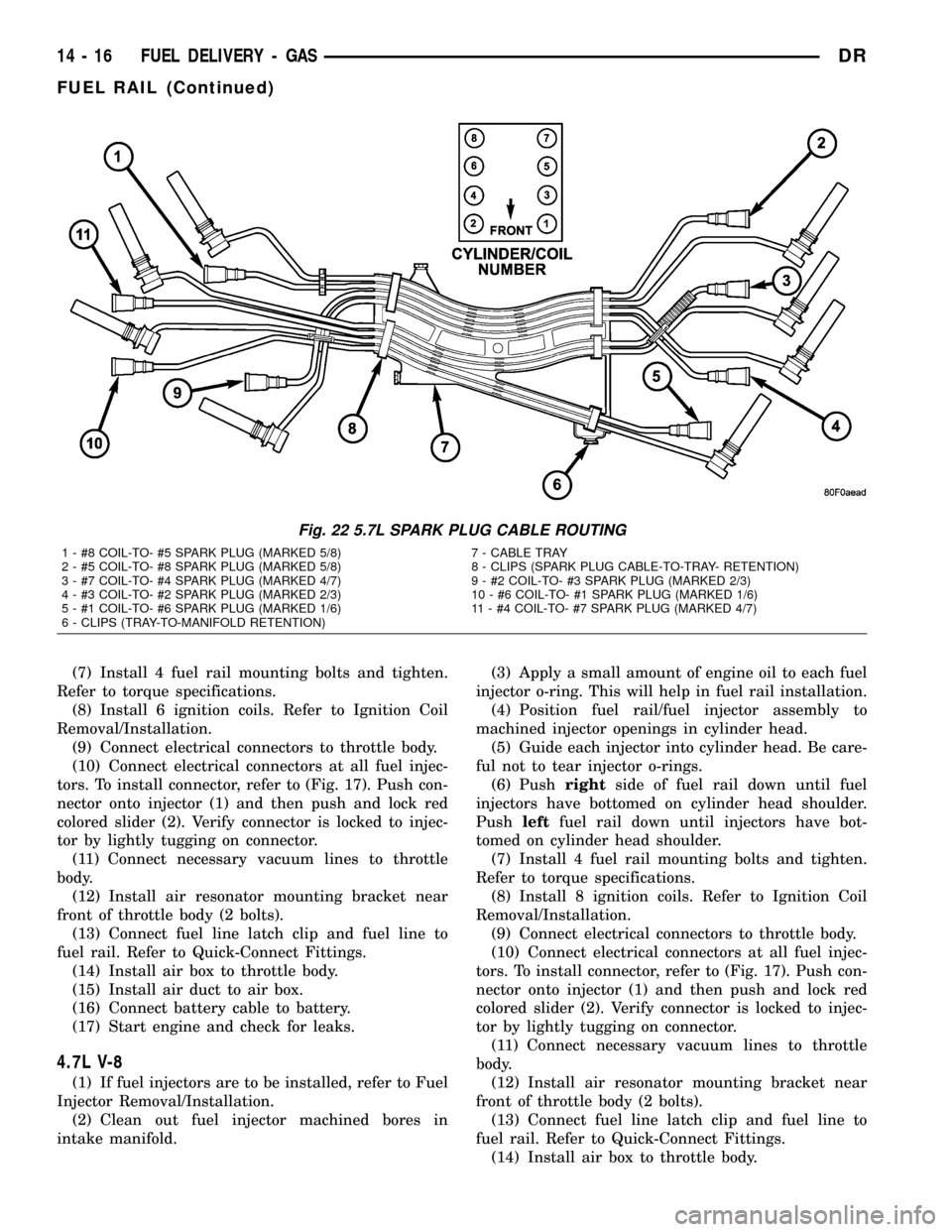

(6) Disconnect all spark plug cables from all spark

plugs and ignition coils. Do not remove cables from

cable routing tray. Note original cable positions while

removing (Fig. 22).

(7) Remove spark plug cable tray from engine by

releasing 4 retaining clips (Fig. 21). Remove tray and

cables from engine as an assembly.

(8) Disconnect electrical connectors at all 8 igni-

tion coils. Refer to Ignition Coil Removal/Installation.

(9) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(10) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(11) Disconnect electrical connectors at all throttle

body sensors.

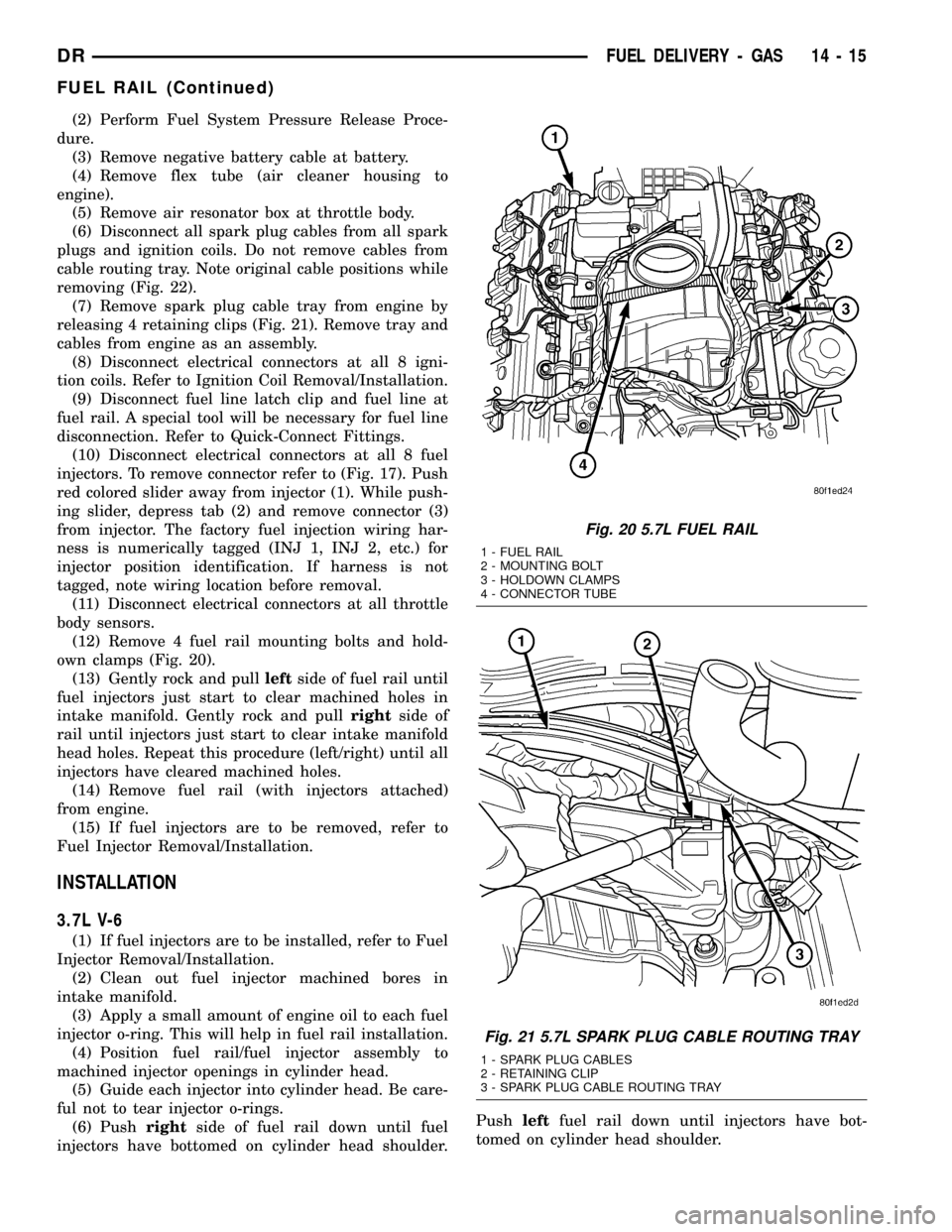

(12) Remove 4 fuel rail mounting bolts and hold-

own clamps (Fig. 20).

(13) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

intake manifold. Gently rock and pullrightside of

rail until injectors just start to clear intake manifold

head holes. Repeat this procedure (left/right) until all

injectors have cleared machined holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

INSTALLATION

3.7L V-6

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

Fig. 20 5.7L FUEL RAIL

1 - FUEL RAIL

2 - MOUNTING BOLT

3 - HOLDOWN CLAMPS

4 - CONNECTOR TUBE

Fig. 21 5.7L SPARK PLUG CABLE ROUTING TRAY

1 - SPARK PLUG CABLES

2 - RETAINING CLIP

3 - SPARK PLUG CABLE ROUTING TRAY

DRFUEL DELIVERY - GAS 14 - 15

FUEL RAIL (Continued)

Page 1585 of 2627

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

4.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.

Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 8 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

Fig. 22 5.7L SPARK PLUG CABLE ROUTING

1 - #8 COIL-TO- #5 SPARK PLUG (MARKED 5/8) 7 - CABLE TRAY

2 - #5 COIL-TO- #8 SPARK PLUG (MARKED 5/8) 8 - CLIPS (SPARK PLUG CABLE-TO-TRAY- RETENTION)

3 - #7 COIL-TO- #4 SPARK PLUG (MARKED 4/7) 9 - #2 COIL-TO- #3 SPARK PLUG (MARKED 2/3)

4 - #3 COIL-TO- #2 SPARK PLUG (MARKED 2/3) 10 - #6 COIL-TO- #1 SPARK PLUG (MARKED 1/6)

5 - #1 COIL-TO- #6 SPARK PLUG (MARKED 1/6) 11 - #4 COIL-TO- #7 SPARK PLUG (MARKED 4/7)

6 - CLIPS (TRAY-TO-MANIFOLD RETENTION)

14 - 16 FUEL DELIVERY - GASDR

FUEL RAIL (Continued)

Page 1586 of 2627

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

5.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.

(5) Guide each injector into intake manifold. Be

careful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on shoulders. Pushleftfuel

rail down until injectors have bottomed on shoulders.

(7) Install 4 fuel rail holdown clamps and 4 mount-

ing bolts. Refer to Torque Specifications.

(8) Position spark plug cable tray and cable assem-

bly to intake manifold. Snap 4 cable tray retaining

clips into intake manifold.

(9) Install all cables to spark plugs and ignition

coils.

(10) Connect electrical connector to throttle body.

(11) Install electrical connectors to all 8 ignition

coils. Refer to Ignition Coil Removal/Installation.

(12) Connect electrical connector to throttle body.

(13) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(14) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(15) Install air resonator to throttle body (2 bolts).

(16) Install flexible air duct to air box.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

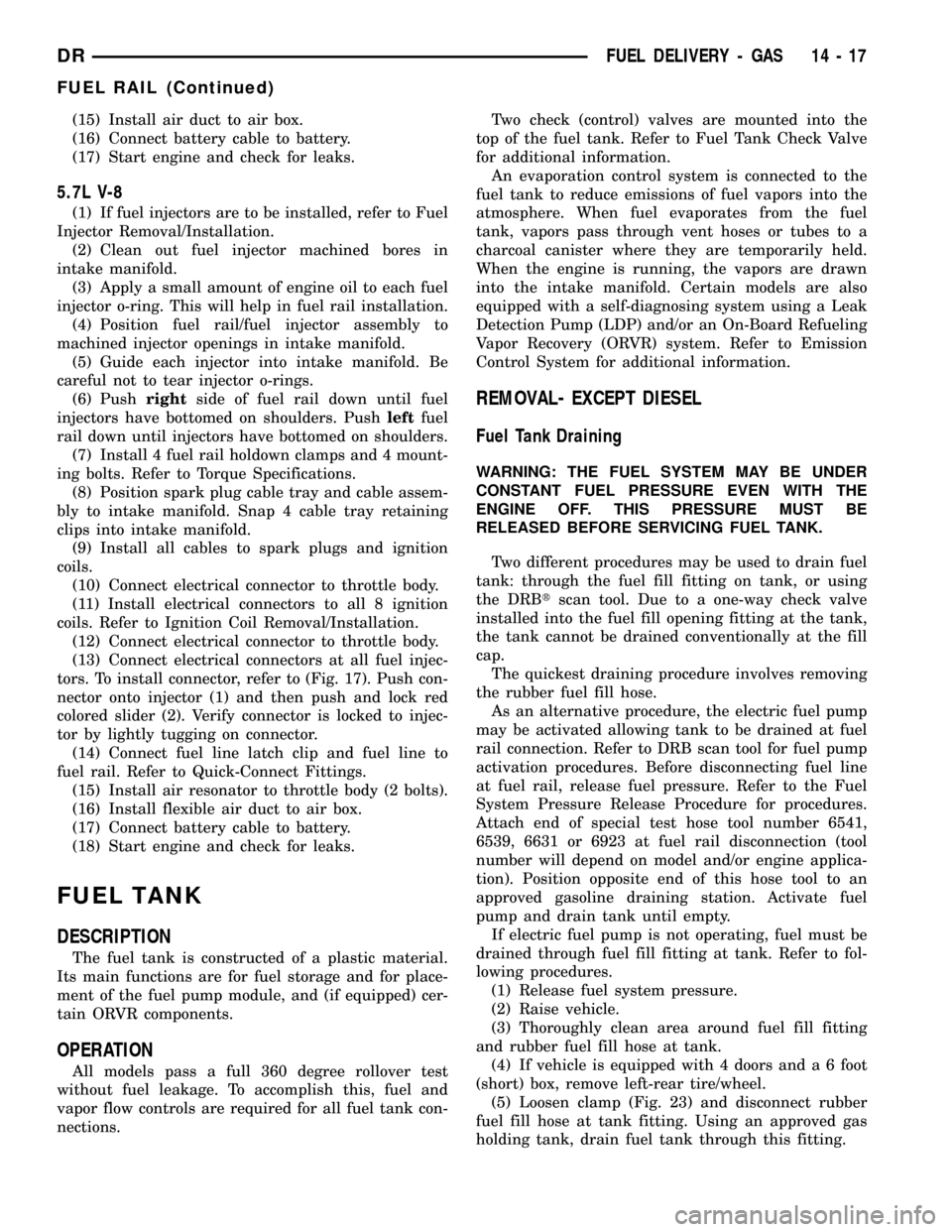

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module, and (if equipped) cer-

tain ORVR components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.Two check (control) valves are mounted into the

top of the fuel tank. Refer to Fuel Tank Check Valve

for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an On-Board Refueling

Vapor Recovery (ORVR) system. Refer to Emission

Control System for additional information.

REMOVAL- EXCEPT DIESEL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

Two different procedures may be used to drain fuel

tank: through the fuel fill fitting on tank, or using

the DRBtscan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank,

the tank cannot be drained conventionally at the fill

cap.

The quickest draining procedure involves removing

the rubber fuel fill hose.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine applica-

tion). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel must be

drained through fuel fill fitting at tank. Refer to fol-

lowing procedures.

(1) Release fuel system pressure.

(2) Raise vehicle.

(3) Thoroughly clean area around fuel fill fitting

and rubber fuel fill hose at tank.

(4) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

(5) Loosen clamp (Fig. 23) and disconnect rubber

fuel fill hose at tank fitting. Using an approved gas

holding tank, drain fuel tank through this fitting.

DRFUEL DELIVERY - GAS 14 - 17

FUEL RAIL (Continued)

Page 1590 of 2627

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................21

INSTALLATION.........................21

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................24

INSTALLATION.........................25

FUEL INJECTOR

DESCRIPTION.........................26

OPERATION

OPERATION - FUEL INJECTOR..........26

OPERATION - PCM OUTPUT............27

REMOVAL.............................27

INSTALLATION.........................27

FUEL PUMP RELAY

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................29

INSTALLATION.........................29INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................31

MAP SENSOR

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................33

INSTALLATION.........................34

OXYGEN SENSOR

DESCRIPTION.........................35

REMOVAL.............................35

INSTALLATION.........................36

PTO SWITCH

DESCRIPTION.........................36

OPERATION...........................36

THROTTLE BODY

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37

THROTTLE CONTROL CABLE

REMOVAL.............................38

INSTALLATION.........................40

THROTTLE POSITION SENSOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................43

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

DRFUEL INJECTION - GAS 14 - 21

Page 1596 of 2627

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

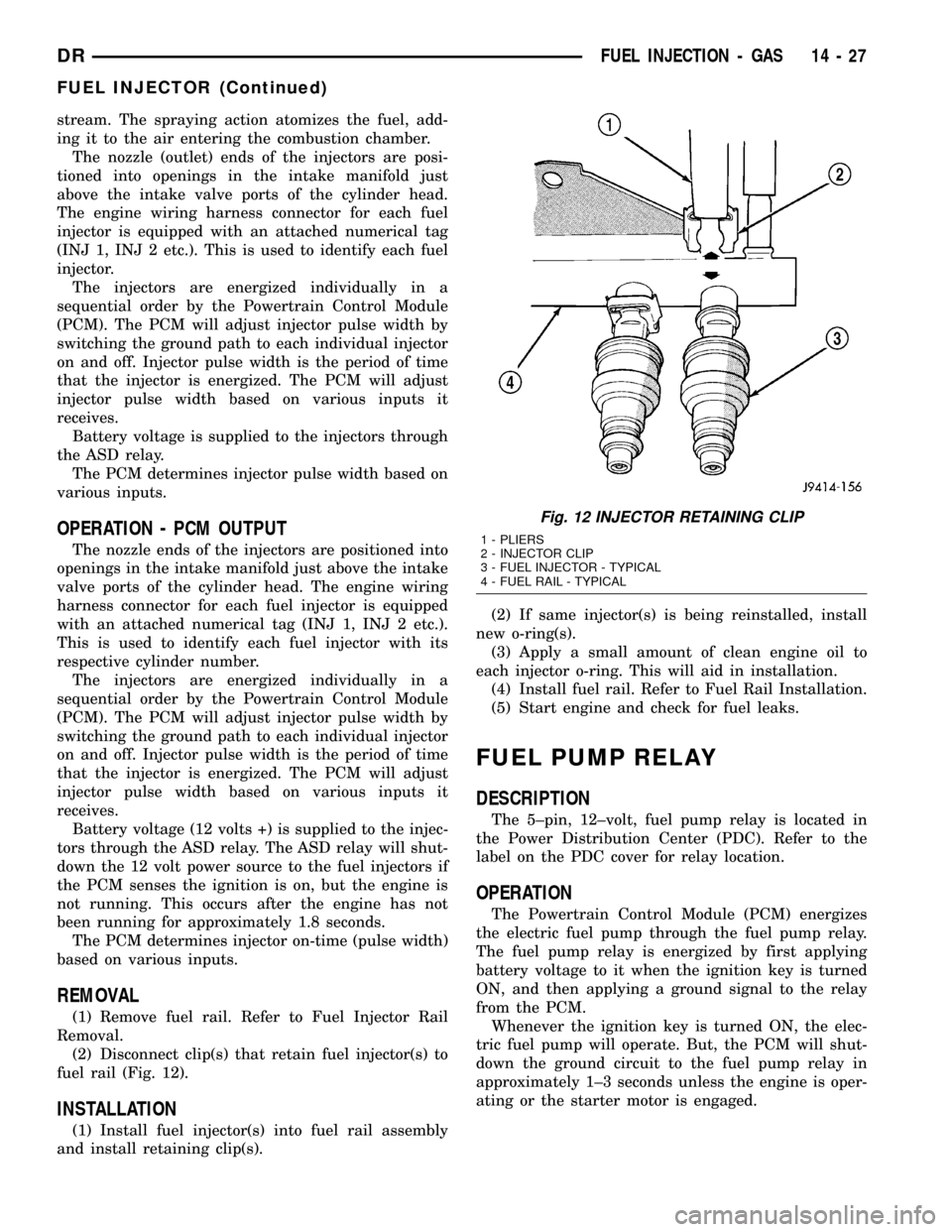

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 12).

INSTALLATION

(1) Install fuel injector(s) into fuel rail assembly

and install retaining clip(s).(2) If same injector(s) is being reinstalled, install

new o-ring(s).

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Install fuel rail. Refer to Fuel Rail Installation.

(5) Start engine and check for fuel leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

Fig. 12 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

DRFUEL INJECTION - GAS 14 - 27

FUEL INJECTOR (Continued)