Power steering DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1524 of 2627

(23) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(24) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(25) Install the radiator upper hose and clamps.

(26) Add engine oil.

(27) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(28) Connect the battery cables.

(29) Start engine and inspect for leaks.

GEAR HOUSING COVER

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(10) Remove the cooling fan support/hub from the

front of the engine.

(11) Raise the vehicle on hoist.

(12) Remove power steering pump.

(13) Remove accessory drive belt tensioner.

(14) Remove the crankshaft damper and speed

indicator ring (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - REMOVAL).

(15) Lower the vehicle.

(16) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

INSTALLATION

(1) Install a new front crankshaft oil seal.

(2) Obtain a seal pilot/installation tool from a

crankshaft front seal service kit and install the pilot

into the seal.

(3) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover.

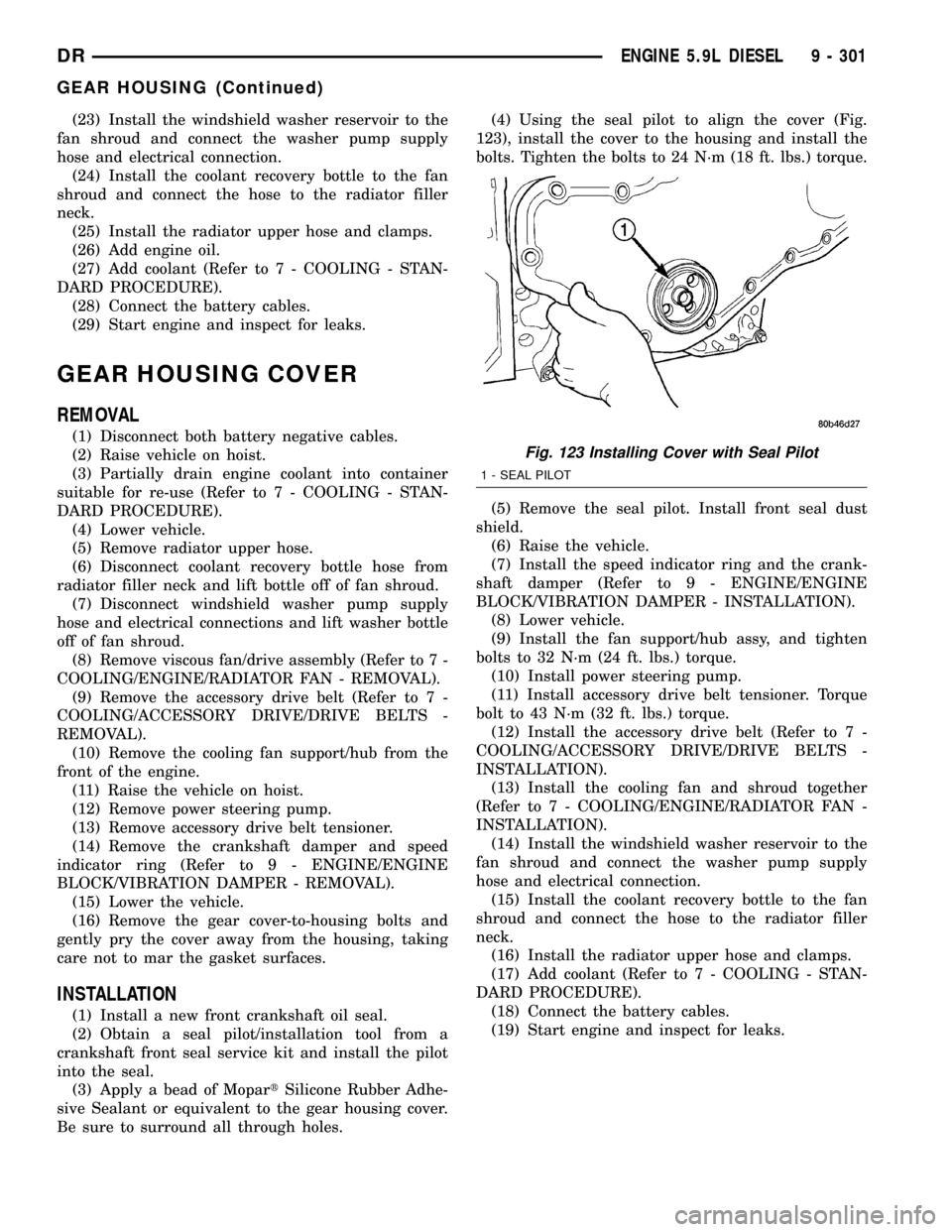

Be sure to surround all through holes.(4) Using the seal pilot to align the cover (Fig.

123), install the cover to the housing and install the

bolts. Tighten the bolts to 24 N´m (18 ft. lbs.) torque.

(5) Remove the seal pilot. Install front seal dust

shield.

(6) Raise the vehicle.

(7) Install the speed indicator ring and the crank-

shaft damper (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - INSTALLATION).

(8) Lower vehicle.

(9) Install the fan support/hub assy, and tighten

bolts to 32 N´m (24 ft. lbs.) torque.

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.) torque.

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install the cooling fan and shroud together

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(14) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(15) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(16) Install the radiator upper hose and clamps.

(17) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(18) Connect the battery cables.

(19) Start engine and inspect for leaks.

Fig. 123 Installing Cover with Seal Pilot

1 - SEAL PILOT

DRENGINE 5.9L DIESEL 9 - 301

GEAR HOUSING (Continued)

Page 1573 of 2627

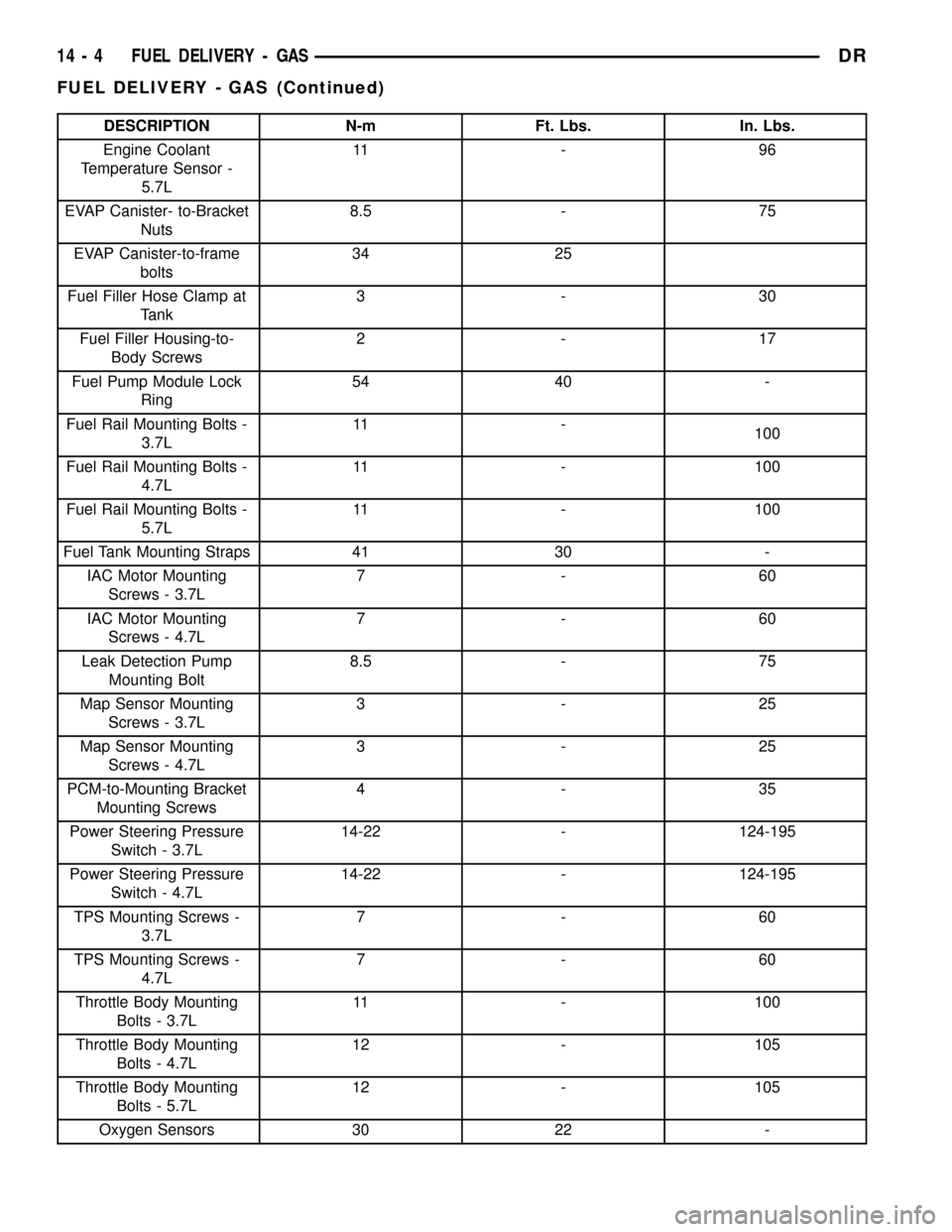

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Engine Coolant

Temperature Sensor -

5.7L11 - 9 6

EVAP Canister- to-Bracket

Nuts8.5 - 75

EVAP Canister-to-frame

bolts34 25

Fuel Filler Hose Clamp at

Tank3-30

Fuel Filler Housing-to-

Body Screws2-17

Fuel Pump Module Lock

Ring54 40 -

Fuel Rail Mounting Bolts -

3.7L11 -

100

Fuel Rail Mounting Bolts -

4.7L11 - 100

Fuel Rail Mounting Bolts -

5.7L11 - 100

Fuel Tank Mounting Straps 41 30 -

IAC Motor Mounting

Screws - 3.7L7-60

IAC Motor Mounting

Screws - 4.7L7-60

Leak Detection Pump

Mounting Bolt8.5 - 75

Map Sensor Mounting

Screws - 3.7L3-25

Map Sensor Mounting

Screws - 4.7L3-25

PCM-to-Mounting Bracket

Mounting Screws4-35

Power Steering Pressure

Switch - 3.7L14-22 - 124-195

Power Steering Pressure

Switch - 4.7L14-22 - 124-195

TPS Mounting Screws -

3.7L7-60

TPS Mounting Screws -

4.7L7-60

Throttle Body Mounting

Bolts - 3.7L11 - 100

Throttle Body Mounting

Bolts - 4.7L12 - 105

Throttle Body Mounting

Bolts - 5.7L12 - 105

Oxygen Sensors 30 22 -

14 - 4 FUEL DELIVERY - GASDR

FUEL DELIVERY - GAS (Continued)

Page 1597 of 2627

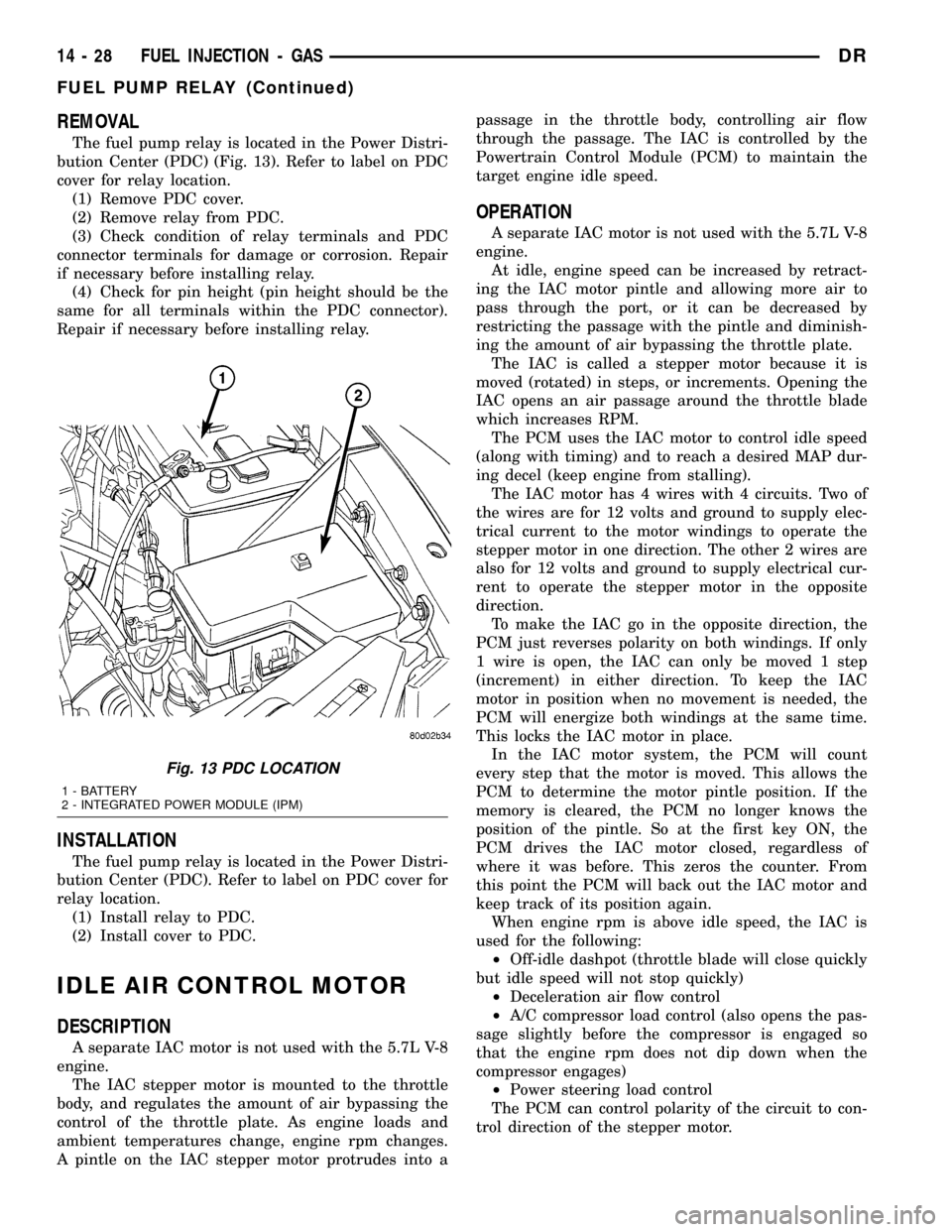

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 13). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC). Refer to label on PDC cover for

relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

A separate IAC motor is not used with the 5.7L V-8

engine.

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into apassage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

A separate IAC motor is not used with the 5.7L V-8

engine.

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

Fig. 13 PDC LOCATION

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

14 - 28 FUEL INJECTION - GASDR

FUEL PUMP RELAY (Continued)

Page 1598 of 2627

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

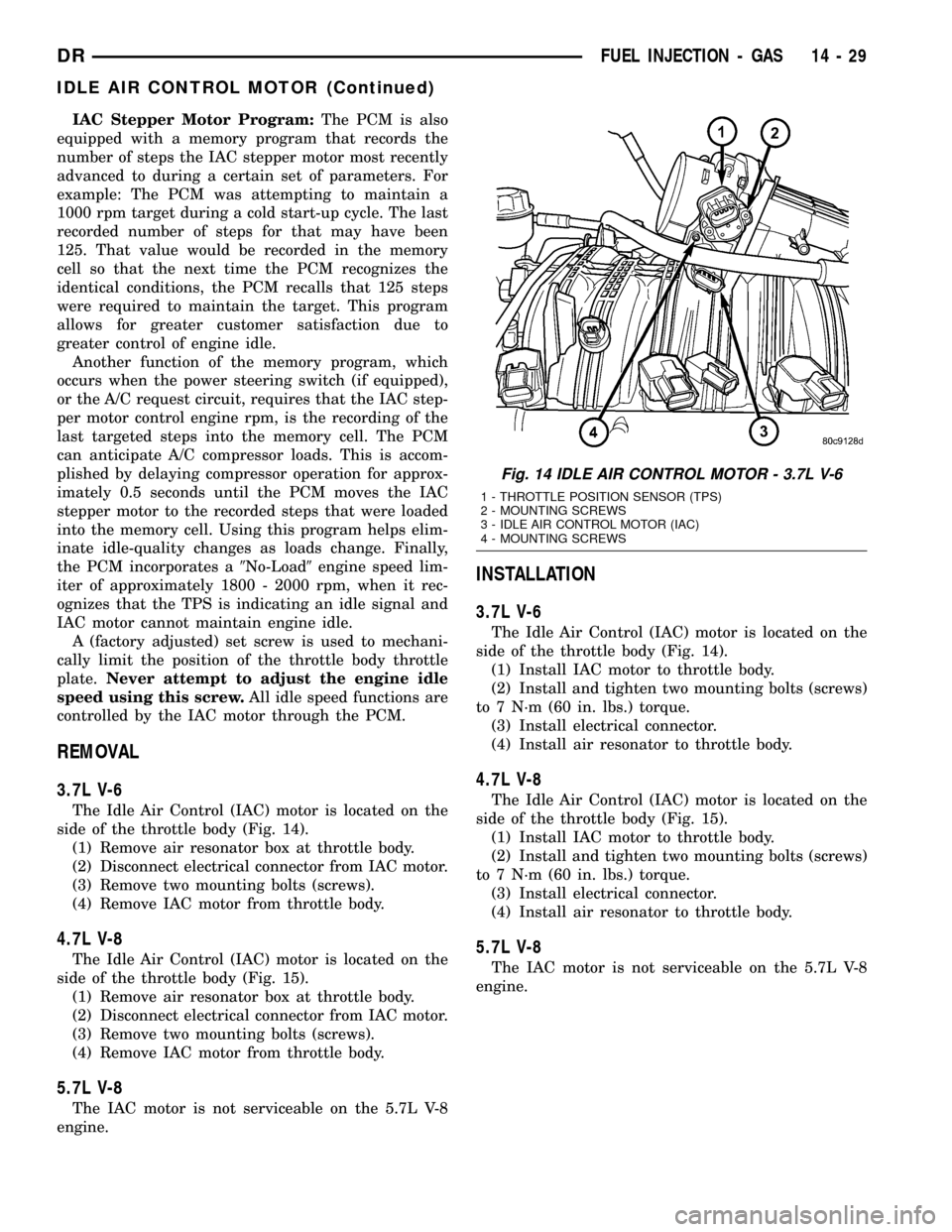

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

INSTALLATION

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

Fig. 14 IDLE AIR CONTROL MOTOR - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

DRFUEL INJECTION - GAS 14 - 29

IDLE AIR CONTROL MOTOR (Continued)

Page 1656 of 2627

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM....................2

DIAGNOSIS AND TESTING - POWER

STEERING FLOW AND PRESSURE........4

SPECIAL TOOLS

STEERING...........................5COLUMN...............................6

GEAR - INDEPENDENT FRONT SUSPENSION..17

GEAR - LINK/COIL.......................20

LINKAGE - INDEPENDENT FRONT

SUSPENSION...........................32

LINKAGE - LINK/COIL....................34

PUMP.................................39

STEERING

DESCRIPTION

CAUTION: MOPARTATF+4 is to be used in the

power steering system. No other power steering or

automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

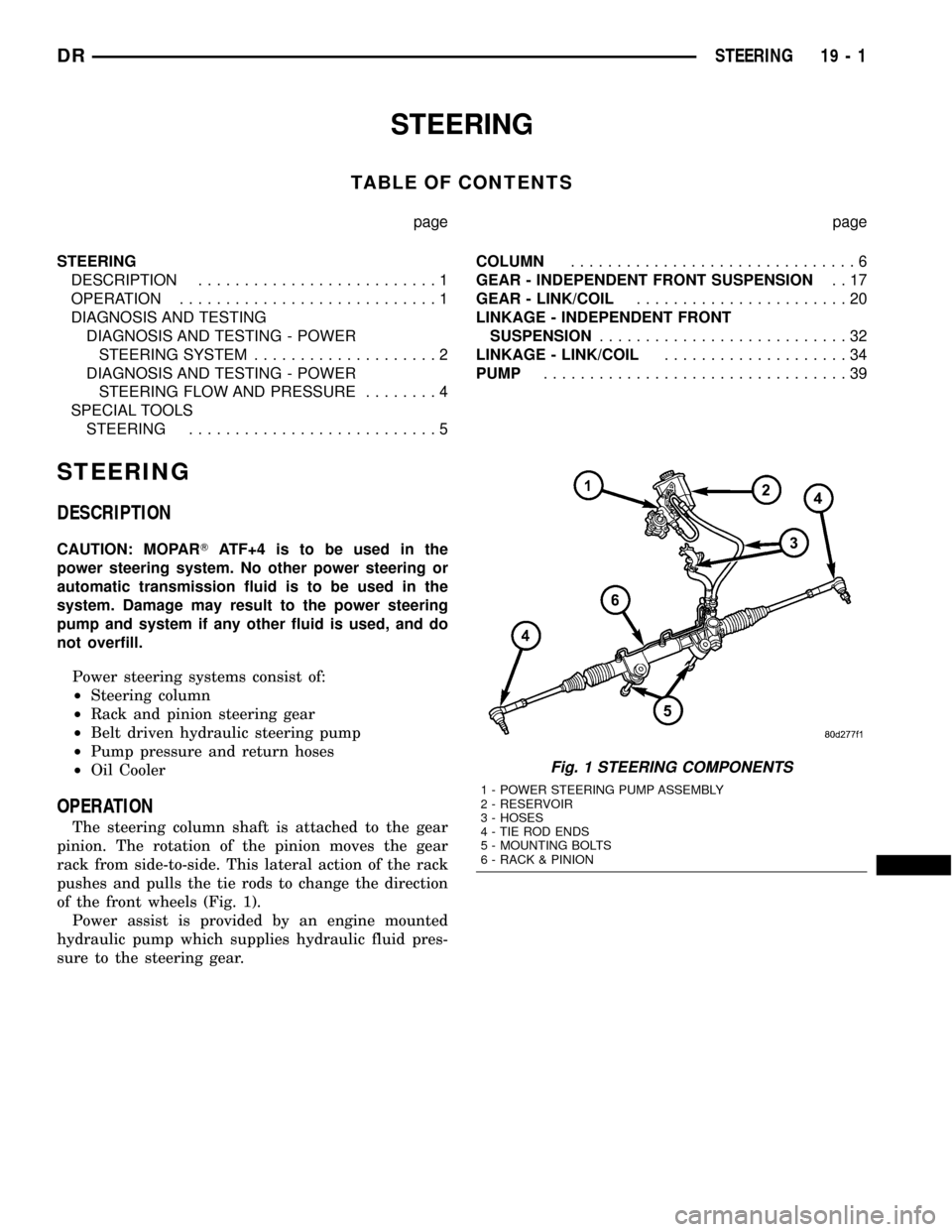

Power steering systems consist of:

²Steering column

²Rack and pinion steering gear

²Belt driven hydraulic steering pump

²Pump pressure and return hoses

²Oil Cooler

OPERATION

The steering column shaft is attached to the gear

pinion. The rotation of the pinion moves the gear

rack from side-to-side. This lateral action of the rack

pushes and pulls the tie rods to change the direction

of the front wheels (Fig. 1).

Power assist is provided by an engine mounted

hydraulic pump which supplies hydraulic fluid pres-

sure to the steering gear.

Fig. 1 STEERING COMPONENTS

1 - POWER STEERING PUMP ASSEMBLY

2 - RESERVOIR

3 - HOSES

4 - TIE ROD ENDS

5 - MOUNTING BOLTS

6 - RACK & PINION

DRSTEERING 19 - 1

Page 1657 of 2627

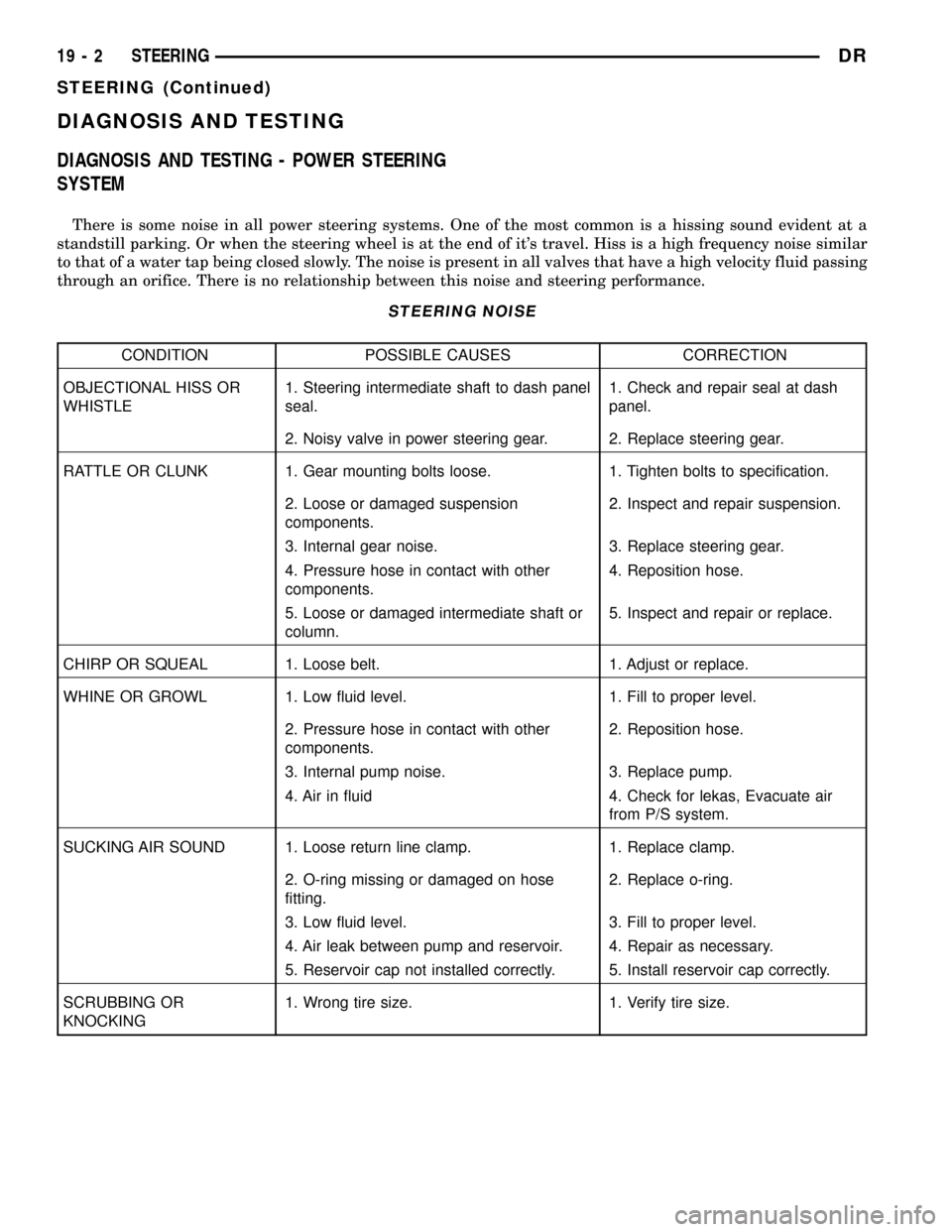

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING

SYSTEM

There is some noise in all power steering systems. One of the most common is a hissing sound evident at a

standstill parking. Or when the steering wheel is at the end of it's travel. Hiss is a high frequency noise similar

to that of a water tap being closed slowly. The noise is present in all valves that have a high velocity fluid passing

through an orifice. There is no relationship between this noise and steering performance.

STEERING NOISE

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONAL HISS OR

WHISTLE1. Steering intermediate shaft to dash panel

seal.1. Check and repair seal at dash

panel.

2. Noisy valve in power steering gear. 2. Replace steering gear.

RATTLE OR CLUNK 1. Gear mounting bolts loose. 1. Tighten bolts to specification.

2. Loose or damaged suspension

components.2. Inspect and repair suspension.

3. Internal gear noise. 3. Replace steering gear.

4. Pressure hose in contact with other

components.4. Reposition hose.

5. Loose or damaged intermediate shaft or

column.5. Inspect and repair or replace.

CHIRP OR SQUEAL 1. Loose belt. 1. Adjust or replace.

WHINE OR GROWL 1. Low fluid level. 1. Fill to proper level.

2. Pressure hose in contact with other

components.2. Reposition hose.

3. Internal pump noise. 3. Replace pump.

4. Air in fluid 4. Check for lekas, Evacuate air

from P/S system.

SUCKING AIR SOUND 1. Loose return line clamp. 1. Replace clamp.

2. O-ring missing or damaged on hose

fitting.2. Replace o-ring.

3. Low fluid level. 3. Fill to proper level.

4. Air leak between pump and reservoir. 4. Repair as necessary.

5. Reservoir cap not installed correctly. 5. Install reservoir cap correctly.

SCRUBBING OR

KNOCKING1. Wrong tire size. 1. Verify tire size.

19 - 2 STEERINGDR

STEERING (Continued)

Page 1659 of 2627

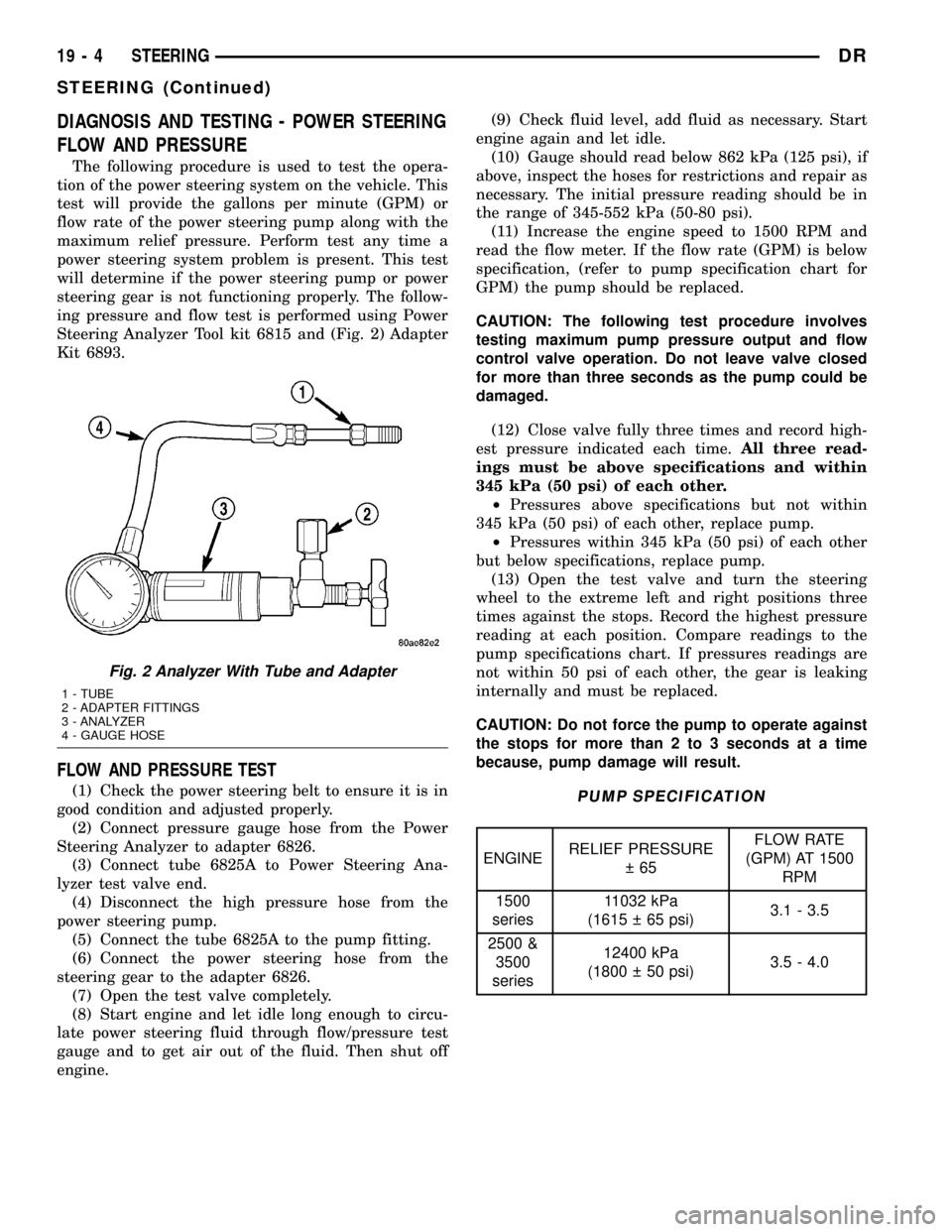

DIAGNOSIS AND TESTING - POWER STEERING

FLOW AND PRESSURE

The following procedure is used to test the opera-

tion of the power steering system on the vehicle. This

test will provide the gallons per minute (GPM) or

flow rate of the power steering pump along with the

maximum relief pressure. Perform test any time a

power steering system problem is present. This test

will determine if the power steering pump or power

steering gear is not functioning properly. The follow-

ing pressure and flow test is performed using Power

Steering Analyzer Tool kit 6815 and (Fig. 2) Adapter

Kit 6893.

FLOW AND PRESSURE TEST

(1) Check the power steering belt to ensure it is in

good condition and adjusted properly.

(2) Connect pressure gauge hose from the Power

Steering Analyzer to adapter 6826.

(3) Connect tube 6825A to Power Steering Ana-

lyzer test valve end.

(4) Disconnect the high pressure hose from the

power steering pump.

(5) Connect the tube 6825A to the pump fitting.

(6) Connect the power steering hose from the

steering gear to the adapter 6826.

(7) Open the test valve completely.

(8) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.(9) Check fluid level, add fluid as necessary. Start

engine again and let idle.

(10) Gauge should read below 862 kPa (125 psi), if

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure reading should be in

the range of 345-552 kPa (50-80 psi).

(11) Increase the engine speed to 1500 RPM and

read the flow meter. If the flow rate (GPM) is below

specification, (refer to pump specification chart for

GPM) the pump should be replaced.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than three seconds as the pump could be

damaged.

(12) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be above specifications and within

345 kPa (50 psi) of each other.

²Pressures above specifications but not within

345 kPa (50 psi) of each other, replace pump.

²Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

(13) Open the test valve and turn the steering

wheel to the extreme left and right positions three

times against the stops. Record the highest pressure

reading at each position. Compare readings to the

pump specifications chart. If pressures readings are

not within 50 psi of each other, the gear is leaking

internally and must be replaced.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 3 seconds at a time

because, pump damage will result.PUMP SPECIFICATION

ENGINERELIEF PRESSURE

65FLOW RATE

(GPM) AT 1500

RPM

1500

series11032 kPa

(1615 65 psi)3.1 - 3.5

2500 &

3500

series12400 kPa

(1800 50 psi)3.5 - 4.0

Fig. 2 Analyzer With Tube and Adapter

1 - TUBE

2 - ADAPTER FITTINGS

3 - ANALYZER

4 - GAUGE HOSE

19 - 4 STEERINGDR

STEERING (Continued)

Page 1660 of 2627

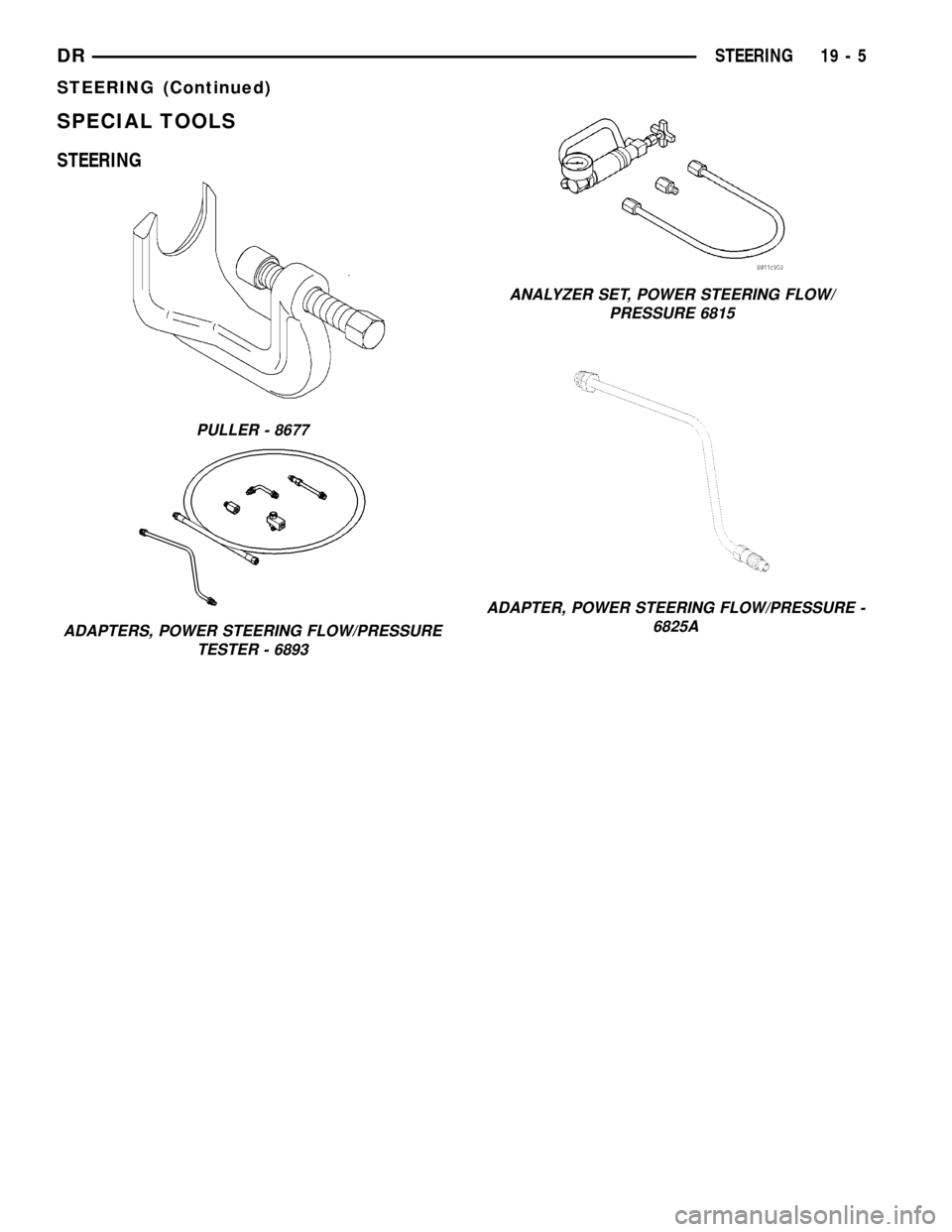

SPECIAL TOOLS

STEERING

PULLER - 8677

ADAPTERS, POWER STEERING FLOW/PRESSURE

TESTER - 6893

ANALYZER SET, POWER STEERING FLOW/

PRESSURE 6815

ADAPTER, POWER STEERING FLOW/PRESSURE -

6825A

DRSTEERING 19 - 5

STEERING (Continued)

Page 1672 of 2627

GEAR - INDEPENDENT FRONT SUSPENSION

TABLE OF CONTENTS

page page

GEAR - INDEPENDENT FRONT SUSPENSION

DESCRIPTION.........................17

REMOVAL.............................17

INSTALLATION.........................18

SPECIFICATIONS

TORQUE CHART......................19BUSHING

REMOVAL.............................19

INSTALLATION.........................19

GEAR - INDEPENDENT FRONT

SUSPENSION

DESCRIPTION

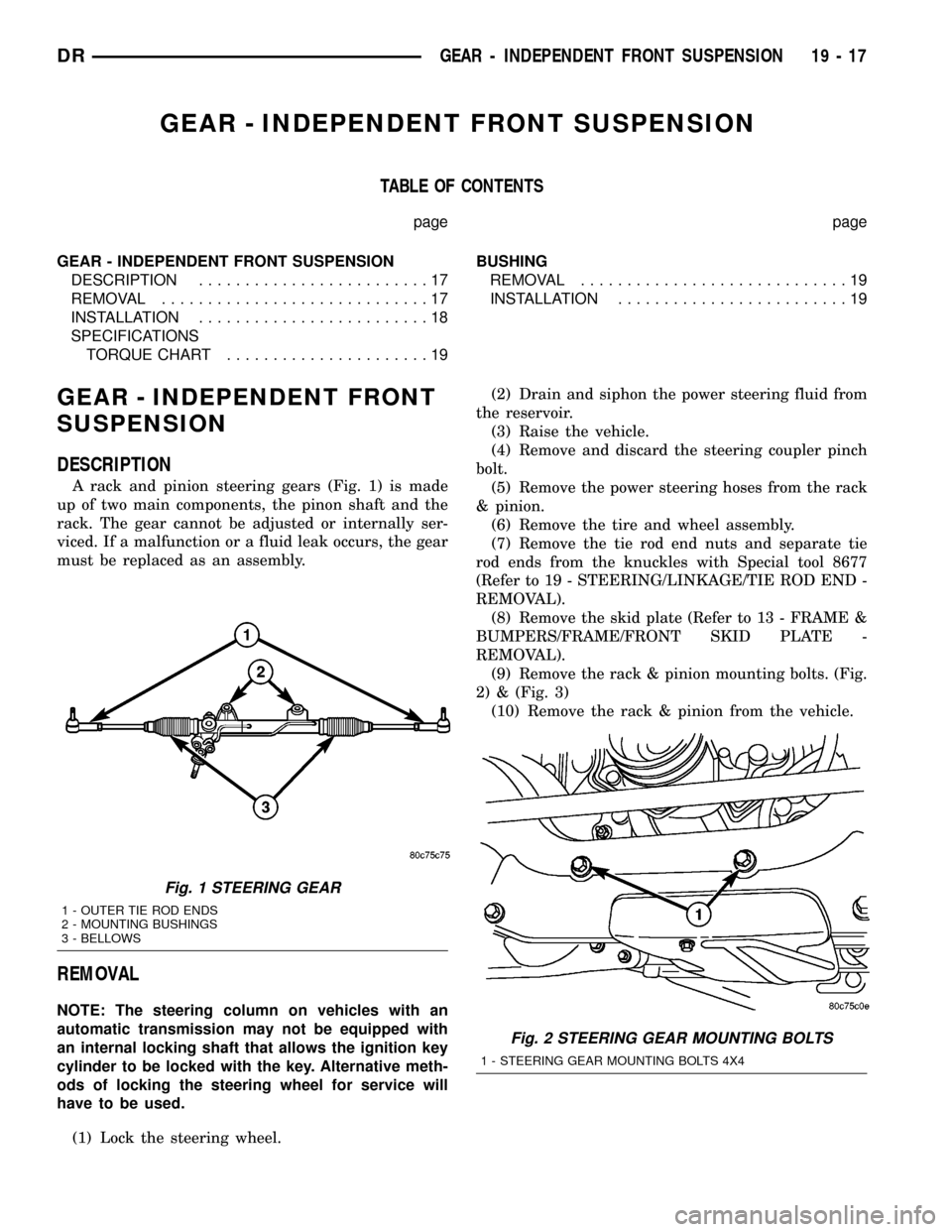

A rack and pinion steering gears (Fig. 1) is made

up of two main components, the pinon shaft and the

rack. The gear cannot be adjusted or internally ser-

viced. If a malfunction or a fluid leak occurs, the gear

must be replaced as an assembly.

REMOVAL

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

(1) Lock the steering wheel.(2) Drain and siphon the power steering fluid from

the reservoir.

(3) Raise the vehicle.

(4) Remove and discard the steering coupler pinch

bolt.

(5) Remove the power steering hoses from the rack

& pinion.

(6) Remove the tire and wheel assembly.

(7) Remove the tie rod end nuts and separate tie

rod ends from the knuckles with Special tool 8677

(Refer to 19 - STEERING/LINKAGE/TIE ROD END -

REMOVAL).

(8) Remove the skid plate (Refer to 13 - FRAME &

BUMPERS/FRAME/FRONT SKID PLATE -

REMOVAL).

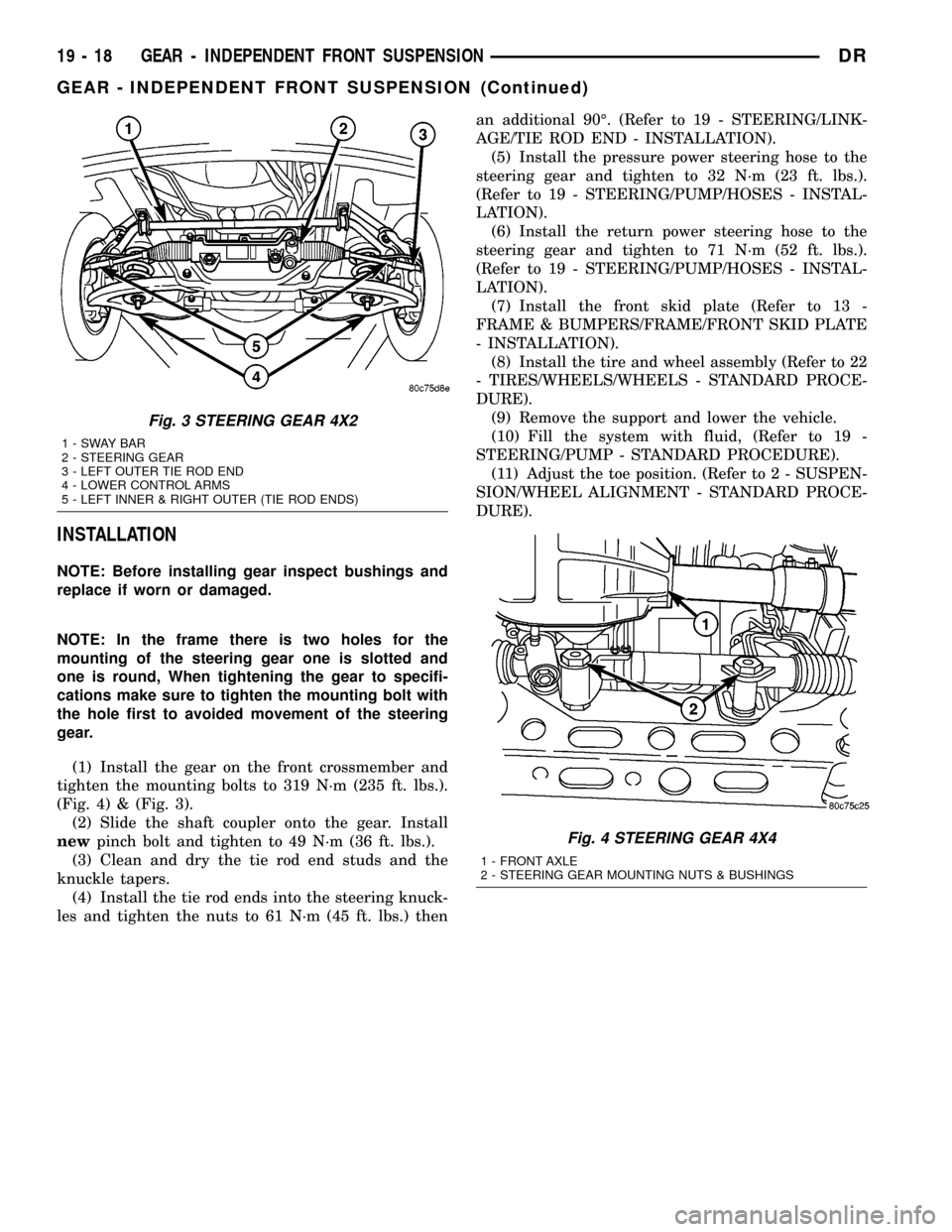

(9) Remove the rack & pinion mounting bolts. (Fig.

2) & (Fig. 3)

(10) Remove the rack & pinion from the vehicle.

Fig. 1 STEERING GEAR

1 - OUTER TIE ROD ENDS

2 - MOUNTING BUSHINGS

3 - BELLOWS

Fig. 2 STEERING GEAR MOUNTING BOLTS

1 - STEERING GEAR MOUNTING BOLTS 4X4

DRGEAR - INDEPENDENT FRONT SUSPENSION 19 - 17

Page 1673 of 2627

INSTALLATION

NOTE: Before installing gear inspect bushings and

replace if worn or damaged.

NOTE: In the frame there is two holes for the

mounting of the steering gear one is slotted and

one is round, When tightening the gear to specifi-

cations make sure to tighten the mounting bolt with

the hole first to avoided movement of the steering

gear.

(1) Install the gear on the front crossmember and

tighten the mounting bolts to 319 N´m (235 ft. lbs.).

(Fig. 4) & (Fig. 3).

(2) Slide the shaft coupler onto the gear. Install

newpinch bolt and tighten to 49 N´m (36 ft. lbs.).

(3) Clean and dry the tie rod end studs and the

knuckle tapers.

(4) Install the tie rod ends into the steering knuck-

les and tighten the nuts to 61 N´m (45 ft. lbs.) thenan additional 90É. (Refer to 19 - STEERING/LINK-

AGE/TIE ROD END - INSTALLATION).

(5) Install the pressure power steering hose to the

steering gear and tighten to 32 N´m (23 ft. lbs.).

(Refer to 19 - STEERING/PUMP/HOSES - INSTAL-

LATION).

(6) Install the return power steering hose to the

steering gear and tighten to 71 N´m (52 ft. lbs.).

(Refer to 19 - STEERING/PUMP/HOSES - INSTAL-

LATION).

(7) Install the front skid plate (Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT SKID PLATE

- INSTALLATION).

(8) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Remove the support and lower the vehicle.

(10) Fill the system with fluid, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

(11) Adjust the toe position. (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

Fig. 3 STEERING GEAR 4X2

1-SWAYBAR

2 - STEERING GEAR

3 - LEFT OUTER TIE ROD END

4 - LOWER CONTROL ARMS

5 - LEFT INNER & RIGHT OUTER (TIE ROD ENDS)

Fig. 4 STEERING GEAR 4X4

1 - FRONT AXLE

2 - STEERING GEAR MOUNTING NUTS & BUSHINGS

19 - 18 GEAR - INDEPENDENT FRONT SUSPENSIONDR

GEAR - INDEPENDENT FRONT SUSPENSION (Continued)