Electronic control module DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 832 of 2627

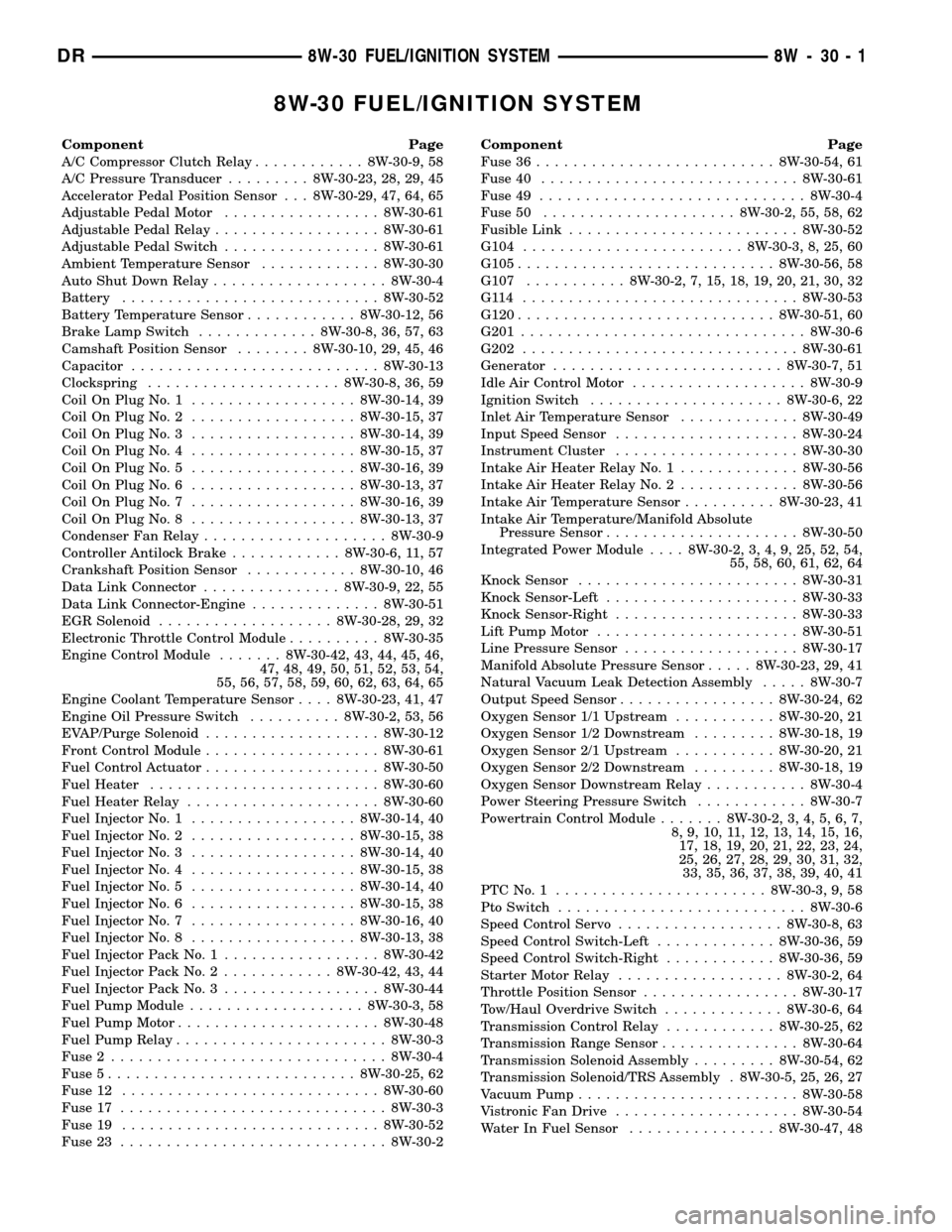

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch Relay............ 8W-30-9, 58

A/C Pressure Transducer......... 8W-30-23, 28, 29, 45

Accelerator Pedal Position Sensor . . . 8W-30-29, 47, 64, 65

Adjustable Pedal Motor................. 8W-30-61

Adjustable Pedal Relay.................. 8W-30-61

Adjustable Pedal Switch................. 8W-30-61

Ambient Temperature Sensor............. 8W-30-30

Auto Shut Down Relay................... 8W-30-4

Battery............................ 8W-30-52

Battery Temperature Sensor............ 8W-30-12, 56

Brake Lamp Switch............. 8W-30-8, 36, 57, 63

Camshaft Position Sensor........ 8W-30-10, 29, 45, 46

Capacitor........................... 8W-30-13

Clockspring..................... 8W-30-8, 36, 59

Coil On Plug No. 1.................. 8W-30-14, 39

Coil On Plug No. 2.................. 8W-30-15, 37

Coil On Plug No. 3.................. 8W-30-14, 39

Coil On Plug No. 4.................. 8W-30-15, 37

Coil On Plug No. 5.................. 8W-30-16, 39

Coil On Plug No. 6.................. 8W-30-13, 37

Coil On Plug No. 7.................. 8W-30-16, 39

Coil On Plug No. 8.................. 8W-30-13, 37

Condenser Fan Relay.................... 8W-30-9

Controller Antilock Brake............ 8W-30-6, 11, 57

Crankshaft Position Sensor............ 8W-30-10, 46

Data Link Connector............... 8W-30-9, 22, 55

Data Link Connector-Engine.............. 8W-30-51

EGR Solenoid................... 8W-30-28, 29, 32

Electronic Throttle Control Module.......... 8W-30-35

Engine Control Module....... 8W-30-42, 43, 44, 45, 46,

47, 48, 49, 50, 51, 52, 53, 54,

55, 56, 57, 58, 59, 60, 62, 63, 64, 65

Engine Coolant Temperature Sensor.... 8W-30-23, 41, 47

Engine Oil Pressure Switch.......... 8W-30-2, 53, 56

EVAP/Purge Solenoid................... 8W-30-12

Front Control Module................... 8W-30-61

Fuel Control Actuator................... 8W-30-50

Fuel Heater......................... 8W-30-60

Fuel Heater Relay..................... 8W-30-60

Fuel Injector No. 1.................. 8W-30-14, 40

Fuel Injector No. 2.................. 8W-30-15, 38

Fuel Injector No. 3.................. 8W-30-14, 40

Fuel Injector No. 4.................. 8W-30-15, 38

Fuel Injector No. 5.................. 8W-30-14, 40

Fuel Injector No. 6.................. 8W-30-15, 38

Fuel Injector No. 7.................. 8W-30-16, 40

Fuel Injector No. 8.................. 8W-30-13, 38

Fuel Injector Pack No. 1................. 8W-30-42

Fuel Injector Pack No. 2............ 8W-30-42, 43, 44

Fuel Injector Pack No. 3................. 8W-30-44

Fuel Pump Module................... 8W-30-3, 58

Fuel Pump Motor...................... 8W-30-48

Fuel Pump Relay....................... 8W-30-3

Fuse 2.............................. 8W-30-4

Fuse 5........................... 8W-30-25, 62

Fuse 12............................ 8W-30-60

Fuse 17............................. 8W-30-3

Fuse 19............................ 8W-30-52

Fuse 23............................. 8W-30-2Component Page

Fuse 36.......................... 8W-30-54, 61

Fuse 40............................ 8W-30-61

Fuse 49............................. 8W-30-4

Fuse 50..................... 8W-30-2, 55, 58, 62

Fusible Link......................... 8W-30-52

G104........................ 8W-30-3, 8, 25, 60

G105............................ 8W-30-56, 58

G107........... 8W-30-2, 7, 15, 18, 19, 20, 21, 30, 32

G114 .............................. 8W-30-53

G120............................ 8W-30-51, 60

G201............................... 8W-30-6

G202.............................. 8W-30-61

Generator......................... 8W-30-7, 51

Idle Air Control Motor................... 8W-30-9

Ignition Switch..................... 8W-30-6, 22

Inlet Air Temperature Sensor............. 8W-30-49

Input Speed Sensor.................... 8W-30-24

Instrument Cluster.................... 8W-30-30

Intake Air Heater Relay No. 1............. 8W-30-56

Intake Air Heater Relay No. 2............. 8W-30-56

Intake Air Temperature Sensor.......... 8W-30-23, 41

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30-50

Integrated Power Module.... 8W-30-2, 3, 4, 9, 25, 52, 54,

55, 58, 60, 61, 62, 64

Knock Sensor........................ 8W-30-31

Knock Sensor-Left..................... 8W-30-33

Knock Sensor-Right.................... 8W-30-33

Lift Pump Motor...................... 8W-30-51

Line Pressure Sensor................... 8W-30-17

Manifold Absolute Pressure Sensor..... 8W-30-23, 29, 41

Natural Vacuum Leak Detection Assembly..... 8W-30-7

Output Speed Sensor................. 8W-30-24, 62

Oxygen Sensor 1/1 Upstream........... 8W-30-20, 21

Oxygen Sensor 1/2 Downstream......... 8W-30-18, 19

Oxygen Sensor 2/1 Upstream........... 8W-30-20, 21

Oxygen Sensor 2/2 Downstream......... 8W-30-18, 19

Oxygen Sensor Downstream Relay........... 8W-30-4

Power Steering Pressure Switch............ 8W-30-7

Powertrain Control Module....... 8W-30-2, 3, 4, 5, 6, 7,

8, 9, 10, 11, 12, 13, 14, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24,

25, 26, 27, 28, 29, 30, 31, 32,

33, 35, 36, 37, 38, 39, 40, 41

PTCNo.1 ....................... 8W-30-3, 9, 58

Pto Switch........................... 8W-30-6

Speed Control Servo.................. 8W-30-8, 63

Speed Control Switch-Left............. 8W-30-36, 59

Speed Control Switch-Right............ 8W-30-36, 59

Starter Motor Relay.................. 8W-30-2, 64

Throttle Position Sensor................. 8W-30-17

Tow/Haul Overdrive Switch............. 8W-30-6, 64

Transmission Control Relay............ 8W-30-25, 62

Transmission Range Sensor............... 8W-30-64

Transmission Solenoid Assembly......... 8W-30-54, 62

Transmission Solenoid/TRS Assembly . 8W-30-5, 25, 26, 27

Vacuum Pump........................ 8W-30-58

Vistronic Fan Drive.................... 8W-30-54

Water In Fuel Sensor................ 8W-30-47, 48

DR8W-30 FUEL/IGNITION SYSTEM 8W - 30 - 1

Page 1050 of 2627

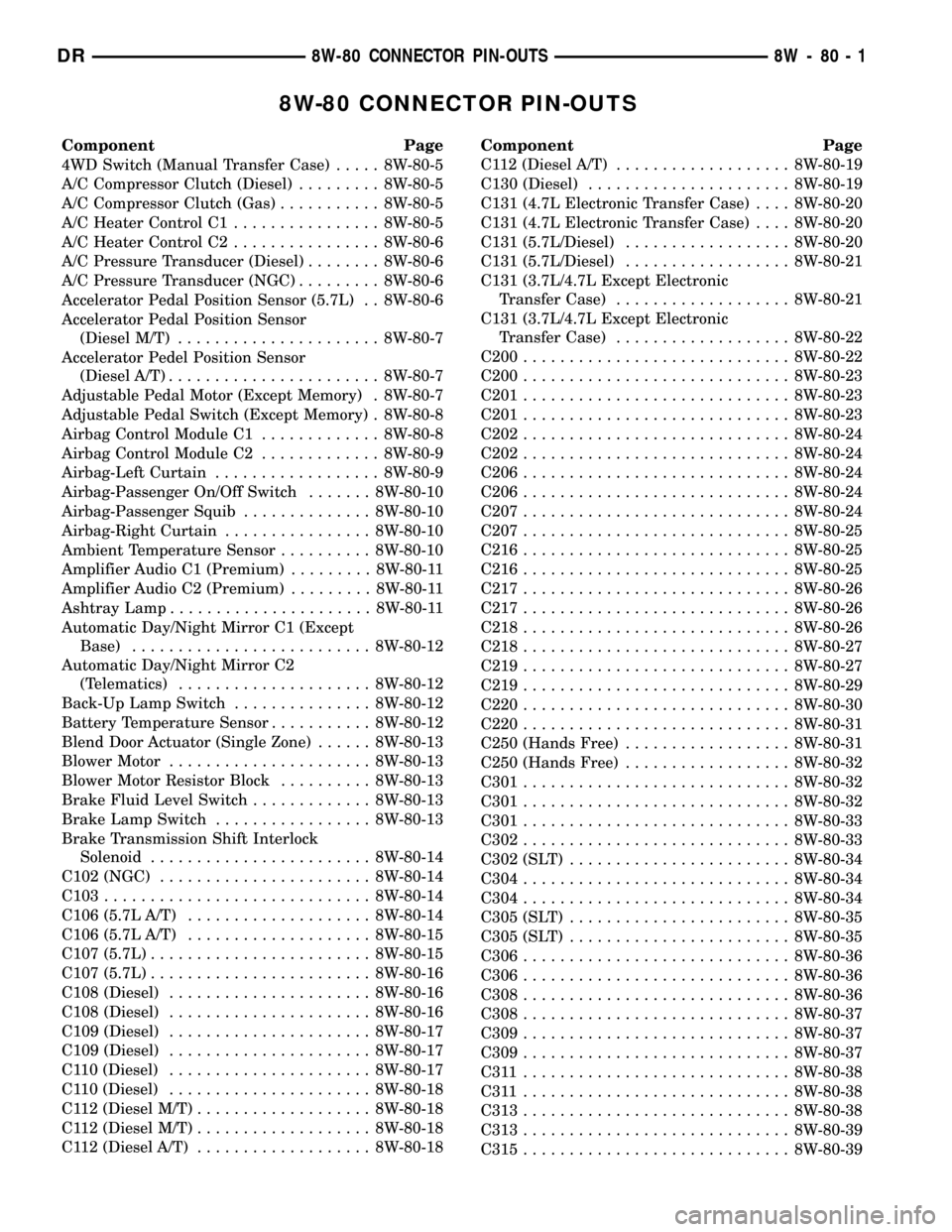

8W-80 CONNECTOR PIN-OUTS

Component Page

4WD Switch (Manual Transfer Case)..... 8W-80-5

A/C Compressor Clutch (Diesel)......... 8W-80-5

A/C Compressor Clutch (Gas)........... 8W-80-5

A/C Heater Control C1................ 8W-80-5

A/C Heater Control C2................ 8W-80-6

A/C Pressure Transducer (Diesel)........ 8W-80-6

A/C Pressure Transducer (NGC)......... 8W-80-6

Accelerator Pedal Position Sensor (5.7L) . . 8W-80-6

Accelerator Pedal Position Sensor

(Diesel M/T)...................... 8W-80-7

Accelerator Pedel Position Sensor

(Diesel A/T)....................... 8W-80-7

Adjustable Pedal Motor (Except Memory) . 8W-80-7

Adjustable Pedal Switch (Except Memory) . 8W-80-8

Airbag Control Module C1............. 8W-80-8

Airbag Control Module C2............. 8W-80-9

Airbag-Left Curtain.................. 8W-80-9

Airbag-Passenger On/Off Switch....... 8W-80-10

Airbag-Passenger Squib.............. 8W-80-10

Airbag-Right Curtain................ 8W-80-10

Ambient Temperature Sensor.......... 8W-80-10

Amplifier Audio C1 (Premium)......... 8W-80-11

Amplifier Audio C2 (Premium)......... 8W-80-11

Ashtray Lamp...................... 8W-80-11

Automatic Day/Night Mirror C1 (Except

Base).......................... 8W-80-12

Automatic Day/Night Mirror C2

(Telematics)..................... 8W-80-12

Back-Up Lamp Switch............... 8W-80-12

Battery Temperature Sensor........... 8W-80-12

Blend Door Actuator (Single Zone)...... 8W-80-13

Blower Motor...................... 8W-80-13

Blower Motor Resistor Block.......... 8W-80-13

Brake Fluid Level Switch............. 8W-80-13

Brake Lamp Switch................. 8W-80-13

Brake Transmission Shift Interlock

Solenoid........................ 8W-80-14

C102 (NGC)....................... 8W-80-14

C103............................. 8W-80-14

C106 (5.7L A/T).................... 8W-80-14

C106 (5.7L A/T).................... 8W-80-15

C107 (5.7L)........................ 8W-80-15

C107 (5.7L)........................ 8W-80-16

C108 (Diesel)...................... 8W-80-16

C108 (Diesel)...................... 8W-80-16

C109 (Diesel)...................... 8W-80-17

C109 (Diesel)...................... 8W-80-17

C110 (Diesel)...................... 8W-80-17

C110 (Diesel)...................... 8W-80-18

C112 (Diesel M/T)................... 8W-80-18

C112 (Diesel M/T)................... 8W-80-18

C112 (Diesel A/T)................... 8W-80-18Component Page

C112 (Diesel A/T)................... 8W-80-19

C130 (Diesel)...................... 8W-80-19

C131 (4.7L Electronic Transfer Case).... 8W-80-20

C131 (4.7L Electronic Transfer Case).... 8W-80-20

C131 (5.7L/Diesel).................. 8W-80-20

C131 (5.7L/Diesel).................. 8W-80-21

C131 (3.7L/4.7L Except Electronic

Transfer Case)................... 8W-80-21

C131 (3.7L/4.7L Except Electronic

Transfer Case)................... 8W-80-22

C200............................. 8W-80-22

C200............................. 8W-80-23

C201............................. 8W-80-23

C201............................. 8W-80-23

C202............................. 8W-80-24

C202............................. 8W-80-24

C206............................. 8W-80-24

C206............................. 8W-80-24

C207............................. 8W-80-24

C207............................. 8W-80-25

C216............................. 8W-80-25

C216............................. 8W-80-25

C217............................. 8W-80-26

C217............................. 8W-80-26

C218............................. 8W-80-26

C218............................. 8W-80-27

C219............................. 8W-80-27

C219............................. 8W-80-29

C220............................. 8W-80-30

C220............................. 8W-80-31

C250 (Hands Free).................. 8W-80-31

C250 (Hands Free).................. 8W-80-32

C301............................. 8W-80-32

C301............................. 8W-80-32

C301............................. 8W-80-33

C302............................. 8W-80-33

C302 (SLT)........................ 8W-80-34

C304............................. 8W-80-34

C304............................. 8W-80-34

C305 (SLT)........................ 8W-80-35

C305 (SLT)........................ 8W-80-35

C306............................. 8W-80-36

C306............................. 8W-80-36

C308............................. 8W-80-36

C308............................. 8W-80-37

C309............................. 8W-80-37

C309............................. 8W-80-37

C311 ............................. 8W-80-38

C311 ............................. 8W-80-38

C313............................. 8W-80-38

C313............................. 8W-80-39

C315............................. 8W-80-39

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 1

Page 1123 of 2627

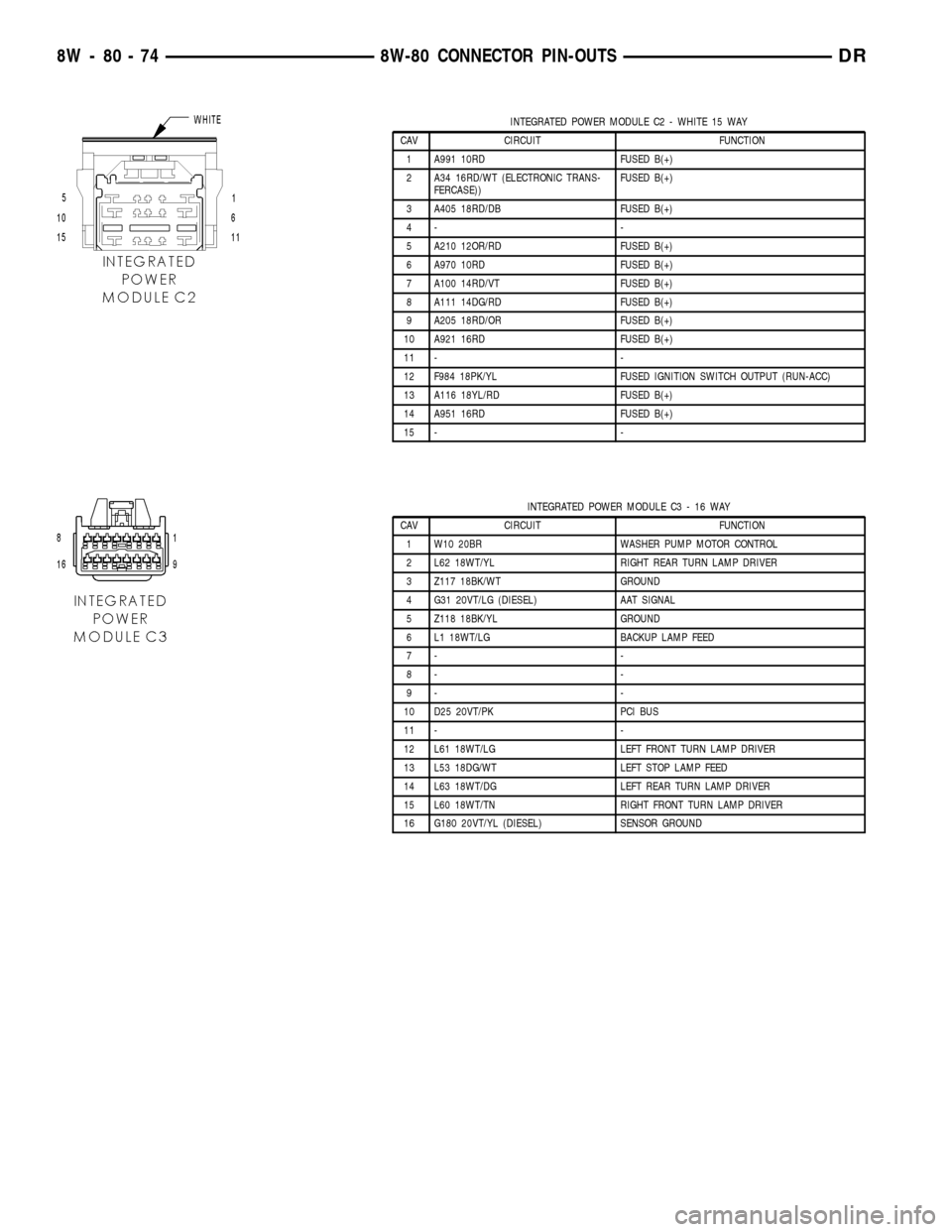

INTEGRATED POWER MODULE C2 - WHITE 15 WAY

CAV CIRCUIT FUNCTION

1 A991 10RD FUSED B(+)

2 A34 16RD/WT (ELECTRONIC TRANS-

FERCASE))FUSED B(+)

3 A405 18RD/DB FUSED B(+)

4- -

5 A210 12OR/RD FUSED B(+)

6 A970 10RD FUSED B(+)

7 A100 14RD/VT FUSED B(+)

8 A111 14DG/RD FUSED B(+)

9 A205 18RD/OR FUSED B(+)

10 A921 16RD FUSED B(+)

11 - -

12 F984 18PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

13 A116 18YL/RD FUSED B(+)

14 A951 16RD FUSED B(+)

15 - -

INTEGRATED POWER MODULE C3 - 16 WAY

CAV CIRCUIT FUNCTION

1 W10 20BR WASHER PUMP MOTOR CONTROL

2 L62 18WT/YL RIGHT REAR TURN LAMP DRIVER

3 Z117 18BK/WT GROUND

4 G31 20VT/LG (DIESEL) AAT SIGNAL

5 Z118 18BK/YL GROUND

6 L1 18WT/LG BACKUP LAMP FEED

7- -

8- -

9- -

10 D25 20VT/PK PCI BUS

11 - -

12 L61 18WT/LG LEFT FRONT TURN LAMP DRIVER

13 L53 18DG/WT LEFT STOP LAMP FEED

14 L63 18WT/DG LEFT REAR TURN LAMP DRIVER

15 L60 18WT/TN RIGHT FRONT TURN LAMP DRIVER

16 G180 20VT/YL (DIESEL) SENSOR GROUND

8W - 80 - 74 8W-80 CONNECTOR PIN-OUTSDR

Page 1216 of 2627

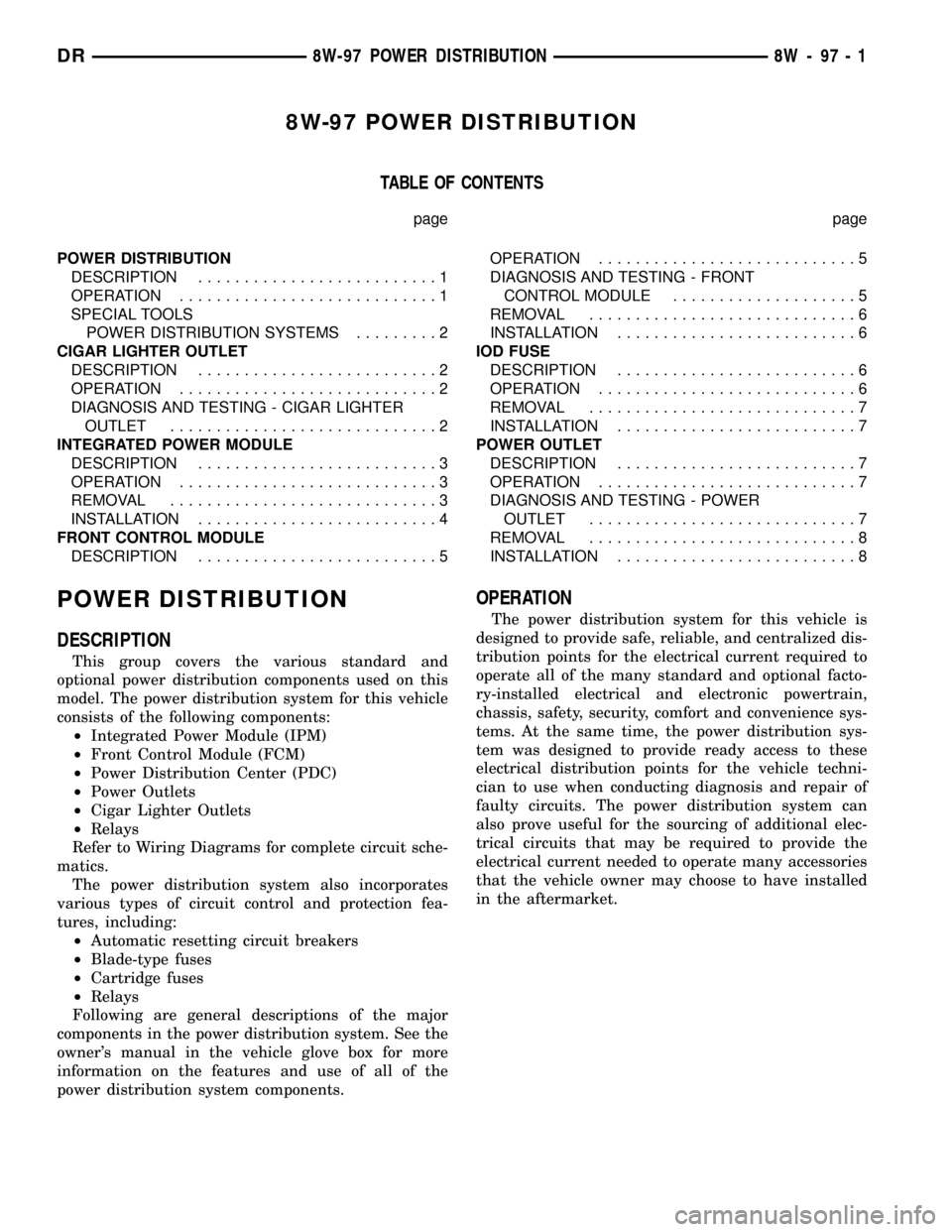

8W-97 POWER DISTRIBUTION

TABLE OF CONTENTS

page page

POWER DISTRIBUTION

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

CIGAR LIGHTER OUTLET

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET.............................2

INTEGRATED POWER MODULE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................4

FRONT CONTROL MODULE

DESCRIPTION..........................5OPERATION............................5

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE....................5

REMOVAL.............................6

INSTALLATION..........................6

IOD FUSE

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................7

INSTALLATION..........................7

POWER OUTLET

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - POWER

OUTLET.............................7

REMOVAL.............................8

INSTALLATION..........................8

POWER DISTRIBUTION

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Distribution Center (PDC)

²Power Outlets

²Cigar Lighter Outlets

²Relays

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Cartridge fuses

²Relays

Following are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide the

electrical current needed to operate many accessories

that the vehicle owner may choose to have installed

in the aftermarket.

DR8W-97 POWER DISTRIBUTION 8W - 97 - 1

Page 1218 of 2627

INTEGRATED POWER MODULE

DESCRIPTION

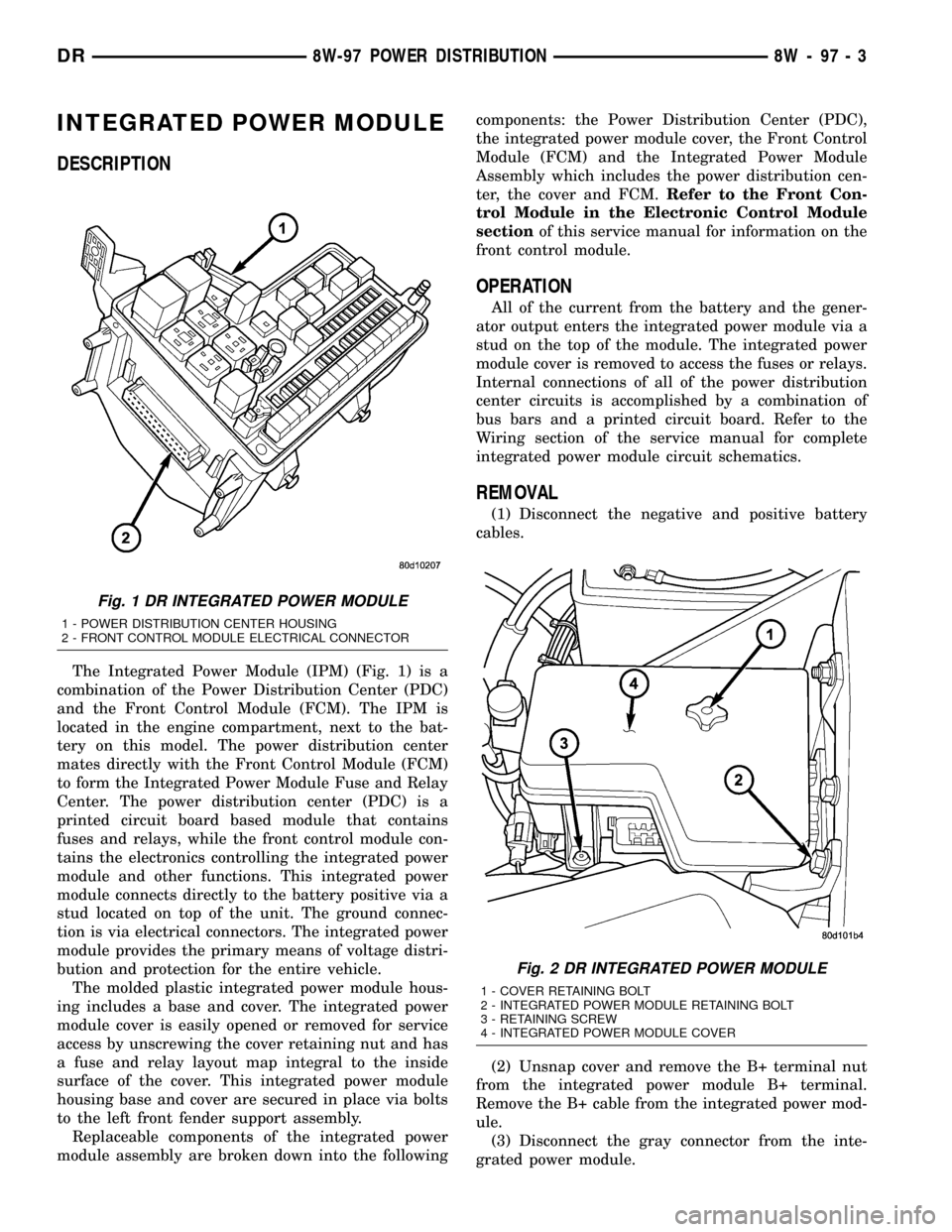

The Integrated Power Module (IPM) (Fig. 1) is a

combination of the Power Distribution Center (PDC)

and the Front Control Module (FCM). The IPM is

located in the engine compartment, next to the bat-

tery on this model. The power distribution center

mates directly with the Front Control Module (FCM)

to form the Integrated Power Module Fuse and Relay

Center. The power distribution center (PDC) is a

printed circuit board based module that contains

fuses and relays, while the front control module con-

tains the electronics controlling the integrated power

module and other functions. This integrated power

module connects directly to the battery positive via a

stud located on top of the unit. The ground connec-

tion is via electrical connectors. The integrated power

module provides the primary means of voltage distri-

bution and protection for the entire vehicle.

The molded plastic integrated power module hous-

ing includes a base and cover. The integrated power

module cover is easily opened or removed for service

access by unscrewing the cover retaining nut and has

a fuse and relay layout map integral to the inside

surface of the cover. This integrated power module

housing base and cover are secured in place via bolts

to the left front fender support assembly.

Replaceable components of the integrated power

module assembly are broken down into the followingcomponents: the Power Distribution Center (PDC),

the integrated power module cover, the Front Control

Module (FCM) and the Integrated Power Module

Assembly which includes the power distribution cen-

ter, the cover and FCM.Refer to the Front Con-

trol Module in the Electronic Control Module

sectionof this service manual for information on the

front control module.

OPERATION

All of the current from the battery and the gener-

ator output enters the integrated power module via a

stud on the top of the module. The integrated power

module cover is removed to access the fuses or relays.

Internal connections of all of the power distribution

center circuits is accomplished by a combination of

bus bars and a printed circuit board. Refer to the

Wiring section of the service manual for complete

integrated power module circuit schematics.

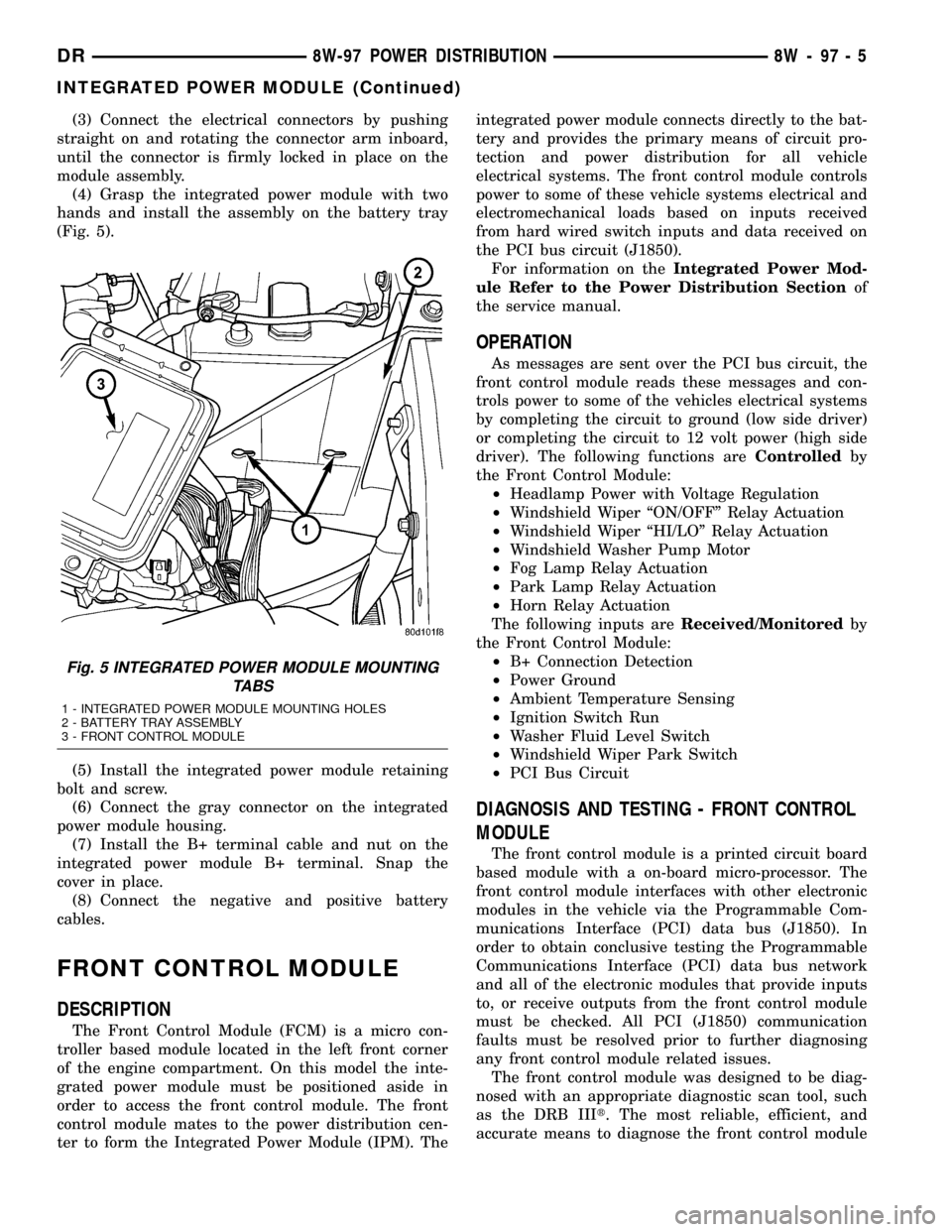

REMOVAL

(1) Disconnect the negative and positive battery

cables.

(2) Unsnap cover and remove the B+ terminal nut

from the integrated power module B+ terminal.

Remove the B+ cable from the integrated power mod-

ule.

(3) Disconnect the gray connector from the inte-

grated power module.

Fig. 1 DR INTEGRATED POWER MODULE

1 - POWER DISTRIBUTION CENTER HOUSING

2 - FRONT CONTROL MODULE ELECTRICAL CONNECTOR

Fig. 2 DR INTEGRATED POWER MODULE

1 - COVER RETAINING BOLT

2 - INTEGRATED POWER MODULE RETAINING BOLT

3 - RETAINING SCREW

4 - INTEGRATED POWER MODULE COVER

DR8W-97 POWER DISTRIBUTION 8W - 97 - 3

Page 1220 of 2627

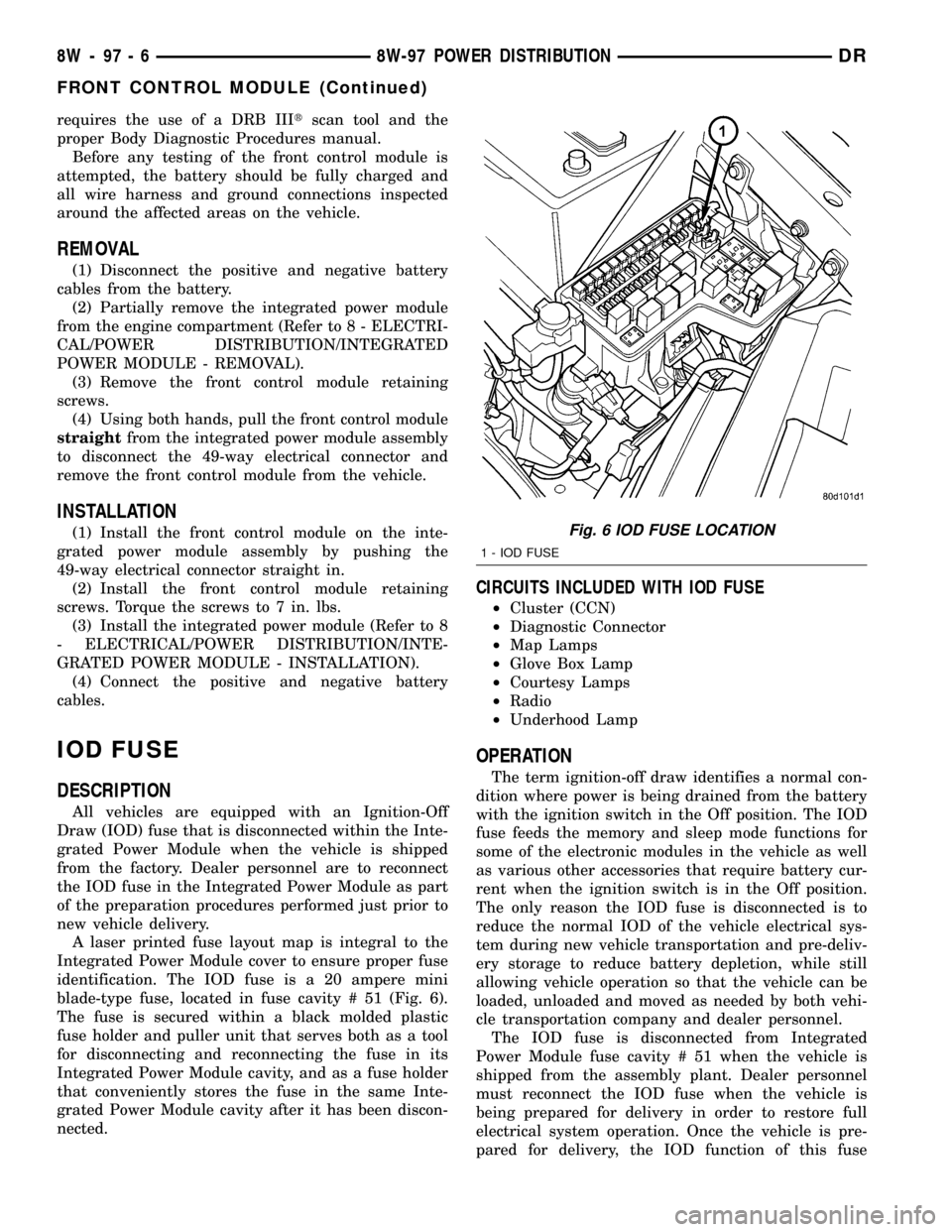

(3) Connect the electrical connectors by pushing

straight on and rotating the connector arm inboard,

until the connector is firmly locked in place on the

module assembly.

(4) Grasp the integrated power module with two

hands and install the assembly on the battery tray

(Fig. 5).

(5) Install the integrated power module retaining

bolt and screw.

(6) Connect the gray connector on the integrated

power module housing.

(7) Install the B+ terminal cable and nut on the

integrated power module B+ terminal. Snap the

cover in place.

(8) Connect the negative and positive battery

cables.

FRONT CONTROL MODULE

DESCRIPTION

The Front Control Module (FCM) is a micro con-

troller based module located in the left front corner

of the engine compartment. On this model the inte-

grated power module must be positioned aside in

order to access the front control module. The front

control module mates to the power distribution cen-

ter to form the Integrated Power Module (IPM). Theintegrated power module connects directly to the bat-

tery and provides the primary means of circuit pro-

tection and power distribution for all vehicle

electrical systems. The front control module controls

power to some of these vehicle systems electrical and

electromechanical loads based on inputs received

from hard wired switch inputs and data received on

the PCI bus circuit (J1850).

For information on theIntegrated Power Mod-

ule Refer to the Power Distribution Sectionof

the service manual.

OPERATION

As messages are sent over the PCI bus circuit, the

front control module reads these messages and con-

trols power to some of the vehicles electrical systems

by completing the circuit to ground (low side driver)

or completing the circuit to 12 volt power (high side

driver). The following functions areControlledby

the Front Control Module:

²Headlamp Power with Voltage Regulation

²Windshield Wiper ªON/OFFº Relay Actuation

²Windshield Wiper ªHI/LOº Relay Actuation

²Windshield Washer Pump Motor

²Fog Lamp Relay Actuation

²Park Lamp Relay Actuation

²Horn Relay Actuation

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Power Ground

²Ambient Temperature Sensing

²Ignition Switch Run

²Washer Fluid Level Switch

²Windshield Wiper Park Switch

²PCI Bus Circuit

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

Fig. 5 INTEGRATED POWER MODULE MOUNTING

TABS

1 - INTEGRATED POWER MODULE MOUNTING HOLES

2 - BATTERY TRAY ASSEMBLY

3 - FRONT CONTROL MODULE

DR8W-97 POWER DISTRIBUTION 8W - 97 - 5

INTEGRATED POWER MODULE (Continued)

Page 1221 of 2627

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

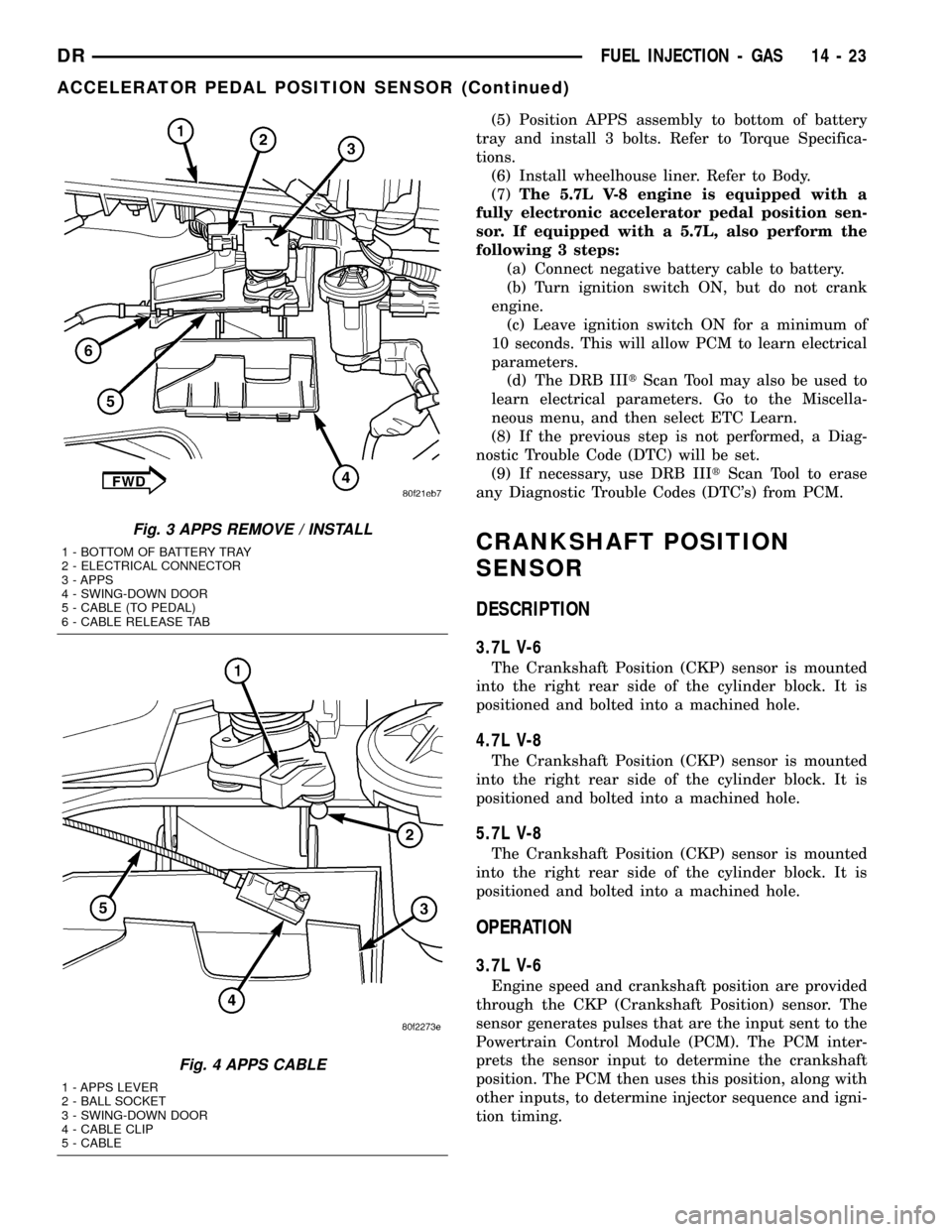

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is disconnected within the Inte-

grated Power Module when the vehicle is shipped

from the factory. Dealer personnel are to reconnect

the IOD fuse in the Integrated Power Module as part

of the preparation procedures performed just prior to

new vehicle delivery.

A laser printed fuse layout map is integral to the

Integrated Power Module cover to ensure proper fuse

identification. The IOD fuse is a 20 ampere mini

blade-type fuse, located in fuse cavity # 51 (Fig. 6).

The fuse is secured within a black molded plastic

fuse holder and puller unit that serves both as a tool

for disconnecting and reconnecting the fuse in its

Integrated Power Module cavity, and as a fuse holder

that conveniently stores the fuse in the same Inte-

grated Power Module cavity after it has been discon-

nected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cluster (CCN)

²Diagnostic Connector

²Map Lamps

²Glove Box Lamp

²Courtesy Lamps

²Radio

²Underhood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position.

The only reason the IOD fuse is disconnected is to

reduce the normal IOD of the vehicle electrical sys-

tem during new vehicle transportation and pre-deliv-

ery storage to reduce battery depletion, while still

allowing vehicle operation so that the vehicle can be

loaded, unloaded and moved as needed by both vehi-

cle transportation company and dealer personnel.

The IOD fuse is disconnected from Integrated

Power Module fuse cavity # 51 when the vehicle is

shipped from the assembly plant. Dealer personnel

must reconnect the IOD fuse when the vehicle is

being prepared for delivery in order to restore full

electrical system operation. Once the vehicle is pre-

pared for delivery, the IOD function of this fuse

Fig. 6 IOD FUSE LOCATION

1 - IOD FUSE

8W - 97 - 6 8W-97 POWER DISTRIBUTIONDR

FRONT CONTROL MODULE (Continued)

Page 1592 of 2627

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7)The 5.7L V-8 engine is equipped with a

fully electronic accelerator pedal position sen-

sor. If equipped with a 5.7L, also perform the

following 3 steps:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(d) The DRB IIItScan Tool may also be used to

learn electrical parameters. Go to the Miscella-

neous menu, and then select ETC Learn.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM inter-

prets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

DRFUEL INJECTION - GAS 14 - 23

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1614 of 2627

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM

The fuel system used on the Cummins engine is an

electronically controlled, Bosch HPCR (High-Pressure

Common Rail) system. The HPCR system consists of

five main components:

²Electric Fuel Transfer (lift) Pump

²Fuel Pump/Gear Pump (attached to fuel injec-

tion pump)

²High-Pressure Fuel Injection Pump

²Fuel Injection Rail

²Fuel Injectors

Also to be considered as part of the overall fuel

system are:

²Accelerator Pedal

²Air Cleaner Housing/Element

²Fuel Drain Manifold (passage)

²Fuel Drain Valve (at filter)

²Fuel Filter/Water Separator

²Fuel Heater

²Fuel Heater Relay

²Fuel Level (gauge) Sending Unit

²Fuel Pressure Limiting Valve

²Fuel Tank

²Fuel Tank Module (containing fuel gauge send-

ing unit and separate fuel filter located at bottom of

tank module)

²Fuel Tank Filler/Vent Tube Assembly

²Fuel Tank Filler Tube Cap

²Fuel Tubes/Lines/Hoses

²High-Pressure Fuel Injector Lines

²In-Tank Fuel Filter (at bottom of fuel tank mod-

ule)

²Low-Pressure Fuel Supply Lines

²Low-Pressure Fuel Return Line

²Overflow Valve

²Quick-Connect Fuel Line Fittings

²Throttle Cable

²Water Draining (maintenance)

²Water-In-Fuel (WIF) Sensor

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure fuel is then accumulated in the fuel rail.

High pressure fuel is constantly supplied to the injec-

tors by the fuel rail. The Engine Control Module

(ECM) controls the fueling and timing of the engine

by actuating the injectors.Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail monitors the actual fuel pressure and provides it

as an input to the ECM. When the actuator is

opened, the maximum amount of fuel is being sup-

plied to the fuel injection pump. Any fuel that does

not enter the injection pump is directed to the over-

flow valve. The overflow valve regulates how much

excess fuel is used for lubrication of the pump and

how much is returned to the tank through the drain

manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23,206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 160,000 KPA (23,206

PSI). USE EXTREME CAUTION WHEN INSPECTING

FOR HIGH-PRESSURE FUEL LEAKS. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

Certain fuel system components can be found in

(Fig. 1), or (Fig. 2).

DRFUEL DELIVERY - DIESEL 14 - 45

Page 1622 of 2627

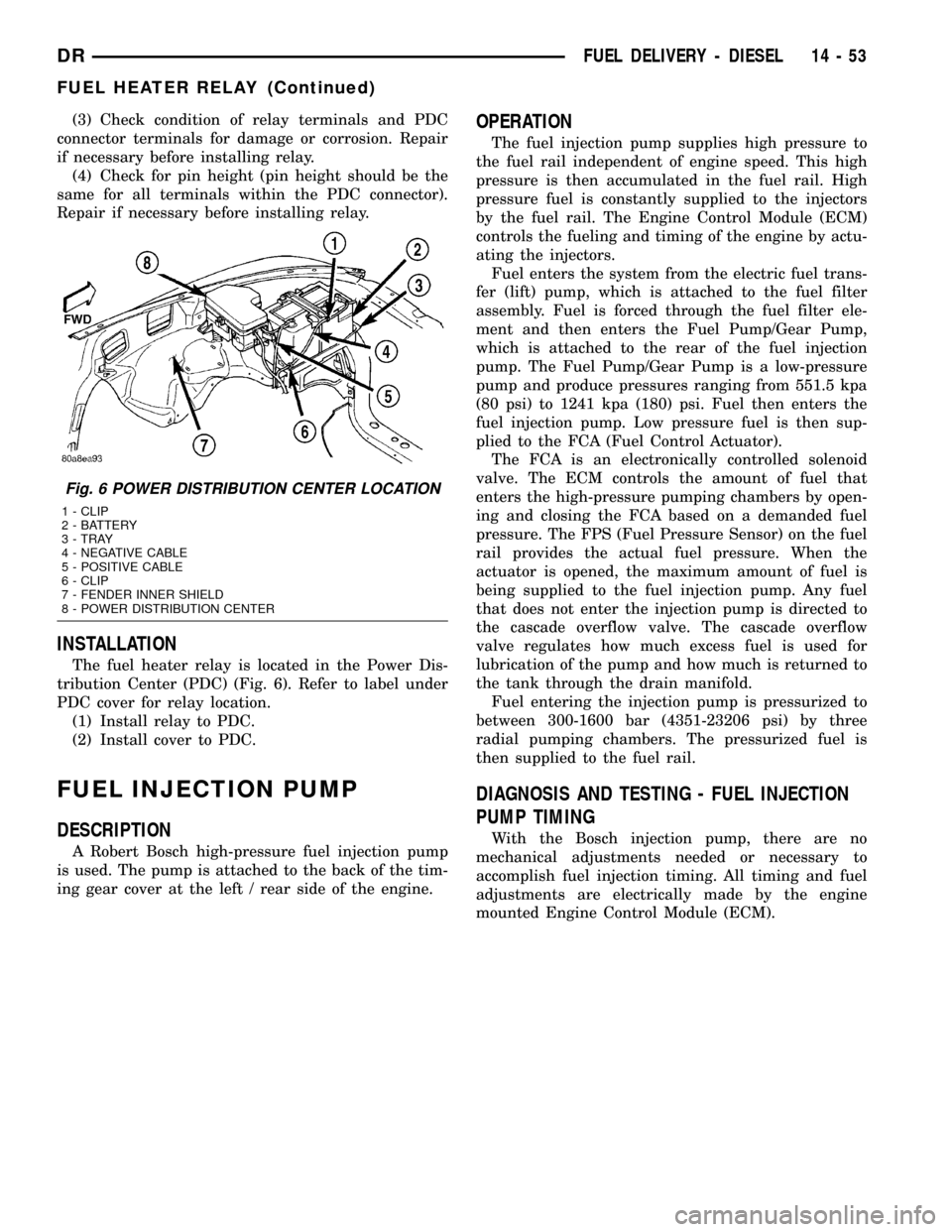

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

FUEL INJECTION PUMP

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump

is used. The pump is attached to the back of the tim-

ing gear cover at the left / rear side of the engine.

OPERATION

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure is then accumulated in the fuel rail. High

pressure fuel is constantly supplied to the injectors

by the fuel rail. The Engine Control Module (ECM)

controls the fueling and timing of the engine by actu-

ating the injectors.

Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the cascade overflow valve. The cascade overflow

valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to

the tank through the drain manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING

With the Bosch injection pump, there are no

mechanical adjustments needed or necessary to

accomplish fuel injection timing. All timing and fuel

adjustments are electrically made by the engine

mounted Engine Control Module (ECM).

Fig. 6 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

DRFUEL DELIVERY - DIESEL 14 - 53

FUEL HEATER RELAY (Continued)