FRONT HUB DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2137 of 2627

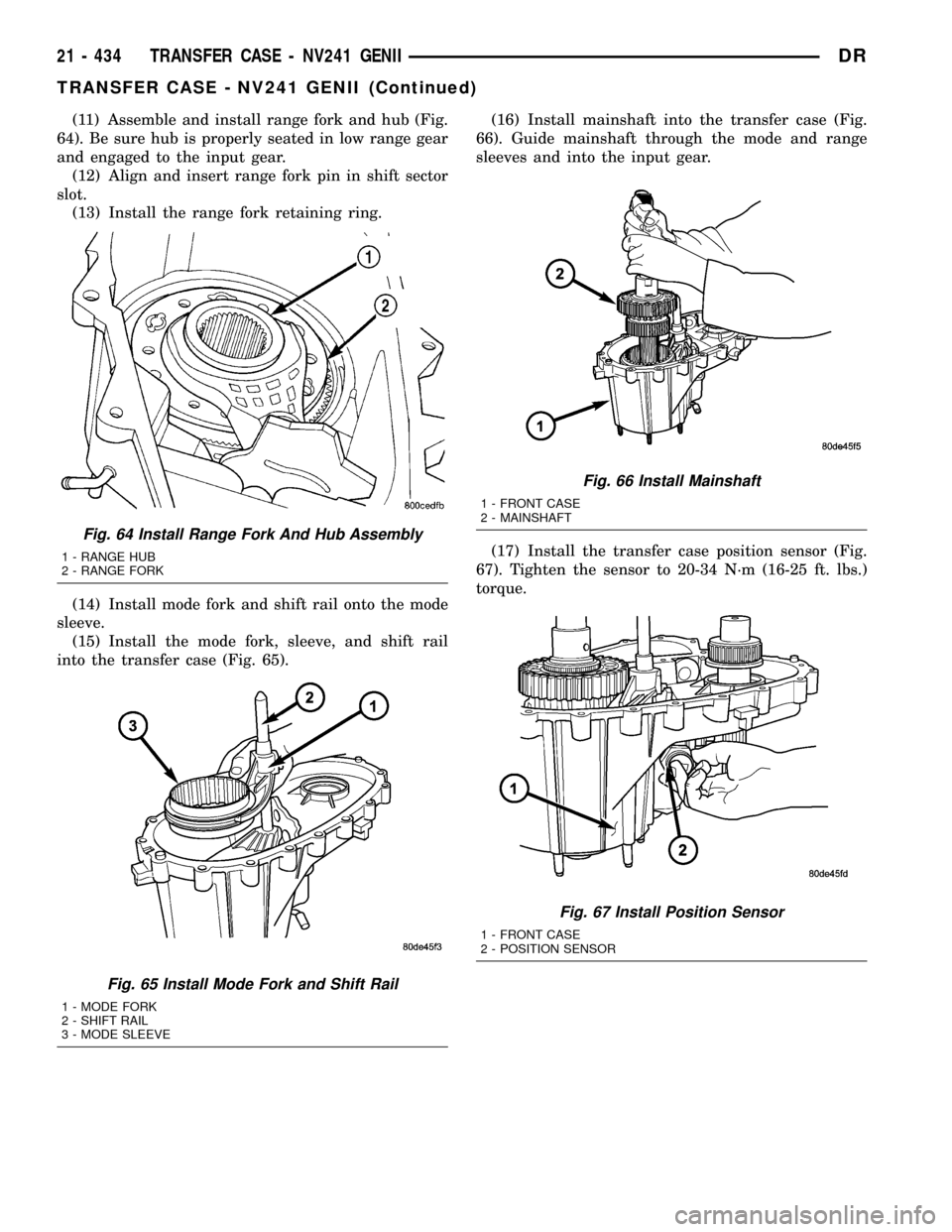

(11) Assemble and install range fork and hub (Fig.

64). Be sure hub is properly seated in low range gear

and engaged to the input gear.

(12) Align and insert range fork pin in shift sector

slot.

(13) Install the range fork retaining ring.

(14) Install mode fork and shift rail onto the mode

sleeve.

(15) Install the mode fork, sleeve, and shift rail

into the transfer case (Fig. 65).(16) Install mainshaft into the transfer case (Fig.

66). Guide mainshaft through the mode and range

sleeves and into the input gear.

(17) Install the transfer case position sensor (Fig.

67). Tighten the sensor to 20-34 N´m (16-25 ft. lbs.)

torque.

Fig. 64 Install Range Fork And Hub Assembly

1 - RANGE HUB

2 - RANGE FORK

Fig. 65 Install Mode Fork and Shift Rail

1 - MODE FORK

2 - SHIFT RAIL

3 - MODE SLEEVE

Fig. 66 Install Mainshaft

1 - FRONT CASE

2 - MAINSHAFT

Fig. 67 Install Position Sensor

1 - FRONT CASE

2 - POSITION SENSOR

21 - 434 TRANSFER CASE - NV241 GENIIDR

TRANSFER CASE - NV241 GENII (Continued)

Page 2139 of 2627

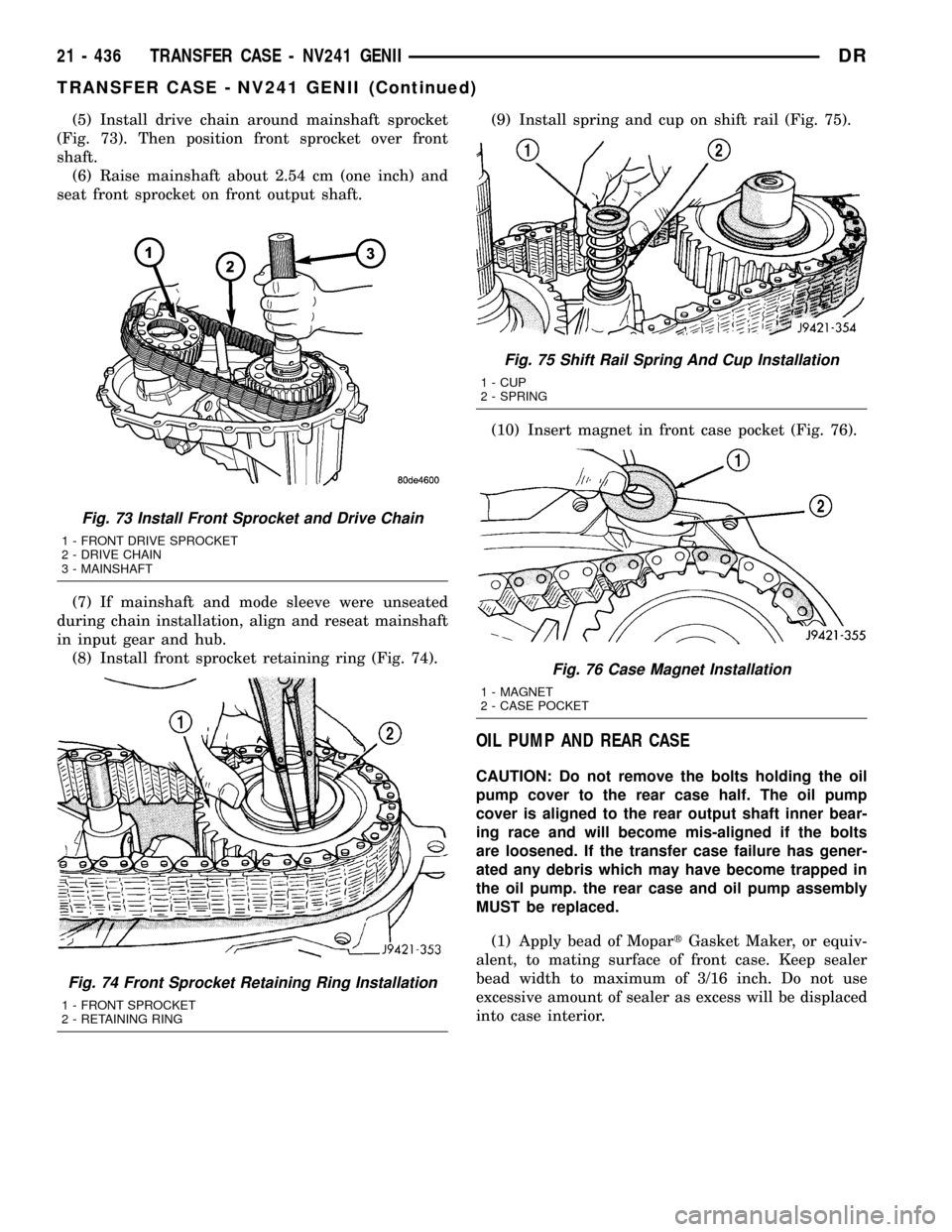

(5) Install drive chain around mainshaft sprocket

(Fig. 73). Then position front sprocket over front

shaft.

(6) Raise mainshaft about 2.54 cm (one inch) and

seat front sprocket on front output shaft.

(7) If mainshaft and mode sleeve were unseated

during chain installation, align and reseat mainshaft

in input gear and hub.

(8) Install front sprocket retaining ring (Fig. 74).(9) Install spring and cup on shift rail (Fig. 75).

(10) Insert magnet in front case pocket (Fig. 76).

OIL PUMP AND REAR CASE

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(1) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

Fig. 73 Install Front Sprocket and Drive Chain

1 - FRONT DRIVE SPROCKET

2 - DRIVE CHAIN

3 - MAINSHAFT

Fig. 74 Front Sprocket Retaining Ring Installation

1 - FRONT SPROCKET

2 - RETAINING RING

Fig. 75 Shift Rail Spring And Cup Installation

1 - CUP

2 - SPRING

Fig. 76 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

21 - 436 TRANSFER CASE - NV241 GENIIDR

TRANSFER CASE - NV241 GENII (Continued)

Page 2140 of 2627

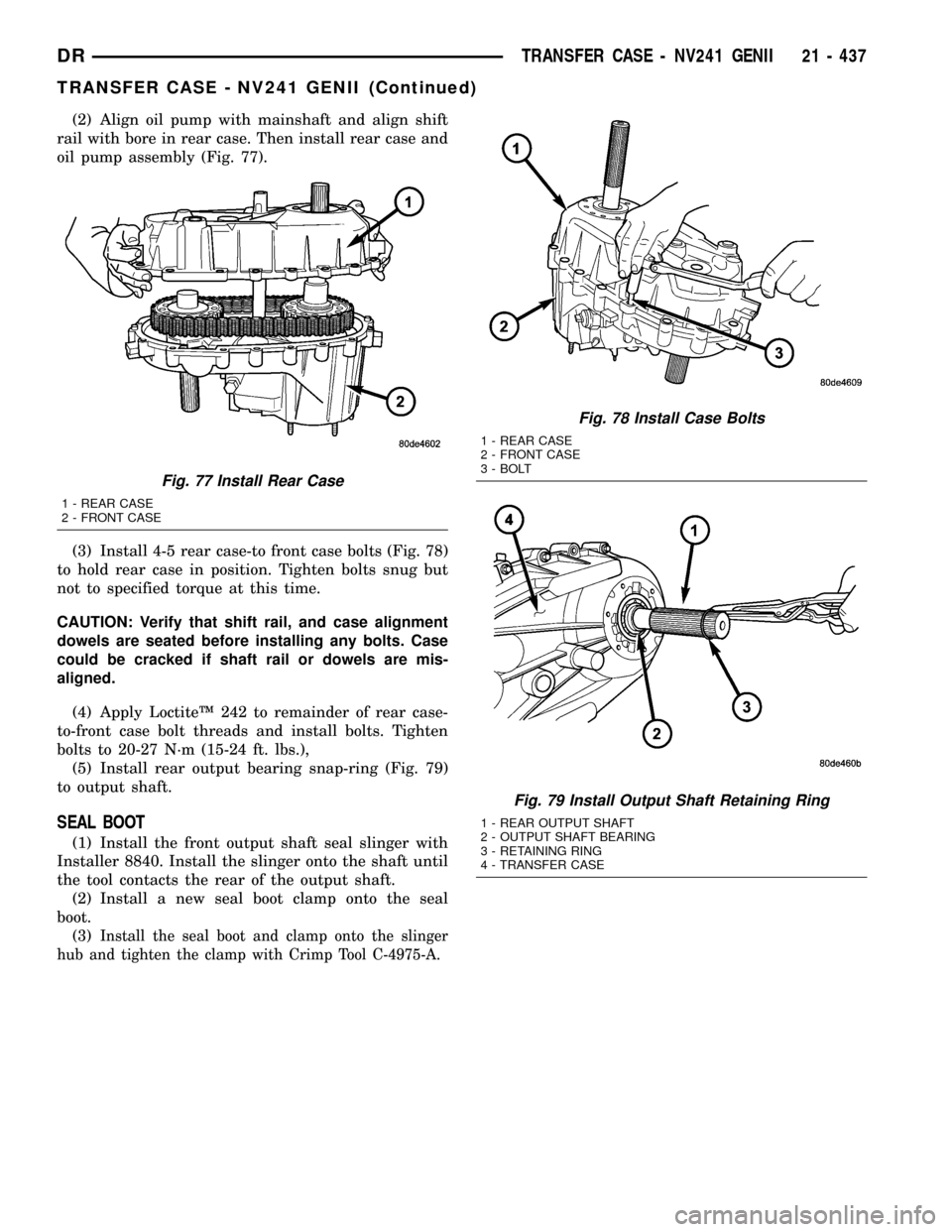

(2) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 77).

(3) Install 4-5 rear case-to front case bolts (Fig. 78)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.

(4) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Tighten

bolts to 20-27 N´m (15-24 ft. lbs.),

(5) Install rear output bearing snap-ring (Fig. 79)

to output shaft.

SEAL BOOT

(1) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(2) Install a new seal boot clamp onto the seal

boot.

(3)

Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool C-4975-A.

Fig. 77 Install Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 78 Install Case Bolts

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

Fig. 79 Install Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - OUTPUT SHAFT BEARING

3 - RETAINING RING

4 - TRANSFER CASE

DRTRANSFER CASE - NV241 GENII 21 - 437

TRANSFER CASE - NV241 GENII (Continued)

Page 2145 of 2627

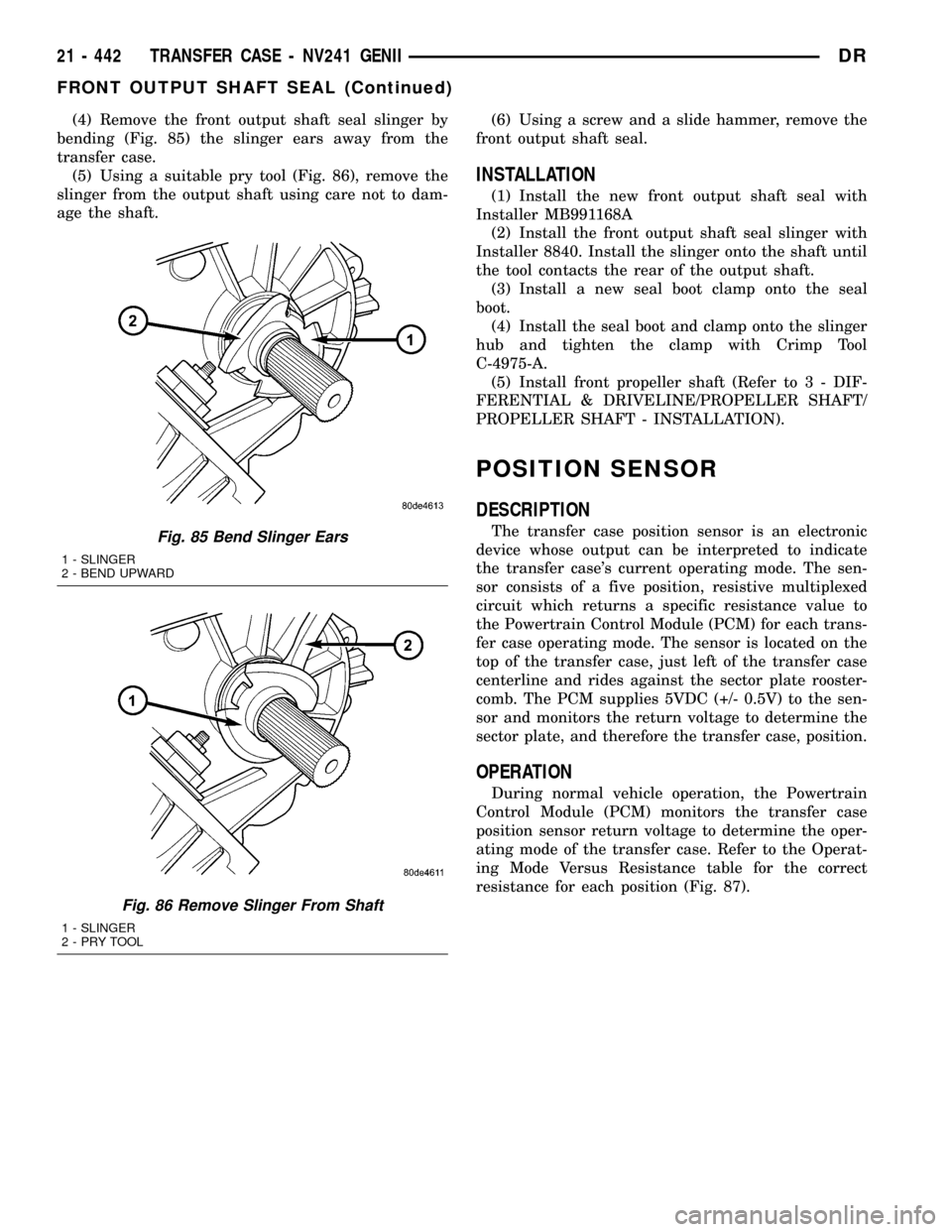

(4) Remove the front output shaft seal slinger by

bending (Fig. 85) the slinger ears away from the

transfer case.

(5) Using a suitable pry tool (Fig. 86), remove the

slinger from the output shaft using care not to dam-

age the shaft.(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A

(2) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(3) Install a new seal boot clamp onto the seal

boot.

(4) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

(5) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

POSITION SENSOR

DESCRIPTION

The transfer case position sensor is an electronic

device whose output can be interpreted to indicate

the transfer case's current operating mode. The sen-

sor consists of a five position, resistive multiplexed

circuit which returns a specific resistance value to

the Powertrain Control Module (PCM) for each trans-

fer case operating mode. The sensor is located on the

top of the transfer case, just left of the transfer case

centerline and rides against the sector plate rooster-

comb. The PCM supplies 5VDC (+/- 0.5V) to the sen-

sor and monitors the return voltage to determine the

sector plate, and therefore the transfer case, position.

OPERATION

During normal vehicle operation, the Powertrain

Control Module (PCM) monitors the transfer case

position sensor return voltage to determine the oper-

ating mode of the transfer case. Refer to the Operat-

ing Mode Versus Resistance table for the correct

resistance for each position (Fig. 87).

Fig. 85 Bend Slinger Ears

1 - SLINGER

2 - BEND UPWARD

Fig. 86 Remove Slinger From Shaft

1 - SLINGER

2-PRYTOOL

21 - 442 TRANSFER CASE - NV241 GENIIDR

FRONT OUTPUT SHAFT SEAL (Continued)

Page 2151 of 2627

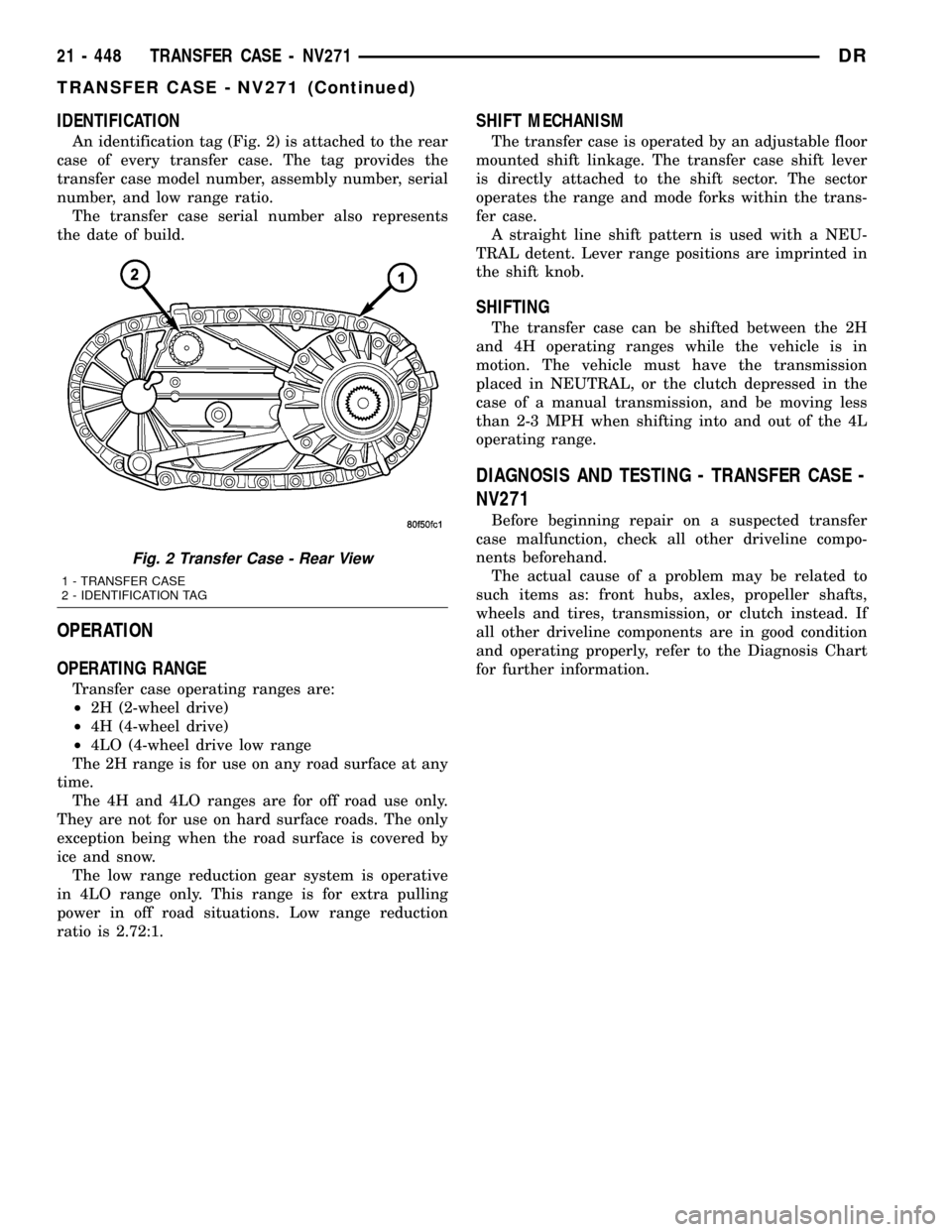

IDENTIFICATION

An identification tag (Fig. 2) is attached to the rear

case of every transfer case. The tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

OPERATING RANGE

Transfer case operating ranges are:

²2H (2-wheel drive)

²4H (4-wheel drive)

²4LO (4-wheel drive low range

The 2H range is for use on any road surface at any

time.

The 4H and 4LO ranges are for off road use only.

They are not for use on hard surface roads. The only

exception being when the road surface is covered by

ice and snow.

The low range reduction gear system is operative

in 4LO range only. This range is for extra pulling

power in off road situations. Low range reduction

ratio is 2.72:1.

SHIFT MECHANISM

The transfer case is operated by an adjustable floor

mounted shift linkage. The transfer case shift lever

is directly attached to the shift sector. The sector

operates the range and mode forks within the trans-

fer case.

A straight line shift pattern is used with a NEU-

TRAL detent. Lever range positions are imprinted in

the shift knob.

SHIFTING

The transfer case can be shifted between the 2H

and 4H operating ranges while the vehicle is in

motion. The vehicle must have the transmission

placed in NEUTRAL, or the clutch depressed in the

case of a manual transmission, and be moving less

than 2-3 MPH when shifting into and out of the 4L

operating range.

DIAGNOSIS AND TESTING - TRANSFER CASE -

NV271

Before beginning repair on a suspected transfer

case malfunction, check all other driveline compo-

nents beforehand.

The actual cause of a problem may be related to

such items as: front hubs, axles, propeller shafts,

wheels and tires, transmission, or clutch instead. If

all other driveline components are in good condition

and operating properly, refer to the Diagnosis Chart

for further information.

Fig. 2 Transfer Case - Rear View

1 - TRANSFER CASE

2 - IDENTIFICATION TAG

21 - 448 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2159 of 2627

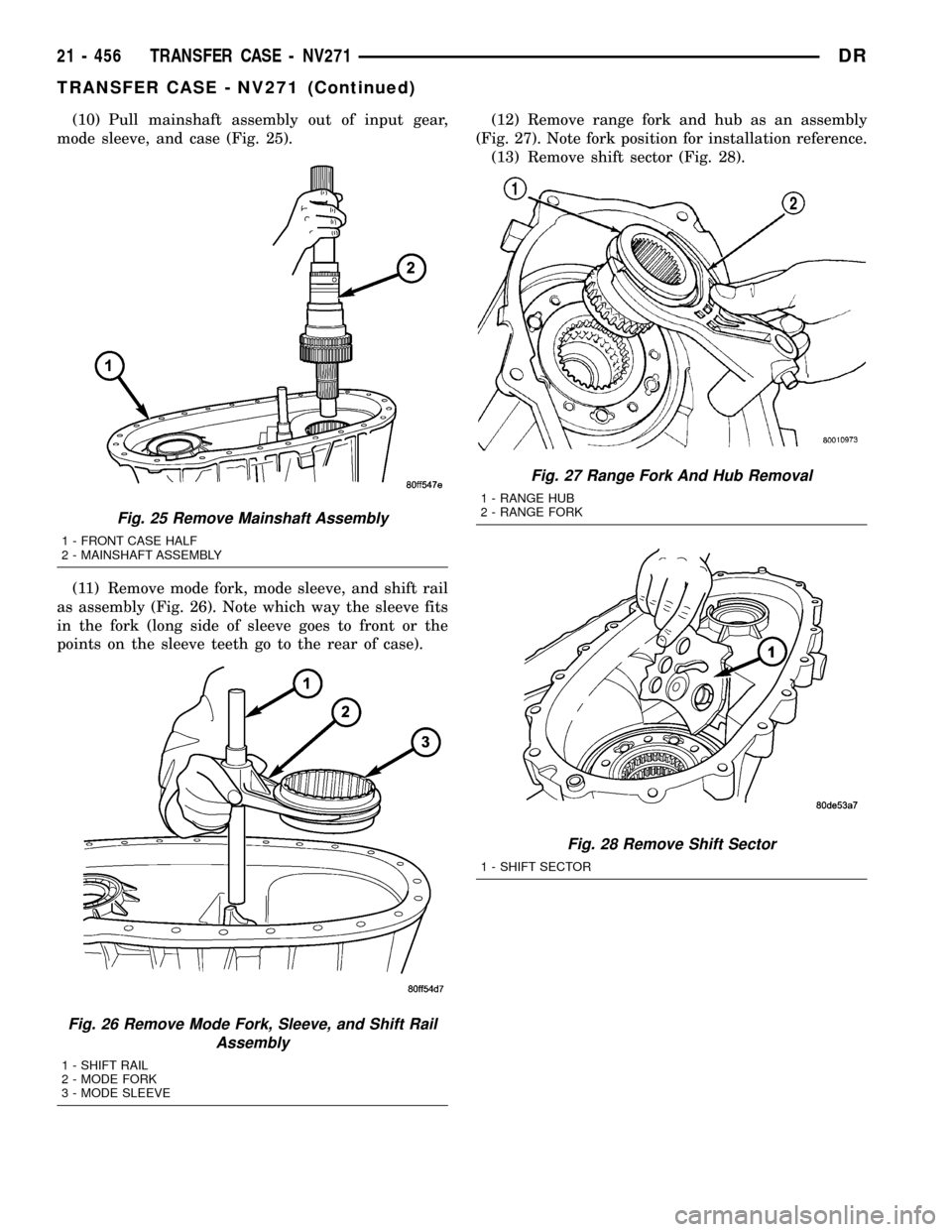

(10) Pull mainshaft assembly out of input gear,

mode sleeve, and case (Fig. 25).

(11) Remove mode fork, mode sleeve, and shift rail

as assembly (Fig. 26). Note which way the sleeve fits

in the fork (long side of sleeve goes to front or the

points on the sleeve teeth go to the rear of case).(12) Remove range fork and hub as an assembly

(Fig. 27). Note fork position for installation reference.

(13) Remove shift sector (Fig. 28).

Fig. 25 Remove Mainshaft Assembly

1 - FRONT CASE HALF

2 - MAINSHAFT ASSEMBLY

Fig. 26 Remove Mode Fork, Sleeve, and Shift Rail

Assembly

1 - SHIFT RAIL

2 - MODE FORK

3 - MODE SLEEVE

Fig. 27 Range Fork And Hub Removal

1 - RANGE HUB

2 - RANGE FORK

Fig. 28 Remove Shift Sector

1 - SHIFT SECTOR

21 - 456 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2162 of 2627

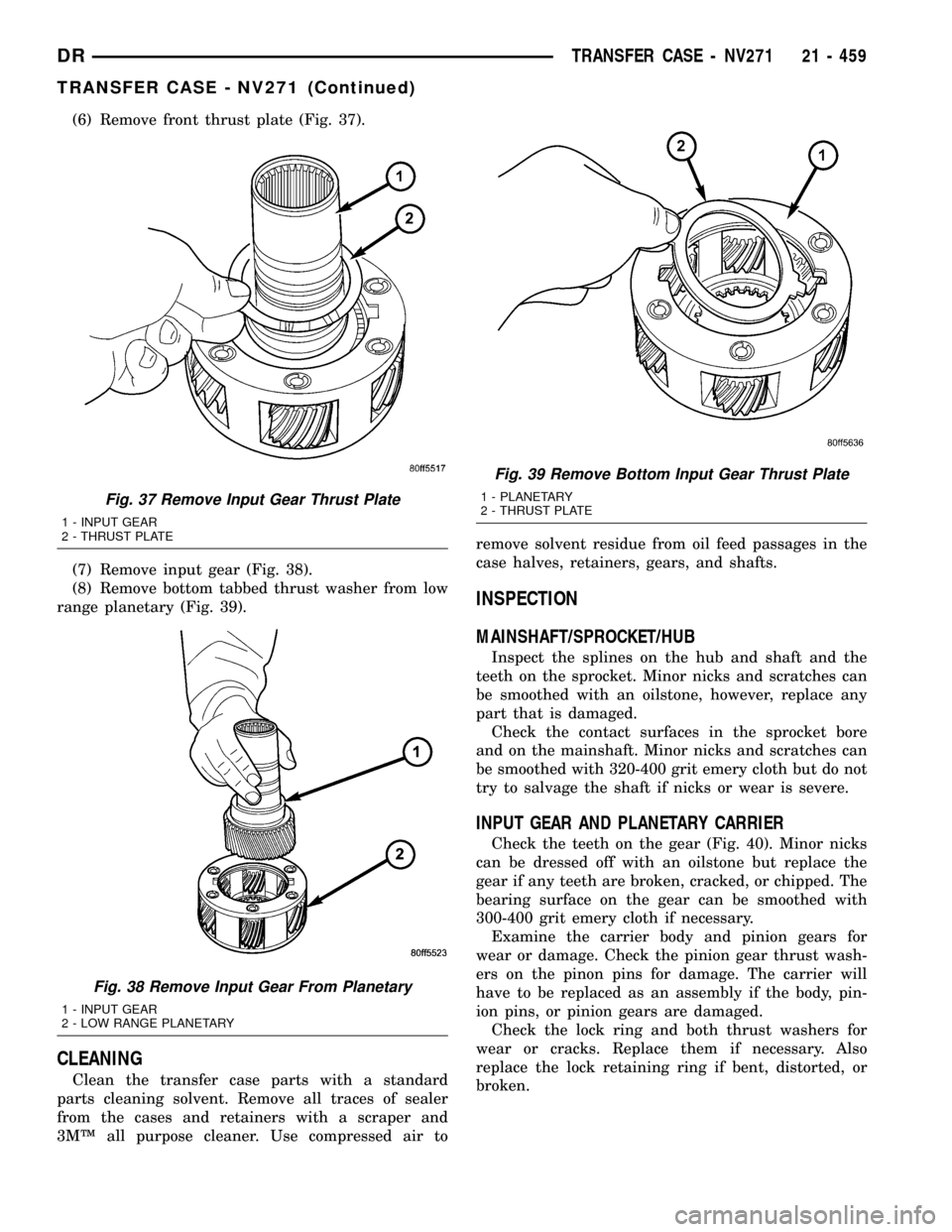

(6) Remove front thrust plate (Fig. 37).

(7) Remove input gear (Fig. 38).

(8) Remove bottom tabbed thrust washer from low

range planetary (Fig. 39).

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and

3MŸ all purpose cleaner. Use compressed air toremove solvent residue from oil feed passages in the

case halves, retainers, gears, and shafts.

INSPECTION

MAINSHAFT/SPROCKET/HUB

Inspect the splines on the hub and shaft and the

teeth on the sprocket. Minor nicks and scratches can

be smoothed with an oilstone, however, replace any

part that is damaged.

Check the contact surfaces in the sprocket bore

and on the mainshaft. Minor nicks and scratches can

be smoothed with 320-400 grit emery cloth but do not

try to salvage the shaft if nicks or wear is severe.

INPUT GEAR AND PLANETARY CARRIER

Check the teeth on the gear (Fig. 40). Minor nicks

can be dressed off with an oilstone but replace the

gear if any teeth are broken, cracked, or chipped. The

bearing surface on the gear can be smoothed with

300-400 grit emery cloth if necessary.

Examine the carrier body and pinion gears for

wear or damage. Check the pinion gear thrust wash-

ers on the pinon pins for damage. The carrier will

have to be replaced as an assembly if the body, pin-

ion pins, or pinion gears are damaged.

Check the lock ring and both thrust washers for

wear or cracks. Replace them if necessary. Also

replace the lock retaining ring if bent, distorted, or

broken.

Fig. 37 Remove Input Gear Thrust Plate

1 - INPUT GEAR

2 - THRUST PLATE

Fig. 38 Remove Input Gear From Planetary

1 - INPUT GEAR

2 - LOW RANGE PLANETARY

Fig. 39 Remove Bottom Input Gear Thrust Plate

1 - PLANETARY

2 - THRUST PLATE

DRTRANSFER CASE - NV271 21 - 459

TRANSFER CASE - NV271 (Continued)

Page 2163 of 2627

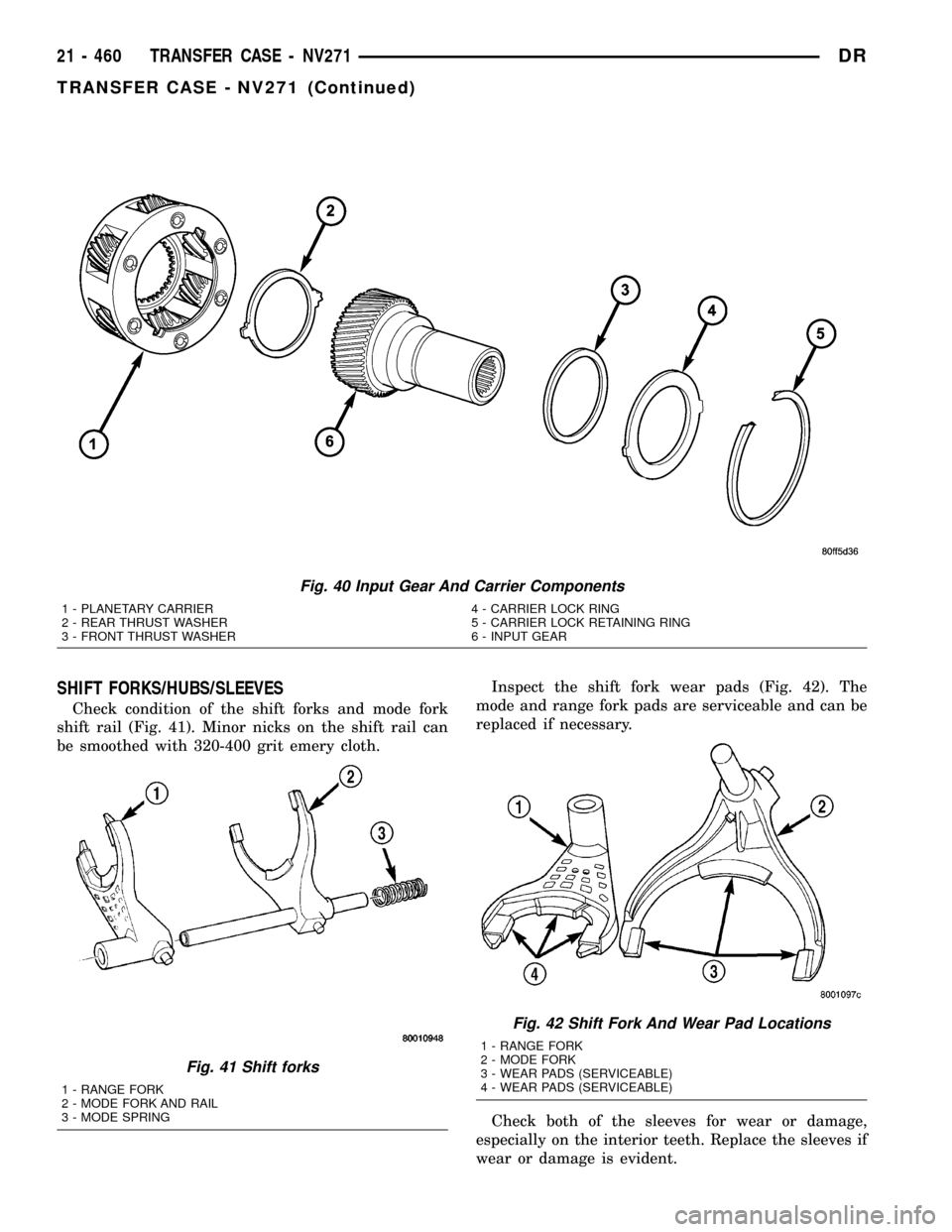

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail (Fig. 41). Minor nicks on the shift rail can

be smoothed with 320-400 grit emery cloth.Inspect the shift fork wear pads (Fig. 42). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

Fig. 40 Input Gear And Carrier Components

1 - PLANETARY CARRIER 4 - CARRIER LOCK RING

2 - REAR THRUST WASHER 5 - CARRIER LOCK RETAINING RING

3 - FRONT THRUST WASHER 6 - INPUT GEAR

Fig. 41 Shift forks

1 - RANGE FORK

2 - MODE FORK AND RAIL

3 - MODE SPRING

Fig. 42 Shift Fork And Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

21 - 460 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2169 of 2627

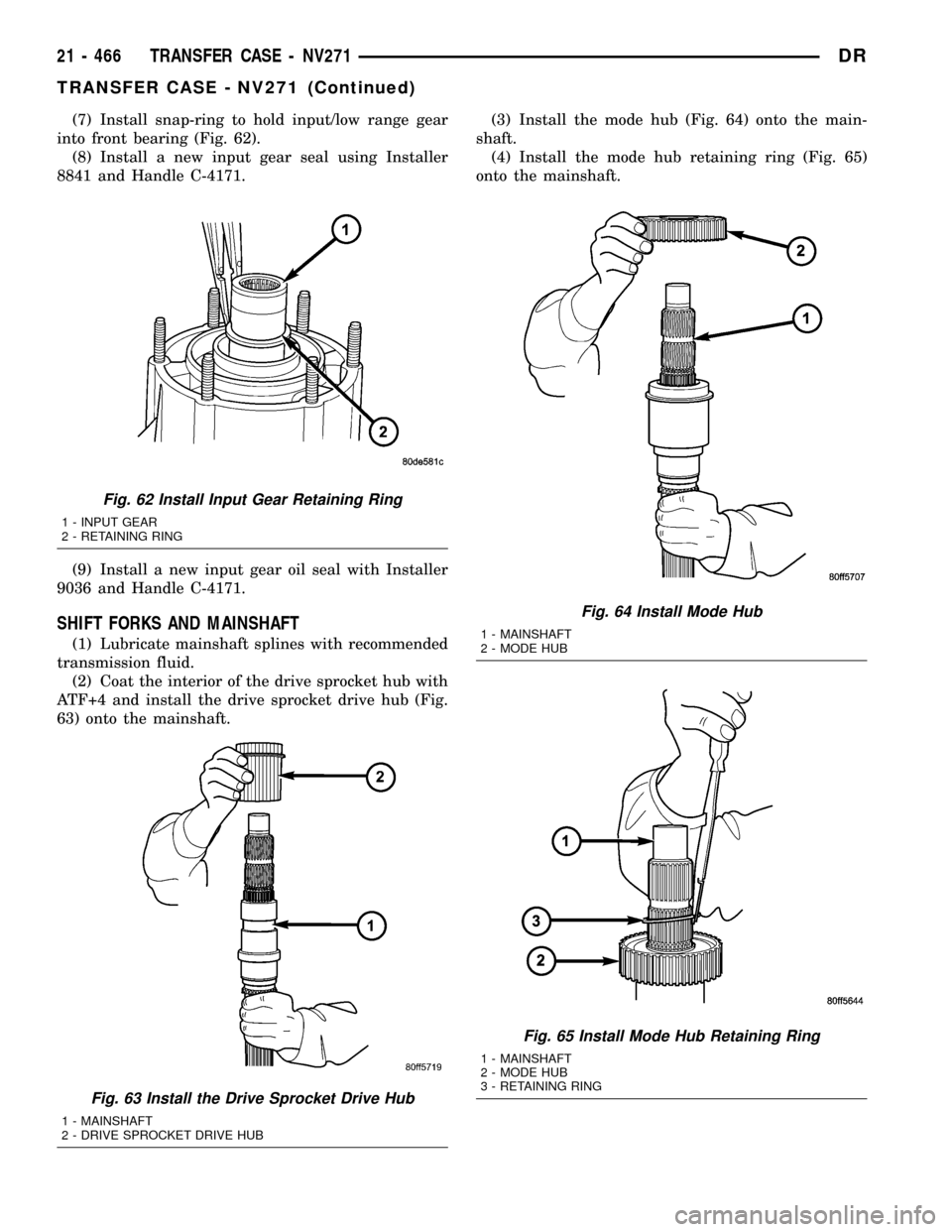

(7) Install snap-ring to hold input/low range gear

into front bearing (Fig. 62).

(8) Install a new input gear seal using Installer

8841 and Handle C-4171.

(9) Install a new input gear oil seal with Installer

9036 and Handle C-4171.

SHIFT FORKS AND MAINSHAFT

(1) Lubricate mainshaft splines with recommended

transmission fluid.

(2) Coat the interior of the drive sprocket hub with

ATF+4 and install the drive sprocket drive hub (Fig.

63) onto the mainshaft.(3) Install the mode hub (Fig. 64) onto the main-

shaft.

(4) Install the mode hub retaining ring (Fig. 65)

onto the mainshaft.

Fig. 62 Install Input Gear Retaining Ring

1 - INPUT GEAR

2 - RETAINING RING

Fig. 63 Install the Drive Sprocket Drive Hub

1 - MAINSHAFT

2 - DRIVE SPROCKET DRIVE HUB

Fig. 64 Install Mode Hub

1 - MAINSHAFT

2 - MODE HUB

Fig. 65 Install Mode Hub Retaining Ring

1 - MAINSHAFT

2 - MODE HUB

3 - RETAINING RING

21 - 466 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2170 of 2627

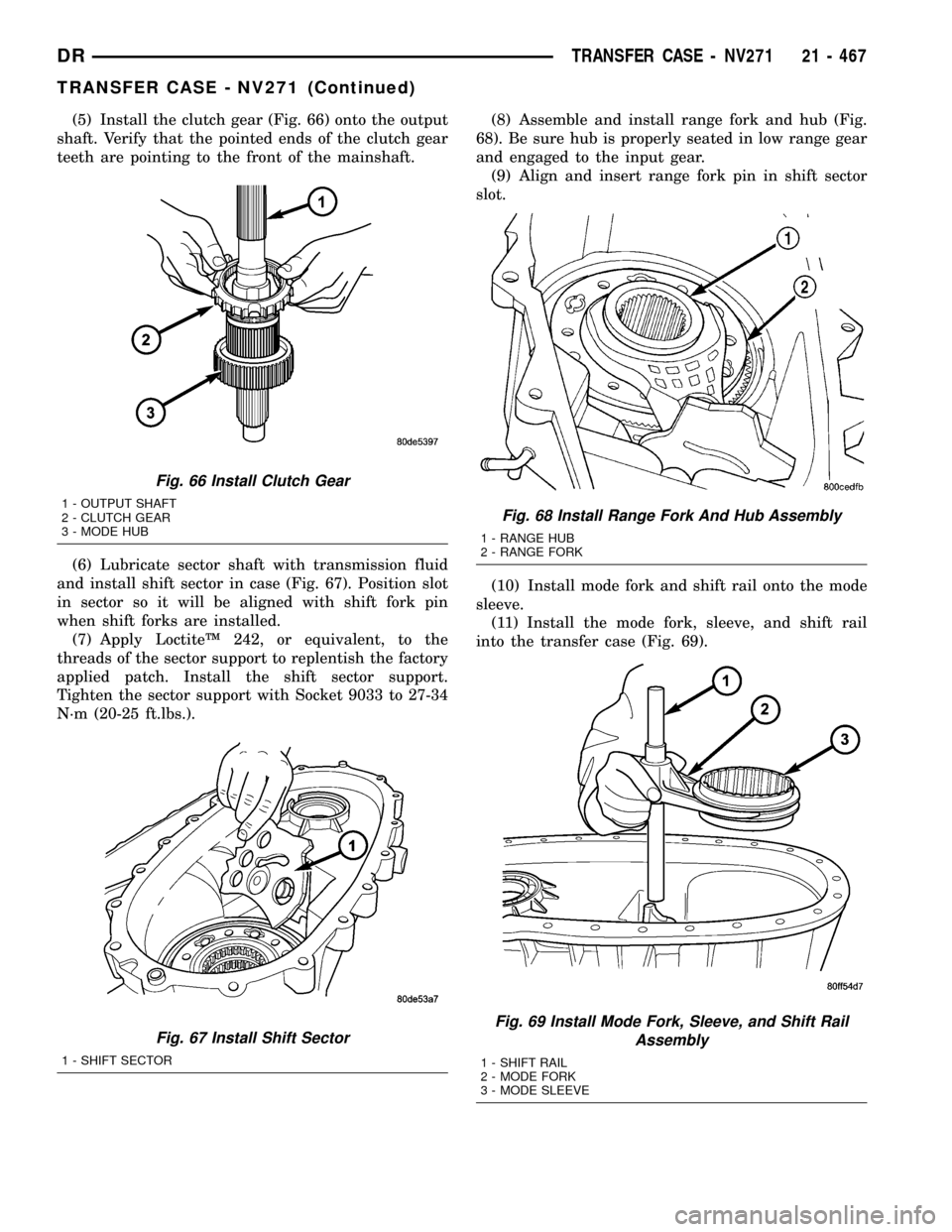

(5) Install the clutch gear (Fig. 66) onto the output

shaft. Verify that the pointed ends of the clutch gear

teeth are pointing to the front of the mainshaft.

(6) Lubricate sector shaft with transmission fluid

and install shift sector in case (Fig. 67). Position slot

in sector so it will be aligned with shift fork pin

when shift forks are installed.

(7) Apply LoctiteŸ 242, or equivalent, to the

threads of the sector support to replentish the factory

applied patch. Install the shift sector support.

Tighten the sector support with Socket 9033 to 27-34

N´m (20-25 ft.lbs.).(8) Assemble and install range fork and hub (Fig.

68). Be sure hub is properly seated in low range gear

and engaged to the input gear.

(9) Align and insert range fork pin in shift sector

slot.

(10) Install mode fork and shift rail onto the mode

sleeve.

(11) Install the mode fork, sleeve, and shift rail

into the transfer case (Fig. 69).

Fig. 66 Install Clutch Gear

1 - OUTPUT SHAFT

2 - CLUTCH GEAR

3 - MODE HUB

Fig. 67 Install Shift Sector

1 - SHIFT SECTOR

Fig. 68 Install Range Fork And Hub Assembly

1 - RANGE HUB

2 - RANGE FORK

Fig. 69 Install Mode Fork, Sleeve, and Shift Rail

Assembly

1 - SHIFT RAIL

2 - MODE FORK

3 - MODE SLEEVE

DRTRANSFER CASE - NV271 21 - 467

TRANSFER CASE - NV271 (Continued)