Tie DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2532 of 2627

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING TUBING

AND FITTINGS

CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

A good rule for the flexible hose lines is to keep the

radius of all bends at least 10 times the diameter of

the hose. Sharper bends will reduce the flow of

refrigerant. The flexible hose lines should be routed

so they are at least 3 inches (80 mm) from the

exhaust manifold. Inspect all flexible hose lines to

make sure they are in good condition and properly

routed.

The use of correct wrenches when making connec-

tions is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain sta-

ble as long as moisture-free refrigerant and refrig-

erant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities. Before disconnecting a component,

clean the outside of the fittings thoroughly to pre-

vent contamination from entering the refrigerant

system.

When opening a refrigeration system, have every-

thing you will need to repair the system ready. This

will minimize the amount of time the system must

be opened. Cap or plug all lines and fittings as

soon as they are opened. This will help prevent the

entrance of dirt and moisture. All new lines and

components should be capped or sealed until they

are ready to be used. Before connecting a compo-

nent, clean the outside of the fittings thoroughly to

prevent contamination from entering the refrigerant

system.

All tools, including the refrigerant dispensing mani-

fold, the manifold gauge set, and test hoses should

be kept clean and dry.

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil willabsorb moisture readily out of the air. This moisture

will convert into acids within a closed system.

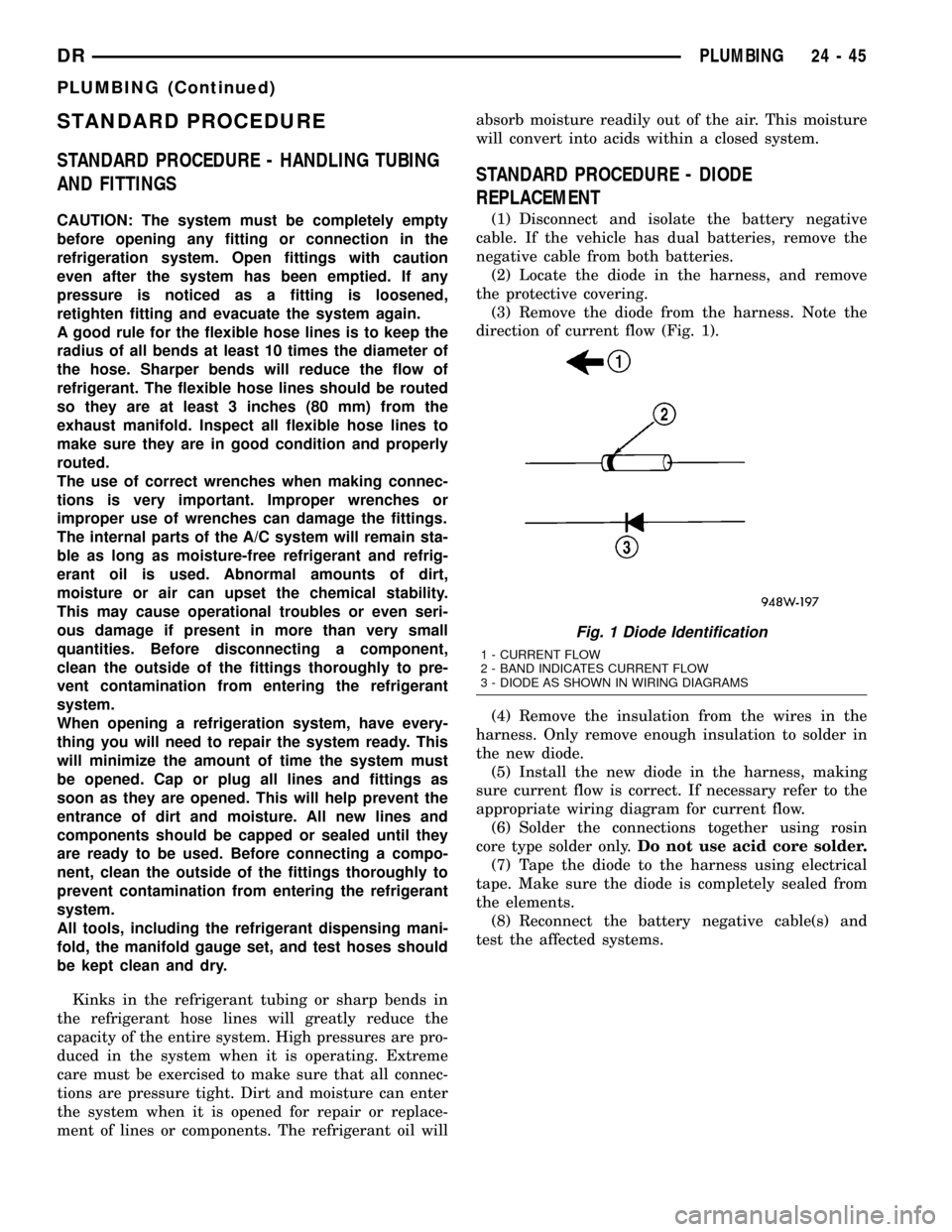

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect and isolate the battery negative

cable. If the vehicle has dual batteries, remove the

negative cable from both batteries.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness. Note the

direction of current flow (Fig. 1).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connections together using rosin

core type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape. Make sure the diode is completely sealed from

the elements.

(8) Reconnect the battery negative cable(s) and

test the affected systems.

Fig. 1 Diode Identification

1 - CURRENT FLOW

2 - BAND INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN WIRING DIAGRAMS

DRPLUMBING 24 - 45

PLUMBING (Continued)

Page 2535 of 2627

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports.

NOTE: Always refer to the underhood HVAC Speci-

fication label for the refrigerant fill level of the vehi-

cle being serviced.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transmission in park or manual

transmission in neutral

²Engine at idle

²A/C mode control set to outside air

²A/C mode control set to panel mode

²A/C temperature control set to full cool

²Blower motor control set on highest speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure (Refer to 8 - ELECTRICAL/WIRING DIAGRAM

INFORMATION - DIAGNOSIS AND TESTING).

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood HVAC

specfication tag.

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

The A/C system on models equipped with the 5.9L

engine use a Sanden SD-7 reciprocating swash plate-

type compressor. This compressor has a fixed dis-

placement of 165 cubic centimeter (10.068 cubic

inches) and has both the suction and discharge ports

located on the cylinder head.

The A/C system on models equipped with the 3.7L,

4.7L and 5.7L engines use a Denso 10S17 reciprocat-

ing swash plate-type compressor. This compressor

has a fixed displacement of 170 cubic centimeter and

has both the suction and discharge ports located on

the cylinder head.

A label identifying the use of R-134a refrigerant is

located on both A/C compressors.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is on the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

24 - 48 PLUMBINGDR

PLUMBING (Continued)

Page 2556 of 2627

designs. Useonlyrefrigerant oil of the same type as

recommended to service the refrigerant system

(always refer to the specification tagincluded

with the replacement A/C compressor or the under-

hood A/C system specification tag).

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

CAUTION: The refrigerant oil in the R-134a A/C sys-

tem is unique depending on the A/C compressor

used. Use only PAG oils that are designed to work

with R-134a refrigerant and the A/C compressor in

the vehicle. Always refer to the underhood A/C Sys-

tem Specification Label for the correct oil designa-

tion.

It is important to have the correct amount of lubri-

cant in the A/C refrigerant system to ensure proper

lubrication of the A/C compressor. Too little lubricant

will result in damage to the compressor. Too much

lubricant will reduce the cooling capacity of the A/C

system and consequently result in higher discharge

air temperatures.

The lubricant used in the compressor is polyalka-

lene glycol PAG lubricant. Only the refrigerant lubri-

cant approved for use with this vehicle should be

used to service the system. Do not use any other

lubricant. The lubricant container should be kept

tightly capped until it is ready for use. Refrigerant

lubricant will quickly absorb any moisture it comes

in contact with.

It will not be necessary to check the oil level in the

A/C compressor or to add oil, unless there has beenan oil loss. An oil loss may occur due to component

replacement, or a rupture or leak from a refrigerant

line, connector fitting, component or component seal.

If a leak occurs, add 30 milliliters (1 fluid ounce) of

the recommended refrigerant oil to the refrigerant

system after the repair has been made. Refrigerant

oil loss will be evident at the leak point by the pres-

ence of a wet, shiny surface around the leak.

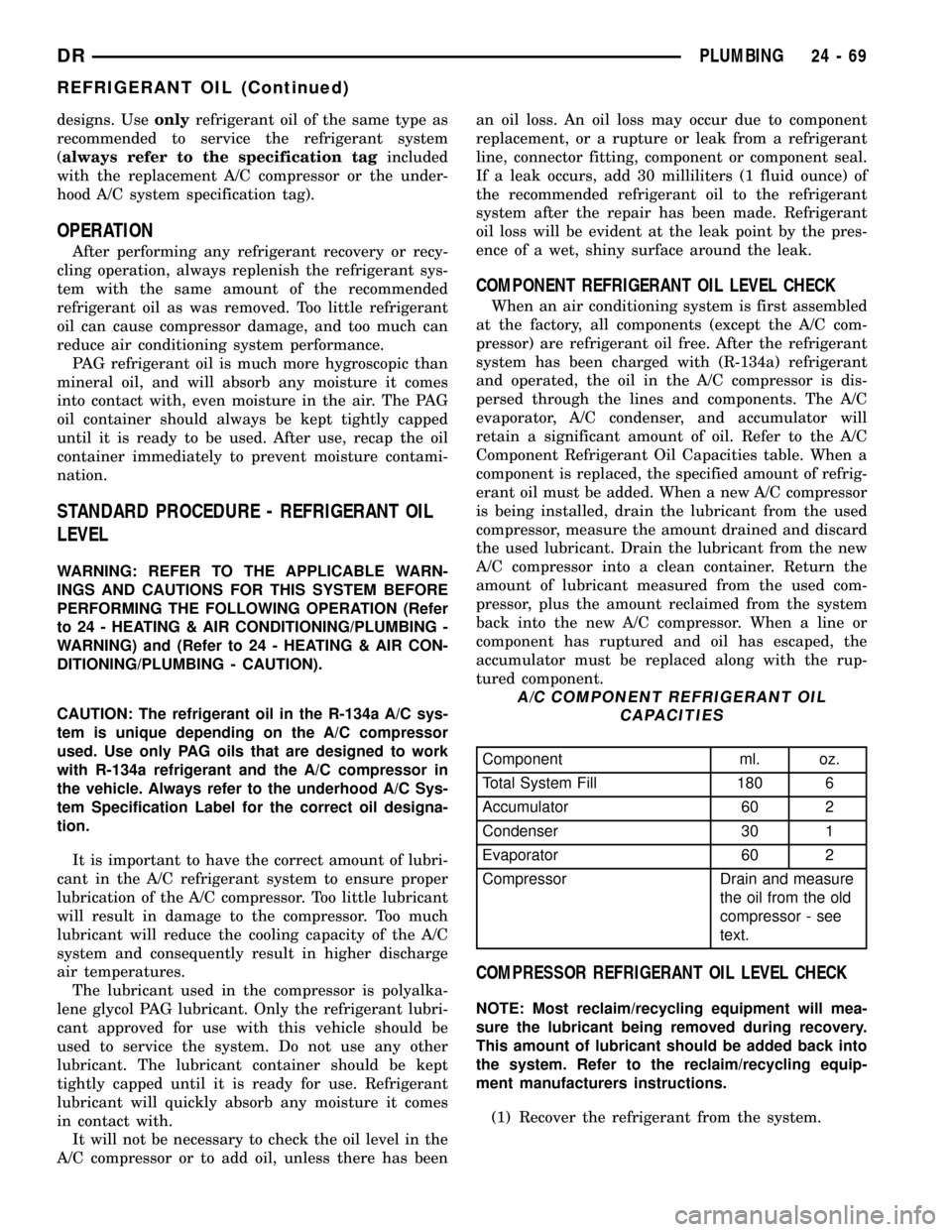

COMPONENT REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assembled

at the factory, all components (except the A/C com-

pressor) are refrigerant oil free. After the refrigerant

system has been charged with (R-134a) refrigerant

and operated, the oil in the A/C compressor is dis-

persed through the lines and components. The A/C

evaporator, A/C condenser, and accumulator will

retain a significant amount of oil. Refer to the A/C

Component Refrigerant Oil Capacities table. When a

component is replaced, the specified amount of refrig-

erant oil must be added. When a new A/C compressor

is being installed, drain the lubricant from the used

compressor, measure the amount drained and discard

the used lubricant. Drain the lubricant from the new

A/C compressor into a clean container. Return the

amount of lubricant measured from the used com-

pressor, plus the amount reclaimed from the system

back into the new A/C compressor. When a line or

component has ruptured and oil has escaped, the

accumulator must be replaced along with the rup-

tured component.

A/C COMPONENT REFRIGERANT OIL

CAPACITIES

Component ml. oz.

Total System Fill 180 6

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressor Drain and measure

the oil from the old

compressor - see

text.

COMPRESSOR REFRIGERANT OIL LEVEL CHECK

NOTE: Most reclaim/recycling equipment will mea-

sure the lubricant being removed during recovery.

This amount of lubricant should be added back into

the system. Refer to the reclaim/recycling equip-

ment manufacturers instructions.

(1) Recover the refrigerant from the system.

DRPLUMBING 24 - 69

REFRIGERANT OIL (Continued)

Page 2562 of 2627

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - STATE DISPLAY TEST

MODE...............................1

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE...............................1

DESCRIPTION - DIAGNOSTIC TROUBLE

CODES..............................1

DESCRIPTION - TASK MANAGER..........1DESCRIPTION - MONITORED SYSTEMS....2

DESCRIPTION - TRIP DEFINITION.........4

DESCRIPTION - COMPONENT MONITORS . . 4

OPERATION

OPERATION..........................5

OPERATION - TASK MANAGER...........5

OPERATION - NON-MONITORED CIRCUITS . . 8

EVAPORATIVE EMISSIONS................10

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connect

the DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Obtain the applicable Powertrain Diagnostic

Manual.

(2) Obtain the DRB Scan Tool.

(3) Connect the DRB Scan Tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(4) Turn the ignition switch on and access the

ªRead Faultº screen.

(5) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(6) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

DESCRIPTION - TASK MANAGER

The PCM is responsible for efficiently coordinating

the operation of all the emissions-related compo-

nents. The PCM is also responsible for determining if

the diagnostic systems are operating properly. The

software designed to carry out these responsibilities

is call the 'Task Manager'.

DREMISSIONS CONTROL 25 - 1

Page 2566 of 2627

OPERATION

OPERATION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

problem is repaired or ceases to exist, the PCM can-

cels the code after 40 warm-up cycles. Diagnostic

trouble codes that affect vehicle emissions illuminate

the Malfunction Indicator Lamp (MIL). The MIL is

displayed as an engine icon (graphic) on the instru-

ment panel. Refer to Malfunction Indicator Lamp in

this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example,assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

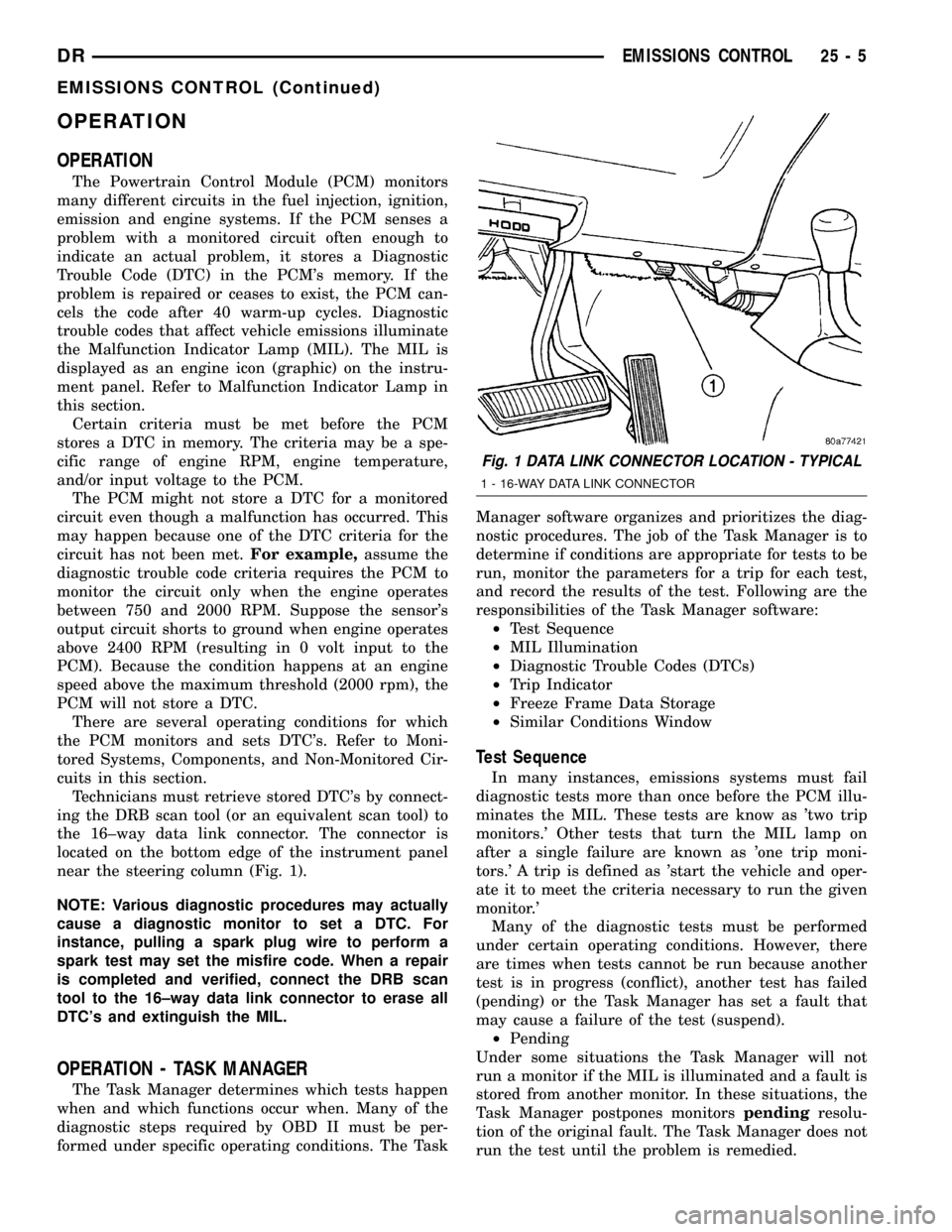

Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector. The connector is

located on the bottom edge of the instrument panel

near the steering column (Fig. 1).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL.

OPERATION - TASK MANAGER

The Task Manager determines which tests happen

when and which functions occur when. Many of the

diagnostic steps required by OBD II must be per-

formed under specific operating conditions. The TaskManager software organizes and prioritizes the diag-

nostic procedures. The job of the Task Manager is to

determine if conditions are appropriate for tests to be

run, monitor the parameters for a trip for each test,

and record the results of the test. Following are the

responsibilities of the Task Manager software:

²Test Sequence

²MIL Illumination

²Diagnostic Trouble Codes (DTCs)

²Trip Indicator

²Freeze Frame Data Storage

²Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail

diagnostic tests more than once before the PCM illu-

minates the MIL. These tests are know as 'two trip

monitors.' Other tests that turn the MIL lamp on

after a single failure are known as 'one trip moni-

tors.' A trip is defined as 'start the vehicle and oper-

ate it to meet the criteria necessary to run the given

monitor.'

Many of the diagnostic tests must be performed

under certain operating conditions. However, there

are times when tests cannot be run because another

test is in progress (conflict), another test has failed

(pending) or the Task Manager has set a fault that

may cause a failure of the test (suspend).

²Pending

Under some situations the Task Manager will not

run a monitor if the MIL is illuminated and a fault is

stored from another monitor. In these situations, the

Task Manager postpones monitorspendingresolu-

tion of the original fault. The Task Manager does not

run the test until the problem is remedied.

Fig. 1 DATA LINK CONNECTOR LOCATION - TYPICAL

1 - 16-WAY DATA LINK CONNECTOR

DREMISSIONS CONTROL 25 - 5

EMISSIONS CONTROL (Continued)

Page 2567 of 2627

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

25 - 6 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2591 of 2627

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR............24-19

BLOCK - INSPECTION, ENGINE . 9-128,9-205,9-39

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR...................24-19

BLOCK - INSTALLATION, BRAKE

JUNCTION...........................5-24

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR..........................24-18

BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR..........................24-19

BLOCK - REMOVAL, BRAKE JUNCTION....5-24

BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-37

BLOCK HEATER - 5.9L DIESEL -

INSTALLATION, ENGINE................7-38

BLOCK HEATER - 5.9L DIESEL -

OPERATION, ENGINE...................7-38

BLOCK HEATER - 5.9L DIESEL -

REMOVAL, ENGINE....................7-38

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-36

BLOCK HEATER - DIAGNOSIS AND

TESTING, ENGINE.....................7-36

BLOCK HEATER - INSTALLATION,

ENGINE.............................7-37

BLOCK HEATER - OPERATION, ENGINE....7-36

BLOCK HEATER - REMOVAL, ENGINE......7-37

BLOCK REFACING - STANDARD

PROCEDURE, CYLINDER...............9-264

BLOWER MOTOR - DESCRIPTION.......24-28

BLOWER MOTOR - DIAGNOSIS AND

TESTING.............................24-28

BLOWER MOTOR - INSTALLATION.......24-31

BLOWER MOTOR - OPERATION.........24-28

BLOWER MOTOR - REMOVAL...........24-31

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION.......................24-18

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING.............24-19

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION.......................24-19

BLOWER MOTOR RESISTOR BLOCK -

OPERATION.........................24-18

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL..........................24-19

BLOWER MOTOR SWITCH -

DESCRIPTION.......................24-20

BLOWER MOTOR SWITCH - DIAGNOSIS

AND TESTING.......................24-20

BLOWER MOTOR SWITCH - OPERATION . . 24-20

BODY - ADJUSTMENTS, VALVE........21-310

BODY - ASSEMBLY, VALVE......21-299,21-414

BODY & CABLE - DESCRIPTION,

ANTENNA...........................8A-4

BODY & CABLE - INSTALLATION,

ANTENNA...........................8A-6

BODY & CABLE - OPERATION, ANTENNA . . . 8A-4

BODY & CABLE - REMOVAL, ANTENNA....8A-6

BODY - CLEANING, VALVE......21-298,21-412

BODY - DESCRIPTION, THROTTLE.......14-36

BODY - DESCRIPTION, VALVE....21-267,21-408

BODY - DISASSEMBLY, VALVE . . . 21-287,21-410

BODY - INSPECTION, VALVE.....21-298,21-413

BODY - INSTALLATION, THROTTLE.......14-37

BODY - INSTALLATION, VALVE . . . 21-309,21-414

BODY - OPERATION, THROTTLE.........14-36

BODY - OPERATION, VALVE.....21-272,21-408

BODY - REMOVAL, THROTTLE..........14-36

BODY - REMOVAL, VALVE.......21-286,21-410

BODY AND CABLE - DIAGNOSIS AND

TESTING, ANTENNA

...................8A-4

BODY CODE PLATE - DESCRIPTION

.....Intro.-3

BODY ISOLATORS - INSTALLATION

......23-37

BODY ISOLATORS - REMOVAL

..........23-36

BODY LUBRICATION - STANDARD

PROCEDURE

.........................23-3

BODY OPENING DIMENSIONS -

SPECIFICATIONS

.....................23-99

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC

.................23-3

BODY SIDE MOLDINGS - INSTALLATION

. . 23-36

BODY SIDE MOLDINGS - REMOVAL

......23-36

BODY, SPECIAL TOOLS

................23-14

BODY VENT - INSTALLATION

...........23-71

BODY VENT - REMOVAL

...............23-71

BOOST PRESSURE - DIAGNOSIS AND

TESTING, TURBOCHARGER

.............11-11BOOSTER - DESCRIPTION, POWER

BRAKE..............................5-29

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-30

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-25

BOOSTER - INSTALLATION, HYDRO-

BOOST BRAKE........................5-32

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-29

BOOSTER - OPERATION, POWER BRAKE . . . 5-29

BOOSTER - REMOVAL, HYDRO-BOOST

BRAKE..............................5-31

BOOSTER - REMOVAL, POWER BRAKE....5-29

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-62

BOOT - INSTALLATION, EXTENSION

HOUSING SEAL AND DUST......21-476,21-571

BOOT - REMOVAL, 4WD FLOOR SHIFT....23-62

BOOT - REMOVAL, EXTENSION HOUSING

SEAL AND DUST..............21-476,21-571

BORE - DE-GLAZE - STANDARD

PROCEDURE, CYLINDER...............9-264

BORE HONING - STANDARD

PROCEDURE, CYLINDER...........9-128,9-38

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-267

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-265

BOX - INSTALLATION, CARGO..........23-37

BOX - INSTALLATION, GLOVE...........23-52

BOX - INSTALLATION, WITH CARGO . 8L-22,8L-23,

8L-24,8L-7,8L-9

BOX - INSTALLATION, WITHOUT CARGO . . 8L-22,

8L-23,8L-24,8L-8,8L-9

BOX - REMOVAL, CARGO..............23-37

BOX - REMOVAL, GLOVE..............23-52

BOX - REMOVAL, WITH CARGO....8L-22,8L-24,

8L-7,8L-9

BOX - REMOVAL, WITHOUT CARGO.....8L-22,

8L-23,8L-24,8L-7,8L-9

BOX - TIE DOWN - INSTALLATION,

CARGO............................23-38

BOX - TIE DOWN - REMOVAL, CARGO....23-38

BOX LAMP/SWITCH - INSTALLATION,

GLOVE.............................8L-28

BOX LAMP/SWITCH - REMOVAL, GLOVE . . 8L-27

BOX LATCH - INSTALLATION, GLOVE.....23-52

BOX LATCH - REMOVAL, GLOVE.........23-52

B-PILLAR GRAB HANDLE -

INSTALLATION.......................23-68

B-PILLAR GRAB HANDLE - REMOVAL....23-68

B-PILLAR LOWER TRIM - INSTALLATION . . 23-64

B-PILLAR LOWER TRIM - REMOVAL.....23-63

B-PILLAR UPPER TRIM - INSTALLATION . . 23-64

B-PILLAR UPPER TRIM - REMOVAL......23-64

BRACKET - INSTALLATION, REAR VIEW

MIRROR SUPPORT...................23-70

BRACKET - INSTALLATION, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKET - REMOVAL, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKETS - INSTALLATION, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRACKETS - REMOVAL, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRAKE - CLEANING, REAR DRUM IN

HAT ................................5-39

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - DESCRIPTION, PARKING........5-36

BRAKE - INSPECTION, REAR DRUM IN

HAT ................................5-39

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, PARKING..........5-36

BRAKE - REMOVAL, CONTROLLER

ANTILOCK

...........................8E-3

BRAKE BLEEDING - STANDARD

PROCEDURE, ABS

.....................5-46

BRAKE BOOSTER - DESCRIPTION,

POWER

.............................5-29

BRAKE BOOSTER - INSTALLATION,

HYDRO-BOOST

.......................5-32

BRAKE BOOSTER - INSTALLATION,

POWER

.............................5-29BRAKE BOOSTER - OPERATION, POWER . . . 5-29

BRAKE BOOSTER - REMOVAL,

HYDRO-BOOST.......................5-31

BRAKE BOOSTER - REMOVAL, POWER....5-29

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-38

BRAKE CABLE - INSTALLATION, REAR

PARK...............................5-38

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-36

BRAKE CABLE - REMOVAL, REAR PARK . . . 5-37

BRAKE CALIPER ADAPTER MOUNT -

INSTALLATION, DISC...................5-22

BRAKE CALIPERS - DESCRIPTION, DISC . . . 5-16

BRAKE CALIPERS - OPERATION, DISC.....5-16

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-23

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-23

BRAKE FLUID, SPECIFICATIONS..........5-23

BRAKE HOSE - INSTALLATION, FRONT.....5-13

BRAKE HOSE - INSTALLATION, REAR......5-12

BRAKE HOSE - REMOVAL, REAR.........5-11

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-19

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-20

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-19

BRAKE JUNCTION BLOCK -

INSTALLATION.........................5-24

BRAKE JUNCTION BLOCK - REMOVAL.....5-24

BRAKE LAMP SWITCH - DESCRIPTION....8L-9

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-10

BRAKE LAMP SWITCH - INSTALLATION . . . 8L-11

BRAKE LAMP SWITCH - OPERATION......8L-9

BRAKE LAMP SWITCH - REMOVAL......8L-10

BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC VARIABLE....5-49

BRAKE PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE................5-49

BRAKE ROTOR, DIAGNOSIS AND

TESTING - DISC......................5-32

BRAKE SHOES - ADJUSTMENT, PARKING . . 5-41

BRAKE, SPECIFICATIONS - BASE.........5-10

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-2

BRAKE TRANSMISSION SHIFT

INTERLOCK - ADJUSTMENTS....21-196,21-365

BRAKE TRANSMISSION SHIFT

INTERLOCK - DIAGNOSIS AND

TESTING....................21-196,21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DESCRIPTION . . . 21-196,

21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - OPERATION.....21-196,

21-364

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION.......................8J-19

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-19

BRAKES - ABS - DESCRIPTION...........5-45

BRAKES - ABS - OPERATION............5-45

BRAKES, SPECIAL TOOLS - BASE.........5-5

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH............24-10

BREATHER - INSTALLATION,

CRANKCASE

........................9-243

BREATHER - REMOVAL, CRANKCASE

.....9-242

BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT BELT

................8O-38

BUCKLE - REMOVAL, FRONT OUTBOARD

SEAT BELT

.........................8O-37

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE

........................8F-10

BUMPER - INSTALLATION, FRONT

........13-2

BUMPER - INSTALLATION, JOUNCE

.......2-43

BUMPER - INSTALLATION, REAR

.........13-4

BUMPER - REMOVAL, FRONT

............13-2

BUMPER - REMOVAL, JOUNCE

...........2-43

BUMPER - REMOVAL, REAR

.............13-3

BUMPERS (3500) - INSTALLATION,

AUXILIARY SPRING

....................2-43

BUMPERS (3500) - REMOVAL,

AUXILIARY SPRING

....................2-43

4 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2592 of 2627

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF..........21-201,21-366

BUSHING - INSTALLATION.............19-19

BUSHING - INSTALLATION, TORSION

BAR CROSS MEMBER..................2-15

BUSHING - REMOVAL.................19-19

BUSHING - REMOVAL, TORSION BAR

CROSSMEMBER......................2-13

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING................21-440

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING................21-440

BUSHINGS - 2WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-15

BUSHINGS - 2WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - 4WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-14

BUSHINGS - 4WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-13

BUSHINGS - INSTALLATION.............2-43

BUSHINGS - REMOVAL.................2-43

BUZZ, SQUEAK & RATTLE - STANDARD

PROCEDURE........................23-11

BYPASS - DESCRIPTION, WATER PUMP . . . 7-59

BYPASS - OPERATION, WATER PUMP.....7-60

C205F - ADJUSTMENTS, FRONT AXLE.....3-32

C205F - DIAGNOSIS AND TESTING,

FRONT AXLE.........................3-27

C205F - INSTALLATION, FRONT AXLE.....3-31

C205F - REMOVAL, FRONT AXLE...........3-31

C205F - SPECIAL TOOLS, FRONT AXLE....3-40

C205F - SPECIFICATIONS, FRONT AXLE....3-39

CAB - INSTALLATION, QUAD......8O-36,8O-61

CAB - INSTALLATION, STANDARD . . 8O-35,8O-61

CAB - REMOVAL, QUAD..........8O-33,8O-60

CAB - REMOVAL, STANDARD......8O-32,8O-59

CAB BACK PANEL TRIM -

INSTALLATION, REAR.................23-69

CAB BACK PANEL TRIM - REMOVAL,

REAR..............................23-68

CAB CLEARANCE LAMP - INSTALLATION . . 8L-12

CAB CLEARANCE LAMP - REMOVAL.....8L-11

CABLE - ADJUSTMENTS, THROTTLE

VALVE ............................21-254

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, SPARK PLUG.....8I-21

CABLE - DESCRIPTION, THROTTLE

VALVE ............................21-253

CABLE - DIAGNOSIS AND TESTING,

ANTENNA BODY......................8A-4

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT..................21-210,21-368

CABLE - INSTALLATION................8P-5

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, CHECK.........23-15

CABLE - INSTALLATION, FRONT

PARKING BRAKE......................5-38

CABLE - INSTALLATION, GEARSHIFT....21-211,

21-370

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-7

CABLE - INSTALLATION, LEFT REAR......5-39

CABLE - INSTALLATION, REAR PARK

BRAKE..............................5-38

CABLE - INSTALLATION, RIGHT REAR.....5-38

CABLE - INSTALLATION, SPARK PLUG....8I-22

CABLE - INSTALLATION, THROTTLE

CONTROL.....................14-40,14-84

CABLE - OPERATION...................8P-4

CABLE - OPERATION, ANTENNA BODY

.....8A-4

CABLE - OPERATION, SPARK PLUG

.......8I-21

CABLE - REMOVAL

....................8P-4

CABLE - REMOVAL, ANTENNA BODY

......8A-6

CABLE - REMOVAL, CHECK

.............23-15

CABLE - REMOVAL, FRONT PARKING

BRAKE

..............................5-36

CABLE - REMOVAL, GEARSHIFT

. . 21-210,21-369

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA

...........................8A-7

CABLE - REMOVAL, LEFT REAR

..........5-38

CABLE - REMOVAL, REAR PARK BRAKE

. . . 5-37

CABLE - REMOVAL, RIGHT REAR

.........5-37

CABLE - REMOVAL, SPARK PLUG

........8I-22

CABLE - REMOVAL, THROTTLE

CONTROL

.....................14-38,14-83CABLE, ADJUSTMENTS - GEARSHIFT . . . 21-212,

21-370

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-4

CABLE ROUTING, 5.7L V-8 ENGINE -

FIRING ORDER........................8I-4

CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH RELEASE........23-47

CABLE/HANDLE ASSEMBLY - REMOVAL,

LATCH RELEASE.....................23-47

CABLES - DESCRIPTION, BATTERY.......8F-14

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-15

CABLES - INSTALLATION, BATTERY......8F-17

CABLES - OPERATION, BATTERY........8F-15

CABLES - REMOVAL, BATTERY..........8F-16

CALIBRATION - STANDARD PROCEDURE,

COMPASS...........................8M-3

CALIPER ADAPTER MOUNT -

INSTALLATION, DISC BRAKE............5-22

CALIPERS - DESCRIPTION, DISC BRAKE . . . 5-16

CALIPERS - OPERATION, DISC BRAKE.....5-16

CAM BORE REPAIR - STANDARD

PROCEDURE........................9-267

CAMBER AND CASTER ADJUSTMENT -

STANDARD PROCEDURE.................2-4

CAMBER, CASTER AND TOE

ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING CLUTCH....21-237

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING CLUTCH.....21-236

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING CLUTCH . . 21-236

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH...........................21-236

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING CLUTCH . . . 21-237

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING CLUTCH....21-236

CAMSHAFT - INSTALLATION.......9-206,9-271

CAMSHAFT - REMOVAL..........9-205,9-268

CAMSHAFT BEARINGS - INSTALLATION . . . 9-271

CAMSHAFT BEARINGS - REMOVAL......9-268

CAMSHAFT CORE HOLE PLUG -

INSTALLATION.......................9-206

CAMSHAFT CORE HOLE PLUG -

REMOVAL..........................9-205

CAMSHAFT POSITION SENSOR -

DESCRIPTION.......................14-71

CAMSHAFT POSITION SENSOR -

DESCRIPTION.........................8I-7

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................14-72

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................8I-10

CAMSHAFT POSITION SENSOR -

OPERATION.........................14-71

CAMSHAFT POSITION SENSOR -

OPERATION..........................8I-7

CAMSHAFT POSITION SENSOR -

REMOVAL..........................14-72

CAMSHAFT POSITION SENSOR -

REMOVAL............................8I-9

CAMSHAFT(S) - DESCRIPTION.......9-25,9-35

CAMSHAFT(S) - INSTALLATION......9-27,9-36

CAMSHAFT(S) - LEFT - DESCRIPTION....9-114

CAMSHAFT(S) - LEFT - INSTALLATION....9-116

CAMSHAFT(S) - LEFT - REMOVAL.......9-115

CAMSHAFT(S) - REMOVAL..........9-25,9-35

CAMSHAFT(S) - RIGHT - DESCRIPTION . . . 9-119

CAMSHAFT(S) - RIGHT - INSTALLATION . . 9-120

CAMSHAFT(S) - RIGHT - REMOVAL......9-119

CANISTER - DESCRIPTION, VAPOR......25-22

CANISTER - INSTALLATION, VAPOR......25-22

CANISTER - OPERATION, VAPOR........25-22

CANISTER - REMOVAL, VAPOR..........25-22

CAP - DESCRIPTION, FUEL FILLER.......25-13

CAP - DESCRIPTION, RADIATOR

PRESSURE

..........................7-57

CAP - DIAGNOSIS AND TESTING,

RADIATOR

...........................7-58

CAP - OPERATION, FUEL FILLER

........25-13

CAP - OPERATION, RADIATOR

PRESSURE

..........................7-58

CAPACITIES, SPECIFICATIONS - FLUID

......0-5CAPACITOR - DESCRIPTION, IGNITION

COIL...............................8I-21

CAPACITOR - INSTALLATION, IGNITION

COIL...............................8I-21

CAPACITOR - OPERATION, IGNITION

COIL...............................8I-21

CAPACITOR - REMOVAL, IGNITION COIL . . . 8I-21

CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING, RADIATOR.....7-58

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, DOUBLE...................3-17

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, DOUBLE................3-16

CARGO BOX - INSTALLATION...........23-37

CARGO BOX - INSTALLATION, WITH.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - INSTALLATION, WITHOUT . . 8L-22,

8L-23,8L-24,8L-8,8L-9

CARGO BOX - REMOVAL...............23-37

CARGO BOX - REMOVAL, WITH....8L-22,8L-24,

8L-7,8L-9

CARGO BOX - REMOVAL, WITHOUT.....8L-22,

8L-23,8L-24,8L-7,8L-9

CARGO BOX - TIE DOWN -

INSTALLATION.......................23-38

CARGO BOX - TIE DOWN - REMOVAL....23-38

CARGO LAMP INDICATOR -

DESCRIPTION.......................8J-20

CARGO LAMP INDICATOR - OPERATION . . 8J-20

CARPETS AND FLOOR MATS -

INSTALLATION.......................23-65

CARPETS AND FLOOR MATS - REMOVAL . . . 23-65

CASCADE OVERFLOW VALVE -

DESCRIPTION.......................14-66

CASCADE OVERFLOW VALVE -

OPERATION.........................14-66

CASE - DESCRIPTION, TRANSFER.........0-4

CASE - NV241 GENII - ASSEMBLY,

TRANSFER.........................21-428

CASE - NV241 GENII - CLEANING,

TRANSFER.........................21-426

CASE - NV241 GENII - DESCRIPTION,

TRANSFER.........................21-415

CASE - NV241 GENII - DIAGNOSIS AND

TESTING, TRANSFER.................21-416

CASE - NV241 GENII - DISASSEMBLY,

TRANSFER.........................21-417

CASE - NV241 GENII - INSPECTION,

TRANSFER.........................21-426

CASE - NV241 GENII - INSTALLATION,

TRANSFER.........................21-438

CASE - NV241 GENII - OPERATION,

TRANSFER.........................21-415

CASE - NV241 GENII - REMOVAL,

TRANSFER.........................21-417

CASE - NV243 - ASSEMBLY, TRANSFER . . 21-496

CASE - NV243 - CLEANING, TRANSFER . . 21-493

CASE - NV243 - DESCRIPTION,

TRANSFER.........................21-482

CASE - NV243 - DIAGNOSIS AND

TESTING, TRANSFER.................21-483

CASE - NV243 - DISASSEMBLY,

TRANSFER.........................21-484

CASE - NV243 - INSPECTION, TRANSFER . 21-493

CASE - NV243 - INSTALLATION,

TRANSFER.........................21-505

CASE - NV243 - OPERATION, TRANSFER . 21-483

CASE - NV243 - REMOVAL, TRANSFER . . 21-484

CASE - NV244 - DIAGNOSIS AND

TESTING, TRANSFER.................21-513

CASE - NV244 GENII - ASSEMBLY,

TRANSFER.........................21-525

CASE - NV244 GENII - CLEANING,

TRANSFER.........................21-523

CASE - NV244 GENII - DESCRIPTION,

TRANSFER.........................21-512

CASE - NV244 GENII - DISASSEMBLY,

TRANSFER.........................21-514

CASE - NV244 GENII - INSPECTION,

TRANSFER.........................21-523

CASE - NV244 GENII - INSTALLATION,

TRANSFER

.........................21-534

CASE - NV244 GENII - OPERATION,

TRANSFER

.........................21-513

CASE - NV244 GENII - REMOVAL,

TRANSFER

.........................21-514

CASE - NV271 - ASSEMBLY, TRANSFER

. . 21-461

CASE - NV271 - CLEANING, TRANSFER

. . 21-459

DRINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2598 of 2627

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT....................23-92

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, REAR.....................23-93

DOOR INNER BELT MOLDING -

INSTALLATION, FRONT................23-93

DOOR INNER BELT MOLDING -

INSTALLATION, REAR.................23-94

DOOR INNER BELT MOLDING -

REMOVAL, FRONT....................23-93

DOOR INNER BELT MOLDING -

REMOVAL, REAR.....................23-94

DOOR LOCK MOTOR - DESCRIPTION......8N-4

DOOR LOCK MOTOR - DIAGNOSIS AND

TESTING............................8N-4

DOOR LOCK MOTOR - OPERATION.......8N-4

DOOR MODULE - DESCRIPTION, DRIVER . . 8N-5

DOOR MODULE - DIAGNOSIS AND

TESTING, DRIVER.....................8N-6

DOOR MODULE - INSTALLATION,

DRIVER.............................8N-7

DOOR MODULE - OPERATION, DRIVER....8N-5

DOOR MODULE - REMOVAL, DRIVER.....8N-7

DOOR OPENING SEAL - INSTALLATION . . . 23-92

DOOR OPENING SEAL - REMOVAL.......23-92

DOOR OUTER BELT MOLDING -

INSTALLATION, FRONT................23-93

DOOR OUTER BELT MOLDING -

INSTALLATION, REAR.................23-94

DOOR OUTER BELT MOLDING -

REMOVAL, FRONT....................23-92

DOOR OUTER BELT MOLDING -

REMOVAL, REAR.....................23-93

DOOR SILL TRIM COVER -

INSTALLATION, REAR.................23-71

DOOR SILL TRIM COVER - REMOVAL,

REAR..............................23-71

DOUBLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY..........................3-17

DOUBLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY........................3-16

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE................5-10

DRAG LINK - INSTALLATION............19-36

DRAG LINK - REMOVAL...............19-36

DRAIN AND REFILL - STANDARD

PROCEDURE, FLUID.....21-441,21-476,21-507,

21-537,21-571

DRAIN CIRCUIT - OPERATION, FUEL.....14-67

DRAINBACK VALVE - DESCRIPTION,

TORQUE CONVERTER................21-261

DRAINBACK VALVE - OPERATION,

TORQUE CONVERTER................21-261

DRAINBACK VALVE - STANDARD

PROCEDURE, TORQUE CONVERTER.....21-261

DRAINING AT FUEL FILTER - STANDARD

PROCEDURES, WATER................14-47

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-11

DRIP RAIL WEATHERSTRIP -

INSTALLATION.......................23-91

DRIP RAIL WEATHERSTRIP - REMOVAL . . 23-91

DRIP RAIL WEATHERSTRIP RETAINER -

INSTALLATION.......................23-92

DRIP RAIL WEATHERSTRIP RETAINER -

REMOVAL..........................23-92

DRIVE - DIAGNOSIS AND TESTING,

ELECTRONICALLY CONTROLLED

VISCOUS FAN........................7-52

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN........................7-50

DRIVE BELT - 3.7L / 4.7L -

INSTALLATION........................7-26

DRIVE BELT - 3.7L / 4.7L - REMOVAL.....7-26

DRIVE BELT - 5.9L DIESEL -

INSTALLATION........................7-29

DRIVE BELT - 5.9L DIESEL - REMOVAL....7-29

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY.....................7-24,7-27

DRIVE LEARN - STANDARD PROCEDURE . . 8E-23

DRIVE SYSTEM - DESCRIPTION, TIMING

. . 9-166

DRIVE SYSTEM - OPERATION, TIMING

....9-166

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- DESCRIPTION, FAN

...................7-52

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- OPERATION, FAN

....................7-52

DRIVE VISCOUS CLUTCH-GAS ENGINES

- DESCRIPTION, FAN

...................7-50DRIVE VISCOUS CLUTCH-GAS ENGINES

- OPERATION, FAN....................7-50

DRIVER AIRBAG - ASSEMBLY..........8O-26

DRIVER AIRBAG - DESCRIPTION........8O-23

DRIVER AIRBAG - DISASSEMBLY........8O-25

DRIVER AIRBAG - INSTALLATION.......8O-28

DRIVER AIRBAG - OPERATION..........8O-23

DRIVER AIRBAG - REMOVAL...........8O-24

DRIVER DOOR MODULE - DESCRIPTION . . . 8N-5

DRIVER DOOR MODULE - DIAGNOSIS

AND TESTING........................8N-6

DRIVER DOOR MODULE - INSTALLATION . . 8N-7

DRIVER DOOR MODULE - OPERATION....8N-5

DRIVER DOOR MODULE - REMOVAL......8N-7

DRIVER SEAT SWITCH - DESCRIPTION . . . 8N-14

DRIVER SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8N-14

DRIVER SEAT SWITCH - INSTALLATION . . 8N-15

DRIVER SEAT SWITCH - OPERATION.....8N-14

DRIVER SEAT SWITCH - REMOVAL......8N-15

DRIVER SIDE BEZEL - INSTALLATION,

INSTRUMENT PANEL..................23-58

DRIVER SIDE BEZEL - REMOVAL,

INSTRUMENT PANEL..................23-58

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE...........8W-01-10

DRUM IN HAT BRAKE - CLEANING,

REAR...............................5-39

DRUM IN HAT BRAKE - INSPECTION,

REAR...............................5-39

DUAL REAR WHEEL INSTALLATION -

STANDARD PROCEDURE...............22-12

DUAL WHEELS - INSTALLATION, REAR....5-35

DUAL WHEELS - REMOVAL, REAR........5-34

DUCT - INSTALLATION, DEFROSTER.....24-32

DUCT - INSTALLATION, FLOOR

DISTRIBUTION.......................24-34

DUCT - REMOVAL, DEFROSTER.........24-32

DUCT - REMOVAL, FLOOR

DISTRIBUTION.......................24-33

DUCTS - INSTALLATION, INSTRUMENT

PANEL.............................24-37

DUCTS - INSTALLATION, INSTRUMENT

PANEL DEMISTER....................24-37

DUCTS - REMOVAL, INSTRUMENT

PANEL.............................24-37

DUCTS - REMOVAL, INSTRUMENT

PANEL DEMISTER....................24-36

DUST BOOT - INSTALLATION,

EXTENSION HOUSING SEAL.....21-476,21-571

DUST BOOT - REMOVAL, EXTENSION

HOUSING SEAL...............21-476,21-571

ECM - DESCRIPTION...................8E-3

ECM - OPERATION....................8E-3

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING......21-201,21-366

ELECTRICAL CONTROLS - DIAGNOSIS

AND TESTING, OVERDRIVE............21-262

ELECTRONIC GOVERNOR -

DESCRIPTION......................21-197

ELECTRONIC GOVERNOR -

INSTALLATION......................21-200

ELECTRONIC GOVERNOR - OPERATION . . 21-198

ELECTRONIC GOVERNOR - REMOVAL . . . 21-199

ELECTRONIC VARIABLE BRAKE

PROPORTIONING - DESCRIPTION........5-49

ELECTRONIC VARIABLE BRAKE

PROPORTIONING - OPERATION..........5-49

ELECTRONIC VEHICLE INFO CENTER -

DESCRIPTION........................8M-7

ELECTRONIC VEHICLE INFO CENTER -

INSTALLATION.......................8M-9

ELECTRONIC VEHICLE INFO CENTER -

OPERATION.........................8M-7

ELECTRONIC VEHICLE INFO CENTER -

REMOVAL...........................8M-9

ELECTRONIC VEHICLE INFORMATION

CENTER - DIAGNOSIS AND TESTING

......8M-8

ELECTRONIC VEHICLE INFORMATION

CENTER PROGRAMMING - STANDARD

PROCEDURE

.........................8M-8

ELECTRONICALLY CONTROLLED

VISCOUS FAN DRIVE - DIAGNOSIS

AND TESTING

........................7-52

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES - STANDARD

PROCEDURE

......................8W-01-8

ELEMENT - DESCRIPTION, HEATED SEAT

. . 8G-9ELEMENT - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-10

ELEMENT - INSTALLATION, AIR

CLEANER..................9-107,9-21,9-249

ELEMENT - INSTALLATION, HEATED

SEAT ..............................8G-10

ELEMENT - OPERATION, HEATED SEAT . . . 8G-10

ELEMENT - REMOVAL, AIR CLEANER....9-107,

9-21,9-248

ELEMENT - REMOVAL, HEATED SEAT....8G-10

EMISSION CONTROL INFORMATION

(VECI) - DESCRIPTION, VEHICLE.......Intro.-2

END - DIAGNOSIS AND TESTING, OUTER

TIE ROD............................19-32

END - INSTALLATION, OUTER TIE ROD . . . 19-33

END - INSTALLATION, TIE ROD.........19-37

END - REMOVAL, OUTER TIE ROD.......19-32

END - REMOVAL, TIE ROD.............19-37

ENGINE - 3.7L - DESCRIPTION............9-3

ENGINE - 5.7L - DESCRIPTION..........9-182

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW 3.7L/4.7L/5.7L............7-1

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL...............0-1

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIESEL...............7-7

ENGINE - DIAGNOSIS AND TESTING,

DIESEL.............................11-5

ENGINE - DIAGNOSIS AND TESTING,

GAS................................11-4

ENGINE - FIRING ORDER / CABLE

ROUTING, 5.7L V-8....................8I-4

ENGINE - INSTALLATION...............9-242

ENGINE - INSTALLATION, 3.7L/4.7L AND

5.7L HEMI.....................24-59,24-73

ENGINE - INSTALLATION, 5.9L DIESEL . . . 24-54,

24-58,24-72

ENGINE - INSTALLATION, DIESEL........8R-17

ENGINE - INSTALLATION, EXCEPT

DIESEL............................8R-17

ENGINE - INSTALLATION, GAS..........19-26

ENGINE - REMOVAL..................9-241

ENGINE - REMOVAL, 3.7L/4.7L AND 5.7L

HEMI.........................24-57,24-71

ENGINE - REMOVAL, 5.9L DIESEL . . 24-53,24-56,

24-70

ENGINE - REMOVAL, DIESEL...........8R-16

ENGINE - REMOVAL, EXCEPT DIESEL....8R-15

ENGINE - REMOVAL, GAS..............19-25

ENGINE - SPECIFICATIONS, 3.7L.........9-12

ENGINE - SPECIFICATIONS, 4.7L.........9-99

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 5.9L

DIESEL.............................7-18

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 5.9L

DIESEL.............................7-19

ENGINE - TORQUE, FUEL SYSTEM -

DIESEL............................14-48

ENGINE 5.9L DIESEL - DESCRIPTION.....9-232

ENGINE BLOCK - CLEANING . . . 9-128,9-205,9-39

ENGINE BLOCK - DESCRIPTION.....9-128,9-38

ENGINE BLOCK - INSPECTION . 9-128,9-205,9-39

ENGINE BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION........................7-37

ENGINE BLOCK HEATER - 5.9L DIESEL -

INSTALLATION........................7-38

ENGINE BLOCK HEATER - 5.9L DIESEL -

OPERATION..........................7-38

ENGINE BLOCK HEATER - 5.9L DIESEL -

REMOVAL...........................7-38

ENGINE BLOCK HEATER - DESCRIPTION . . . 7-36

ENGINE BLOCK HEATER - DIAGNOSIS

AND TESTING........................7-36

ENGINE BLOCK HEATER - INSTALLATION . . . 7-37

ENGINE BLOCK HEATER - OPERATION.....7-36

ENGINE BLOCK HEATER - REMOVAL......7-37

ENGINE CONTROL MODULE -

INSTALLATION........................8E-4

ENGINE CONTROL MODULE - REMOVAL . . . 8E-4

ENGINE COOLANT - DESCRIPTION

........7-31

ENGINE COOLANT - DESCRIPTION

.........0-3

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION

...............7-38

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION

...............7-41

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION

.................7-38

DRINDEX 11

Description Group-Page Description Group-Page Description Group-Page

Page 2600 of 2627

FIRING ORDER / CABLE ROUTING, 5.7L

V-8 ENGINE..........................8I-4

FIRING ORDER, 3.7L V-6 - ENGINE........8I-4

FIRING ORDER, 4.7L V-8 - ENGINE........8I-4

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-48

FITTING - DESCRIPTION, QUICK

CONNECT............................14-8

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING...........9-129

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING.....9-134,9-207

FITTING - STANDARD PROCEDURE,

PISTON...................9-139,9-211,9-51

FITTING - STANDARD PROCEDURE,

PISTON RING.........9-142,9-213,9-284,9-53

FITTING, STANDARD PROCEDURE -

CONNECTING ROD BEARING............9-49

FITTING, STANDARD PROCEDURE -

MAIN BEARING.......................9-44

FITTINGS - STANDARD PROCEDURE,

HANDLING TUBING...................24-45

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT......................14-8

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-27

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-27

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED....................5-10

FLARING - STANDARD PROCEDURE, ISO . . . 5-11

FLEX PLATE - INSTALLATION . . 9-138,9-210,9-48

FLEX PLATE - REMOVAL.......9-138,9-210,9-48

FLOOR - INSTALLATION, LOAD..........23-72

FLOOR - REMOVAL, LOAD.............23-71

FLOOR CONSOLE - INSTALLATION.......23-67

FLOOR CONSOLE - REMOVAL...........23-67

FLOOR DISTRIBUTION DUCT -

INSTALLATION.......................24-34

FLOOR DISTRIBUTION DUCT - REMOVAL . 24-33

FLOOR MATS - INSTALLATION, CARPETS . 23-65

FLOOR MATS - REMOVAL, CARPETS.....23-65

FLOOR SHIFT BOOT - INSTALLATION,

4WD ..............................23-62

FLOOR SHIFT BOOT - REMOVAL, 4WD....23-62

FLOOR SUPPORT CYLINDER -

INSTALLATION, LOAD.................23-72

FLOOR SUPPORT CYLINDER -

REMOVAL, LOAD.....................23-72

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-3

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..............7-54,7-56

FLOW 3.7L/4.7L/5.7L ENGINE -

DESCRIPTION, COOLING SYSTEM.........7-1

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION................19-43

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID - DESCRIPTION, POWER

STEERING............................0-3

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT............21-201,21-366

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE........21-203,21-367

FLUID CAPACITIES, SPECIFICATIONS.......0-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING................21-202,21-366

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-23

FLUID COOLER - INSTALLATION.........19-43

FLUID COOLER - REMOVAL............19-43

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.....21-441,21-476,21-507,21-537,

21-571

FLUID INDICATOR - DESCRIPTION,

WASHER

...........................8J-44

FLUID INDICATOR - OPERATION,

WASHER

...........................8J-44

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING

.........21-144,21-318

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT

.....21-201,

21-366

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE

..............................5-23FLUID LEVEL CHECK - STANDARD

PROCEDURE.................21-202,21-366

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-43

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-9

FLUID LEVEL SWITCH - INSTALLATION,

WASHER...........................8R-11

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-9

FLUID LEVEL SWITCH - REMOVAL,

WASHER...........................8R-10

FLUID RESERVOIR - INSTALLATION.......5-24

FLUID RESERVOIR - REMOVAL..........5-23

FLUID, SPECIFICATIONS - BRAKE.........5-23

FLUSH - SPECIFICATIONS, GAP.........23-95

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-17

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-40

FLYWHEEL - ASSEMBLY................6-11

FLYWHEEL - DIAGNOSIS AND TESTING....6-10

FLYWHEEL - DISASSEMBLY.............6-11

FLYWHEEL - INSTALLATION.............6-11

FLYWHEEL - REMOVAL.................6-11

FOG LAMP - INSTALLATION............8L-12

FOG LAMP - REMOVAL................8L-12

FOG LAMP RELAY - DESCRIPTION.......8L-12

FOG LAMP RELAY - INSTALLATION........8L-13

FOG LAMP RELAY - OPERATION.........8L-13

FOG LAMP RELAY - REMOVAL..........8L-13

FOOTMANS LOOP BRACKETS -

INSTALLATION, SEAT BACK REAR.......23-85

FOOTMANS LOOP BRACKETS -

REMOVAL, SEAT BACK REAR...........23-85

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE . . 9-239,9-9,

9-94

FRAME - INSTALLATION, GRILLE........23-40

FRAME - REAR - INSTALLATION, SEAT

CUSHION...........................23-85

FRAME - REAR - REMOVAL, SEAT

CUSHION...........................23-85

FRAME - REMOVAL, GRILLE............23-40

FRAME DIMENSIONS - SPECIFICATIONS . . 13-16

FRAME H-SECTION REPLACEMENT -

STANDARD PROCEDURE, REAR.........13-13

FRAME RAIL TIP REPLACEMENT -

STANDARD PROCEDURE, LIGHT DUTY

FRONT..............................13-4

FREE MODULE - INSTALLATION, HANDS . . . 8T-2

FREE MODULE - REMOVAL, HANDS.......8T-2

FRONT - INSTALLATION....5-16,5-21,5-22,5-34

FRONT - INSTALLATION...............22-14

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL.............9-136,9-208,9-275,9-46

FRONT - INSTALLATION, PROPELLER

SHAFT - HD...........................3-7

FRONT - INSTALLATION, PROPELLER

SHAFT- LD............................3-7

FRONT - INSTALLATION, SEAT..........23-81

FRONT - INSTALLATION, SEAT BACK

CUSHION / COVER...................23-82

FRONT - INSTALLATION, SEAT CUSHION

/ COVER............................23-83

FRONT - REMOVAL........5-13,5-17,5-21,5-33

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL................9-135,9-208,9-275,9-46

FRONT - REMOVAL, PROPELLER SHAFT

- HD ................................3-7

FRONT - REMOVAL, PROPELLER SHAFT-

LD ..................................3-6

FRONT - REMOVAL, SEAT..............23-81

FRONT - REMOVAL, SEAT BACK

CUSHION / COVER...................23-82

FRONT - REMOVAL, SEAT CUSHION /

COVER.............................23-83

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-2

FRONT AXLE - 9 1/4 AA -

ADJUSTMENTS

.......................3-59

FRONT AXLE - 9 1/4 AA - DIAGNOSIS

AND TESTING

........................3-54

FRONT AXLE - 9 1/4 AA - INSTALLATION

. . . 3-58

FRONT AXLE - 9 1/4 AA - REMOVAL

......3-57

FRONT AXLE - 9 1/4 AA - SPECIAL

TOOLS

..............................3-64FRONT AXLE - 9 1/4 AA -

SPECIFICATIONS......................3-63

FRONT AXLE - C205F - ADJUSTMENTS....3-32

FRONT AXLE - C205F - DIAGNOSIS AND

TESTING............................3-27

FRONT AXLE - C205F - INSTALLATION.....3-31

FRONT AXLE - C205F - REMOVAL........3-31

FRONT AXLE - C205F - SPECIAL TOOLS . . . 3-40

FRONT AXLE - C205F - SPECIFICATIONS . . . 3-39

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT.....................21-216

FRONT BEARING - REMOVAL, OUTPUT

SHAFT............................21-216

FRONT BRAKE HOSE - INSTALLATION.....5-13

FRONT BUMPER - INSTALLATION.........13-2

FRONT BUMPER - REMOVAL............13-2

FRONT CENTER SEAT BELT -

INSTALLATION......................8O-31

FRONT CENTER SEAT BELT - REMOVAL . . 8O-30

FRONT CENTER SEAT BELT &

RETRACTOR - INSTALLATION...........8O-29

FRONT CENTER SEAT BELT &

RETRACTOR - REMOVAL..............8O-29

FRONT CLUTCH - ASSEMBLY..........21-207

FRONT CLUTCH - DESCRIPTION........21-205

FRONT CLUTCH - DISASSEMBLY.......21-205

FRONT CLUTCH - INSPECTION.........21-206

FRONT CLUTCH - OPERATION.........21-205

FRONT CONTROL MODULE -

DESCRIPTION.....................8W-97-5

FRONT CONTROL MODULE -

DESCRIPTION........................8E-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING.....................8W-97-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING........................8E-5

FRONT CONTROL MODULE -

INSTALLATION....................8W-97-6

FRONT CONTROL MODULE -

INSTALLATION........................8E-5

FRONT CONTROL MODULE - OPERATION . 8W-97-5

FRONT CONTROL MODULE - OPERATION . . 8E-5

FRONT CONTROL MODULE - REMOVAL . 8W-97-6

FRONT CONTROL MODULE - REMOVAL....8E-5

FRONT CROSSMEMBER - INSTALLATION . . 13-22

FRONT CROSSMEMBER - REMOVAL.....13-22

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION........23-92

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL............23-92

FRONT DOOR INNER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR INNER BELT MOLDING -

REMOVAL..........................23-93

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR OUTER BELT MOLDING -

REMOVAL..........................23-92

FRONT FASCIA - INSTALLATION..........13-3

FRONT FASCIA - REMOVAL..............13-2

FRONT FENDER - INSTALLATION........23-39

FRONT FENDER - REMOVAL............23-39

FRONT FRAME RAIL TIP REPLACEMENT

- STANDARD PROCEDURE, LIGHT

DUTY...............................13-4

FRONT HOSE - REMOVAL...............5-12

FRONT MOUNT - INSTALLATION . . . 9-147,9-218,

9-287,9-59

FRONT MOUNT - REMOVAL . . 9-146,9-217,9-286,

9-58

FRONT OUTBOARD SEAT BELT BUCKLE -

INSTALLATION......................8O-38

FRONT OUTBOARD SEAT BELT BUCKLE -

REMOVAL..........................8O-37

FRONT OUTPUT SHAFT SEAL -

INSTALLATION . . . 21-442,21-477,21-508,21-538,

21-572

FRONT OUTPUT SHAFT SEAL -

REMOVAL . 21-441,21-477,21-507,21-537,21-572

FRONT PARKING BRAKE CABLE -

INSTALLATION........................5-38

FRONT PARKING BRAKE CABLE -

REMOVAL

...........................5-36

FRONT SEAL - INSTALLATION, OIL

PUMP

............................21-391

FRONT SEAL - REMOVAL, OIL PUMP

....21-391

FRONT SERVO - ASSEMBLY

...........21-209

FRONT SERVO - CLEANING

...........21-209

DRINDEX 13

Description Group-Page Description Group-Page Description Group-Page