cluster DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 701 of 2627

is released before parking the wiper blades near the

base of the windshield. If the control knob is held in

the depressed Wash position for more than about

thirty seconds, washer system operation will be sus-

pended until the control knob is released for about

two seconds then cycled back to the Wash position.

OPERATION

The wiper and washer system is designed to pro-

vide the vehicle operator with a convenient, safe, and

reliable means of maintaining visibility through the

windshield glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blades to wipe the

outside surface of the glass, as well as into the

hydraulic action of the washer system to apply

washer fluid stored in an on-board reservoir to the

area of the glass to be wiped. When combined, these

components provide the means to effectively main-

tain clear visibility for the vehicle operator by remov-

ing excess accumulations of rain, snow, bugs, mud, or

other minor debris from the outside windshield glass

surface that might be encountered while driving the

vehicle under numerous types of inclement operating

conditions.

The vehicle operator initiates all wiper and washer

system functions with the control knob on the end of

the control stalk of the multi-function switch that

extends from the left side of the steering column, just

below the steering wheel. Rotating the control knob

on the end of the control stalk, selects the Off, Delay,

Low, or High wiper system operating modes. In the

Delay mode, the control knob also allows the vehicle

operator to select from one of five intermittent wipe

Delay intervals. Depressing the control knob towards

the steering column actuates the momentary washer

system switch, which selects the Wash, Wipe-After-

Wash, and Pulse Wipe Modes depending upon when

and how long the switch is held closed. The multi-

function switch provides hard wired resistor multi-

plexed inputs to the instrument cluster for all of the

wiper and washer system functions. The instrument

cluster then sends electronic messages to the Front

Control Module (FCM) over the Programmable Com-

munications Interface (PCI) data bus requesting the

appropriate wiper and washer system operating

modes.

Wiper and washer system operation are completely

controlled by the instrument cluster and FCM logic

circuits, and that logic will only allow these systems

to operate when the ignition switch is in the Acces-

sory or On positions. Battery current is directed from

a B(+) fuse in the Integrated Power Module (IPM) to

the wiper on/off relay and the wiper high/low relay in

the IPM through a fused B(+) circuit. The FCM useslow side drivers to control wiper system operation by

energizing or de-energizing the wiper high/low and

wiper on/off relays. The FCM uses a high side driver

to control the operation of the washer pump motor

unit. The multi-function switch circuitry receives a

clean ground output from the instrument cluster on a

multi-function switch return circuit, then provides

resistor multiplexed inputs to the instrument cluster

on an intermittent wipe mux circuit to indicate the

selected wiper system mode and on a wash/beam

select mux circuit to indicate the selected washer sys-

tem mode.

The hard wired circuits and components of the

wiper and washer system may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the

instrument cluster, the FCM, or the electronic mes-

sage inputs to or outputs from the instrument cluster

or FCM that control the wiper and washer system

operating modes. The most reliable, efficient, and

accurate means to diagnose the instrument cluster or

the FCM inputs and outputs related to the various

wiper and washer system operating modes requires

the use of a DRBIIItscan tool. Refer to the appro-

priate diagnostic information.

OPERATING MODES

Following are paragraphs that briefly describe the

operation of each of the wiper and washer system

operating modes.

CONTINUOUS WIPE MODE

When the Low position of the control knob on the

control stalk of the multi-function switch is selected

the instrument cluster sends an electronic wiper

switch low message to the FCM, then the FCM ener-

gizes the wiper on/off relay. This directs battery cur-

rent through the normally open contacts of the

energized wiper on/off relay and the normally closed

contacts of the de-energized wiper high/low relay to

the low speed brush of the wiper motor, causing the

wipers to cycle at low speed.

When the High position of the control knob is

selected the instrument cluster sends an electronic

wiper switch high message to the FCM, then the

FCM energizes both the wiper on/off relay and the

wiper high/low relay. This directs battery current

through the normally open contacts of the energized

wiper on/off relay and the normally open contacts of

the energized wiper high/low relay to the high speed

brush of the wiper motor, causing the wipers to cycle

at high speed.

When the Off position of the multi-function switch

control knob is selected, the instrument cluster sends

an electronic wiper switch off message to the FCM. If

8R - 4 WIPERS/WASHERSDR

WIPERS/WASHERS (Continued)

Page 702 of 2627

the wiper motor was operating at high speed, the

FCM immediately de-energizes the wiper high/low

relay causing the wiper motor to return to low speed

operation. Then one of two events will occur. The

event that occurs depends upon the position of the

wiper blades on the windshield at the moment that

the control knob Off position is selected.

If the wiper blades are in the down position on the

windshield when the Off position is selected, the

park switch that is integral to the wiper motor is

closed to ground and provides a hard wired park

switch sense input to the FCM. The FCM then de-en-

ergizes the wiper on/off relay and the wiper motor

ceases to operate. If the wiper blades are not in the

down position on the windshield at the moment the

Off position is selected, the park switch is an open

circuit and the FCM keeps the wiper on/off relay

energized, which causes the wiper motor to continue

running at low speed until the wiper blades are in

the down position on the windshield and the park

switch input to the FCM is again closed to ground.

INTERMITTENT WIPE MODE

When the control knob on the control stalk of the

multi-function switch is moved to one of the Delay

interval positions the instrument cluster sends an

electronic wiper switch delay message to the FCM,

then the FCM electronic intermittent wipe logic cir-

cuit responds by calculating the correct length of

time between wiper sweeps based upon the selected

delay interval input. The FCM monitors the changing

state of the wiper motor park switch through a hard

wired park switch sense input. This input allows the

FCM to determine the proper intervals at which to

energize and de-energize the wiper on/off relay to

operate the wiper motor intermittently for one low

speed cycle at a time.

The FCM logic is also programmed to provide vehi-

cle speed sensitivity to the selected intermittent wipe

delay intervals. In order to provide this feature the

FCM monitors electronic vehicle speed messages

from the Powertrain Control Module (PCM) and dou-

bles the selected delay interval whenever the vehicle

speed is about sixteen kilometers-per-hour (ten miles-

per-hour) or less.

PULSE WIPE MODE

When the control knob on the control stalk of the

multi-function switch is depressed to the momentary

Wash position for less than about one-half second,

the instrument cluster sends an electronic washer

switch message to the FCM, then the FCM the ener-

gizes the wiper on/off relay for one complete wipe

cycle. The FCM de-energizes the relay when the state

of the park switch sense changes to ground, parking

the wiper blades near the base of the windshield.WASH MODE

When the control knob on the control stalk of the

multi-function switch is depressed to the momentary

Wash position for more than about one-half second,

the instrument cluster sends an electronic washer

switch message to the FCM, then the FCM directs

battery current to the washer pump/motor unit. This

will cause the washer pump/motor unit to be ener-

gized for as long as the Wash switch is held closed up

to about thirty seconds, and to de-energize when the

front Wash switch is released.

When the control knob is depressed to the momen-

tary Wash position while the wiper system is operat-

ing in one of the Delay interval positions, the washer

pump/motor operation is the same. However, the

FCM also energizes the wiper on/off relay to override

the selected delay interval and operate the wiper

motor in a continuous low speed mode for as long as

the control knob is held depressed, then de-energizes

the relay and reverts to the selected delay mode

interval several wipe cycles after the control knob is

released. If the control knob is held depressed for

more than about thirty seconds, the FCM will sus-

pend washer pump/motor operation until the knob is

released for about two seconds, then cycled back to

the Wash position.

WIPE-AFTER-WASH MODE

When the control knob on the control stalk of the

multi-function switch is depressed to the momentary

Wash position for more than about one-half second

while the wiper system is not operating, the instru-

ment cluster sends an electronic washer switch mes-

sage to the FCM, then the FCM the directs battery

current to the washer pump/motor unit and energizes

the wiper on/off relay. This will cause the washer

pump/motor unit to be energized and operate the

wiper motor in a continuous low speed mode for as

long as the Wash switch is held closed up to about

thirty seconds. When the control knob is released,

the FCM de-energizes the washer pump/motor unit,

but allows the wiper motor to operate for several

additional wipe cycles before it de-energizes the

wiper on/off relay and parks the wiper blades near

the base of the windshield.

If the control knob is held depressed for more than

about thirty seconds, the FCM will suspend washer

pump/motor operation until the knob is released for

about two seconds, then cycled back to the Wash

position; however, the wipers will continue to operate

for as long as the Wash switch is held closed. The

FCM monitors the changing state of the wiper motor

park switch through a hard wired wiper park switch

sense circuit input. This input allows the FCM to

count the number of wipe cycles that occur after the

Wash switch is released, and to determine the proper

DRWIPERS/WASHERS 8R - 5

WIPERS/WASHERS (Continued)

Page 703 of 2627

interval at which to de-energize the wiper on/off

relay to complete the wipe-after-wash mode cycle.

DIAGNOSIS AND TESTING - WIPER &

WASHER SYSTEM

If the wiper motor operates, but the wipers do not

move on the windshield, replace the faulty wiper

module. If the washer pump/motor operates, but no

washer fluid is dispensed on the glass; or, if the wip-

ers operate, but chatter, lift, or do not clear the glass,

clean and inspect the wiper and washer system com-

ponents as required. (Refer to 8 - ELECTRICAL/

WIPERS/WASHERS - CLEANING) and (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - INSPECTION).

For diagnosis and testing of the multi-function

switch (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/MULTI-FUNCTION SWITCH -

DIAGNOSIS AND TESTING). Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

The hard wired circuits and components of the

wiper and washer system may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the

instrument cluster, the Front Control Module (FCM),

or the electronic message inputs to or outputs from

the instrument cluster and the FCM that control the

various wiper and washer system operating modes.

The most reliable, efficient, and accurate means to

diagnose the instrument cluster, the FCM, or the

electronic message inputs and outputs related to the

various wiper and washer system operating modes

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

CLEANING - WIPER & WASHER SYSTEM

WIPER SYSTEM

The squeegees of wiper blades exposed to the ele-

ments for a long time tend to lose their wiping effec-

tiveness. Periodic cleaning of the squeegees is

suggested to remove any deposits of salt or road film.

The wiper blades, arms, and windshield glass should

only be cleaned using a sponge or soft cloth and

windshield washer fluid, a mild detergent, or a non-

abrasive cleaner. If the wiper blades continue to

leave streaks, smears, hazing, or beading on the

glass after thorough cleaning of the squeegees and

the glass, the entire wiper blade assembly must be

replaced.

CAUTION: Protect the rubber squeegees of the

wiper blades from any petroleum-based cleaners,

solvents, or contaminants. These products can rap-

idly deteriorate the rubber squeegees.

WASHER SYSTEM

If the washer system is contaminated with foreign

material, drain the washer reservoir by removing the

washer pump/motor from the reservoir. Clean foreign

material from the inside of the washer pump/motor

inlet filter screen and the washer reservoir using

clean washer fluid, a mild detergent, or a non-abra-

sive cleaner. Flush foreign material from the washer

system plumbing by first disconnecting the washer

hoses from the washer nozzles, then running the

washer pump/motor to run clean washer fluid or

water through the system. Plugged or restricted

washer nozzles should be carefully back-flushed

using compressed air. If the washer nozzle obstruc-

tion cannot be cleared, replace the washer nozzle.

CAUTION: Never introduce petroleum-based clean-

ers, solvents, or contaminants into the washer sys-

tem. These products can rapidly deteriorate the

rubber seals and hoses of the washer system, as

well as the rubber squeegees of the wiper blades.

CAUTION: Never use compressed air to flush the

washer system plumbing. Compressed air pres-

sures are too great for the washer system plumbing

components and will result in further system dam-

age. Never use sharp instruments to clear a

plugged washer nozzle or damage to the nozzle ori-

fice and improper nozzle spray patterns will result.

8R - 6 WIPERS/WASHERSDR

WIPERS/WASHERS (Continued)

Page 707 of 2627

(FCM) on a sensor return circuit and the washer

fluid switch sense input to the FCM. When the

switch closes, the FCM senses the ground on the

washer fluid switch sense circuit. The FCM is pro-

grammed to respond to this input by sending an elec-

tronic washer fluid indicator lamp-on message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus. The instrument

cluster responds to this message by illuminating the

washer fluid indicator and by sounding an audible

chime tone warning.

The washer fluid level switch may be diagnosed

and tested using conventional diagnostic tools and

procedures. However, conventional diagnostic meth-

ods may not prove conclusive in the diagnosis of the

instrument cluster, the FCM, or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the

washer fluid visual and/or audible indicators. The

most reliable, efficient, and accurate means to diag-

nose the washer fluid level indicator, the instrument

cluster, the FCM, or the electronic message inputs

and outputs related to the washer fluid indicator

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

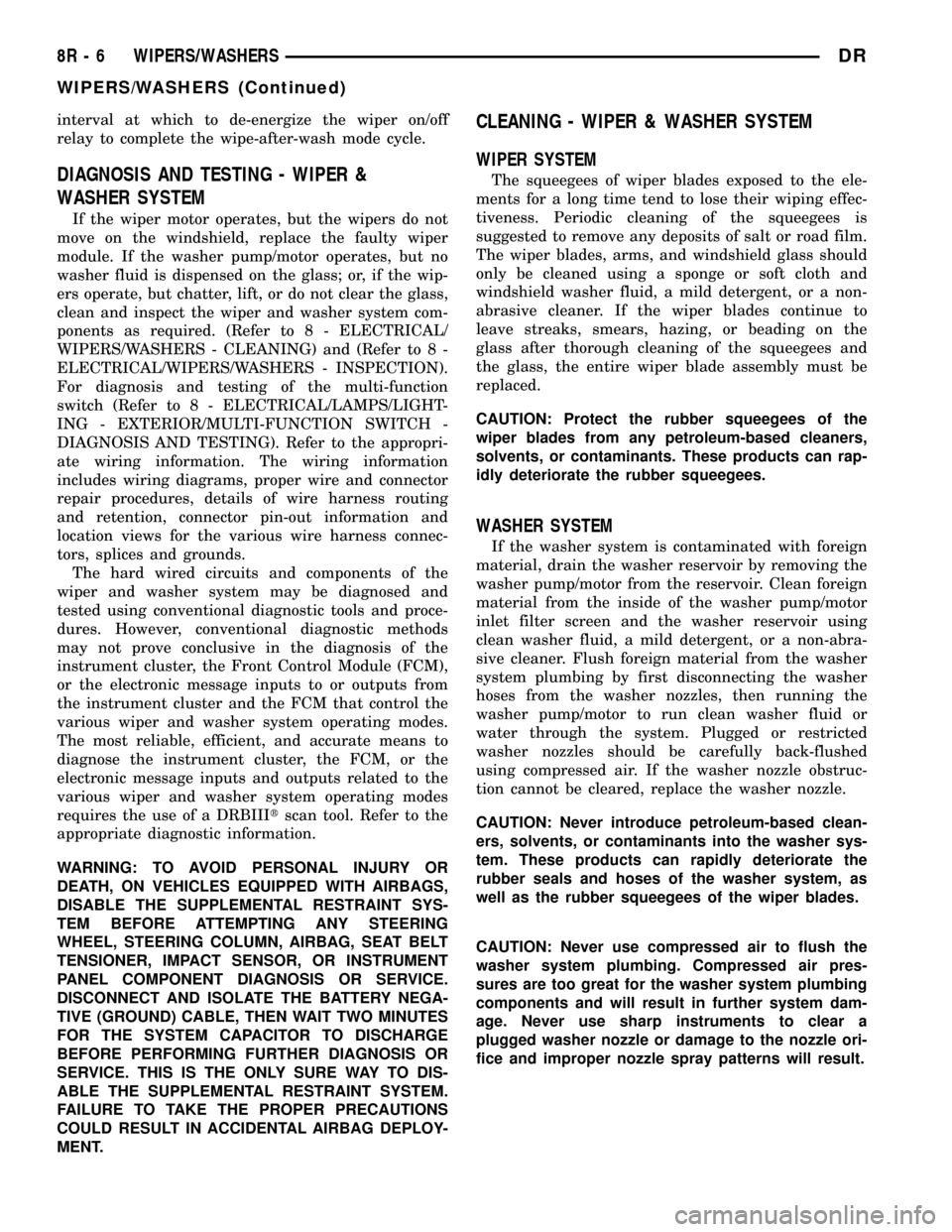

REMOVAL

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor unit and

allow the washer fluid to drain into a clean container

for reuse.

(4) Disconnect the right (except diesel engine) or

left (diesel engine only) headlamp and dash wire har-

ness connector for the washer fluid level switch from

the switch connector receptacle (Fig. 7) or (Fig. 8).

NOTE: The pivoting float of the washer fluid level

switch must be in a horizontal position within the

reservoir in order to be removed. With the reservoir

empty and in an upright position, the pivoting float

will orient itself to the horizontal position when the

switch connector receptacle is pointed straight

upwards.

(5) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed nipple of the

washer fluid level switch out of the rubber grommet

seal on the reservoir sump. Care must be taken not

to damage the reservoir.

(6) Remove the washer fluid level switch from the

washer reservoir.(7) Remove the rubber grommet seal from the

washer fluid level switch mounting hole in the

washer reservoir and discard.

Fig. 7 Washer Fluid Level Switch Remove/Install -

Except Diesel Engine

1 - WASHER HOSE

2 - WASHER RESERVOIR

3 - WASHER FLUID LEVEL SWITCH

4 - WIRE HARNESS

5 - WASHER PUMP/MOTOR

Fig. 8 Washer Fluid Level Switch Remove/Install -

Diesel Engine

1 - WIRE HARNESS

2 - WASHER RESERVOIR

3 - WASHER PUMP/MOTOR

4 - WASHER HOSE

5 - WASHER FLUID LEVEL SWITCH

8R - 10 WIPERS/WASHERSDR

WASHER FLUID LEVEL SWITCH (Continued)

Page 710 of 2627

(7) Reinstall both wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - INSTALLATION).

WASHER PUMP/MOTOR

DESCRIPTION

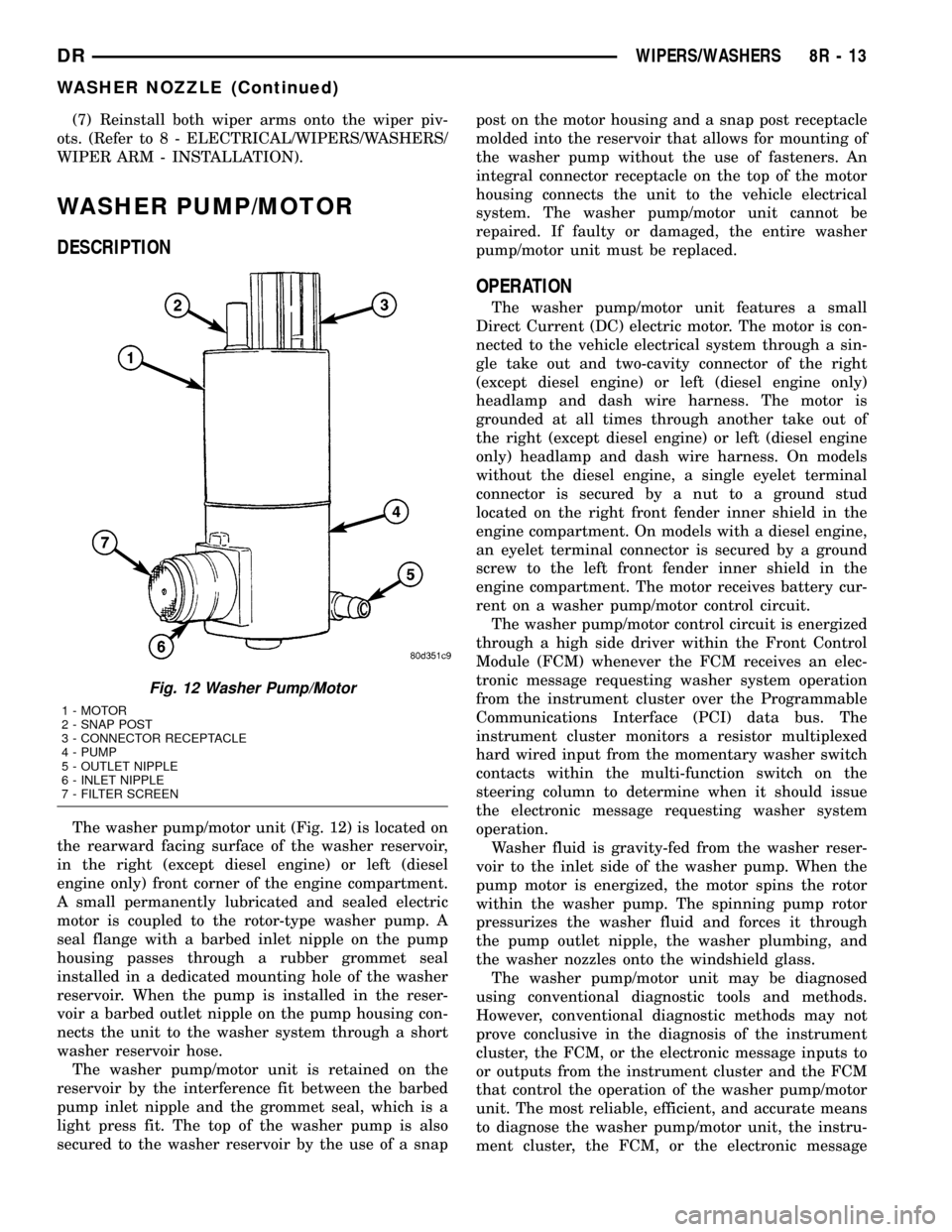

The washer pump/motor unit (Fig. 12) is located on

the rearward facing surface of the washer reservoir,

in the right (except diesel engine) or left (diesel

engine only) front corner of the engine compartment.

A small permanently lubricated and sealed electric

motor is coupled to the rotor-type washer pump. A

seal flange with a barbed inlet nipple on the pump

housing passes through a rubber grommet seal

installed in a dedicated mounting hole of the washer

reservoir. When the pump is installed in the reser-

voir a barbed outlet nipple on the pump housing con-

nects the unit to the washer system through a short

washer reservoir hose.

The washer pump/motor unit is retained on the

reservoir by the interference fit between the barbed

pump inlet nipple and the grommet seal, which is a

light press fit. The top of the washer pump is also

secured to the washer reservoir by the use of a snappost on the motor housing and a snap post receptacle

molded into the reservoir that allows for mounting of

the washer pump without the use of fasteners. An

integral connector receptacle on the top of the motor

housing connects the unit to the vehicle electrical

system. The washer pump/motor unit cannot be

repaired. If faulty or damaged, the entire washer

pump/motor unit must be replaced.

OPERATION

The washer pump/motor unit features a small

Direct Current (DC) electric motor. The motor is con-

nected to the vehicle electrical system through a sin-

gle take out and two-cavity connector of the right

(except diesel engine) or left (diesel engine only)

headlamp and dash wire harness. The motor is

grounded at all times through another take out of

the right (except diesel engine) or left (diesel engine

only) headlamp and dash wire harness. On models

without the diesel engine, a single eyelet terminal

connector is secured by a nut to a ground stud

located on the right front fender inner shield in the

engine compartment. On models with a diesel engine,

an eyelet terminal connector is secured by a ground

screw to the left front fender inner shield in the

engine compartment. The motor receives battery cur-

rent on a washer pump/motor control circuit.

The washer pump/motor control circuit is energized

through a high side driver within the Front Control

Module (FCM) whenever the FCM receives an elec-

tronic message requesting washer system operation

from the instrument cluster over the Programmable

Communications Interface (PCI) data bus. The

instrument cluster monitors a resistor multiplexed

hard wired input from the momentary washer switch

contacts within the multi-function switch on the

steering column to determine when it should issue

the electronic message requesting washer system

operation.

Washer fluid is gravity-fed from the washer reser-

voir to the inlet side of the washer pump. When the

pump motor is energized, the motor spins the rotor

within the washer pump. The spinning pump rotor

pressurizes the washer fluid and forces it through

the pump outlet nipple, the washer plumbing, and

the washer nozzles onto the windshield glass.

The washer pump/motor unit may be diagnosed

using conventional diagnostic tools and methods.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the instrument

cluster, the FCM, or the electronic message inputs to

or outputs from the instrument cluster and the FCM

that control the operation of the washer pump/motor

unit. The most reliable, efficient, and accurate means

to diagnose the washer pump/motor unit, the instru-

ment cluster, the FCM, or the electronic message

Fig. 12 Washer Pump/Motor

1 - MOTOR

2 - SNAP POST

3 - CONNECTOR RECEPTACLE

4 - PUMP

5 - OUTLET NIPPLE

6 - INLET NIPPLE

7 - FILTER SCREEN

DRWIPERS/WASHERS 8R - 13

WASHER NOZZLE (Continued)

Page 718 of 2627

The wiper high/low relay can be diagnosed using

conventional diagnostic tools and methods. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the instrument cluster, the

Front Control Module (FCM), or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the wiper

high/low relay. The most reliable, efficient, and accu-

rate means to diagnose the wiper high/low relay, the

instrument cluster, the FCM, or the electronic mes-

sage inputs and outputs related to the wiper high/low

relay operation requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - WIPER HIGH/LOW

RELAY

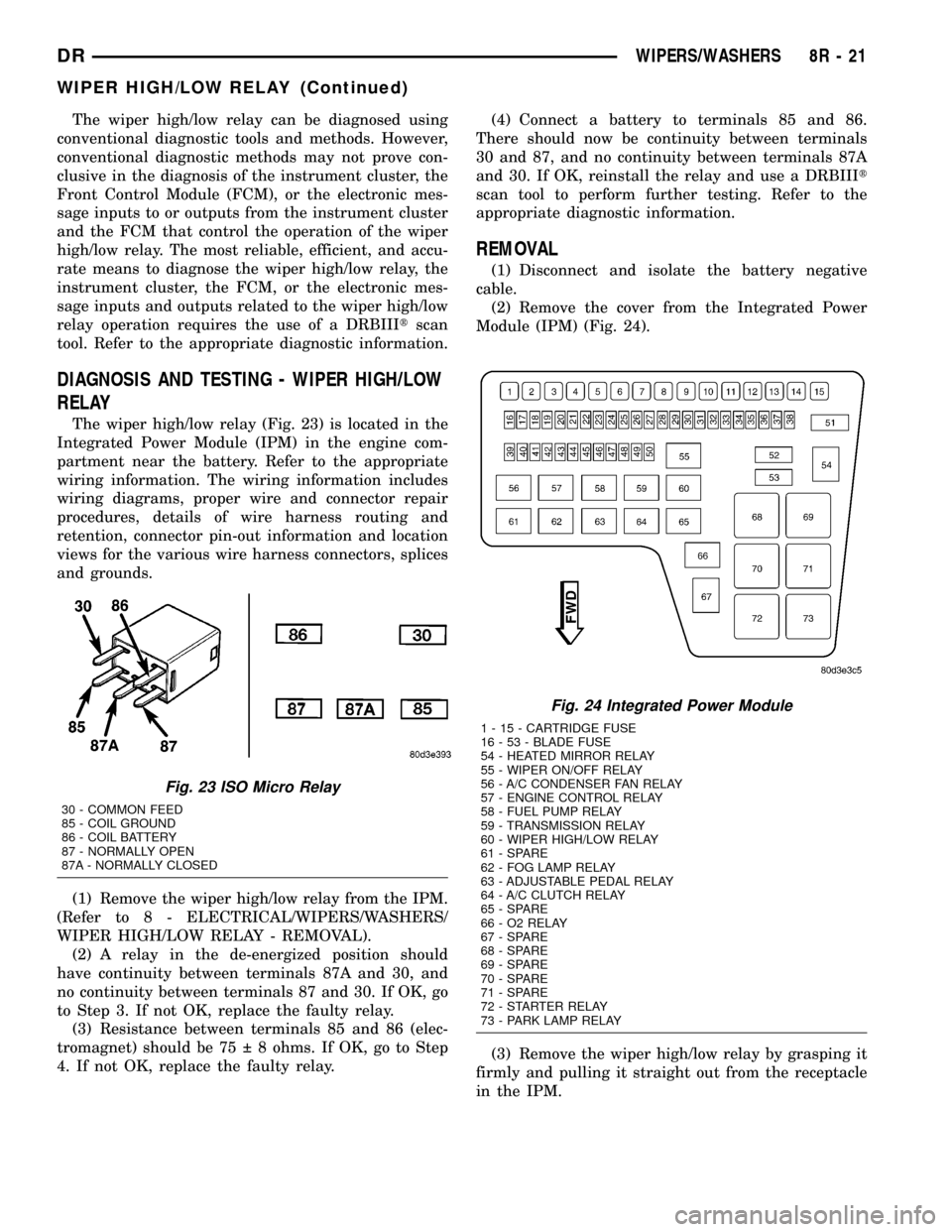

The wiper high/low relay (Fig. 23) is located in the

Integrated Power Module (IPM) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(1) Remove the wiper high/low relay from the IPM.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER HIGH/LOW RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Integrated Power

Module (IPM) (Fig. 24).

(3) Remove the wiper high/low relay by grasping it

firmly and pulling it straight out from the receptacle

in the IPM.

Fig. 23 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 24 Integrated Power Module

1 - 15 - CARTRIDGE FUSE

16 - 53 - BLADE FUSE

54 - HEATED MIRROR RELAY

55 - WIPER ON/OFF RELAY

56 - A/C CONDENSER FAN RELAY

57 - ENGINE CONTROL RELAY

58 - FUEL PUMP RELAY

59 - TRANSMISSION RELAY

60 - WIPER HIGH/LOW RELAY

61 - SPARE

62 - FOG LAMP RELAY

63 - ADJUSTABLE PEDAL RELAY

64 - A/C CLUTCH RELAY

65 - SPARE

66 - O2 RELAY

67 - SPARE

68 - SPARE

69 - SPARE

70 - SPARE

71 - SPARE

72 - STARTER RELAY

73 - PARK LAMP RELAY

DRWIPERS/WASHERS 8R - 21

WIPER HIGH/LOW RELAY (Continued)

Page 722 of 2627

The wiper on/off relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

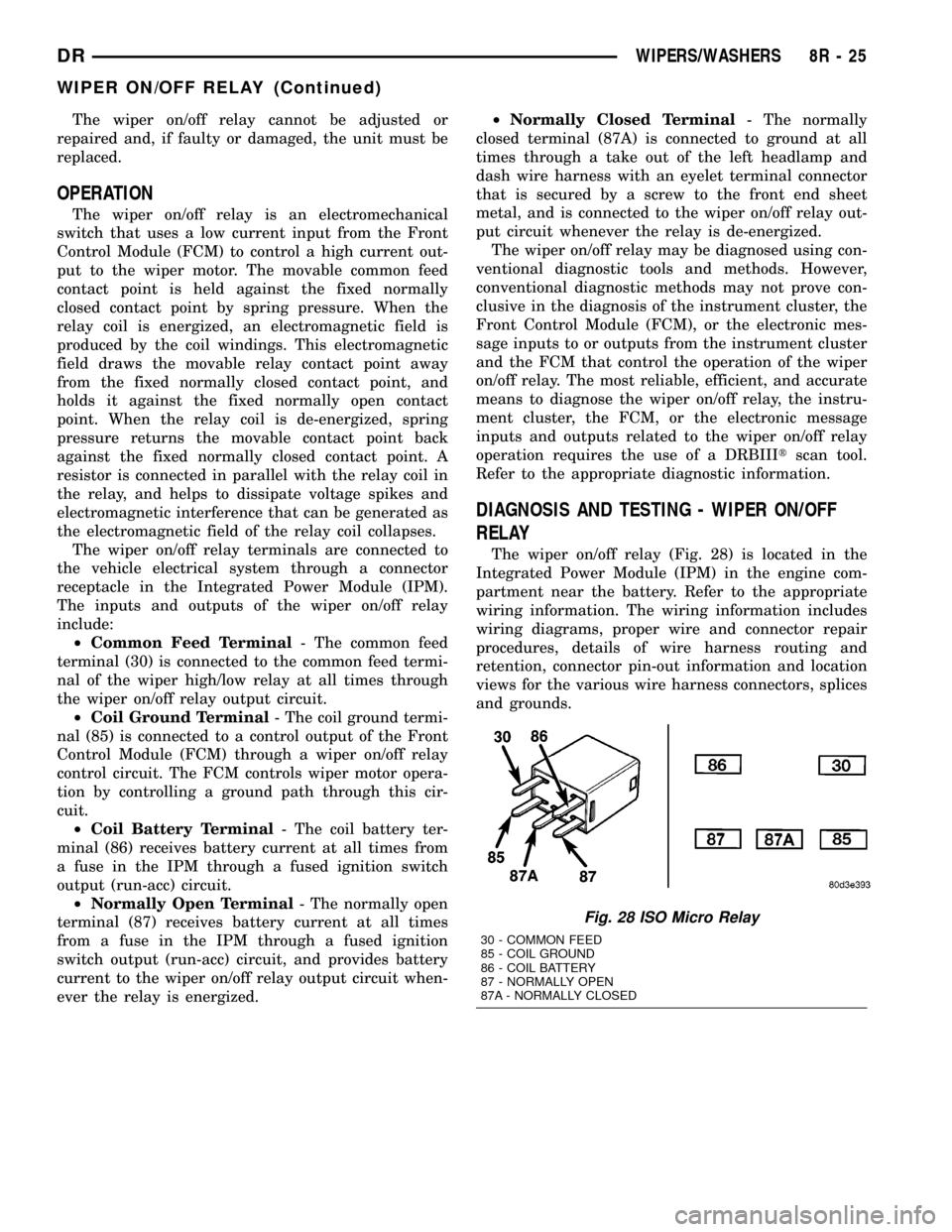

The wiper on/off relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control a high current out-

put to the wiper motor. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper on/off relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the wiper on/off relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the common feed termi-

nal of the wiper high/low relay at all times through

the wiper on/off relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Front

Control Module (FCM) through a wiper on/off relay

control circuit. The FCM controls wiper motor opera-

tion by controlling a ground path through this cir-

cuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the IPM through a fused ignition switch

output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a fuse in the IPM through a fused ignition

switch output (run-acc) circuit, and provides battery

current to the wiper on/off relay output circuit when-

ever the relay is energized.²Normally Closed Terminal- The normally

closed terminal (87A) is connected to ground at all

times through a take out of the left headlamp and

dash wire harness with an eyelet terminal connector

that is secured by a screw to the front end sheet

metal, and is connected to the wiper on/off relay out-

put circuit whenever the relay is de-energized.

The wiper on/off relay may be diagnosed using con-

ventional diagnostic tools and methods. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the instrument cluster, the

Front Control Module (FCM), or the electronic mes-

sage inputs to or outputs from the instrument cluster

and the FCM that control the operation of the wiper

on/off relay. The most reliable, efficient, and accurate

means to diagnose the wiper on/off relay, the instru-

ment cluster, the FCM, or the electronic message

inputs and outputs related to the wiper on/off relay

operation requires the use of a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - WIPER ON/OFF

RELAY

The wiper on/off relay (Fig. 28) is located in the

Integrated Power Module (IPM) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

Fig. 28 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

DRWIPERS/WASHERS 8R - 25

WIPER ON/OFF RELAY (Continued)

Page 726 of 2627

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING.................. 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATION..... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 DRWIRING 8W - 1

Page 744 of 2627

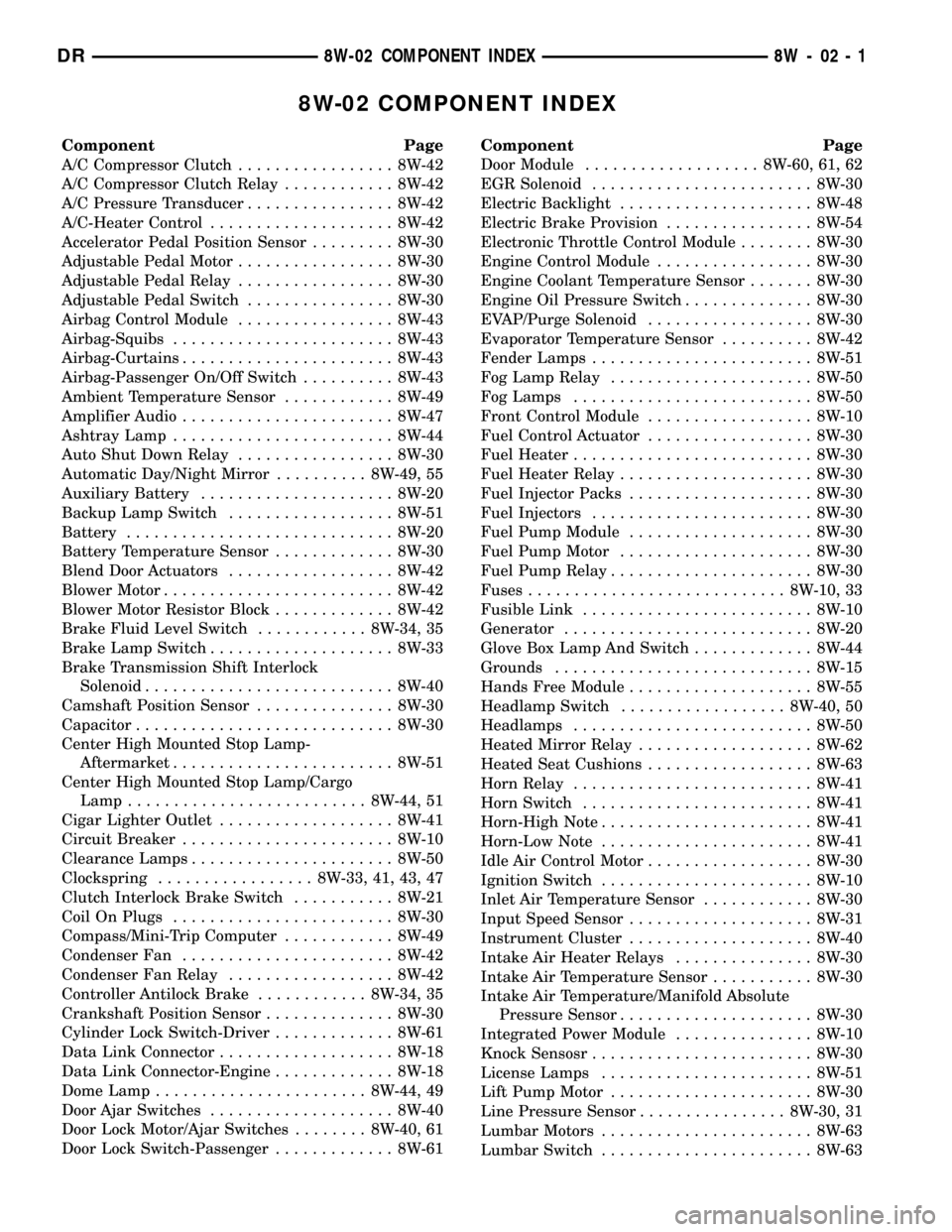

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Compressor Clutch Relay............ 8W-42

A/C Pressure Transducer................ 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Adjustable Pedal Motor................. 8W-30

Adjustable Pedal Relay................. 8W-30

Adjustable Pedal Switch................ 8W-30

Airbag Control Module................. 8W-43

Airbag-Squibs........................ 8W-43

Airbag-Curtains....................... 8W-43

Airbag-Passenger On/Off Switch.......... 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier Audio....................... 8W-47

Ashtray Lamp........................ 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror.......... 8W-49, 55

Auxiliary Battery..................... 8W-20

Backup Lamp Switch.................. 8W-51

Battery............................. 8W-20

Battery Temperature Sensor............. 8W-30

Blend Door Actuators.................. 8W-42

Blower Motor......................... 8W-42

Blower Motor Resistor Block............. 8W-42

Brake Fluid Level Switch............ 8W-34, 35

Brake Lamp Switch.................... 8W-33

Brake Transmission Shift Interlock

Solenoid........................... 8W-40

Camshaft Position Sensor............... 8W-30

Capacitor............................ 8W-30

Center High Mounted Stop Lamp-

Aftermarket........................ 8W-51

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-44, 51

Cigar Lighter Outlet................... 8W-41

Circuit Breaker....................... 8W-10

Clearance Lamps...................... 8W-50

Clockspring................. 8W-33, 41, 43, 47

Clutch Interlock Brake Switch........... 8W-21

Coil On Plugs........................ 8W-30

Compass/Mini-Trip Computer............ 8W-49

Condenser Fan....................... 8W-42

Condenser Fan Relay.................. 8W-42

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switch-Driver............. 8W-61

Data Link Connector................... 8W-18

Data Link Connector-Engine............. 8W-18

Dome Lamp....................... 8W-44, 49

Door Ajar Switches.................... 8W-40

Door Lock Motor/Ajar Switches........ 8W-40, 61

Door Lock Switch-Passenger............. 8W-61Component Page

Door Module................... 8W-60, 61, 62

EGR Solenoid........................ 8W-30

Electric Backlight..................... 8W-48

Electric Brake Provision................ 8W-54

Electronic Throttle Control Module........ 8W-30

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fender Lamps........................ 8W-51

Fog Lamp Relay...................... 8W-50

Fog Lamps.......................... 8W-50

Front Control Module.................. 8W-10

Fuel Control Actuator.................. 8W-30

Fuel Heater.......................... 8W-30

Fuel Heater Relay..................... 8W-30

Fuel Injector Packs.................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Motor..................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuses............................ 8W-10, 33

Fusible Link......................... 8W-10

Generator........................... 8W-20

Glove Box Lamp And Switch............. 8W-44

Grounds............................ 8W-15

Hands Free Module.................... 8W-55

Headlamp Switch.................. 8W-40, 50

Headlamps.......................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Seat Cushions.................. 8W-63

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn-High Note....................... 8W-41

Horn-Low Note....................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Inlet Air Temperature Sensor............ 8W-30

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Heater Relays............... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30

Integrated Power Module............... 8W-10

Knock Sensosr........................ 8W-30

License Lamps....................... 8W-51

Lift Pump Motor...................... 8W-30

Line Pressure Sensor................ 8W-30, 31

Lumbar Motors....................... 8W-63

Lumbar Switch....................... 8W-63

DR8W-02 COMPONENT INDEX 8W - 02 - 1

Page 746 of 2627

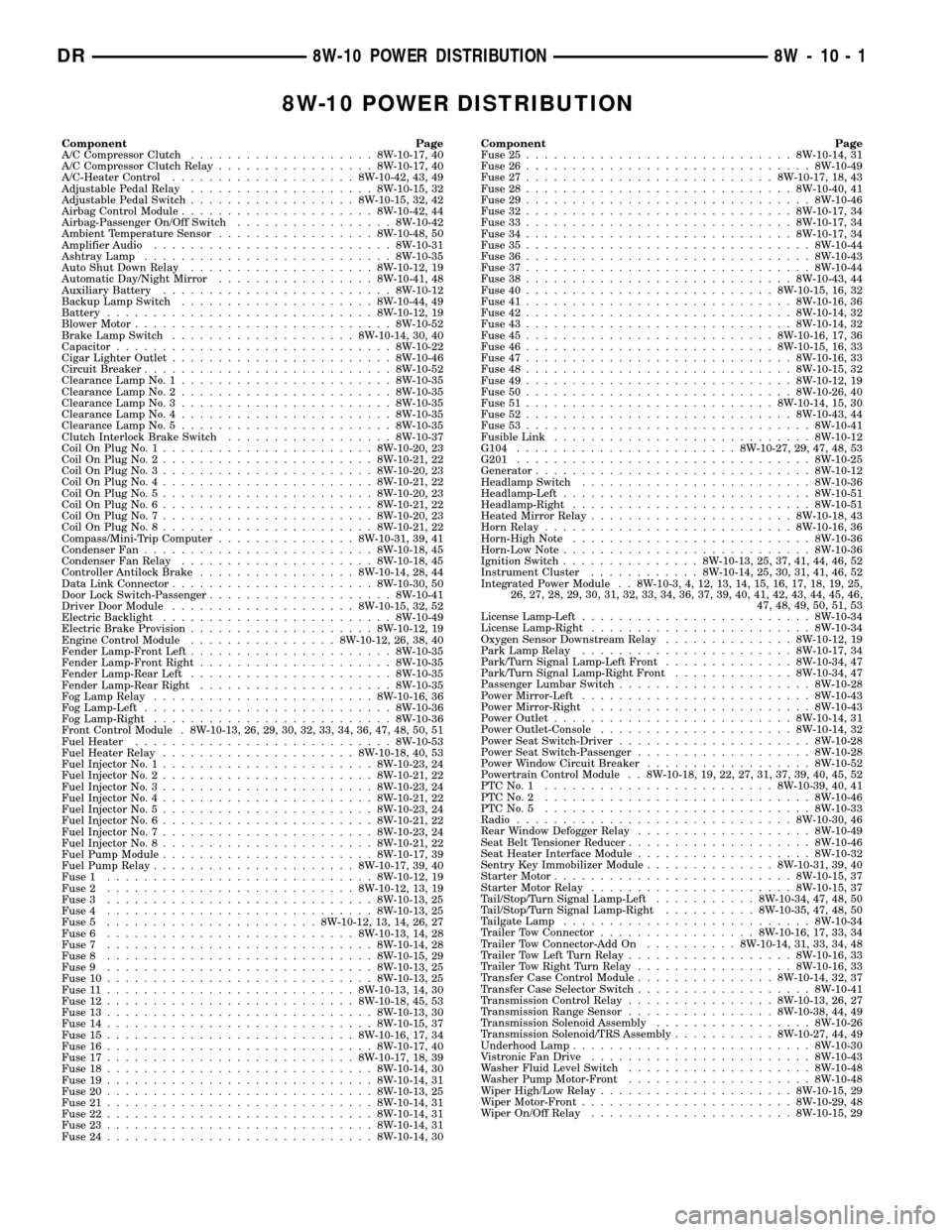

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch....................8W-10-17, 40

A/C Compressor Clutch Relay.................8W-10-17, 40

A/C-Heater Control....................8W-10-42, 43, 49

Adjustable Pedal Relay....................8W-10-15, 32

Adjustable Pedal Switch..................8W-10-15, 32, 42

Airbag Control Module.....................8W-10-42, 44

Airbag-Passenger On/Off Switch.................8W-10-42

Ambient Temperature Sensor.................8W-10-48, 50

Amplifier Audio..........................8W-10-31

Ashtray Lamp...........................8W-10-35

Auto Shut Down Relay....................8W-10-12, 19

Automatic Day/Night Mirror.................8W-10-41, 48

Auxiliary Battery.........................8W-10-12

Backup Lamp Switch.....................8W-10-44, 49

Battery.............................8W-10-12, 19

Blower Motor............................8W-10-52

Brake Lamp Switch....................8W-10-14, 30, 40

Capacitor..............................8W-10-22

Cigar Lighter Outlet........................8W-10-46

Circuit Breaker...........................8W-10-52

Clearance Lamp No. 1.......................8W-10-35

Clearance Lamp No. 2.......................8W-10-35

Clearance Lamp No. 3.......................8W-10-35

Clearance Lamp No. 4.......................8W-10-35

Clearance Lamp No. 5.......................8W-10-35

Clutch Interlock Brake Switch..................8W-10-37

Coil On Plug No. 1.......................8W-10-20, 23

Coil On Plug No. 2.......................8W-10-21, 22

Coil On Plug No. 3.......................8W-10-20, 23

Coil On Plug No. 4.......................8W-10-21, 22

Coil On Plug No. 5.......................8W-10-20, 23

Coil On Plug No. 6.......................8W-10-21, 22

Coil On Plug No. 7.......................8W-10-20, 23

Coil On Plug No. 8.......................8W-10-21, 22

Compass/Mini-Trip Computer...............8W-10-31, 39, 41

Condenser Fan.........................8W-10-18, 45

Condenser Fan Relay.....................8W-10-18, 45

Controller Antilock Brake.................8W-10-14, 28, 44

Data Link Connector......................8W-10-30, 50

Door Lock Switch-Passenger....................8W-10-41

Driver Door Module....................8W-10-15, 32, 52

Electric Backlight.........................8W-10-49

Electric Brake Provision....................8W-10-12, 19

Engine Control Module................8W-10-12, 26, 38, 40

Fender Lamp-Front Left......................8W-10-35

Fender Lamp-Front Right.....................8W-10-35

Fender Lamp-Rear Left......................8W-10-35

Fender Lamp-Rear Right.....................8W-10-35

Fog Lamp Relay........................8W-10-16, 36

Fog Lamp-Left...........................8W-10-36

Fog Lamp-Right..........................8W-10-36

Front Control Module . 8W-10-13, 26, 29, 30, 32, 33, 34, 36, 47, 48, 50, 51

Fuel Heater............................8W-10-53

Fuel Heater Relay.....................8W-10-18, 40, 53

Fuel Injector No. 1.......................8W-10-23, 24

Fuel Injector No. 2.......................8W-10-21, 22

Fuel Injector No. 3.......................8W-10-23, 24

Fuel Injector No. 4.......................8W-10-21, 22

Fuel Injector No. 5.......................8W-10-23, 24

Fuel Injector No. 6.......................8W-10-21, 22

Fuel Injector No. 7.......................8W-10-23, 24

Fuel Injector No. 8.......................8W-10-21, 22

Fuel Pump Module.......................8W-10-17, 39

Fuel Pump Relay......................8W-10-17, 39, 40

Fuse 1.............................8W-10-12, 19

Fuse 2...........................8W-10-12, 13, 19

Fuse 3.............................8W-10-13, 25

Fuse 4.............................8W-10-13, 25

Fuse 5.......................8W-10-12, 13, 14, 26, 27

Fuse 6...........................8W-10-13, 14, 28

Fuse 7.............................8W-10-14, 28

Fuse 8.............................8W-10-15, 29

Fuse 9.............................8W-10-13, 25

Fuse 10.............................8W-10-13, 25

Fuse 11...........................8W-10-13, 14, 30

Fuse 12...........................8W-10-18, 45, 53

Fuse 13.............................8W-10-13, 30

Fuse 14.............................8W-10-15, 37

Fuse 15...........................8W-10-16, 17, 34

Fuse 16.............................8W-10-17, 40

Fuse 17...........................8W-10-17, 18, 39

Fuse 18.............................8W-10-14, 30

Fuse 19.............................8W-10-14, 31

Fuse 20.............................8W-10-13, 25

Fuse 21.............................8W-10-14, 31

Fuse 22.............................8W-10-14, 31

Fuse 23.............................8W-10-14, 31

Fuse 24.............................8W-10-14, 30Component Page

Fuse 25.............................8W-10-14, 31

Fuse 26...............................8W-10-49

Fuse 27...........................8W-10-17, 18, 43

Fuse 28.............................8W-10-40, 41

Fuse 29...............................8W-10-46

Fuse 32.............................8W-10-17, 34

Fuse 33.............................8W-10-17, 34

Fuse 34.............................8W-10-17, 34

Fuse 35...............................8W-10-44

Fuse 36...............................8W-10-43

Fuse 37...............................8W-10-44

Fuse 38.............................8W-10-43, 44

Fuse 40...........................8W-10-15, 16, 32

Fuse 41.............................8W-10-16, 36

Fuse 42.............................8W-10-14, 32

Fuse 43.............................8W-10-14, 32

Fuse 45...........................8W-10-16, 17, 36

Fuse 46...........................8W-10-15, 16, 33

Fuse 47.............................8W-10-16, 33

Fuse 48.............................8W-10-15, 32

Fuse 49.............................8W-10-12, 19

Fuse 50.............................8W-10-26, 40

Fuse 51...........................8W-10-14, 15, 30

Fuse 52.............................8W-10-43, 44

Fuse 53...............................8W-10-41

Fusible Link............................8W-10-12

G104........................8W-10-27, 29, 47, 48, 53

G201................................8W-10-25

Generator..............................8W-10-12

Headlamp Switch.........................8W-10-36

Headlamp-Left...........................8W-10-51

Headlamp-Right..........................8W-10-51

Heated Mirror Relay......................8W-10-18, 43

Horn Relay...........................8W-10-16, 36

Horn-High Note..........................8W-10-36

Horn-Low Note...........................8W-10-36

Ignition Switch...............8W-10-13, 25, 37, 41, 44, 46, 52

Instrument Cluster............8W-10-14, 25, 30, 31, 41, 46, 52

Integrated Power Module . . 8W-10-3, 4, 12, 13, 14, 15, 16, 17, 18, 19, 25,

26, 27, 28, 29, 30, 31, 32, 33, 34, 36, 37, 39, 40, 41, 42, 43, 44, 45, 46,

47, 48, 49, 50, 51, 53

License Lamp-Left.........................8W-10-34

License Lamp-Right........................8W-10-34

Oxygen Sensor Downstream Relay..............8W-10-12, 19

Park Lamp Relay.......................8W-10-17, 34

Park/Turn Signal Lamp-Left Front..............8W-10-34, 47

Park/Turn Signal Lamp-Right Front.............8W-10-34, 47

Passenger Lumbar Switch.....................8W-10-28

Power Mirror-Left.........................8W-10-43

Power Mirror-Right........................8W-10-43

Power Outlet..........................8W-10-14, 31

Power Outlet-Console.....................8W-10-14, 32

Power Seat Switch-Driver.....................8W-10-28

Power Seat Switch-Passenger...................8W-10-28

Power Window Circuit Breaker..................8W-10-52

Powertrain Control Module . . 8W-10-18, 19, 22, 27, 31, 37, 39, 40, 45, 52

PTCNo.1 .........................8W-10-39, 40, 41

PTCNo.2 .............................8W-10-46

PTCNo.5 .............................8W-10-33

Radio..............................8W-10-30, 46

Rear Window Defogger Relay...................8W-10-49

Seat Belt Tensioner Reducer....................8W-10-46

Seat Heater Interface Module...................8W-10-32

Sentry Key Immobilizer Module..............8W-10-31, 39, 40

Starter Motor..........................8W-10-15, 37

Starter Motor Relay......................8W-10-15, 37

Tail/Stop/Turn Signal Lamp-Left...........8W-10-34, 47, 48, 50

Tail/Stop/Turn Signal Lamp-Right..........8W-10-35, 47, 48, 50

Tailgate Lamp...........................8W-10-34

Trailer Tow Connector.................8W-10-16, 17, 33, 34

Trailer Tow Connector-Add On..........8W-10-14, 31, 33, 34, 48

Trailer Tow Left Turn Relay..................8W-10-16, 33

Trailer Tow Right Turn Relay.................8W-10-16, 33

Transfer Case Control Module...............8W-10-14, 32, 37

Transfer Case Selector Switch...................8W-10-41

Transmission Control Relay................8W-10-13, 26, 27

Transmission Range Sensor................8W-10-38, 44, 49

Transmission Solenoid Assembly.................8W-10-26

Transmission Solenoid/TRS Assembly...........8W-10-27, 44, 49

Underhood Lamp..........................8W-10-30

Vistronic Fan Drive........................8W-10-43

Washer Fluid Level Switch....................8W-10-48

Washer Pump Motor-Front....................8W-10-48

Wiper High/Low Relay.....................8W-10-15, 29

Wiper Motor-Front.......................8W-10-29, 48

Wiper On/Off Relay......................8W-10-15, 29

DR8W-10 POWER DISTRIBUTION 8W - 10 - 1