Intake DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1414 of 2627

(6) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(7) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(8) Remove the upper crossmember and top core

support.

NOTE: It is not necessary to drain A/C system for

engine removal.

(9) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(10) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR -

REMOVAL).

(11) Remove the intake manifold and IAFM as an

assembly(Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - REMOVAL).

(12) Disconnect the heater hoses.

NOTE: It is not necessary to disconnect P/S hoses

from pump, for P/S pump removal.

(13) Remove the power steering pump and set

aside.

(14) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(15) Raise and support the vehicle on a hoist and

drain the engine oil.

(16) Remove engine front mount thru-bolt nuts.

(17) Remove right side axle retaining bolts.

(18) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(19) Disconnect exhaust pipe at manifolds.

(20) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(21) Remove the structural dust cover and trans-

mission inspection cover,(Refer to 9 - ENGINE/EN-

GINE BLOCK/STRUCTURAL COVER - REMOVAL).

(22) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).

(23) Remove transmission bell housing to engine

block bolts.

(24) Lower the vehicle.

(25) Install engine lift fixture, special tool # 8984.

(26) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Install engine lift fixture Special tool # 8984.

(2) Position the engine in the engine compartment.

(3) Lower engine into compartment and align

engine with transmission:²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Position the thru-bolt into the support cushion

brackets.

(5) Lower engine assembly until engine mount

through bolts rest in mount perches.

(6) Install remaining transmission to engine block

mounting bolts and tighten.

(7) Tighten engine mount through bolts.

(8) Install drive plate to torque converter bolts.

(Automatic transmission models)

(9) Install the structural dust cover and transmis-

sion dust cover,(Refer to 9 - ENGINE/ENGINE

BLOCK/STRUCTURAL COVER - INSTALLATION).

(10) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(11) Install exhaust pipe to manifold.

(12) Lower the vehicle.

(13) Remove engine lift fixture, special tool # 8984.

(14) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(15) Reinstall the power steering pump.

(16) Connect the heater hoses.

(17) Install the intake manifold.

(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(20) Install a/c compressor and lines (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

(21) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(22) Install upper radiator support crossmember.

(23) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(24) Connect the radiator lower hose.

(25) Connect the transmission oil cooler lines to

the radiator.

(26) Install the fan shroud.

(27) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(28) Connect the radiator upper hose.

(29) Install the washer bottle.

(30) Connect the transmission cooler lines.

DRENGINE - 5.7L 9 - 191

ENGINE - 5.7L (Continued)

Page 1417 of 2627

VALVE TIMING

DESCRIPTION SPECIFICATION

Intake

Opens (BTDC) 7.0É

Closes (ATDC) 253.0É

Exhaust

Opens (BTDC) 233É

Closes (ATDC) 27É

Duration 253.70É

Valve Overlap 34É

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.05 mm (0.0019 in.)

Valve Seat Width (Finish)

Intake 1.018 - 1.62 mm

(0.0464 - 0.0637 in.)

Exhaust 1.48 - 1.92 mm

(0.0582 - 0.0755 in.)

Guide Bore Diameter

(Std.)7.975 - 8.00 mm

(0.313 - 0.314 in.)

HYDRAULIC TAPPETS

DESCRIPTION SPECIFICATION

Metric Standard

Body Diameter 21.387 - 21.405

mm0.8420 - 0.8427

in.

Clearance (To

Bore)0.020 - 0.063

mm0.0007 - 0.0024

in.

Dry Lash 3.0 mm (at the

valve)0.1181 in.

VALVES

DESCRIPTION SPECIFICATION

Face Angle 45.0É - 45.5É

Head Diameter

Intake 50.67 - 50.93 mm

(1.99 - 2.00 in.)

Exhaust 39.27 - 39.53 mm

(1.54 - 1.55 in.)

Length (Overall)

Intake 123.38 - 123.76 mm

(4.857 - 4.872 in.)

Exhaust 120.475 - 120.855 mm

(4.743 - 4.758 in.)

Stem Diameter

Intake 7.935 - 7.953 mm

(0.312 - 0.313 in.)

Exhaust 7.905 - 7.925 mm

(0.311 - 0.312 in.)

Stem - to - Guide

Clearance

Intake 0.022 - 0.065 mm

(0.0008 - 0.0025 in.)

Exhaust 0.050 - 0.095 mm

(0.0019 - 0.0037 in.)

Valve Lift ( @ Zero Lash)

Intake 12.0 mm (0.472 in.)

Exhaust 11.70 mm (0.460 in.)

9 - 194 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1418 of 2627

VALVE SPRING

DESCRIPTION SPECIFICATION

Spring Force (Valve

Closed)

Intake and Exhaust 422.0 N @ 46.0 mm

(95lbs. @ 1.81 in.)

Spring Force (Valve

Open)

Intake and Exhaust @ 33.5 mm

Number of Coils

Intake and Exhaust 7.4

Wire Diameter

Intake and Exhaust 5.39 ý 4.52 mm

(0.212 - 0.177 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Intake and Exhaust 46.0 mm (1.81 in.)

OIL PUMP

DESCRIPTION SPECIFICATION

Clearance Over Rotors

(MAX)0.095 mm (0.0038 in.)

Outer Rotor to Pump

Body Clearance (MAX).235 mm (.009 in.)

Tip Clearance Between

Rotors (MAX)0.150 mm (0.006 in.)

OIL PRESSURE

SPECIFICATION SPECIFICATION

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine

TORQUE

TORQUE CHART 5.7L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Block Pipe Plugs

(1/4 NPT)20 Ð 177

(3/8 NPT) 27 Ð 240

Camshaft SprocketÐBolt 122 90 Ð

Camshaft Tensioner

PlateÐBolts28 Ð 250

Timing Chain Case CoverÐ

Bolts28 Ð 250

Lifting Stud 55 40 Ð

Connecting Rod CapÐBolts 21

plus

90É

Turn15

plus

90É

TurnÐ

Main Bearing CapÐBolts

M-1227

plus

90É

TurnÐÐ

Crossbolts

M-828 Ð Ð

Cylinder HeadÐBolts

M-12 Bolts

Step 1 34 25 Ð

Step 2 54 40 Ð

Step 3 Turn

90ÉTurn

90ÉÐ

M-8 Bolts Ð

Step 1 20 15 Ð

Step 2 34 25 Ð

Cylinder Head CoverÐBolts 8 Ð 70

Exhaust Manifold to Cylinder

Head25 Ð 220

Flexplate to crankshaftÐBolts 95 70 Ð

Flywheel to crankshaftÐBolts 75 55 Ð

Front InsulatorÐThrough

bolt/nut95 70 Ð

Front Insulator to Support

Bracket

ÐStud Nut (4WD) 41 30 Ð

ÐThrough Bolt/Nut (4WD) 102 75 Ð

Front Insulator to BlockÐ

Bolts (2WD)95 70 Ð

DRENGINE - 5.7L 9 - 195

ENGINE - 5.7L (Continued)

Page 1419 of 2627

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

GeneratorÐMounting Bolt 55 40 Ð

Intake ManifoldÐBolts Refer to Procedure

Lifter Guide Holder 12 Ð 106

Oil Pan Bolts 12 - 105

Oil Dipstick Tube 12 Ð 105

Oil PanÐDrain Plug 34 25 Ð

Oil PumpÐAttaching Bolts 28 Ð 250

Oil Pump Pickup Tube ± Bolt

and Nut28 Ð 250

Rear Seal Retainer Attaching

Bolts15 Ð 132

Rear Insulator to BracketÐ 68 50 Ð

Through-Bolt (2WD)

Rear Insulator to

Crossmember41 30 Ð

Support BracketÐNut (2WD)

Rear Insulator to

CrossmemberÐ68 50 Ð

Nuts (4WD)

Rear Insulator to

TransmissionÐ68 50 Ð

Bolts (4WD)

Rear Insulator BracketÐBolts 68 50 Ð

(4WD Automatic)

Rear Support Bracket to 41 30 Ð

Crossmember FlangeÐNuts

Rear Support Plate to

Transfer41 30 Ð

CaseÐBolts

Rocker ArmÐBolts 22 Ð 195

Spark Plugs Ð Ð Ð

Thermostat HousingÐBolts 28 Ð 250

Throttle BodyÐBolts 12 Ð 105

Transfer Case to Insulator 204 105 Ð

Mounting PlateÐNuts

Transmission Support

BracketÐ68 50 Ð

Bolts (2WD)

Vibration DamperÐBolt 176 129 Ð

Water Pump to Timing Chain 28 Ð 250

Case CoverÐBoltsSPECIAL TOOLS

5.7L ENGINE

CRANKSHAFT DAMPER REMOVER INSERT - 8513-A

Bloc±Chek±Kit C-3685±A

Bore Size Indicator C-119

Puller 8454

Crankshaft Damper Installer 8512

9 - 196 ENGINE - 5.7LDR

ENGINE - 5.7L (Continued)

Page 1422 of 2627

AIR INTAKE SYSTEM

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

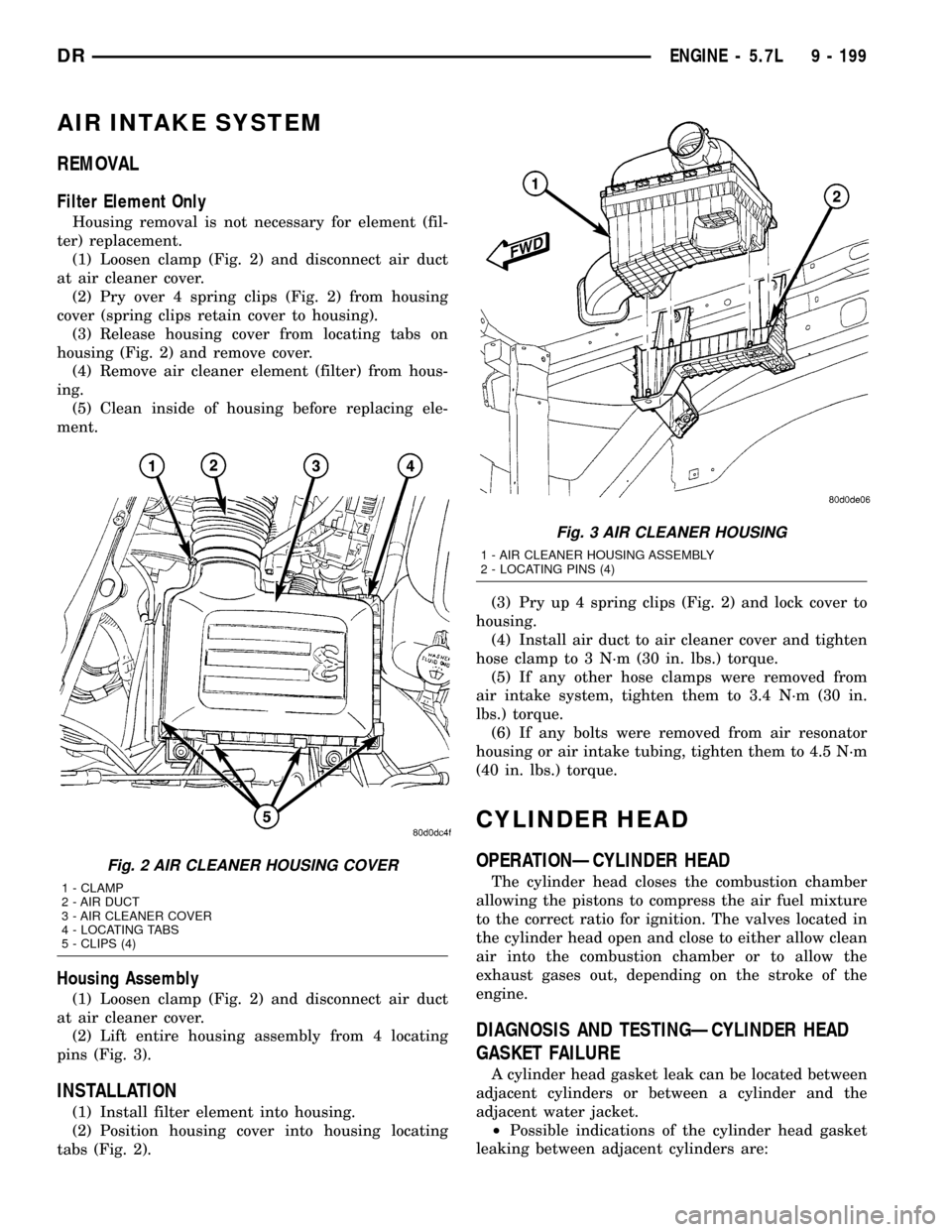

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 2) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 2) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

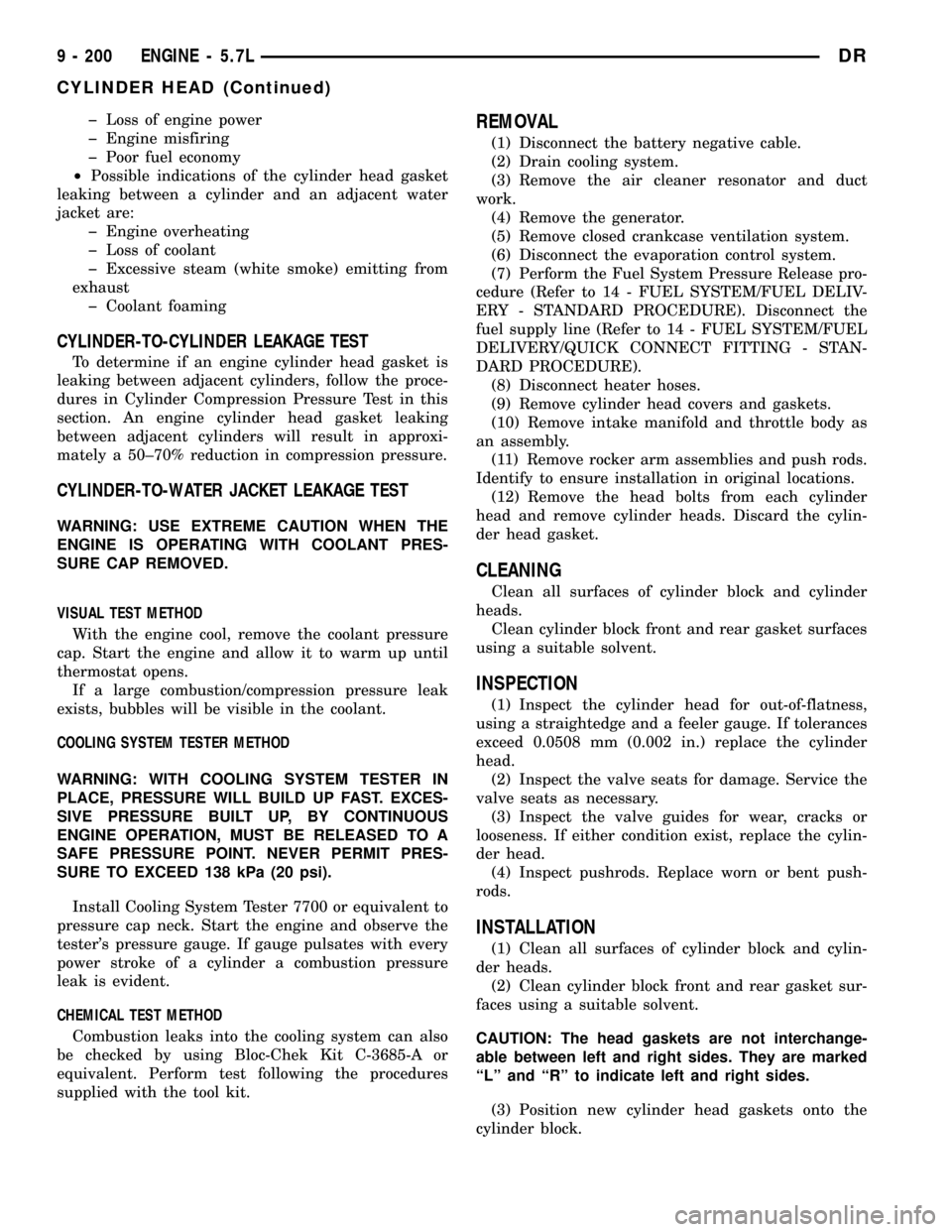

(2) Lift entire housing assembly from 4 locating

pins (Fig. 3).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 2).(3) Pry up 4 spring clips (Fig. 2) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture

to the correct ratio for ignition. The valves located in

the cylinder head open and close to either allow clean

air into the combustion chamber or to allow the

exhaust gases out, depending on the stroke of the

engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

Fig. 2 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 3 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

DRENGINE - 5.7L 9 - 199

Page 1423 of 2627

þ Loss of engine power

þ Engine misfiring

þ Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

þ Engine overheating

þ Loss of coolant

þ Excessive steam (white smoke) emitting from

exhaust

þ Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system.

(3) Remove the air cleaner resonator and duct

work.

(4) Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel supply line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect heater hoses.

(9) Remove cylinder head covers and gaskets.

(10) Remove intake manifold and throttle body as

an assembly.

(11) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(12) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

(4) Inspect pushrods. Replace worn or bent push-

rods.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylin-

der heads.

(2) Clean cylinder block front and rear gasket sur-

faces using a suitable solvent.

CAUTION: The head gaskets are not interchange-

able between left and right sides. They are marked

ªLº and ªRº to indicate left and right sides.

(3) Position new cylinder head gaskets onto the

cylinder block.

9 - 200 ENGINE - 5.7LDR

CYLINDER HEAD (Continued)

Page 1424 of 2627

CAUTION: The head gaskets are marked ªTOPº to

indicate which side goes up.

(4) Position cylinder heads onto head gaskets and

cylinder block.

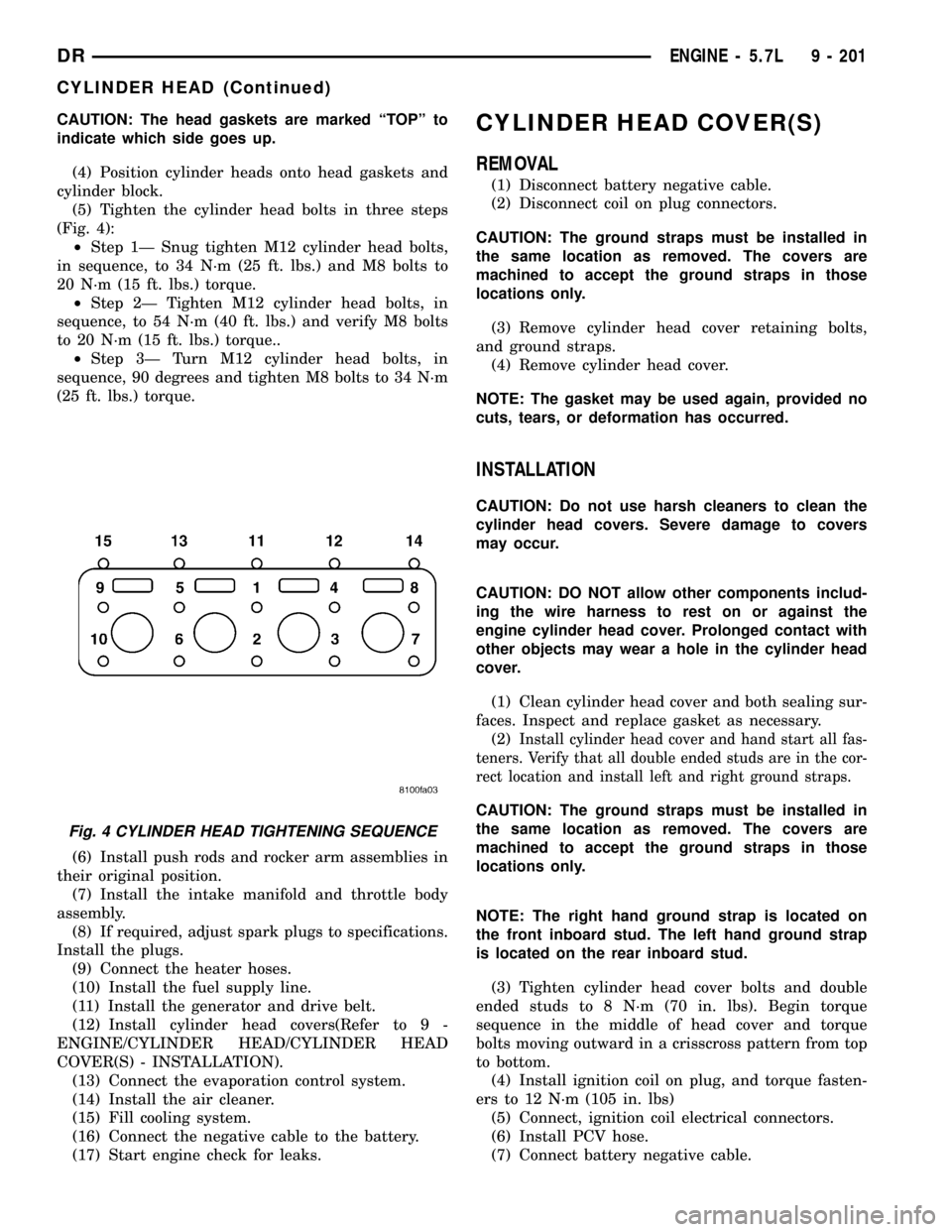

(5) Tighten the cylinder head bolts in three steps

(Fig. 4):

²Step 1Ð Snug tighten M12 cylinder head bolts,

in sequence, to 34 N´m (25 ft. lbs.) and M8 bolts to

20 N´m (15 ft. lbs.) torque.

²Step 2Ð Tighten M12 cylinder head bolts, in

sequence, to 54 N´m (40 ft. lbs.) and verify M8 bolts

to 20 N´m (15 ft. lbs.) torque..

²Step 3Ð Turn M12 cylinder head bolts, in

sequence, 90 degrees and tighten M8 bolts to 34 N´m

(25 ft. lbs.) torque.

(6) Install push rods and rocker arm assemblies in

their original position.

(7) Install the intake manifold and throttle body

assembly.

(8) If required, adjust spark plugs to specifications.

Install the plugs.

(9) Connect the heater hoses.

(10) Install the fuel supply line.

(11) Install the generator and drive belt.

(12) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Connect the evaporation control system.

(14) Install the air cleaner.

(15) Fill cooling system.

(16) Connect the negative cable to the battery.

(17) Start engine check for leaks.CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect coil on plug connectors.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

(3) Remove cylinder head cover retaining bolts,

and ground straps.

(4) Remove cylinder head cover.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2)

Install cylinder head cover and hand start all fas-

teners. Verify that all double ended studs are in the cor-

rect location and install left and right ground straps.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

NOTE: The right hand ground strap is located on

the front inboard stud. The left hand ground strap

is located on the rear inboard stud.

(3) Tighten cylinder head cover bolts and double

ended studs to 8 N´m (70 in. lbs). Begin torque

sequence in the middle of head cover and torque

bolts moving outward in a crisscross pattern from top

to bottom.

(4) Install ignition coil on plug, and torque fasten-

ers to 12 N´m (105 in. lbs)

(5) Connect, ignition coil electrical connectors.

(6) Install PCV hose.

(7) Connect battery negative cable.

Fig. 4 CYLINDER HEAD TIGHTENING SEQUENCE

DRENGINE - 5.7L 9 - 201

CYLINDER HEAD (Continued)

Page 1425 of 2627

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

DESCRIPTION

Both the intake and exhaust valves are made of

steel. The intake valve is 50.93 mm (2.00 inches) in

diameter and the exhaust valve is 39.53 mm (1.55

inches) in diameter. All valves use three bead lock

keepers to retain the springs and promote valve rota-

tion.

STANDARD PROCEDURE - REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.018 - 1.62 mm (0.0464 -

0.0637 in.) and the exhaust seat must be 1.48 - 1.92

mm (0.058 - 0.075 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 46.0 mm (1.81 in.).

VALVE FACE AND VALVE SEAT ANGLE CHART

DESCRIPTION SPECIFICATION

SEAT WIDTH

INTAKE 1.018 - 1.62 mm

(0.0464 - 0.0637 in.)

EXHAUST 1.48 - 1.92 mm

(0.058 - 0.075 in.)

FACE ANGLE

(INT. AND EXT.) 45É - 45

1¤2É

SEAT ANGLE

(INT. AND EXT.) 44

1¤2É - 45É

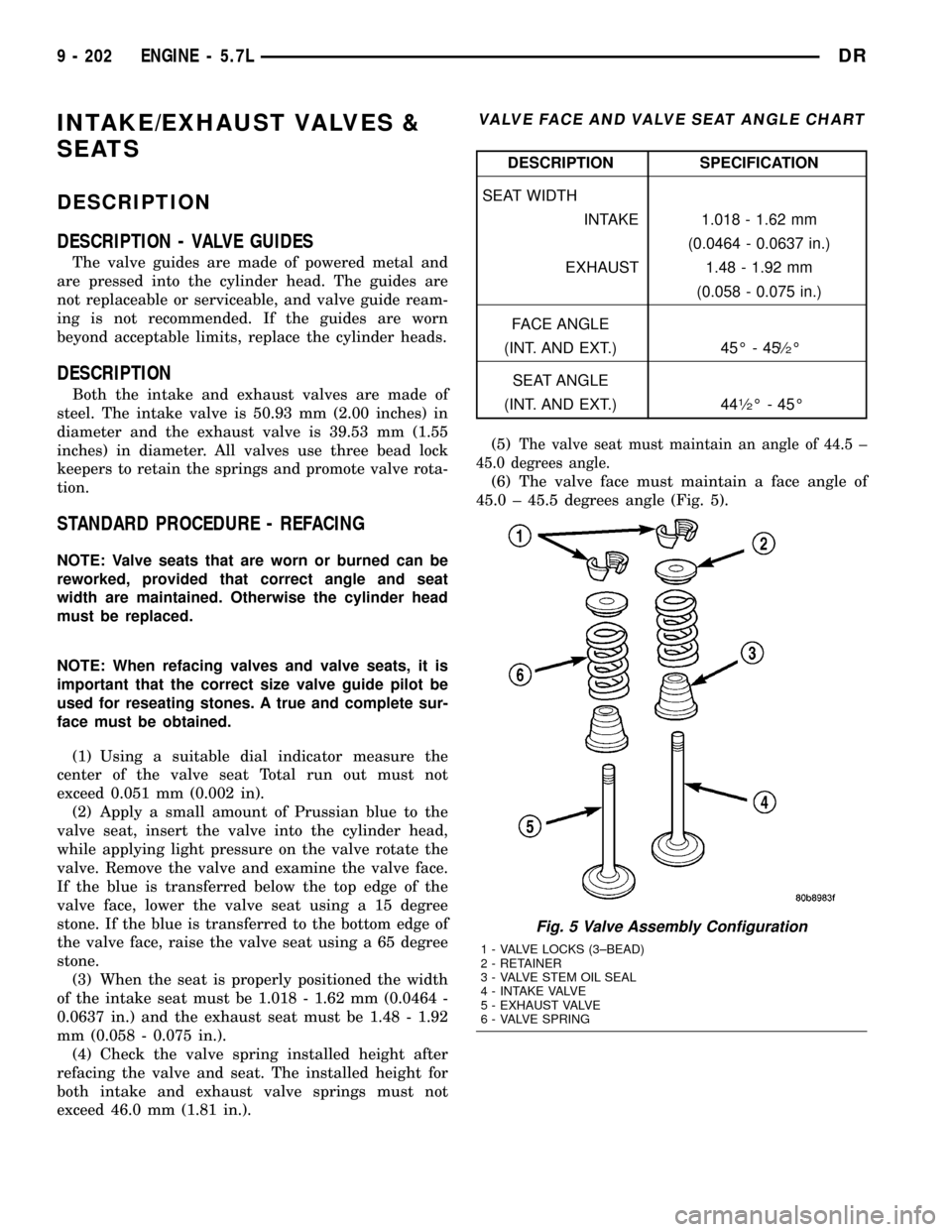

(5)

The valve seat must maintain an angle of 44.5 ±

45.0 degrees angle.

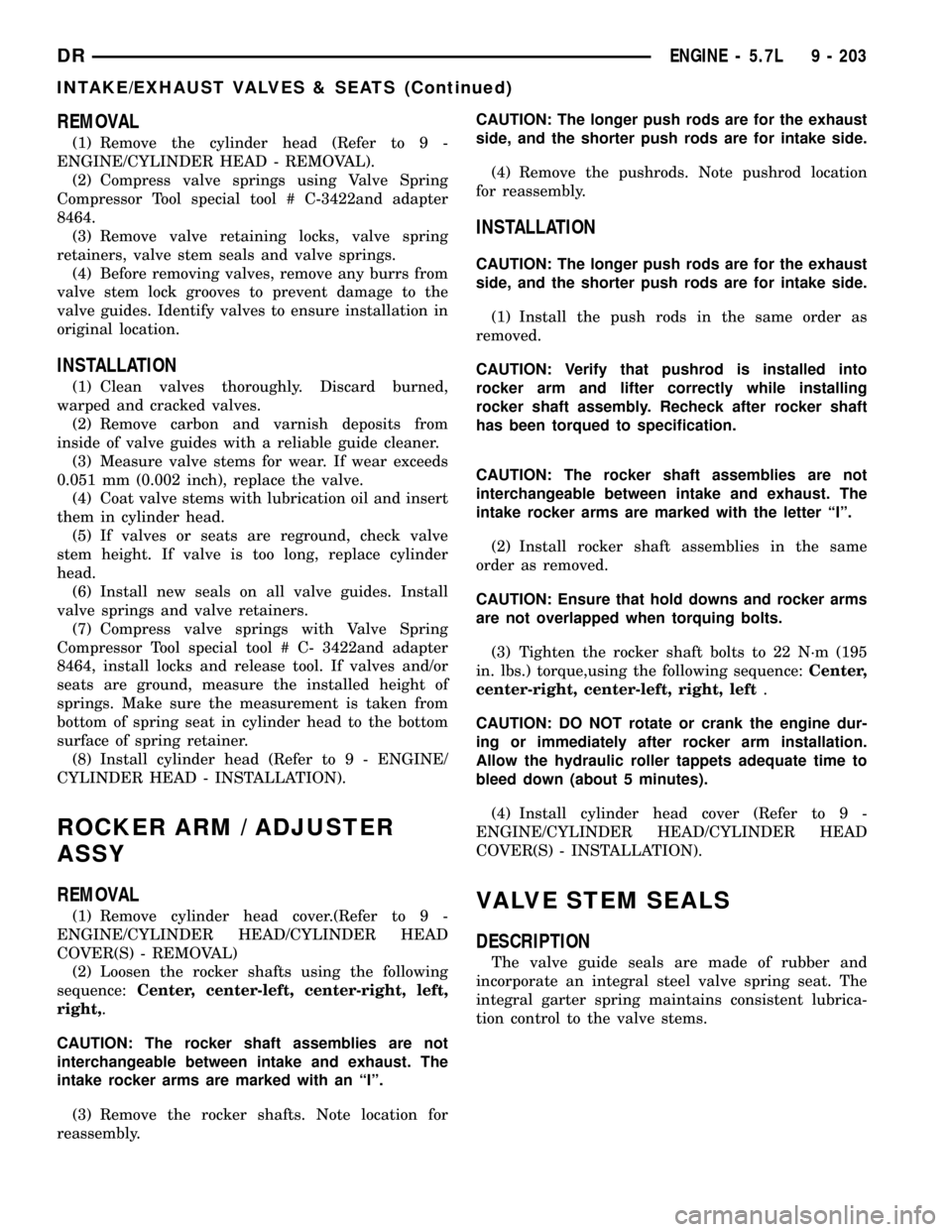

(6) The valve face must maintain a face angle of

45.0 ± 45.5 degrees angle (Fig. 5).

Fig. 5 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

9 - 202 ENGINE - 5.7LDR

Page 1426 of 2627

REMOVAL

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Compress valve springs using Valve Spring

Compressor Tool special tool # C-3422and adapter

8464.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

INSTALLATION

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(3) Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

(4) Coat valve stems with lubrication oil and insert

them in cylinder head.

(5) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(6) Install new seals on all valve guides. Install

valve springs and valve retainers.

(7) Compress valve springs with Valve Spring

Compressor Tool special tool # C- 3422and adapter

8464, install locks and release tool. If valves and/or

seats are ground, measure the installed height of

springs. Make sure the measurement is taken from

bottom of spring seat in cylinder head to the bottom

surface of spring retainer.

(8) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

ROCKER ARM / ADJUSTER

ASSY

REMOVAL

(1) Remove cylinder head cover.(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Loosen the rocker shafts using the following

sequence:Center, center-left, center-right, left,

right,.

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with an ªIº.

(3) Remove the rocker shafts. Note location for

reassembly.CAUTION: The longer push rods are for the exhaust

side, and the shorter push rods are for intake side.

(4) Remove the pushrods. Note pushrod location

for reassembly.

INSTALLATION

CAUTION: The longer push rods are for the exhaust

side, and the shorter push rods are for intake side.

(1) Install the push rods in the same order as

removed.

CAUTION: Verify that pushrod is installed into

rocker arm and lifter correctly while installing

rocker shaft assembly. Recheck after rocker shaft

has been torqued to specification.

CAUTION: The rocker shaft assemblies are not

interchangeable between intake and exhaust. The

intake rocker arms are marked with the letter ªIº.

(2) Install rocker shaft assemblies in the same

order as removed.

CAUTION: Ensure that hold downs and rocker arms

are not overlapped when torquing bolts.

(3) Tighten the rocker shaft bolts to 22 N´m (195

in. lbs.) torque,using the following sequence:Center,

center-right, center-left, right, left.

CAUTION: DO NOT rotate or crank the engine dur-

ing or immediately after rocker arm installation.

Allow the hydraulic roller tappets adequate time to

bleed down (about 5 minutes).

(4) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE STEM SEALS

DESCRIPTION

The valve guide seals are made of rubber and

incorporate an integral steel valve spring seat. The

integral garter spring maintains consistent lubrica-

tion control to the valve stems.

DRENGINE - 5.7L 9 - 203

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1427 of 2627

VALVE SPRINGS

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner assembly.

(3) Remove air intake resonator.

(4) Remove spark plug cables.

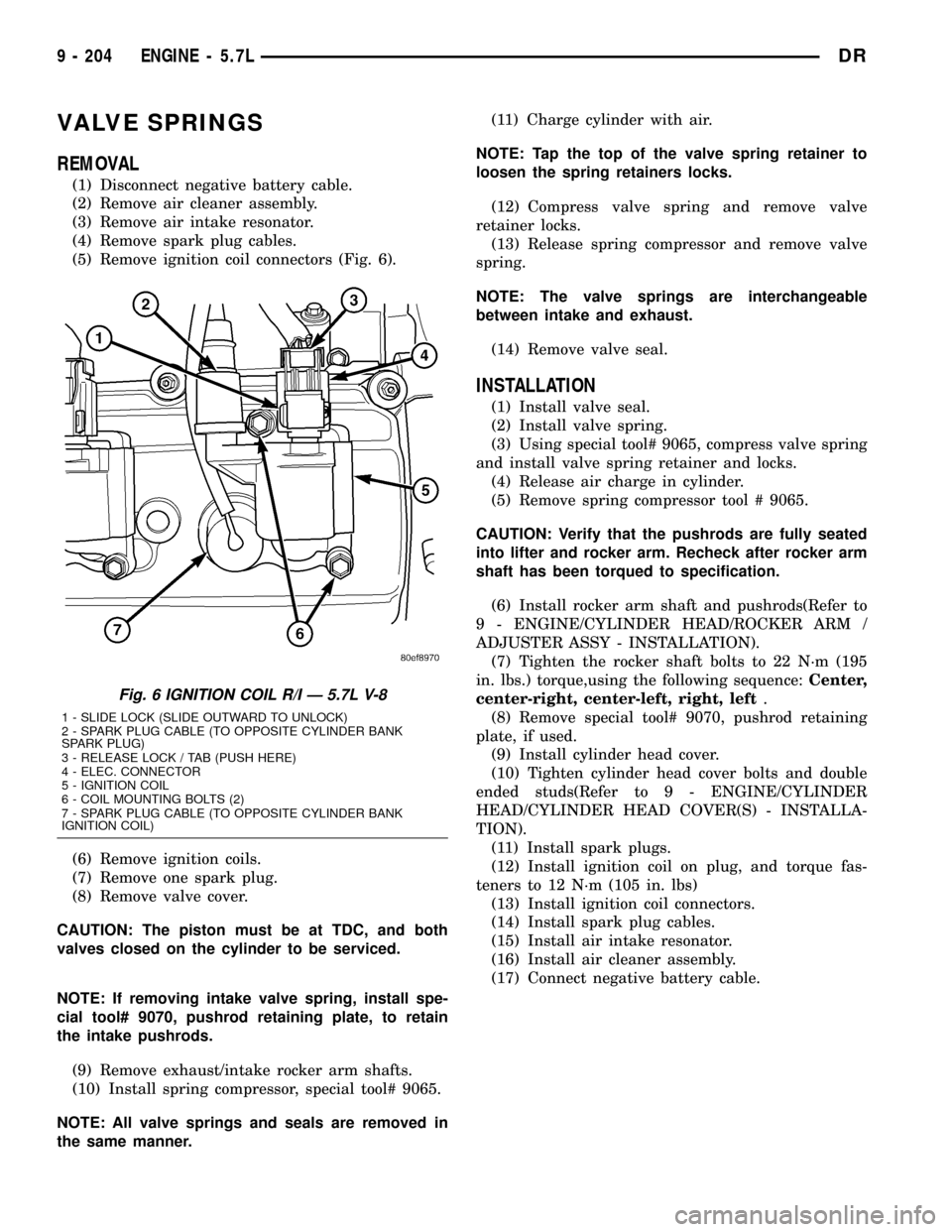

(5) Remove ignition coil connectors (Fig. 6).

(6) Remove ignition coils.

(7) Remove one spark plug.

(8) Remove valve cover.

CAUTION: The piston must be at TDC, and both

valves closed on the cylinder to be serviced.

NOTE: If removing intake valve spring, install spe-

cial tool# 9070, pushrod retaining plate, to retain

the intake pushrods.

(9) Remove exhaust/intake rocker arm shafts.

(10) Install spring compressor, special tool# 9065.

NOTE: All valve springs and seals are removed in

the same manner.(11) Charge cylinder with air.

NOTE: Tap the top of the valve spring retainer to

loosen the spring retainers locks.

(12) Compress valve spring and remove valve

retainer locks.

(13) Release spring compressor and remove valve

spring.

NOTE: The valve springs are interchangeable

between intake and exhaust.

(14) Remove valve seal.

INSTALLATION

(1) Install valve seal.

(2) Install valve spring.

(3) Using special tool# 9065, compress valve spring

and install valve spring retainer and locks.

(4) Release air charge in cylinder.

(5) Remove spring compressor tool # 9065.

CAUTION: Verify that the pushrods are fully seated

into lifter and rocker arm. Recheck after rocker arm

shaft has been torqued to specification.

(6) Install rocker arm shaft and pushrods(Refer to

9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - INSTALLATION).

(7) Tighten the rocker shaft bolts to 22 N´m (195

in. lbs.) torque,using the following sequence:Center,

center-right, center-left, right, left.

(8) Remove special tool# 9070, pushrod retaining

plate, if used.

(9) Install cylinder head cover.

(10) Tighten cylinder head cover bolts and double

ended studs(Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

(11) Install spark plugs.

(12) Install ignition coil on plug, and torque fas-

teners to 12 N´m (105 in. lbs)

(13) Install ignition coil connectors.

(14) Install spark plug cables.

(15) Install air intake resonator.

(16) Install air cleaner assembly.

(17) Connect negative battery cable.

Fig. 6 IGNITION COIL R/I Ð 5.7L V-8

1 - SLIDE LOCK (SLIDE OUTWARD TO UNLOCK)

2 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

SPARK PLUG)

3 - RELEASE LOCK / TAB (PUSH HERE)

4 - ELEC. CONNECTOR

5 - IGNITION COIL

6 - COIL MOUNTING BOLTS (2)

7 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

IGNITION COIL)

9 - 204 ENGINE - 5.7LDR