Car seat DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2362 of 2627

INSTALLATION

(1) Route the shoulder belt through the slot in the

trim.

(2) Position the trim and seat the attachment clips

fully.

(3) Install the seat belt anchor bolt and tighten to

40 N´m (30 ft. lbs.).

(4) Install the upper c-pillar trim. (Refer to 23 -

BODY/INTERIOR/C-PILLAR UPPER TRIM -

INSTALLATION)

C-PILLAR UPPER TRIM

REMOVAL

(1) Remove the seat belt turning loop. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT TURNING

LOOP ADJUSTER - REMOVAL)

(2) Using a trim stick C-4755 or equivalent,

remove the upper c-pillar trim. (Fig. 11)

INSTALLATION

(1) Position the upper c-pillar trim and seat the

attachment clips fully.

(2) Install the seat belt turning loop. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT TURNING

LOOP ADJUSTER - INSTALLATION)

FLOOR CONSOLE

REMOVAL

(1) Remove the 4WD shifter boot. (Refer to 23 -

BODY/INTERIOR/4WD FLOOR SHIFT BOOT -

REMOVAL)

(2) Using a trim stick C-4755 or equivalent, pry up

the transmission shifter boot from the console.

(3) Remove the transmission shifter extension.

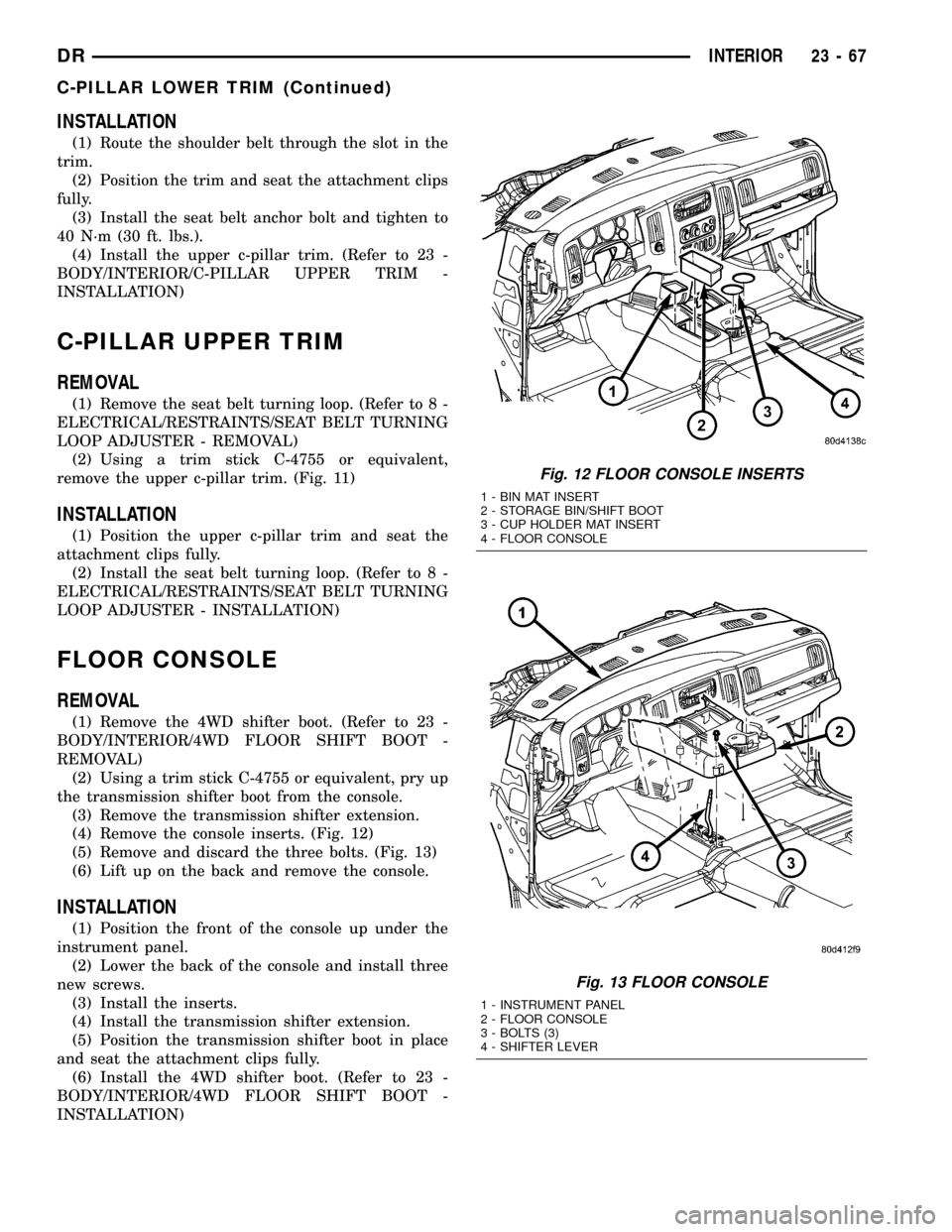

(4) Remove the console inserts. (Fig. 12)

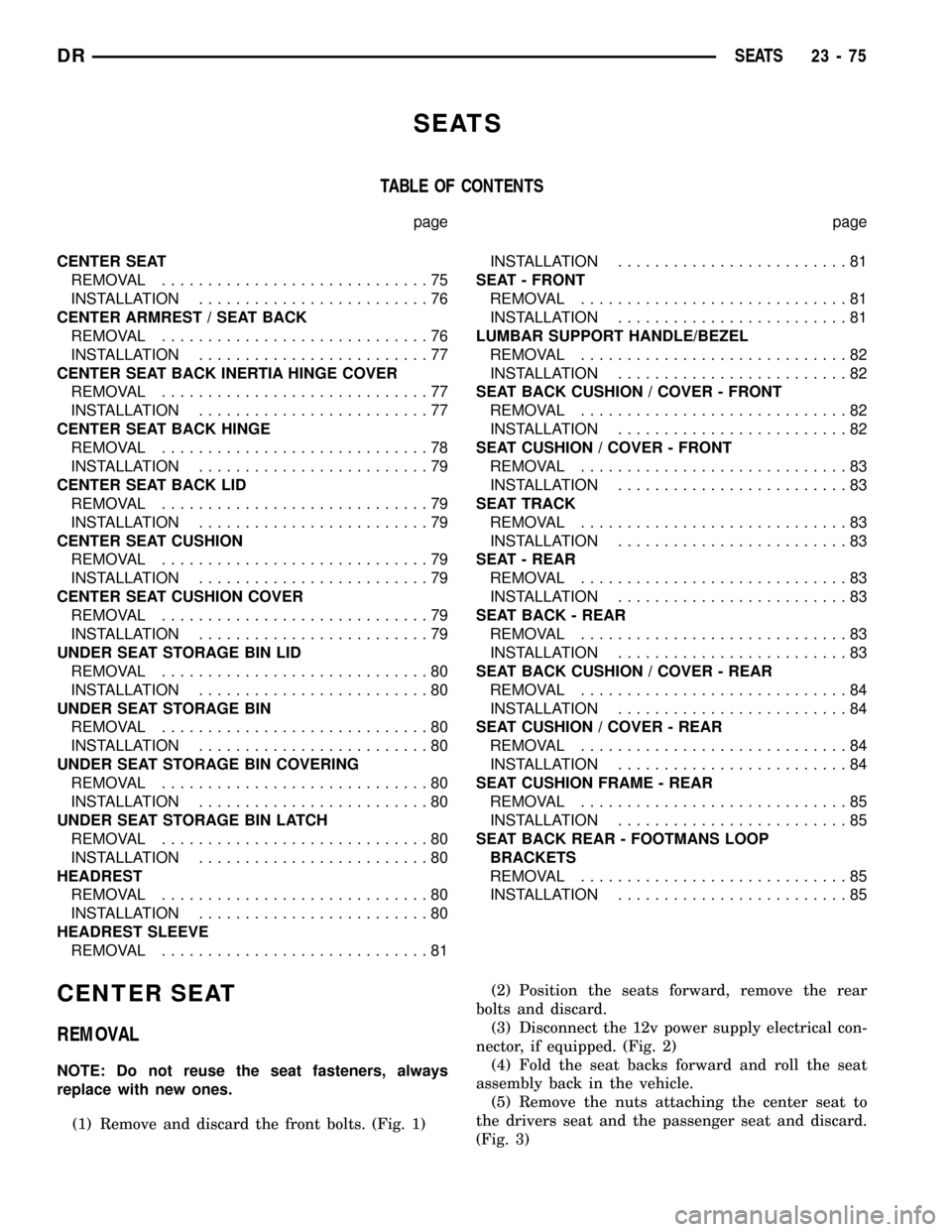

(5) Remove and discard the three bolts. (Fig. 13)

(6) Lift up on the back and remove the console.

INSTALLATION

(1) Position the front of the console up under the

instrument panel.

(2) Lower the back of the console and install three

new screws.

(3) Install the inserts.

(4) Install the transmission shifter extension.

(5) Position the transmission shifter boot in place

and seat the attachment clips fully.

(6) Install the 4WD shifter boot. (Refer to 23 -

BODY/INTERIOR/4WD FLOOR SHIFT BOOT -

INSTALLATION)

Fig. 12 FLOOR CONSOLE INSERTS

1 - BIN MAT INSERT

2 - STORAGE BIN/SHIFT BOOT

3 - CUP HOLDER MAT INSERT

4 - FLOOR CONSOLE

Fig. 13 FLOOR CONSOLE

1 - INSTRUMENT PANEL

2 - FLOOR CONSOLE

3 - BOLTS (3)

4 - SHIFTER LEVER

DRINTERIOR 23 - 67

C-PILLAR LOWER TRIM (Continued)

Page 2370 of 2627

SEATS

TABLE OF CONTENTS

page page

CENTER SEAT

REMOVAL.............................75

INSTALLATION.........................76

CENTER ARMREST / SEAT BACK

REMOVAL.............................76

INSTALLATION.........................77

CENTER SEAT BACK INERTIA HINGE COVER

REMOVAL.............................77

INSTALLATION.........................77

CENTER SEAT BACK HINGE

REMOVAL.............................78

INSTALLATION.........................79

CENTER SEAT BACK LID

REMOVAL.............................79

INSTALLATION.........................79

CENTER SEAT CUSHION

REMOVAL.............................79

INSTALLATION.........................79

CENTER SEAT CUSHION COVER

REMOVAL.............................79

INSTALLATION.........................79

UNDER SEAT STORAGE BIN LID

REMOVAL.............................80

INSTALLATION.........................80

UNDER SEAT STORAGE BIN

REMOVAL.............................80

INSTALLATION.........................80

UNDER SEAT STORAGE BIN COVERING

REMOVAL.............................80

INSTALLATION.........................80

UNDER SEAT STORAGE BIN LATCH

REMOVAL.............................80

INSTALLATION.........................80

HEADREST

REMOVAL.............................80

INSTALLATION.........................80

HEADREST SLEEVE

REMOVAL.............................81INSTALLATION.........................81

SEAT - FRONT

REMOVAL.............................81

INSTALLATION.........................81

LUMBAR SUPPORT HANDLE/BEZEL

REMOVAL.............................82

INSTALLATION.........................82

SEAT BACK CUSHION / COVER - FRONT

REMOVAL.............................82

INSTALLATION.........................82

SEAT CUSHION / COVER - FRONT

REMOVAL.............................83

INSTALLATION.........................83

SEAT TRACK

REMOVAL.............................83

INSTALLATION.........................83

SEAT - REAR

REMOVAL.............................83

INSTALLATION.........................83

SEAT BACK - REAR

REMOVAL.............................83

INSTALLATION.........................83

SEAT BACK CUSHION / COVER - REAR

REMOVAL.............................84

INSTALLATION.........................84

SEAT CUSHION / COVER - REAR

REMOVAL.............................84

INSTALLATION.........................84

SEAT CUSHION FRAME - REAR

REMOVAL.............................85

INSTALLATION.........................85

SEAT BACK REAR - FOOTMANS LOOP

BRACKETS

REMOVAL.............................85

INSTALLATION.........................85

CENTER SEAT

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

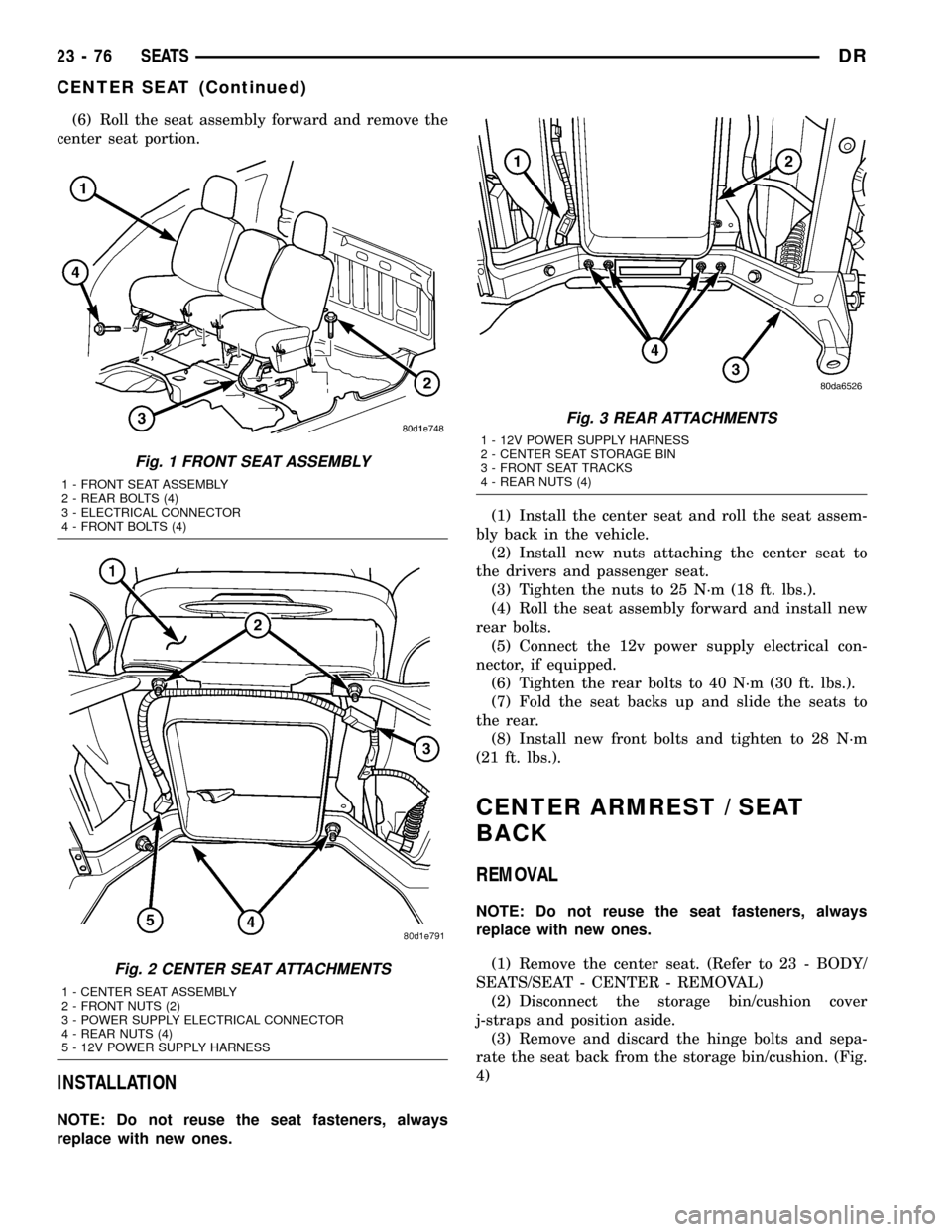

(1) Remove and discard the front bolts. (Fig. 1)(2) Position the seats forward, remove the rear

bolts and discard.

(3) Disconnect the 12v power supply electrical con-

nector, if equipped. (Fig. 2)

(4) Fold the seat backs forward and roll the seat

assembly back in the vehicle.

(5) Remove the nuts attaching the center seat to

the drivers seat and the passenger seat and discard.

(Fig. 3)

DRSEATS 23 - 75

Page 2371 of 2627

(6) Roll the seat assembly forward and remove the

center seat portion.

INSTALLATION

NOTE: Do not reuse the seat fasteners, always

replace with new ones.(1) Install the center seat and roll the seat assem-

bly back in the vehicle.

(2) Install new nuts attaching the center seat to

the drivers and passenger seat.

(3) Tighten the nuts to 25 N´m (18 ft. lbs.).

(4) Roll the seat assembly forward and install new

rear bolts.

(5) Connect the 12v power supply electrical con-

nector, if equipped.

(6) Tighten the rear bolts to 40 N´m (30 ft. lbs.).

(7) Fold the seat backs up and slide the seats to

the rear.

(8) Install new front bolts and tighten to 28 N´m

(21 ft. lbs.).

CENTER ARMREST / SEAT

BACK

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Remove the center seat. (Refer to 23 - BODY/

SEATS/SEAT - CENTER - REMOVAL)

(2) Disconnect the storage bin/cushion cover

j-straps and position aside.

(3) Remove and discard the hinge bolts and sepa-

rate the seat back from the storage bin/cushion. (Fig.

4)

Fig. 1 FRONT SEAT ASSEMBLY

1 - FRONT SEAT ASSEMBLY

2 - REAR BOLTS (4)

3 - ELECTRICAL CONNECTOR

4 - FRONT BOLTS (4)

Fig. 2 CENTER SEAT ATTACHMENTS

1 - CENTER SEAT ASSEMBLY

2 - FRONT NUTS (2)

3 - POWER SUPPLY ELECTRICAL CONNECTOR

4 - REAR NUTS (4)

5 - 12V POWER SUPPLY HARNESS

Fig. 3 REAR ATTACHMENTS

1 - 12V POWER SUPPLY HARNESS

2 - CENTER SEAT STORAGE BIN

3 - FRONT SEAT TRACKS

4 - REAR NUTS (4)

23 - 76 SEATSDR

CENTER SEAT (Continued)

Page 2373 of 2627

(1) Position the hinge cover over the hinge and

close over the lock tabs.

(2) Install the pivot bolt and tighten to 10 N´m (89

in. lbs.).

(3) Reposition the storage bin/cushion cover.

(4) Connect the zip strip.

CENTER SEAT BACK HINGE

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Remove the seat back. (Refer to 23 - BODY/

SEATS/CENTER ARMREST / SEAT BACK -

REMOVAL)

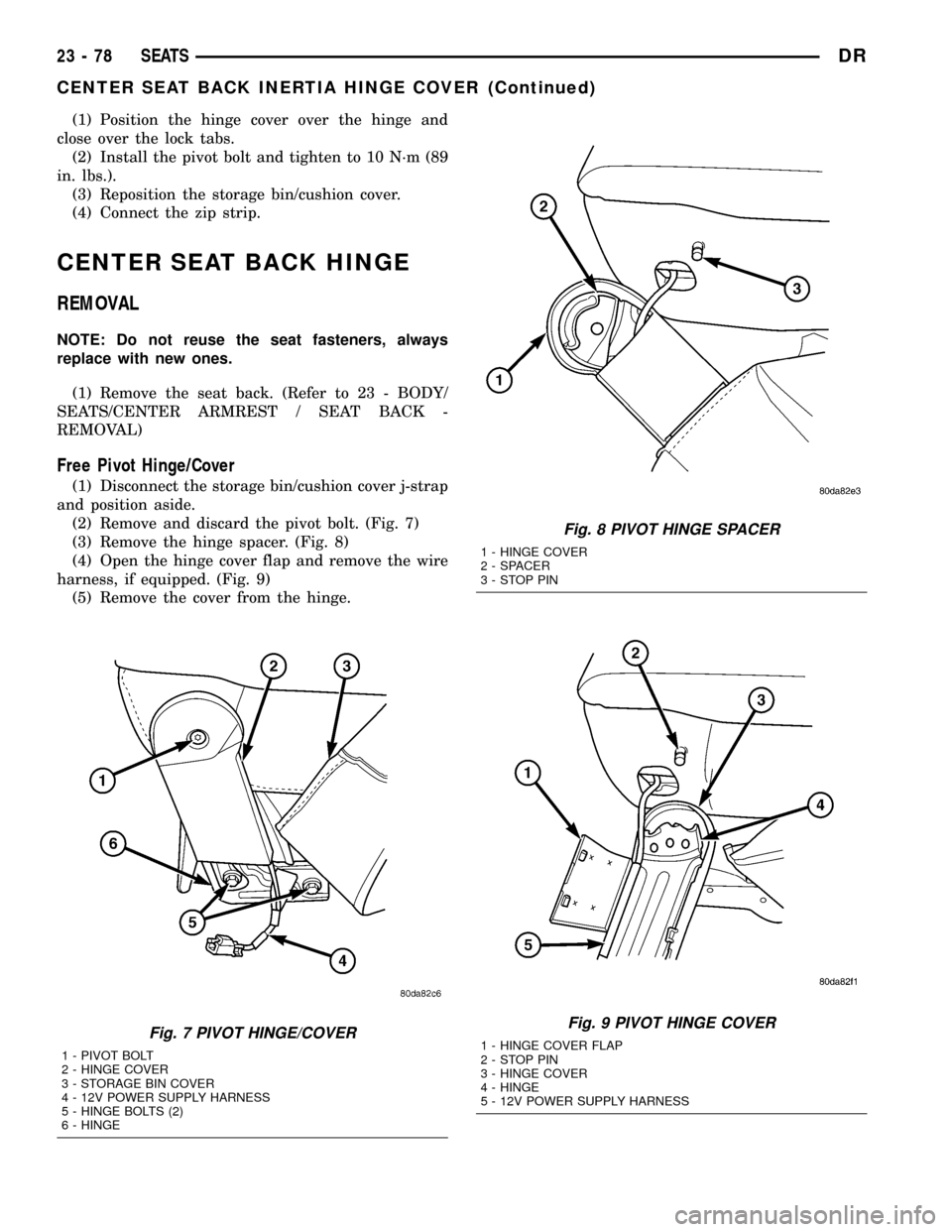

Free Pivot Hinge/Cover

(1) Disconnect the storage bin/cushion cover j-strap

and position aside.

(2) Remove and discard the pivot bolt. (Fig. 7)

(3) Remove the hinge spacer. (Fig. 8)

(4) Open the hinge cover flap and remove the wire

harness, if equipped. (Fig. 9)

(5) Remove the cover from the hinge.

Fig. 7 PIVOT HINGE/COVER

1 - PIVOT BOLT

2 - HINGE COVER

3 - STORAGE BIN COVER

4 - 12V POWER SUPPLY HARNESS

5 - HINGE BOLTS (2)

6 - HINGE

Fig. 8 PIVOT HINGE SPACER

1 - HINGE COVER

2 - SPACER

3-STOPPIN

Fig. 9 PIVOT HINGE COVER

1 - HINGE COVER FLAP

2-STOPPIN

3 - HINGE COVER

4 - HINGE

5 - 12V POWER SUPPLY HARNESS

23 - 78 SEATSDR

CENTER SEAT BACK INERTIA HINGE COVER (Continued)

Page 2374 of 2627

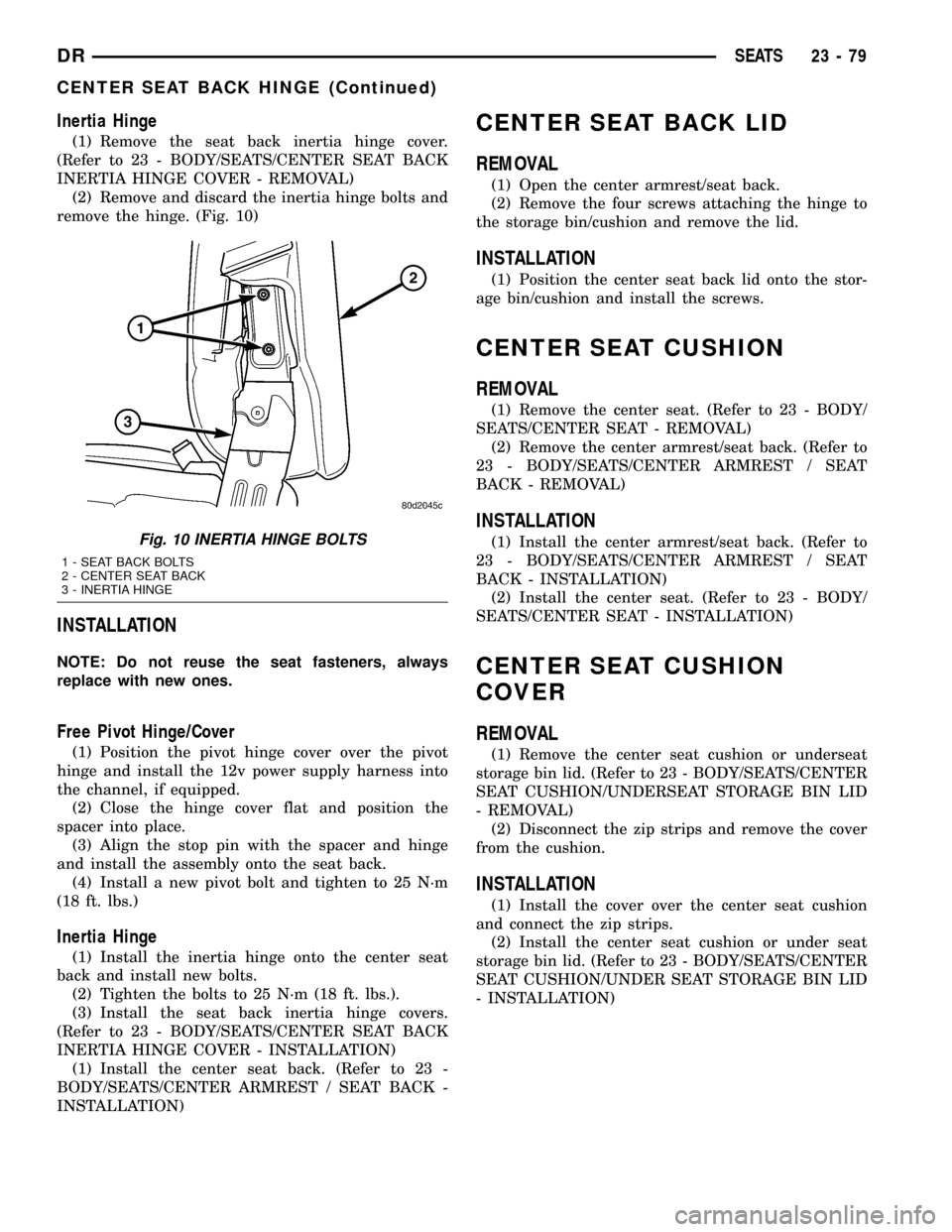

Inertia Hinge

(1) Remove the seat back inertia hinge cover.

(Refer to 23 - BODY/SEATS/CENTER SEAT BACK

INERTIA HINGE COVER - REMOVAL)

(2) Remove and discard the inertia hinge bolts and

remove the hinge. (Fig. 10)

INSTALLATION

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

Free Pivot Hinge/Cover

(1) Position the pivot hinge cover over the pivot

hinge and install the 12v power supply harness into

the channel, if equipped.

(2) Close the hinge cover flat and position the

spacer into place.

(3) Align the stop pin with the spacer and hinge

and install the assembly onto the seat back.

(4) Install a new pivot bolt and tighten to 25 N´m

(18 ft. lbs.)

Inertia Hinge

(1) Install the inertia hinge onto the center seat

back and install new bolts.

(2) Tighten the bolts to 25 N´m (18 ft. lbs.).

(3) Install the seat back inertia hinge covers.

(Refer to 23 - BODY/SEATS/CENTER SEAT BACK

INERTIA HINGE COVER - INSTALLATION)

(1) Install the center seat back. (Refer to 23 -

BODY/SEATS/CENTER ARMREST / SEAT BACK -

INSTALLATION)

CENTER SEAT BACK LID

REMOVAL

(1) Open the center armrest/seat back.

(2) Remove the four screws attaching the hinge to

the storage bin/cushion and remove the lid.

INSTALLATION

(1) Position the center seat back lid onto the stor-

age bin/cushion and install the screws.

CENTER SEAT CUSHION

REMOVAL

(1) Remove the center seat. (Refer to 23 - BODY/

SEATS/CENTER SEAT - REMOVAL)

(2) Remove the center armrest/seat back. (Refer to

23 - BODY/SEATS/CENTER ARMREST / SEAT

BACK - REMOVAL)

INSTALLATION

(1) Install the center armrest/seat back. (Refer to

23 - BODY/SEATS/CENTER ARMREST / SEAT

BACK - INSTALLATION)

(2) Install the center seat. (Refer to 23 - BODY/

SEATS/CENTER SEAT - INSTALLATION)

CENTER SEAT CUSHION

COVER

REMOVAL

(1) Remove the center seat cushion or underseat

storage bin lid. (Refer to 23 - BODY/SEATS/CENTER

SEAT CUSHION/UNDERSEAT STORAGE BIN LID

- REMOVAL)

(2) Disconnect the zip strips and remove the cover

from the cushion.

INSTALLATION

(1) Install the cover over the center seat cushion

and connect the zip strips.

(2) Install the center seat cushion or under seat

storage bin lid. (Refer to 23 - BODY/SEATS/CENTER

SEAT CUSHION/UNDER SEAT STORAGE BIN LID

- INSTALLATION)

Fig. 10 INERTIA HINGE BOLTS

1 - SEAT BACK BOLTS

2 - CENTER SEAT BACK

3 - INERTIA HINGE

DRSEATS 23 - 79

CENTER SEAT BACK HINGE (Continued)

Page 2375 of 2627

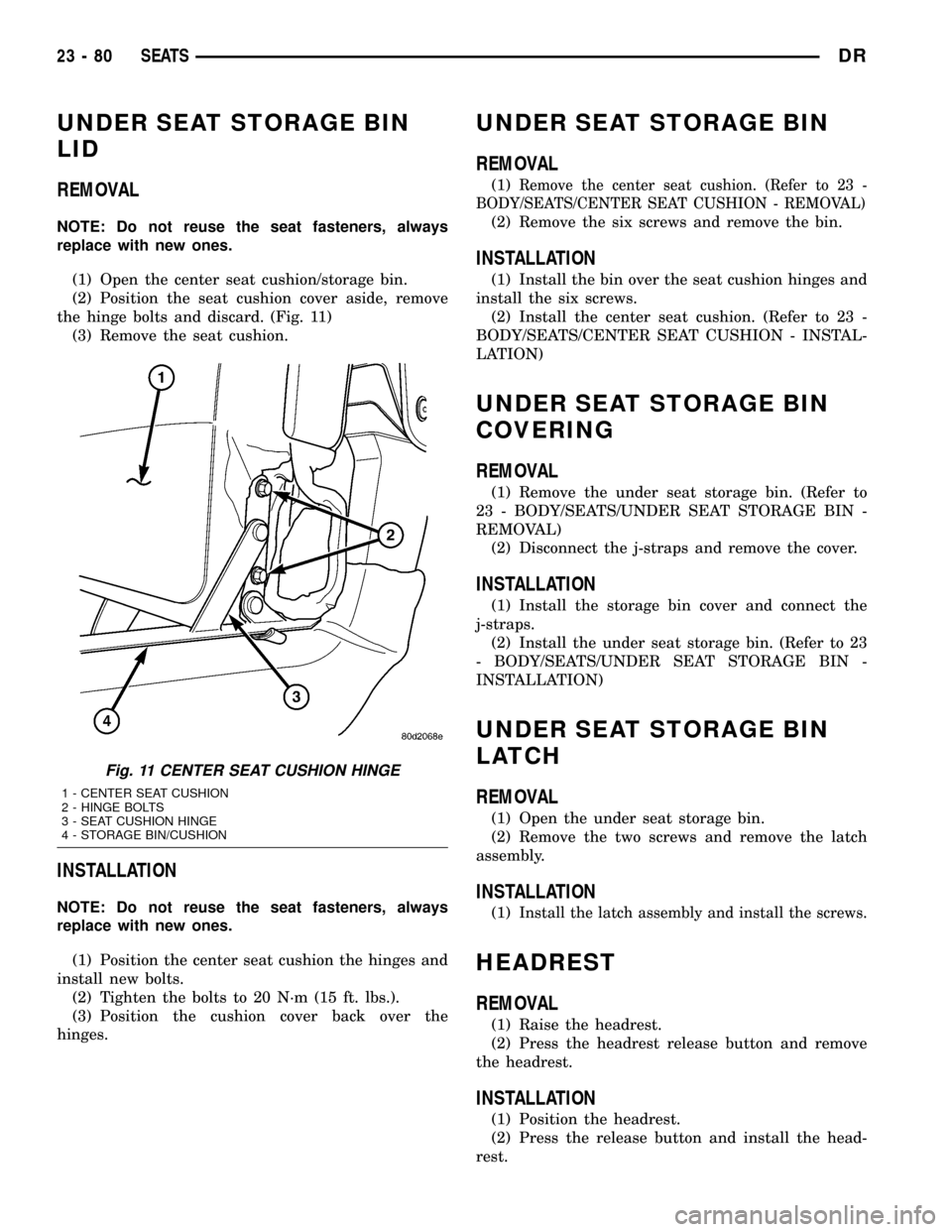

UNDER SEAT STORAGE BIN

LID

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Open the center seat cushion/storage bin.

(2) Position the seat cushion cover aside, remove

the hinge bolts and discard. (Fig. 11)

(3) Remove the seat cushion.

INSTALLATION

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Position the center seat cushion the hinges and

install new bolts.

(2) Tighten the bolts to 20 N´m (15 ft. lbs.).

(3) Position the cushion cover back over the

hinges.

UNDER SEAT STORAGE BIN

REMOVAL

(1)Remove the center seat cushion. (Refer to 23 -

BODY/SEATS/CENTER SEAT CUSHION - REMOVAL)

(2) Remove the six screws and remove the bin.

INSTALLATION

(1) Install the bin over the seat cushion hinges and

install the six screws.

(2) Install the center seat cushion. (Refer to 23 -

BODY/SEATS/CENTER SEAT CUSHION - INSTAL-

LATION)

UNDER SEAT STORAGE BIN

COVERING

REMOVAL

(1) Remove the under seat storage bin. (Refer to

23 - BODY/SEATS/UNDER SEAT STORAGE BIN -

REMOVAL)

(2) Disconnect the j-straps and remove the cover.

INSTALLATION

(1) Install the storage bin cover and connect the

j-straps.

(2) Install the under seat storage bin. (Refer to 23

- BODY/SEATS/UNDER SEAT STORAGE BIN -

INSTALLATION)

UNDER SEAT STORAGE BIN

LATCH

REMOVAL

(1) Open the under seat storage bin.

(2) Remove the two screws and remove the latch

assembly.

INSTALLATION

(1)Install the latch assembly and install the screws.

HEADREST

REMOVAL

(1) Raise the headrest.

(2) Press the headrest release button and remove

the headrest.

INSTALLATION

(1) Position the headrest.

(2) Press the release button and install the head-

rest.

Fig. 11 CENTER SEAT CUSHION HINGE

1 - CENTER SEAT CUSHION

2 - HINGE BOLTS

3 - SEAT CUSHION HINGE

4 - STORAGE BIN/CUSHION

23 - 80 SEATSDR

Page 2376 of 2627

HEADREST SLEEVE

REMOVAL

(1) Remove the headrest. (Refer to 23 - BODY/

SEATS/HEADREST - REMOVAL)

(2) Grasp the sleeves and pull up and out of the

seat back to remove.

INSTALLATION

(1) Position each headrest sleeve into correct seat

back hole and press into place fully.

(2) Install the headrest. (Refer to 23 - BODY/

SEATS/HEADREST - INSTALLATION)

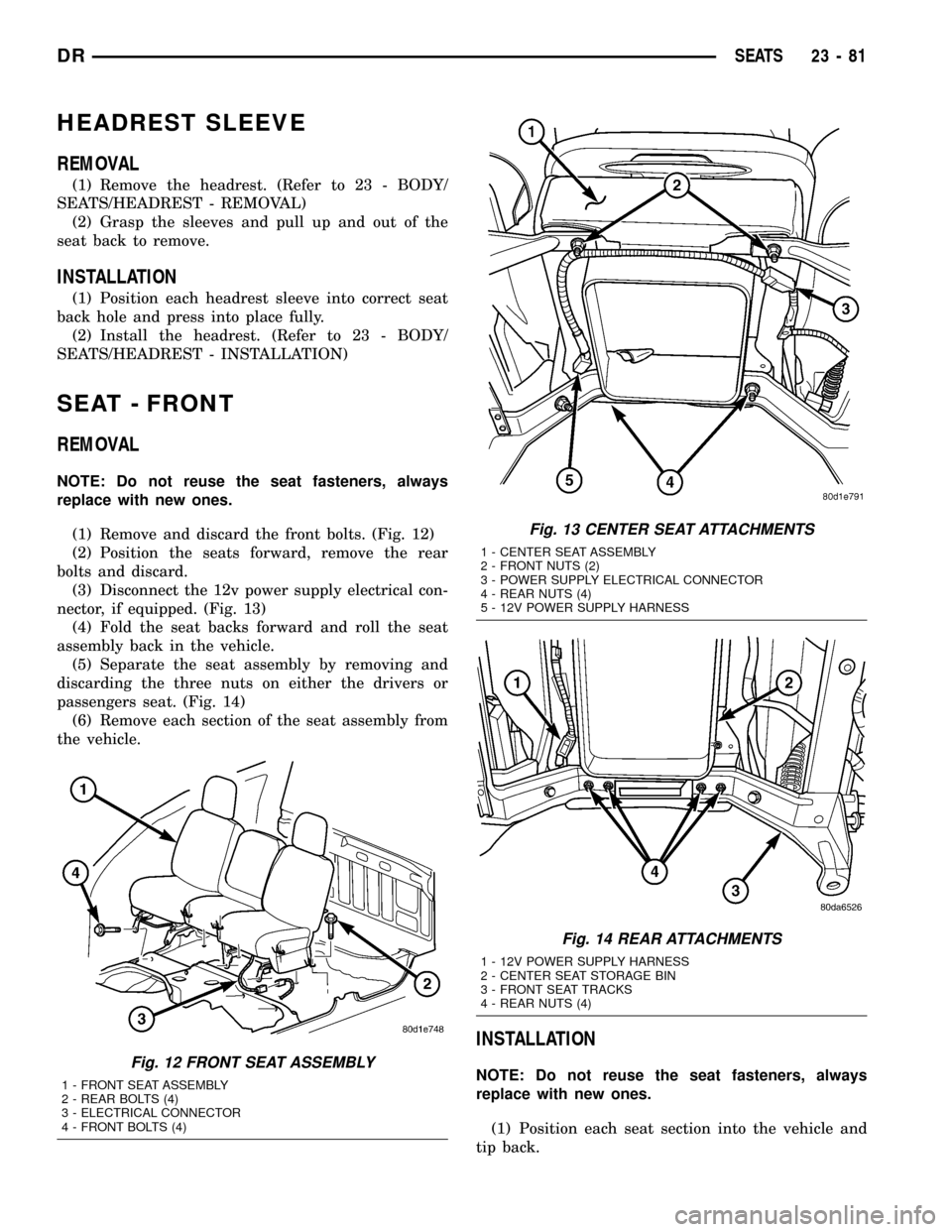

SEAT - FRONT

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Remove and discard the front bolts. (Fig. 12)

(2) Position the seats forward, remove the rear

bolts and discard.

(3) Disconnect the 12v power supply electrical con-

nector, if equipped. (Fig. 13)

(4) Fold the seat backs forward and roll the seat

assembly back in the vehicle.

(5) Separate the seat assembly by removing and

discarding the three nuts on either the drivers or

passengers seat. (Fig. 14)

(6) Remove each section of the seat assembly from

the vehicle.

INSTALLATION

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Position each seat section into the vehicle and

tip back.Fig. 12 FRONT SEAT ASSEMBLY

1 - FRONT SEAT ASSEMBLY

2 - REAR BOLTS (4)

3 - ELECTRICAL CONNECTOR

4 - FRONT BOLTS (4)

Fig. 13 CENTER SEAT ATTACHMENTS

1 - CENTER SEAT ASSEMBLY

2 - FRONT NUTS (2)

3 - POWER SUPPLY ELECTRICAL CONNECTOR

4 - REAR NUTS (4)

5 - 12V POWER SUPPLY HARNESS

Fig. 14 REAR ATTACHMENTS

1 - 12V POWER SUPPLY HARNESS

2 - CENTER SEAT STORAGE BIN

3 - FRONT SEAT TRACKS

4 - REAR NUTS (4)

DRSEATS 23 - 81

Page 2377 of 2627

(2) Install the three nuts attaching the center seat

section to the other seat, and tighten to 25 N´m (18

ft. lbs.).

(3) Roll the seat assembly forward and install new

rear bolts.

(4) Connect the 12v power supply electrical con-

nector.

(5) Tighten the rear bolts to 40 N´m (30 ft. lbs.).

(6) Fold the seat backs up and slide the seats to

the rear.

(7) Install new front bolts and tighten to 28 N´m

(21 ft. lbs.).

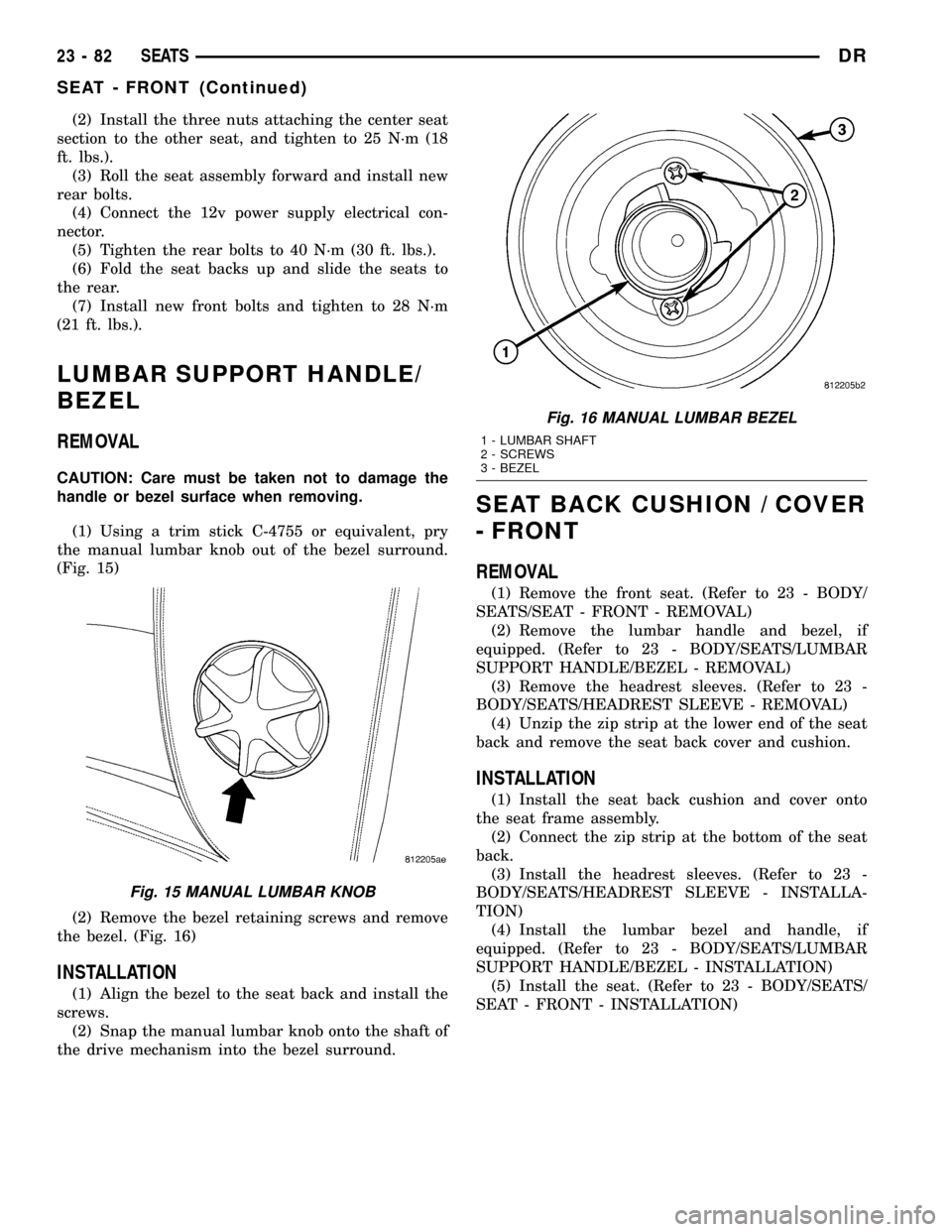

LUMBAR SUPPORT HANDLE/

BEZEL

REMOVAL

CAUTION: Care must be taken not to damage the

handle or bezel surface when removing.

(1) Using a trim stick C-4755 or equivalent, pry

the manual lumbar knob out of the bezel surround.

(Fig. 15)

(2) Remove the bezel retaining screws and remove

the bezel. (Fig. 16)

INSTALLATION

(1) Align the bezel to the seat back and install the

screws.

(2) Snap the manual lumbar knob onto the shaft of

the drive mechanism into the bezel surround.

SEAT BACK CUSHION / COVER

- FRONT

REMOVAL

(1) Remove the front seat. (Refer to 23 - BODY/

SEATS/SEAT - FRONT - REMOVAL)

(2) Remove the lumbar handle and bezel, if

equipped. (Refer to 23 - BODY/SEATS/LUMBAR

SUPPORT HANDLE/BEZEL - REMOVAL)

(3) Remove the headrest sleeves. (Refer to 23 -

BODY/SEATS/HEADREST SLEEVE - REMOVAL)

(4) Unzip the zip strip at the lower end of the seat

back and remove the seat back cover and cushion.

INSTALLATION

(1) Install the seat back cushion and cover onto

the seat frame assembly.

(2) Connect the zip strip at the bottom of the seat

back.

(3) Install the headrest sleeves. (Refer to 23 -

BODY/SEATS/HEADREST SLEEVE - INSTALLA-

TION)

(4) Install the lumbar bezel and handle, if

equipped. (Refer to 23 - BODY/SEATS/LUMBAR

SUPPORT HANDLE/BEZEL - INSTALLATION)

(5) Install the seat. (Refer to 23 - BODY/SEATS/

SEAT - FRONT - INSTALLATION)

Fig. 15 MANUAL LUMBAR KNOB

Fig. 16 MANUAL LUMBAR BEZEL

1 - LUMBAR SHAFT

2 - SCREWS

3 - BEZEL

23 - 82 SEATSDR

SEAT - FRONT (Continued)

Page 2514 of 2627

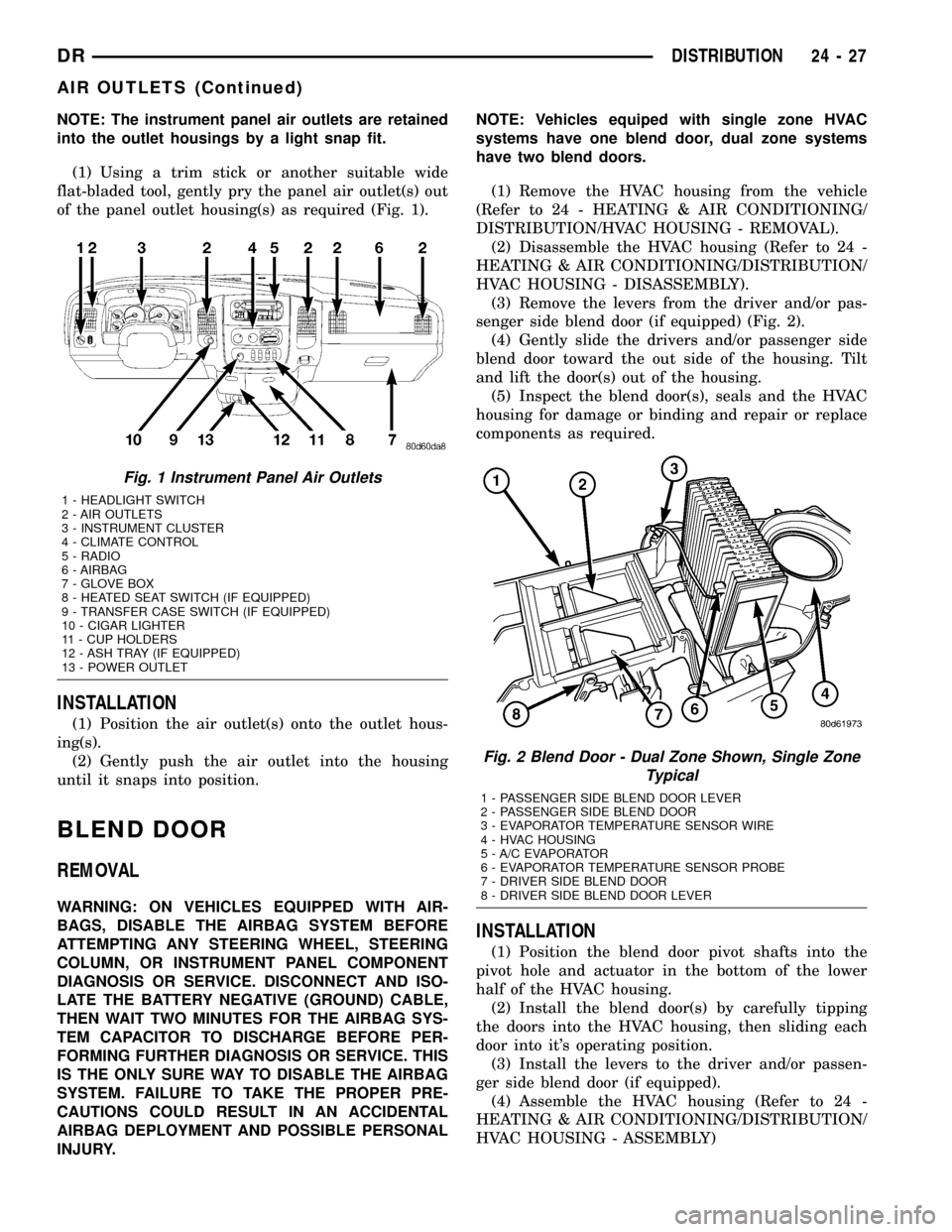

NOTE: The instrument panel air outlets are retained

into the outlet housings by a light snap fit.

(1) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the panel air outlet(s) out

of the panel outlet housing(s) as required (Fig. 1).

INSTALLATION

(1) Position the air outlet(s) onto the outlet hous-

ing(s).

(2) Gently push the air outlet into the housing

until it snaps into position.

BLEND DOOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

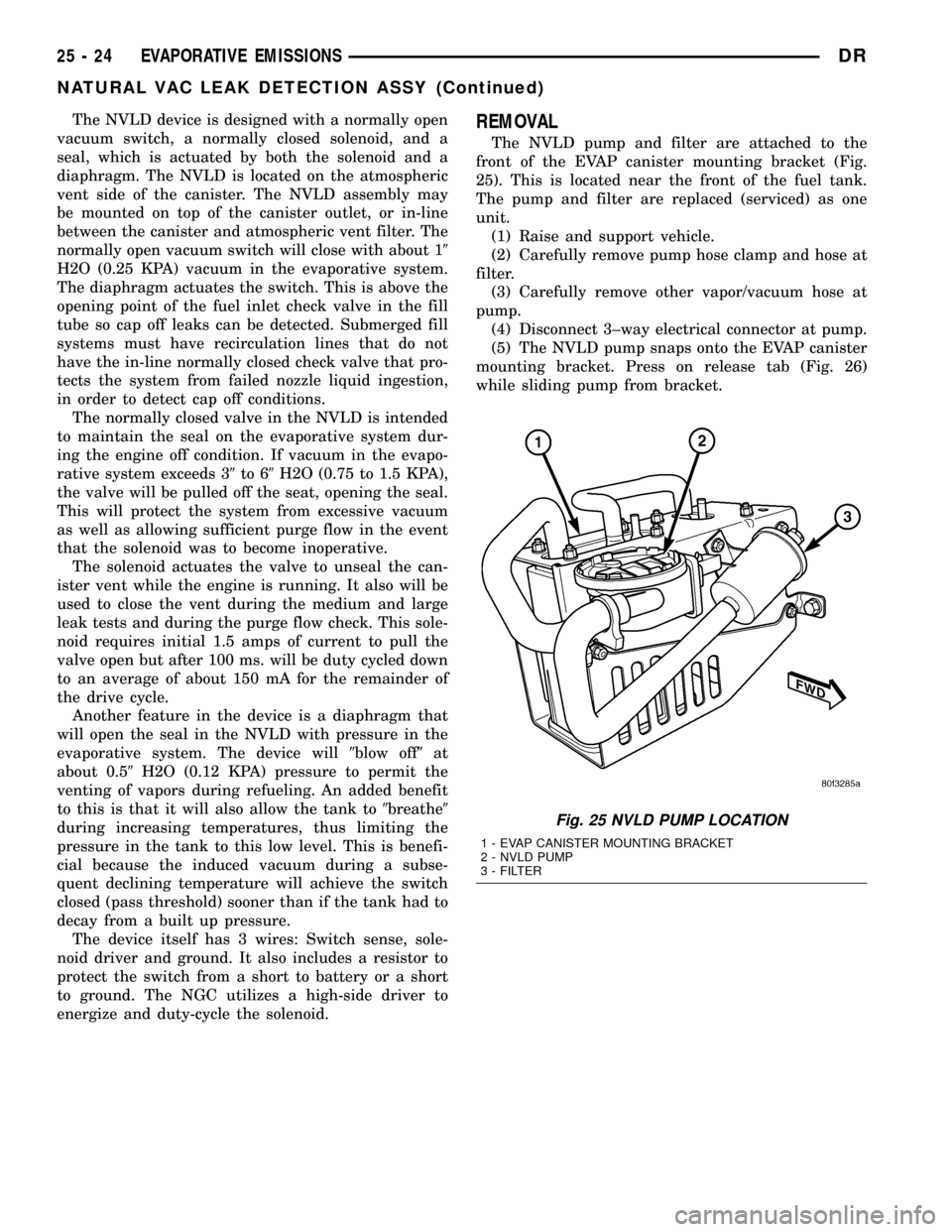

INJURY.NOTE: Vehicles equiped with single zone HVAC

systems have one blend door, dual zone systems

have two blend doors.

(1) Remove the HVAC housing from the vehicle

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disassemble the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - DISASSEMBLY).

(3) Remove the levers from the driver and/or pas-

senger side blend door (if equipped) (Fig. 2).

(4) Gently slide the drivers and/or passenger side

blend door toward the out side of the housing. Tilt

and lift the door(s) out of the housing.

(5) Inspect the blend door(s), seals and the HVAC

housing for damage or binding and repair or replace

components as required.

INSTALLATION

(1) Position the blend door pivot shafts into the

pivot hole and actuator in the bottom of the lower

half of the HVAC housing.

(2) Install the blend door(s) by carefully tipping

the doors into the HVAC housing, then sliding each

door into it's operating position.

(3) Install the levers to the driver and/or passen-

ger side blend door (if equipped).

(4) Assemble the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY)

Fig. 1 Instrument Panel Air Outlets

1 - HEADLIGHT SWITCH

2 - AIR OUTLETS

3 - INSTRUMENT CLUSTER

4 - CLIMATE CONTROL

5 - RADIO

6 - AIRBAG

7 - GLOVE BOX

8 - HEATED SEAT SWITCH (IF EQUIPPED)

9 - TRANSFER CASE SWITCH (IF EQUIPPED)

10 - CIGAR LIGHTER

11 - CUP HOLDERS

12 - ASH TRAY (IF EQUIPPED)

13 - POWER OUTLET

Fig. 2 Blend Door - Dual Zone Shown, Single Zone

Typical

1 - PASSENGER SIDE BLEND DOOR LEVER

2 - PASSENGER SIDE BLEND DOOR

3 - EVAPORATOR TEMPERATURE SENSOR WIRE

4 - HVAC HOUSING

5 - A/C EVAPORATOR

6 - EVAPORATOR TEMPERATURE SENSOR PROBE

7 - DRIVER SIDE BLEND DOOR

8 - DRIVER SIDE BLEND DOOR LEVER

DRDISTRIBUTION 24 - 27

AIR OUTLETS (Continued)

Page 2585 of 2627

The NVLD device is designed with a normally open

vacuum switch, a normally closed solenoid, and a

seal, which is actuated by both the solenoid and a

diaphragm. The NVLD is located on the atmospheric

vent side of the canister. The NVLD assembly may

be mounted on top of the canister outlet, or in-line

between the canister and atmospheric vent filter. The

normally open vacuum switch will close with about 19

H2O (0.25 KPA) vacuum in the evaporative system.

The diaphragm actuates the switch. This is above the

opening point of the fuel inlet check valve in the fill

tube so cap off leaks can be detected. Submerged fill

systems must have recirculation lines that do not

have the in-line normally closed check valve that pro-

tects the system from failed nozzle liquid ingestion,

in order to detect cap off conditions.

The normally closed valve in the NVLD is intended

to maintain the seal on the evaporative system dur-

ing the engine off condition. If vacuum in the evapo-

rative system exceeds 39to 69H2O (0.75 to 1.5 KPA),

the valve will be pulled off the seat, opening the seal.

This will protect the system from excessive vacuum

as well as allowing sufficient purge flow in the event

that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the can-

ister vent while the engine is running. It also will be

used to close the vent during the medium and large

leak tests and during the purge flow check. This sole-

noid requires initial 1.5 amps of current to pull the

valve open but after 100 ms. will be duty cycled down

to an average of about 150 mA for the remainder of

the drive cycle.

Another feature in the device is a diaphragm that

will open the seal in the NVLD with pressure in the

evaporative system. The device will9blow off9at

about 0.59H2O (0.12 KPA) pressure to permit the

venting of vapors during refueling. An added benefit

to this is that it will also allow the tank to9breathe9

during increasing temperatures, thus limiting the

pressure in the tank to this low level. This is benefi-

cial because the induced vacuum during a subse-

quent declining temperature will achieve the switch

closed (pass threshold) sooner than if the tank had to

decay from a built up pressure.

The device itself has 3 wires: Switch sense, sole-

noid driver and ground. It also includes a resistor to

protect the switch from a short to battery or a short

to ground. The NGC utilizes a high-side driver to

energize and duty-cycle the solenoid.REMOVAL

The NVLD pump and filter are attached to the

front of the EVAP canister mounting bracket (Fig.

25). This is located near the front of the fuel tank.

The pump and filter are replaced (serviced) as one

unit.

(1) Raise and support vehicle.

(2) Carefully remove pump hose clamp and hose at

filter.

(3) Carefully remove other vapor/vacuum hose at

pump.

(4) Disconnect 3±way electrical connector at pump.

(5) The NVLD pump snaps onto the EVAP canister

mounting bracket. Press on release tab (Fig. 26)

while sliding pump from bracket.

Fig. 25 NVLD PUMP LOCATION

1 - EVAP CANISTER MOUNTING BRACKET

2 - NVLD PUMP

3 - FILTER

25 - 24 EVAPORATIVE EMISSIONSDR

NATURAL VAC LEAK DETECTION ASSY (Continued)