Sensor DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 609 of 2627

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (the LED in the mirror

switch is lighted) position. Cover the forward facing

ambient photocell sensor to keep out any ambient

light.NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

REMOVAL

For removal procedures, (Refer to 23 - BODY/IN-

TERIOR/REAR VIEW MIRROR - REMOVAL).

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH

The power mirror switch is included with the

Driver Door Module. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR MODULE - DIAGNOSIS

AND TESTING).

REMOVAL

The power mirror switch is included with the

Driver Door Module. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR MODULE - REMOVAL).

SIDEVIEW MIRROR

REMOVAL

(Refer to 23 - BODY/EXTERIOR/SIDE VIEW MIR-

ROR - REMOVAL).

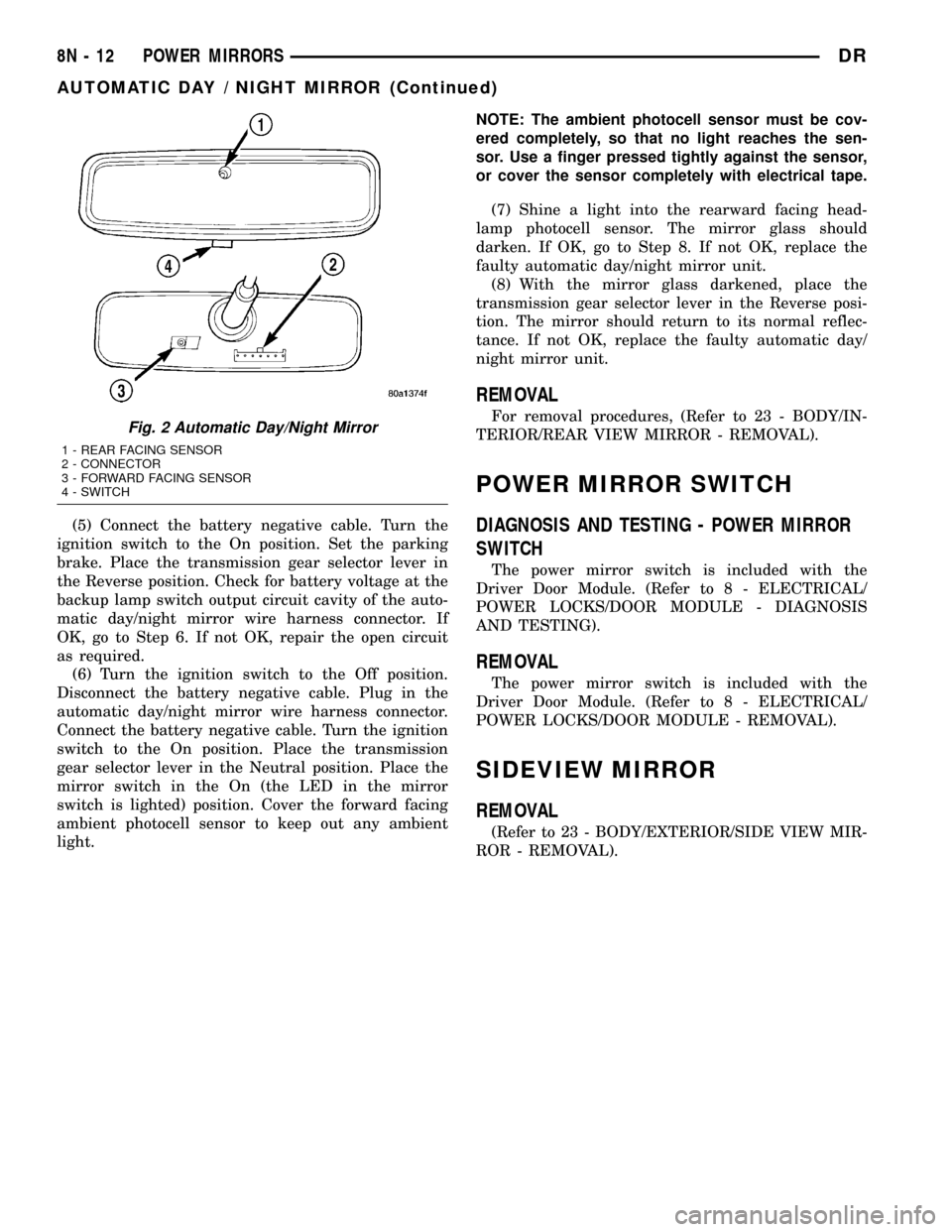

Fig. 2 Automatic Day/Night Mirror

1 - REAR FACING SENSOR

2 - CONNECTOR

3 - FORWARD FACING SENSOR

4 - SWITCH

8N - 12 POWER MIRRORSDR

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 621 of 2627

SEAT BELT TENSION REDUCER

DESCRIPTION.........................53

OPERATION...........................54

DIAGNOSIS AND TESTING - SEAT BELT

TENSION REDUCER...................54

SEAT BELT TURNING LOOP ADJUSTER

REMOVAL.............................55

INSTALLATION.........................55

SIDE CURTAIN AIRBAG

DESCRIPTION.........................56

OPERATION...........................56REMOVAL.............................57

INSTALLATION.........................58

SIDE IMPACT SENSOR

DESCRIPTION.........................59

OPERATION...........................59

REMOVAL

REMOVAL - STANDARD CAB............59

REMOVAL - QUAD CAB................60

INSTALLATION

INSTALLATION - STANDARD CAB.........61

INSTALLATION - QUAD CAB.............61

RESTRAINTS

DESCRIPTION

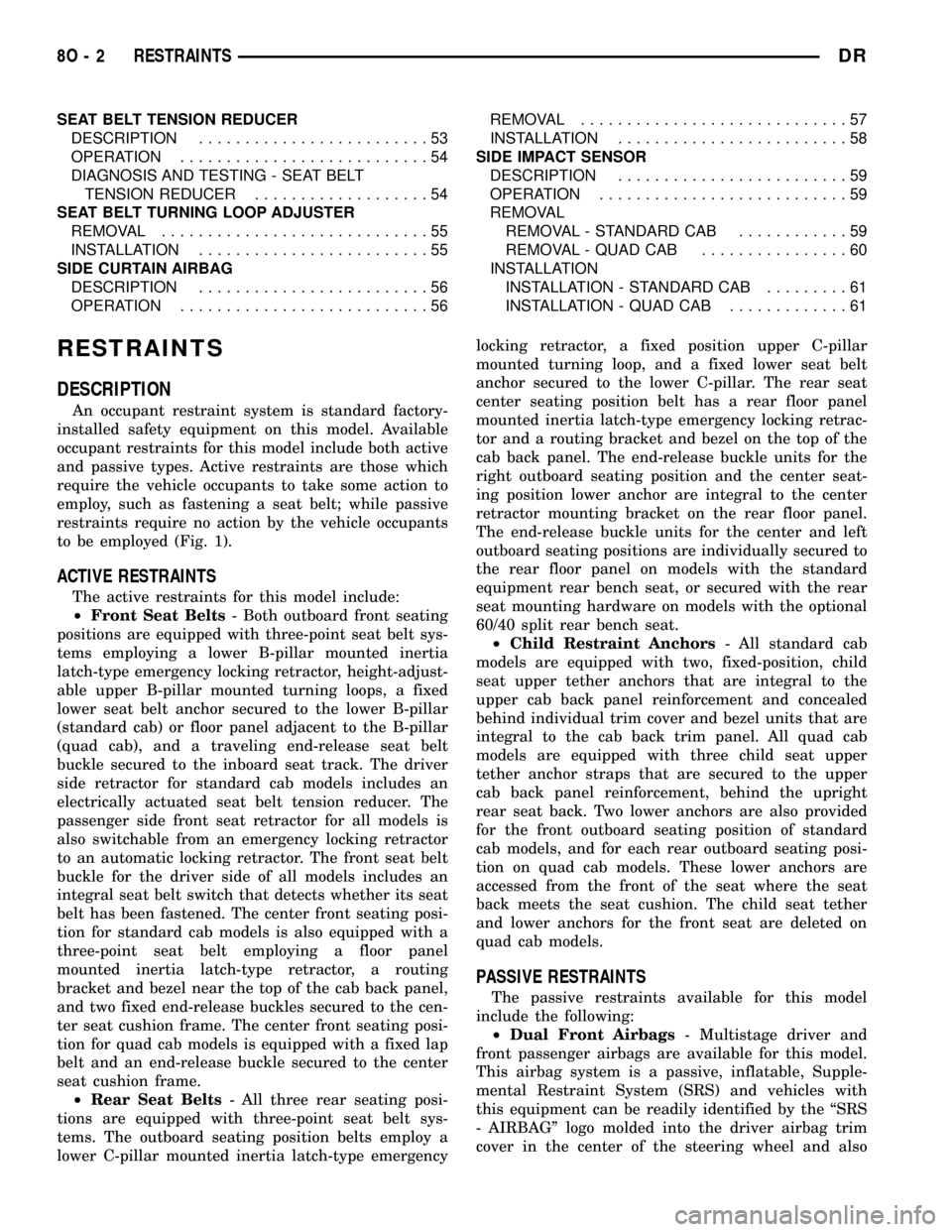

An occupant restraint system is standard factory-

installed safety equipment on this model. Available

occupant restraints for this model include both active

and passive types. Active restraints are those which

require the vehicle occupants to take some action to

employ, such as fastening a seat belt; while passive

restraints require no action by the vehicle occupants

to be employed (Fig. 1).

ACTIVE RESTRAINTS

The active restraints for this model include:

²Front Seat Belts- Both outboard front seating

positions are equipped with three-point seat belt sys-

tems employing a lower B-pillar mounted inertia

latch-type emergency locking retractor, height-adjust-

able upper B-pillar mounted turning loops, a fixed

lower seat belt anchor secured to the lower B-pillar

(standard cab) or floor panel adjacent to the B-pillar

(quad cab), and a traveling end-release seat belt

buckle secured to the inboard seat track. The driver

side retractor for standard cab models includes an

electrically actuated seat belt tension reducer. The

passenger side front seat retractor for all models is

also switchable from an emergency locking retractor

to an automatic locking retractor. The front seat belt

buckle for the driver side of all models includes an

integral seat belt switch that detects whether its seat

belt has been fastened. The center front seating posi-

tion for standard cab models is also equipped with a

three-point seat belt employing a floor panel

mounted inertia latch-type retractor, a routing

bracket and bezel near the top of the cab back panel,

and two fixed end-release buckles secured to the cen-

ter seat cushion frame. The center front seating posi-

tion for quad cab models is equipped with a fixed lap

belt and an end-release buckle secured to the center

seat cushion frame.

²Rear Seat Belts- All three rear seating posi-

tions are equipped with three-point seat belt sys-

tems. The outboard seating position belts employ a

lower C-pillar mounted inertia latch-type emergencylocking retractor, a fixed position upper C-pillar

mounted turning loop, and a fixed lower seat belt

anchor secured to the lower C-pillar. The rear seat

center seating position belt has a rear floor panel

mounted inertia latch-type emergency locking retrac-

tor and a routing bracket and bezel on the top of the

cab back panel. The end-release buckle units for the

right outboard seating position and the center seat-

ing position lower anchor are integral to the center

retractor mounting bracket on the rear floor panel.

The end-release buckle units for the center and left

outboard seating positions are individually secured to

the rear floor panel on models with the standard

equipment rear bench seat, or secured with the rear

seat mounting hardware on models with the optional

60/40 split rear bench seat.

²Child Restraint Anchors- All standard cab

models are equipped with two, fixed-position, child

seat upper tether anchors that are integral to the

upper cab back panel reinforcement and concealed

behind individual trim cover and bezel units that are

integral to the cab back trim panel. All quad cab

models are equipped with three child seat upper

tether anchor straps that are secured to the upper

cab back panel reinforcement, behind the upright

rear seat back. Two lower anchors are also provided

for the front outboard seating position of standard

cab models, and for each rear outboard seating posi-

tion on quad cab models. These lower anchors are

accessed from the front of the seat where the seat

back meets the seat cushion. The child seat tether

and lower anchors for the front seat are deleted on

quad cab models.

PASSIVE RESTRAINTS

The passive restraints available for this model

include the following:

²Dual Front Airbags- Multistage driver and

front passenger airbags are available for this model.

This airbag system is a passive, inflatable, Supple-

mental Restraint System (SRS) and vehicles with

this equipment can be readily identified by the ªSRS

- AIRBAGº logo molded into the driver airbag trim

cover in the center of the steering wheel and also

8O - 2 RESTRAINTSDR

Page 622 of 2627

into the passenger airbag door on the instrument

panel above the glove box (Fig. 2). Vehicles with the

airbag system can also be identified by the airbag

indicator, which will illuminate in the instrument

cluster for about six seconds as a bulb test each time

the ignition switch is turned to the On position. A

pyrotechnic-type seat belt tensioner is integral to the

front outboard seat belt retractors mounted on each

lower B-pillar of all models equipped with dual front

airbags.

²Side Curtain Airbags- Optional side curtain

airbags are available for this model when it is also

equipped with dual front airbags. This airbag systemis a passive, inflatable, Supplemental Restraint Sys-

tem (SRS) and vehicles with this equipment can be

readily identified by a molded identification trim but-

ton with the ªSRS - AIRBAGº logo located on the

headliner above each B-pillar (Fig. 2).

The supplemental restraint system includes the

following major components, which are described in

further detail elsewhere in this service information:

²Airbag Control Module- The Airbag Control

Module (ACM) is also sometimes referred to as the

Occupant Restraint Controller (ORC). The ACM is

located on a mount on the floor panel transmission

tunnel, below the center of the instrument panel.

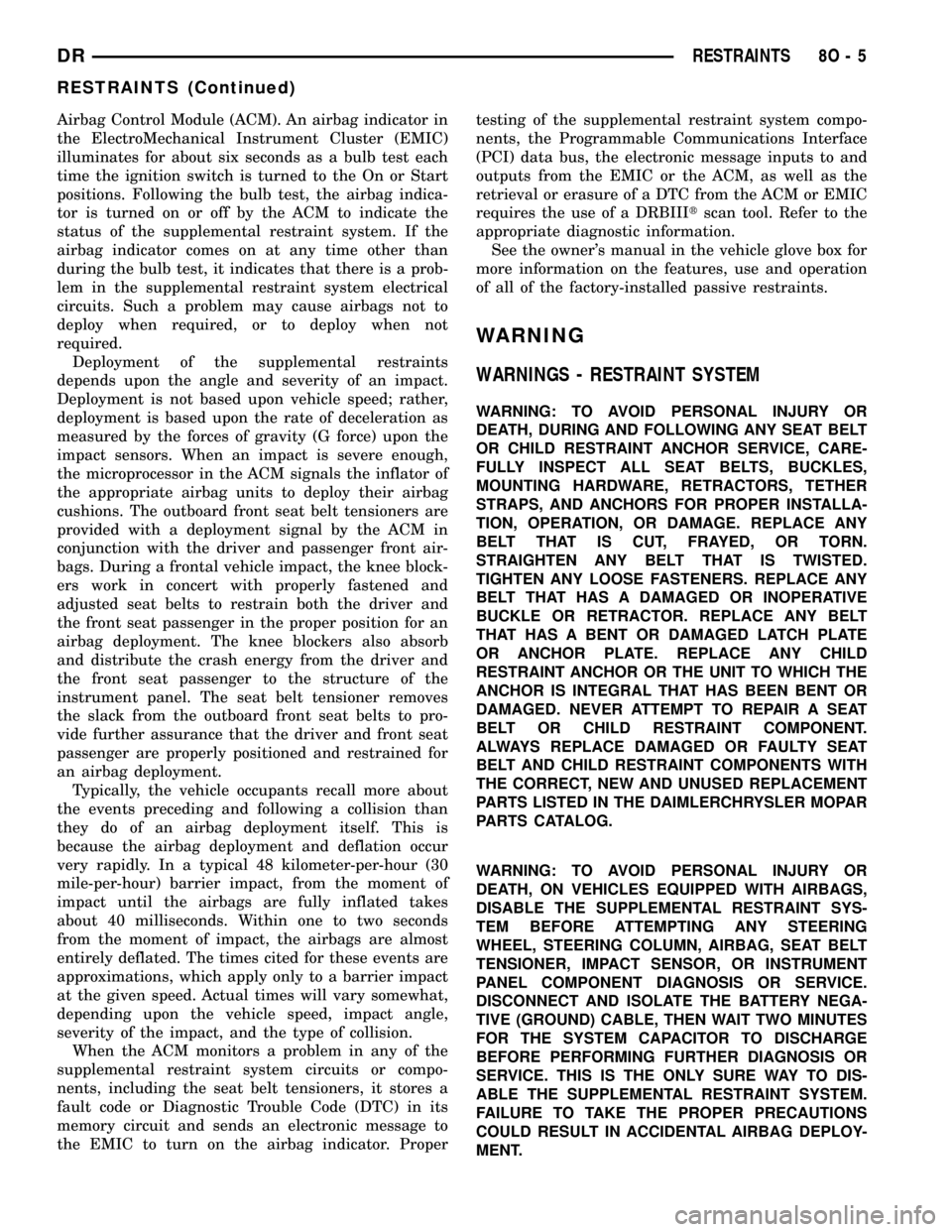

Fig. 1 Supplemental Restraint System

1 - AIRBAG CONTROL MODULE

2 - PASSENGER AIRBAG

3 - PASSENGER AIRBAG ON/OFF SWITCH (STD CAB ONLY)

4 - DRIVER AIRBAG5 - SIDE CURTAIN AIRBAG (2)

6 - SIDE IMPACT SENSOR (2 - W/SIDE CURTAIN AIRBAGS

ONLY)

7 - SEAT BELT TENSIONER (2)

DRRESTRAINTS 8O - 3

RESTRAINTS (Continued)

Page 623 of 2627

²Airbag Indicator- The airbag indicator is inte-

gral to the ElectroMechanical Instrument Cluster

(EMIC), which is located on the instrument panel in

front of the driver.

²Clockspring- The clockspring is located near

the top of the steering column, directly beneath the

steering wheel.

²Driver Airbag- The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover.

²Driver Knee Blocker- The driver knee blocker

is a structural unit secured to the back side of and

integral to the instrument panel steering column

opening cover.

²Passenger Airbag- The passenger airbag is

located on the instrument panel, beneath the passen-

ger airbag door on the instrument panel above the

glove box on the passenger side of the vehicle.

²Passenger Airbag On/Off Switch- Standard

cab models without a rear seat are equipped with a

passenger airbag on/off switch, which is located on

the right side of the instrument panel center bezel.

²Passenger Knee Blocker- The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door.

²Seat Belt Tensioner- The seat belt tensioner

is integral to the front outboard seat belt retractor

units on vehicles equipped with dual front airbags.

²Side Impact Sensor- Two side impact sensors

are used on vehicles equipped with the optional side

curtain airbags, one left side and one right side. One

sensor is located behind the B-pillar trim near the

base of each B-pillar.

²Side Curtain Airbag- In vehicles equipped

with this option, a side curtain airbag is located on

each inside roof side rail above the headliner, and

extends from the A-pillar to the B-pillar on standard

cab models, and from the A-pillar to the C-pillar on

quad cab models.The ACM and the EMIC each contain a central

processing unit and programming that allow them to

communicate with each other using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used by the

ACM for control of the airbag indicator on all models

equipped with dual front airbags. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

COMMUNICATION - DESCRIPTION).

Hard wired circuitry connects the supplemental

restraint system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system,

and to the supplemental restraint system compo-

nents through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

ACTIVE RESTRAINTS

The primary passenger restraints in this or any

other vehicle are the standard equipment factory-in-

stalled seat belts and child restraint anchors. Seat

belts and child restraint anchors are referred to as

an active restraint because the vehicle occupants are

required to physically fasten and properly adjust

these restraints in order to benefit from them. See

the owner's manual in the vehicle glove box for more

information on the features, use and operation of all

of the factory-installed active restraints.

PASSIVE RESTRAINTS

The passive restraints are referred to as a supple-

mental restraint system because they were designed

and are intended to enhance the protection for the

occupants of the vehicleonlywhen used in conjunc-

tion with the seat belts. They are referred to as pas-

sive restraints because the vehicle occupants are not

required to do anything to make them operate; how-

ever, the vehicle occupants must be wearing their

seat belts in order to obtain the maximum safety

benefit from the factory-installed supplemental

restraint system.

The supplemental restraint system electrical cir-

cuits are continuously monitored and controlled by a

microprocessor and software contained within the

Fig. 2 SRS Logo

8O - 4 RESTRAINTSDR

RESTRAINTS (Continued)

Page 624 of 2627

Airbag Control Module (ACM). An airbag indicator in

the ElectroMechanical Instrument Cluster (EMIC)

illuminates for about six seconds as a bulb test each

time the ignition switch is turned to the On or Start

positions. Following the bulb test, the airbag indica-

tor is turned on or off by the ACM to indicate the

status of the supplemental restraint system. If the

airbag indicator comes on at any time other than

during the bulb test, it indicates that there is a prob-

lem in the supplemental restraint system electrical

circuits. Such a problem may cause airbags not to

deploy when required, or to deploy when not

required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.

Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensors. When an impact is severe enough,

the microprocessor in the ACM signals the inflator of

the appropriate airbag units to deploy their airbag

cushions. The outboard front seat belt tensioners are

provided with a deployment signal by the ACM in

conjunction with the driver and passenger front air-

bags. During a frontal vehicle impact, the knee block-

ers work in concert with properly fastened and

adjusted seat belts to restrain both the driver and

the front seat passenger in the proper position for an

airbag deployment. The knee blockers also absorb

and distribute the crash energy from the driver and

the front seat passenger to the structure of the

instrument panel. The seat belt tensioner removes

the slack from the outboard front seat belts to pro-

vide further assurance that the driver and front seat

passenger are properly positioned and restrained for

an airbag deployment.

Typically, the vehicle occupants recall more about

the events preceding and following a collision than

they do of an airbag deployment itself. This is

because the airbag deployment and deflation occur

very rapidly. In a typical 48 kilometer-per-hour (30

mile-per-hour) barrier impact, from the moment of

impact until the airbags are fully inflated takes

about 40 milliseconds. Within one to two seconds

from the moment of impact, the airbags are almost

entirely deflated. The times cited for these events are

approximations, which apply only to a barrier impact

at the given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

supplemental restraint system circuits or compo-

nents, including the seat belt tensioners, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Propertesting of the supplemental restraint system compo-

nents, the Programmable Communications Interface

(PCI) data bus, the electronic message inputs to and

outputs from the EMIC or the ACM, as well as the

retrieval or erasure of a DTC from the ACM or EMIC

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passive restraints.

WARNING

WARNINGS - RESTRAINT SYSTEM

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

DRRESTRAINTS 8O - 5

RESTRAINTS (Continued)

Page 625 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH AIRBAGS,

BEFORE PERFORMING ANY WELDING OPERA-

TIONS DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE AND DISCONNECT

ALL WIRE HARNESS CONNECTORS FROM THE

AIRBAG CONTROL MODULE (ACM). FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND OTHER POSSIBLE DAMAGE TO THE SUPPLE-

MENTAL RESTRAINT SYSTEM CIRCUITS AND COM-

PONENTS.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DO NOT ATTEMPT TO DISMANTLE AN AIR-

BAG UNIT OR TAMPER WITH ITS INFLATOR. DO

NOT PUNCTURE, INCINERATE, OR BRING INTO

CONTACT WITH ELECTRICITY. DO NOT STORE AT

TEMPERATURES EXCEEDING 93É C (200É F). AN

AIRBAG INFLATOR UNIT MAY CONTAIN SODIUM

AZIDE AND POTASSIUM NITRATE. THESE MATERI-

ALS ARE POISONOUS AND EXTREMELY FLAMMA-

BLE. CONTACT WITH ACID, WATER, OR HEAVY

METALS MAY PRODUCE HARMFUL AND IRRITAT-

ING GASES (SODIUM HYDROXIDE IS FORMED IN

THE PRESENCE OF MOISTURE) OR COMBUSTIBLE

COMPOUNDS. AN AIRBAG INFLATOR UNIT MAY

ALSO CONTAIN A GAS CANISTER PRESSURIZED

TO OVER 2500 PSI.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, WHEN HANDLING A SEAT BELT TEN-

SIONER RETRACTOR, PROPER CARE SHOULD BE

EXERCISED TO KEEP FINGERS OUT FROM UNDER

THE RETRACTOR COVER AND AWAY FROM THE

SEAT BELT WEBBING WHERE IT EXITS FROM THE

RETRACTOR COVER.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, REPLACE ALL RESTRAINT SYSTEM COM-

PONENTS ONLY WITH PARTS SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

SUBSTITUTE PARTS MAY APPEAR INTERCHANGE-

ABLE, BUT INTERNAL DIFFERENCES MAY RESULT

IN INFERIOR OCCUPANT PROTECTION.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE RESTRAINT SYSTEM

COMPONENTS MUST NEVER BE REPLACED WITH

ANY SUBSTITUTES. THESE FASTENERS HAVE

SPECIAL COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE RESTRAINT SYSTEM. ANY

TIME A NEW FASTENER IS NEEDED, REPLACE ITWITH THE CORRECT FASTENERS PROVIDED IN

THE SERVICE PACKAGE OR SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, WHEN A STEERING COLUMN HAS AN AIR-

BAG UNIT ATTACHED, NEVER PLACE THE COL-

UMN ON THE FLOOR OR ANY OTHER SURFACE

WITH THE STEERING WHEEL OR AIRBAG UNIT

FACE DOWN.

DIAGNOSIS AND TESTING - SUPPLEMENTAL

RESTRAINT SYSTEM

Proper diagnosis and testing of the supplemental

restraint system components, the Programmable

Communications Interface (PCI) data bus, the data

bus electronic message inputs to and outputs from

the ElectroMechanical Instrument Cluster (EMIC),

the Airbag Control Module (ACM), as well as the

retrieval or erasure of a Diagnostic Trouble Code

(DTC) from the ACM requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be per-

mitted near the inflator on the back of a non-de-

ployed airbag or seat belt tensioner. When carrying a

non-deployed airbag, the trim cover or airbag cushion

side of the unit should be pointed away from the

body to minimize injury in the event of an accidental

deployment. If the airbag unit is placed on a bench or

any other surface, the trim cover or airbag cushion

side of the unit should be face up to minimize move-

8O - 6 RESTRAINTSDR

RESTRAINTS (Continued)

Page 626 of 2627

ment in the event of an accidental deployment. When

handling a non-deployed seat belt tensioner, take

proper care to keep fingers out from under the

retractor cover and away from the seat belt webbing

where it exits from the retractor cover. In addition,

the supplemental restraint system should be dis-

armed whenever any steering wheel, steering col-

umn, seat belt tensioner, airbag, impact sensor, or

instrument panel components require diagnosis or

service. Failure to observe this warning could result

in accidental airbag deployment and possible per-

sonal injury.

All damaged, faulty or non-deployed airbags and

seat belt tensioners which are replaced on vehicles

are to be handled and disposed of properly. If an air-

bag or seat belt tensioner unit is faulty or damaged

and non-deployed, refer to the Hazardous Substance

Control System for proper disposal. Dispose of all

non-deployed and deployed airbags and seat belt ten-

sioners in a manner consistent with state, provincial,

local and federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags and seat belt tensioners must be stored in

their original, special container until they are used

for service. Also, they must be stored in a clean, dry

environment; away from sources of extreme heat,

sparks, and high electrical energy. Always place or

store any airbag on a surface with its trim cover or

airbag cushion side facing up, to minimize movement

in case of an accidental deployment.

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use follow-

ing a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring

must be replaced. If the passenger airbag is

deployed, the passenger airbag door must be

replaced. The seat belt tensioners are deployed by

the same signal that deploys the driver and passen-

ger airbags and must also be replaced if either front

airbag has been deployed. If a side curtain airbag

has been deployed, the complete airbag unit, the

headliner, as well as the upper A, B, and C-pillar

trim must be replaced. These components are not

intended for reuse and will be damaged or weakened

as a result of a supplemental restraint deployment,

which may or may not be obvious during a visual

inspection.

It is also critical that the mounting surfaces and/or

mounting brackets for the Airbag Control Module

(ACM) and the side impact sensors be closely

inspected and restored to their original conditions fol-lowing any vehicle impact damage. Because the ACM

and each impact sensor are used by the supplemental

restraint system to monitor or confirm the direction

and severity of a vehicle impact, improper orientation

or insecure fastening of these components may cause

airbags not to deploy when required, or to deploy

when not required.

All other vehicle components should be closely

inspected following any supplemental restraint

deployment, but are to be replaced only as required

by the extent of the visible damage incurred.

AIRBAG SQUIB STATUS

Multistage airbags with multiple initiators (squibs)

must be checked to determine that all squibs were

used during the deployment event. The driver and

passenger airbags in this model are deployed by elec-

trical signals generated by the Airbag Control Mod-

ule (ACM) through the driver or passenger squib 1

and squib 2 circuits to the two initiators in the air-

bag inflators. Typically, both initiators are used and

all potentially hazardous chemicals are burned dur-

ing an airbag deployment event. However, it is possi-

ble for only one initiator to be used due to an airbag

system fault; therefore, it is always necessary to con-

firm that both initiators have been used in order to

avoid the improper handling or disposal of poten-

tially live pyrotechnic or hazardous materials. The

following procedure should be performed using a

DRBIIItscan tool to verify the status of both airbag

squibs before either deployed airbag is removed from

the vehicle for disposal.

CAUTION: Deployed front airbags having two initia-

tors (squibs) in the airbag inflator may or may not

have live pyrotechnic material within the inflator. Do

not dispose of these airbags unless you are sure of

complete deployment. Refer to the Hazardous Sub-

stance Control System for proper disposal proce-

dures. Dispose of all non-deployed and deployed

airbags in a manner consistent with state, provin-

cial, local, and federal regulations.

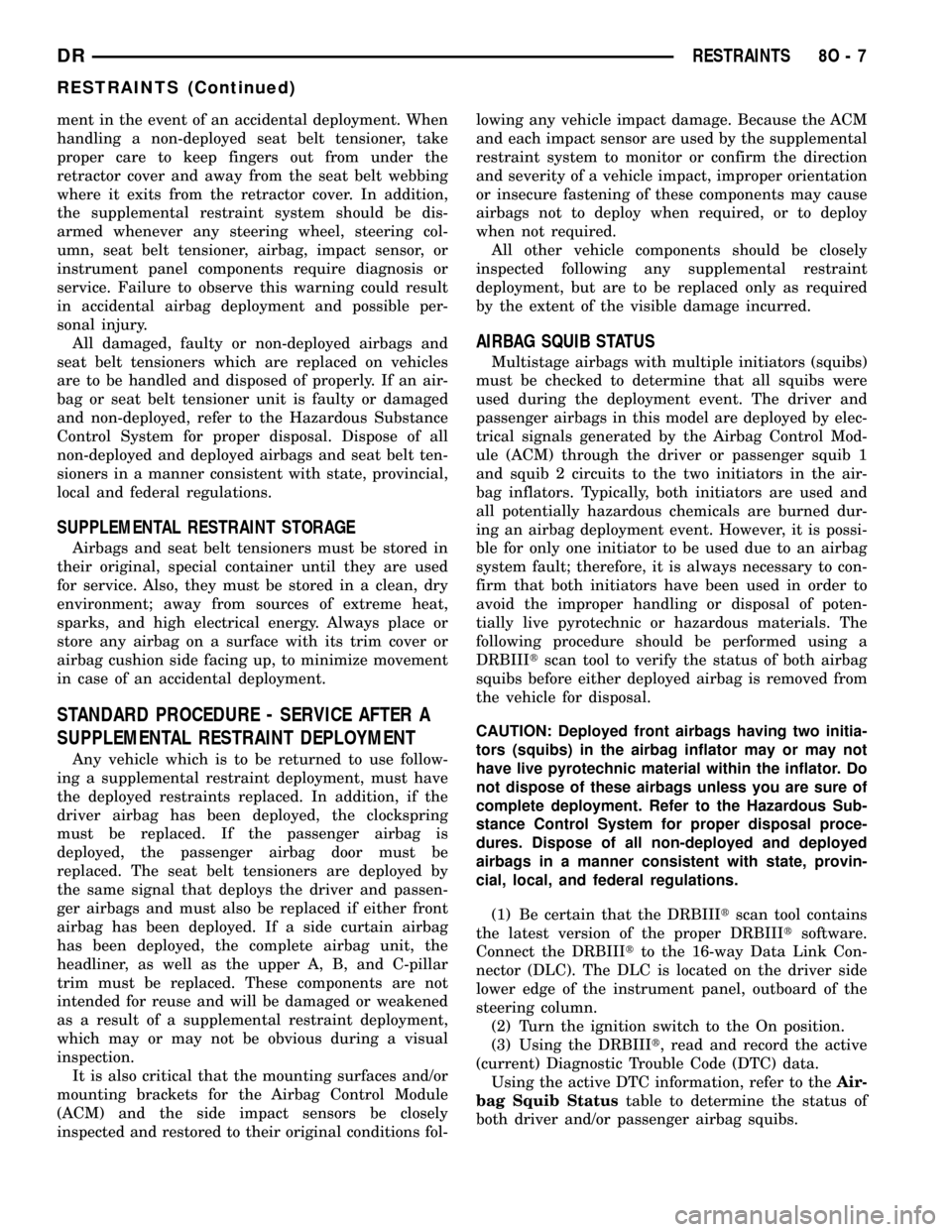

(1) Be certain that the DRBIIItscan tool contains

the latest version of the proper DRBIIItsoftware.

Connect the DRBIIItto the 16-way Data Link Con-

nector (DLC). The DLC is located on the driver side

lower edge of the instrument panel, outboard of the

steering column.

(2) Turn the ignition switch to the On position.

(3) Using the DRBIIIt, read and record the active

(current) Diagnostic Trouble Code (DTC) data.

Using the active DTC information, refer to theAir-

bag Squib Statustable to determine the status of

both driver and/or passenger airbag squibs.

DRRESTRAINTS 8O - 7

RESTRAINTS (Continued)

Page 628 of 2627

CAUTION: Deployed front airbags having two initia-

tors (squibs) in the airbag inflator may or may not

have live pyrotechnic material within the inflator. Do

not dispose of these airbags unless you are sure of

complete deployment. Refer to AIRBAG SQUIB STA-

TUS. All damaged, faulty, or non-deployed supple-

mental restraints which are replaced on vehicles

are to be handled and disposed of properly. If an

airbag or seat belt tensioner unit is faulty or dam-

aged and non-deployed, refer to the Hazardous

Substance Control System for proper disposal. Be

certain to dispose of all non-deployed and deployed

supplemental restraints in a manner consistent with

state, provincial, local and federal regulations.

(3) Next, remove the deployed supplemental

restraints from the vehicle. Refer to the appropriate

service removal procedures.

(4) You may need to vacuum the interior of the

vehicle a second time to recover all of the powder.

STANDARD PROCEDURE - VERIFICATION TEST

The following procedure should be performed using

a DRBIIItscan tool to verify proper supplemental

restraint system operation following the service or

replacement of any supplemental restraint system

component.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS ORSERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) During the following test, the battery negative

cable remains disconnected and isolated, as it was

during the supplemental restraint system component

removal and installation procedures.

(2) Be certain that the DRBIIItscan tool contains

the latest version of the proper DRBIIItsoftware.

Connect the DRBIIItto the 16-way Data Link Con-

nector (DLC). The DLC is located on the driver side

lower edge of the instrument panel, outboard of the

steering column (Fig. 5).

(3) Turn the ignition switch to the On position and

exit the vehicle with the DRBIIItscan tool.

(4) Check to be certain that nobody is in the vehi-

cle, then reconnect the battery negative cable.

(5) Using the DRBIIIt, read and record the active

(current) Diagnostic Trouble Code (DTC) data.

(6) Next, use the DRBIIItto read and record any

stored (historical) DTC data.

(7) If any DTC is found in Step 5 or Step 6, refer

to the appropriate diagnostic information.

(8) Use the DRBIIItto erase the stored DTC data.

If any problems remain, the stored DTC data will not

erase. Refer to the appropriate diagnostic informa-

tion to diagnose any stored DTC that will not erase.

Fig. 4 Vacuum Heater and A/C Outlets - Typical

Fig. 5 16-Way Data Link Connector - Typical

1 - 16-WAY DATA LINK CONNECTOR

2 - BOTTOM OF INSTRUMENT PANEL

DRRESTRAINTS 8O - 9

RESTRAINTS (Continued)

Page 629 of 2627

If the stored DTC information is successfully erased,

go to Step 9.

(9) Turn the ignition switch to the Off position for

about fifteen seconds, and then back to the On posi-

tion. Observe the airbag indicator in the instrument

cluster. It should illuminate for six to eight seconds,

and then go out. This indicates that the supplemen-

tal restraint system is functioning normally and that

the repairs are complete. If the airbag indicator fails

to light, or lights and stays on, there is still an active

supplemental restraint system fault or malfunction.

Refer to the appropriate diagnostic information to

diagnose the problem.

ACM COVER

REMOVAL

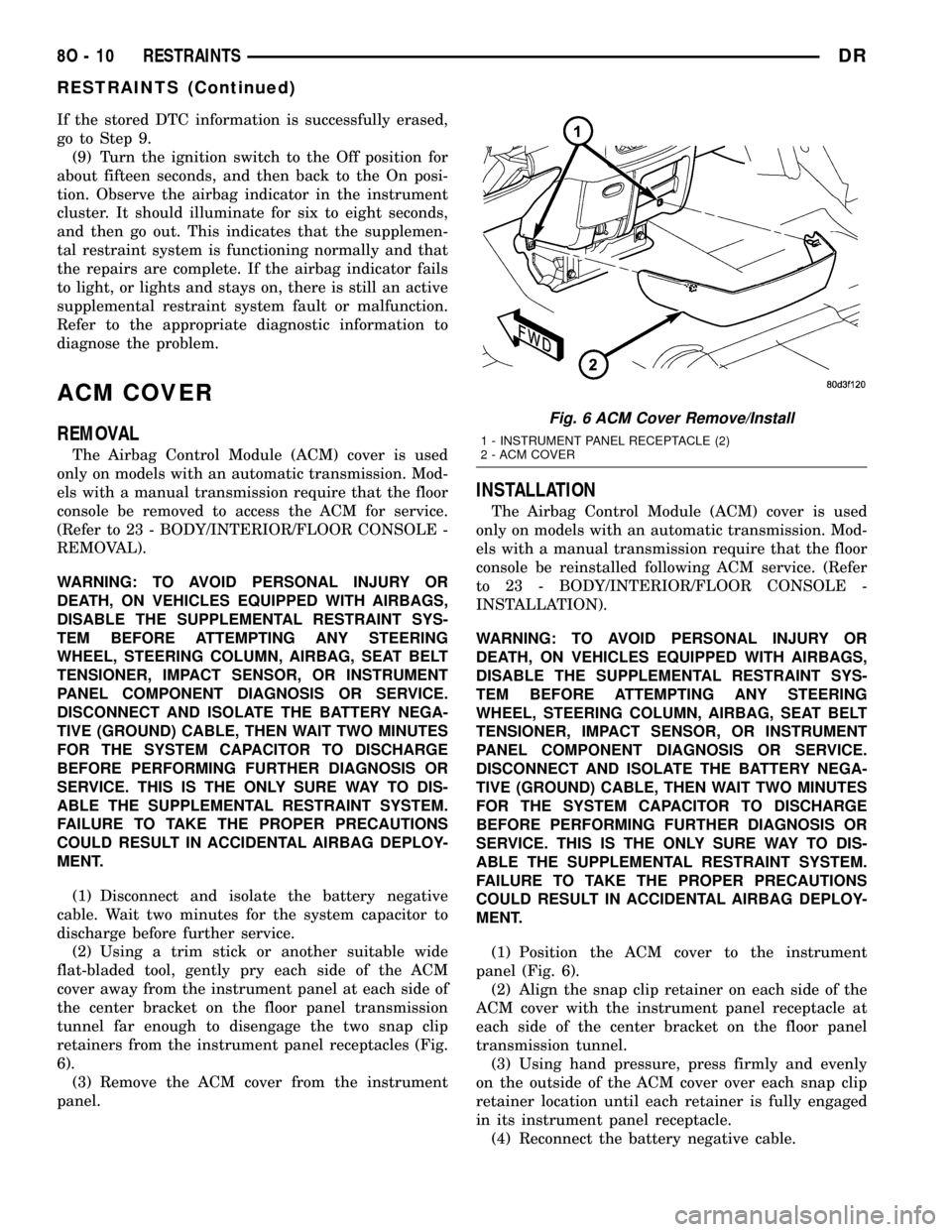

The Airbag Control Module (ACM) cover is used

only on models with an automatic transmission. Mod-

els with a manual transmission require that the floor

console be removed to access the ACM for service.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each side of the ACM

cover away from the instrument panel at each side of

the center bracket on the floor panel transmission

tunnel far enough to disengage the two snap clip

retainers from the instrument panel receptacles (Fig.

6).

(3) Remove the ACM cover from the instrument

panel.

INSTALLATION

The Airbag Control Module (ACM) cover is used

only on models with an automatic transmission. Mod-

els with a manual transmission require that the floor

console be reinstalled following ACM service. (Refer

to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Position the ACM cover to the instrument

panel (Fig. 6).

(2) Align the snap clip retainer on each side of the

ACM cover with the instrument panel receptacle at

each side of the center bracket on the floor panel

transmission tunnel.

(3) Using hand pressure, press firmly and evenly

on the outside of the ACM cover over each snap clip

retainer location until each retainer is fully engaged

in its instrument panel receptacle.

(4) Reconnect the battery negative cable.

Fig. 6 ACM Cover Remove/Install

1 - INSTRUMENT PANEL RECEPTACLE (2)

2 - ACM COVER

8O - 10 RESTRAINTSDR

RESTRAINTS (Continued)

Page 630 of 2627

AIRBAG CONTROL MODULE

DESCRIPTION

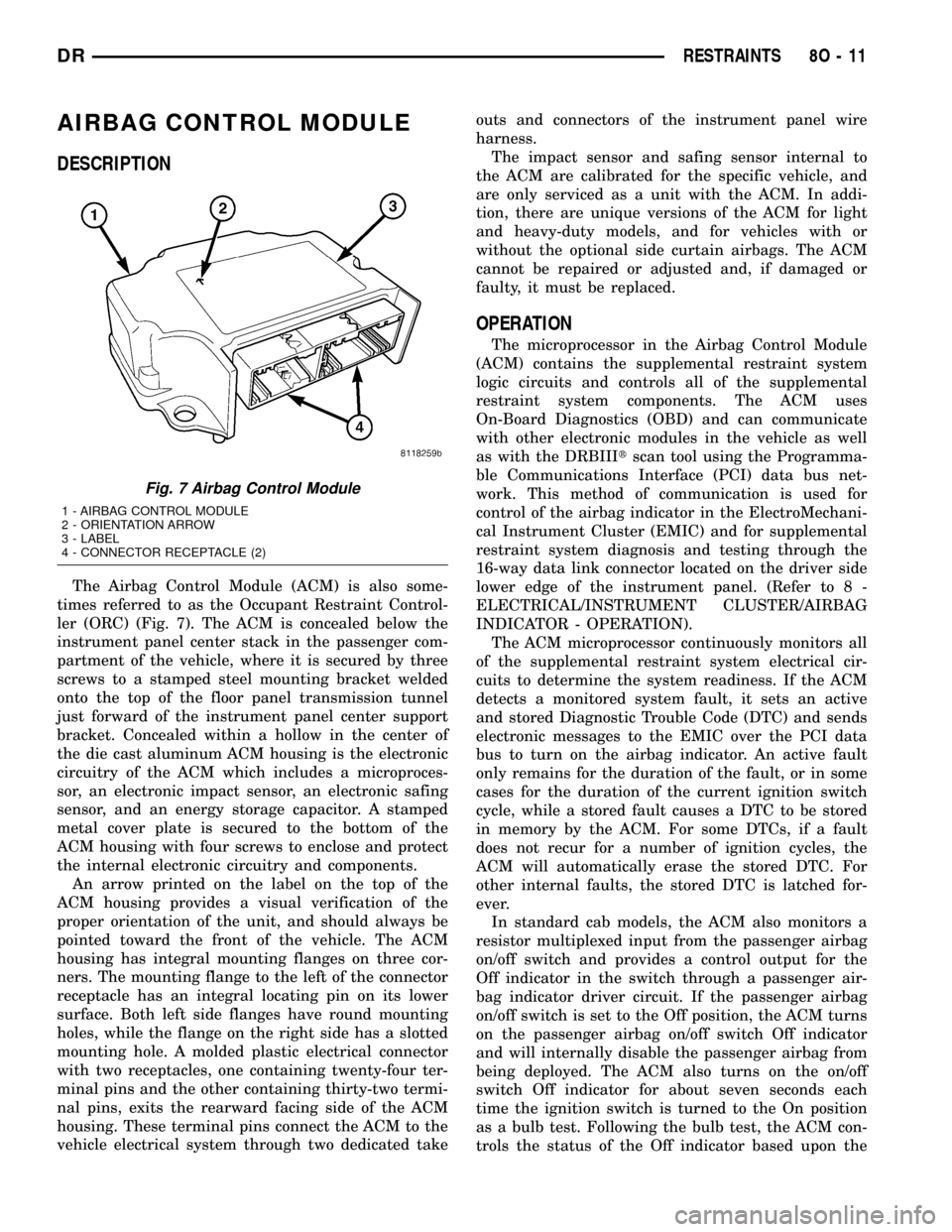

The Airbag Control Module (ACM) is also some-

times referred to as the Occupant Restraint Control-

ler (ORC) (Fig. 7). The ACM is concealed below the

instrument panel center stack in the passenger com-

partment of the vehicle, where it is secured by three

screws to a stamped steel mounting bracket welded

onto the top of the floor panel transmission tunnel

just forward of the instrument panel center support

bracket. Concealed within a hollow in the center of

the die cast aluminum ACM housing is the electronic

circuitry of the ACM which includes a microproces-

sor, an electronic impact sensor, an electronic safing

sensor, and an energy storage capacitor. A stamped

metal cover plate is secured to the bottom of the

ACM housing with four screws to enclose and protect

the internal electronic circuitry and components.

An arrow printed on the label on the top of the

ACM housing provides a visual verification of the

proper orientation of the unit, and should always be

pointed toward the front of the vehicle. The ACM

housing has integral mounting flanges on three cor-

ners. The mounting flange to the left of the connector

receptacle has an integral locating pin on its lower

surface. Both left side flanges have round mounting

holes, while the flange on the right side has a slotted

mounting hole. A molded plastic electrical connector

with two receptacles, one containing twenty-four ter-

minal pins and the other containing thirty-two termi-

nal pins, exits the rearward facing side of the ACM

housing. These terminal pins connect the ACM to the

vehicle electrical system through two dedicated takeouts and connectors of the instrument panel wire

harness.

The impact sensor and safing sensor internal to

the ACM are calibrated for the specific vehicle, and

are only serviced as a unit with the ACM. In addi-

tion, there are unique versions of the ACM for light

and heavy-duty models, and for vehicles with or

without the optional side curtain airbags. The ACM

cannot be repaired or adjusted and, if damaged or

faulty, it must be replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the supplemental restraint system

logic circuits and controls all of the supplemental

restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with other electronic modules in the vehicle as well

as with the DRBIIItscan tool using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used for

control of the airbag indicator in the ElectroMechani-

cal Instrument Cluster (EMIC) and for supplemental

restraint system diagnosis and testing through the

16-way data link connector located on the driver side

lower edge of the instrument panel. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER/AIRBAG

INDICATOR - OPERATION).

The ACM microprocessor continuously monitors all

of the supplemental restraint system electrical cir-

cuits to determine the system readiness. If the ACM

detects a monitored system fault, it sets an active

and stored Diagnostic Trouble Code (DTC) and sends

electronic messages to the EMIC over the PCI data

bus to turn on the airbag indicator. An active fault

only remains for the duration of the fault, or in some

cases for the duration of the current ignition switch

cycle, while a stored fault causes a DTC to be stored

in memory by the ACM. For some DTCs, if a fault

does not recur for a number of ignition cycles, the

ACM will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

In standard cab models, the ACM also monitors a

resistor multiplexed input from the passenger airbag

on/off switch and provides a control output for the

Off indicator in the switch through a passenger air-

bag indicator driver circuit. If the passenger airbag

on/off switch is set to the Off position, the ACM turns

on the passenger airbag on/off switch Off indicator

and will internally disable the passenger airbag from

being deployed. The ACM also turns on the on/off

switch Off indicator for about seven seconds each

time the ignition switch is turned to the On position

as a bulb test. Following the bulb test, the ACM con-

trols the status of the Off indicator based upon the

Fig. 7 Airbag Control Module

1 - AIRBAG CONTROL MODULE

2 - ORIENTATION ARROW

3 - LABEL

4 - CONNECTOR RECEPTACLE (2)

DRRESTRAINTS 8O - 11