One DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 296 of 2627

FRONT WHEEL SPEED

SENSOR

DESCRIPTION

The ABS brake system uses 3 wheel speed sensors.

A sensor is mounted to each front hub/bearings. The

third sensor is mounted on top of the rear axle dif-

ferential housing.

OPERATION

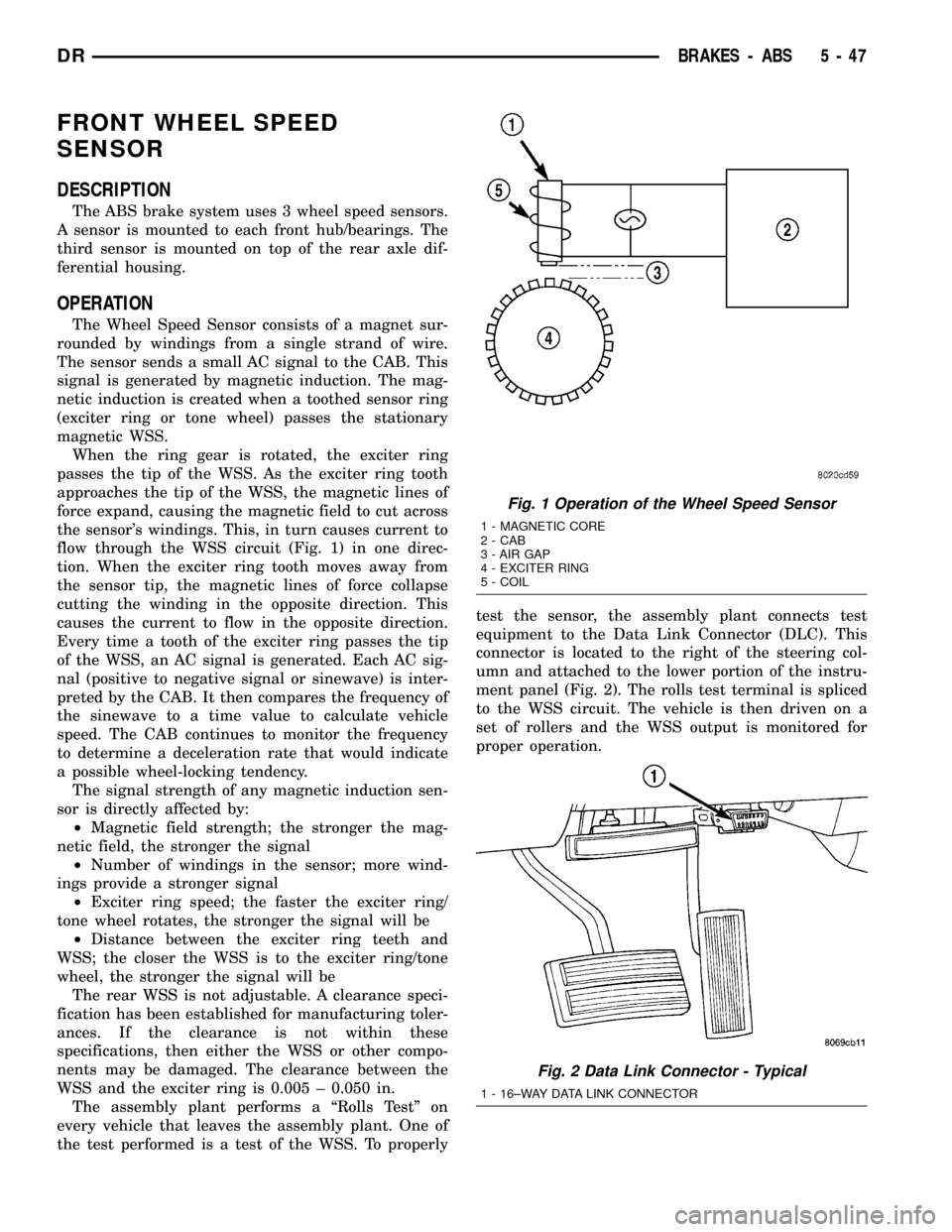

The Wheel Speed Sensor consists of a magnet sur-

rounded by windings from a single strand of wire.

The sensor sends a small AC signal to the CAB. This

signal is generated by magnetic induction. The mag-

netic induction is created when a toothed sensor ring

(exciter ring or tone wheel) passes the stationary

magnetic WSS.

When the ring gear is rotated, the exciter ring

passes the tip of the WSS. As the exciter ring tooth

approaches the tip of the WSS, the magnetic lines of

force expand, causing the magnetic field to cut across

the sensor's windings. This, in turn causes current to

flow through the WSS circuit (Fig. 1) in one direc-

tion. When the exciter ring tooth moves away from

the sensor tip, the magnetic lines of force collapse

cutting the winding in the opposite direction. This

causes the current to flow in the opposite direction.

Every time a tooth of the exciter ring passes the tip

of the WSS, an AC signal is generated. Each AC sig-

nal (positive to negative signal or sinewave) is inter-

preted by the CAB. It then compares the frequency of

the sinewave to a time value to calculate vehicle

speed. The CAB continues to monitor the frequency

to determine a deceleration rate that would indicate

a possible wheel-locking tendency.

The signal strength of any magnetic induction sen-

sor is directly affected by:

²Magnetic field strength; the stronger the mag-

netic field, the stronger the signal

²Number of windings in the sensor; more wind-

ings provide a stronger signal

²Exciter ring speed; the faster the exciter ring/

tone wheel rotates, the stronger the signal will be

²Distance between the exciter ring teeth and

WSS; the closer the WSS is to the exciter ring/tone

wheel, the stronger the signal will be

The rear WSS is not adjustable. A clearance speci-

fication has been established for manufacturing toler-

ances. If the clearance is not within these

specifications, then either the WSS or other compo-

nents may be damaged. The clearance between the

WSS and the exciter ring is 0.005 ± 0.050 in.

The assembly plant performs a ªRolls Testº on

every vehicle that leaves the assembly plant. One of

the test performed is a test of the WSS. To properlytest the sensor, the assembly plant connects test

equipment to the Data Link Connector (DLC). This

connector is located to the right of the steering col-

umn and attached to the lower portion of the instru-

ment panel (Fig. 2). The rolls test terminal is spliced

to the WSS circuit. The vehicle is then driven on a

set of rollers and the WSS output is monitored for

proper operation.

Fig. 1 Operation of the Wheel Speed Sensor

1 - MAGNETIC CORE

2 - CAB

3 - AIR GAP

4 - EXCITER RING

5 - COIL

Fig. 2 Data Link Connector - Typical

1 - 16±WAY DATA LINK CONNECTOR

DRBRAKES - ABS 5 - 47

Page 298 of 2627

TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The Antilock brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to

diagnose the Antilock Brake system. For test proce-

dures refer to the Chassis Diagnostic Manual.

HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING

Vehicles equipped with ABS use electronic variable

brake proportioning (EVBP) to balance front-to-rear

braking. The EVBP is used in place of a rear propor-

tioning valve. The EVBP system uses the ABS sys-

tem to control the slip of the rear wheels in partial

braking range. The braking force of the rear wheels

is controlled electronically by using the inlet and out-

let valves located in the integrated control unit

(ICU).

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

EVBP is able to decrease, hold and increase rear

brake pressure without activating full ABS control.

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor, low

pressure accumulators, inlet valves, outlet valves and

noise attenuators.

OPERATION

Accumulators in the valve body store extra fluid

released to the system for ABS mode operation. The

pump provides the fluid volume needed and is oper-

ated by a DC type motor. The motor is controlled by

the CAB.

The valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

NOTE: The three modes mentioned below do occur

but not necessarily in the order listed everytime.

During antilock braking, solenoid valve pressure

modulation occurs in three stages, pressure increase,

pressure hold, and pressure decrease. The valves are

all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the CAB closes the inlet

then opens the outlet valve, which also opens the

return circuit to the accumulators. Fluid pressure is

allowed to bleed off (decrease) as needed to prevent

wheel lock.

Once the period of high wheel slip has ended, the

CAB closes the outlet valve and begins a pressure

increase or hold cycle as needed.

PRESSURE HOLD

Both solenoid valves are closed in the pressure

hold cycle but only the inlet valve is energized. Fluid

apply pressure in the control channel is maintained

at a constant rate. The CAB maintains the hold cycle

until sensor inputs indicate a pressure change is nec-

essary.

DRBRAKES - ABS 5 - 49

Page 299 of 2627

PRESSURE INCREASE

The inlet valve is open and the outlet valve is

closed during the pressure increase cycle. The pres-

sure increase cycle is used to reapply thew brakes.

This cycle controls re-application of fluid apply pres-

sure.

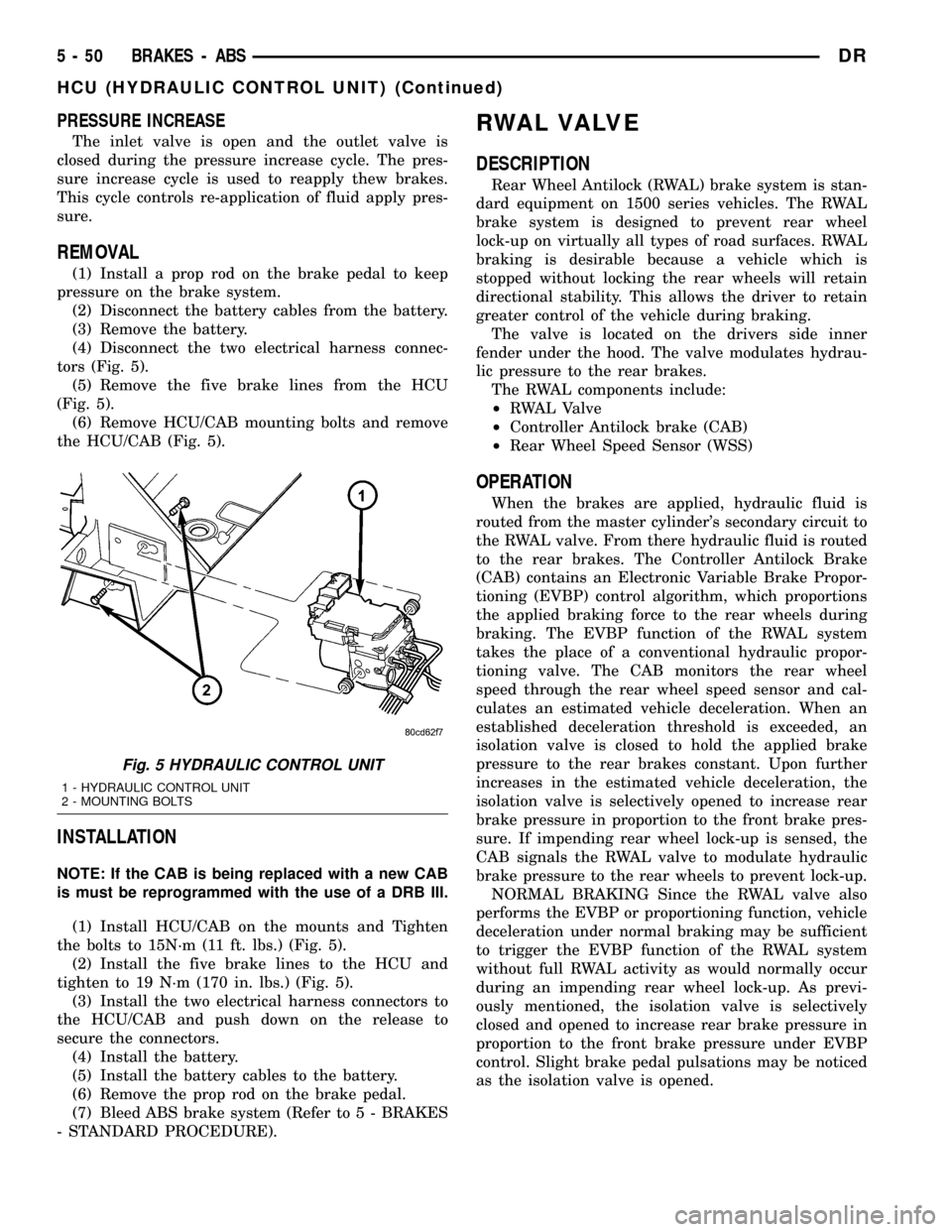

REMOVAL

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Disconnect the battery cables from the battery.

(3) Remove the battery.

(4) Disconnect the two electrical harness connec-

tors (Fig. 5).

(5) Remove the five brake lines from the HCU

(Fig. 5).

(6) Remove HCU/CAB mounting bolts and remove

the HCU/CAB (Fig. 5).

INSTALLATION

NOTE: If the CAB is being replaced with a new CAB

is must be reprogrammed with the use of a DRB III.

(1) Install HCU/CAB on the mounts and Tighten

the bolts to 15N´m (11 ft. lbs.) (Fig. 5).

(2) Install the five brake lines to the HCU and

tighten to 19 N´m (170 in. lbs.) (Fig. 5).

(3) Install the two electrical harness connectors to

the HCU/CAB and push down on the release to

secure the connectors.

(4) Install the battery.

(5) Install the battery cables to the battery.

(6) Remove the prop rod on the brake pedal.

(7) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

RWAL VALVE

DESCRIPTION

Rear Wheel Antilock (RWAL) brake system is stan-

dard equipment on 1500 series vehicles. The RWAL

brake system is designed to prevent rear wheel

lock-up on virtually all types of road surfaces. RWAL

braking is desirable because a vehicle which is

stopped without locking the rear wheels will retain

directional stability. This allows the driver to retain

greater control of the vehicle during braking.

The valve is located on the drivers side inner

fender under the hood. The valve modulates hydrau-

lic pressure to the rear brakes.

The RWAL components include:

²RWAL Valve

²Controller Antilock brake (CAB)

²Rear Wheel Speed Sensor (WSS)

OPERATION

When the brakes are applied, hydraulic fluid is

routed from the master cylinder's secondary circuit to

the RWAL valve. From there hydraulic fluid is routed

to the rear brakes. The Controller Antilock Brake

(CAB) contains an Electronic Variable Brake Propor-

tioning (EVBP) control algorithm, which proportions

the applied braking force to the rear wheels during

braking. The EVBP function of the RWAL system

takes the place of a conventional hydraulic propor-

tioning valve. The CAB monitors the rear wheel

speed through the rear wheel speed sensor and cal-

culates an estimated vehicle deceleration. When an

established deceleration threshold is exceeded, an

isolation valve is closed to hold the applied brake

pressure to the rear brakes constant. Upon further

increases in the estimated vehicle deceleration, the

isolation valve is selectively opened to increase rear

brake pressure in proportion to the front brake pres-

sure. If impending rear wheel lock-up is sensed, the

CAB signals the RWAL valve to modulate hydraulic

brake pressure to the rear wheels to prevent lock-up.

NORMAL BRAKING Since the RWAL valve also

performs the EVBP or proportioning function, vehicle

deceleration under normal braking may be sufficient

to trigger the EVBP function of the RWAL system

without full RWAL activity as would normally occur

during an impending rear wheel lock-up. As previ-

ously mentioned, the isolation valve is selectively

closed and opened to increase rear brake pressure in

proportion to the front brake pressure under EVBP

control. Slight brake pedal pulsations may be noticed

as the isolation valve is opened.

Fig. 5 HYDRAULIC CONTROL UNIT

1 - HYDRAULIC CONTROL UNIT

2 - MOUNTING BOLTS

5 - 50 BRAKES - ABSDR

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 302 of 2627

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

WARNING.............................1

DIAGNOSIS AND TESTING................1

SPECIFICATIONS........................5

CLUTCH DISC

REMOVAL.............................5

INSTALLATION..........................5

CLUTCH HOUSING

DIAGNOSIS AND TESTING................7

REMOVAL.............................9

INSTALLATION..........................9

CLUTCH RELEASE BEARING

REMOVAL.............................9

INSTALLATION.........................10

FLYWHEEL

DIAGNOSIS AND TESTING................10REMOVAL.............................11

DISASSEMBLY.........................11

ASSEMBLY............................11

INSTALLATION.........................11

PILOT BEARING

REMOVAL.............................11

INSTALLATION.........................12

LINKAGE

REMOVAL.............................12

INSTALLATION.........................12

CLUTCH PEDAL POSITION SWITCH

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING................13

CLUTCH

WARNING

WARNING: Exercise care when servicing clutch

components. Factory installed clutch discs do not

contain asbestos fibers. Dust and dirt on clutch

parts may contain asbestos fibers from aftermarket

components. Breathing excessive concentrations of

these fibers can cause serious bodily harm. Wear a

respirator during service and never clean clutch

components with compressed air or with a dry

brush. Either clean the components with water

dampened rags or use a vacuum cleaner specifi-

cally designed to remove asbestos fibers and dust.

Do not create dust by sanding a clutch discs.

Replace the disc if the friction material is damaged.

Dispose of all dust and dirt containing asbestos

fibers in sealed bags or containers. This will mini-

mize exposure to yourself and to others. Follow all

recommended safety practices prescribed by the

occupational safety and health administration

(OSHA) and the environmental safety agency (EPA),

for the handling and disposal of products contain-

ing asbestos. Failure to follow these instructions

may result in personal injury or death

DIAGNOSIS AND TESTING

Road test and inspect components to determine a

clutch problem. Road test the vehicle at normalspeeds. Shift the transmission through all gear

ranges and observe clutch action. If clutch chatters,

grabs, slips or does not release properly, remove and

inspect clutch components. If problem is noise or

hard shifting, further diagnosis may be needed to the

transmission and driveline component.

CLUTCH CONTAMINATION

Contamination is a frequent cause of clutch mal-

functions. Oil, water or clutch fluid on the clutch disc

and pressure plate surfaces will cause chatter, slip

and grab. Oil contamination indicates a leak at

either the rear main seal or transmission input shaft.

Clutch fluid leaks are usually from damaged slave

cylinder push rod seals. Heat buildup caused by slip-

page between the pressure plate, disc and flywheel

can bake the oil residue onto the components. The

glaze-like residue ranges in color from amber to

black.

Road splash contamination is dirt/water entering

the clutch housing due to loose bolts, housing cracks.

Driving through deep water puddles can force water/

road splash into the housing through such openings.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems can be

caused by worn or damage clutch components.

Release problems can cause hard shifting and

noise. Look for leaks at clutch cylinders, connecting

line and loose slave cylinder bolts. Also worn/loose

release fork, pivot stud, clutch disc, pressure plate or

release bearing.

DRCLUTCH 6 - 1

Page 303 of 2627

Engagement problems can cause slip, chatter/shud-

der and noisy operation. The causes may be clutch

disc contamination, wear, distortion or flywheel dam-

age.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain

another disc if runout is excessive.

Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten-

ing.

FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. Minor fly-

wheel scoring can be cleaned up by hand with 180

grit emery or with turning equipment. Remove only

enough material to reduce scoring (approximately

0.001 - 0.003 in.). Heavy stock removal isnot rec-

ommended.Replace the flywheel if scoring is severe

and deeper than 0.076 mm (0.003 in.). Excessive

stock removal can result in flywheel cracking or

warpage after installation; it can also weaken the fly-

wheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

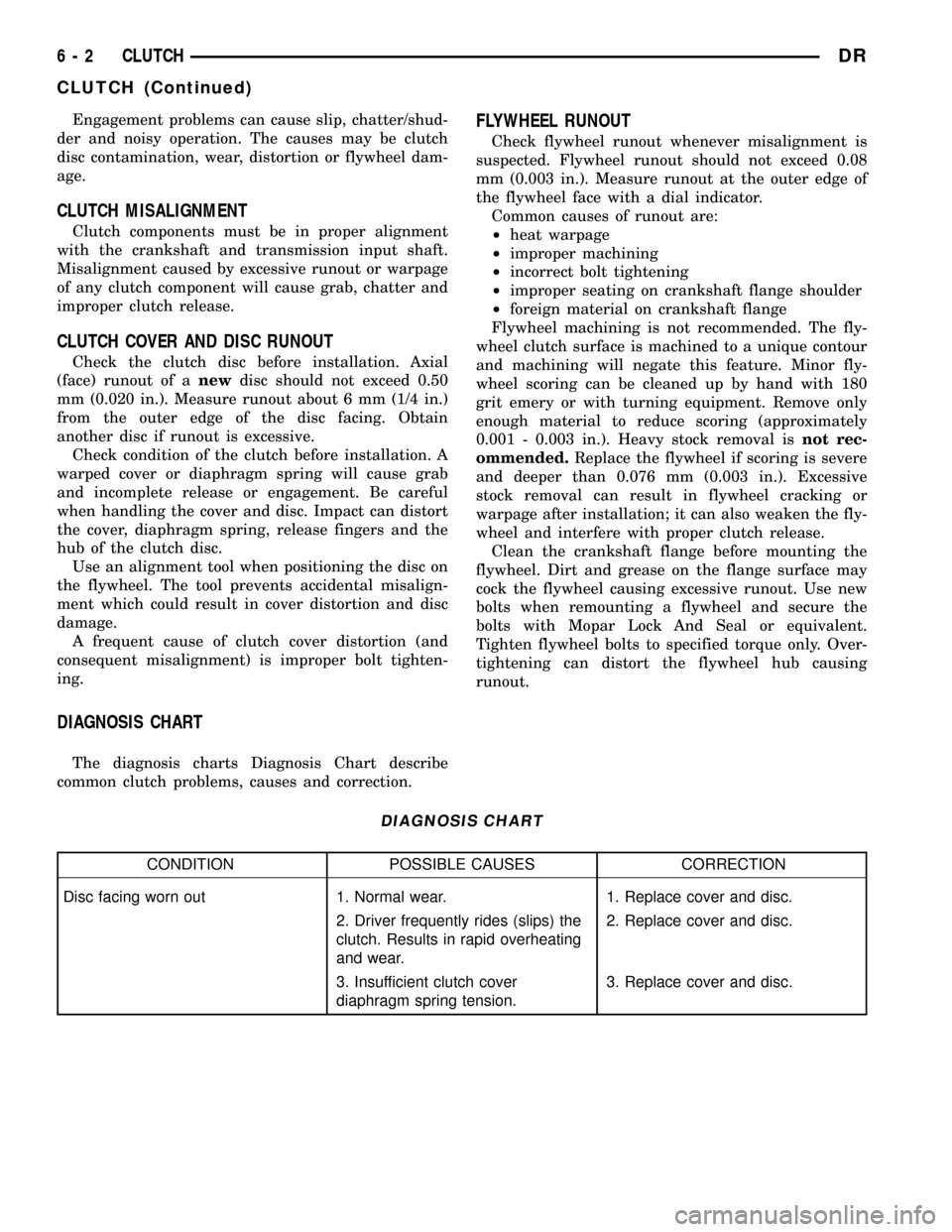

DIAGNOSIS CHART

The diagnosis charts Diagnosis Chart describe

common clutch problems, causes and correction.

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Disc facing worn out 1. Normal wear. 1. Replace cover and disc.

2. Driver frequently rides (slips) the

clutch. Results in rapid overheating

and wear.2. Replace cover and disc.

3. Insufficient clutch cover

diaphragm spring tension.3. Replace cover and disc.

6 - 2 CLUTCHDR

CLUTCH (Continued)

Page 304 of 2627

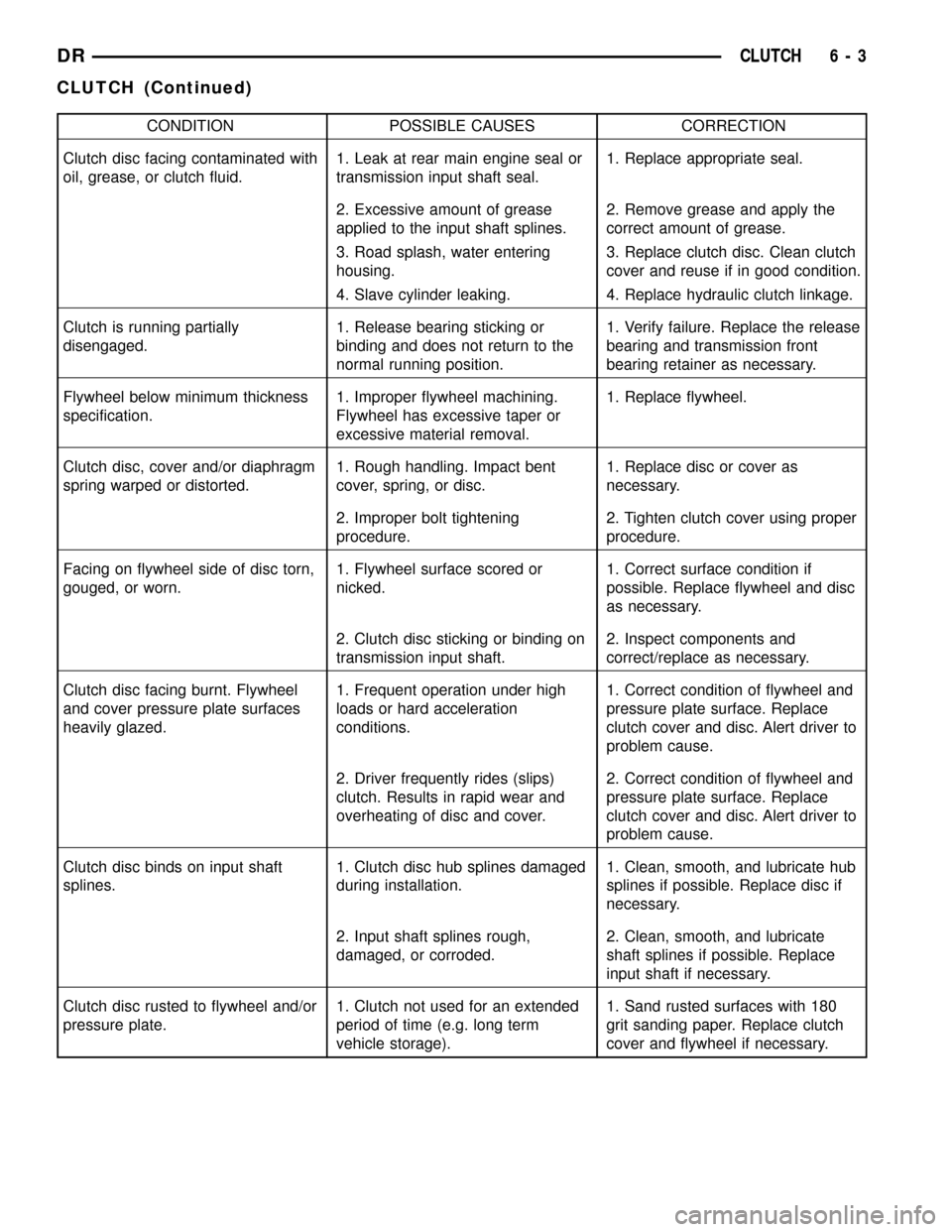

CONDITION POSSIBLE CAUSES CORRECTION

Clutch disc facing contaminated with

oil, grease, or clutch fluid.1. Leak at rear main engine seal or

transmission input shaft seal.1. Replace appropriate seal.

2. Excessive amount of grease

applied to the input shaft splines.2. Remove grease and apply the

correct amount of grease.

3. Road splash, water entering

housing.3. Replace clutch disc. Clean clutch

cover and reuse if in good condition.

4. Slave cylinder leaking. 4. Replace hydraulic clutch linkage.

Clutch is running partially

disengaged.1. Release bearing sticking or

binding and does not return to the

normal running position.1. Verify failure. Replace the release

bearing and transmission front

bearing retainer as necessary.

Flywheel below minimum thickness

specification.1. Improper flywheel machining.

Flywheel has excessive taper or

excessive material removal.1. Replace flywheel.

Clutch disc, cover and/or diaphragm

spring warped or distorted.1. Rough handling. Impact bent

cover, spring, or disc.1. Replace disc or cover as

necessary.

2. Improper bolt tightening

procedure.2. Tighten clutch cover using proper

procedure.

Facing on flywheel side of disc torn,

gouged, or worn.1. Flywheel surface scored or

nicked.1. Correct surface condition if

possible. Replace flywheel and disc

as necessary.

2. Clutch disc sticking or binding on

transmission input shaft.2. Inspect components and

correct/replace as necessary.

Clutch disc facing burnt. Flywheel

and cover pressure plate surfaces

heavily glazed.1. Frequent operation under high

loads or hard acceleration

conditions.1. Correct condition of flywheel and

pressure plate surface. Replace

clutch cover and disc. Alert driver to

problem cause.

2. Driver frequently rides (slips)

clutch. Results in rapid wear and

overheating of disc and cover.2. Correct condition of flywheel and

pressure plate surface. Replace

clutch cover and disc. Alert driver to

problem cause.

Clutch disc binds on input shaft

splines.1. Clutch disc hub splines damaged

during installation.1. Clean, smooth, and lubricate hub

splines if possible. Replace disc if

necessary.

2. Input shaft splines rough,

damaged, or corroded.2. Clean, smooth, and lubricate

shaft splines if possible. Replace

input shaft if necessary.

Clutch disc rusted to flywheel and/or

pressure plate.1. Clutch not used for an extended

period of time (e.g. long term

vehicle storage).1. Sand rusted surfaces with 180

grit sanding paper. Replace clutch

cover and flywheel if necessary.

DRCLUTCH 6 - 3

CLUTCH (Continued)

Page 305 of 2627

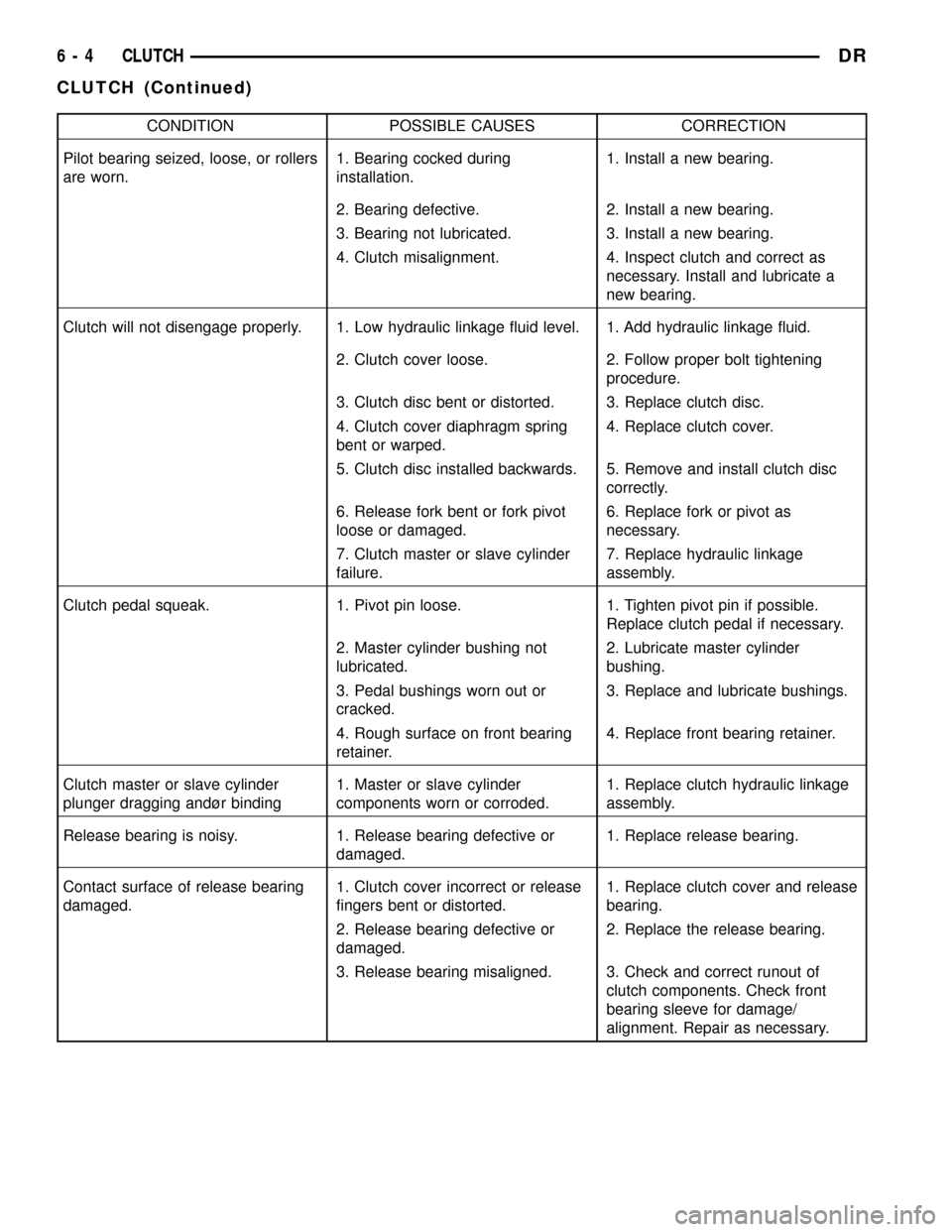

CONDITION POSSIBLE CAUSES CORRECTION

Pilot bearing seized, loose, or rollers

are worn.1. Bearing cocked during

installation.1. Install a new bearing.

2. Bearing defective. 2. Install a new bearing.

3. Bearing not lubricated. 3. Install a new bearing.

4. Clutch misalignment. 4. Inspect clutch and correct as

necessary. Install and lubricate a

new bearing.

Clutch will not disengage properly. 1. Low hydraulic linkage fluid level. 1. Add hydraulic linkage fluid.

2. Clutch cover loose. 2. Follow proper bolt tightening

procedure.

3. Clutch disc bent or distorted. 3. Replace clutch disc.

4. Clutch cover diaphragm spring

bent or warped.4. Replace clutch cover.

5. Clutch disc installed backwards. 5. Remove and install clutch disc

correctly.

6. Release fork bent or fork pivot

loose or damaged.6. Replace fork or pivot as

necessary.

7. Clutch master or slave cylinder

failure.7. Replace hydraulic linkage

assembly.

Clutch pedal squeak. 1. Pivot pin loose. 1. Tighten pivot pin if possible.

Replace clutch pedal if necessary.

2. Master cylinder bushing not

lubricated.2. Lubricate master cylinder

bushing.

3. Pedal bushings worn out or

cracked.3. Replace and lubricate bushings.

4. Rough surface on front bearing

retainer.4. Replace front bearing retainer.

Clutch master or slave cylinder

plunger dragging andùr binding1. Master or slave cylinder

components worn or corroded.1. Replace clutch hydraulic linkage

assembly.

Release bearing is noisy. 1. Release bearing defective or

damaged.1. Replace release bearing.

Contact surface of release bearing

damaged.1. Clutch cover incorrect or release

fingers bent or distorted.1. Replace clutch cover and release

bearing.

2. Release bearing defective or

damaged.2. Replace the release bearing.

3. Release bearing misaligned. 3. Check and correct runout of

clutch components. Check front

bearing sleeve for damage/

alignment. Repair as necessary.

6 - 4 CLUTCHDR

CLUTCH (Continued)

Page 306 of 2627

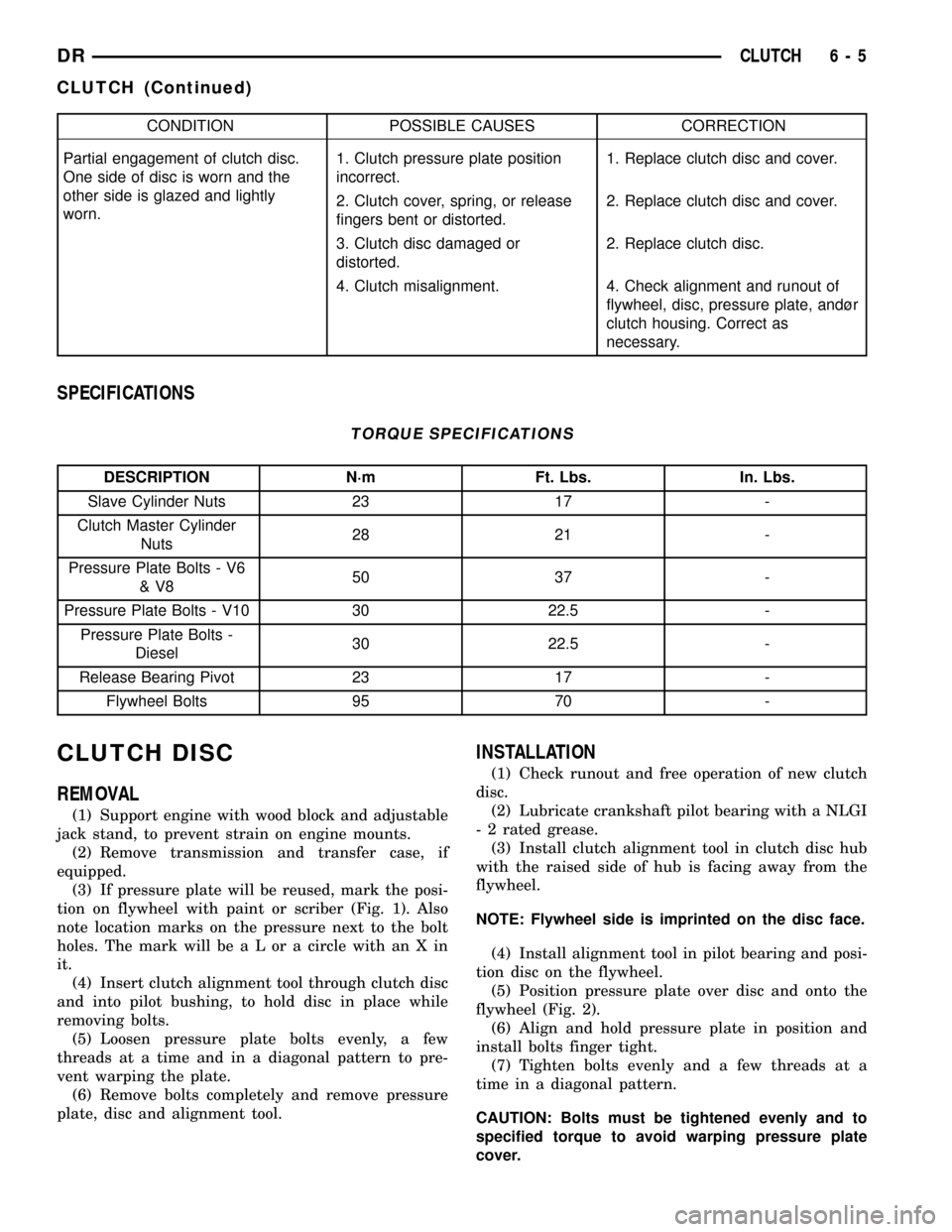

CONDITION POSSIBLE CAUSES CORRECTION

Partial engagement of clutch disc.

One side of disc is worn and the

other side is glazed and lightly

worn.1. Clutch pressure plate position

incorrect.1. Replace clutch disc and cover.

2. Clutch cover, spring, or release

fingers bent or distorted.2. Replace clutch disc and cover.

3. Clutch disc damaged or

distorted.2. Replace clutch disc.

4. Clutch misalignment. 4. Check alignment and runout of

flywheel, disc, pressure plate, andùr

clutch housing. Correct as

necessary.

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Slave Cylinder Nuts 23 17 -

Clutch Master Cylinder

Nuts28 21 -

Pressure Plate Bolts - V6

&V850 37 -

Pressure Plate Bolts - V10 30 22.5 -

Pressure Plate Bolts -

Diesel30 22.5 -

Release Bearing Pivot 23 17 -

Flywheel Bolts 95 70 -

CLUTCH DISC

REMOVAL

(1) Support engine with wood block and adjustable

jack stand, to prevent strain on engine mounts.

(2) Remove transmission and transfer case, if

equipped.

(3) If pressure plate will be reused, mark the posi-

tion on flywheel with paint or scriber (Fig. 1). Also

note location marks on the pressure next to the bolt

holes. The mark will be a L or a circle with an X in

it.

(4) Insert clutch alignment tool through clutch disc

and into pilot bushing, to hold disc in place while

removing bolts.

(5) Loosen pressure plate bolts evenly, a few

threads at a time and in a diagonal pattern to pre-

vent warping the plate.

(6) Remove bolts completely and remove pressure

plate, disc and alignment tool.

INSTALLATION

(1) Check runout and free operation of new clutch

disc.

(2) Lubricate crankshaft pilot bearing with a NLGI

- 2 rated grease.

(3) Install clutch alignment tool in clutch disc hub

with the raised side of hub is facing away from the

flywheel.

NOTE: Flywheel side is imprinted on the disc face.

(4) Install alignment tool in pilot bearing and posi-

tion disc on the flywheel.

(5) Position pressure plate over disc and onto the

flywheel (Fig. 2).

(6) Align and hold pressure plate in position and

install bolts finger tight.

(7) Tighten bolts evenly and a few threads at a

time in a diagonal pattern.

CAUTION: Bolts must be tightened evenly and to

specified torque to avoid warping pressure plate

cover.

DRCLUTCH 6 - 5

CLUTCH (Continued)

Page 308 of 2627

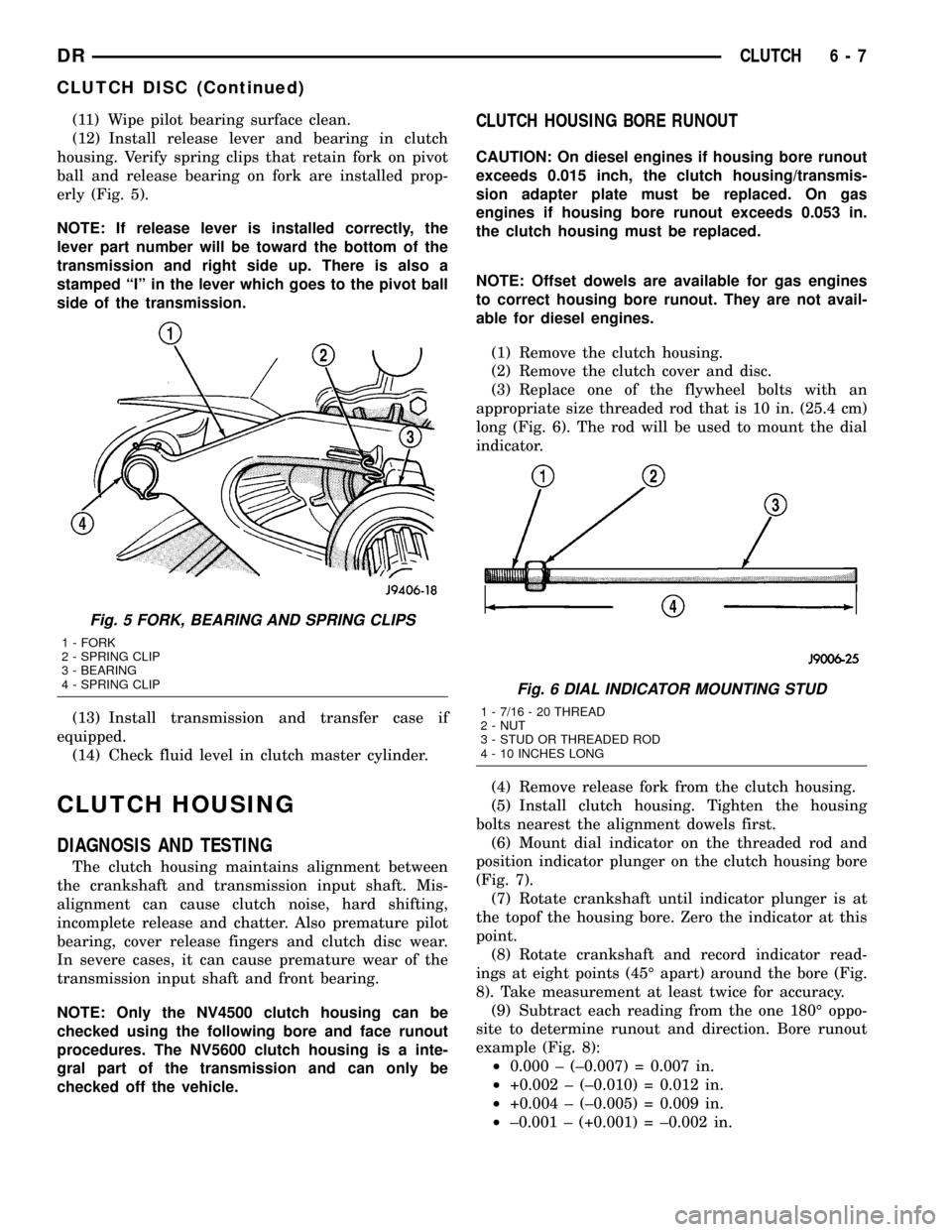

(11) Wipe pilot bearing surface clean.

(12) Install release lever and bearing in clutch

housing. Verify spring clips that retain fork on pivot

ball and release bearing on fork are installed prop-

erly (Fig. 5).

NOTE: If release lever is installed correctly, the

lever part number will be toward the bottom of the

transmission and right side up. There is also a

stamped ªIº in the lever which goes to the pivot ball

side of the transmission.

(13) Install transmission and transfer case if

equipped.

(14) Check fluid level in clutch master cylinder.

CLUTCH HOUSING

DIAGNOSIS AND TESTING

The clutch housing maintains alignment between

the crankshaft and transmission input shaft. Mis-

alignment can cause clutch noise, hard shifting,

incomplete release and chatter. Also premature pilot

bearing, cover release fingers and clutch disc wear.

In severe cases, it can cause premature wear of the

transmission input shaft and front bearing.

NOTE: Only the NV4500 clutch housing can be

checked using the following bore and face runout

procedures. The NV5600 clutch housing is a inte-

gral part of the transmission and can only be

checked off the vehicle.

CLUTCH HOUSING BORE RUNOUT

CAUTION: On diesel engines if housing bore runout

exceeds 0.015 inch, the clutch housing/transmis-

sion adapter plate must be replaced. On gas

engines if housing bore runout exceeds 0.053 in.

the clutch housing must be replaced.

NOTE: Offset dowels are available for gas engines

to correct housing bore runout. They are not avail-

able for diesel engines.

(1) Remove the clutch housing.

(2) Remove the clutch cover and disc.

(3) Replace one of the flywheel bolts with an

appropriate size threaded rod that is 10 in. (25.4 cm)

long (Fig. 6). The rod will be used to mount the dial

indicator.

(4) Remove release fork from the clutch housing.

(5) Install clutch housing. Tighten the housing

bolts nearest the alignment dowels first.

(6) Mount dial indicator on the threaded rod and

position indicator plunger on the clutch housing bore

(Fig. 7).

(7) Rotate crankshaft until indicator plunger is at

the topof the housing bore. Zero the indicator at this

point.

(8) Rotate crankshaft and record indicator read-

ings at eight points (45É apart) around the bore (Fig.

8). Take measurement at least twice for accuracy.

(9) Subtract each reading from the one 180É oppo-

site to determine runout and direction. Bore runout

example (Fig. 8):

²0.000 ± (±0.007) = 0.007 in.

²+0.002 ± (±0.010) = 0.012 in.

²+0.004 ± (±0.005) = 0.009 in.

²±0.001 ± (+0.001) = ±0.002 in.

Fig. 5 FORK, BEARING AND SPRING CLIPS

1 - FORK

2 - SPRING CLIP

3 - BEARING

4 - SPRING CLIP

Fig. 6 DIAL INDICATOR MOUNTING STUD

1 - 7/16 - 20 THREAD

2 - NUT

3 - STUD OR THREADED ROD

4 - 10 INCHES LONG

DRCLUTCH 6 - 7

CLUTCH DISC (Continued)

Page 311 of 2627

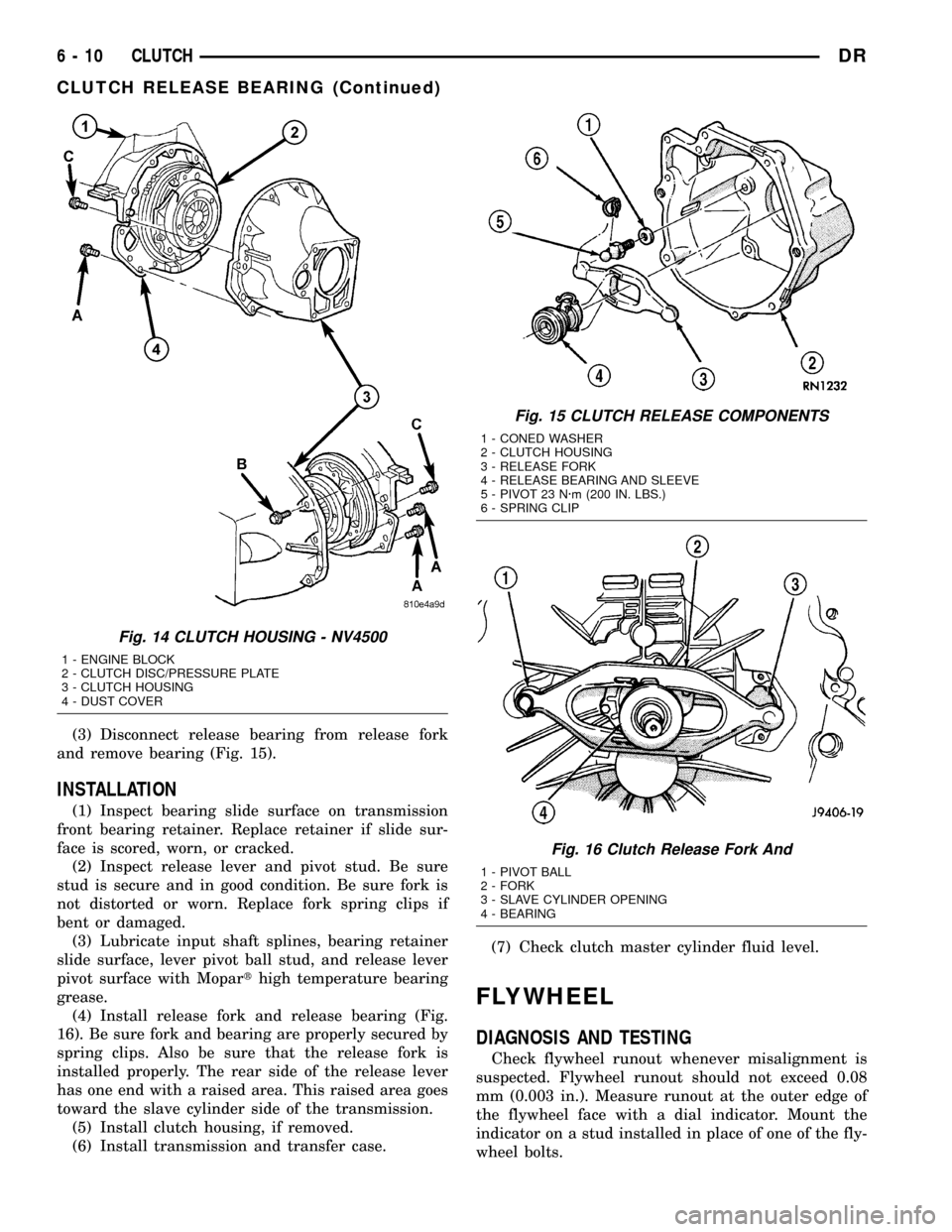

(3) Disconnect release bearing from release fork

and remove bearing (Fig. 15).

INSTALLATION

(1) Inspect bearing slide surface on transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(2) Inspect release lever and pivot stud. Be sure

stud is secure and in good condition. Be sure fork is

not distorted or worn. Replace fork spring clips if

bent or damaged.

(3) Lubricate input shaft splines, bearing retainer

slide surface, lever pivot ball stud, and release lever

pivot surface with Moparthigh temperature bearing

grease.

(4) Install release fork and release bearing (Fig.

16). Be sure fork and bearing are properly secured by

spring clips. Also be sure that the release fork is

installed properly. The rear side of the release lever

has one end with a raised area. This raised area goes

toward the slave cylinder side of the transmission.

(5) Install clutch housing, if removed.

(6) Install transmission and transfer case.(7) Check clutch master cylinder fluid level.

FLYWHEEL

DIAGNOSIS AND TESTING

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on a stud installed in place of one of the fly-

wheel bolts.

Fig. 14 CLUTCH HOUSING - NV4500

1 - ENGINE BLOCK

2 - CLUTCH DISC/PRESSURE PLATE

3 - CLUTCH HOUSING

4 - DUST COVER

Fig. 15 CLUTCH RELEASE COMPONENTS

1 - CONED WASHER

2 - CLUTCH HOUSING

3 - RELEASE FORK

4 - RELEASE BEARING AND SLEEVE

5 - PIVOT 23 N´m (200 IN. LBS.)

6 - SPRING CLIP

Fig. 16 Clutch Release Fork And

1 - PIVOT BALL

2 - FORK

3 - SLAVE CYLINDER OPENING

4 - BEARING

6 - 10 CLUTCHDR

CLUTCH RELEASE BEARING (Continued)