rear axle DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 283 of 2627

REMOVAL - REAR

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts (Fig.

61).(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/DISC BRAKE CALIPER ADAPTER -

REMOVAL)

(5) Remove the retaining clips and rotor assembly

(Fig. 61).

REMOVAL - REAR DUAL WHEELS

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts.

(5) Remove the rear axle shaft from the housing

on dual rear wheels, (Refer to 3 - DIFFERENTIAL &

DRIVELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

REMOVAL).

(6) Remove the hub and rotor assembly (C3500

only) (Fig. 62).

INSTALLATION

INSTALLATION - FRONT

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Install the rotor onto the hub/bearing wheel

studs.

(3) Install the caliper adapter assembly,(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION) and tighten

adapter bolts to:

(4) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE) and lower the vehicle.

(5) Apply the brakes several times to seat brake

pads. Be sure to obtain firm pedal before moving

vehicle.

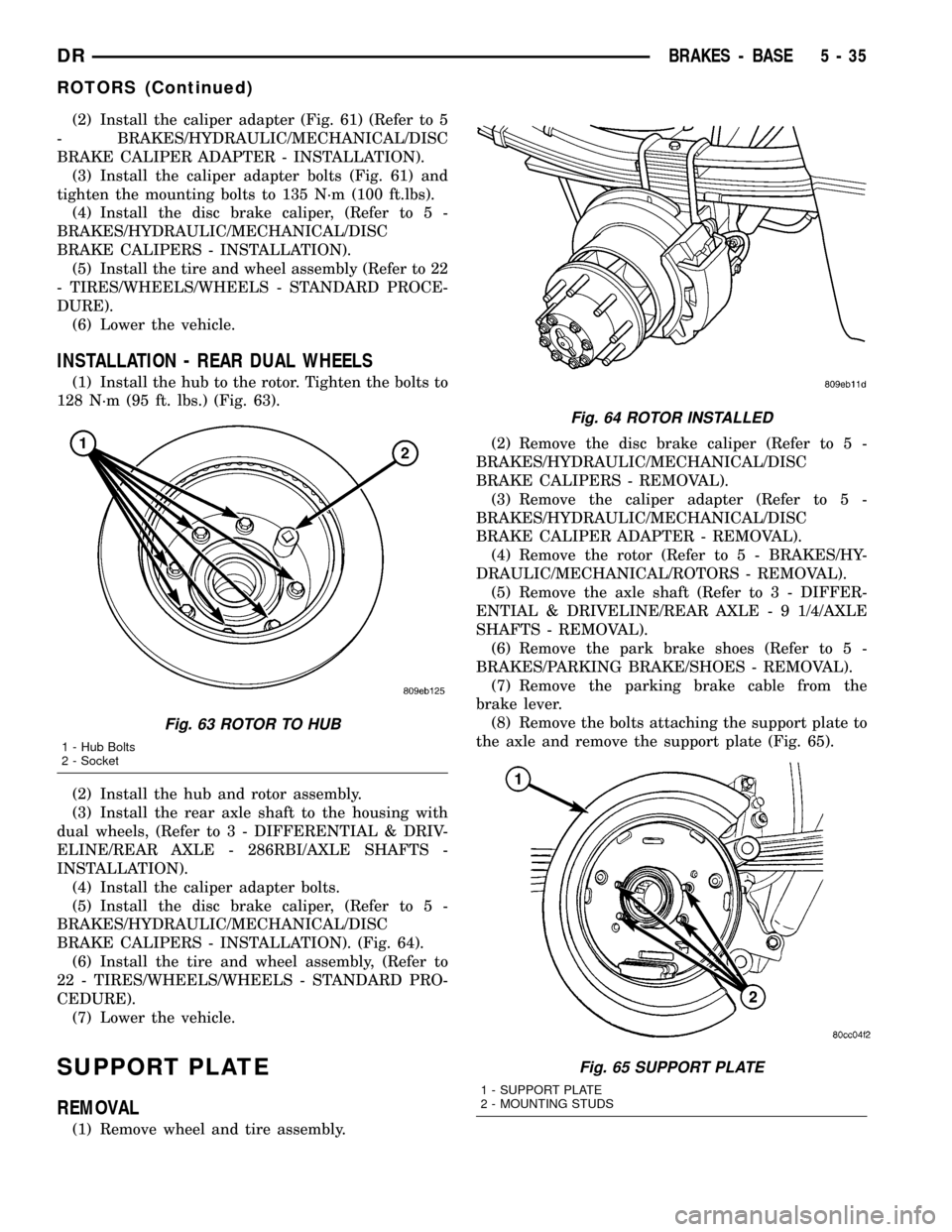

INSTALLATION - REAR

(1) Install the rotor to the axleshaft (Fig. 61).

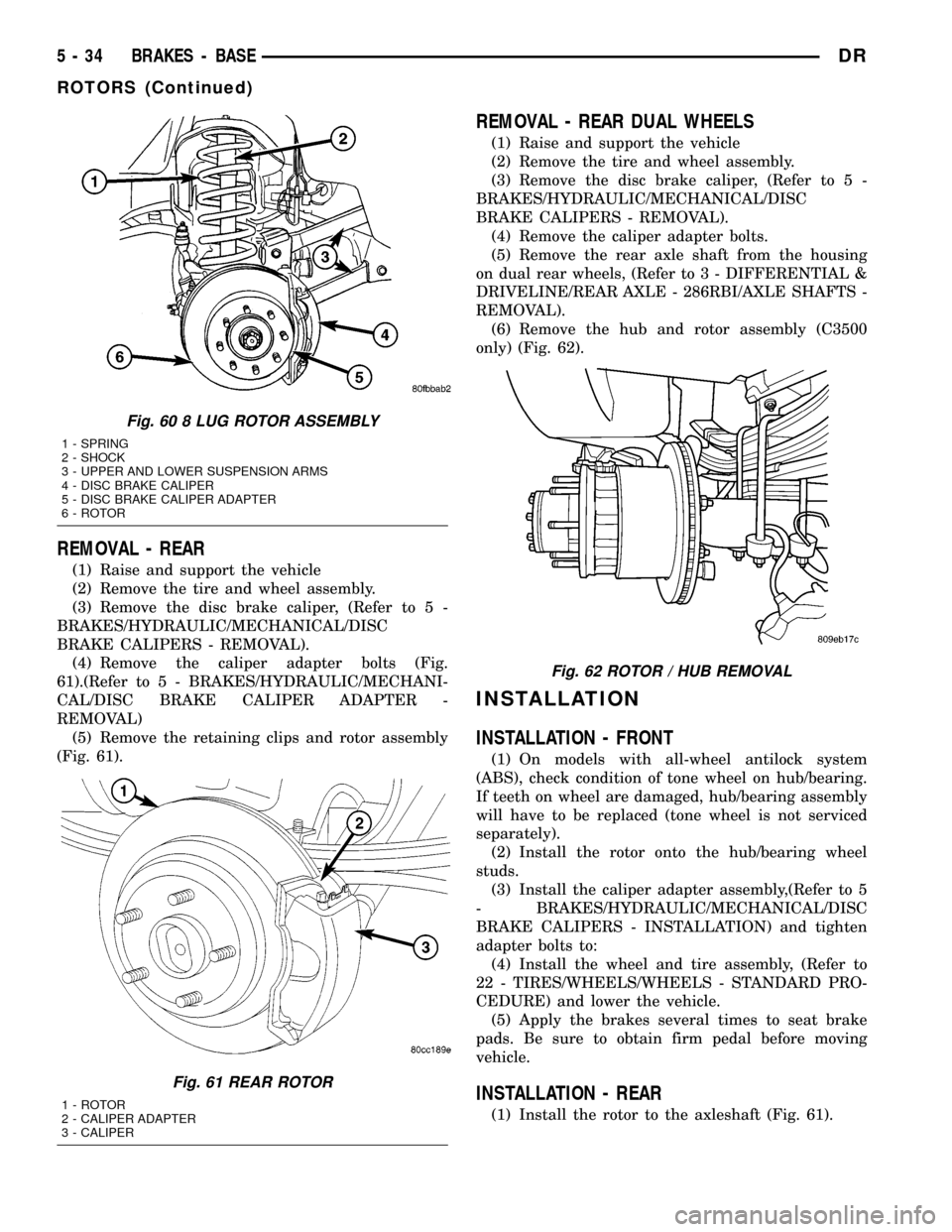

Fig. 60 8 LUG ROTOR ASSEMBLY

1 - SPRING

2 - SHOCK

3 - UPPER AND LOWER SUSPENSION ARMS

4 - DISC BRAKE CALIPER

5 - DISC BRAKE CALIPER ADAPTER

6 - ROTOR

Fig. 61 REAR ROTOR

1 - ROTOR

2 - CALIPER ADAPTER

3 - CALIPER

Fig. 62 ROTOR / HUB REMOVAL

5 - 34 BRAKES - BASEDR

ROTORS (Continued)

Page 284 of 2627

(2) Install the caliper adapter (Fig. 61) (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(3) Install the caliper adapter bolts (Fig. 61) and

tighten the mounting bolts to 135 N´m (100 ft.lbs).

(4) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(5) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(6) Lower the vehicle.

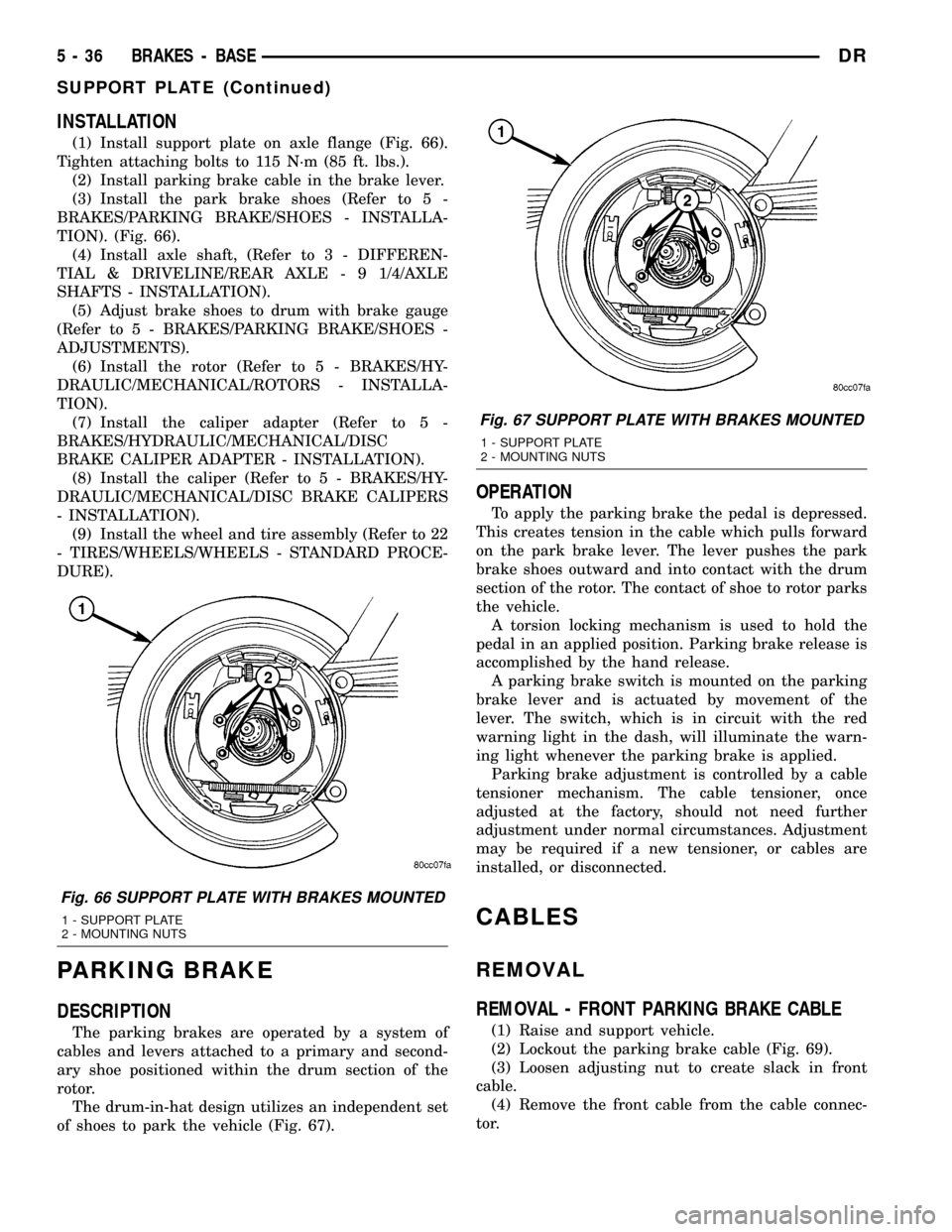

INSTALLATION - REAR DUAL WHEELS

(1) Install the hub to the rotor. Tighten the bolts to

128 N´m (95 ft. lbs.) (Fig. 63).

(2) Install the hub and rotor assembly.

(3) Install the rear axle shaft to the housing with

dual wheels, (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

INSTALLATION).

(4) Install the caliper adapter bolts.

(5) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION). (Fig. 64).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

SUPPORT PLATE

REMOVAL

(1) Remove wheel and tire assembly.(2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

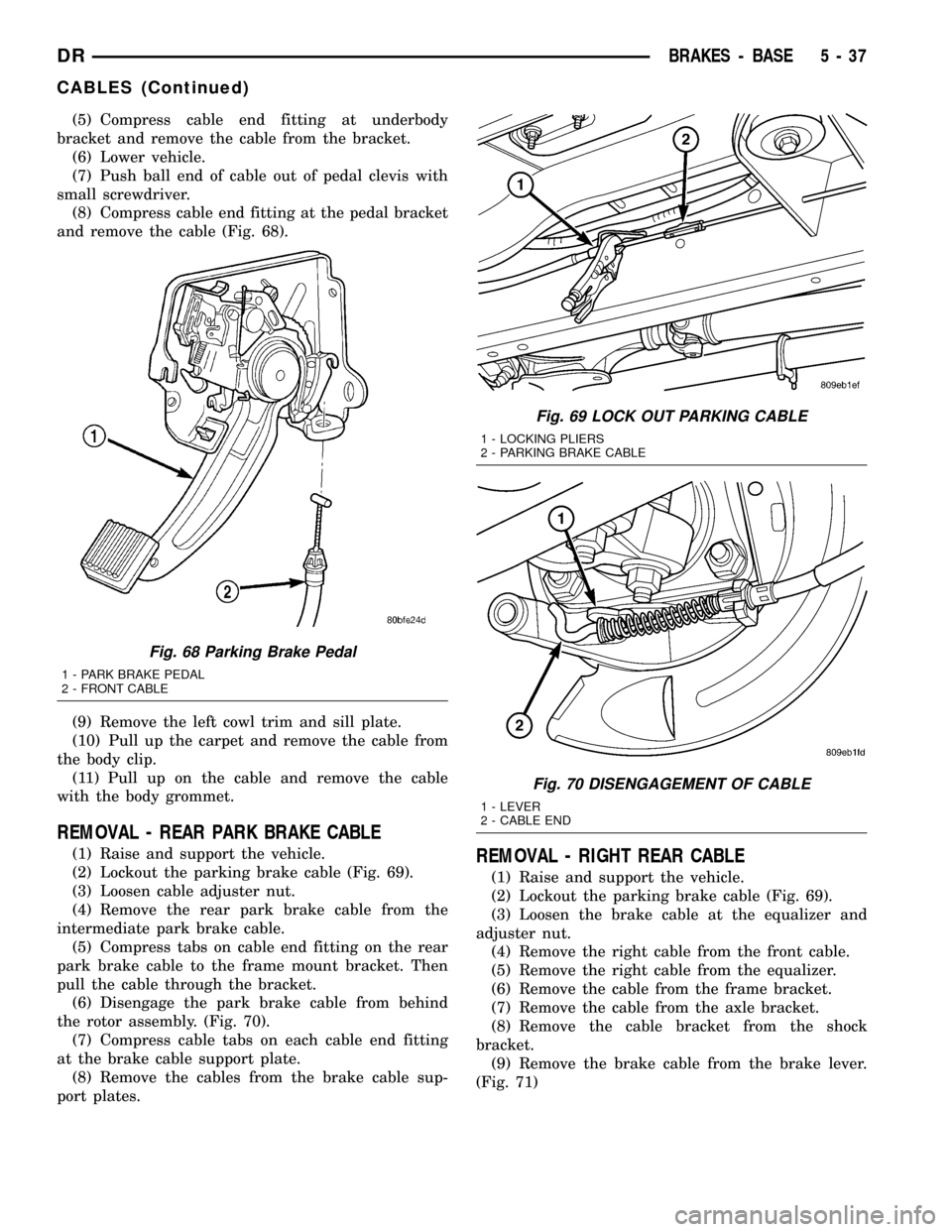

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 65).

Fig. 63 ROTOR TO HUB

1 - Hub Bolts

2 - Socket

Fig. 64 ROTOR INSTALLED

Fig. 65 SUPPORT PLATE

1 - SUPPORT PLATE

2 - MOUNTING STUDS

DRBRAKES - BASE 5 - 35

ROTORS (Continued)

Page 285 of 2627

INSTALLATION

(1) Install support plate on axle flange (Fig. 66).

Tighten attaching bolts to 115 N´m (85 ft. lbs.).

(2) Install parking brake cable in the brake lever.

(3) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 66).

(4) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(5) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

(6) Install the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(7) Install the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(8) Install the caliper (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(9) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

PARKING BRAKE

DESCRIPTION

The parking brakes are operated by a system of

cables and levers attached to a primary and second-

ary shoe positioned within the drum section of the

rotor.

The drum-in-hat design utilizes an independent set

of shoes to park the vehicle (Fig. 67).

OPERATION

To apply the parking brake the pedal is depressed.

This creates tension in the cable which pulls forward

on the park brake lever. The lever pushes the park

brake shoes outward and into contact with the drum

section of the rotor. The contact of shoe to rotor parks

the vehicle.

A torsion locking mechanism is used to hold the

pedal in an applied position. Parking brake release is

accomplished by the hand release.

A parking brake switch is mounted on the parking

brake lever and is actuated by movement of the

lever. The switch, which is in circuit with the red

warning light in the dash, will illuminate the warn-

ing light whenever the parking brake is applied.

Parking brake adjustment is controlled by a cable

tensioner mechanism. The cable tensioner, once

adjusted at the factory, should not need further

adjustment under normal circumstances. Adjustment

may be required if a new tensioner, or cables are

installed, or disconnected.

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE CABLE

(1) Raise and support vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen adjusting nut to create slack in front

cable.

(4) Remove the front cable from the cable connec-

tor.

Fig. 66 SUPPORT PLATE WITH BRAKES MOUNTED

1 - SUPPORT PLATE

2 - MOUNTING NUTS

Fig. 67 SUPPORT PLATE WITH BRAKES MOUNTED

1 - SUPPORT PLATE

2 - MOUNTING NUTS

5 - 36 BRAKES - BASEDR

SUPPORT PLATE (Continued)

Page 286 of 2627

(5) Compress cable end fitting at underbody

bracket and remove the cable from the bracket.

(6) Lower vehicle.

(7) Push ball end of cable out of pedal clevis with

small screwdriver.

(8) Compress cable end fitting at the pedal bracket

and remove the cable (Fig. 68).

(9) Remove the left cowl trim and sill plate.

(10) Pull up the carpet and remove the cable from

the body clip.

(11) Pull up on the cable and remove the cable

with the body grommet.

REMOVAL - REAR PARK BRAKE CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen cable adjuster nut.

(4) Remove the rear park brake cable from the

intermediate park brake cable.

(5) Compress tabs on cable end fitting on the rear

park brake cable to the frame mount bracket. Then

pull the cable through the bracket.

(6) Disengage the park brake cable from behind

the rotor assembly. (Fig. 70).

(7) Compress cable tabs on each cable end fitting

at the brake cable support plate.

(8) Remove the cables from the brake cable sup-

port plates.REMOVAL - RIGHT REAR CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen the brake cable at the equalizer and

adjuster nut.

(4) Remove the right cable from the front cable.

(5) Remove the right cable from the equalizer.

(6) Remove the cable from the frame bracket.

(7) Remove the cable from the axle bracket.

(8) Remove the cable bracket from the shock

bracket.

(9) Remove the brake cable from the brake lever.

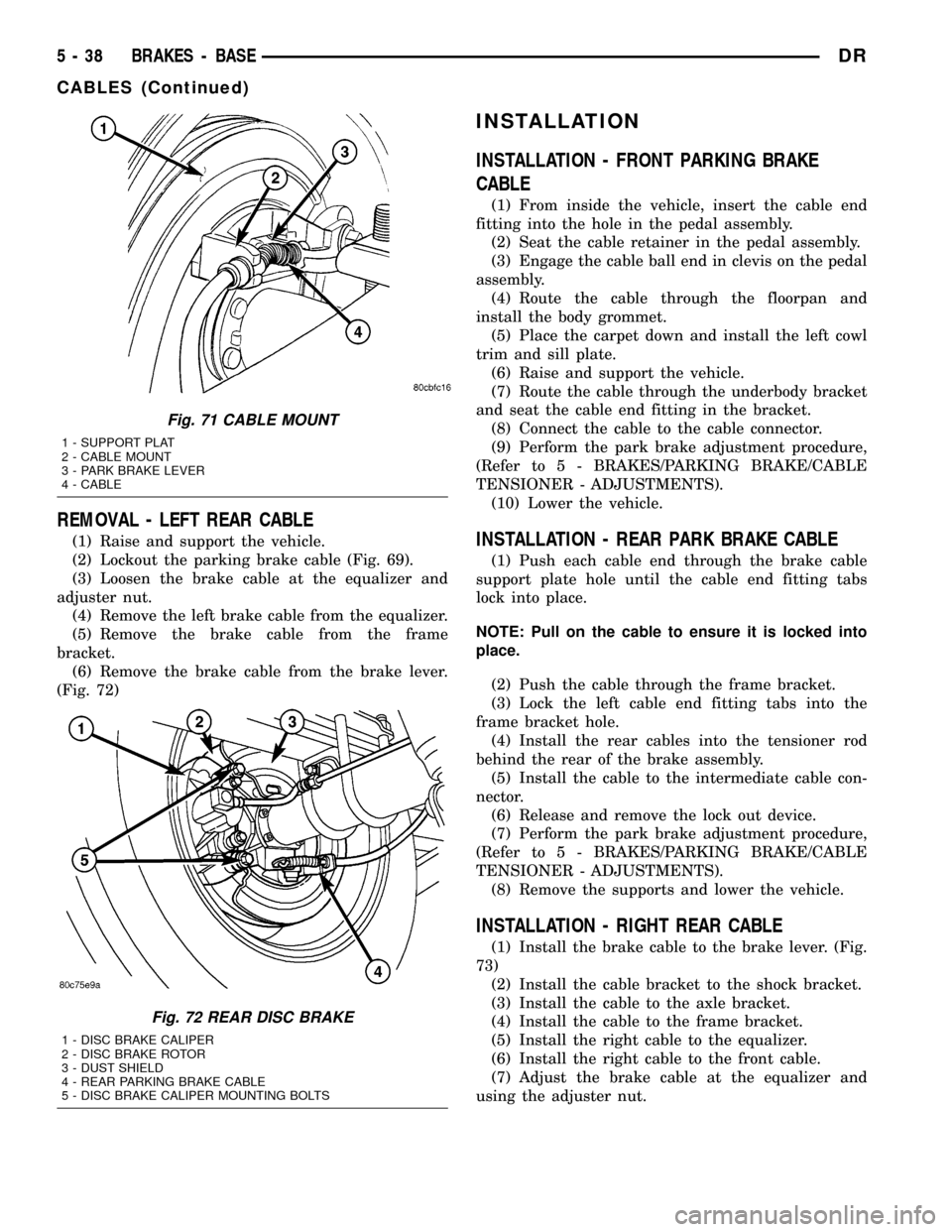

(Fig. 71)

Fig. 68 Parking Brake Pedal

1 - PARK BRAKE PEDAL

2 - FRONT CABLE

Fig. 69 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 70 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 37

CABLES (Continued)

Page 287 of 2627

REMOVAL - LEFT REAR CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen the brake cable at the equalizer and

adjuster nut.

(4) Remove the left brake cable from the equalizer.

(5) Remove the brake cable from the frame

bracket.

(6) Remove the brake cable from the brake lever.

(Fig. 72)

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE

(1) From inside the vehicle, insert the cable end

fitting into the hole in the pedal assembly.

(2) Seat the cable retainer in the pedal assembly.

(3) Engage the cable ball end in clevis on the pedal

assembly.

(4) Route the cable through the floorpan and

install the body grommet.

(5) Place the carpet down and install the left cowl

trim and sill plate.

(6) Raise and support the vehicle.

(7) Route the cable through the underbody bracket

and seat the cable end fitting in the bracket.

(8) Connect the cable to the cable connector.

(9) Perform the park brake adjustment procedure,

(Refer to 5 - BRAKES/PARKING BRAKE/CABLE

TENSIONER - ADJUSTMENTS).

(10) Lower the vehicle.

INSTALLATION - REAR PARK BRAKE CABLE

(1) Push each cable end through the brake cable

support plate hole until the cable end fitting tabs

lock into place.

NOTE: Pull on the cable to ensure it is locked into

place.

(2) Push the cable through the frame bracket.

(3) Lock the left cable end fitting tabs into the

frame bracket hole.

(4) Install the rear cables into the tensioner rod

behind the rear of the brake assembly.

(5) Install the cable to the intermediate cable con-

nector.

(6) Release and remove the lock out device.

(7) Perform the park brake adjustment procedure,

(Refer to 5 - BRAKES/PARKING BRAKE/CABLE

TENSIONER - ADJUSTMENTS).

(8) Remove the supports and lower the vehicle.

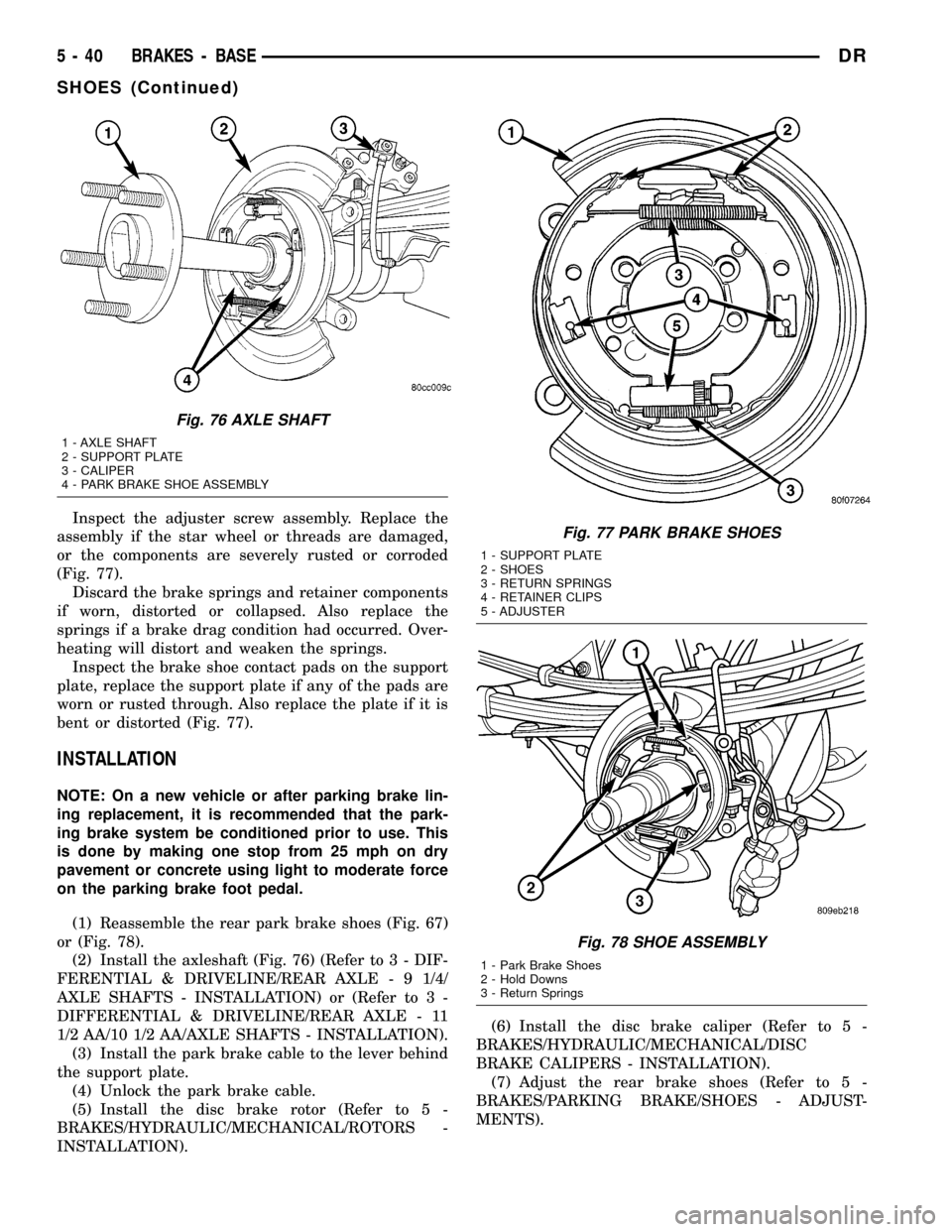

INSTALLATION - RIGHT REAR CABLE

(1) Install the brake cable to the brake lever. (Fig.

73)

(2) Install the cable bracket to the shock bracket.

(3) Install the cable to the axle bracket.

(4) Install the cable to the frame bracket.

(5) Install the right cable to the equalizer.

(6) Install the right cable to the front cable.

(7) Adjust the brake cable at the equalizer and

using the adjuster nut.

Fig. 71 CABLE MOUNT

1 - SUPPORT PLAT

2 - CABLE MOUNT

3 - PARK BRAKE LEVER

4 - CABLE

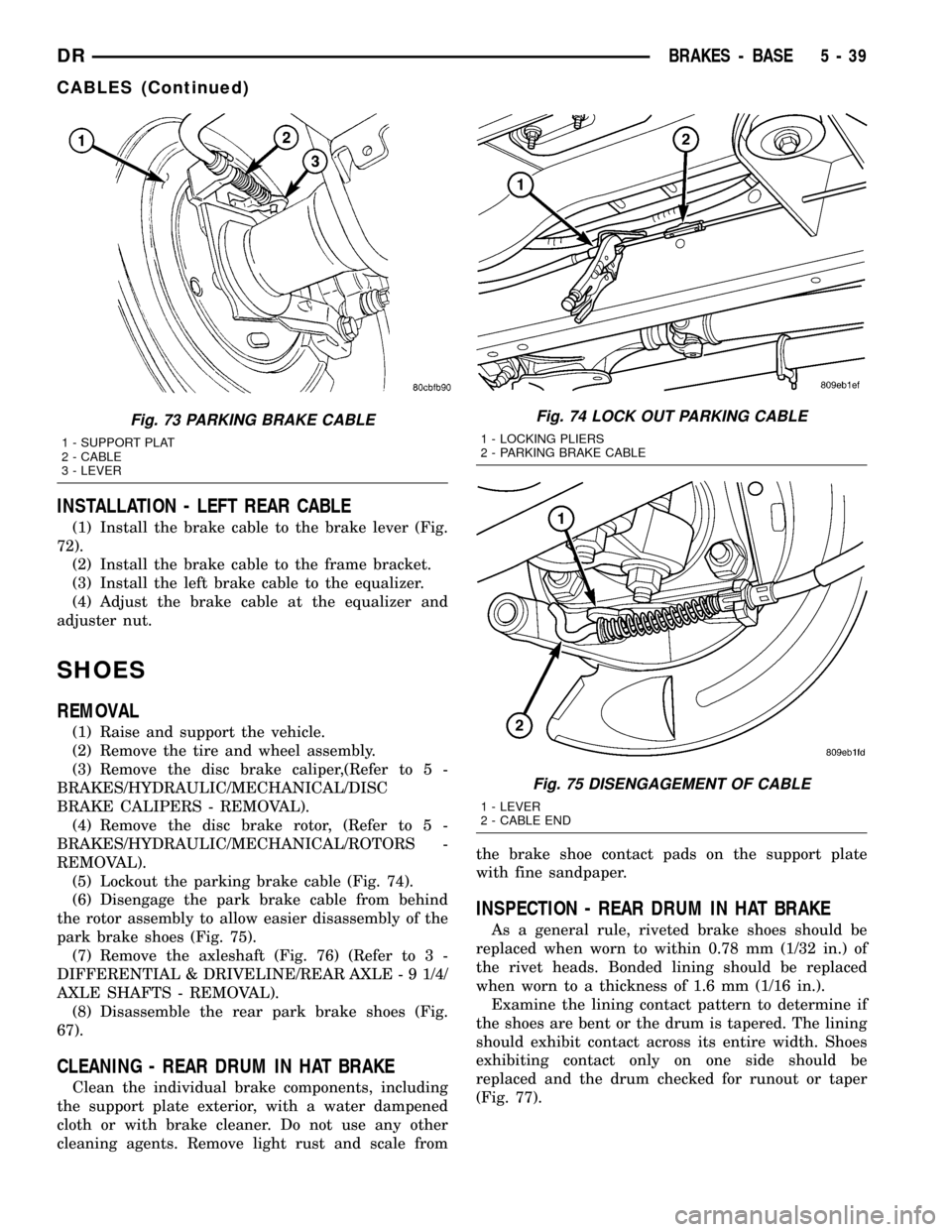

Fig. 72 REAR DISC BRAKE

1 - DISC BRAKE CALIPER

2 - DISC BRAKE ROTOR

3 - DUST SHIELD

4 - REAR PARKING BRAKE CABLE

5 - DISC BRAKE CALIPER MOUNTING BOLTS

5 - 38 BRAKES - BASEDR

CABLES (Continued)

Page 288 of 2627

INSTALLATION - LEFT REAR CABLE

(1) Install the brake cable to the brake lever (Fig.

72).

(2) Install the brake cable to the frame bracket.

(3) Install the left brake cable to the equalizer.

(4) Adjust the brake cable at the equalizer and

adjuster nut.

SHOES

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper,(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the disc brake rotor, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(5) Lockout the parking brake cable (Fig. 74).

(6) Disengage the park brake cable from behind

the rotor assembly to allow easier disassembly of the

park brake shoes (Fig. 75).

(7) Remove the axleshaft (Fig. 76) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - REMOVAL).

(8) Disassemble the rear park brake shoes (Fig.

67).

CLEANING - REAR DRUM IN HAT BRAKE

Clean the individual brake components, including

the support plate exterior, with a water dampened

cloth or with brake cleaner. Do not use any other

cleaning agents. Remove light rust and scale fromthe brake shoe contact pads on the support plate

with fine sandpaper.

INSPECTION - REAR DRUM IN HAT BRAKE

As a general rule, riveted brake shoes should be

replaced when worn to within 0.78 mm (1/32 in.) of

the rivet heads. Bonded lining should be replaced

when worn to a thickness of 1.6 mm (1/16 in.).

Examine the lining contact pattern to determine if

the shoes are bent or the drum is tapered. The lining

should exhibit contact across its entire width. Shoes

exhibiting contact only on one side should be

replaced and the drum checked for runout or taper

(Fig. 77).

Fig. 73 PARKING BRAKE CABLE

1 - SUPPORT PLAT

2 - CABLE

3 - LEVER

Fig. 74 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 75 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 39

CABLES (Continued)

Page 289 of 2627

Inspect the adjuster screw assembly. Replace the

assembly if the star wheel or threads are damaged,

or the components are severely rusted or corroded

(Fig. 77).

Discard the brake springs and retainer components

if worn, distorted or collapsed. Also replace the

springs if a brake drag condition had occurred. Over-

heating will distort and weaken the springs.

Inspect the brake shoe contact pads on the support

plate, replace the support plate if any of the pads are

worn or rusted through. Also replace the plate if it is

bent or distorted (Fig. 77).

INSTALLATION

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(1) Reassemble the rear park brake shoes (Fig. 67)

or (Fig. 78).

(2) Install the axleshaft (Fig. 76) (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - INSTALLATION) or (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 11

1/2 AA/10 1/2 AA/AXLE SHAFTS - INSTALLATION).

(3) Install the park brake cable to the lever behind

the support plate.

(4) Unlock the park brake cable.

(5) Install the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).(6) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(7) Adjust the rear brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - ADJUST-

MENTS).

Fig. 76 AXLE SHAFT

1 - AXLE SHAFT

2 - SUPPORT PLATE

3 - CALIPER

4 - PARK BRAKE SHOE ASSEMBLY

Fig. 77 PARK BRAKE SHOES

1 - SUPPORT PLATE

2 - SHOES

3 - RETURN SPRINGS

4 - RETAINER CLIPS

5 - ADJUSTER

Fig. 78 SHOE ASSEMBLY

1 - Park Brake Shoes

2 - Hold Downs

3 - Return Springs

5 - 40 BRAKES - BASEDR

SHOES (Continued)

Page 296 of 2627

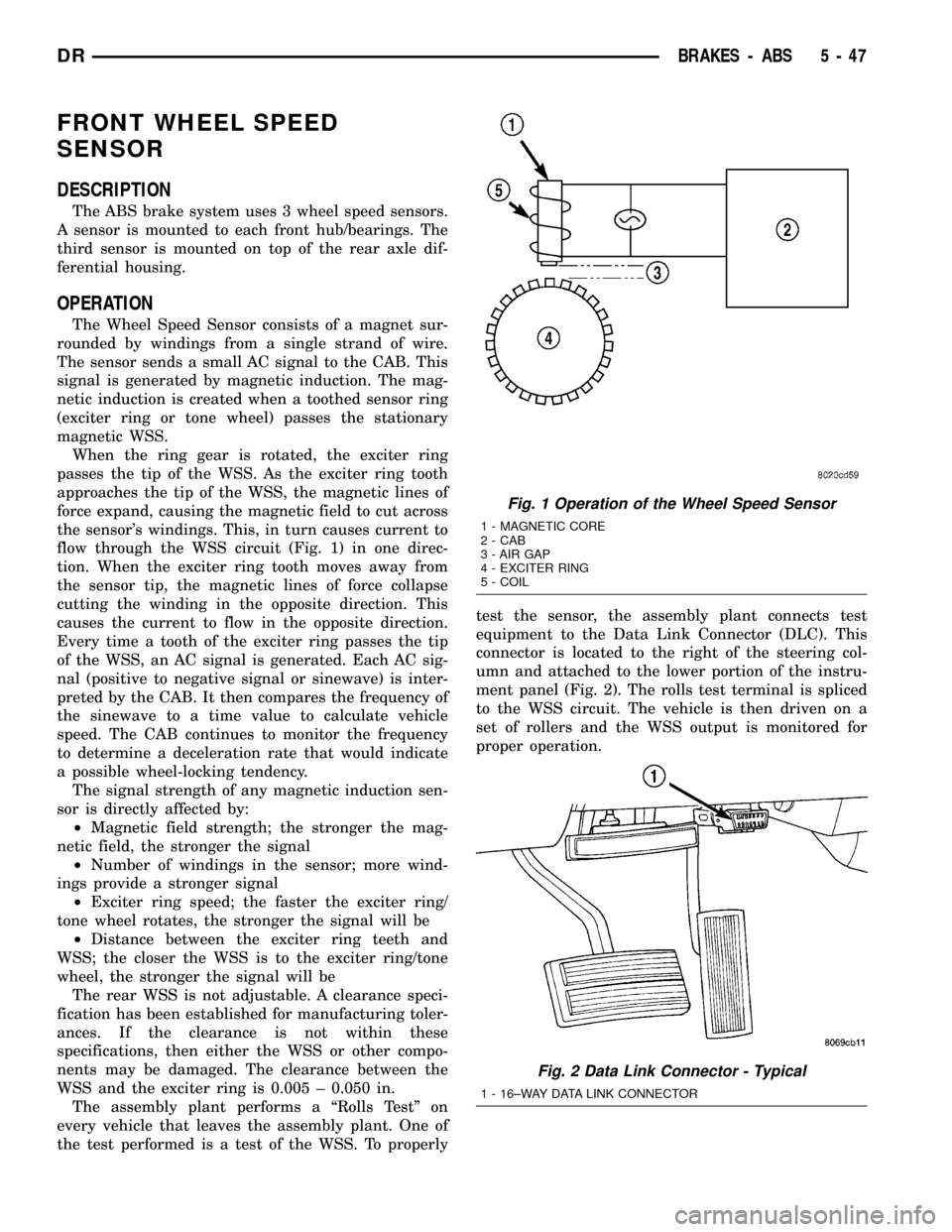

FRONT WHEEL SPEED

SENSOR

DESCRIPTION

The ABS brake system uses 3 wheel speed sensors.

A sensor is mounted to each front hub/bearings. The

third sensor is mounted on top of the rear axle dif-

ferential housing.

OPERATION

The Wheel Speed Sensor consists of a magnet sur-

rounded by windings from a single strand of wire.

The sensor sends a small AC signal to the CAB. This

signal is generated by magnetic induction. The mag-

netic induction is created when a toothed sensor ring

(exciter ring or tone wheel) passes the stationary

magnetic WSS.

When the ring gear is rotated, the exciter ring

passes the tip of the WSS. As the exciter ring tooth

approaches the tip of the WSS, the magnetic lines of

force expand, causing the magnetic field to cut across

the sensor's windings. This, in turn causes current to

flow through the WSS circuit (Fig. 1) in one direc-

tion. When the exciter ring tooth moves away from

the sensor tip, the magnetic lines of force collapse

cutting the winding in the opposite direction. This

causes the current to flow in the opposite direction.

Every time a tooth of the exciter ring passes the tip

of the WSS, an AC signal is generated. Each AC sig-

nal (positive to negative signal or sinewave) is inter-

preted by the CAB. It then compares the frequency of

the sinewave to a time value to calculate vehicle

speed. The CAB continues to monitor the frequency

to determine a deceleration rate that would indicate

a possible wheel-locking tendency.

The signal strength of any magnetic induction sen-

sor is directly affected by:

²Magnetic field strength; the stronger the mag-

netic field, the stronger the signal

²Number of windings in the sensor; more wind-

ings provide a stronger signal

²Exciter ring speed; the faster the exciter ring/

tone wheel rotates, the stronger the signal will be

²Distance between the exciter ring teeth and

WSS; the closer the WSS is to the exciter ring/tone

wheel, the stronger the signal will be

The rear WSS is not adjustable. A clearance speci-

fication has been established for manufacturing toler-

ances. If the clearance is not within these

specifications, then either the WSS or other compo-

nents may be damaged. The clearance between the

WSS and the exciter ring is 0.005 ± 0.050 in.

The assembly plant performs a ªRolls Testº on

every vehicle that leaves the assembly plant. One of

the test performed is a test of the WSS. To properlytest the sensor, the assembly plant connects test

equipment to the Data Link Connector (DLC). This

connector is located to the right of the steering col-

umn and attached to the lower portion of the instru-

ment panel (Fig. 2). The rolls test terminal is spliced

to the WSS circuit. The vehicle is then driven on a

set of rollers and the WSS output is monitored for

proper operation.

Fig. 1 Operation of the Wheel Speed Sensor

1 - MAGNETIC CORE

2 - CAB

3 - AIR GAP

4 - EXCITER RING

5 - COIL

Fig. 2 Data Link Connector - Typical

1 - 16±WAY DATA LINK CONNECTOR

DRBRAKES - ABS 5 - 47

Page 297 of 2627

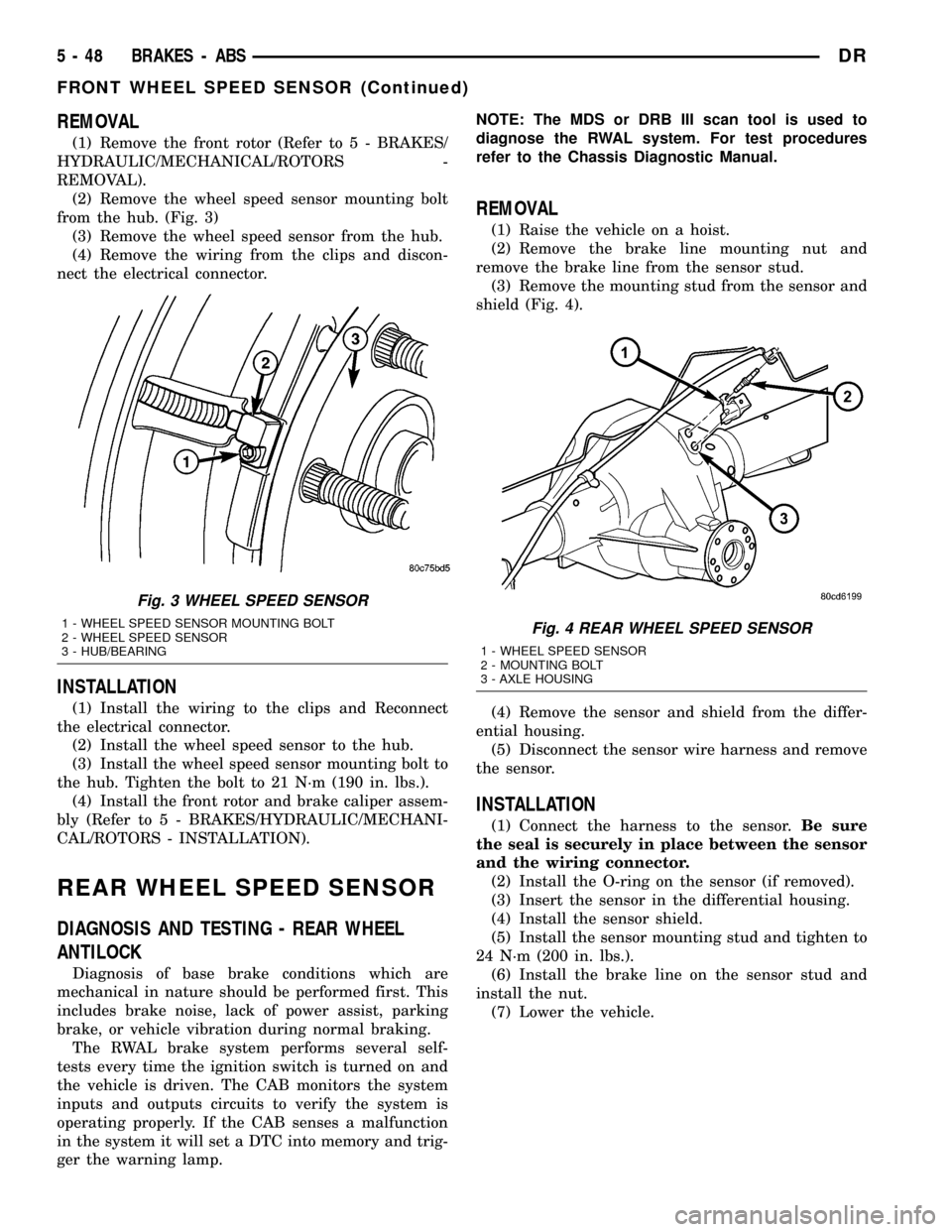

REMOVAL

(1) Remove the front rotor (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(2) Remove the wheel speed sensor mounting bolt

from the hub. (Fig. 3)

(3) Remove the wheel speed sensor from the hub.

(4) Remove the wiring from the clips and discon-

nect the electrical connector.

INSTALLATION

(1) Install the wiring to the clips and Reconnect

the electrical connector.

(2) Install the wheel speed sensor to the hub.

(3) Install the wheel speed sensor mounting bolt to

the hub. Tighten the bolt to 21 N´m (190 in. lbs.).

(4) Install the front rotor and brake caliper assem-

bly (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/ROTORS - INSTALLATION).

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The RWAL brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.NOTE: The MDS or DRB III scan tool is used to

diagnose the RWAL system. For test procedures

refer to the Chassis Diagnostic Manual.

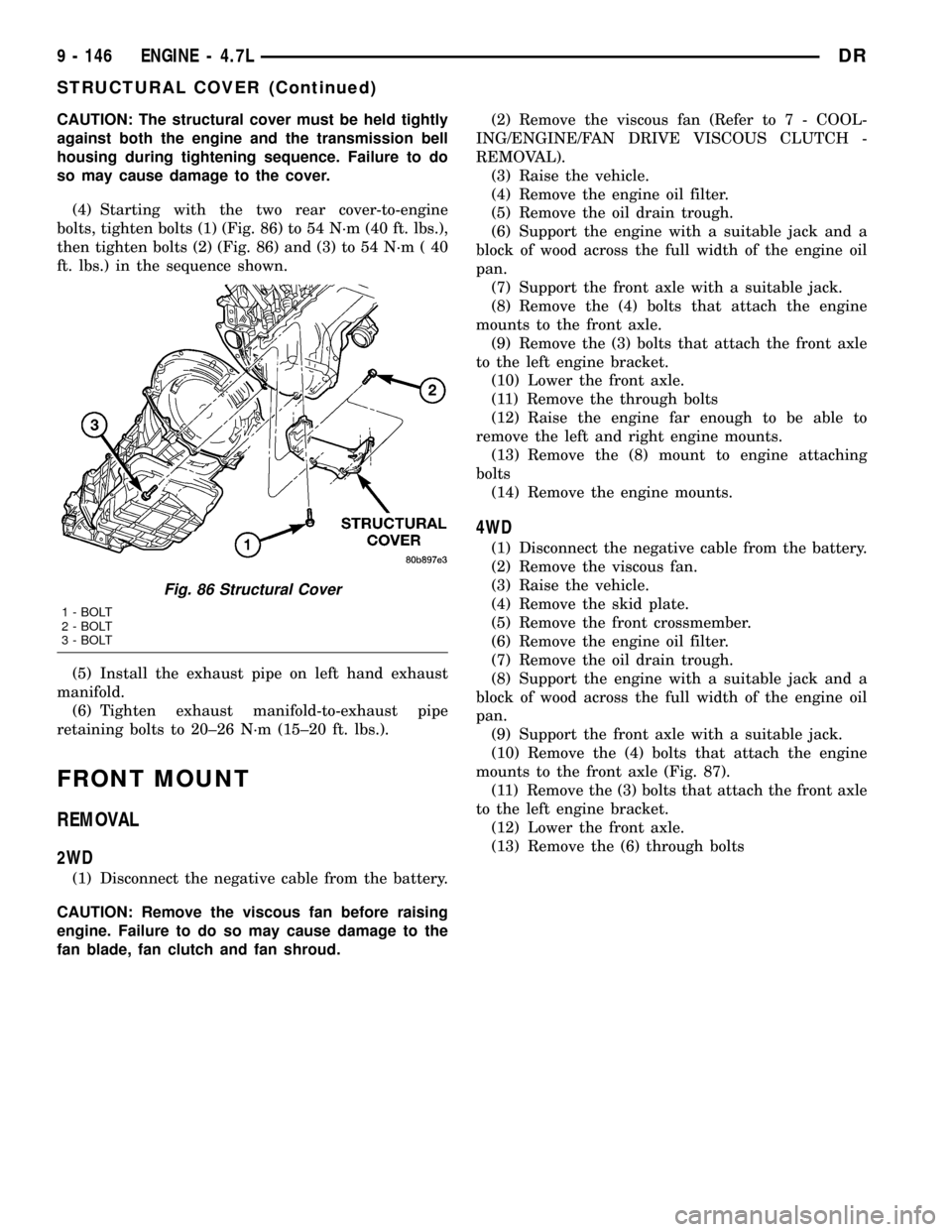

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Remove the brake line mounting nut and

remove the brake line from the sensor stud.

(3) Remove the mounting stud from the sensor and

shield (Fig. 4).

(4) Remove the sensor and shield from the differ-

ential housing.

(5) Disconnect the sensor wire harness and remove

the sensor.

INSTALLATION

(1) Connect the harness to the sensor.Be sure

the seal is securely in place between the sensor

and the wiring connector.

(2) Install the O-ring on the sensor (if removed).

(3) Insert the sensor in the differential housing.

(4) Install the sensor shield.

(5) Install the sensor mounting stud and tighten to

24 N´m (200 in. lbs.).

(6) Install the brake line on the sensor stud and

install the nut.

(7) Lower the vehicle.

Fig. 3 WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - HUB/BEARINGFig. 4 REAR WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR

2 - MOUNTING BOLT

3 - AXLE HOUSING

5 - 48 BRAKES - ABSDR

FRONT WHEEL SPEED SENSOR (Continued)

Page 1369 of 2627

CAUTION: The structural cover must be held tightly

against both the engine and the transmission bell

housing during tightening sequence. Failure to do

so may cause damage to the cover.

(4) Starting with the two rear cover-to-engine

bolts, tighten bolts (1) (Fig. 86) to 54 N´m (40 ft. lbs.),

then tighten bolts (2) (Fig. 86) and (3) to 54 N´m ( 40

ft. lbs.) in the sequence shown.

(5) Install the exhaust pipe on left hand exhaust

manifold.

(6) Tighten exhaust manifold-to-exhaust pipe

retaining bolts to 20±26 N´m (15±20 ft. lbs.).

FRONT MOUNT

REMOVAL

2WD

(1) Disconnect the negative cable from the battery.

CAUTION: Remove the viscous fan before raising

engine. Failure to do so may cause damage to the

fan blade, fan clutch and fan shroud.(2) Remove the viscous fan (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(3) Raise the vehicle.

(4) Remove the engine oil filter.

(5) Remove the oil drain trough.

(6) Support the engine with a suitable jack and a

block of wood across the full width of the engine oil

pan.

(7) Support the front axle with a suitable jack.

(8) Remove the (4) bolts that attach the engine

mounts to the front axle.

(9) Remove the (3) bolts that attach the front axle

to the left engine bracket.

(10) Lower the front axle.

(11) Remove the through bolts

(12) Raise the engine far enough to be able to

remove the left and right engine mounts.

(13) Remove the (8) mount to engine attaching

bolts

(14) Remove the engine mounts.

4WD

(1) Disconnect the negative cable from the battery.

(2) Remove the viscous fan.

(3) Raise the vehicle.

(4) Remove the skid plate.

(5) Remove the front crossmember.

(6) Remove the engine oil filter.

(7) Remove the oil drain trough.

(8) Support the engine with a suitable jack and a

block of wood across the full width of the engine oil

pan.

(9) Support the front axle with a suitable jack.

(10) Remove the (4) bolts that attach the engine

mounts to the front axle (Fig. 87).

(11) Remove the (3) bolts that attach the front axle

to the left engine bracket.

(12) Lower the front axle.

(13) Remove the (6) through bolts

Fig. 86 Structural Cover

1 - BOLT

2 - BOLT

3 - BOLT

9 - 146 ENGINE - 4.7LDR

STRUCTURAL COVER (Continued)