Fig DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2289 of 2627

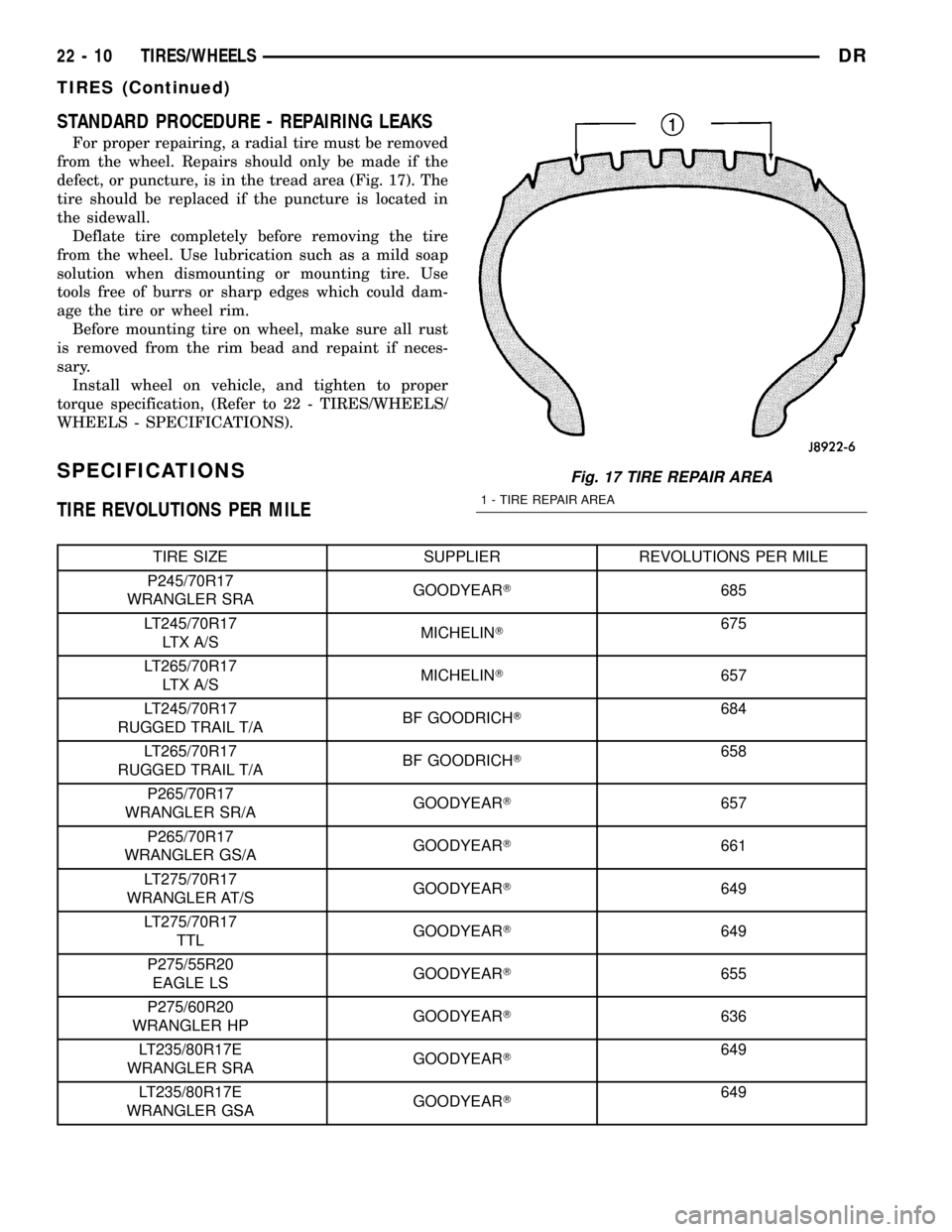

STANDARD PROCEDURE - REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 17). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges which could dam-

age the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and tighten to proper

torque specification, (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE

TIRE SIZE SUPPLIER REVOLUTIONS PER MILE

P245/70R17

WRANGLER SRAGOODYEART685

LT245/70R17

LTX A/SMICHELINT675

LT265/70R17

LTX A/SMICHELINT657

LT245/70R17

RUGGED TRAIL T/ABF GOODRICHT684

LT265/70R17

RUGGED TRAIL T/ABF GOODRICHT658

P265/70R17

WRANGLER SR/AGOODYEART657

P265/70R17

WRANGLER GS/AGOODYEART661

LT275/70R17

WRANGLER AT/SGOODYEART649

LT275/70R17

TTLGOODYEART649

P275/55R20

EAGLE LSGOODYEART655

P275/60R20

WRANGLER HPGOODYEART636

LT235/80R17E

WRANGLER SRAGOODYEART649

LT235/80R17E

WRANGLER GSAGOODYEART649

Fig. 17 TIRE REPAIR AREA

1 - TIRE REPAIR AREA

22 - 10 TIRES/WHEELSDR

TIRES (Continued)

Page 2290 of 2627

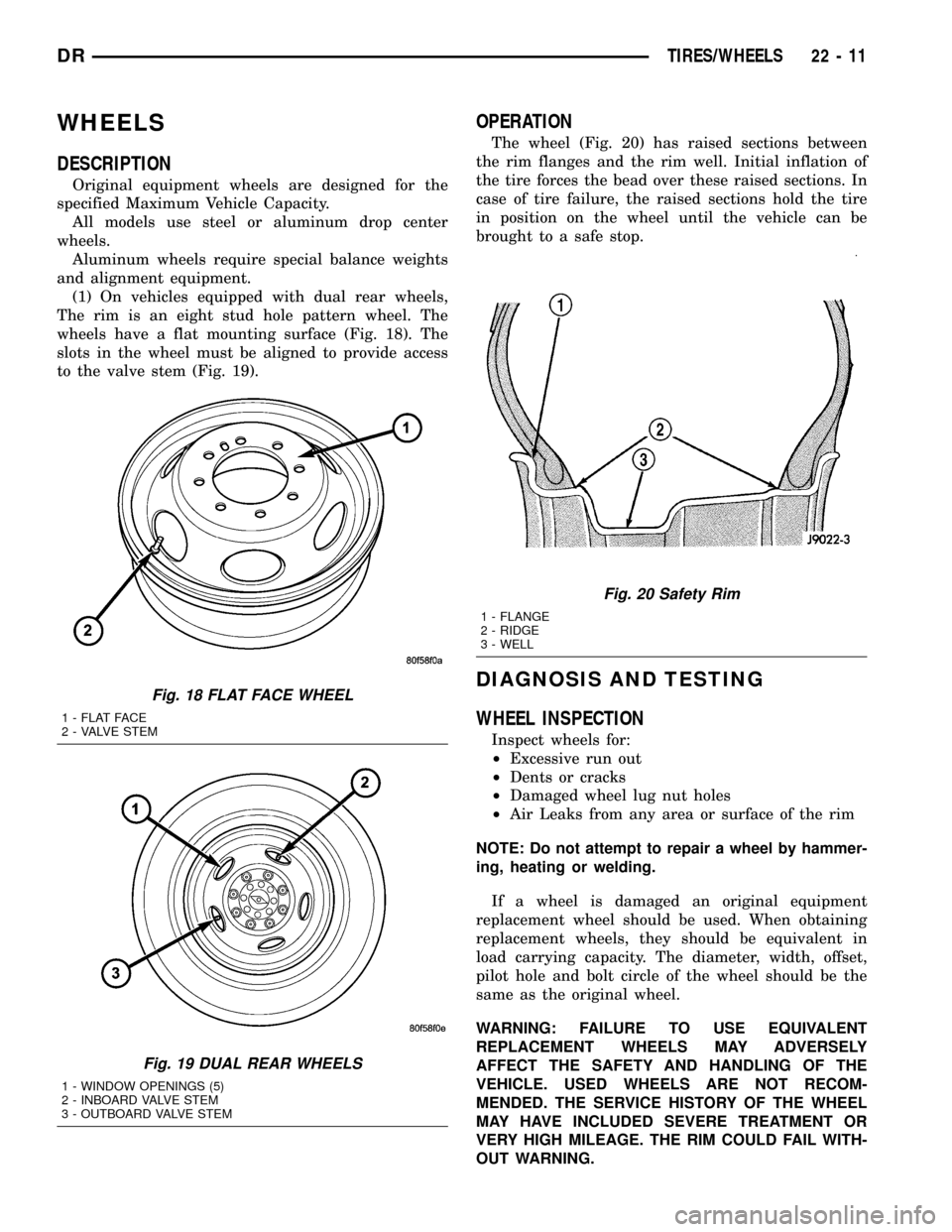

WHEELS

DESCRIPTION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or aluminum drop center

wheels.

Aluminum wheels require special balance weights

and alignment equipment.

(1) On vehicles equipped with dual rear wheels,

The rim is an eight stud hole pattern wheel. The

wheels have a flat mounting surface (Fig. 18). The

slots in the wheel must be aligned to provide access

to the valve stem (Fig. 19).

OPERATION

The wheel (Fig. 20) has raised sections between

the rim flanges and the rim well. Initial inflation of

the tire forces the bead over these raised sections. In

case of tire failure, the raised sections hold the tire

in position on the wheel until the vehicle can be

brought to a safe stop.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

Fig. 18 FLAT FACE WHEEL

1 - FLAT FACE

2 - VALVE STEM

Fig. 19 DUAL REAR WHEELS

1 - WINDOW OPENINGS (5)

2 - INBOARD VALVE STEM

3 - OUTBOARD VALVE STEM

Fig. 20 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

DRTIRES/WHEELS 22 - 11

Page 2291 of 2627

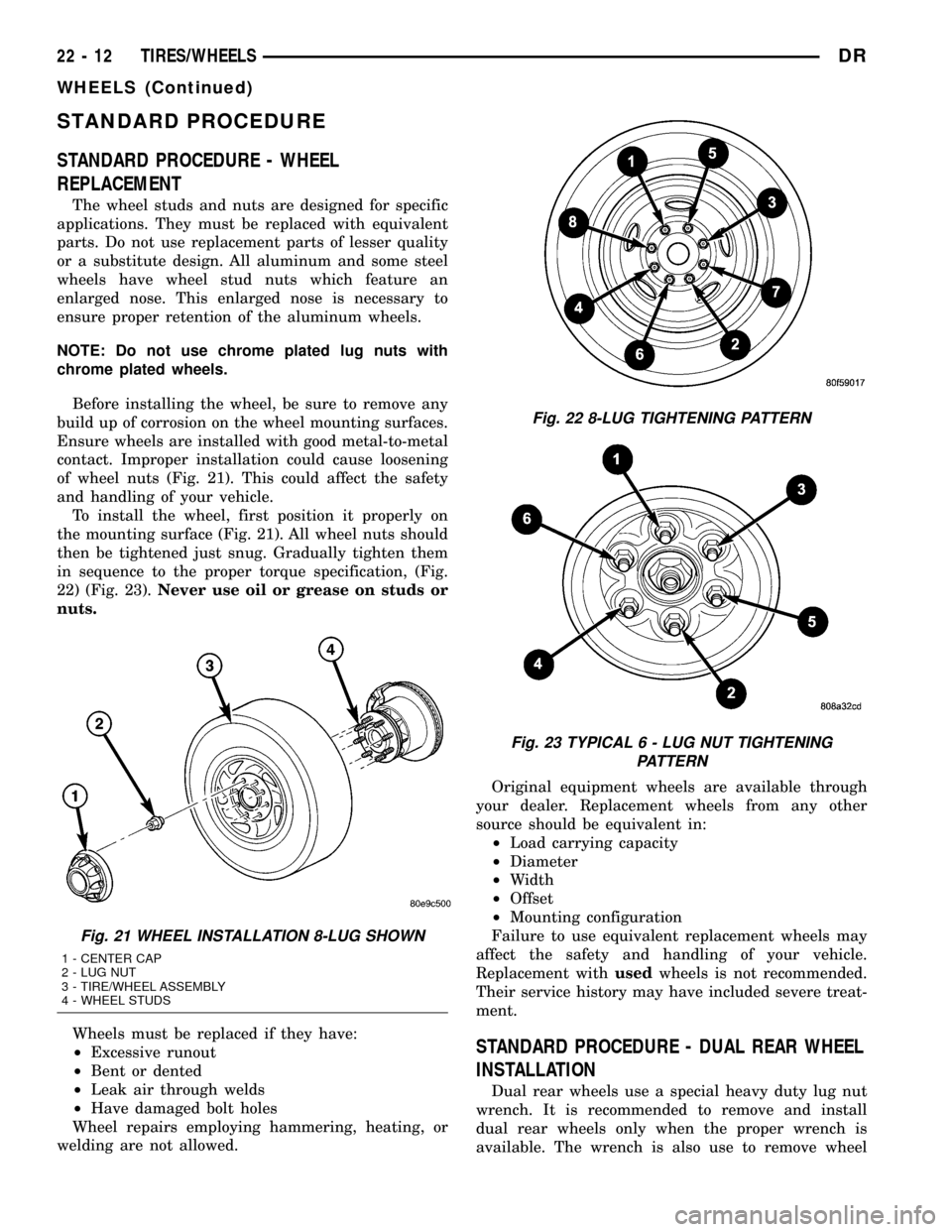

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

REPLACEMENT

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an

enlarged nose. This enlarged nose is necessary to

ensure proper retention of the aluminum wheels.

NOTE: Do not use chrome plated lug nuts with

chrome plated wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts (Fig. 21). This could affect the safety

and handling of your vehicle.

To install the wheel, first position it properly on

the mounting surface (Fig. 21). All wheel nuts should

then be tightened just snug. Gradually tighten them

in sequence to the proper torque specification, (Fig.

22) (Fig. 23).Never use oil or grease on studs or

nuts.

Wheels must be replaced if they have:

²Excessive runout

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width

²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

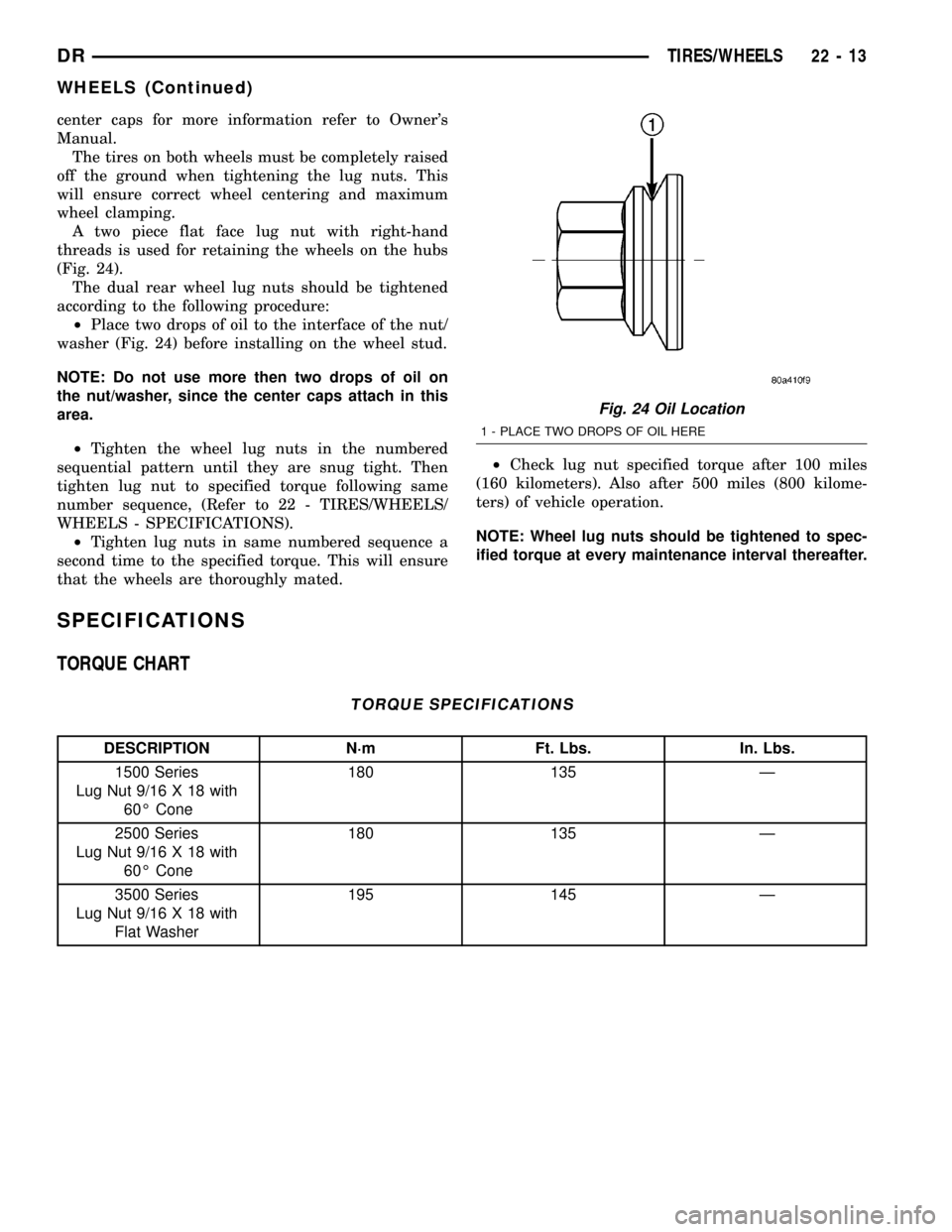

STANDARD PROCEDURE - DUAL REAR WHEEL

INSTALLATION

Dual rear wheels use a special heavy duty lug nut

wrench. It is recommended to remove and install

dual rear wheels only when the proper wrench is

available. The wrench is also use to remove wheel

Fig. 21 WHEEL INSTALLATION 8-LUG SHOWN

1 - CENTER CAP

2 - LUG NUT

3 - TIRE/WHEEL ASSEMBLY

4 - WHEEL STUDS

Fig. 22 8-LUG TIGHTENING PATTERN

Fig. 23 TYPICAL 6 - LUG NUT TIGHTENING

PATTERN

22 - 12 TIRES/WHEELSDR

WHEELS (Continued)

Page 2292 of 2627

center caps for more information refer to Owner's

Manual.

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts. This

will ensure correct wheel centering and maximum

wheel clamping.

A two piece flat face lug nut with right-hand

threads is used for retaining the wheels on the hubs

(Fig. 24).

The dual rear wheel lug nuts should be tightened

according to the following procedure:

²Place two drops of oil to the interface of the nut/

washer (Fig. 24) before installing on the wheel stud.

NOTE: Do not use more then two drops of oil on

the nut/washer, since the center caps attach in this

area.

²Tighten the wheel lug nuts in the numbered

sequential pattern until they are snug tight. Then

tighten lug nut to specified torque following same

number sequence, (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

²Tighten lug nuts in same numbered sequence a

second time to the specified torque. This will ensure

that the wheels are thoroughly mated.²Check lug nut specified torque after 100 miles

(160 kilometers). Also after 500 miles (800 kilome-

ters) of vehicle operation.

NOTE: Wheel lug nuts should be tightened to spec-

ified torque at every maintenance interval thereafter.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

1500 Series

Lug Nut 9/16 X 18 with

60É Cone180 135 Ð

2500 Series

Lug Nut 9/16 X 18 with

60É Cone180 135 Ð

3500 Series

Lug Nut 9/16 X 18 with

Flat Washer195 145 Ð

Fig. 24 Oil Location

1 - PLACE TWO DROPS OF OIL HERE

DRTIRES/WHEELS 22 - 13

WHEELS (Continued)

Page 2293 of 2627

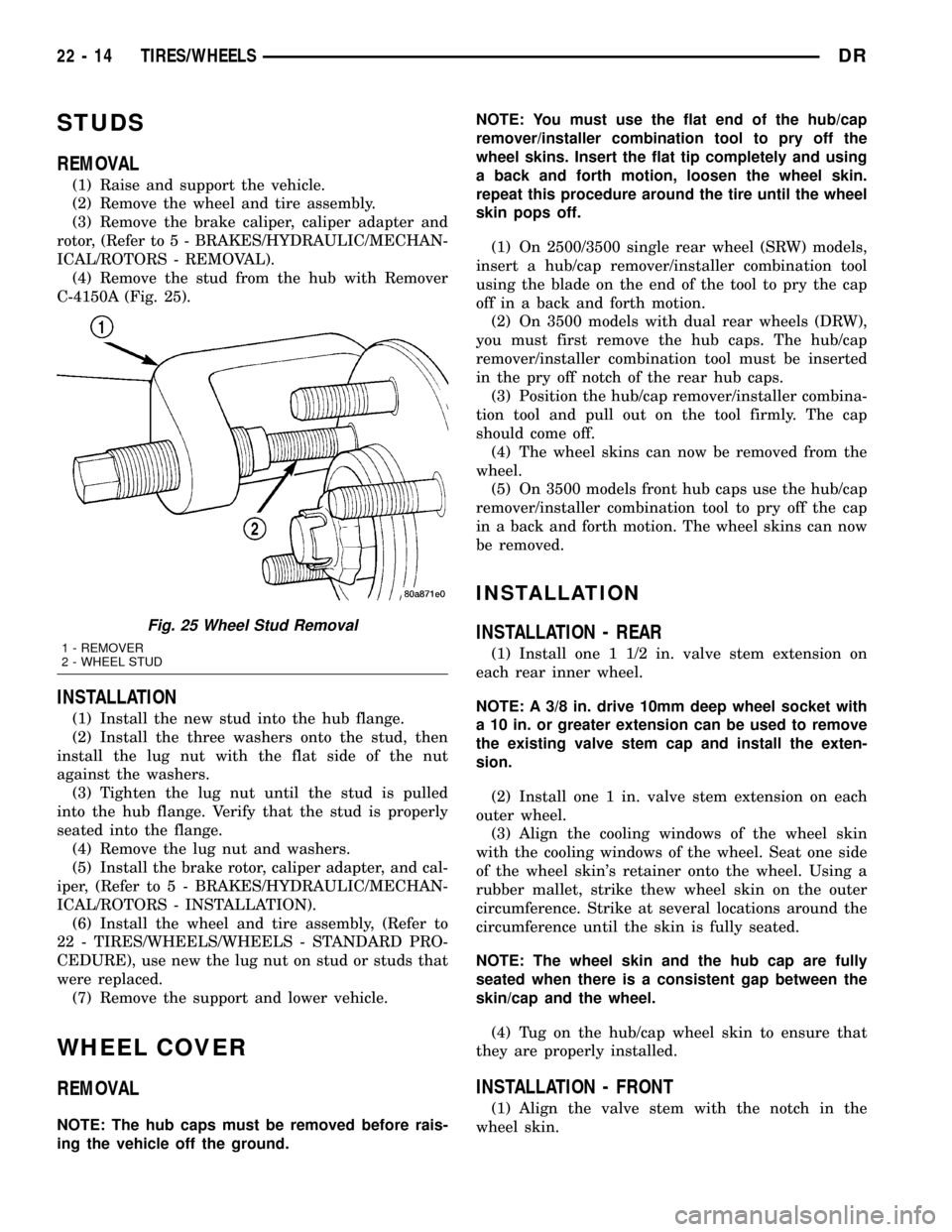

STUDS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper, caliper adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove the stud from the hub with Remover

C-4150A (Fig. 25).

INSTALLATION

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and cal-

iper, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - INSTALLATION).

(6) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE), use new the lug nut on stud or studs that

were replaced.

(7) Remove the support and lower vehicle.

WHEEL COVER

REMOVAL

NOTE: The hub caps must be removed before rais-

ing the vehicle off the ground.NOTE: You must use the flat end of the hub/cap

remover/installer combination tool to pry off the

wheel skins. Insert the flat tip completely and using

a back and forth motion, loosen the wheel skin.

repeat this procedure around the tire until the wheel

skin pops off.

(1) On 2500/3500 single rear wheel (SRW) models,

insert a hub/cap remover/installer combination tool

using the blade on the end of the tool to pry the cap

off in a back and forth motion.

(2) On 3500 models with dual rear wheels (DRW),

you must first remove the hub caps. The hub/cap

remover/installer combination tool must be inserted

in the pry off notch of the rear hub caps.

(3) Position the hub/cap remover/installer combina-

tion tool and pull out on the tool firmly. The cap

should come off.

(4) The wheel skins can now be removed from the

wheel.

(5) On 3500 models front hub caps use the hub/cap

remover/installer combination tool to pry off the cap

in a back and forth motion. The wheel skins can now

be removed.

INSTALLATION

INSTALLATION - REAR

(1) Install one 1 1/2 in. valve stem extension on

each rear inner wheel.

NOTE: A 3/8 in. drive 10mm deep wheel socket with

a 10 in. or greater extension can be used to remove

the existing valve stem cap and install the exten-

sion.

(2) Install one 1 in. valve stem extension on each

outer wheel.

(3) Align the cooling windows of the wheel skin

with the cooling windows of the wheel. Seat one side

of the wheel skin's retainer onto the wheel. Using a

rubber mallet, strike thew wheel skin on the outer

circumference. Strike at several locations around the

circumference until the skin is fully seated.

NOTE: The wheel skin and the hub cap are fully

seated when there is a consistent gap between the

skin/cap and the wheel.

(4) Tug on the hub/cap wheel skin to ensure that

they are properly installed.

INSTALLATION - FRONT

(1) Align the valve stem with the notch in the

wheel skin.

Fig. 25 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

22 - 14 TIRES/WHEELSDR

Page 2301 of 2627

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

RRIM REINFORCED REACTION

INJECTED MOLDEDPUR, RRIM FASCIAS, BODY PANELS,

BODY TRIMS

TPE THERMO POLYETHYLENE TPE, HYTREL, BEXLOY-V FASCIAS, BUMPERS,

CLADDINGS

TPO THERMOPOLYOLEFIN POLYTROPE, RENFLEX,

SANTOPRENE, VISAFLEX,

ETA, APEX, TPO, SHIELDS,

CLADDINGSBUMPERS, END CAPS,

TELCAR, RUBBER, STRIPS,

SIGHT, INTERIOR B POST

TPP THERMO-POLYPROPYLENE TPP BUMPERS

TPU THERMOPOLYURETHANE,

POLYESTERTPU, HYTREL, TEXIN,

ESTANEBUMPERS, BODY SIDE,

MOLDINGS, FENDERS,

FASCIAS

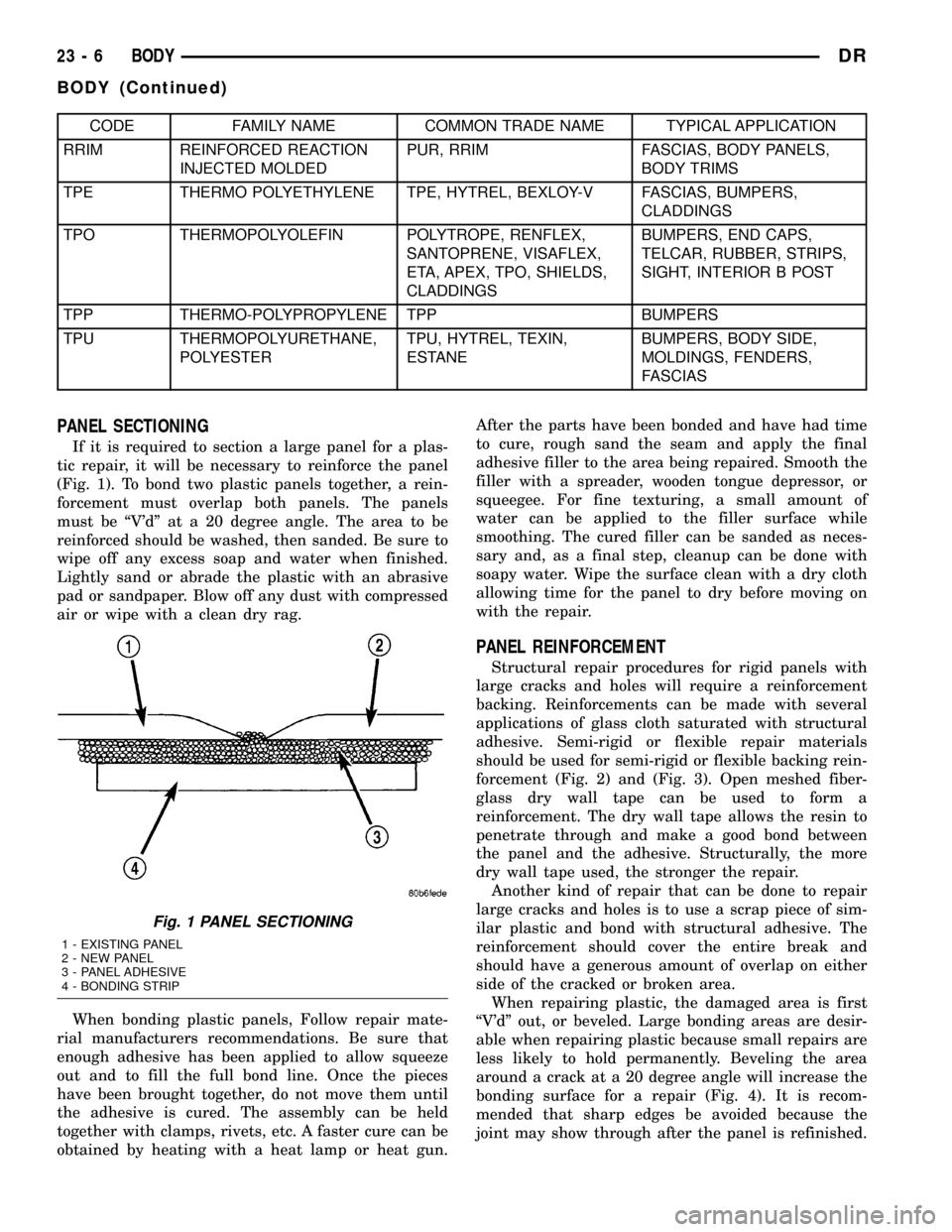

PANEL SECTIONING

If it is required to section a large panel for a plas-

tic repair, it will be necessary to reinforce the panel

(Fig. 1). To bond two plastic panels together, a rein-

forcement must overlap both panels. The panels

must be ªV'dº at a 20 degree angle. The area to be

reinforced should be washed, then sanded. Be sure to

wipe off any excess soap and water when finished.

Lightly sand or abrade the plastic with an abrasive

pad or sandpaper. Blow off any dust with compressed

air or wipe with a clean dry rag.

When bonding plastic panels, Follow repair mate-

rial manufacturers recommendations. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.After the parts have been bonded and have had time

to cure, rough sand the seam and apply the final

adhesive filler to the area being repaired. Smooth the

filler with a spreader, wooden tongue depressor, or

squeegee. For fine texturing, a small amount of

water can be applied to the filler surface while

smoothing. The cured filler can be sanded as neces-

sary and, as a final step, cleanup can be done with

soapy water. Wipe the surface clean with a dry cloth

allowing time for the panel to dry before moving on

with the repair.

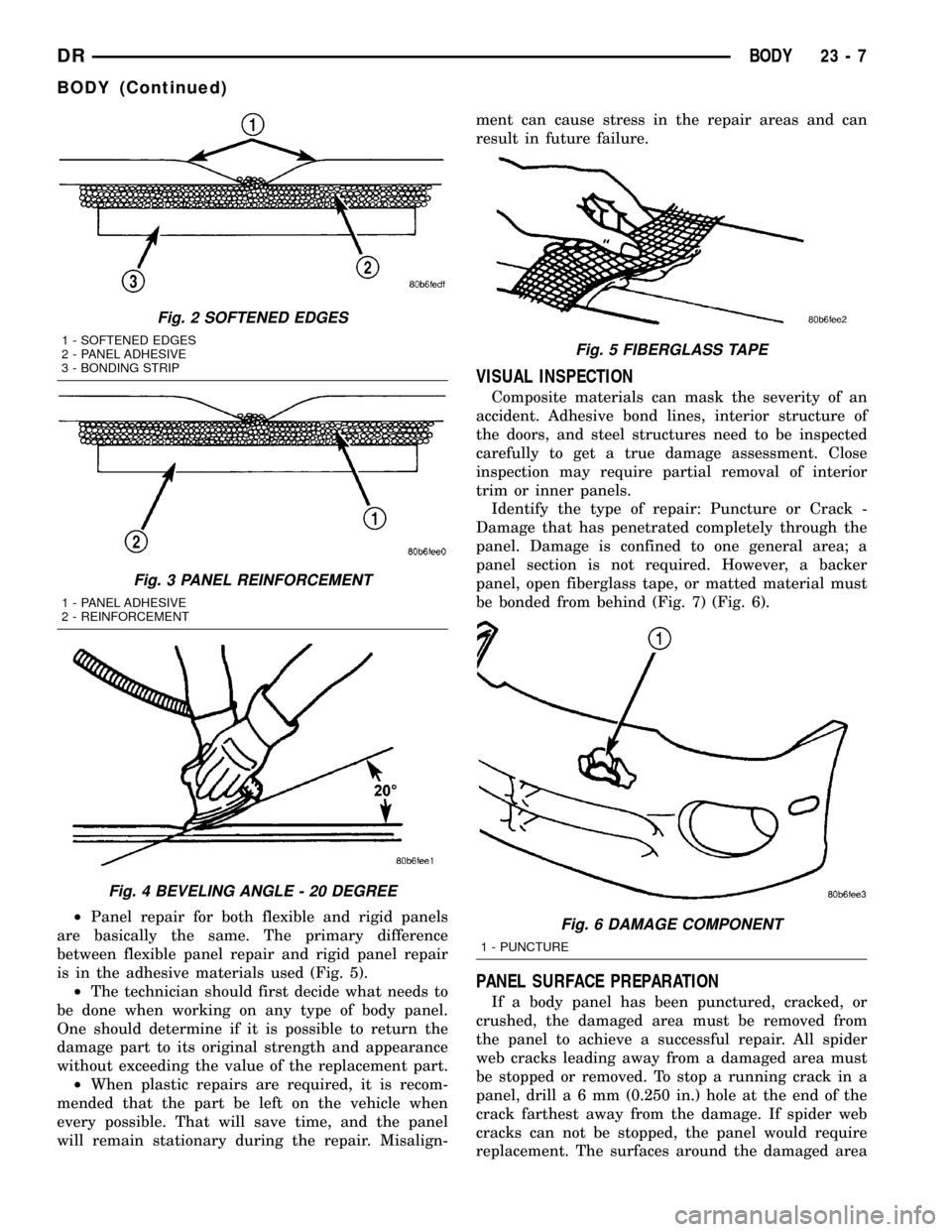

PANEL REINFORCEMENT

Structural repair procedures for rigid panels with

large cracks and holes will require a reinforcement

backing. Reinforcements can be made with several

applications of glass cloth saturated with structural

adhesive. Semi-rigid or flexible repair materials

should be used for semi-rigid or flexible backing rein-

forcement (Fig. 2) and (Fig. 3). Open meshed fiber-

glass dry wall tape can be used to form a

reinforcement. The dry wall tape allows the resin to

penetrate through and make a good bond between

the panel and the adhesive. Structurally, the more

dry wall tape used, the stronger the repair.

Another kind of repair that can be done to repair

large cracks and holes is to use a scrap piece of sim-

ilar plastic and bond with structural adhesive. The

reinforcement should cover the entire break and

should have a generous amount of overlap on either

side of the cracked or broken area.

When repairing plastic, the damaged area is first

ªV'dº out, or beveled. Large bonding areas are desir-

able when repairing plastic because small repairs are

less likely to hold permanently. Beveling the area

around a crack at a 20 degree angle will increase the

bonding surface for a repair (Fig. 4). It is recom-

mended that sharp edges be avoided because the

joint may show through after the panel is refinished.

Fig. 1 PANEL SECTIONING

1 - EXISTING PANEL

2 - NEW PANEL

3 - PANEL ADHESIVE

4 - BONDING STRIP

23 - 6 BODYDR

BODY (Continued)

Page 2302 of 2627

²Panel repair for both flexible and rigid panels

are basically the same. The primary difference

between flexible panel repair and rigid panel repair

is in the adhesive materials used (Fig. 5).

²The technician should first decide what needs to

be done when working on any type of body panel.

One should determine if it is possible to return the

damage part to its original strength and appearance

without exceeding the value of the replacement part.

²When plastic repairs are required, it is recom-

mended that the part be left on the vehicle when

every possible. That will save time, and the panel

will remain stationary during the repair. Misalign-ment can cause stress in the repair areas and can

result in future failure.

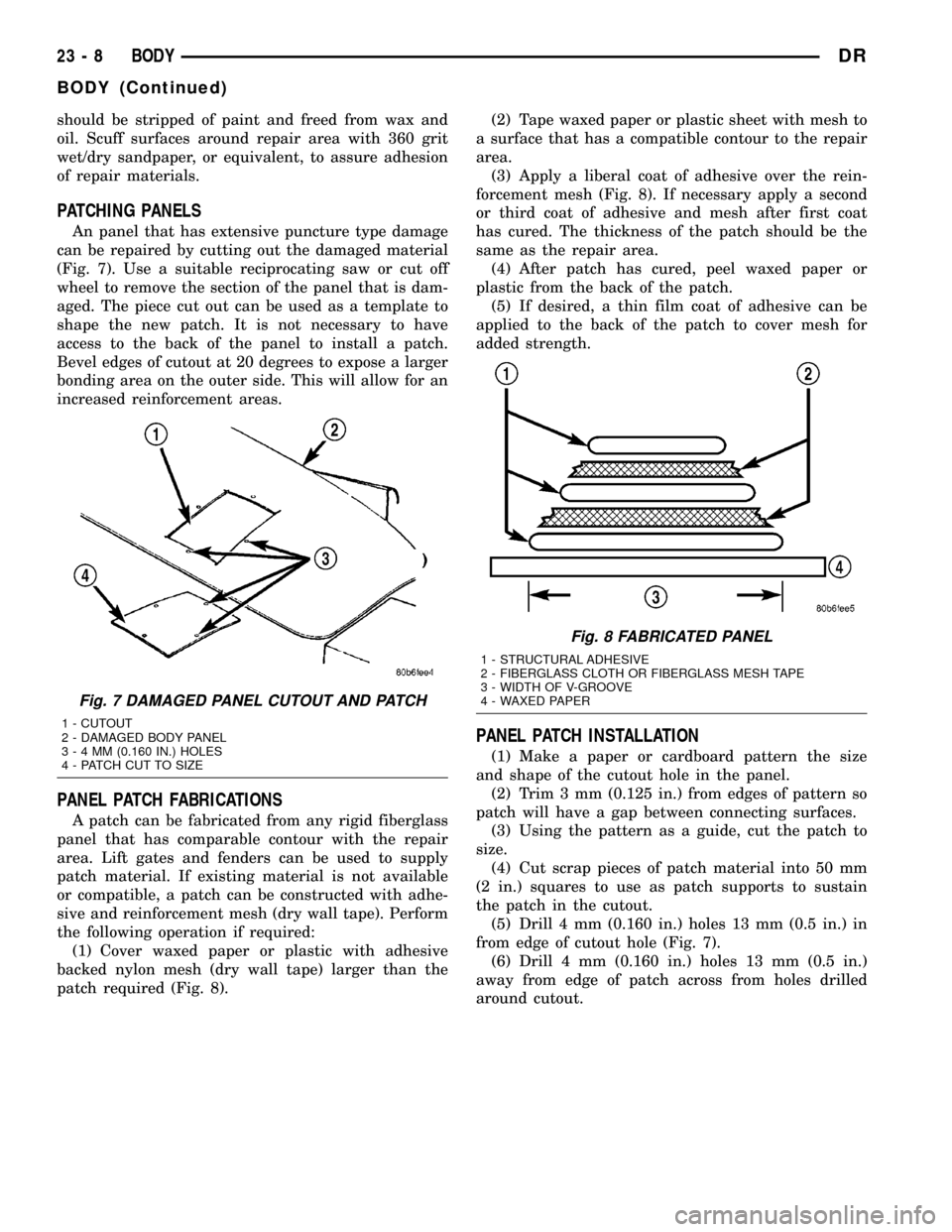

VISUAL INSPECTION

Composite materials can mask the severity of an

accident. Adhesive bond lines, interior structure of

the doors, and steel structures need to be inspected

carefully to get a true damage assessment. Close

inspection may require partial removal of interior

trim or inner panels.

Identify the type of repair: Puncture or Crack -

Damage that has penetrated completely through the

panel. Damage is confined to one general area; a

panel section is not required. However, a backer

panel, open fiberglass tape, or matted material must

be bonded from behind (Fig. 7) (Fig. 6).

PANEL SURFACE PREPARATION

If a body panel has been punctured, cracked, or

crushed, the damaged area must be removed from

the panel to achieve a successful repair. All spider

web cracks leading away from a damaged area must

be stopped or removed. To stop a running crack in a

panel, drilla6mm(0.250 in.) hole at the end of the

crack farthest away from the damage. If spider web

cracks can not be stopped, the panel would require

replacement. The surfaces around the damaged area

Fig. 2 SOFTENED EDGES

1 - SOFTENED EDGES

2 - PANEL ADHESIVE

3 - BONDING STRIP

Fig. 3 PANEL REINFORCEMENT

1 - PANEL ADHESIVE

2 - REINFORCEMENT

Fig. 4 BEVELING ANGLE - 20 DEGREE

Fig. 5 FIBERGLASS TAPE

Fig. 6 DAMAGE COMPONENT

1 - PUNCTURE

DRBODY 23 - 7

BODY (Continued)

Page 2303 of 2627

should be stripped of paint and freed from wax and

oil. Scuff surfaces around repair area with 360 grit

wet/dry sandpaper, or equivalent, to assure adhesion

of repair materials.

PATCHING PANELS

An panel that has extensive puncture type damage

can be repaired by cutting out the damaged material

(Fig. 7). Use a suitable reciprocating saw or cut off

wheel to remove the section of the panel that is dam-

aged. The piece cut out can be used as a template to

shape the new patch. It is not necessary to have

access to the back of the panel to install a patch.

Bevel edges of cutout at 20 degrees to expose a larger

bonding area on the outer side. This will allow for an

increased reinforcement areas.

PANEL PATCH FABRICATIONS

A patch can be fabricated from any rigid fiberglass

panel that has comparable contour with the repair

area. Lift gates and fenders can be used to supply

patch material. If existing material is not available

or compatible, a patch can be constructed with adhe-

sive and reinforcement mesh (dry wall tape). Perform

the following operation if required:

(1) Cover waxed paper or plastic with adhesive

backed nylon mesh (dry wall tape) larger than the

patch required (Fig. 8).(2) Tape waxed paper or plastic sheet with mesh to

a surface that has a compatible contour to the repair

area.

(3) Apply a liberal coat of adhesive over the rein-

forcement mesh (Fig. 8). If necessary apply a second

or third coat of adhesive and mesh after first coat

has cured. The thickness of the patch should be the

same as the repair area.

(4) After patch has cured, peel waxed paper or

plastic from the back of the patch.

(5) If desired, a thin film coat of adhesive can be

applied to the back of the patch to cover mesh for

added strength.

PANEL PATCH INSTALLATION

(1) Make a paper or cardboard pattern the size

and shape of the cutout hole in the panel.

(2) Trim 3 mm (0.125 in.) from edges of pattern so

patch will have a gap between connecting surfaces.

(3) Using the pattern as a guide, cut the patch to

size.

(4) Cut scrap pieces of patch material into 50 mm

(2 in.) squares to use as patch supports to sustain

the patch in the cutout.

(5) Drill 4 mm (0.160 in.) holes 13 mm (0.5 in.) in

from edge of cutout hole (Fig. 7).

(6) Drill 4 mm (0.160 in.) holes 13 mm (0.5 in.)

away from edge of patch across from holes drilled

around cutout.

Fig. 7 DAMAGED PANEL CUTOUT AND PATCH

1 - CUTOUT

2 - DAMAGED BODY PANEL

3-4MM(0.160 IN.) HOLES

4 - PATCH CUT TO SIZE

Fig. 8 FABRICATED PANEL

1 - STRUCTURAL ADHESIVE

2 - FIBERGLASS CLOTH OR FIBERGLASS MESH TAPE

3 - WIDTH OF V-GROOVE

4 - WAXED PAPER

23 - 8 BODYDR

BODY (Continued)

Page 2304 of 2627

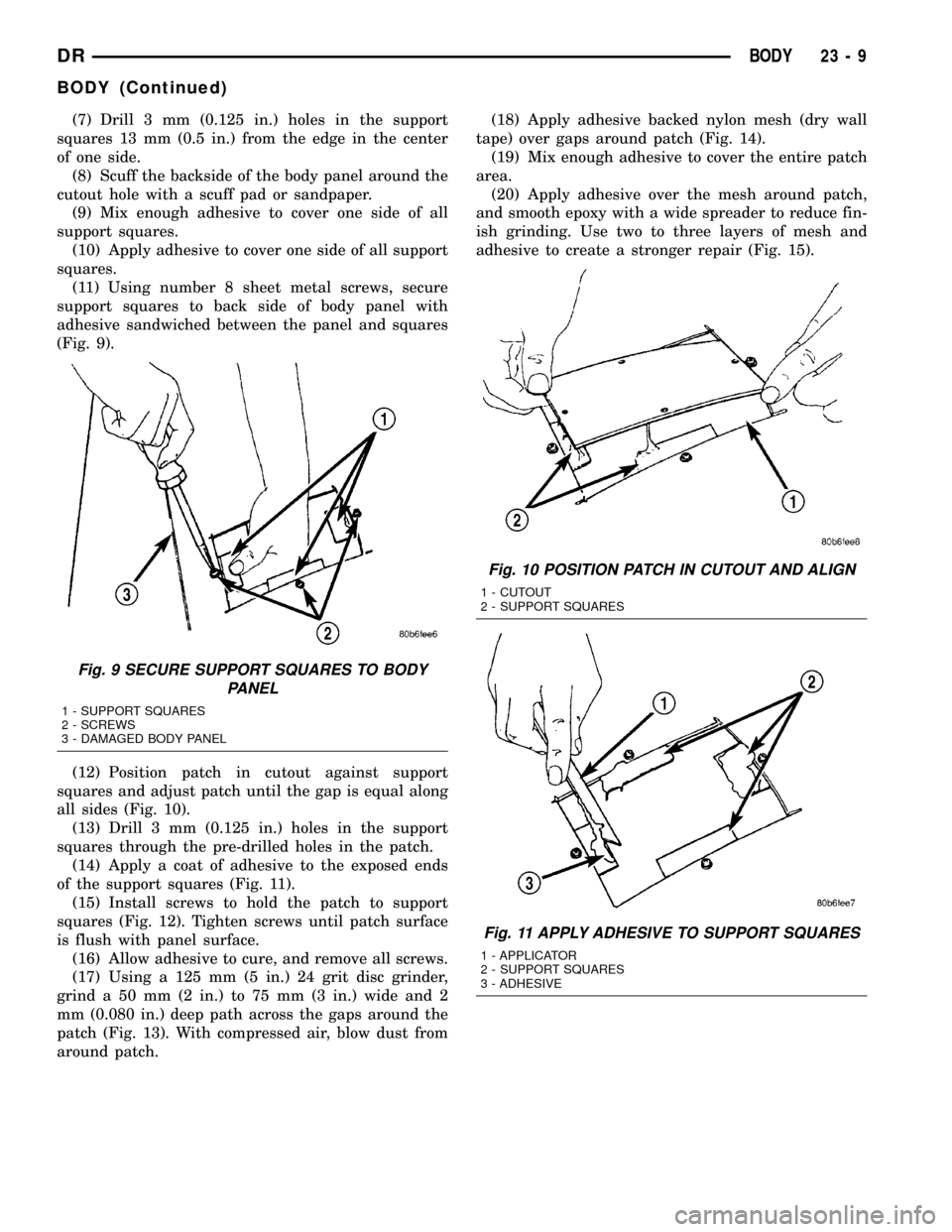

(7) Drill 3 mm (0.125 in.) holes in the support

squares 13 mm (0.5 in.) from the edge in the center

of one side.

(8) Scuff the backside of the body panel around the

cutout hole with a scuff pad or sandpaper.

(9) Mix enough adhesive to cover one side of all

support squares.

(10) Apply adhesive to cover one side of all support

squares.

(11) Using number 8 sheet metal screws, secure

support squares to back side of body panel with

adhesive sandwiched between the panel and squares

(Fig. 9).

(12) Position patch in cutout against support

squares and adjust patch until the gap is equal along

all sides (Fig. 10).

(13) Drill 3 mm (0.125 in.) holes in the support

squares through the pre-drilled holes in the patch.

(14) Apply a coat of adhesive to the exposed ends

of the support squares (Fig. 11).

(15) Install screws to hold the patch to support

squares (Fig. 12). Tighten screws until patch surface

is flush with panel surface.

(16) Allow adhesive to cure, and remove all screws.

(17) Using a 125 mm (5 in.) 24 grit disc grinder,

grind a 50 mm (2 in.) to 75 mm (3 in.) wide and 2

mm (0.080 in.) deep path across the gaps around the

patch (Fig. 13). With compressed air, blow dust from

around patch.(18) Apply adhesive backed nylon mesh (dry wall

tape) over gaps around patch (Fig. 14).

(19) Mix enough adhesive to cover the entire patch

area.

(20) Apply adhesive over the mesh around patch,

and smooth epoxy with a wide spreader to reduce fin-

ish grinding. Use two to three layers of mesh and

adhesive to create a stronger repair (Fig. 15).

Fig. 9 SECURE SUPPORT SQUARES TO BODY

PANEL

1 - SUPPORT SQUARES

2 - SCREWS

3 - DAMAGED BODY PANEL

Fig. 10 POSITION PATCH IN CUTOUT AND ALIGN

1 - CUTOUT

2 - SUPPORT SQUARES

Fig. 11 APPLY ADHESIVE TO SUPPORT SQUARES

1 - APPLICATOR

2 - SUPPORT SQUARES

3 - ADHESIVE

DRBODY 23 - 9

BODY (Continued)

Page 2305 of 2627

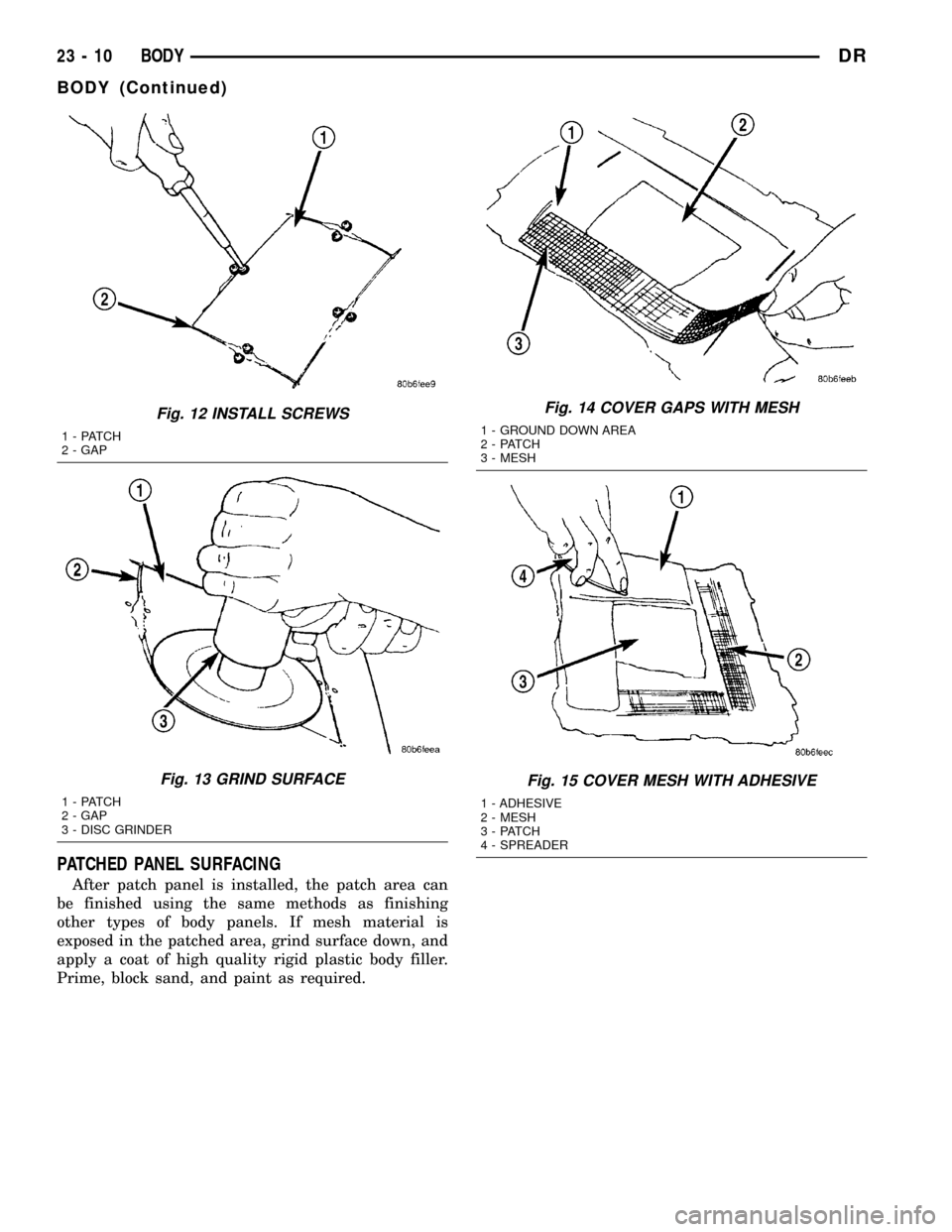

PATCHED PANEL SURFACING

After patch panel is installed, the patch area can

be finished using the same methods as finishing

other types of body panels. If mesh material is

exposed in the patched area, grind surface down, and

apply a coat of high quality rigid plastic body filler.

Prime, block sand, and paint as required.

Fig. 12 INSTALL SCREWS

1 - PATCH

2 - GAP

Fig. 13 GRIND SURFACE

1 - PATCH

2 - GAP

3 - DISC GRINDER

Fig. 14 COVER GAPS WITH MESH

1 - GROUND DOWN AREA

2 - PATCH

3 - MESH

Fig. 15 COVER MESH WITH ADHESIVE

1 - ADHESIVE

2 - MESH

3 - PATCH

4 - SPREADER

23 - 10 BODYDR

BODY (Continued)