section 5 DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2553 of 2627

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

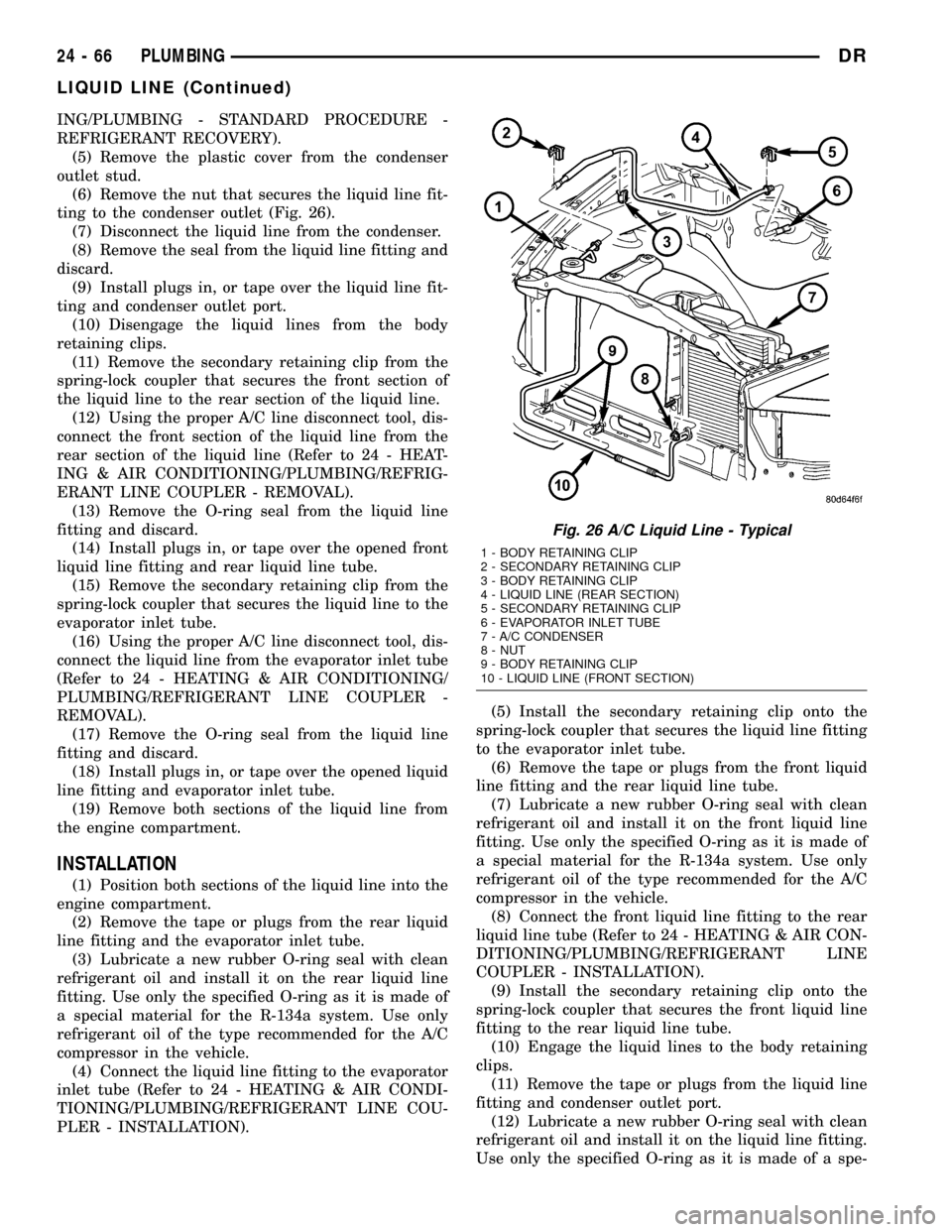

(5) Remove the plastic cover from the condenser

outlet stud.

(6) Remove the nut that secures the liquid line fit-

ting to the condenser outlet (Fig. 26).

(7) Disconnect the liquid line from the condenser.

(8) Remove the seal from the liquid line fitting and

discard.

(9) Install plugs in, or tape over the liquid line fit-

ting and condenser outlet port.

(10) Disengage the liquid lines from the body

retaining clips.

(11) Remove the secondary retaining clip from the

spring-lock coupler that secures the front section of

the liquid line to the rear section of the liquid line.

(12) Using the proper A/C line disconnect tool, dis-

connect the front section of the liquid line from the

rear section of the liquid line (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT LINE COUPLER - REMOVAL).

(13) Remove the O-ring seal from the liquid line

fitting and discard.

(14) Install plugs in, or tape over the opened front

liquid line fitting and rear liquid line tube.

(15) Remove the secondary retaining clip from the

spring-lock coupler that secures the liquid line to the

evaporator inlet tube.

(16) Using the proper A/C line disconnect tool, dis-

connect the liquid line from the evaporator inlet tube

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT LINE COUPLER -

REMOVAL).

(17) Remove the O-ring seal from the liquid line

fitting and discard.

(18) Install plugs in, or tape over the opened liquid

line fitting and evaporator inlet tube.

(19) Remove both sections of the liquid line from

the engine compartment.

INSTALLATION

(1) Position both sections of the liquid line into the

engine compartment.

(2) Remove the tape or plugs from the rear liquid

line fitting and the evaporator inlet tube.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the rear liquid line

fitting. Use only the specified O-ring as it is made of

a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(4) Connect the liquid line fitting to the evaporator

inlet tube (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/REFRIGERANT LINE COU-

PLER - INSTALLATION).(5) Install the secondary retaining clip onto the

spring-lock coupler that secures the liquid line fitting

to the evaporator inlet tube.

(6) Remove the tape or plugs from the front liquid

line fitting and the rear liquid line tube.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the front liquid line

fitting. Use only the specified O-ring as it is made of

a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(8) Connect the front liquid line fitting to the rear

liquid line tube (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/REFRIGERANT LINE

COUPLER - INSTALLATION).

(9) Install the secondary retaining clip onto the

spring-lock coupler that secures the front liquid line

fitting to the rear liquid line tube.

(10) Engage the liquid lines to the body retaining

clips.

(11) Remove the tape or plugs from the liquid line

fitting and condenser outlet port.

(12) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

Use only the specified O-ring as it is made of a spe-

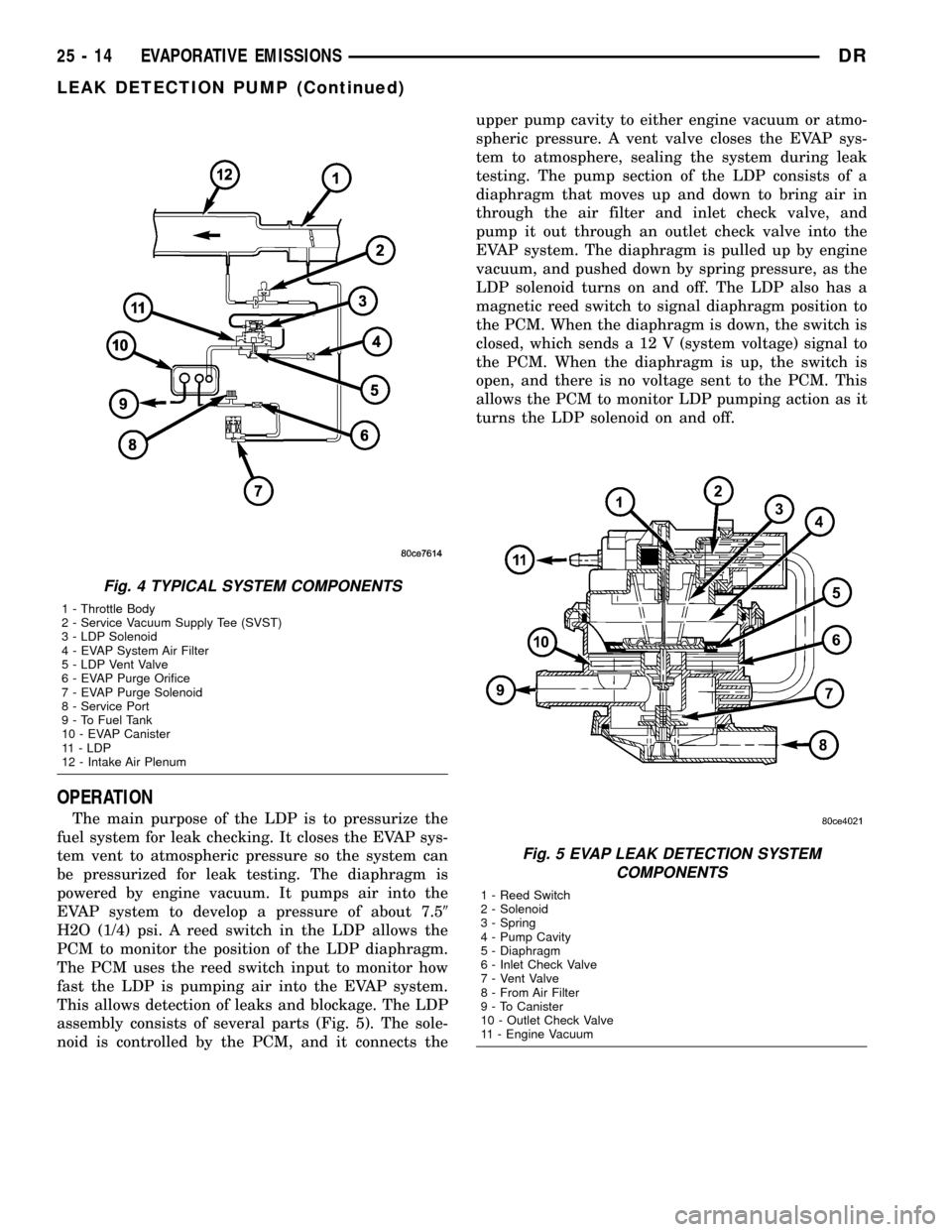

Fig. 26 A/C Liquid Line - Typical

1 - BODY RETAINING CLIP

2 - SECONDARY RETAINING CLIP

3 - BODY RETAINING CLIP

4 - LIQUID LINE (REAR SECTION)

5 - SECONDARY RETAINING CLIP

6 - EVAPORATOR INLET TUBE

7 - A/C CONDENSER

8 - NUT

9 - BODY RETAINING CLIP

10 - LIQUID LINE (FRONT SECTION)

24 - 66 PLUMBINGDR

LIQUID LINE (Continued)

Page 2557 of 2627

(2) Disconnect the refrigerant lines from the A/C

compressor. Cap open lines to prevent moisture from

entering the system.

(3) Remove the A/C compressor from the vehicle.

(4) From the suction and discharge ports on the

A/C compressor, drain the lubricant from the old A/C

compressor into a clean container.

(5) From the suction and discharge ports on the

A/C compressor, drain the lubricant from the new

A/C compressor into a clean container.

(6) Install new lubricant back into the new A/C

compressor in the amount measured from the used

compressor, plus adding any amount of lubricant lost

when the refrigerant system was reclaimed.

(7) Install the A/C compressor and connect the

refrigerant lines. Then evacuate and charge refriger-

ant system.

SERVICE PORT VALVE CORE

DESCRIPTION

A/C SERVICE PORT VALVE CORES

The A/C service port valve cores are serviceable

items. The A/C pressure transducer is mounted on

the high side service port which is located on the dis-

charge line near the A/C compressor. The low side

service port is located on the suction line near the

accumulator outlet tube.

REMOVAL - SERVICE PORT VALVE CORES

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the protective cap from the low side

service port as necessary.

(2) Remove the A/C pressure transducer from the

high side service port as necessary (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

PRESSURE TRANSDUCER - REMOVAL).

(3) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT - STANDARD

PROCEDURE).

(4) Using a standard Schrader-type valve core tool,

remove the valve core from the service ports as

required.

(5) Install a plug in or tape over the opened ser-

vice port(s).

INSTALLATION

(1) Lubricate the A/C service port valve core with

clean refrigerant oil prior to installation. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(2) Remove the tape or plug from the A/C service

port.

CAUTION: A valve core that is not fully seated in

the A/C service port can result in damage to the

valve during refrigerant system evacuation and

charge. Such damage may result in a loss of sys-

tem refrigerant while uncoupling the charge adapt-

ers.

(3) Using a standard Schrader-type valve core tool,

install and tighten the replacement valve core into

the A/C service ports as required.

(4) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(5) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

(6) Install the A/C pressure transducer to the high

side service port as necessary (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CONTROLS/A/C

PRESSURE TRANSDUCER - INSTALLATION).

(7) Install the protective cap onto the A/C service

ports as required.

SUCTION LINE

DESCRIPTION

The suction line is the refrigerant line that goes

from the evaporator outlet tube to the compressor

inlet port. The suction line for the 5.9L Diesel engine

is only serviced as an assembly with the discharge

line. The suction line has no serviceable parts except

the rubber O-rings. If the suction line is found to be

leaking or is damaged, it must be replaced.

REMOVAL

REMOVAL - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

24 - 70 PLUMBINGDR

REFRIGERANT OIL (Continued)

Page 2558 of 2627

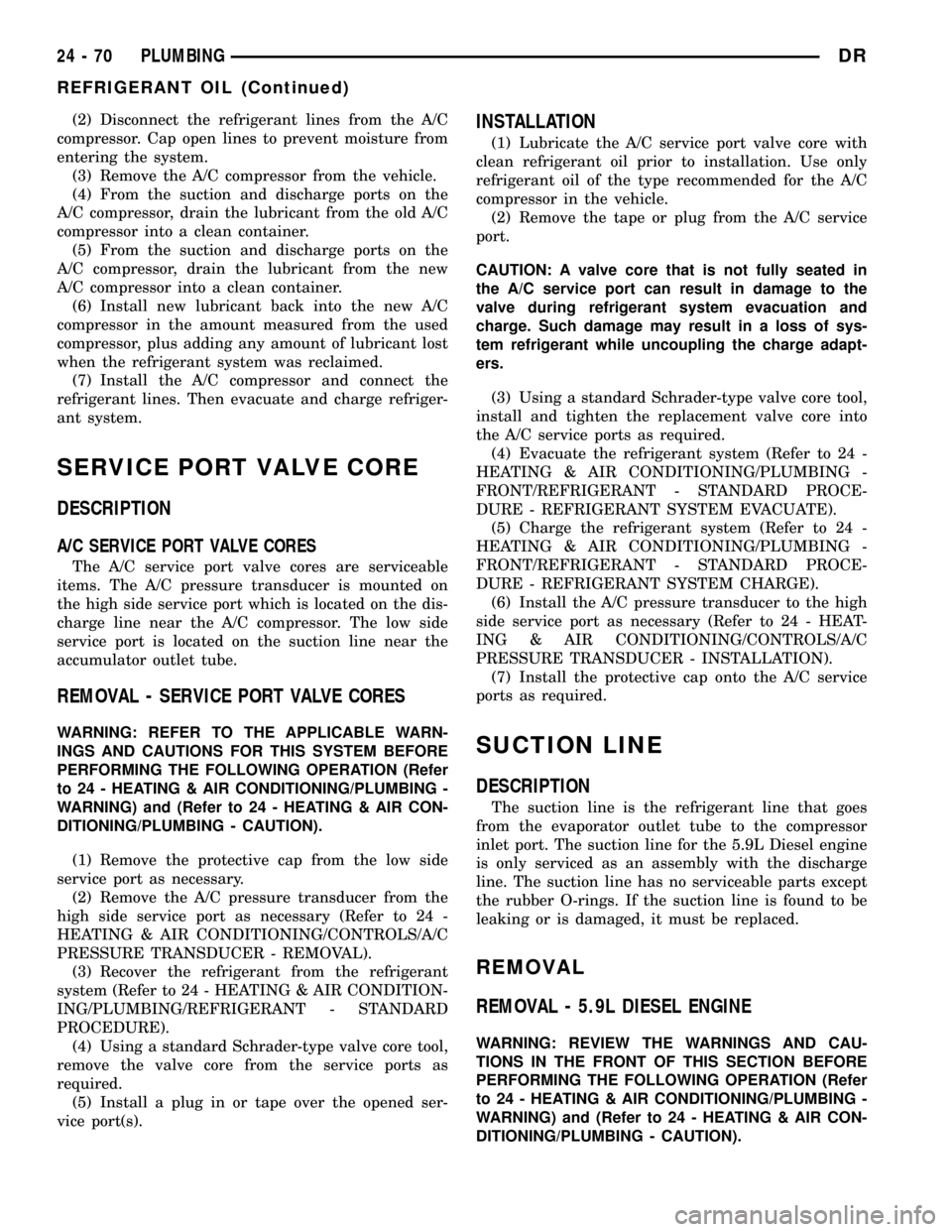

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Disconnect the wire harness connector from the

A/C pressure transducer.

(4) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 29).

(5) Disconnect the discharge line from the con-

denser.

(6) Remove the O-ring seal from the discharge line

fitting and discard.

(7) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(8) Remove the bolt that secures the suction/dis-

charge line assembly to the A/C compressor.

(9) Disconnect the suction/discharge line assembly

from the A/C compressor.

(10) Remove the O-ring seals from the suction and

discharge line fittings and discard.

(11) Install plugs in, or tape over all of the opened

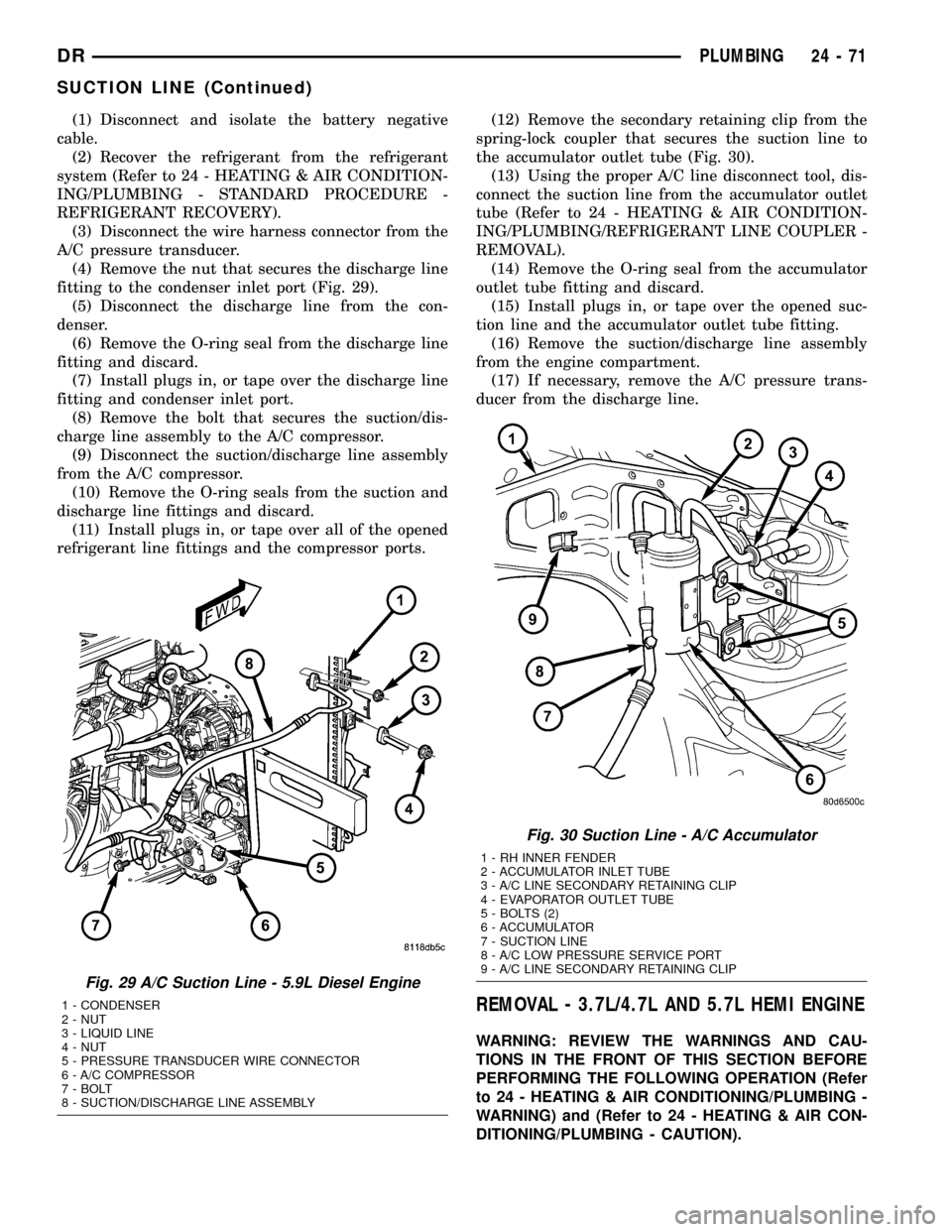

refrigerant line fittings and the compressor ports.(12) Remove the secondary retaining clip from the

spring-lock coupler that secures the suction line to

the accumulator outlet tube (Fig. 30).

(13) Using the proper A/C line disconnect tool, dis-

connect the suction line from the accumulator outlet

tube (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT LINE COUPLER -

REMOVAL).

(14) Remove the O-ring seal from the accumulator

outlet tube fitting and discard.

(15) Install plugs in, or tape over the opened suc-

tion line and the accumulator outlet tube fitting.

(16) Remove the suction/discharge line assembly

from the engine compartment.

(17) If necessary, remove the A/C pressure trans-

ducer from the discharge line.

REMOVAL - 3.7L/4.7L AND 5.7L HEMI ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

Fig. 29 A/C Suction Line - 5.9L Diesel Engine

1 - CONDENSER

2 - NUT

3 - LIQUID LINE

4 - NUT

5 - PRESSURE TRANSDUCER WIRE CONNECTOR

6 - A/C COMPRESSOR

7 - BOLT

8 - SUCTION/DISCHARGE LINE ASSEMBLY

Fig. 30 Suction Line - A/C Accumulator

1 - RH INNER FENDER

2 - ACCUMULATOR INLET TUBE

3 - A/C LINE SECONDARY RETAINING CLIP

4 - EVAPORATOR OUTLET TUBE

5 - BOLTS (2)

6 - ACCUMULATOR

7 - SUCTION LINE

8 - A/C LOW PRESSURE SERVICE PORT

9 - A/C LINE SECONDARY RETAINING CLIP

DRPLUMBING 24 - 71

SUCTION LINE (Continued)

Page 2566 of 2627

OPERATION

OPERATION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

problem is repaired or ceases to exist, the PCM can-

cels the code after 40 warm-up cycles. Diagnostic

trouble codes that affect vehicle emissions illuminate

the Malfunction Indicator Lamp (MIL). The MIL is

displayed as an engine icon (graphic) on the instru-

ment panel. Refer to Malfunction Indicator Lamp in

this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example,assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

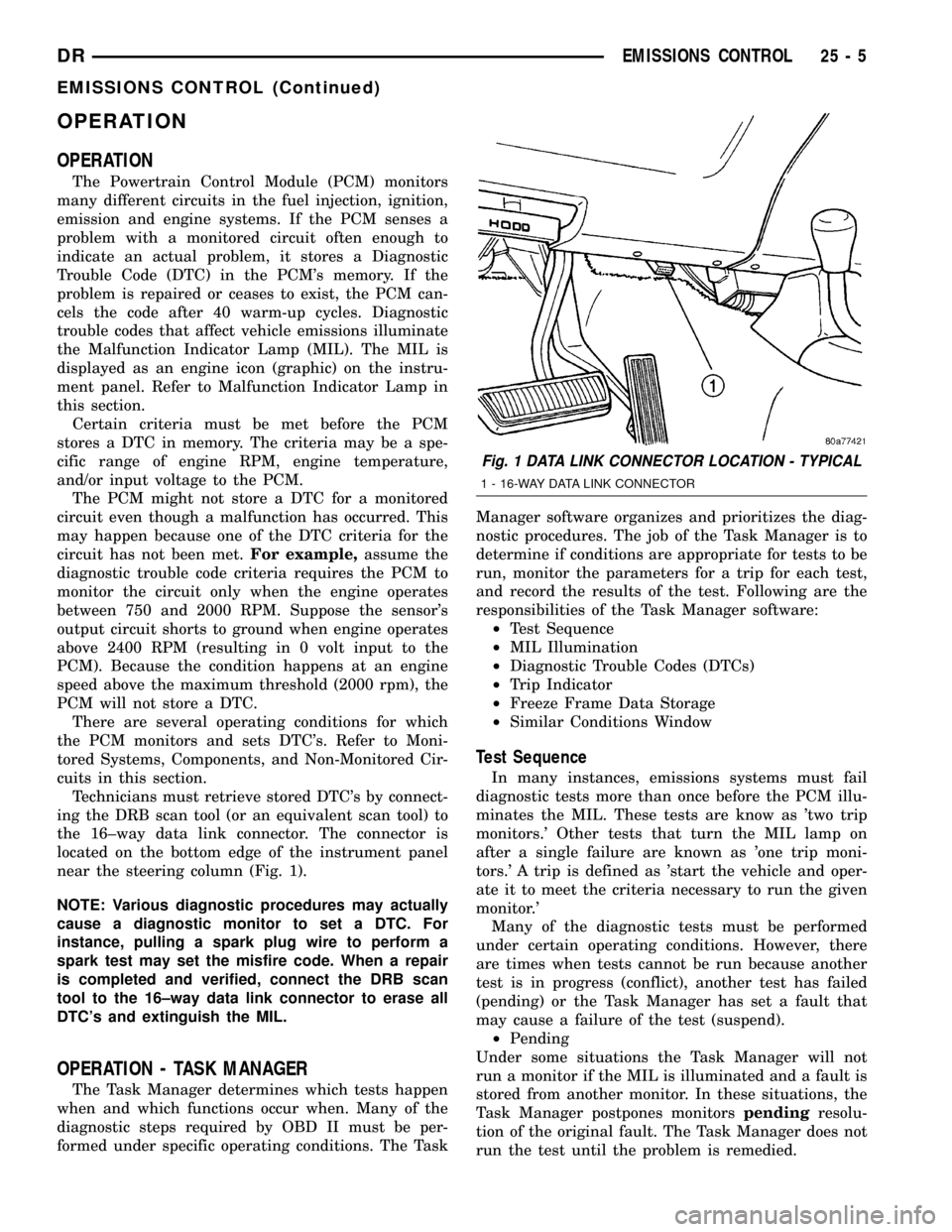

Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector. The connector is

located on the bottom edge of the instrument panel

near the steering column (Fig. 1).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL.

OPERATION - TASK MANAGER

The Task Manager determines which tests happen

when and which functions occur when. Many of the

diagnostic steps required by OBD II must be per-

formed under specific operating conditions. The TaskManager software organizes and prioritizes the diag-

nostic procedures. The job of the Task Manager is to

determine if conditions are appropriate for tests to be

run, monitor the parameters for a trip for each test,

and record the results of the test. Following are the

responsibilities of the Task Manager software:

²Test Sequence

²MIL Illumination

²Diagnostic Trouble Codes (DTCs)

²Trip Indicator

²Freeze Frame Data Storage

²Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail

diagnostic tests more than once before the PCM illu-

minates the MIL. These tests are know as 'two trip

monitors.' Other tests that turn the MIL lamp on

after a single failure are known as 'one trip moni-

tors.' A trip is defined as 'start the vehicle and oper-

ate it to meet the criteria necessary to run the given

monitor.'

Many of the diagnostic tests must be performed

under certain operating conditions. However, there

are times when tests cannot be run because another

test is in progress (conflict), another test has failed

(pending) or the Task Manager has set a fault that

may cause a failure of the test (suspend).

²Pending

Under some situations the Task Manager will not

run a monitor if the MIL is illuminated and a fault is

stored from another monitor. In these situations, the

Task Manager postpones monitorspendingresolu-

tion of the original fault. The Task Manager does not

run the test until the problem is remedied.

Fig. 1 DATA LINK CONNECTOR LOCATION - TYPICAL

1 - 16-WAY DATA LINK CONNECTOR

DREMISSIONS CONTROL 25 - 5

EMISSIONS CONTROL (Continued)

Page 2575 of 2627

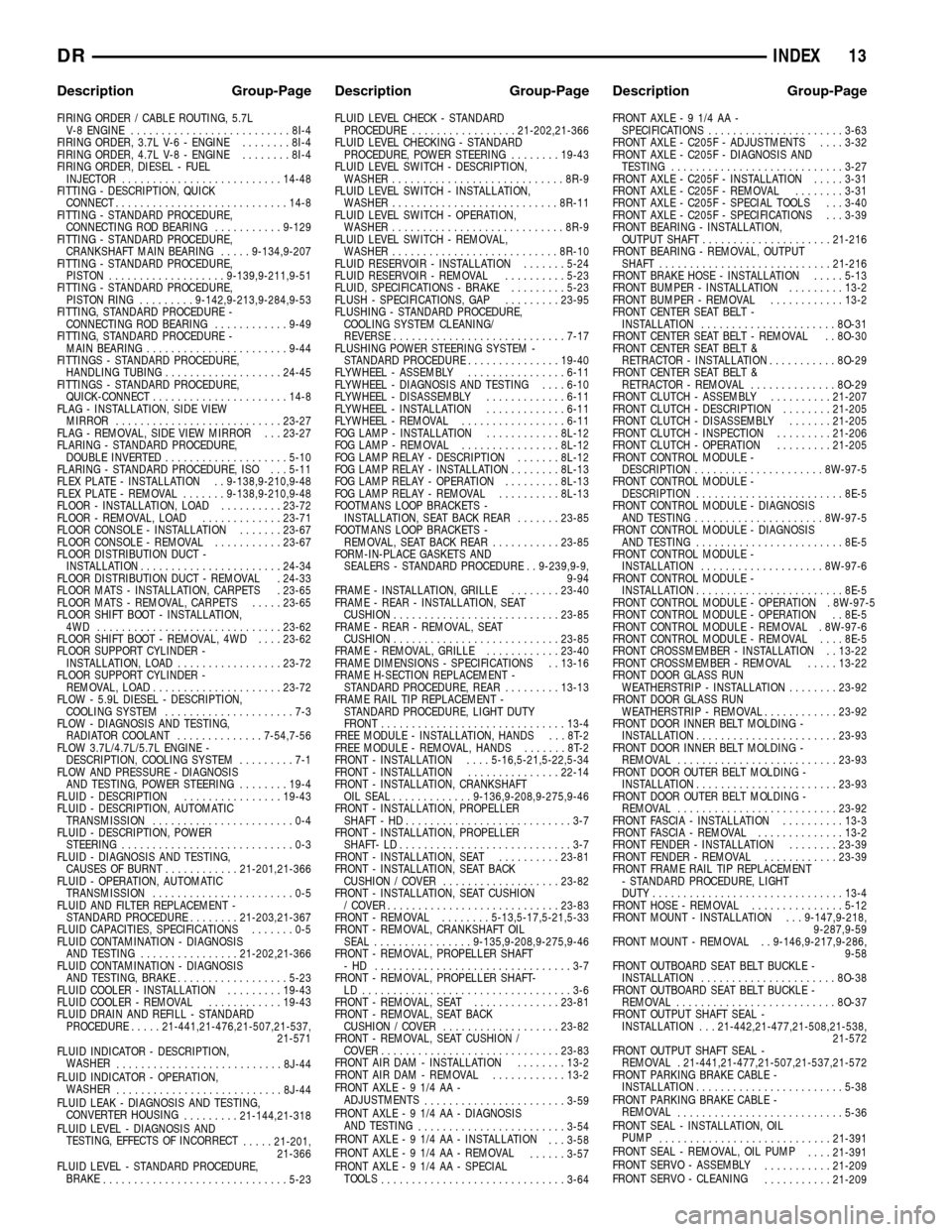

OPERATION

The main purpose of the LDP is to pressurize the

fuel system for leak checking. It closes the EVAP sys-

tem vent to atmospheric pressure so the system can

be pressurized for leak testing. The diaphragm is

powered by engine vacuum. It pumps air into the

EVAP system to develop a pressure of about 7.59

H2O (1/4) psi. A reed switch in the LDP allows the

PCM to monitor the position of the LDP diaphragm.

The PCM uses the reed switch input to monitor how

fast the LDP is pumping air into the EVAP system.

This allows detection of leaks and blockage. The LDP

assembly consists of several parts (Fig. 5). The sole-

noid is controlled by the PCM, and it connects theupper pump cavity to either engine vacuum or atmo-

spheric pressure. A vent valve closes the EVAP sys-

tem to atmosphere, sealing the system during leak

testing. The pump section of the LDP consists of a

diaphragm that moves up and down to bring air in

through the air filter and inlet check valve, and

pump it out through an outlet check valve into the

EVAP system. The diaphragm is pulled up by engine

vacuum, and pushed down by spring pressure, as the

LDP solenoid turns on and off. The LDP also has a

magnetic reed switch to signal diaphragm position to

the PCM. When the diaphragm is down, the switch is

closed, which sends a 12 V (system voltage) signal to

the PCM. When the diaphragm is up, the switch is

open, and there is no voltage sent to the PCM. This

allows the PCM to monitor LDP pumping action as it

turns the LDP solenoid on and off.

Fig. 4 TYPICAL SYSTEM COMPONENTS

1 - Throttle Body

2 - Service Vacuum Supply Tee (SVST)

3 - LDP Solenoid

4 - EVAP System Air Filter

5 - LDP Vent Valve

6 - EVAP Purge Orifice

7 - EVAP Purge Solenoid

8 - Service Port

9 - To Fuel Tank

10 - EVAP Canister

11 - LDP

12 - Intake Air Plenum

Fig. 5 EVAP LEAK DETECTION SYSTEM

COMPONENTS

1 - Reed Switch

2 - Solenoid

3 - Spring

4 - Pump Cavity

5 - Diaphragm

6 - Inlet Check Valve

7 - Vent Valve

8 - From Air Filter

9 - To Canister

10 - Outlet Check Valve

11 - Engine Vacuum

25 - 14 EVAPORATIVE EMISSIONSDR

LEAK DETECTION PUMP (Continued)

Page 2600 of 2627

FIRING ORDER / CABLE ROUTING, 5.7L

V-8 ENGINE..........................8I-4

FIRING ORDER, 3.7L V-6 - ENGINE........8I-4

FIRING ORDER, 4.7L V-8 - ENGINE........8I-4

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-48

FITTING - DESCRIPTION, QUICK

CONNECT............................14-8

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING...........9-129

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING.....9-134,9-207

FITTING - STANDARD PROCEDURE,

PISTON...................9-139,9-211,9-51

FITTING - STANDARD PROCEDURE,

PISTON RING.........9-142,9-213,9-284,9-53

FITTING, STANDARD PROCEDURE -

CONNECTING ROD BEARING............9-49

FITTING, STANDARD PROCEDURE -

MAIN BEARING.......................9-44

FITTINGS - STANDARD PROCEDURE,

HANDLING TUBING...................24-45

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT......................14-8

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-27

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-27

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED....................5-10

FLARING - STANDARD PROCEDURE, ISO . . . 5-11

FLEX PLATE - INSTALLATION . . 9-138,9-210,9-48

FLEX PLATE - REMOVAL.......9-138,9-210,9-48

FLOOR - INSTALLATION, LOAD..........23-72

FLOOR - REMOVAL, LOAD.............23-71

FLOOR CONSOLE - INSTALLATION.......23-67

FLOOR CONSOLE - REMOVAL...........23-67

FLOOR DISTRIBUTION DUCT -

INSTALLATION.......................24-34

FLOOR DISTRIBUTION DUCT - REMOVAL . 24-33

FLOOR MATS - INSTALLATION, CARPETS . 23-65

FLOOR MATS - REMOVAL, CARPETS.....23-65

FLOOR SHIFT BOOT - INSTALLATION,

4WD ..............................23-62

FLOOR SHIFT BOOT - REMOVAL, 4WD....23-62

FLOOR SUPPORT CYLINDER -

INSTALLATION, LOAD.................23-72

FLOOR SUPPORT CYLINDER -

REMOVAL, LOAD.....................23-72

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-3

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..............7-54,7-56

FLOW 3.7L/4.7L/5.7L ENGINE -

DESCRIPTION, COOLING SYSTEM.........7-1

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION................19-43

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID - DESCRIPTION, POWER

STEERING............................0-3

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT............21-201,21-366

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE........21-203,21-367

FLUID CAPACITIES, SPECIFICATIONS.......0-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING................21-202,21-366

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-23

FLUID COOLER - INSTALLATION.........19-43

FLUID COOLER - REMOVAL............19-43

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.....21-441,21-476,21-507,21-537,

21-571

FLUID INDICATOR - DESCRIPTION,

WASHER

...........................8J-44

FLUID INDICATOR - OPERATION,

WASHER

...........................8J-44

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING

.........21-144,21-318

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT

.....21-201,

21-366

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE

..............................5-23FLUID LEVEL CHECK - STANDARD

PROCEDURE.................21-202,21-366

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-43

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-9

FLUID LEVEL SWITCH - INSTALLATION,

WASHER...........................8R-11

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-9

FLUID LEVEL SWITCH - REMOVAL,

WASHER...........................8R-10

FLUID RESERVOIR - INSTALLATION.......5-24

FLUID RESERVOIR - REMOVAL..........5-23

FLUID, SPECIFICATIONS - BRAKE.........5-23

FLUSH - SPECIFICATIONS, GAP.........23-95

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-17

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-40

FLYWHEEL - ASSEMBLY................6-11

FLYWHEEL - DIAGNOSIS AND TESTING....6-10

FLYWHEEL - DISASSEMBLY.............6-11

FLYWHEEL - INSTALLATION.............6-11

FLYWHEEL - REMOVAL.................6-11

FOG LAMP - INSTALLATION............8L-12

FOG LAMP - REMOVAL................8L-12

FOG LAMP RELAY - DESCRIPTION.......8L-12

FOG LAMP RELAY - INSTALLATION........8L-13

FOG LAMP RELAY - OPERATION.........8L-13

FOG LAMP RELAY - REMOVAL..........8L-13

FOOTMANS LOOP BRACKETS -

INSTALLATION, SEAT BACK REAR.......23-85

FOOTMANS LOOP BRACKETS -

REMOVAL, SEAT BACK REAR...........23-85

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE . . 9-239,9-9,

9-94

FRAME - INSTALLATION, GRILLE........23-40

FRAME - REAR - INSTALLATION, SEAT

CUSHION...........................23-85

FRAME - REAR - REMOVAL, SEAT

CUSHION...........................23-85

FRAME - REMOVAL, GRILLE............23-40

FRAME DIMENSIONS - SPECIFICATIONS . . 13-16

FRAME H-SECTION REPLACEMENT -

STANDARD PROCEDURE, REAR.........13-13

FRAME RAIL TIP REPLACEMENT -

STANDARD PROCEDURE, LIGHT DUTY

FRONT..............................13-4

FREE MODULE - INSTALLATION, HANDS . . . 8T-2

FREE MODULE - REMOVAL, HANDS.......8T-2

FRONT - INSTALLATION....5-16,5-21,5-22,5-34

FRONT - INSTALLATION...............22-14

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL.............9-136,9-208,9-275,9-46

FRONT - INSTALLATION, PROPELLER

SHAFT - HD...........................3-7

FRONT - INSTALLATION, PROPELLER

SHAFT- LD............................3-7

FRONT - INSTALLATION, SEAT..........23-81

FRONT - INSTALLATION, SEAT BACK

CUSHION / COVER...................23-82

FRONT - INSTALLATION, SEAT CUSHION

/ COVER............................23-83

FRONT - REMOVAL........5-13,5-17,5-21,5-33

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL................9-135,9-208,9-275,9-46

FRONT - REMOVAL, PROPELLER SHAFT

- HD ................................3-7

FRONT - REMOVAL, PROPELLER SHAFT-

LD ..................................3-6

FRONT - REMOVAL, SEAT..............23-81

FRONT - REMOVAL, SEAT BACK

CUSHION / COVER...................23-82

FRONT - REMOVAL, SEAT CUSHION /

COVER.............................23-83

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-2

FRONT AXLE - 9 1/4 AA -

ADJUSTMENTS

.......................3-59

FRONT AXLE - 9 1/4 AA - DIAGNOSIS

AND TESTING

........................3-54

FRONT AXLE - 9 1/4 AA - INSTALLATION

. . . 3-58

FRONT AXLE - 9 1/4 AA - REMOVAL

......3-57

FRONT AXLE - 9 1/4 AA - SPECIAL

TOOLS

..............................3-64FRONT AXLE - 9 1/4 AA -

SPECIFICATIONS......................3-63

FRONT AXLE - C205F - ADJUSTMENTS....3-32

FRONT AXLE - C205F - DIAGNOSIS AND

TESTING............................3-27

FRONT AXLE - C205F - INSTALLATION.....3-31

FRONT AXLE - C205F - REMOVAL........3-31

FRONT AXLE - C205F - SPECIAL TOOLS . . . 3-40

FRONT AXLE - C205F - SPECIFICATIONS . . . 3-39

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT.....................21-216

FRONT BEARING - REMOVAL, OUTPUT

SHAFT............................21-216

FRONT BRAKE HOSE - INSTALLATION.....5-13

FRONT BUMPER - INSTALLATION.........13-2

FRONT BUMPER - REMOVAL............13-2

FRONT CENTER SEAT BELT -

INSTALLATION......................8O-31

FRONT CENTER SEAT BELT - REMOVAL . . 8O-30

FRONT CENTER SEAT BELT &

RETRACTOR - INSTALLATION...........8O-29

FRONT CENTER SEAT BELT &

RETRACTOR - REMOVAL..............8O-29

FRONT CLUTCH - ASSEMBLY..........21-207

FRONT CLUTCH - DESCRIPTION........21-205

FRONT CLUTCH - DISASSEMBLY.......21-205

FRONT CLUTCH - INSPECTION.........21-206

FRONT CLUTCH - OPERATION.........21-205

FRONT CONTROL MODULE -

DESCRIPTION.....................8W-97-5

FRONT CONTROL MODULE -

DESCRIPTION........................8E-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING.....................8W-97-5

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING........................8E-5

FRONT CONTROL MODULE -

INSTALLATION....................8W-97-6

FRONT CONTROL MODULE -

INSTALLATION........................8E-5

FRONT CONTROL MODULE - OPERATION . 8W-97-5

FRONT CONTROL MODULE - OPERATION . . 8E-5

FRONT CONTROL MODULE - REMOVAL . 8W-97-6

FRONT CONTROL MODULE - REMOVAL....8E-5

FRONT CROSSMEMBER - INSTALLATION . . 13-22

FRONT CROSSMEMBER - REMOVAL.....13-22

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION........23-92

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL............23-92

FRONT DOOR INNER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR INNER BELT MOLDING -

REMOVAL..........................23-93

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION.......................23-93

FRONT DOOR OUTER BELT MOLDING -

REMOVAL..........................23-92

FRONT FASCIA - INSTALLATION..........13-3

FRONT FASCIA - REMOVAL..............13-2

FRONT FENDER - INSTALLATION........23-39

FRONT FENDER - REMOVAL............23-39

FRONT FRAME RAIL TIP REPLACEMENT

- STANDARD PROCEDURE, LIGHT

DUTY...............................13-4

FRONT HOSE - REMOVAL...............5-12

FRONT MOUNT - INSTALLATION . . . 9-147,9-218,

9-287,9-59

FRONT MOUNT - REMOVAL . . 9-146,9-217,9-286,

9-58

FRONT OUTBOARD SEAT BELT BUCKLE -

INSTALLATION......................8O-38

FRONT OUTBOARD SEAT BELT BUCKLE -

REMOVAL..........................8O-37

FRONT OUTPUT SHAFT SEAL -

INSTALLATION . . . 21-442,21-477,21-508,21-538,

21-572

FRONT OUTPUT SHAFT SEAL -

REMOVAL . 21-441,21-477,21-507,21-537,21-572

FRONT PARKING BRAKE CABLE -

INSTALLATION........................5-38

FRONT PARKING BRAKE CABLE -

REMOVAL

...........................5-36

FRONT SEAL - INSTALLATION, OIL

PUMP

............................21-391

FRONT SEAL - REMOVAL, OIL PUMP

....21-391

FRONT SERVO - ASSEMBLY

...........21-209

FRONT SERVO - CLEANING

...........21-209

DRINDEX 13

Description Group-Page Description Group-Page Description Group-Page

Page 2603 of 2627

HEATED SEAT MODULE - INSTALLATION . . . 8E-7

HEATED SEAT MODULE - INSTALLATION . . 8G-15

HEATED SEAT MODULE - OPERATION.....8E-6

HEATED SEAT MODULE - OPERATION....8G-14

HEATED SEAT MODULE - REMOVAL.......8E-7

HEATED SEAT MODULE - REMOVAL.....8G-15

HEATED SEAT SENSOR - DESCRIPTION . . . 8G-11

HEATED SEAT SENSOR - DIAGNOSIS

AND TESTING.......................8G-11

HEATED SEAT SENSOR - OPERATION....8G-11

HEATED SEAT SENSOR - REMOVAL......8G-11

HEATED SEAT SWITCH - DESCRIPTION . . . 8G-11

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8G-12

HEATED SEAT SWITCH - INSTALLATION . . 8G-13

HEATED SEAT SWITCH - OPERATION.....8G-12

HEATED SEAT SWITCH - REMOVAL......8G-13

HEATED SEAT SYSTEM - DESCRIPTION....8G-7

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING........................8G-8

HEATED SEAT SYSTEM - OPERATION.....8G-8

HEATER - 5.9L DIESEL - DESCRIPTION,

ENGINE BLOCK.......................7-37

HEATER - 5.9L DIESEL - INSTALLATION,

ENGINE BLOCK.......................7-38

HEATER - 5.9L DIESEL - OPERATION,

ENGINE BLOCK.......................7-38

HEATER - 5.9L DIESEL - REMOVAL,

ENGINE BLOCK.........................7-38

HEATER - DESCRIPTION, ENGINE BLOCK . . . 7-36

HEATER - DESCRIPTION, FUEL..........14-51

HEATER - DESCRIPTION, INTAKE AIR.....14-80

HEATER - DIAGNOSIS AND TESTING,

ENGINE BLOCK.......................7-36

HEATER - DIAGNOSIS AND TESTING,

FUEL..............................14-52

HEATER - INSTALLATION, ENGINE

BLOCK..............................7-37

HEATER - INSTALLATION, INTAKE AIR....14-80

HEATER - OPERATION, ENGINE BLOCK....7-36

HEATER - OPERATION, FUEL............14-51

HEATER - OPERATION, INTAKE AIR......14-80

HEATER - REMOVAL, ENGINE BLOCK......7-37

HEATER - REMOVAL, INTAKE AIR........14-80

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-1

HEATER CONTROL - DESCRIPTION, A/C . . . 24-14

HEATER CONTROL - INSTALLATION, A/C . . 24-15

HEATER CONTROL - REMOVAL, A/C......24-15

HEATER CORE - DESCRIPTION..........24-63

HEATER CORE - INSTALLATION.........24-63

HEATER CORE - OPERATION............24-63

HEATER CORE - REMOVAL.............24-63

HEATER INLET HOSE - INSTALLATION....24-64

HEATER INLET HOSE - REMOVAL........24-64

HEATER PERFORMANCE TEST -

DIAGNOSIS AND TESTING..............24-6

HEATER RELAY - DESCRIPTION, FUEL....14-52

HEATER RELAY - DESCRIPTION, INTAKE

AIR ...............................14-82

HEATER RELAY - INSTALLATION, FUEL . . . 14-53

HEATER RELAY - INSTALLATION, INTAKE

AIR ...............................14-82

HEATER RELAY - OPERATION, FUEL......14-52

HEATER RELAY - OPERATION, INTAKE

AIR ...............................14-82

HEATER RELAY - REMOVAL, FUEL.......14-52

HEATER RELAY - REMOVAL, INTAKE AIR . . 14-82

HEATER RETURN HOSE - INSTALLATION . . 24-65

HEATER RETURN HOSE - REMOVAL......24-64

HEIGHT ADJUSTMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HEIGHT MEASUREMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HEMI ENGINE - INSTALLATION, 3.7L/4.7L

AND 5.7L......................24-59,24-73

HEMI ENGINE - REMOVAL, 3.7L/4.7L

AND 5.7L......................24-57,24-71

HIGH BEAM INDICATOR - DESCRIPTION

. . 8J-28

HIGH BEAM INDICATOR - OPERATION

....8J-28

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER

...............8L-11

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER

...................8L-11

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER

...............8L-11HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER...................8L-11

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION.......................24-48

HIGH PRESSURE RELIEF VALVE -

OPERATION.........................24-48

HIGH SPEEDS - DESCRIPTION, TIRE

PRESSURE..........................22-7

HIGH/LOW RELAY - DESCRIPTION,

WIPER.............................8R-20

HIGH/LOW RELAY - DIAGNOSIS AND

TESTING, WIPER.....................8R-21

HIGH/LOW RELAY - INSTALLATION,

WIPER.............................8R-22

HIGH/LOW RELAY - OPERATION, WIPER . . 8R-20

HIGH/LOW RELAY - REMOVAL, WIPER . . . 8R-21

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-58

HINGE - INSTALLATION.....23-16,23-22,23-31,

23-46

HINGE - INSTALLATION, CENTER SEAT

BACK..............................23-79

HINGE - REMOVAL....23-16,23-22,23-31,23-46

HINGE - REMOVAL, CENTER SEAT BACK . . 23-78

HINGE COVER - INSTALLATION, CENTER

SEAT BACK INERTIA..................23-77

HINGE COVER - REMOVAL, CENTER

SEAT BACK INERTIA..................23-77

HITCH - INSTALLATION, TRAILER........13-25

HITCH - REMOVAL, TRAILER...........13-25

HOAT COOLANT - DESCRIPTION..........7-32

HOISTING - STANDARD PROCEDURE......0-20

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-14

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-14

HOLDDOWN - OPERATION, BATTERY.....8F-14

HOLDDOWN - REMOVAL, BATTERY......8F-14

HOLDER - INSTALLATION, CUP.........23-51

HOLDER - REMOVAL, CUP.............23-51

HOLDING CLUTCHES - DESCRIPTION....21-371

HOLDING CLUTCHES - OPERATION.....21-372

HOLE PLUG - INSTALLATION, CAMSHAFT

CORE..............................9-206

HOLE PLUG - REMOVAL, CAMSHAFT

CORE..............................9-205

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-8

HONING - STANDARD PROCEDURE,

CYLINDER BORE.................9-128,9-38

HOOD - INSTALLATION................23-47

HOOD - REMOVAL....................23-46

HOOK - INSTALLATION, COAT...........23-66

HOOK - REMOVAL, COAT..............23-66

HOOK ASSEMBLY - INSTALLATION,

FRONT TOW........................13-23

HOOK ASSEMBLY - REMOVAL, FRONT

TOW ..............................13-23

HORN - DIAGNOSIS AND TESTING.......8H-1

HORN - INSTALLATION.................8H-2

HORN - REMOVAL....................8H-2

HORN SWITCH - DESCRIPTION..........8H-2

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-2

HORN SYSTEM - DESCRIPTION..........8H-1

HORN SYSTEM - DIAGNOSIS AND

TESTING............................8H-1

HORN SYSTEM - OPERATION............8H-1

HOSE - GEAR TO COOLER -

INSTALLATION, RETURN..........19-44,19-45

HOSE - GEAR TO COOLER - REMOVAL,

RETURN......................19-44,19-45

HOSE - INSTALLATION, FRONT BRAKE.....5-13

HOSE - INSTALLATION, HEATER INLET....24-64

HOSE - INSTALLATION, HEATER RETURN . 24-65

HOSE - INSTALLATION, PRESSURE . 19-44,19-45

HOSE - INSTALLATION, REAR BRAKE......5-12

HOSE - REMOVAL, FRONT..............5-12

HOSE - REMOVAL, HEATER INLET.......24-64

HOSE - REMOVAL, HEATER RETURN.....24-64

HOSE - REMOVAL, PRESSURE.....19-44,19-45

HOSE - REMOVAL, REAR BRAKE

.........5-11

HOSE - RESERVOIR TO COOLER -

INSTALLATION, RETURN

..........19-44,19-45

HOSE - RESERVOIR TO COOLER -

REMOVAL, RETURN

.............19-44,19-45

HOSE ASSEMBLY - INSTALLATION, REAR

TUBE

...............................5-13

HOSE ASSEMBLY - REMOVAL, REAR

TUBE

...............................5-12HOSE CLAMPS - DESCRIPTION...........7-3

HOSE CLAMPS - OPERATION.............7-5

HOSES/TUBES - DESCRIPTION, WASHER . 8R-11

HOSES/TUBES - OPERATION, WASHER . . . 8R-11

HOUSING - ASSEMBLY, HVAC...........24-35

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH..............................6-7

HOUSING - DISASSEMBLY, HVAC........24-35

HOUSING - INSTALLATION, CLUTCH.......6-9

HOUSING - INSTALLATION, GEAR........9-300

HOUSING - INSTALLATION, HVAC........24-36

HOUSING - INSTALLATION, ROCKER.....9-255

HOUSING - REMOVAL, CLUTCH...........6-9

HOUSING - REMOVAL, GEAR...........9-299

HOUSING - REMOVAL, HVAC...........24-34

HOUSING - REMOVAL, ROCKER.........9-255

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION...........21-440

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION...............21-440

HOUSING COVER - INSTALLATION, GEAR . 9-301

HOUSING COVER - REMOVAL, GEAR.....9-301

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER.........21-144,21-318

HOUSING SEAL - INSTALLATION,

ADAPTER...............21-128,21-364,21-85

HOUSING SEAL - INSTALLATION,

EXTENSION . 21-128,21-201,21-507,21-536,21-85

HOUSING SEAL - REMOVAL, ADAPTER . . 21-128,

21-364,21-85

HOUSING SEAL - REMOVAL,

EXTENSION . 21-128,21-201,21-507,21-536,21-85

HOUSING SEAL AND DUST BOOT -

INSTALLATION, EXTENSION.....21-476,21-571

HOUSING SEAL AND DUST BOOT -

REMOVAL, EXTENSION.........21-476,21-571

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION.....................8W-01-1

H-SECTION REPLACEMENT - STANDARD

PROCEDURE, REAR FRAME............13-13

HUB / BEARING - INSTALLATION.........2-32

HUB / BEARING - REMOVAL.............2-31

HVAC HOUSING - ASSEMBLY...........24-35

HVAC HOUSING - DISASSEMBLY........24-35

HVAC HOUSING - INSTALLATION........24-36

HVAC HOUSING - REMOVAL............24-34

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING........................5-30

HYDRAULIC LASH ADJUSTER -

DIAGNOSIS AND TESTING.........9-125,9-32

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING......21-141,21-316

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS..............21-176,21-337

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING...........................9-210

HYDRAULIC TAPPETS - INSTALLATION . . . 9-211

HYDRAULIC TAPPETS - REMOVAL.......9-211

HYDROBOOST - INSTALLATION..........5-27

HYDROBOOST - INSTALLATION, ALL

EXCEPT.............................5-27

HYDROBOOST - REMOVAL..............5-26

HYDROBOOST - REMOVAL, ALL EXCEPT . . . 5-26

HYDRO-BOOST BRAKE BOOSTER -

INSTALLATION........................5-32

HYDRO-BOOST BRAKE BOOSTER -

REMOVAL

...........................5-31

HYDROFORM FENDER RAIL REPAIR -

STANDARD PROCEDURE

...............13-11

HYDROSTATIC LOCK - STANDARD

PROCEDURE

...................9-190,9-240

IDENTIFICATION - DESCRIPTION,

FASTENER

.........................Intro.-5

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION

.............8W-01-6

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE

..............Intro.-1

IDLE AIR CONTROL MOTOR -

DESCRIPTION

.......................14-28

IDLE AIR CONTROL MOTOR -

INSTALLATION

.......................14-29

IDLE AIR CONTROL MOTOR -

OPERATION

.........................14-28

IDLE AIR CONTROL MOTOR - REMOVAL

. . 14-29

IDLER SHAFT - INSTALLATION

......9-179,9-81

IDLER SHAFT - REMOVAL

..........9-179,9-81

IGNITION - SPECIFICATIONS, TORQUE

.....8I-3

16 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2613 of 2627

RAIL - DESCRIPTION, FUEL INJECTOR....14-78

RAIL - INSTALLATION, FUEL............14-15

RAIL - INSTALLATION, FUEL INJECTOR . . . 14-78

RAIL - OPERATION, FUEL..............14-12

RAIL - OPERATION, FUEL INJECTOR.....14-78

RAIL - REMOVAL, FUEL...............14-13

RAIL - REMOVAL, FUEL INJECTOR.......14-78

RAIL REPAIR - STANDARD PROCEDURE,

HYDROFORM FENDER.................13-11

RAIL TIP REPLACEMENT - STANDARD

PROCEDURE, LIGHT DUTY FRONT

FRAME..............................13-4

RAIL WEATHERSTRIP - INSTALLATION,

DRIP..............................23-91

RAIL WEATHERSTRIP - REMOVAL, DRIP . . 23-91

RAIL WEATHERSTRIP RETAINER -

INSTALLATION, DRIP.................23-92

RAIL WEATHERSTRIP RETAINER -

REMOVAL, DRIP.....................23-92

RANGE SENSOR - DESCRIPTION,

TRANSMISSION...............21-263,21-405

RANGE SENSOR - INSTALLATION,

TRANSMISSION.....................21-266

RANGE SENSOR - OPERATION,

TRANSMISSION...............21-263,21-405

RANGE SENSOR - REMOVAL,

TRANSMISSION.....................21-265

RANGE SENSOR (TRS) - DIAGNOSIS

AND TESTING, TRANSMISSION........21-264

RATINGS, SPECIFICATIONS -

GENERATOR........................8F-20

RE TRANSMISSION, SPECIAL TOOLS....21-191

READING LAMP - DESCRIPTION.........8L-28

READING LAMP - INSTALLATION........8L-29

READING LAMP - OPERATION..........8L-28

READING LAMP - REMOVAL............8L-28

READING/COURTESY LAMP

REPLACEMENT - STANDARD

PROCEDURE.........................8M-3

REAR AXLE - 10 1/2 AA -

ADJUSTMENTS......................3-116

REAR AXLE - 10 1/2 AA - DIAGNOSIS

AND TESTING.......................3-112

REAR AXLE - 10 1/2 AA - INSTALLATION . . 3-116

REAR AXLE - 10 1/2 AA - REMOVAL.....3-115

REAR AXLE - 10 1/2 AA - SPECIAL

TOOLS.............................3-120

REAR AXLE - 10 1/2 AA -

SPECIFICATIONS.....................3-120

REAR AXLE - 11 1/2 AA -

ADJUSTMENTS......................3-144

REAR AXLE - 11 1/2 AA - DIAGNOSIS

AND TESTING.......................3-140

REAR AXLE - 11 1/2 AA - INSTALLATION . . 3-144

REAR AXLE - 11 1/2 AA - REMOVAL.....3-143

REAR AXLE - 11 1/2 AA - SPECIAL

TOOLS.............................3-148

REAR AXLE - 11 1/2 AA -

SPECIFICATIONS.....................3-148

REAR AXLE - 9 1/4 - ADJUSTMENTS......3-83

REAR AXLE - 9 1/4 - DIAGNOSIS AND

TESTING............................3-80

REAR AXLE - 9 1/4 - INSTALLATION......3-83

REAR AXLE - 9 1/4 - REMOVAL..........3-83

REAR AXLE - 9 1/4 - SPECIAL TOOLS.....3-90

REAR AXLE - 9 1/4 - SPECIFICATIONS.....3-90

REAR BEARING - INSTALLATION,

OUTPUT SHAFT.....................21-217

REAR BEARING - REMOVAL, OUTPUT

SHAFT............................21-216

REAR BRAKE HOSE - INSTALLATION......5-12

REAR BRAKE HOSE - REMOVAL..........5-11

REAR BUMPER - INSTALLATION..........13-4

REAR BUMPER - REMOVAL.............13-3

REAR CAB BACK PANEL TRIM -

INSTALLATION.......................23-69

REAR CAB BACK PANEL TRIM -

REMOVAL..........................23-68

REAR CABLE - INSTALLATION, LEFT......5-39

REAR CABLE - INSTALLATION, RIGHT.....5-38

REAR CABLE - REMOVAL, LEFT..........5-38

REAR CABLE - REMOVAL, RIGHT

.........5-37

REAR CENTER SEAT BELT &

RETRACTOR - INSTALLATION

...........8O-45

REAR CENTER SEAT BELT &

RETRACTOR - REMOVAL

..............8O-44

REAR CLUTCH - ASSEMBLY

...........21-249

REAR CLUTCH - CLEANING

...........21-248REAR CLUTCH - DESCRIPTION.........21-247

REAR CLUTCH - DISASSEMBLY........21-248

REAR CLUTCH - INSPECTION..........21-248

REAR CLUTCH - OPERATION..........21-248

REAR DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION........23-93

REAR DOOR GLASS RUN

WEATHERSTRIP - REMOVAL............23-93

REAR DOOR INNER BELT MOLDING -

INSTALLATION.......................23-94

REAR DOOR INNER BELT MOLDING -

REMOVAL..........................23-94

REAR DOOR OUTER BELT MOLDING -

INSTALLATION.......................23-94

REAR DOOR OUTER BELT MOLDING -

REMOVAL..........................23-93

REAR DOOR SILL TRIM COVER -

INSTALLATION.......................23-71

REAR DOOR SILL TRIM COVER -

REMOVAL..........................23-71

REAR DRUM IN HAT BRAKE - CLEANING . . . 5-39

REAR DRUM IN HAT BRAKE -

INSPECTION.........................5-39

REAR DUAL WHEELS - INSTALLATION.....5-35

REAR DUAL WHEELS - REMOVAL........5-34

REAR FENDER - INSTALLATION.........23-44

REAR FENDER - REMOVAL.............23-44

REAR FRAME H-SECTION REPLACEMENT

- STANDARD PROCEDURE.............13-13

REAR MOUNT - INSTALLATION....9-149,9-220,

9-288,9-61

REAR MOUNT - REMOVAL . . . 9-149,9-220,9-288,

9-61

REAR OIL SEAL RETAINER -

INSTALLATION, CRANKSHAFT......9-210,9-277

REAR OIL SEAL RETAINER - REMOVAL,

CRANKSHAFT..................9-209,9-277

REAR OUTBOARD SEAT BELT &

RETRACTOR - INSTALLATION...........8O-47

REAR OUTBOARD SEAT BELT &

RETRACTOR - REMOVAL..............8O-46

REAR PARK BRAKE CABLE -

INSTALLATION........................5-38

REAR PARK BRAKE CABLE - REMOVAL....5-37

REAR PROPELLER SHAFT -

INSTALLATION.........................3-8

REAR PROPELLER SHAFT - REMOVAL......3-8

REAR SEAL AREA LEAKS - DIAGNOSIS

AND TESTING..............9-137,9-209,9-65

REAR SERVO - ASSEMBLY............21-251

REAR SERVO - CLEANING............21-251

REAR SERVO - DESCRIPTION..........21-251

REAR SERVO - DISASSEMBLY.........21-251

REAR SERVO - OPERATION...........21-251

REAR TUBE / HOSE ASSEMBLY -

INSTALLATION........................5-13

REAR TUBE / HOSE ASSEMBLY -

REMOVAL...........................5-12

REAR VIEW MIRROR - REMOVAL........23-69

REAR VIEW MIRROR SUPPORT

BRACKET - INSTALLATION.............23-70

REAR WHEEL ANTILOCK - DIAGNOSIS

AND TESTING

........................5-48

REAR WHEEL INSTALLATION -

STANDARD PROCEDURE, DUAL

.........22-12

REAR WHEEL SPEED SENSOR -

DIAGNOSIS AND TESTING

..............5-49

REAR WHEEL SPEED SENSOR -

INSTALLATION

........................5-48

REAR WHEEL SPEED SENSOR -

REMOVAL

...........................5-48

REAR WHEELHOUSE SPLASH SHIELD -

INSTALLATION

.......................23-41

REAR WHEELHOUSE SPLASH SHIELD -

REMOVAL

..........................23-41

REAR WINDOW DEFOGGER RELAY -

DESCRIPTION

........................8G-2

REAR WINDOW DEFOGGER RELAY -

INSTALLATION

.......................8G-4

REAR WINDOW DEFOGGER RELAY -

OPERATION

..........................8G-3

REAR WINDOW DEFOGGER RELAY -

REMOVAL

...........................8G-3

REAR WINDOW DEFOGGER SWITCH -

DESCRIPTION

........................8G-4

REAR WINDOW DEFOGGER SWITCH -

OPERATION

..........................8G-4REAR WINDOW DEFOGGER SYSTEM -

DIAGNOSIS AND TESTING..............8G-2

RECEIVER - INSTALLATION, ASH........23-51

RECEIVER - REMOVAL, ASH............23-50

RECIRCULATION DOOR - INSTALLATION . . 24-40

RECIRCULATION DOOR - REMOVAL......24-39

RECIRCULATION DOOR ACTUATOR -

DESCRIPTION.......................24-24

RECIRCULATION DOOR ACTUATOR -

INSTALLATION.......................24-25

RECIRCULATION DOOR ACTUATOR -

OPERATION.........................24-24

RECIRCULATION DOOR ACTUATOR -

REMOVAL..........................24-24

RECOVERY - STANDARD PROCEDURE,

REFRIGERANT.......................24-47

RECOVERY CONTAINER- GAS ENGINES -

DESCRIPTION, COOLANT...............7-33

RECOVERY CONTAINER- GAS ENGINES -

INSTALLATION, COOLANT...............7-33

RECOVERY CONTAINER- GAS ENGINES -

OPERATION, COOLANT.................7-33

RECOVERY CONTAINER- GAS ENGINES -

REMOVAL, COOLANT..................7-33

REDUCER - DESCRIPTION, SEAT BELT

TENSION...........................8O-53

REDUCER - DIAGNOSIS AND TESTING,

SEAT BELT TENSION..................8O-54

REDUCER - OPERATION, SEAT BELT

TENSION...........................8O-54

REFACING - STANDARD PROCEDURE . 9-202,9-28

REFACING - STANDARD PROCEDURE,

CYLINDER BLOCK....................9-264

REFILLING COOLING SYSTEM - ALL GAS

ENGINES - STANDARD PROCEDURE......7-18

REFILLING COOLING SYSTEM 5.9L

DIESEL ENGINE - STANDARD

PROCEDURE.........................7-19

REFRIGERANT - DESCRIPTION..........24-67

REFRIGERANT - OPERATION............24-67

REFRIGERANT LINE - DESCRIPTION......24-42

REFRIGERANT LINE COUPLER -

DESCRIPTION.......................24-67

REFRIGERANT LINE COUPLER -

INSTALLATION.......................24-68

REFRIGERANT LINE COUPLER -

OPERATION.........................24-67

REFRIGERANT LINE COUPLER -

REMOVAL..........................24-68

REFRIGERANT LINES - OPERATION......24-42

REFRIGERANT OIL - DESCRIPTION......24-68

REFRIGERANT OIL - OPERATION........24-69

REFRIGERANT OIL LEVEL - STANDARD

PROCEDURE........................24-69

REFRIGERANT RECOVERY - STANDARD

PROCEDURE........................24-47

REFRIGERANT SYSTEM CHARGE -

STANDARD PROCEDURE...............24-47

REFRIGERANT SYSTEM EVACUATE -

STANDARD PROCEDURE...............24-47

REFRIGERANT SYSTEM LEAKS -

DIAGNOSIS AND TESTING.............24-44

REFRIGERANT SYSTEM SERVICE

EQUIPMENT - STANDARD PROCEDURE . . . 24-46

REGULATOR - DESCRIPTION, FUEL

FILTER/PRESSURE.....................14-5

REGULATOR - DESCRIPTION, VOLTAGE . . . 8F-25

REGULATOR - MANUAL - INSTALLATION,

WINDOW......................23-27,23-35

REGULATOR - MANUAL - REMOVAL,

WINDOW......................23-26,23-35

REGULATOR - OPERATION, FUEL

FILTER/PRESSURE.....................14-6

REGULATOR - OPERATION, VOLTAGE.....8F-25

REGULATOR - POWER - INSTALLATION,

WINDOW......................23-26,23-34

REGULATOR - POWER - REMOVAL,

WINDOW......................23-25,23-34

RELAY - DESCRIPTION, A/C

COMPRESSOR CLUTCH...............24-13

RELAY - DESCRIPTION, FOG LAMP......8L-12

RELAY - DESCRIPTION, FUEL HEATER

....14-52

RELAY - DESCRIPTION, FUEL PUMP

.....14-27

RELAY - DESCRIPTION, INTAKE AIR

HEATER

............................14-82

RELAY - DESCRIPTION, PARK LAMP

.....8L-20

RELAY - DESCRIPTION, REAR WINDOW

DEFOGGER

..........................8G-2

26 INDEXDR

Description Group-Page Description Group-Page Description Group-Page