Door DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2347 of 2627

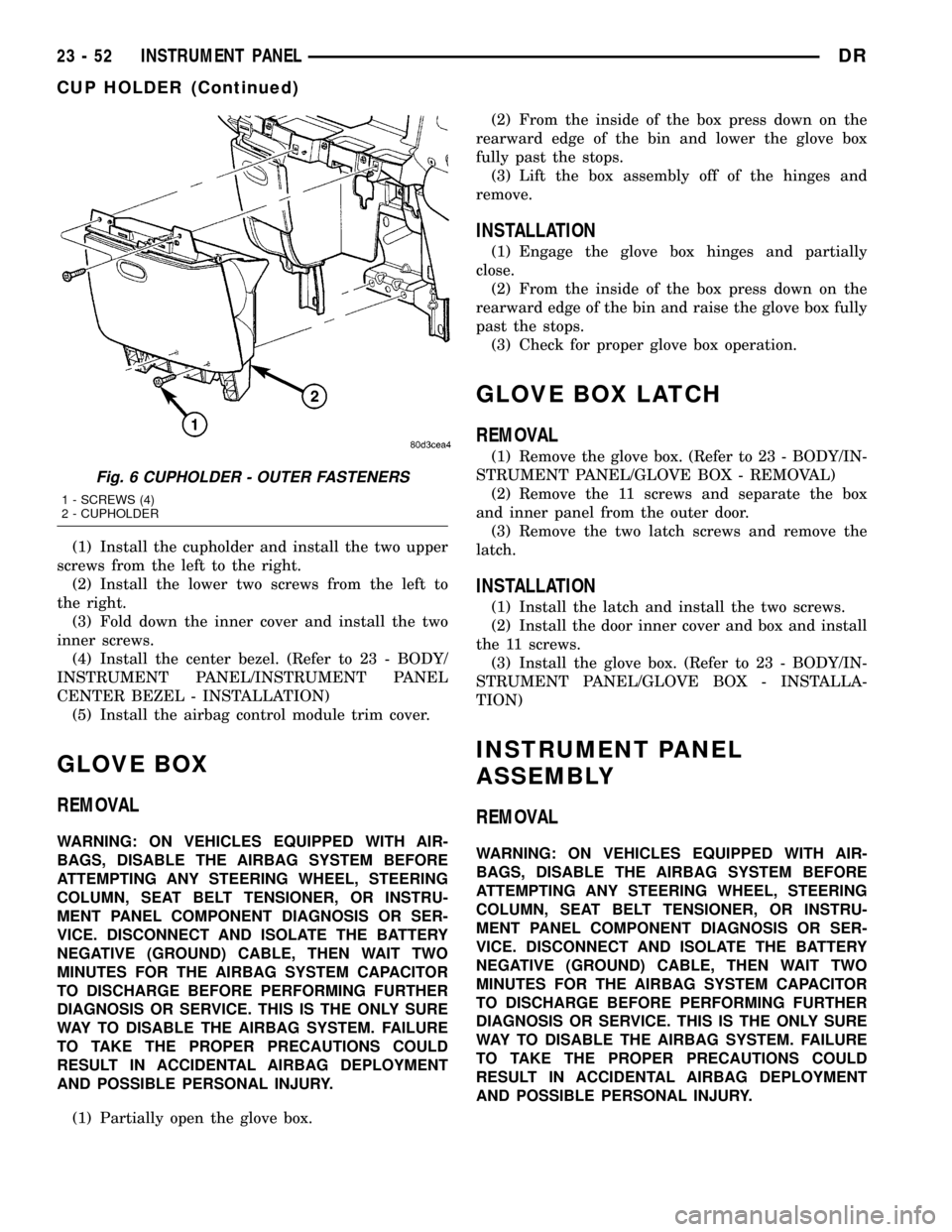

(1) Install the cupholder and install the two upper

screws from the left to the right.

(2) Install the lower two screws from the left to

the right.

(3) Fold down the inner cover and install the two

inner screws.

(4) Install the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - INSTALLATION)

(5) Install the airbag control module trim cover.

GLOVE BOX

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Partially open the glove box.(2) From the inside of the box press down on the

rearward edge of the bin and lower the glove box

fully past the stops.

(3) Lift the box assembly off of the hinges and

remove.

INSTALLATION

(1) Engage the glove box hinges and partially

close.

(2) From the inside of the box press down on the

rearward edge of the bin and raise the glove box fully

past the stops.

(3) Check for proper glove box operation.

GLOVE BOX LATCH

REMOVAL

(1) Remove the glove box. (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL)

(2) Remove the 11 screws and separate the box

and inner panel from the outer door.

(3) Remove the two latch screws and remove the

latch.

INSTALLATION

(1) Install the latch and install the two screws.

(2) Install the door inner cover and box and install

the 11 screws.

(3) Install the glove box. (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION)

INSTRUMENT PANEL

ASSEMBLY

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Fig. 6 CUPHOLDER - OUTER FASTENERS

1 - SCREWS (4)

2 - CUPHOLDER

23 - 52 INSTRUMENT PANELDR

CUP HOLDER (Continued)

Page 2352 of 2627

(2) Position the switch bezel and seat the attach-

ment clips fully.

(3) Seat the clips on the steering column opening

cover and the lower drivers side bezel fully.

INSTRUMENT PANEL CENTER

BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: When removing and installing the center

bezel, use tape or other suitable material to protect

the cupholder and ash receiver from damage.

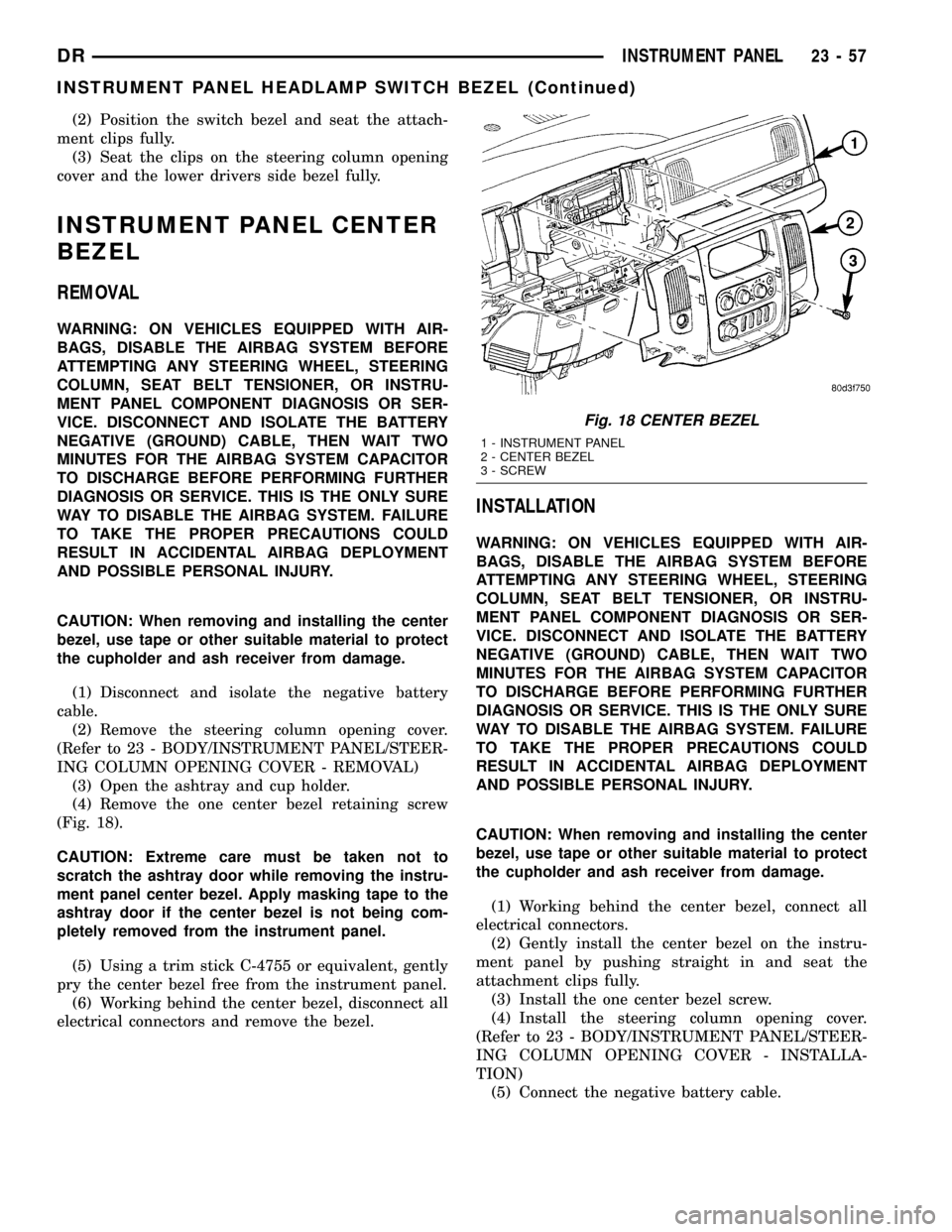

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL)

(3) Open the ashtray and cup holder.

(4) Remove the one center bezel retaining screw

(Fig. 18).

CAUTION: Extreme care must be taken not to

scratch the ashtray door while removing the instru-

ment panel center bezel. Apply masking tape to the

ashtray door if the center bezel is not being com-

pletely removed from the instrument panel.

(5) Using a trim stick C-4755 or equivalent, gently

pry the center bezel free from the instrument panel.

(6) Working behind the center bezel, disconnect all

electrical connectors and remove the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: When removing and installing the center

bezel, use tape or other suitable material to protect

the cupholder and ash receiver from damage.

(1) Working behind the center bezel, connect all

electrical connectors.

(2) Gently install the center bezel on the instru-

ment panel by pushing straight in and seat the

attachment clips fully.

(3) Install the one center bezel screw.

(4) Install the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

(5) Connect the negative battery cable.

Fig. 18 CENTER BEZEL

1 - INSTRUMENT PANEL

2 - CENTER BEZEL

3 - SCREW

DRINSTRUMENT PANEL 23 - 57

INSTRUMENT PANEL HEADLAMP SWITCH BEZEL (Continued)

Page 2357 of 2627

INTERIOR

TABLE OF CONTENTS

page page

INTERIOR

CAUTION.............................62

4WD FLOOR SHIFT BOOT

REMOVAL.............................62

INSTALLATION.........................62

A-PILLAR TRIM/GRAB HANDLE

REMOVAL.............................63

INSTALLATION.........................63

B-PILLAR LOWER TRIM

REMOVAL.............................63

INSTALLATION.........................64

B-PILLAR UPPER TRIM

REMOVAL.............................64

INSTALLATION.........................64

CARPETS AND FLOOR MATS

REMOVAL.............................65

INSTALLATION.........................65

COAT HOOK

REMOVAL.............................66

INSTALLATION.........................66

COWL TRIM

REMOVAL.............................66

INSTALLATION.........................66

C-PILLAR LOWER TRIM

REMOVAL.............................66

INSTALLATION.........................67

C-PILLAR UPPER TRIM

REMOVAL.............................67

INSTALLATION.........................67

FLOOR CONSOLE

REMOVAL.............................67

INSTALLATION.........................67

HEADLINER

REMOVAL.............................68INSTALLATION.........................68

B-PILLAR GRAB HANDLE

REMOVAL.............................68

INSTALLATION.........................68

REAR CAB BACK PANEL TRIM

REMOVAL.............................68

INSTALLATION.........................69

REAR VIEW MIRROR

REMOVAL.............................69

INSTALLATION

INSTALLATION.......................70

INSTALLATION - REAR VIEW MIRROR

SUPPORT BRACKET...................70

SUN VISOR

REMOVAL.............................70

INSTALLATION.........................70

SUN VISOR SUPPORT

REMOVAL.............................70

INSTALLATION.........................71

BODY VENT

REMOVAL.............................71

INSTALLATION.........................71

REAR DOOR SILL TRIM COVER

REMOVAL.............................71

INSTALLATION.........................71

LOAD FLOOR

REMOVAL.............................71

INSTALLATION.........................72

LOAD FLOOR SUPPORT CYLINDER

REMOVAL.............................72

INSTALLATION.........................72

INTERIOR

CAUTION

CAUTION:: Do not attempt to remove interior trim

panels/moldings without first removing the neces-

sary adjacent panels. To avoid damaging the pan-

els, ensure that all the screws and clips are

removed before attempting to remove an interior

trim panel/molding. Trim panels are somewhat flex-

ible but can be damaged if handled improperly.

4WD FLOOR SHIFT BOOT

REMOVAL

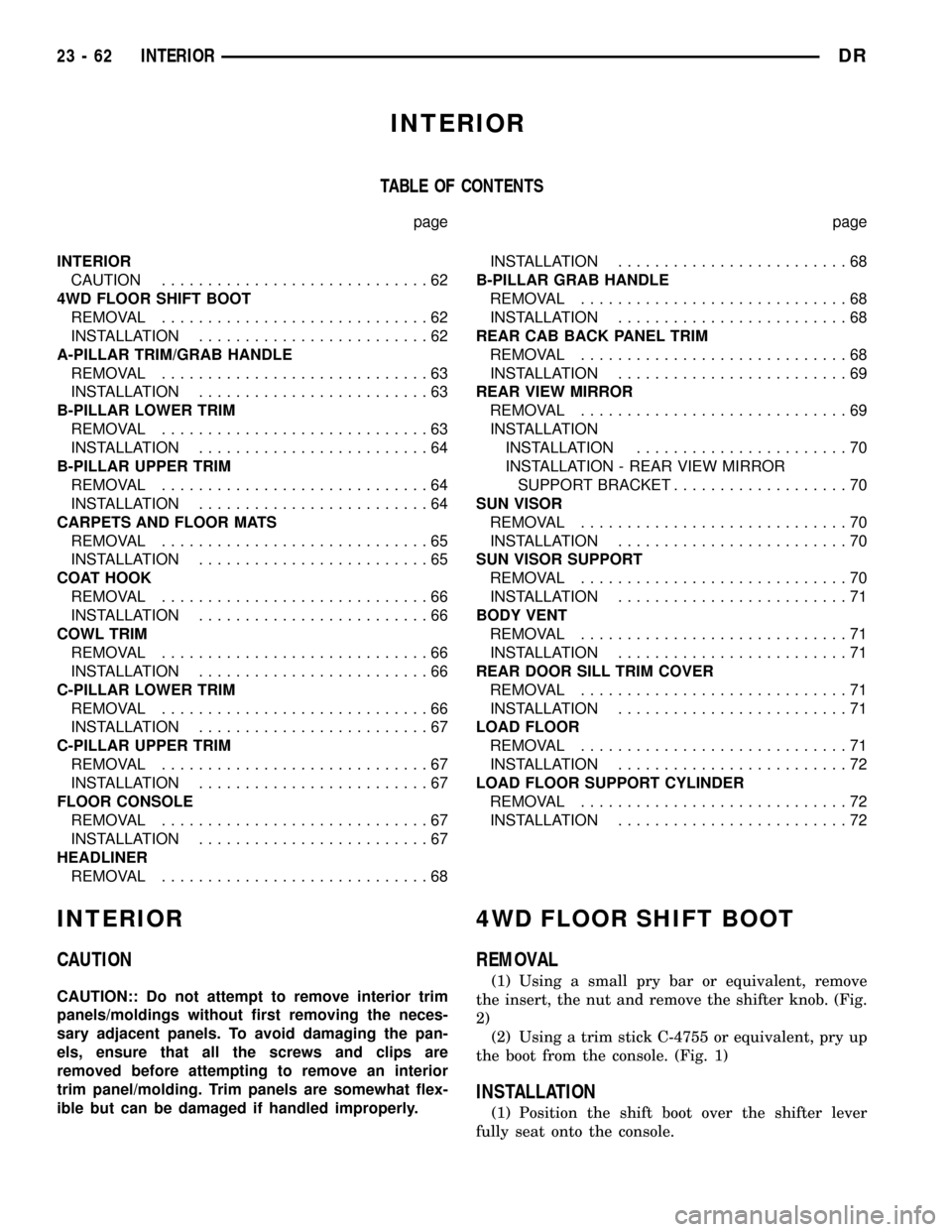

(1) Using a small pry bar or equivalent, remove

the insert, the nut and remove the shifter knob. (Fig.

2)

(2) Using a trim stick C-4755 or equivalent, pry up

the boot from the console. (Fig. 1)

INSTALLATION

(1) Position the shift boot over the shifter lever

fully seat onto the console.

23 - 62 INTERIORDR

Page 2358 of 2627

(2) Install the shifter knob and nut and tighten to

27 N´m (20 ft. lbs.).

(3) Position the insert and seat into the knob fully.

A-PILLAR TRIM/GRAB HANDLE

REMOVAL

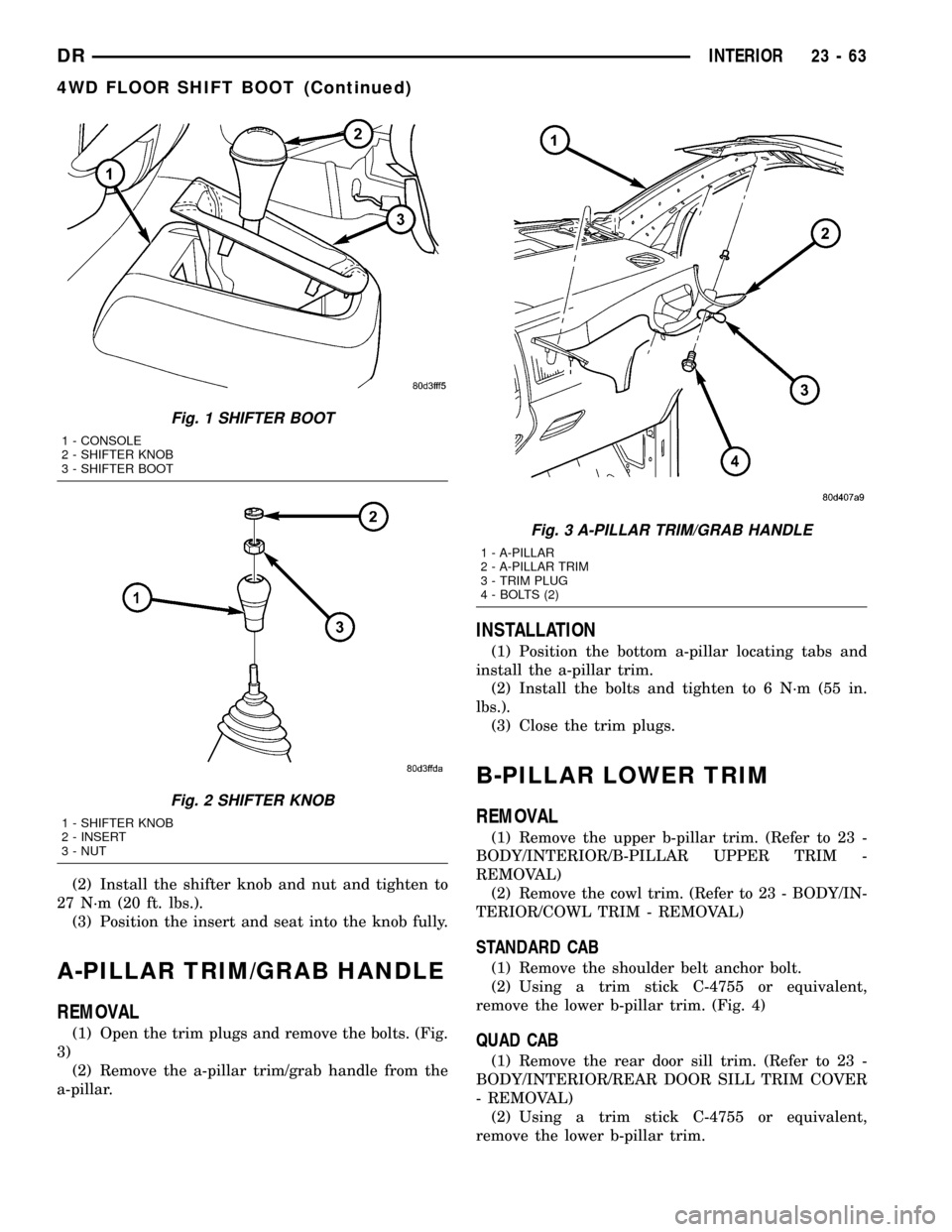

(1) Open the trim plugs and remove the bolts. (Fig.

3)

(2) Remove the a-pillar trim/grab handle from the

a-pillar.

INSTALLATION

(1) Position the bottom a-pillar locating tabs and

install the a-pillar trim.

(2) Install the bolts and tighten to 6 N´m (55 in.

lbs.).

(3) Close the trim plugs.

B-PILLAR LOWER TRIM

REMOVAL

(1) Remove the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(2) Remove the cowl trim. (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM - REMOVAL)

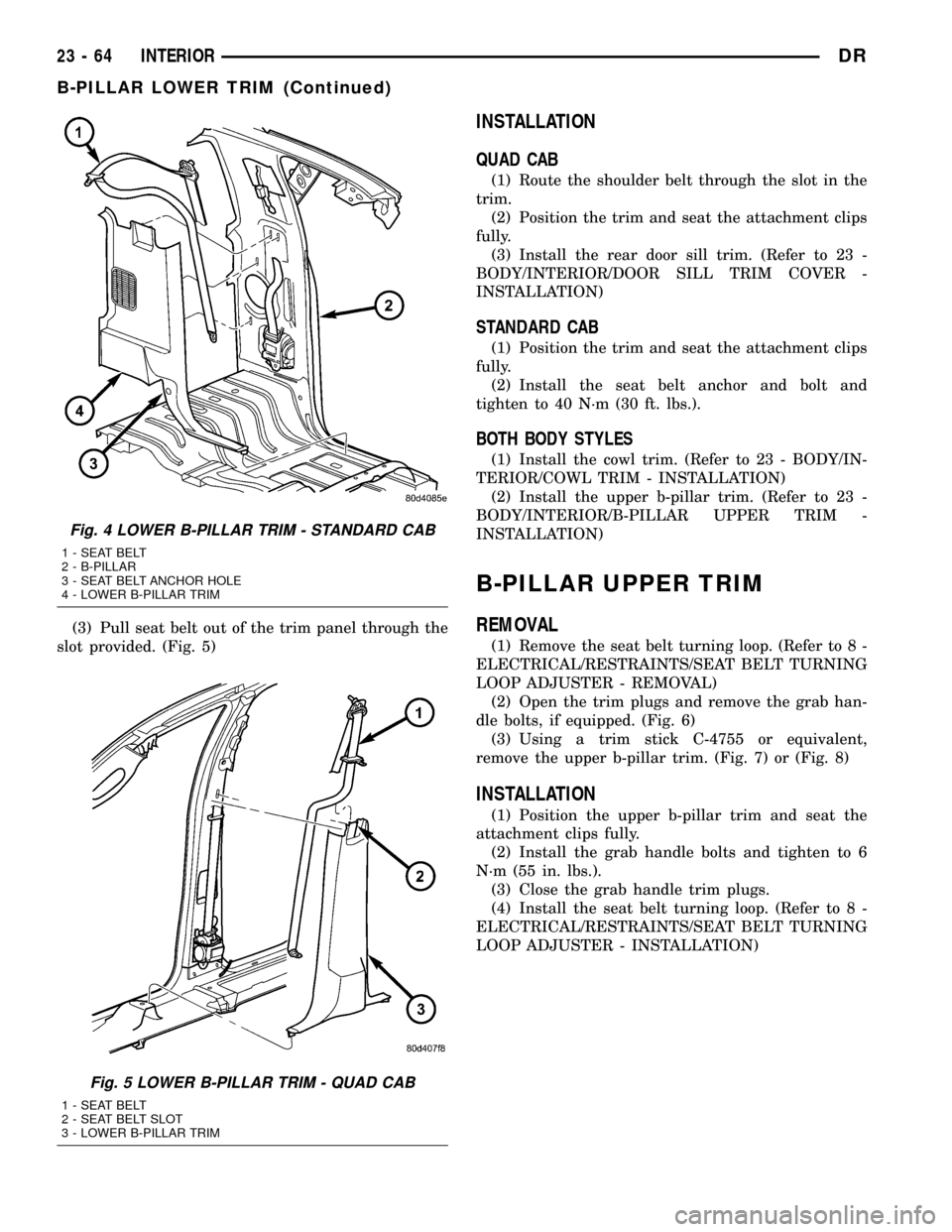

STANDARD CAB

(1) Remove the shoulder belt anchor bolt.

(2) Using a trim stick C-4755 or equivalent,

remove the lower b-pillar trim. (Fig. 4)

QUAD CAB

(1) Remove the rear door sill trim. (Refer to 23 -

BODY/INTERIOR/REAR DOOR SILL TRIM COVER

- REMOVAL)

(2) Using a trim stick C-4755 or equivalent,

remove the lower b-pillar trim.

Fig. 1 SHIFTER BOOT

1 - CONSOLE

2 - SHIFTER KNOB

3 - SHIFTER BOOT

Fig. 2 SHIFTER KNOB

1 - SHIFTER KNOB

2 - INSERT

3 - NUT

Fig. 3 A-PILLAR TRIM/GRAB HANDLE

1 - A-PILLAR

2 - A-PILLAR TRIM

3 - TRIM PLUG

4 - BOLTS (2)

DRINTERIOR 23 - 63

4WD FLOOR SHIFT BOOT (Continued)

Page 2359 of 2627

(3) Pull seat belt out of the trim panel through the

slot provided. (Fig. 5)

INSTALLATION

QUAD CAB

(1) Route the shoulder belt through the slot in the

trim.

(2) Position the trim and seat the attachment clips

fully.

(3) Install the rear door sill trim. (Refer to 23 -

BODY/INTERIOR/DOOR SILL TRIM COVER -

INSTALLATION)

STANDARD CAB

(1) Position the trim and seat the attachment clips

fully.

(2) Install the seat belt anchor and bolt and

tighten to 40 N´m (30 ft. lbs.).

BOTH BODY STYLES

(1) Install the cowl trim. (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM - INSTALLATION)

(2) Install the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION)

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove the seat belt turning loop. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT TURNING

LOOP ADJUSTER - REMOVAL)

(2) Open the trim plugs and remove the grab han-

dle bolts, if equipped. (Fig. 6)

(3) Using a trim stick C-4755 or equivalent,

remove the upper b-pillar trim. (Fig. 7) or (Fig. 8)

INSTALLATION

(1) Position the upper b-pillar trim and seat the

attachment clips fully.

(2) Install the grab handle bolts and tighten to 6

N´m (55 in. lbs.).

(3) Close the grab handle trim plugs.

(4) Install the seat belt turning loop. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT TURNING

LOOP ADJUSTER - INSTALLATION)

Fig. 4 LOWER B-PILLAR TRIM - STANDARD CAB

1 - SEAT BELT

2 - B-PILLAR

3 - SEAT BELT ANCHOR HOLE

4 - LOWER B-PILLAR TRIM

Fig. 5 LOWER B-PILLAR TRIM - QUAD CAB

1 - SEAT BELT

2 - SEAT BELT SLOT

3 - LOWER B-PILLAR TRIM

23 - 64 INTERIORDR

B-PILLAR LOWER TRIM (Continued)

Page 2361 of 2627

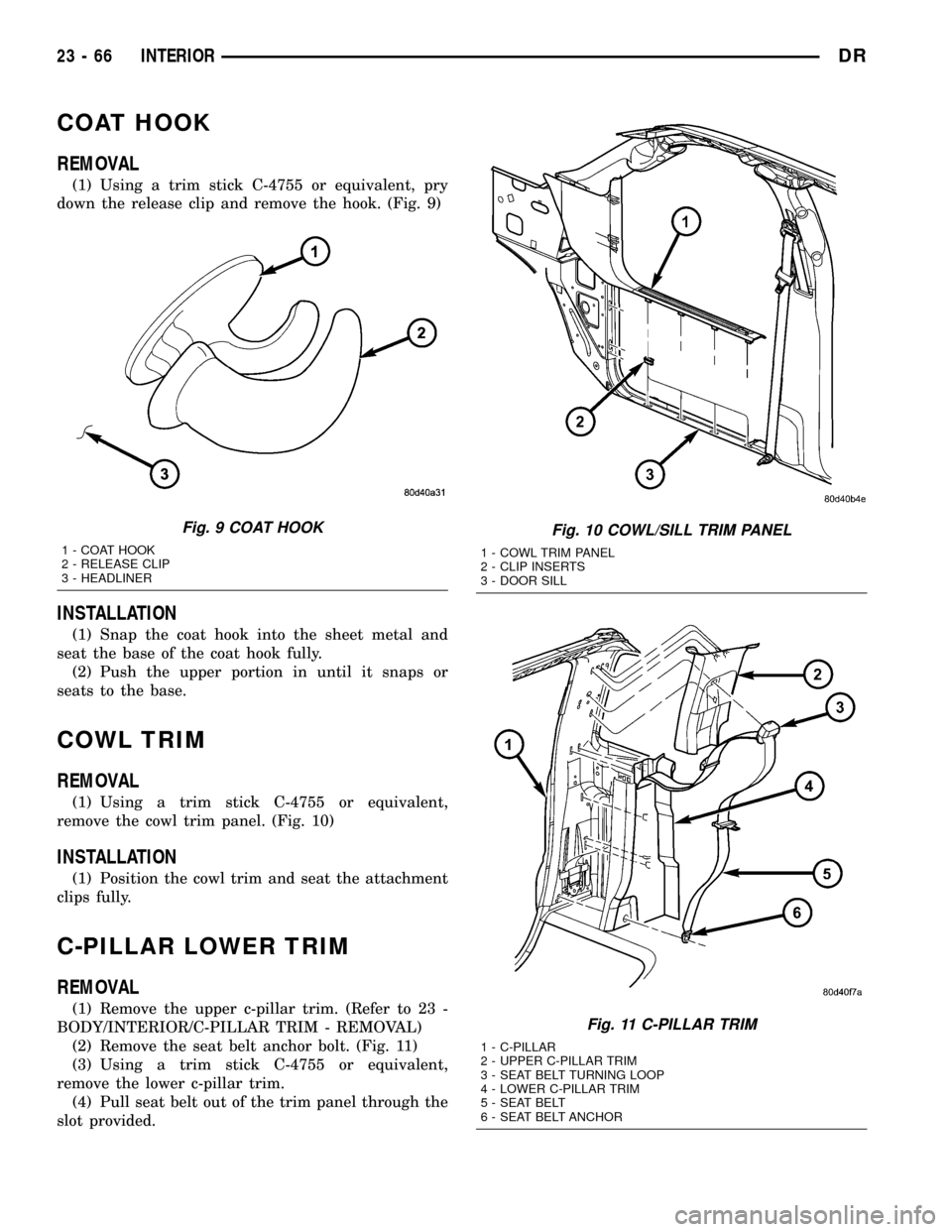

COAT HOOK

REMOVAL

(1) Using a trim stick C-4755 or equivalent, pry

down the release clip and remove the hook. (Fig. 9)

INSTALLATION

(1) Snap the coat hook into the sheet metal and

seat the base of the coat hook fully.

(2) Push the upper portion in until it snaps or

seats to the base.

COWL TRIM

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

remove the cowl trim panel. (Fig. 10)

INSTALLATION

(1) Position the cowl trim and seat the attachment

clips fully.

C-PILLAR LOWER TRIM

REMOVAL

(1) Remove the upper c-pillar trim. (Refer to 23 -

BODY/INTERIOR/C-PILLAR TRIM - REMOVAL)

(2) Remove the seat belt anchor bolt. (Fig. 11)

(3) Using a trim stick C-4755 or equivalent,

remove the lower c-pillar trim.

(4) Pull seat belt out of the trim panel through the

slot provided.

Fig. 9 COAT HOOK

1 - COAT HOOK

2 - RELEASE CLIP

3 - HEADLINER

Fig. 10 COWL/SILL TRIM PANEL

1 - COWL TRIM PANEL

2 - CLIP INSERTS

3 - DOOR SILL

Fig. 11 C-PILLAR TRIM

1 - C-PILLAR

2 - UPPER C-PILLAR TRIM

3 - SEAT BELT TURNING LOOP

4 - LOWER C-PILLAR TRIM

5 - SEAT BELT

6 - SEAT BELT ANCHOR

23 - 66 INTERIORDR

Page 2363 of 2627

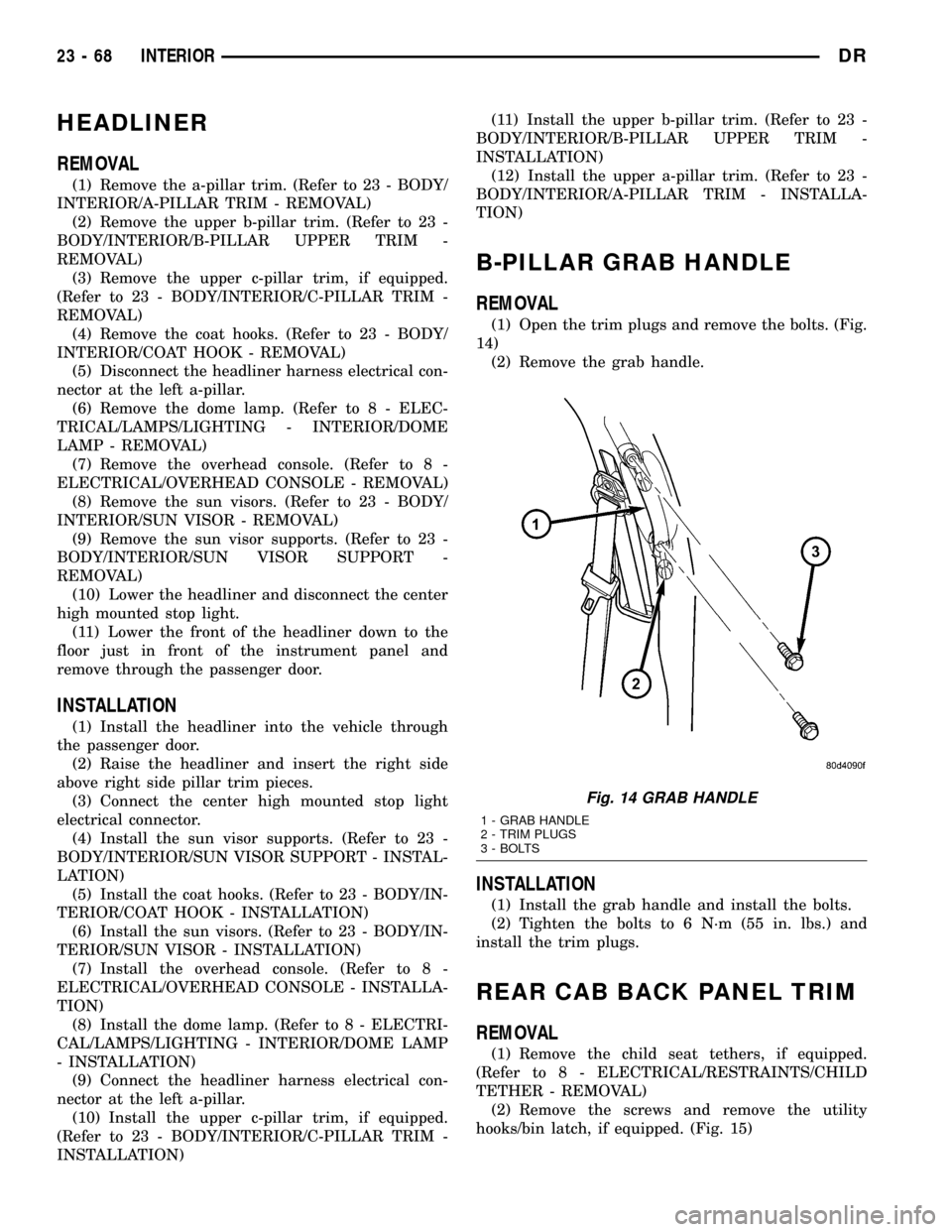

HEADLINER

REMOVAL

(1) Remove the a-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(2) Remove the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(3) Remove the upper c-pillar trim, if equipped.

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

REMOVAL)

(4) Remove the coat hooks. (Refer to 23 - BODY/

INTERIOR/COAT HOOK - REMOVAL)

(5) Disconnect the headliner harness electrical con-

nector at the left a-pillar.

(6) Remove the dome lamp. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - INTERIOR/DOME

LAMP - REMOVAL)

(7) Remove the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL)

(8) Remove the sun visors. (Refer to 23 - BODY/

INTERIOR/SUN VISOR - REMOVAL)

(9) Remove the sun visor supports. (Refer to 23 -

BODY/INTERIOR/SUN VISOR SUPPORT -

REMOVAL)

(10) Lower the headliner and disconnect the center

high mounted stop light.

(11) Lower the front of the headliner down to the

floor just in front of the instrument panel and

remove through the passenger door.

INSTALLATION

(1) Install the headliner into the vehicle through

the passenger door.

(2) Raise the headliner and insert the right side

above right side pillar trim pieces.

(3) Connect the center high mounted stop light

electrical connector.

(4) Install the sun visor supports. (Refer to 23 -

BODY/INTERIOR/SUN VISOR SUPPORT - INSTAL-

LATION)

(5) Install the coat hooks. (Refer to 23 - BODY/IN-

TERIOR/COAT HOOK - INSTALLATION)

(6) Install the sun visors. (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - INSTALLATION)

(7) Install the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION)

(8) Install the dome lamp. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - INTERIOR/DOME LAMP

- INSTALLATION)

(9) Connect the headliner harness electrical con-

nector at the left a-pillar.

(10) Install the upper c-pillar trim, if equipped.

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

INSTALLATION)(11) Install the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION)

(12) Install the upper a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - INSTALLA-

TION)

B-PILLAR GRAB HANDLE

REMOVAL

(1) Open the trim plugs and remove the bolts. (Fig.

14)

(2) Remove the grab handle.

INSTALLATION

(1) Install the grab handle and install the bolts.

(2) Tighten the bolts to 6 N´m (55 in. lbs.) and

install the trim plugs.

REAR CAB BACK PANEL TRIM

REMOVAL

(1) Remove the child seat tethers, if equipped.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CHILD

TETHER - REMOVAL)

(2) Remove the screws and remove the utility

hooks/bin latch, if equipped. (Fig. 15)

Fig. 14 GRAB HANDLE

1 - GRAB HANDLE

2 - TRIM PLUGS

3 - BOLTS

23 - 68 INTERIORDR

Page 2366 of 2627

INSTALLATION

(1) Snap the visor support into the sheet metal

and seat the release clip fully.

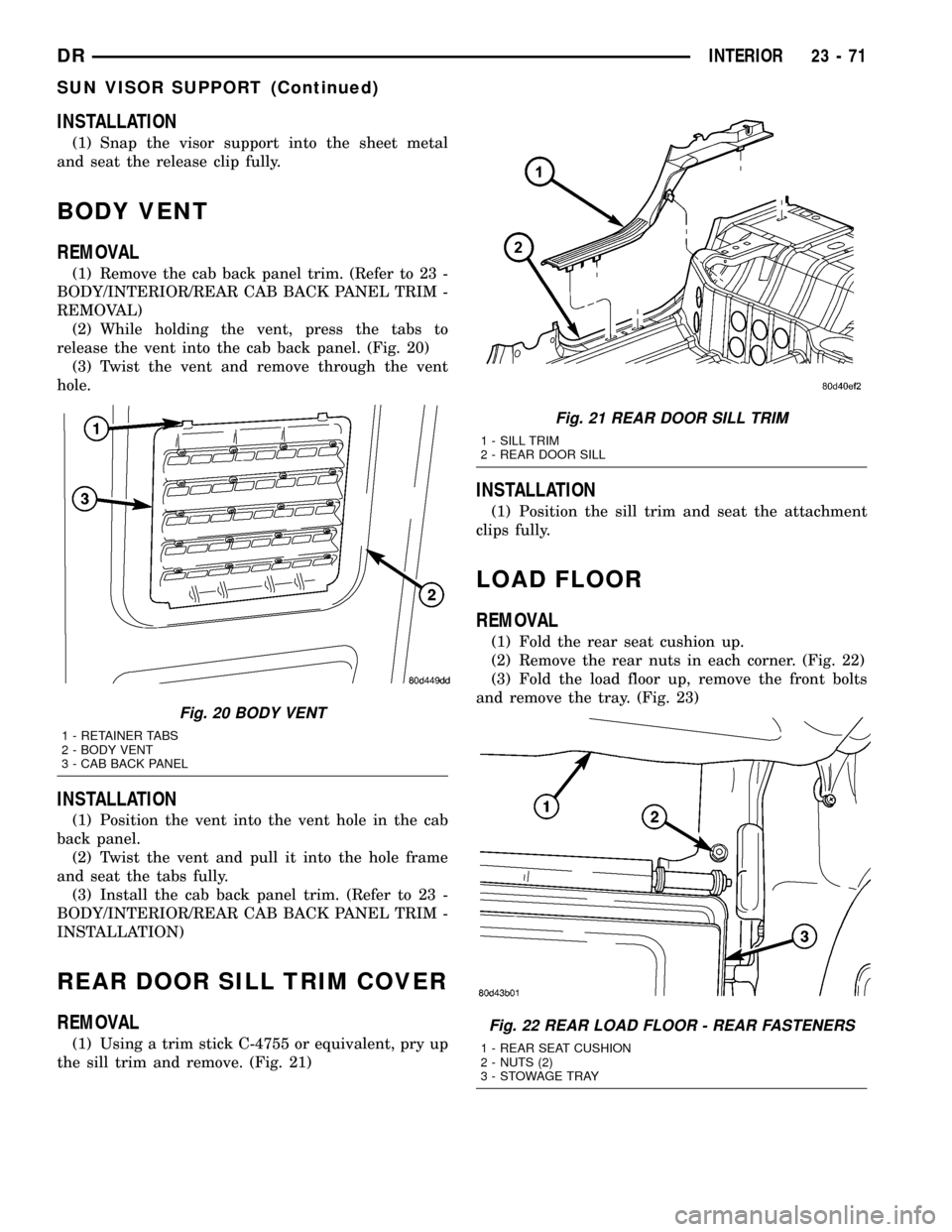

BODY VENT

REMOVAL

(1) Remove the cab back panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CAB BACK PANEL TRIM -

REMOVAL)

(2) While holding the vent, press the tabs to

release the vent into the cab back panel. (Fig. 20)

(3) Twist the vent and remove through the vent

hole.

INSTALLATION

(1) Position the vent into the vent hole in the cab

back panel.

(2) Twist the vent and pull it into the hole frame

and seat the tabs fully.

(3) Install the cab back panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CAB BACK PANEL TRIM -

INSTALLATION)

REAR DOOR SILL TRIM COVER

REMOVAL

(1) Using a trim stick C-4755 or equivalent, pry up

the sill trim and remove. (Fig. 21)

INSTALLATION

(1) Position the sill trim and seat the attachment

clips fully.

LOAD FLOOR

REMOVAL

(1) Fold the rear seat cushion up.

(2) Remove the rear nuts in each corner. (Fig. 22)

(3) Fold the load floor up, remove the front bolts

and remove the tray. (Fig. 23)

Fig. 20 BODY VENT

1 - RETAINER TABS

2 - BODY VENT

3 - CAB BACK PANEL

Fig. 21 REAR DOOR SILL TRIM

1 - SILL TRIM

2 - REAR DOOR SILL

Fig. 22 REAR LOAD FLOOR - REAR FASTENERS

1 - REAR SEAT CUSHION

2 - NUTS (2)

3 - STOWAGE TRAY

DRINTERIOR 23 - 71

SUN VISOR SUPPORT (Continued)

Page 2381 of 2627

STATIONARY GLASS

TABLE OF CONTENTS

page page

BACKLITE

REMOVAL.............................86

INSTALLATION.........................86

BACKLITE VENT GLASS

REMOVAL.............................87

INSTALLATION.........................87WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS.....88

REMOVAL.............................88

INSTALLATION.........................88

BACKLITE

REMOVAL

It is difficult to salvage the backlite during the

removal operation. The backlite is part of the struc-

tural support for the roof. The urethane bonding

used to secure the glass to the fence is difficult to cut

or clean from any surface. Since the molding is set in

urethane, it is unlikely it would be salvaged. Before

removing the backlite, check the availability from the

parts supplier.

The backlite is attached to the window frame with

urethane adhesive. The urethane adhesive is applied

cold and seals the surface area between the window

opening and the glass. The primer adheres the ure-

thane adhesive to the backlite.

(1) Roll down door glass.

(2) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(3) On standard cab models remove the upper

b-pillar trim. (Refer to 23 - BODY/INTERIOR/B-PIL-

LAR UPPER TRIM - REMOVAL)

(4) On quad cab models remove the upper c-pillar

trim. (Refer to 23 - BODY/INTERIOR/C-PILLAR

UPPER TRIM - REMOVAL)

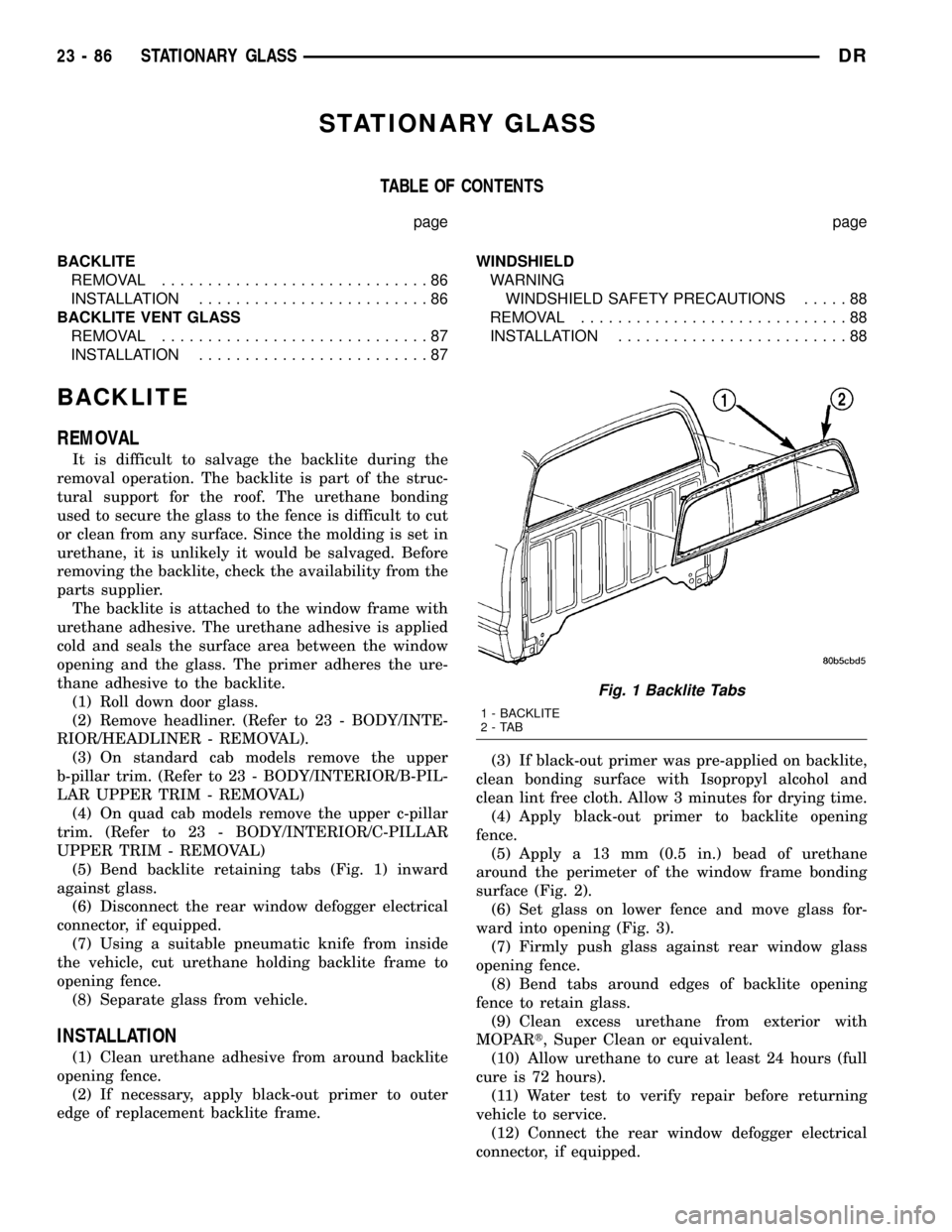

(5) Bend backlite retaining tabs (Fig. 1) inward

against glass.

(6) Disconnect the rear window defogger electrical

connector, if equipped.

(7) Using a suitable pneumatic knife from inside

the vehicle, cut urethane holding backlite frame to

opening fence.

(8) Separate glass from vehicle.

INSTALLATION

(1) Clean urethane adhesive from around backlite

opening fence.

(2) If necessary, apply black-out primer to outer

edge of replacement backlite frame.(3) If black-out primer was pre-applied on backlite,

clean bonding surface with Isopropyl alcohol and

clean lint free cloth. Allow 3 minutes for drying time.

(4) Apply black-out primer to backlite opening

fence.

(5) Apply a 13 mm (0.5 in.) bead of urethane

around the perimeter of the window frame bonding

surface (Fig. 2).

(6) Set glass on lower fence and move glass for-

ward into opening (Fig. 3).

(7) Firmly push glass against rear window glass

opening fence.

(8) Bend tabs around edges of backlite opening

fence to retain glass.

(9) Clean excess urethane from exterior with

MOPARt, Super Clean or equivalent.

(10) Allow urethane to cure at least 24 hours (full

cure is 72 hours).

(11) Water test to verify repair before returning

vehicle to service.

(12) Connect the rear window defogger electrical

connector, if equipped.

Fig. 1 Backlite Tabs

1 - BACKLITE

2-TAB

23 - 86 STATIONARY GLASSDR

Page 2383 of 2627

WINDSHIELD

WARNING

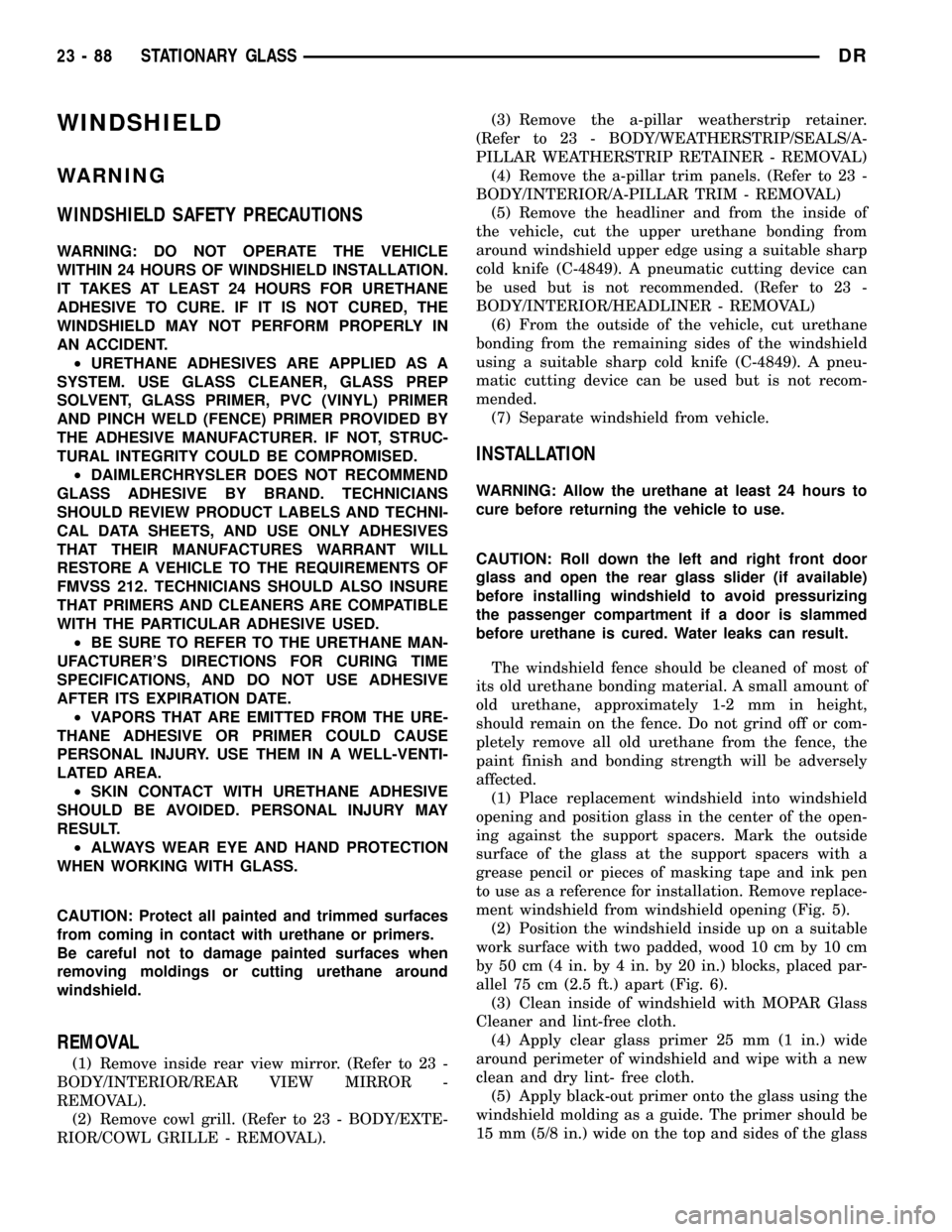

WINDSHIELD SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

²URETHANE ADHESIVES ARE APPLIED AS A

SYSTEM. USE GLASS CLEANER, GLASS PREP

SOLVENT, GLASS PRIMER, PVC (VINYL) PRIMER

AND PINCH WELD (FENCE) PRIMER PROVIDED BY

THE ADHESIVE MANUFACTURER. IF NOT, STRUC-

TURAL INTEGRITY COULD BE COMPROMISED.

²DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVES

THAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

²BE SURE TO REFER TO THE URETHANE MAN-

UFACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

²VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

²SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

²ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

REMOVAL

(1) Remove inside rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR -

REMOVAL).

(2) Remove cowl grill. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - REMOVAL).(3) Remove the a-pillar weatherstrip retainer.

(Refer to 23 - BODY/WEATHERSTRIP/SEALS/A-

PILLAR WEATHERSTRIP RETAINER - REMOVAL)

(4) Remove the a-pillar trim panels. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - REMOVAL)

(5) Remove the headliner and from the inside of

the vehicle, cut the upper urethane bonding from

around windshield upper edge using a suitable sharp

cold knife (C-4849). A pneumatic cutting device can

be used but is not recommended. (Refer to 23 -

BODY/INTERIOR/HEADLINER - REMOVAL)

(6) From the outside of the vehicle, cut urethane

bonding from the remaining sides of the windshield

using a suitable sharp cold knife (C-4849). A pneu-

matic cutting device can be used but is not recom-

mended.

(7) Separate windshield from vehicle.

INSTALLATION

WARNING: Allow the urethane at least 24 hours to

cure before returning the vehicle to use.

CAUTION: Roll down the left and right front door

glass and open the rear glass slider (if available)

before installing windshield to avoid pressurizing

the passenger compartment if a door is slammed

before urethane is cured. Water leaks can result.

The windshield fence should be cleaned of most of

its old urethane bonding material. A small amount of

old urethane, approximately 1-2 mm in height,

should remain on the fence. Do not grind off or com-

pletely remove all old urethane from the fence, the

paint finish and bonding strength will be adversely

affected.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the support spacers. Mark the outside

surface of the glass at the support spacers with a

grease pencil or pieces of masking tape and ink pen

to use as a reference for installation. Remove replace-

ment windshield from windshield opening (Fig. 5).

(2) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 6).

(3) Clean inside of windshield with MOPAR Glass

Cleaner and lint-free cloth.

(4) Apply clear glass primer 25 mm (1 in.) wide

around perimeter of windshield and wipe with a new

clean and dry lint- free cloth.

(5) Apply black-out primer onto the glass using the

windshield molding as a guide. The primer should be

15 mm (5/8 in.) wide on the top and sides of the glass

23 - 88 STATIONARY GLASSDR