warning DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1476 of 2627

INSPECTIONÐPUSHRODS

Inspect the push rod ball and socket for signs of

scoring. Check for cracks where the ball and the

socket are pressed into the tube (Fig. 16).

Roll the push rod on a flat work surface with the

socket end hanging off the edge (Fig. 17). Replace

any push rod that appears to be bent.

INSTALLATION

WARNING: THE OUTSIDE EDGE OF THE HEAD

GASKET IS VERY SHARP. WHEN HANDLING THE

NEW HEAD GASKET, USE CARE NOT TO INJURE

YOURSELF.

(1) Install a new gasket with the part number side

up, and locate the gasket over the dowel sleeves.

(2) Using an engine lifting crane, lower the cylin-

der head onto the engine.

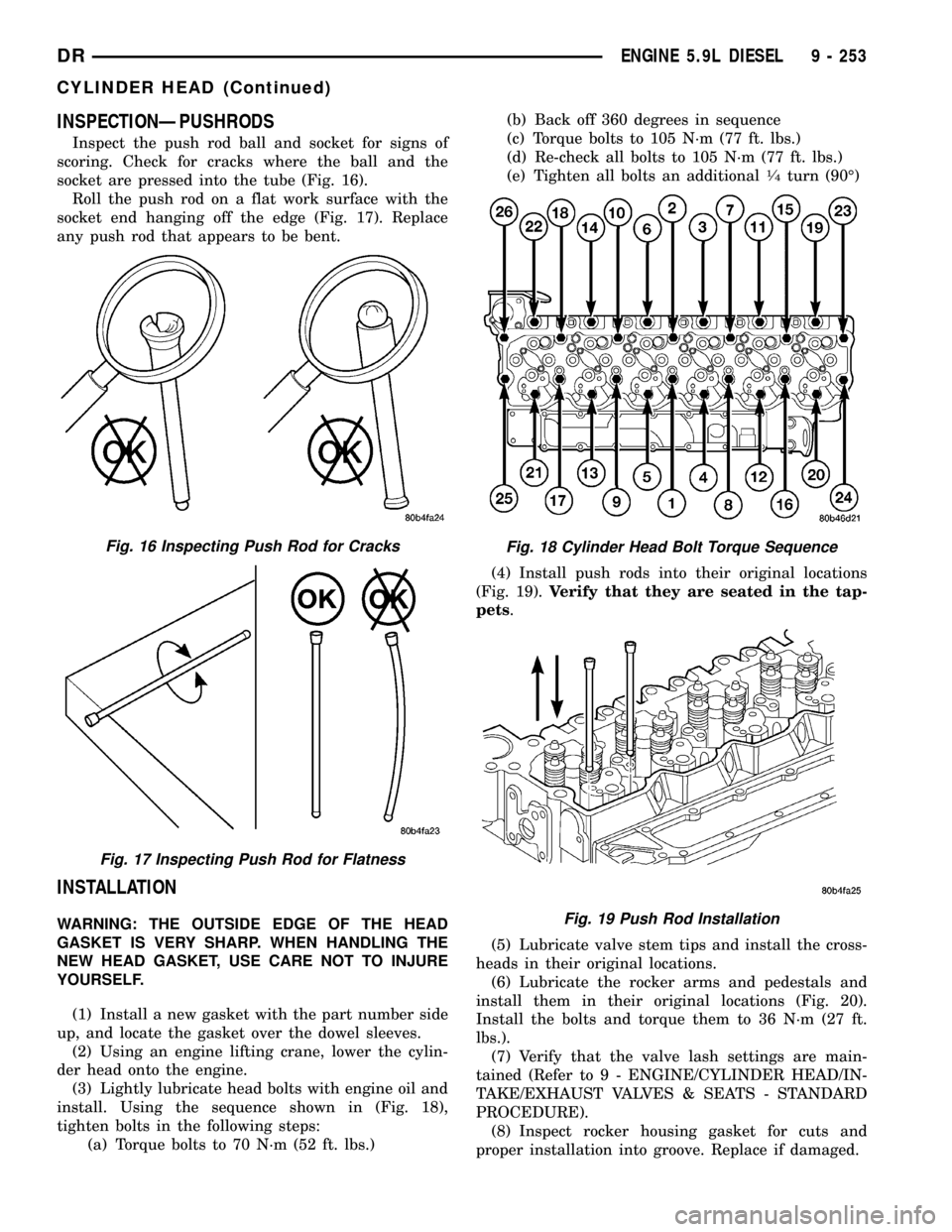

(3) Lightly lubricate head bolts with engine oil and

install. Using the sequence shown in (Fig. 18),

tighten bolts in the following steps:

(a) Torque bolts to 70 N´m (52 ft. lbs.)(b) Back off 360 degrees in sequence

(c) Torque bolts to 105 N´m (77 ft. lbs.)

(d) Re-check all bolts to 105 N´m (77 ft. lbs.)

(e) Tighten all bolts an additional

1¤4turn (90É)

(4) Install push rods into their original locations

(Fig. 19).Verify that they are seated in the tap-

pets.

(5) Lubricate valve stem tips and install the cross-

heads in their original locations.

(6) Lubricate the rocker arms and pedestals and

install them in their original locations (Fig. 20).

Install the bolts and torque them to 36 N´m (27 ft.

lbs.).

(7) Verify that the valve lash settings are main-

tained (Refer to 9 - ENGINE/CYLINDER HEAD/IN-

TAKE/EXHAUST VALVES & SEATS - STANDARD

PROCEDURE).

(8) Inspect rocker housing gasket for cuts and

proper installation into groove. Replace if damaged.

Fig. 16 Inspecting Push Rod for Cracks

Fig. 17 Inspecting Push Rod for Flatness

Fig. 18 Cylinder Head Bolt Torque Sequence

Fig. 19 Push Rod Installation

DRENGINE 5.9L DIESEL 9 - 253

CYLINDER HEAD (Continued)

Page 1496 of 2627

If the crankshaft is within limits, replace the bear-

ing. If the crankshaft is out of limits, grind the

crankshaft to the next smaller size and use oversize

rod bearings.

CRANKSHAFT AND GEAR

DESCRIPTION

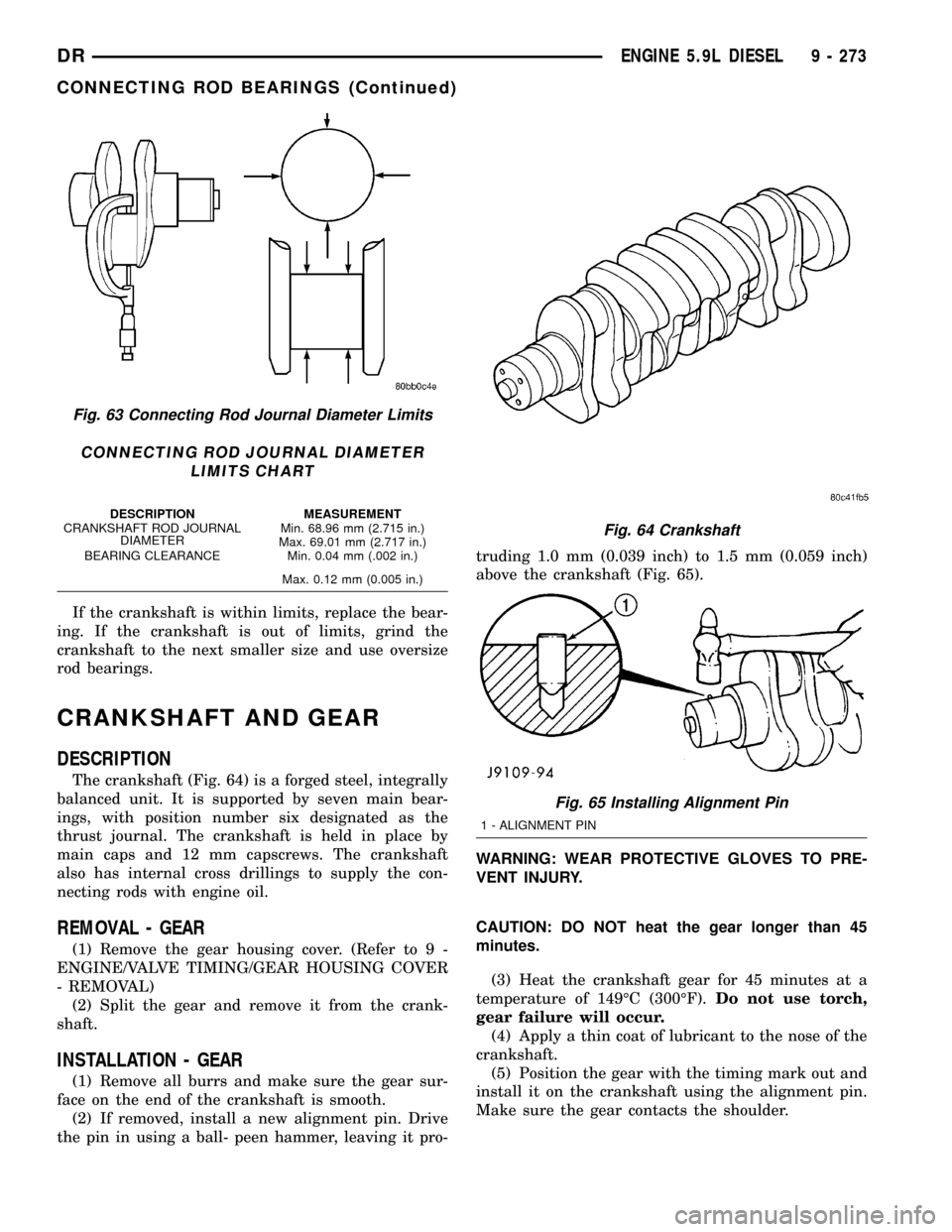

The crankshaft (Fig. 64) is a forged steel, integrally

balanced unit. It is supported by seven main bear-

ings, with position number six designated as the

thrust journal. The crankshaft is held in place by

main caps and 12 mm capscrews. The crankshaft

also has internal cross drillings to supply the con-

necting rods with engine oil.

REMOVAL - GEAR

(1) Remove the gear housing cover. (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL)

(2) Split the gear and remove it from the crank-

shaft.

INSTALLATION - GEAR

(1) Remove all burrs and make sure the gear sur-

face on the end of the crankshaft is smooth.

(2) If removed, install a new alignment pin. Drive

the pin in using a ball- peen hammer, leaving it pro-truding 1.0 mm (0.039 inch) to 1.5 mm (0.059 inch)

above the crankshaft (Fig. 65).

WARNING: WEAR PROTECTIVE GLOVES TO PRE-

VENT INJURY.

CAUTION: DO NOT heat the gear longer than 45

minutes.

(3) Heat the crankshaft gear for 45 minutes at a

temperature of 149ÉC (300ÉF).Do not use torch,

gear failure will occur.

(4) Apply a thin coat of lubricant to the nose of the

crankshaft.

(5) Position the gear with the timing mark out and

install it on the crankshaft using the alignment pin.

Make sure the gear contacts the shoulder.

Fig. 63 Connecting Rod Journal Diameter Limits

CONNECTING ROD JOURNAL DIAMETER

LIMITS CHART

DESCRIPTION MEASUREMENT

CRANKSHAFT ROD JOURNAL

DIAMETERMin. 68.96 mm (2.715 in.)

Max. 69.01 mm (2.717 in.)

BEARING CLEARANCE Min. 0.04 mm (.002 in.)

Max. 0.12 mm (0.005 in.)

Fig. 64 Crankshaft

Fig. 65 Installing Alignment Pin

1 - ALIGNMENT PIN

DRENGINE 5.9L DIESEL 9 - 273

CONNECTING ROD BEARINGS (Continued)

Page 1515 of 2627

OIL

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE OIL LEVEL

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

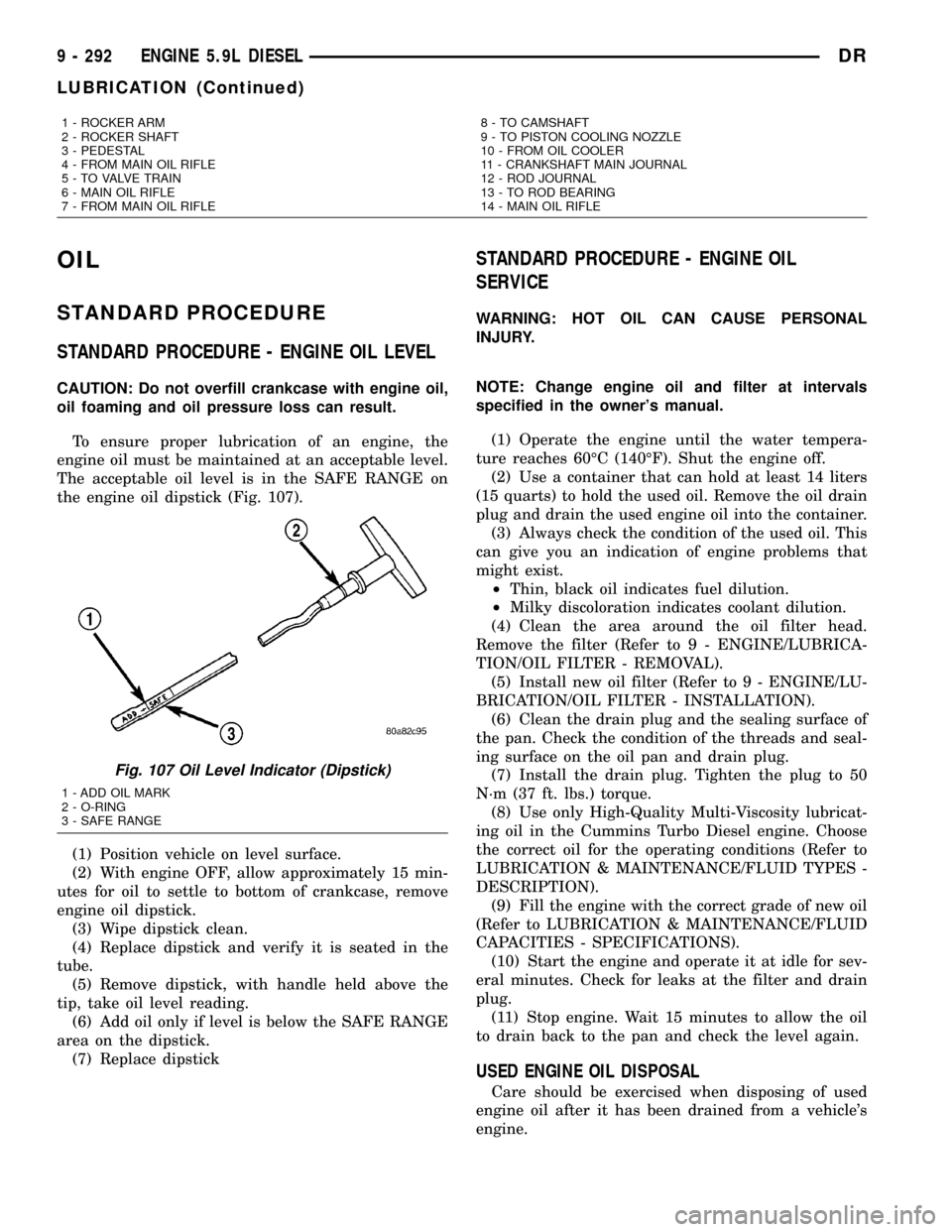

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable oil level is in the SAFE RANGE on

the engine oil dipstick (Fig. 107).

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately 15 min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Replace dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the SAFE RANGE

area on the dipstick.

(7) Replace dipstick

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

NOTE: Change engine oil and filter at intervals

specified in the owner's manual.

(1) Operate the engine until the water tempera-

ture reaches 60ÉC (140ÉF). Shut the engine off.

(2) Use a container that can hold at least 14 liters

(15 quarts) to hold the used oil. Remove the oil drain

plug and drain the used engine oil into the container.

(3) Always check the condition of the used oil. This

can give you an indication of engine problems that

might exist.

²Thin, black oil indicates fuel dilution.

²Milky discoloration indicates coolant dilution.

(4) Clean the area around the oil filter head.

Remove the filter (Refer to 9 - ENGINE/LUBRICA-

TION/OIL FILTER - REMOVAL).

(5) Install new oil filter (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION).

(6) Clean the drain plug and the sealing surface of

the pan. Check the condition of the threads and seal-

ing surface on the oil pan and drain plug.

(7) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(8) Use only High-Quality Multi-Viscosity lubricat-

ing oil in the Cummins Turbo Diesel engine. Choose

the correct oil for the operating conditions (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(9) Fill the engine with the correct grade of new oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

CAPACITIES - SPECIFICATIONS).

(10) Start the engine and operate it at idle for sev-

eral minutes. Check for leaks at the filter and drain

plug.

(11) Stop engine. Wait 15 minutes to allow the oil

to drain back to the pan and check the level again.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing of used

engine oil after it has been drained from a vehicle's

engine.

1 - ROCKER ARM

2 - ROCKER SHAFT

3 - PEDESTAL

4 - FROM MAIN OIL RIFLE

5 - TO VALVE TRAIN

6 - MAIN OIL RIFLE

7 - FROM MAIN OIL RIFLE8 - TO CAMSHAFT

9 - TO PISTON COOLING NOZZLE

10 - FROM OIL COOLER

11 - CRANKSHAFT MAIN JOURNAL

12 - ROD JOURNAL

13 - TO ROD BEARING

14 - MAIN OIL RIFLE

Fig. 107 Oil Level Indicator (Dipstick)

1 - ADD OIL MARK

2 - O-RING

3 - SAFE RANGE

9 - 292 ENGINE 5.9L DIESELDR

LUBRICATION (Continued)

Page 1516 of 2627

OIL COOLER & LINES

CLEANING

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter from below using a cap-style filter

wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional

1¤2turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Install engine support fixture # 8534.

(3) Raise vehicle on hoist.

(4) Disconnect starter cables from starter motor.

(5) Remove transmission and transfer case (if

equipped).

(6) Remove flywheel or flexplate.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(8) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).(9) Install the oil pan drain plug if sealing surface

is not damaged and tighten to 50 N´m (37 ft. lbs.)

torque.

(10) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(11) Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Place suction tube in oil pan and guide them

into place. Using a new tube to block gasket, install

and tighten the suction tube bolts by hand. Starting

with the oil pump inlet bolts, tighten the bolts to 24

N´m (18 ft. lbs.) torque. Tighten the remaining tube

brace bolts to 43 N´m (32 ft. lbs.) torque.

(3) Starting in the center and working outward,

tighten the oil pan bolts to 28 N´m (21 ft. lbs.)

torque.

(4) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 77 N´m

(57 ft. lbs.) torque.

(5) Connect starter motor cables.

(6) Install the flywheel or flexplate. Torque to 137

N´m (101 ft. lbs.).

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Remove the engine support fixture # 8534.

(10) Install battery negative cables.

(11) Fill the crankcase with new engine oil.

(12) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

DRENGINE 5.9L DIESEL 9 - 293

Page 1531 of 2627

SPECIAL TOOLS

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct the

cause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid con-

taminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust mani-

folds and before the inline catalytic converter.

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

REMOVAL

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove the bolts from the crossover pipe to the

catalytic converter connection.

(4) Disconnect oxygen sensor wiring.

(5) Loosen the nuts from the clamp that hold the

catalytic converter to the exhaust pipe flange connec-

tion.

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(6) Remove the T bolt end of the fastener, from the

clamp.

(7) Spread the clamp, and remove the catalytic

converter from the vehicle.

(8) Discard the clamp.

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts.

(4) Remove the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

INSTALLATION

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

TURBOCHARGER TESTER 9022

11 - 6 EXHAUST SYSTEMDR

EXHAUST SYSTEM (Continued)

Page 1540 of 2627

(9) Remove the turbocharger and gasket from the

exhaust manifold.

(10) If the turbocharger is not to be installed

immediately, cover the opening to prevent material

from entering into the manifold.

(11) If replacing the turbocharger, transfer the tur-

bocharger oil supply fitting to the new assembly.

Tighten fitting to 36 N´m (27 ft. lbs.).

(12) Clean and inspect the sealing surface.

CAUTION: The turbocharger is only serviced as an

assembly. Do not attempt to repair the turbocharger

as turbocharger and/or engine damage can result.

CLEANING

WARNING: To prevent damage or personal injury,

do not use a combustable cleaner to clean the tur-

bocharger.

Clean the turbocharger and exhaust manifold

mounting surfaces with a suitable scraper.

INSPECTION

Visually inspect the turbocharger and exhaust

manifold gasket surfaces. Replace stripped or eroded

mounting studs.

(1) Visually inspect the turbocharger for cracks.

The following cracks are NOT acceptable:

²Cracks in the turbine and compressor housing

that go completely through.

²Cracks in the mounting flange that are longer

than 15 mm (0.6 in.).

²Cracks in the mounting flange that intersect

bolt through-holes.

²Two (2) Cracks in the mounting flange that are

closer than 6.4 mm (0.25 in.) together.

(2) Visually inspect the impeller and compressor

wheel fins for nicks, cracks, or chips. Note: Some

impellers may have a factory placed paint mark

which, after normal operation, appears to be a crack.

Remove this mark with a suitable solvent to verify

that it is not a crack.

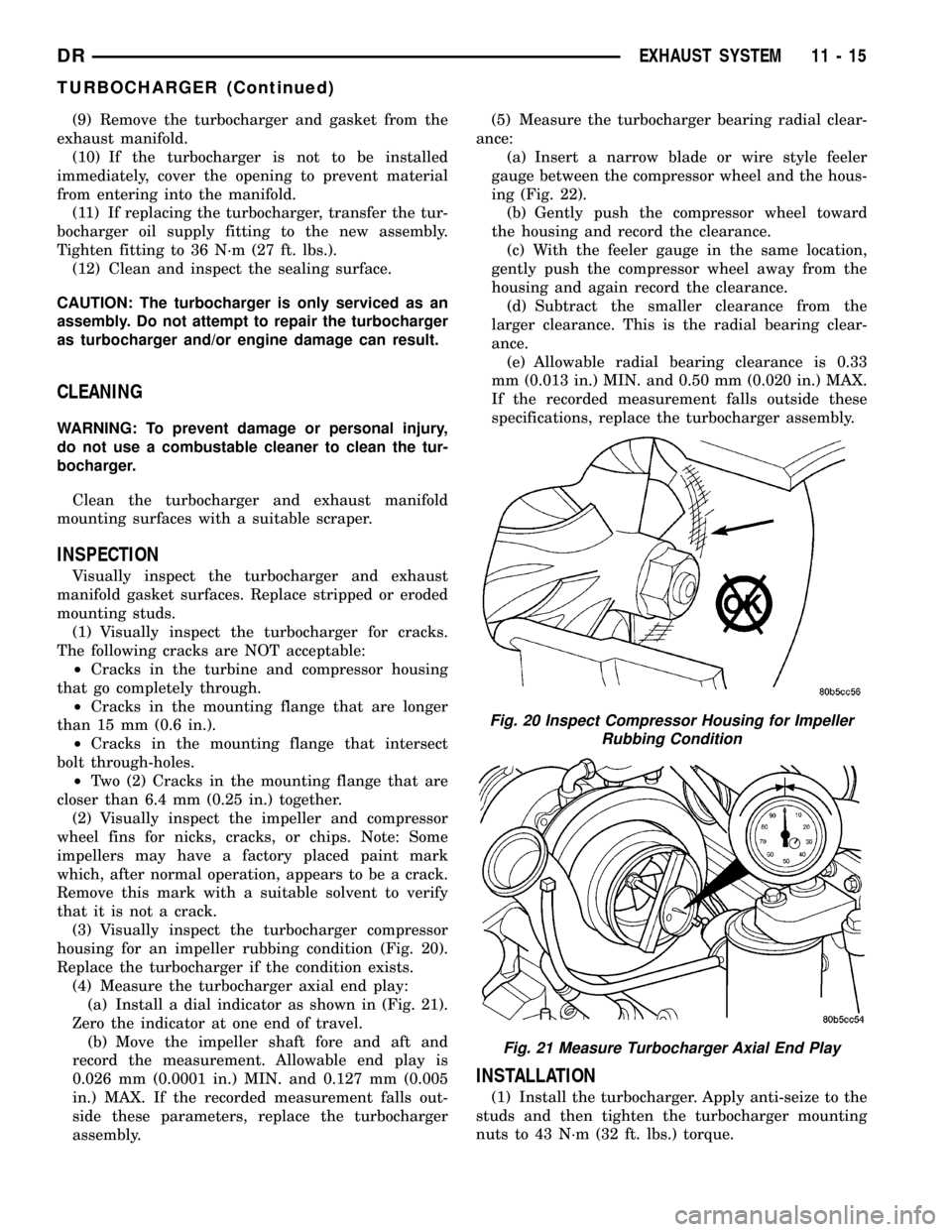

(3) Visually inspect the turbocharger compressor

housing for an impeller rubbing condition (Fig. 20).

Replace the turbocharger if the condition exists.

(4) Measure the turbocharger axial end play:

(a) Install a dial indicator as shown in (Fig. 21).

Zero the indicator at one end of travel.

(b) Move the impeller shaft fore and aft and

record the measurement. Allowable end play is

0.026 mm (0.0001 in.) MIN. and 0.127 mm (0.005

in.) MAX. If the recorded measurement falls out-

side these parameters, replace the turbocharger

assembly.(5) Measure the turbocharger bearing radial clear-

ance:

(a) Insert a narrow blade or wire style feeler

gauge between the compressor wheel and the hous-

ing (Fig. 22).

(b) Gently push the compressor wheel toward

the housing and record the clearance.

(c) With the feeler gauge in the same location,

gently push the compressor wheel away from the

housing and again record the clearance.

(d) Subtract the smaller clearance from the

larger clearance. This is the radial bearing clear-

ance.

(e) Allowable radial bearing clearance is 0.33

mm (0.013 in.) MIN. and 0.50 mm (0.020 in.) MAX.

If the recorded measurement falls outside these

specifications, replace the turbocharger assembly.

INSTALLATION

(1) Install the turbocharger. Apply anti-seize to the

studs and then tighten the turbocharger mounting

nuts to 43 N´m (32 ft. lbs.) torque.

Fig. 20 Inspect Compressor Housing for Impeller

Rubbing Condition

Fig. 21 Measure Turbocharger Axial End Play

DREXHAUST SYSTEM 11 - 15

TURBOCHARGER (Continued)

Page 1542 of 2627

CAUTION: Do not apply more than 138 kPa (20 psi)

air pressure to the charge air cooler system, sever

damage to the charge air cooler system may occur.

(3) Connect a regulated air supply to air fitting on

Tool 9022 Adapter. Set air pressure to a Maximum of

138 kPa (20 psi).

(4) Using soapy water check the rubber sleeves,

charge air cooler and intake manifold for leaks.

REMOVAL

WARNING: IF THE ENGINE WAS JUST TURNED

OFF, THE AIR INTAKE SYSTEM TUBES MAY BE

HOT.

(1) Disconnect the battery negative cables.

(2) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (if A/C

equipped).

(3) Remove the transmission auxiliary cooler

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

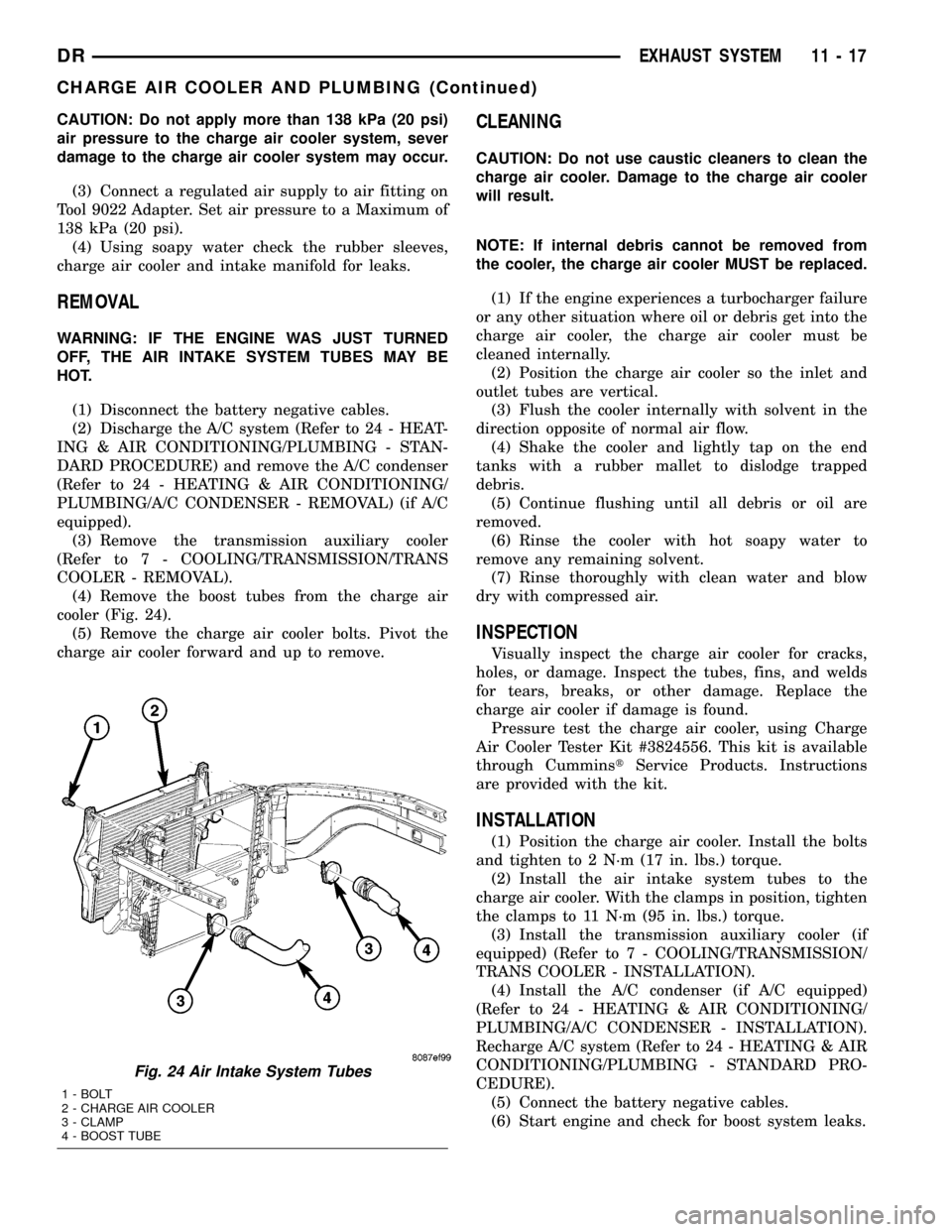

(4) Remove the boost tubes from the charge air

cooler (Fig. 24).

(5) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.

(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4) Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped

debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

(2) Install the air intake system tubes to the

charge air cooler. With the clamps in position, tighten

the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4) Install the A/C condenser (if A/C equipped)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - INSTALLATION).

Recharge A/C system (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(5) Connect the battery negative cables.

(6) Start engine and check for boost system leaks.

Fig. 24 Air Intake System Tubes

1 - BOLT

2 - CHARGE AIR COOLER

3 - CLAMP

4 - BOOST TUBE

DREXHAUST SYSTEM 11 - 17

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1544 of 2627

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT AIR DAM

REMOVAL.............................2

INSTALLATION..........................2

FRONT BUMPER

REMOVAL.............................2

INSTALLATION..........................2

FRONT FASCIA

REMOVAL.............................2

INSTALLATION..........................3

REAR BUMPER

REMOVAL.............................3

INSTALLATION..........................4

FRAME

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 4

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR.................11

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT.............13SPECIFICATIONS

SPECIFICATIONS - WELD PROCESS......15

SPECIFICATIONS - FRAME DIMENSIONS . . . 16

SPECIFICATIONS - TORQUE............22

FRONT CROSSMEMBER

REMOVAL.............................22

INSTALLATION.........................22

FRONT SKID PLATE

REMOVAL.............................23

INSTALLATION.........................23

FRONT TOW HOOK ASSEMBLY

REMOVAL.............................23

INSTALLATION.........................23

TRANSMISSION CROSSMEMBER

REMOVAL.............................24

INSTALLATION.........................24

TRAILER HITCH

REMOVAL.............................25

INSTALLATION.........................25

TRANSFER CASE SKID PLATE

REMOVAL.............................26

INSTALLATION.........................26

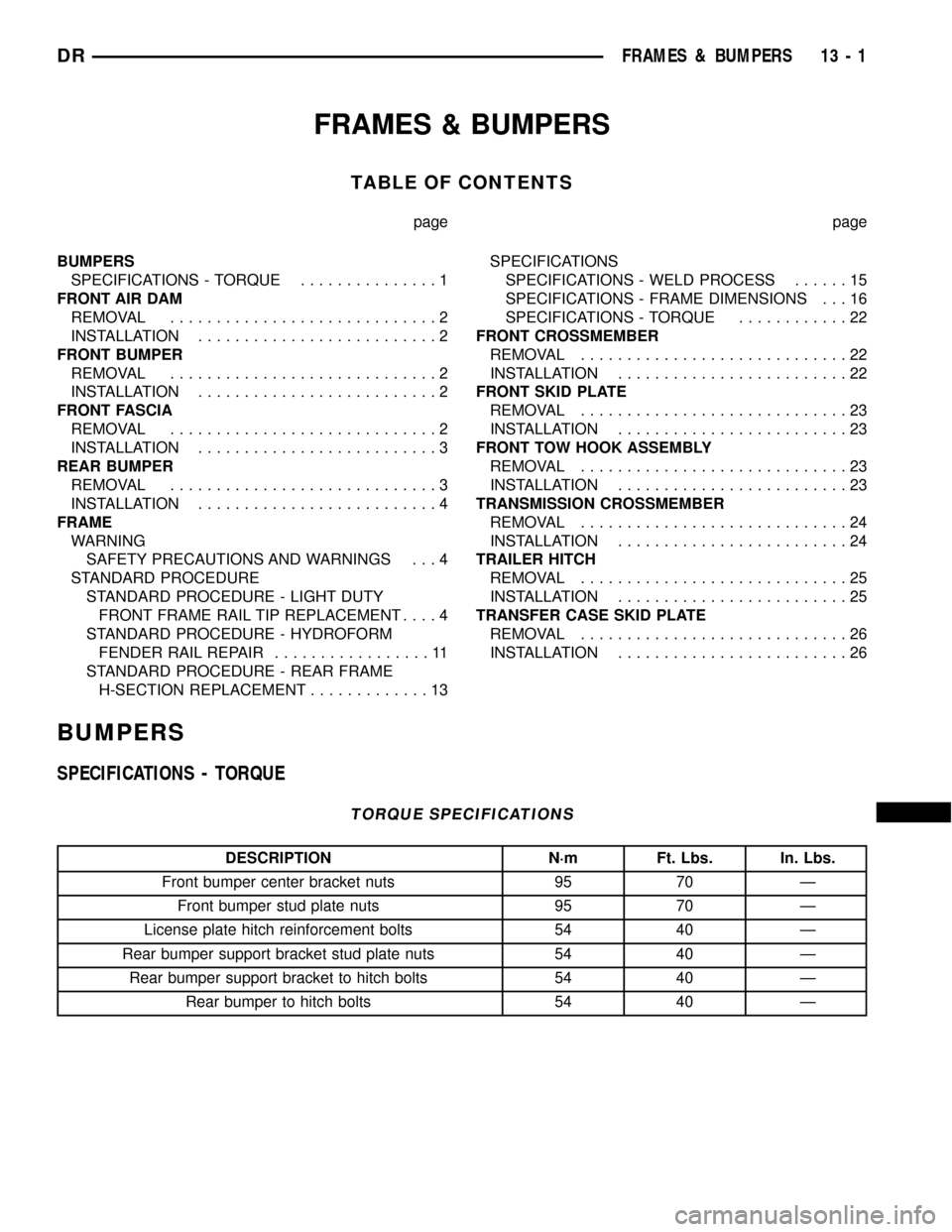

BUMPERS

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 Ð

Front bumper stud plate nuts 95 70 Ð

License plate hitch reinforcement bolts 54 40 Ð

Rear bumper support bracket stud plate nuts 54 40 Ð

Rear bumper support bracket to hitch bolts 54 40 Ð

Rear bumper to hitch bolts 54 40 Ð

DRFRAMES & BUMPERS 13 - 1

Page 1547 of 2627

INSTALLATION

(1) Align the holes in the bumpers to the trailer

hitch pins and install the bumper.

(2) Install the support bracket to the hitch bolts,

loosely.

(3) Install the front upper edge to the trailer hitch

bolts and tighten to 54 N´m (40 ft. lbs.).

(4) Install the license plate reinforcement to hitch

bolts and tighten to 54 N´m (40 ft. lbs.).

(5) Tighten the left bumper bracket bolts to 54

N´m (40 ft. lbs.).

(6) Tighten the right bumper bracket bolts to 54

N´m (40 ft. lbs.).

(7) Connect the trailer light connector electrical

connection, if equipped.

(8) Connect the license plate light electrical con-

nectors.

(9) Install the license plate.

FRAME

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

²BEFORE PROCEEDING WITH FRAME REPAIR

INVOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

²DO NOT ALLOW OPEN FLAME OR HEAT AND

METAL SPATTER FROM ARC WELDING, TO CON-

TACT PLASTIC BODY PANELS. FIRE OR EXPLO-

SION CAN RESULT.

²WHEN WELDED FRAME COMPONENTS ARE

REPLACED, ENSURE COMPLETE PENETRATION

WELD IS ACHIEVED DURING INSTALLATION. IF

NOT, DANGEROUS OPERATING CONDITIONS CAN

RESULT.

²STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN

RESULT.

²DO NOT VENTURE UNDER A HOISTED VEHI-

CLE THAT IS NOT SUPPORTED ON SAFETY

STANDS, PERSONAL INJURY CAN RESULT.

CAUTION: 1500 series Dodge Ram Trucks (2002 and

later) are not designed for snow plow equipment.The front collision repair tips must not be installed

on any truck equipped with a snow plow, or even

intended to be equipped with a snow plow.

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect. Failure to use only pro-

duction fasteners or fasteners of equivalent hard-

ness can result in loosening or failure. Do not drill

any holes in the frame that are not specifically out-

lined in this or other, DaimlerChrysler procedure as

frame rail failure can result. When using heat to

straighten frame components do not exceed 566ÉC

(1050ÉF), metal fatigue can result.

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY FRONT

FRAME RAIL TIP REPLACEMENT

CAUTION: This procedure is designed to replace

the front frame rail tips that have been damaged in

the crush initiator zones. Prior to any cutting, the

vehicle must be mounted on the appropriate frame

repair equipment (ªframe rackº), checked with three

dimensional measuring equipment, and the neces-

sary pull corrections made. If damage remains in

the frame beyond the area covered by this service

part after the pull, the frame must be replaced in its

entirety.

NOTE: Procedures for 4X2 and 4X4 are common

except as noted in this procedure.

(1) Before proceding with this repair procedure

review the required service warnings and precau-

tions. (Refer to 13 - FRAME & BUMPERS/FRAME -

WARNING)

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - REMOVAL)

(4) Remove the bolts and position aside the wire

harness and grounds, if required.

(5) Remove the front bumper. (Refer to 13 -

FRAME & BUMPERS/BUMPERS/FRONT BUMPER

- REMOVAL)

(6) Loosen and lower the stabilizer bar mount and

bar. (Refer to 2 - SUSPENSION/FRONT/STABI-

LIZER BAR - REMOVAL)

13 - 4 FRAMES & BUMPERSDR

REAR BUMPER (Continued)

Page 1554 of 2627

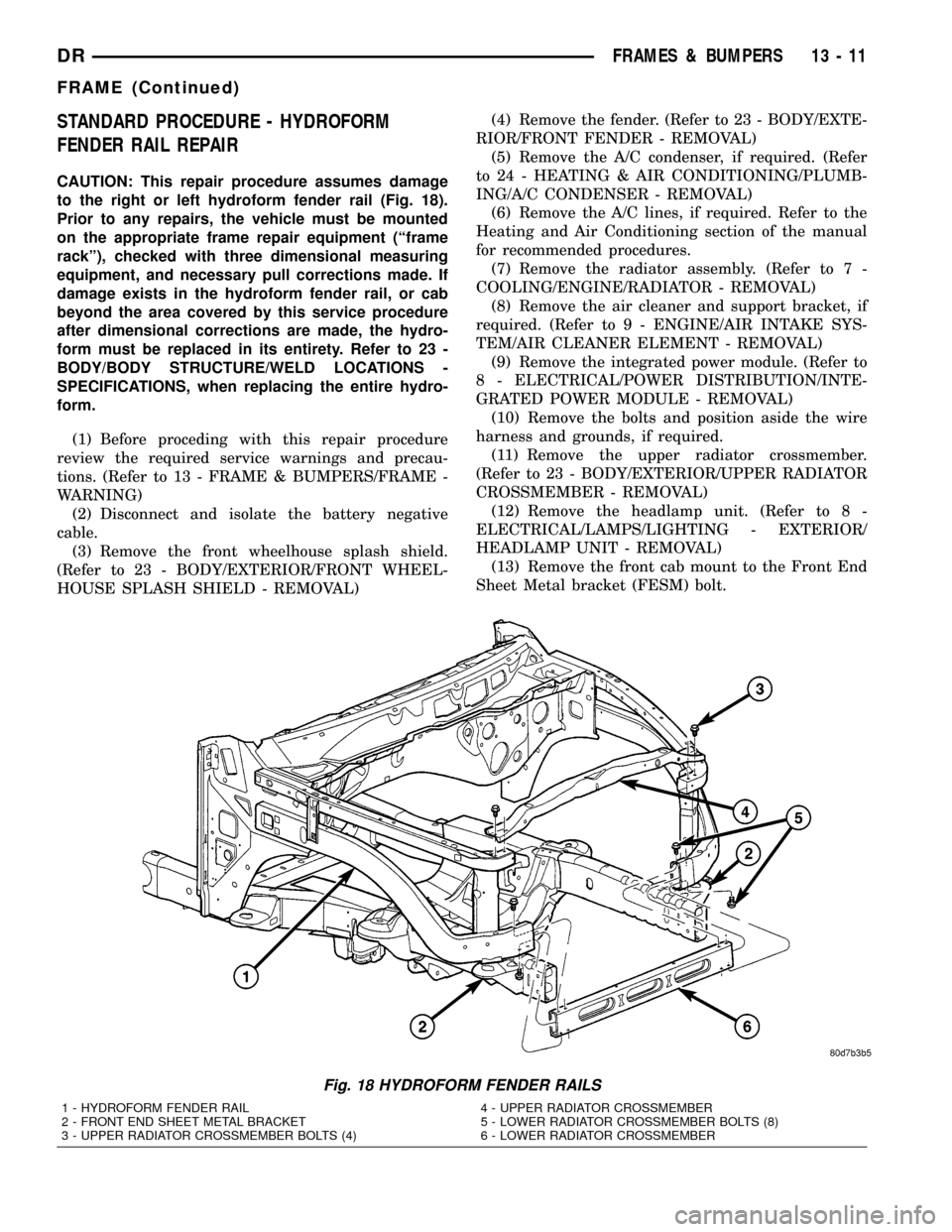

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR

CAUTION: This repair procedure assumes damage

to the right or left hydroform fender rail (Fig. 18).

Prior to any repairs, the vehicle must be mounted

on the appropriate frame repair equipment (ªframe

rackº), checked with three dimensional measuring

equipment, and necessary pull corrections made. If

damage exists in the hydroform fender rail, or cab

beyond the area covered by this service procedure

after dimensional corrections are made, the hydro-

form must be replaced in its entirety. Refer to 23 -

BODY/BODY STRUCTURE/WELD LOCATIONS -

SPECIFICATIONS, when replacing the entire hydro-

form.

(1) Before proceding with this repair procedure

review the required service warnings and precau-

tions. (Refer to 13 - FRAME & BUMPERS/FRAME -

WARNING)

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - REMOVAL)(4) Remove the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - REMOVAL)

(5) Remove the A/C condenser, if required. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - REMOVAL)

(6) Remove the A/C lines, if required. Refer to the

Heating and Air Conditioning section of the manual

for recommended procedures.

(7) Remove the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - REMOVAL)

(8) Remove the air cleaner and support bracket, if

required. (Refer to 9 - ENGINE/AIR INTAKE SYS-

TEM/AIR CLEANER ELEMENT - REMOVAL)

(9) Remove the integrated power module. (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - REMOVAL)

(10) Remove the bolts and position aside the wire

harness and grounds, if required.

(11) Remove the upper radiator crossmember.

(Refer to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - REMOVAL)

(12) Remove the headlamp unit. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

(13) Remove the front cab mount to the Front End

Sheet Metal bracket (FESM) bolt.

Fig. 18 HYDROFORM FENDER RAILS

1 - HYDROFORM FENDER RAIL

2 - FRONT END SHEET METAL BRACKET

3 - UPPER RADIATOR CROSSMEMBER BOLTS (4)4 - UPPER RADIATOR CROSSMEMBER

5 - LOWER RADIATOR CROSSMEMBER BOLTS (8)

6 - LOWER RADIATOR CROSSMEMBER

DRFRAMES & BUMPERS 13 - 11

FRAME (Continued)