abs DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2339 of 2627

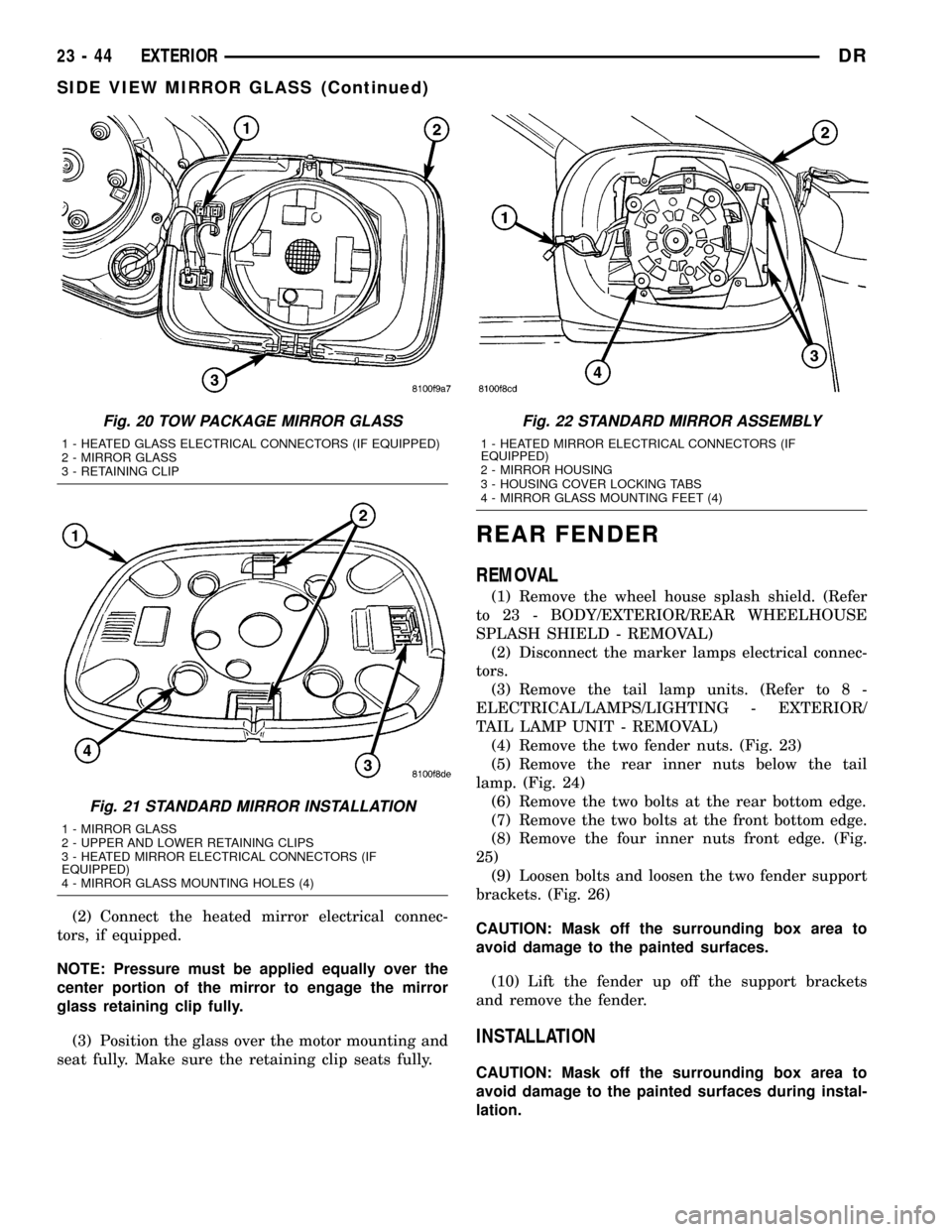

(2) Connect the heated mirror electrical connec-

tors, if equipped.

NOTE: Pressure must be applied equally over the

center portion of the mirror to engage the mirror

glass retaining clip fully.

(3) Position the glass over the motor mounting and

seat fully. Make sure the retaining clip seats fully.

REAR FENDER

REMOVAL

(1) Remove the wheel house splash shield. (Refer

to 23 - BODY/EXTERIOR/REAR WHEELHOUSE

SPLASH SHIELD - REMOVAL)

(2) Disconnect the marker lamps electrical connec-

tors.

(3) Remove the tail lamp units. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

TAIL LAMP UNIT - REMOVAL)

(4) Remove the two fender nuts. (Fig. 23)

(5) Remove the rear inner nuts below the tail

lamp. (Fig. 24)

(6) Remove the two bolts at the rear bottom edge.

(7) Remove the two bolts at the front bottom edge.

(8) Remove the four inner nuts front edge. (Fig.

25)

(9) Loosen bolts and loosen the two fender support

brackets. (Fig. 26)

CAUTION: Mask off the surrounding box area to

avoid damage to the painted surfaces.

(10) Lift the fender up off the support brackets

and remove the fender.

INSTALLATION

CAUTION: Mask off the surrounding box area to

avoid damage to the painted surfaces during instal-

lation.

Fig. 20 TOW PACKAGE MIRROR GLASS

1 - HEATED GLASS ELECTRICAL CONNECTORS (IF EQUIPPED)

2 - MIRROR GLASS

3 - RETAINING CLIP

Fig. 21 STANDARD MIRROR INSTALLATION

1 - MIRROR GLASS

2 - UPPER AND LOWER RETAINING CLIPS

3 - HEATED MIRROR ELECTRICAL CONNECTORS (IF

EQUIPPED)

4 - MIRROR GLASS MOUNTING HOLES (4)

Fig. 22 STANDARD MIRROR ASSEMBLY

1 - HEATED MIRROR ELECTRICAL CONNECTORS (IF

EQUIPPED)

2 - MIRROR HOUSING

3 - HOUSING COVER LOCKING TABS

4 - MIRROR GLASS MOUNTING FEET (4)

23 - 44 EXTERIORDR

SIDE VIEW MIRROR GLASS (Continued)

Page 2345 of 2627

(2) Snap the top edge of the bezel into place fully.

(3) Seat the two bottom clips fully.

(4) Install the two top screws.

(5) Install the center bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - INSTALLATION)

(6) Install the headlamp switch bezel. (Refer to 23

- BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SWITCH BEZEL - INSTALLATION)

ASH RECEIVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

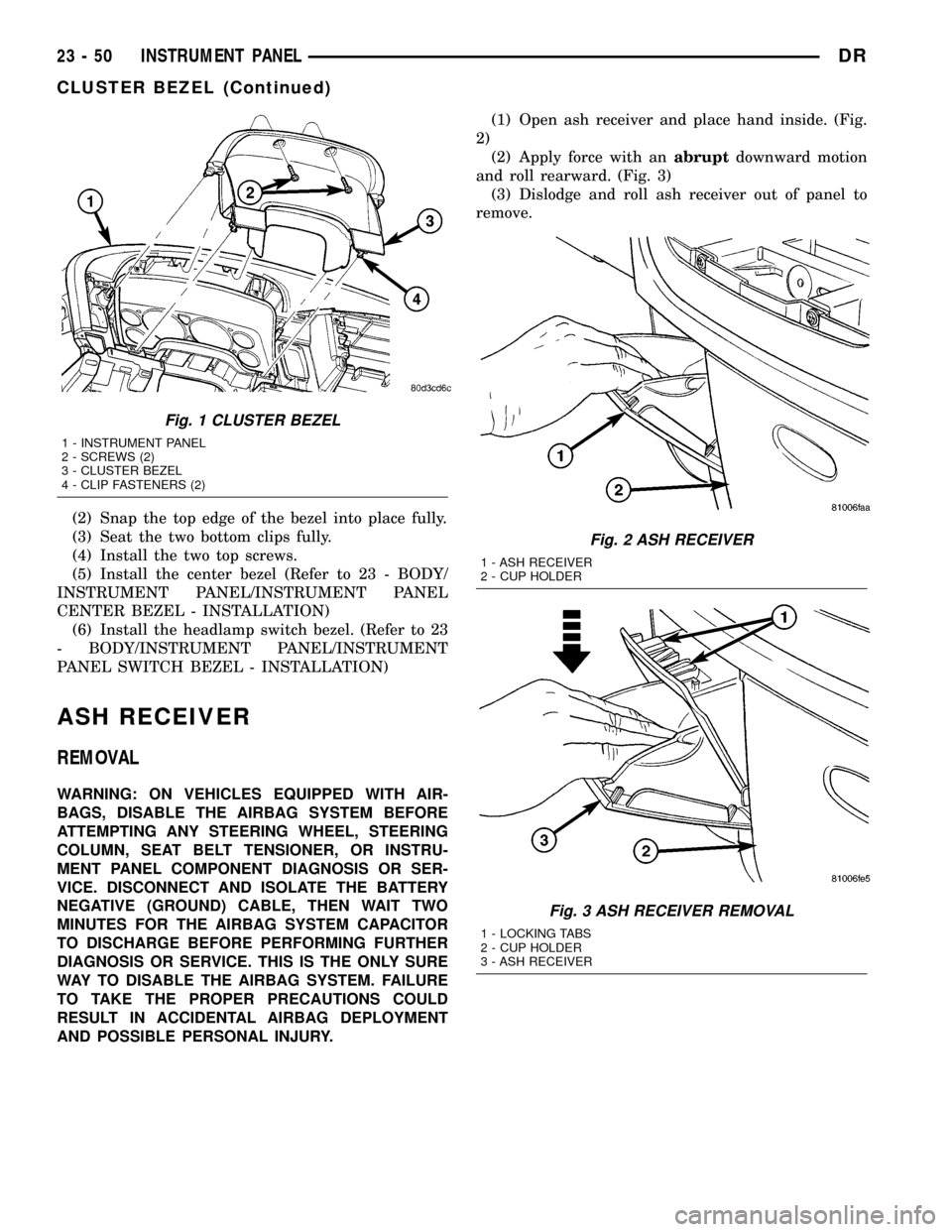

AND POSSIBLE PERSONAL INJURY.(1) Open ash receiver and place hand inside. (Fig.

2)

(2) Apply force with anabruptdownward motion

and roll rearward. (Fig. 3)

(3) Dislodge and roll ash receiver out of panel to

remove.

Fig. 1 CLUSTER BEZEL

1 - INSTRUMENT PANEL

2 - SCREWS (2)

3 - CLUSTER BEZEL

4 - CLIP FASTENERS (2)

Fig. 2 ASH RECEIVER

1 - ASH RECEIVER

2 - CUP HOLDER

Fig. 3 ASH RECEIVER REMOVAL

1 - LOCKING TABS

2 - CUP HOLDER

3 - ASH RECEIVER

23 - 50 INSTRUMENT PANELDR

CLUSTER BEZEL (Continued)

Page 2355 of 2627

(3) Install the storage bin, if equipped. (Refer to 23

- BODY/INSTRUMENT PANEL/STORAGE BIN -

INSTALLATION)

(4) Install the cup holder, if equipped. (Refer to 23

- BODY/INSTRUMENT PANEL/CUP HOLDER -

INSTALLATION)

(5) Install the glove box. (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION)

(6) Install the ash receiver. (Refer to 23 - BODY/

INSTRUMENT PANEL/ASH RECEIVER - INSTAL-

LATION)

(7) Install the passenger side cowl trim panel.

(Refer to 23 - BODY/INTERIOR/COWL TRIM -

INSTALLATION)

(8) Position the passenger side end cap and seat

fully.

STEERING COLUMN OPENING

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

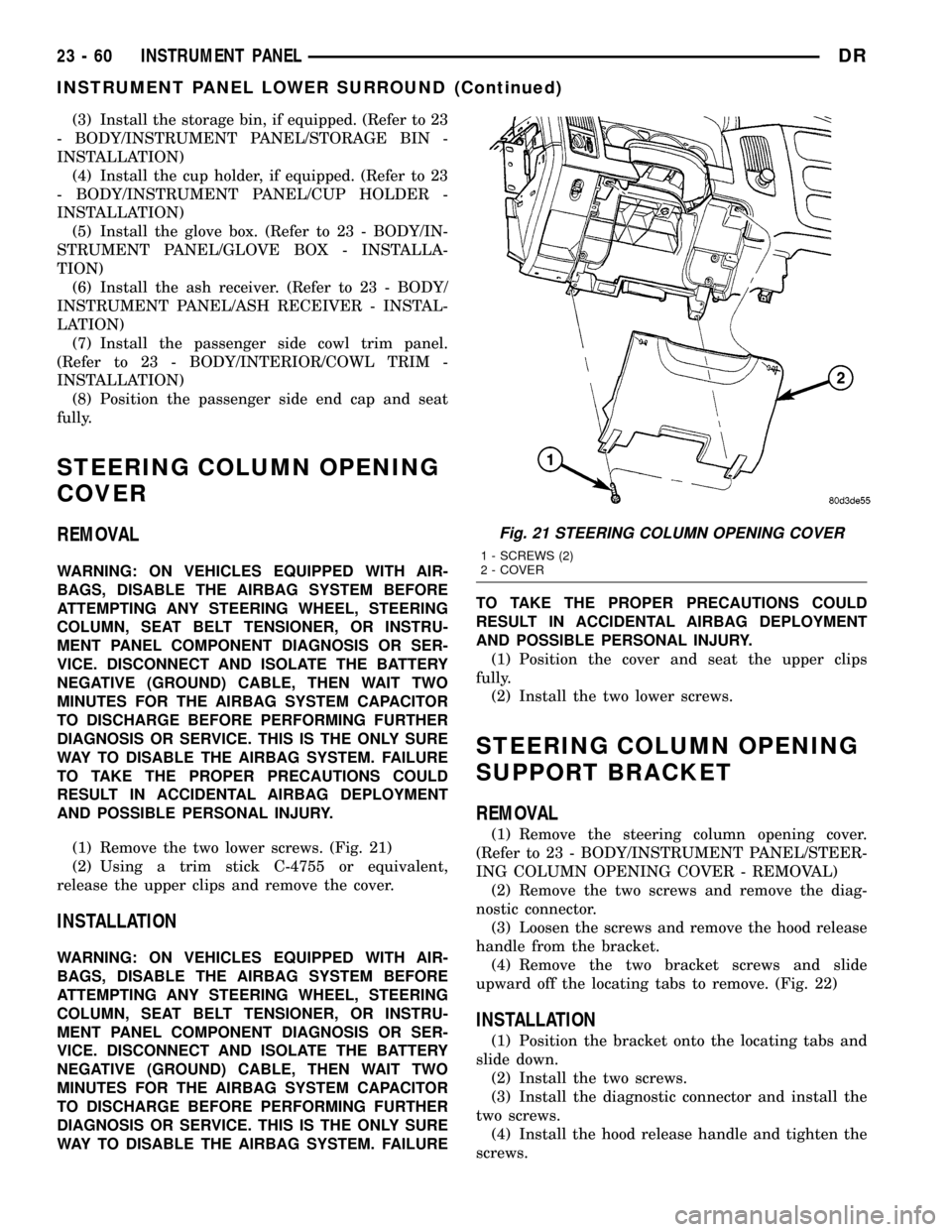

(1) Remove the two lower screws. (Fig. 21)

(2) Using a trim stick C-4755 or equivalent,

release the upper clips and remove the cover.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURETO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the cover and seat the upper clips

fully.

(2) Install the two lower screws.

STEERING COLUMN OPENING

SUPPORT BRACKET

REMOVAL

(1) Remove the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL)

(2) Remove the two screws and remove the diag-

nostic connector.

(3) Loosen the screws and remove the hood release

handle from the bracket.

(4) Remove the two bracket screws and slide

upward off the locating tabs to remove. (Fig. 22)

INSTALLATION

(1) Position the bracket onto the locating tabs and

slide down.

(2) Install the two screws.

(3) Install the diagnostic connector and install the

two screws.

(4) Install the hood release handle and tighten the

screws.

Fig. 21 STEERING COLUMN OPENING COVER

1 - SCREWS (2)

2 - COVER

23 - 60 INSTRUMENT PANELDR

INSTRUMENT PANEL LOWER SURROUND (Continued)

Page 2356 of 2627

(5) Install the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION)

STORAGE BIN

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

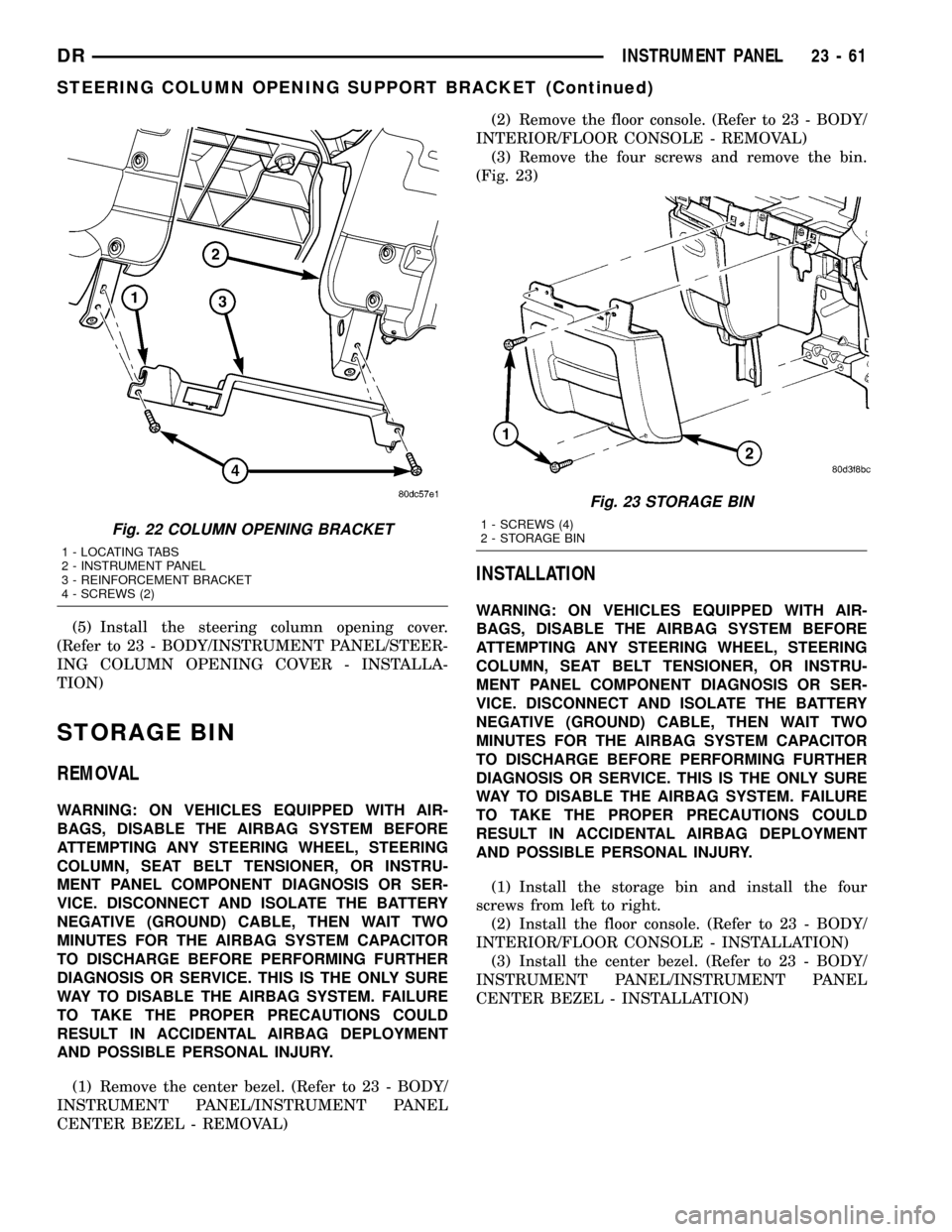

(1) Remove the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - REMOVAL)(2) Remove the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL)

(3) Remove the four screws and remove the bin.

(Fig. 23)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Install the storage bin and install the four

screws from left to right.

(2) Install the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION)

(3) Install the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - INSTALLATION)

Fig. 22 COLUMN OPENING BRACKET

1 - LOCATING TABS

2 - INSTRUMENT PANEL

3 - REINFORCEMENT BRACKET

4 - SCREWS (2)

Fig. 23 STORAGE BIN

1 - SCREWS (4)

2 - STORAGE BIN

DRINSTRUMENT PANEL 23 - 61

STEERING COLUMN OPENING SUPPORT BRACKET (Continued)

Page 2358 of 2627

(2) Install the shifter knob and nut and tighten to

27 N´m (20 ft. lbs.).

(3) Position the insert and seat into the knob fully.

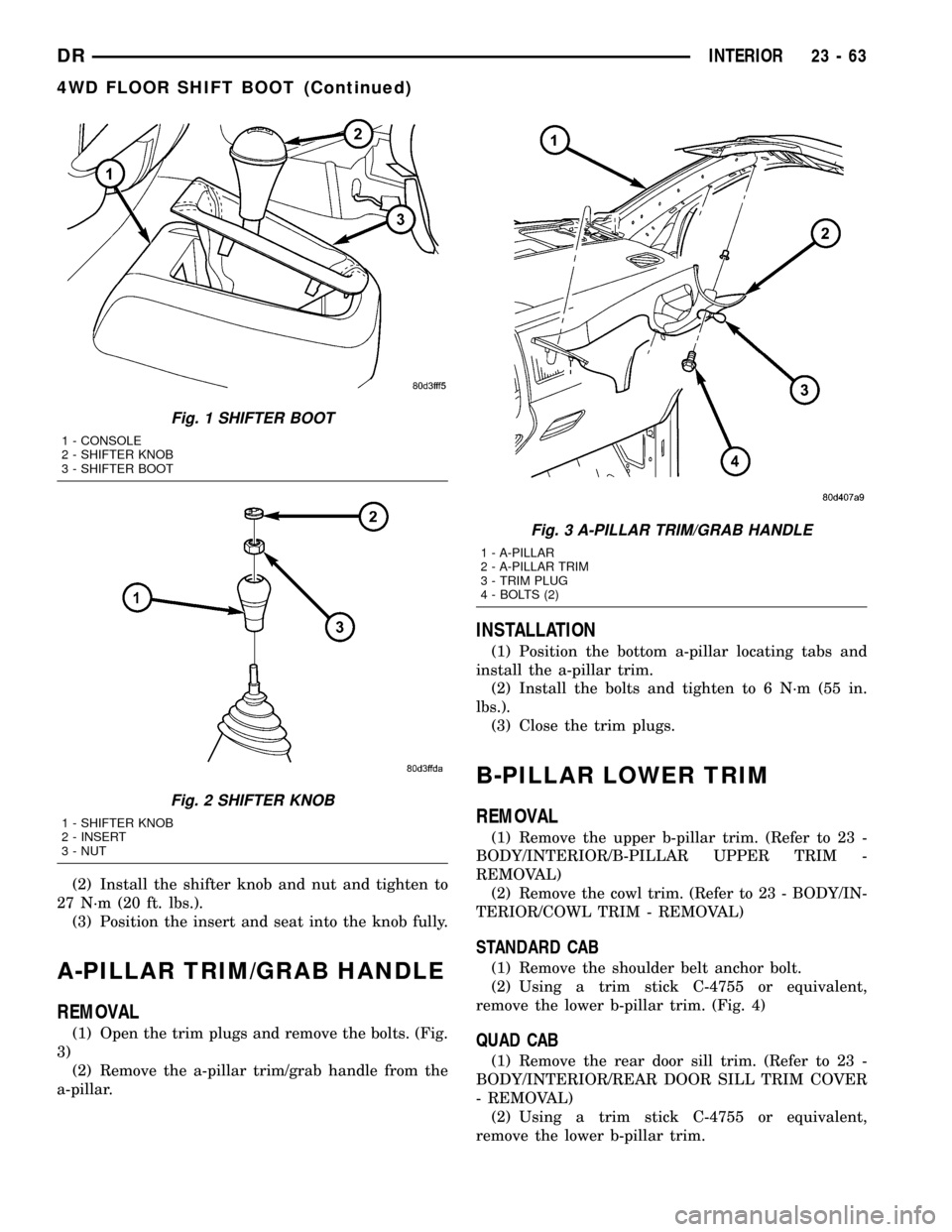

A-PILLAR TRIM/GRAB HANDLE

REMOVAL

(1) Open the trim plugs and remove the bolts. (Fig.

3)

(2) Remove the a-pillar trim/grab handle from the

a-pillar.

INSTALLATION

(1) Position the bottom a-pillar locating tabs and

install the a-pillar trim.

(2) Install the bolts and tighten to 6 N´m (55 in.

lbs.).

(3) Close the trim plugs.

B-PILLAR LOWER TRIM

REMOVAL

(1) Remove the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(2) Remove the cowl trim. (Refer to 23 - BODY/IN-

TERIOR/COWL TRIM - REMOVAL)

STANDARD CAB

(1) Remove the shoulder belt anchor bolt.

(2) Using a trim stick C-4755 or equivalent,

remove the lower b-pillar trim. (Fig. 4)

QUAD CAB

(1) Remove the rear door sill trim. (Refer to 23 -

BODY/INTERIOR/REAR DOOR SILL TRIM COVER

- REMOVAL)

(2) Using a trim stick C-4755 or equivalent,

remove the lower b-pillar trim.

Fig. 1 SHIFTER BOOT

1 - CONSOLE

2 - SHIFTER KNOB

3 - SHIFTER BOOT

Fig. 2 SHIFTER KNOB

1 - SHIFTER KNOB

2 - INSERT

3 - NUT

Fig. 3 A-PILLAR TRIM/GRAB HANDLE

1 - A-PILLAR

2 - A-PILLAR TRIM

3 - TRIM PLUG

4 - BOLTS (2)

DRINTERIOR 23 - 63

4WD FLOOR SHIFT BOOT (Continued)

Page 2366 of 2627

INSTALLATION

(1) Snap the visor support into the sheet metal

and seat the release clip fully.

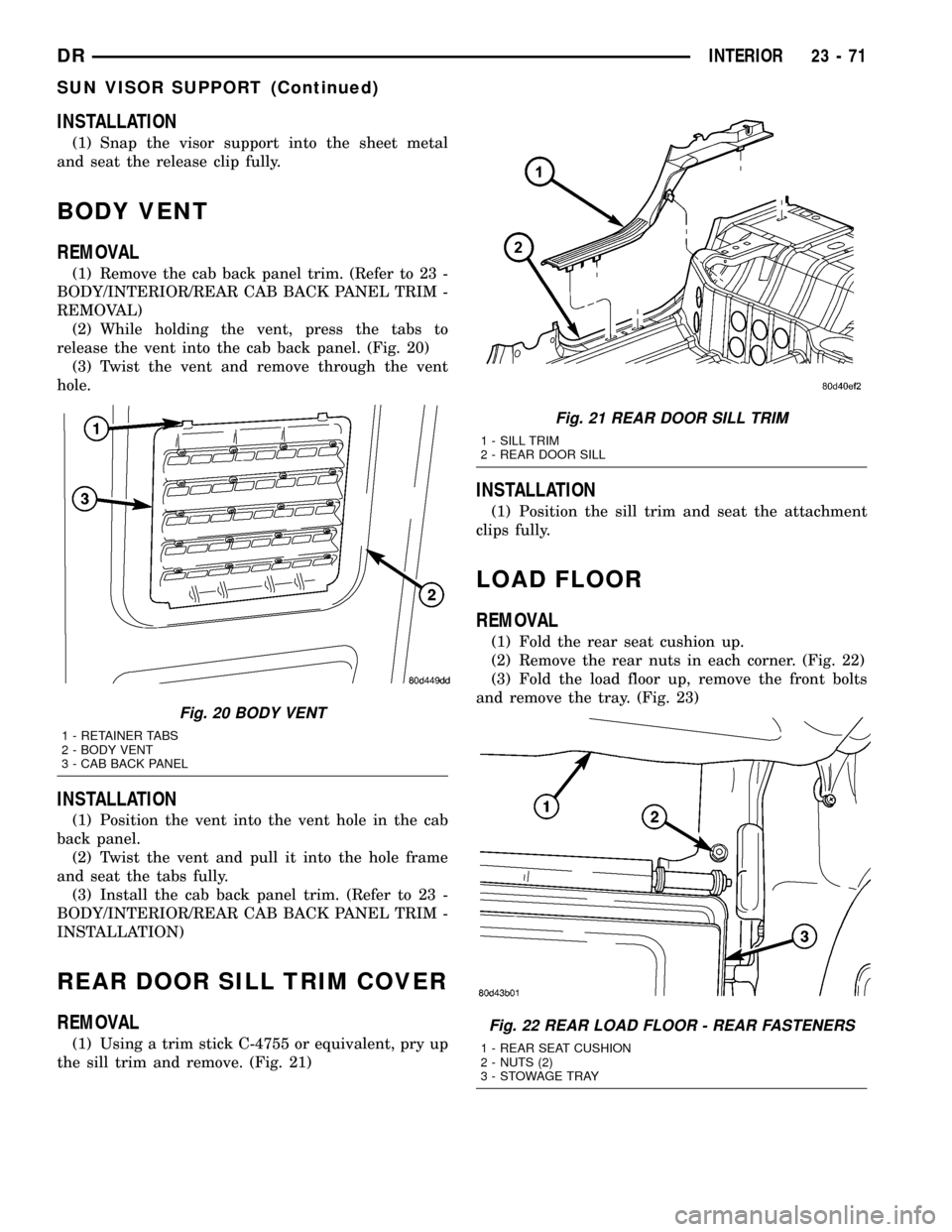

BODY VENT

REMOVAL

(1) Remove the cab back panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CAB BACK PANEL TRIM -

REMOVAL)

(2) While holding the vent, press the tabs to

release the vent into the cab back panel. (Fig. 20)

(3) Twist the vent and remove through the vent

hole.

INSTALLATION

(1) Position the vent into the vent hole in the cab

back panel.

(2) Twist the vent and pull it into the hole frame

and seat the tabs fully.

(3) Install the cab back panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CAB BACK PANEL TRIM -

INSTALLATION)

REAR DOOR SILL TRIM COVER

REMOVAL

(1) Using a trim stick C-4755 or equivalent, pry up

the sill trim and remove. (Fig. 21)

INSTALLATION

(1) Position the sill trim and seat the attachment

clips fully.

LOAD FLOOR

REMOVAL

(1) Fold the rear seat cushion up.

(2) Remove the rear nuts in each corner. (Fig. 22)

(3) Fold the load floor up, remove the front bolts

and remove the tray. (Fig. 23)

Fig. 20 BODY VENT

1 - RETAINER TABS

2 - BODY VENT

3 - CAB BACK PANEL

Fig. 21 REAR DOOR SILL TRIM

1 - SILL TRIM

2 - REAR DOOR SILL

Fig. 22 REAR LOAD FLOOR - REAR FASTENERS

1 - REAR SEAT CUSHION

2 - NUTS (2)

3 - STOWAGE TRAY

DRINTERIOR 23 - 71

SUN VISOR SUPPORT (Continued)

Page 2372 of 2627

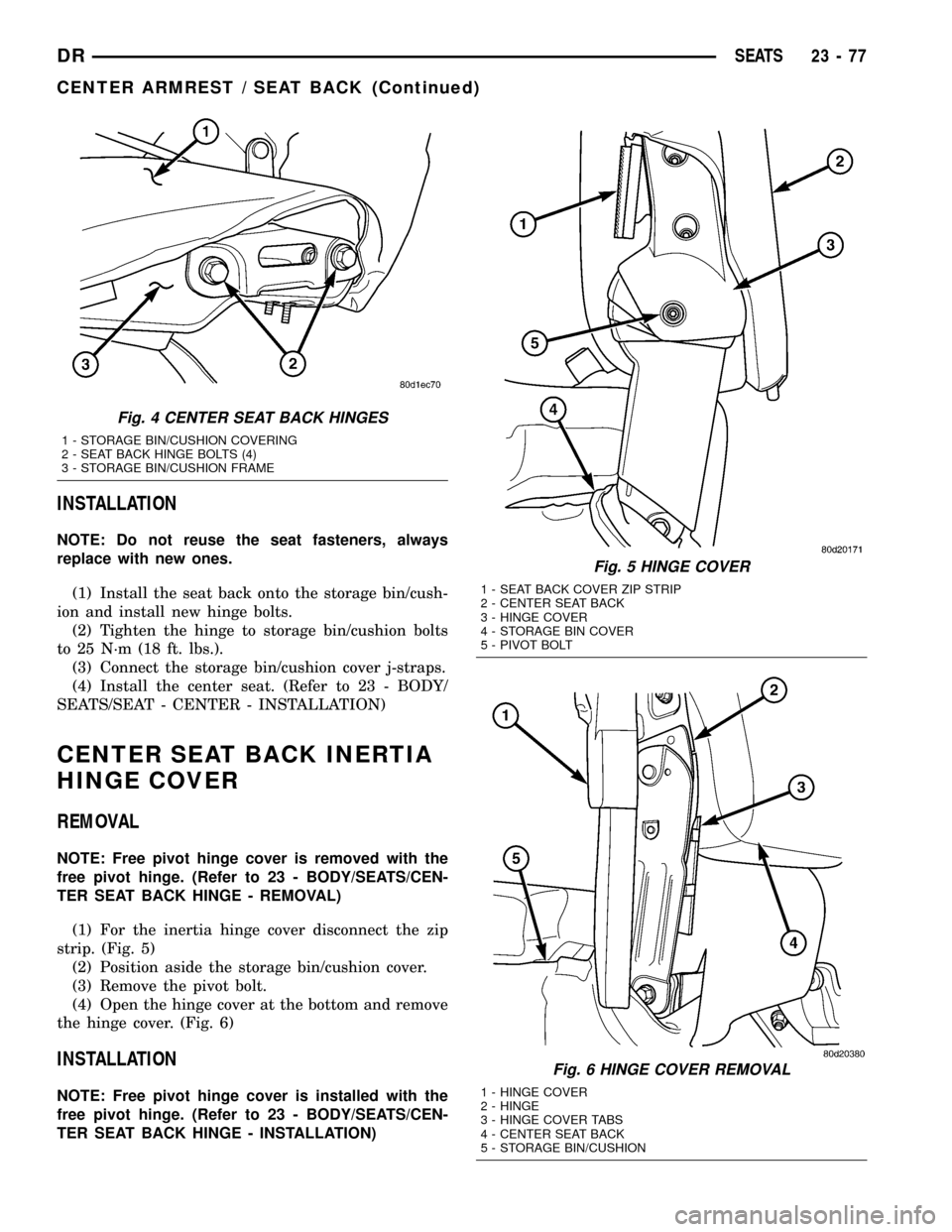

INSTALLATION

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Install the seat back onto the storage bin/cush-

ion and install new hinge bolts.

(2) Tighten the hinge to storage bin/cushion bolts

to 25 N´m (18 ft. lbs.).

(3) Connect the storage bin/cushion cover j-straps.

(4) Install the center seat. (Refer to 23 - BODY/

SEATS/SEAT - CENTER - INSTALLATION)

CENTER SEAT BACK INERTIA

HINGE COVER

REMOVAL

NOTE: Free pivot hinge cover is removed with the

free pivot hinge. (Refer to 23 - BODY/SEATS/CEN-

TER SEAT BACK HINGE - REMOVAL)

(1) For the inertia hinge cover disconnect the zip

strip. (Fig. 5)

(2) Position aside the storage bin/cushion cover.

(3) Remove the pivot bolt.

(4) Open the hinge cover at the bottom and remove

the hinge cover. (Fig. 6)

INSTALLATION

NOTE: Free pivot hinge cover is installed with the

free pivot hinge. (Refer to 23 - BODY/SEATS/CEN-

TER SEAT BACK HINGE - INSTALLATION)

Fig. 4 CENTER SEAT BACK HINGES

1 - STORAGE BIN/CUSHION COVERING

2 - SEAT BACK HINGE BOLTS (4)

3 - STORAGE BIN/CUSHION FRAME

Fig. 5 HINGE COVER

1 - SEAT BACK COVER ZIP STRIP

2 - CENTER SEAT BACK

3 - HINGE COVER

4 - STORAGE BIN COVER

5 - PIVOT BOLT

Fig. 6 HINGE COVER REMOVAL

1 - HINGE COVER

2 - HINGE

3 - HINGE COVER TABS

4 - CENTER SEAT BACK

5 - STORAGE BIN/CUSHION

DRSEATS 23 - 77

CENTER ARMREST / SEAT BACK (Continued)

Page 2373 of 2627

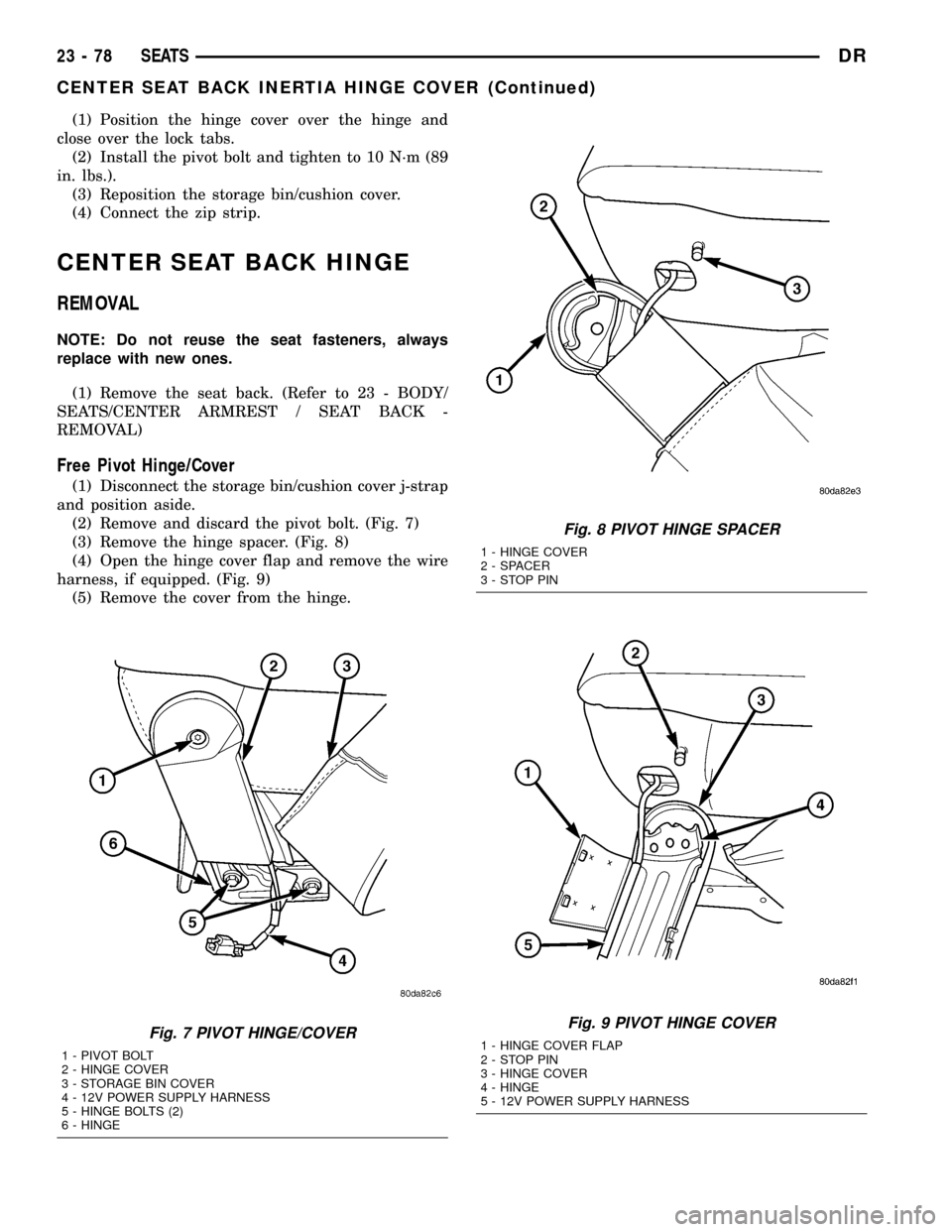

(1) Position the hinge cover over the hinge and

close over the lock tabs.

(2) Install the pivot bolt and tighten to 10 N´m (89

in. lbs.).

(3) Reposition the storage bin/cushion cover.

(4) Connect the zip strip.

CENTER SEAT BACK HINGE

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Remove the seat back. (Refer to 23 - BODY/

SEATS/CENTER ARMREST / SEAT BACK -

REMOVAL)

Free Pivot Hinge/Cover

(1) Disconnect the storage bin/cushion cover j-strap

and position aside.

(2) Remove and discard the pivot bolt. (Fig. 7)

(3) Remove the hinge spacer. (Fig. 8)

(4) Open the hinge cover flap and remove the wire

harness, if equipped. (Fig. 9)

(5) Remove the cover from the hinge.

Fig. 7 PIVOT HINGE/COVER

1 - PIVOT BOLT

2 - HINGE COVER

3 - STORAGE BIN COVER

4 - 12V POWER SUPPLY HARNESS

5 - HINGE BOLTS (2)

6 - HINGE

Fig. 8 PIVOT HINGE SPACER

1 - HINGE COVER

2 - SPACER

3-STOPPIN

Fig. 9 PIVOT HINGE COVER

1 - HINGE COVER FLAP

2-STOPPIN

3 - HINGE COVER

4 - HINGE

5 - 12V POWER SUPPLY HARNESS

23 - 78 SEATSDR

CENTER SEAT BACK INERTIA HINGE COVER (Continued)

Page 2381 of 2627

STATIONARY GLASS

TABLE OF CONTENTS

page page

BACKLITE

REMOVAL.............................86

INSTALLATION.........................86

BACKLITE VENT GLASS

REMOVAL.............................87

INSTALLATION.........................87WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS.....88

REMOVAL.............................88

INSTALLATION.........................88

BACKLITE

REMOVAL

It is difficult to salvage the backlite during the

removal operation. The backlite is part of the struc-

tural support for the roof. The urethane bonding

used to secure the glass to the fence is difficult to cut

or clean from any surface. Since the molding is set in

urethane, it is unlikely it would be salvaged. Before

removing the backlite, check the availability from the

parts supplier.

The backlite is attached to the window frame with

urethane adhesive. The urethane adhesive is applied

cold and seals the surface area between the window

opening and the glass. The primer adheres the ure-

thane adhesive to the backlite.

(1) Roll down door glass.

(2) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(3) On standard cab models remove the upper

b-pillar trim. (Refer to 23 - BODY/INTERIOR/B-PIL-

LAR UPPER TRIM - REMOVAL)

(4) On quad cab models remove the upper c-pillar

trim. (Refer to 23 - BODY/INTERIOR/C-PILLAR

UPPER TRIM - REMOVAL)

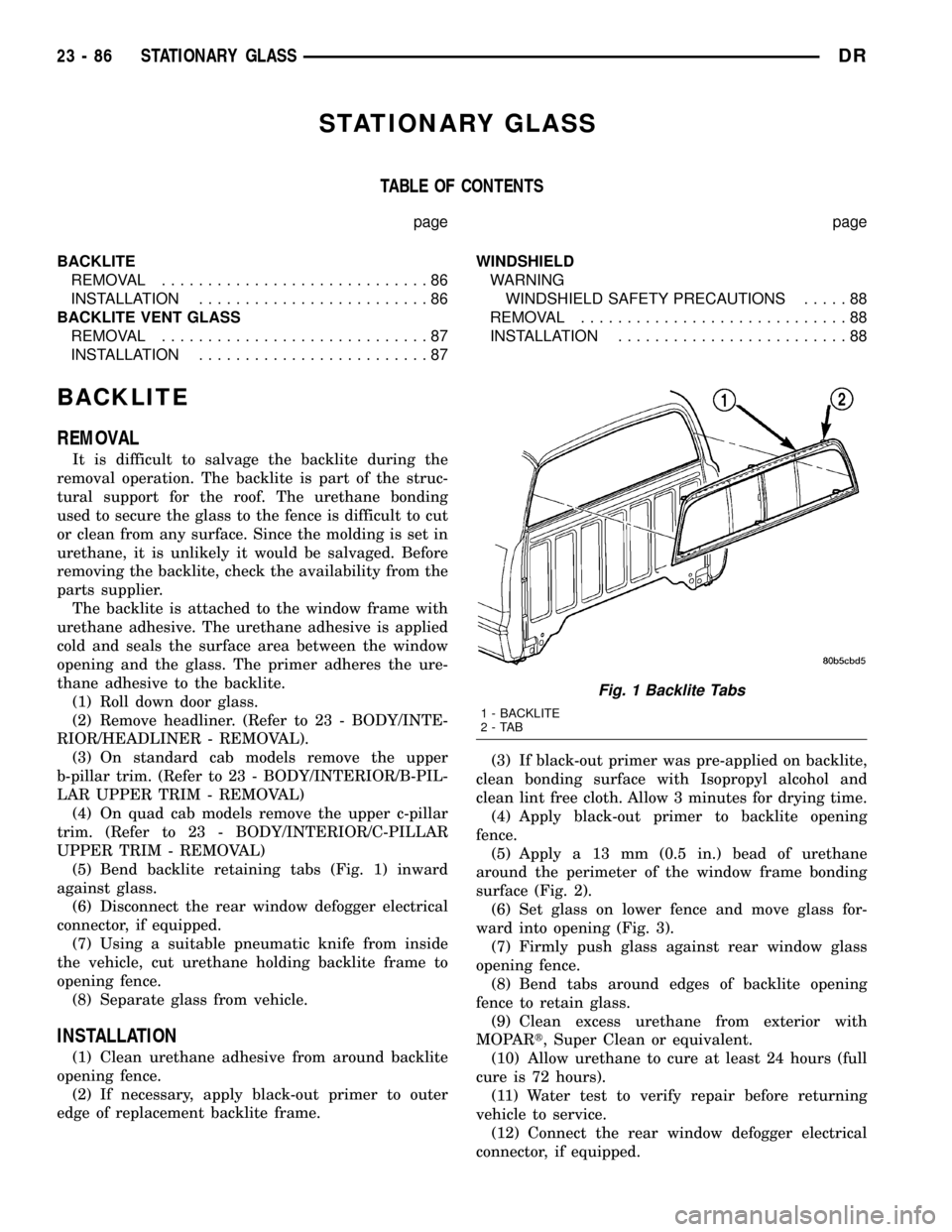

(5) Bend backlite retaining tabs (Fig. 1) inward

against glass.

(6) Disconnect the rear window defogger electrical

connector, if equipped.

(7) Using a suitable pneumatic knife from inside

the vehicle, cut urethane holding backlite frame to

opening fence.

(8) Separate glass from vehicle.

INSTALLATION

(1) Clean urethane adhesive from around backlite

opening fence.

(2) If necessary, apply black-out primer to outer

edge of replacement backlite frame.(3) If black-out primer was pre-applied on backlite,

clean bonding surface with Isopropyl alcohol and

clean lint free cloth. Allow 3 minutes for drying time.

(4) Apply black-out primer to backlite opening

fence.

(5) Apply a 13 mm (0.5 in.) bead of urethane

around the perimeter of the window frame bonding

surface (Fig. 2).

(6) Set glass on lower fence and move glass for-

ward into opening (Fig. 3).

(7) Firmly push glass against rear window glass

opening fence.

(8) Bend tabs around edges of backlite opening

fence to retain glass.

(9) Clean excess urethane from exterior with

MOPARt, Super Clean or equivalent.

(10) Allow urethane to cure at least 24 hours (full

cure is 72 hours).

(11) Water test to verify repair before returning

vehicle to service.

(12) Connect the rear window defogger electrical

connector, if equipped.

Fig. 1 Backlite Tabs

1 - BACKLITE

2-TAB

23 - 86 STATIONARY GLASSDR

Page 2490 of 2627

The panel outlets receive airflow from the HVAC

housing through a molded plastic main panel duct,

center panel duct and two end panel ducts. The two

end panel ducts direct airflow to the left and right

instrument panel outlets, while the center panel duct

directs airflow to the two center panel outlets. Each

of these outlets can be individually adjusted to direct

the flow of air.

The floor outlets receive airflow from the HVAC

housing through the floor distribution duct. The front

floor outlets are integral to the molded plastic floor

distribution duct, which is secured to the bottom of

the housing. The floor outlets cannot be adjusted.

The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a fixed

orifice tube in the liquid line near the condenser out-

let tube to meter refrigerant flow to the evaporator

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, a evaporator tem-

perature sensor is used. The JTEC control module is

programmed to respond to the evaporator tempera-

ture sensor input by cycling the air conditioning com-

pressor clutch as necessary to optimize air

conditioning system performance and to protect the

system from evaporator freezing.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

HVAC housing, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to Recirculation

mode, only air from the passenger compartment

passes through the evaporator. As the passenger com-

partment air dehumidifies, A/C performance levels

rise.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature ofthe moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Wring-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from their

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

PERFORMANCE TEST PROCEDURE

Review Safety Warnings and Cautions before per-

forming this procedure (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). Air temperature in test

room and on vehicle must be 21É C (70É F) minimum

for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C-heater mode control in the Recircu-

lation Mode position, the temperature control knob in

the full cool position, and the blower motor switch to

the highest speed position.

(3) Start the engine and hold at 1,000 rpm with

the A/C compressor clutch engaged.

(4) The engine should be warmed up to operating

temperature with the doors closed and windows

open.

(5) Insert a thermometer in the driver side center

panel A/C-heater outlet and operate the engine for

five minutes.

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity.

(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.

(8) If the discharge air temperature fails to meet

the specifications in the A/C Performance Tempera-

ture chart, refer to the Pressure Diagnosis chart.

DRHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)