tow DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1952 of 2627

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary.

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then partially press

input shaft into retainer (Fig. 215). Use a suitably

sized press tool to support retainer as close to input

shaft as possible.

(4) Install input shaft retaining ring.

(5) Press the input shaft the remainder of the way

into the clutch retainer.

(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricateretainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston. Concave side of spring faces downward

(toward piston).

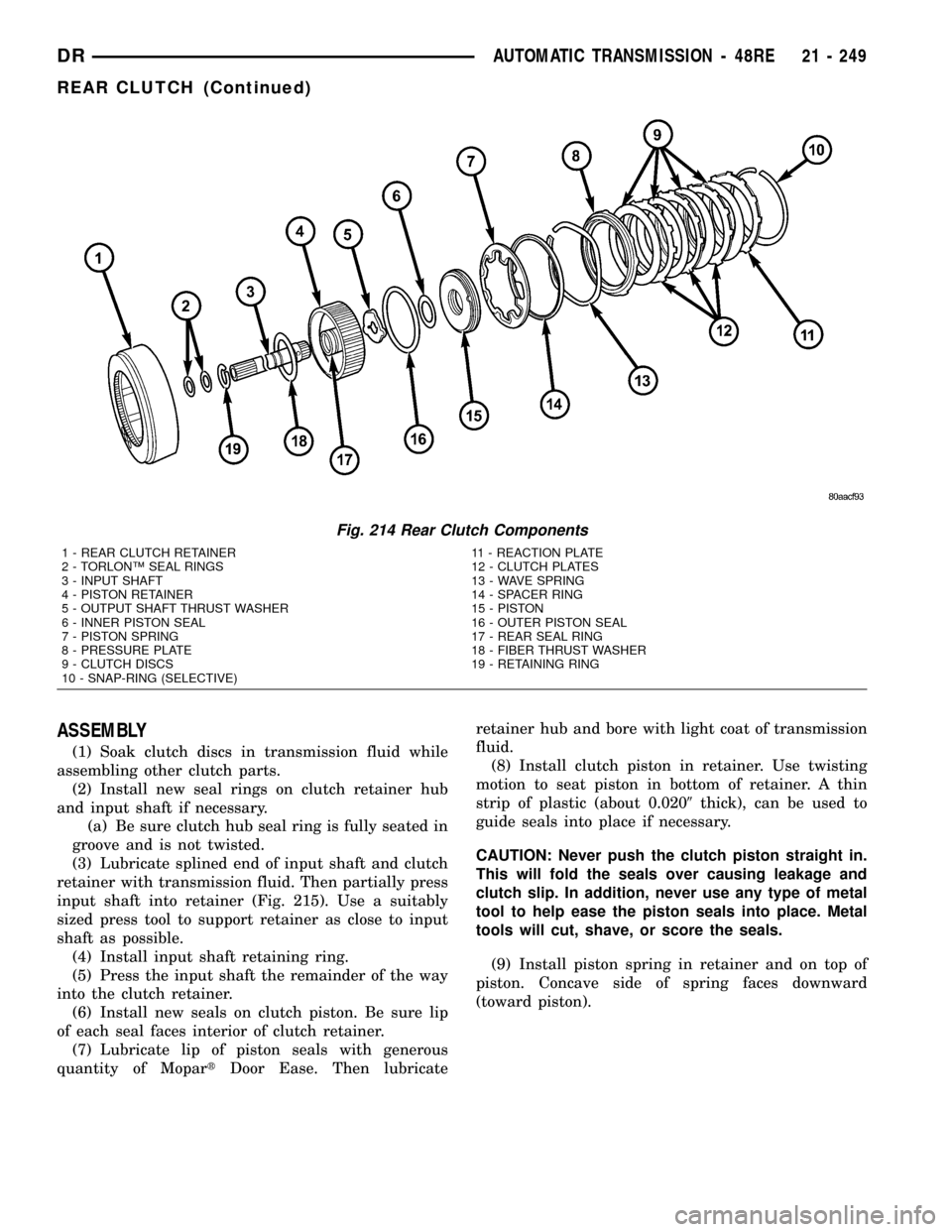

Fig. 214 Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLONŸ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

DRAUTOMATIC TRANSMISSION - 48RE 21 - 249

REAR CLUTCH (Continued)

Page 1953 of 2627

(10) Install the spacer ring and wave spring into

the retainer. Be sure spring is completely seated in

retainer groove.

(11) Install pressure plate (Fig. 214). Ridged side

of plate faces downward (toward piston) and flat side

toward clutch pack.

(12) Install first clutch disc in retainer on top of

pressure plate. Then install a clutch plate followed

by a clutch disc until entire clutch pack is installed

(4 discs and 3 plates are required) (Fig. 214).

(13) Install the reaction plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

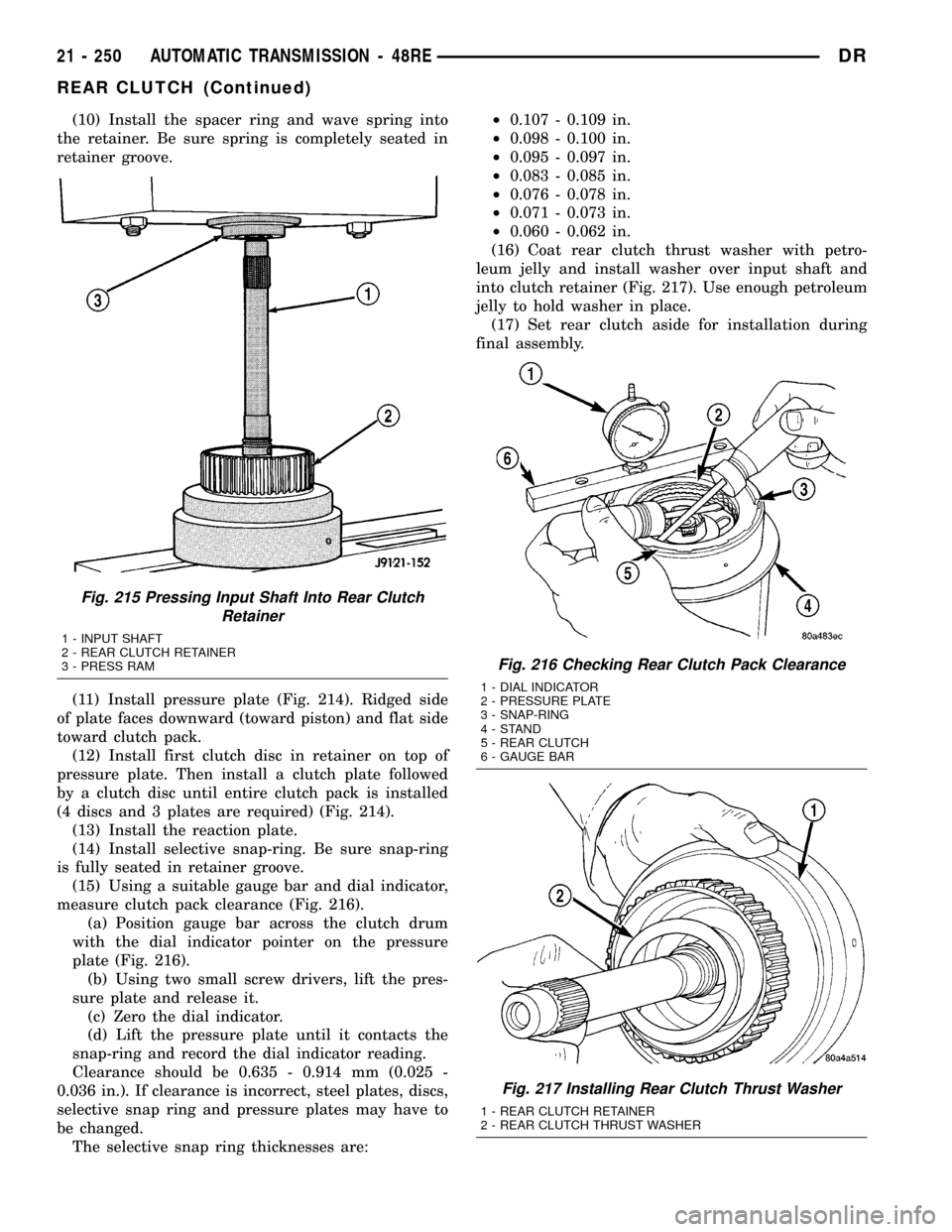

(15) Using a suitable gauge bar and dial indicator,

measure clutch pack clearance (Fig. 216).

(a) Position gauge bar across the clutch drum

with the dial indicator pointer on the pressure

plate (Fig. 216).

(b) Using two small screw drivers, lift the pres-

sure plate and release it.

(c) Zero the dial indicator.

(d) Lift the pressure plate until it contacts the

snap-ring and record the dial indicator reading.

Clearance should be 0.635 - 0.914 mm (0.025 -

0.036 in.). If clearance is incorrect, steel plates, discs,

selective snap ring and pressure plates may have to

be changed.

The selective snap ring thicknesses are:²0.107 - 0.109 in.

²0.098 - 0.100 in.

²0.095 - 0.097 in.

²0.083 - 0.085 in.

²0.076 - 0.078 in.

²0.071 - 0.073 in.

²0.060 - 0.062 in.

(16) Coat rear clutch thrust washer with petro-

leum jelly and install washer over input shaft and

into clutch retainer (Fig. 217). Use enough petroleum

jelly to hold washer in place.

(17) Set rear clutch aside for installation during

final assembly.

Fig. 215 Pressing Input Shaft Into Rear Clutch

Retainer

1 - INPUT SHAFT

2 - REAR CLUTCH RETAINER

3 - PRESS RAM

Fig. 216 Checking Rear Clutch Pack Clearance

1 - DIAL INDICATOR

2 - PRESSURE PLATE

3 - SNAP-RING

4-STAND

5 - REAR CLUTCH

6 - GAUGE BAR

Fig. 217 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER

21 - 250 AUTOMATIC TRANSMISSION - 48REDR

REAR CLUTCH (Continued)

Page 1962 of 2627

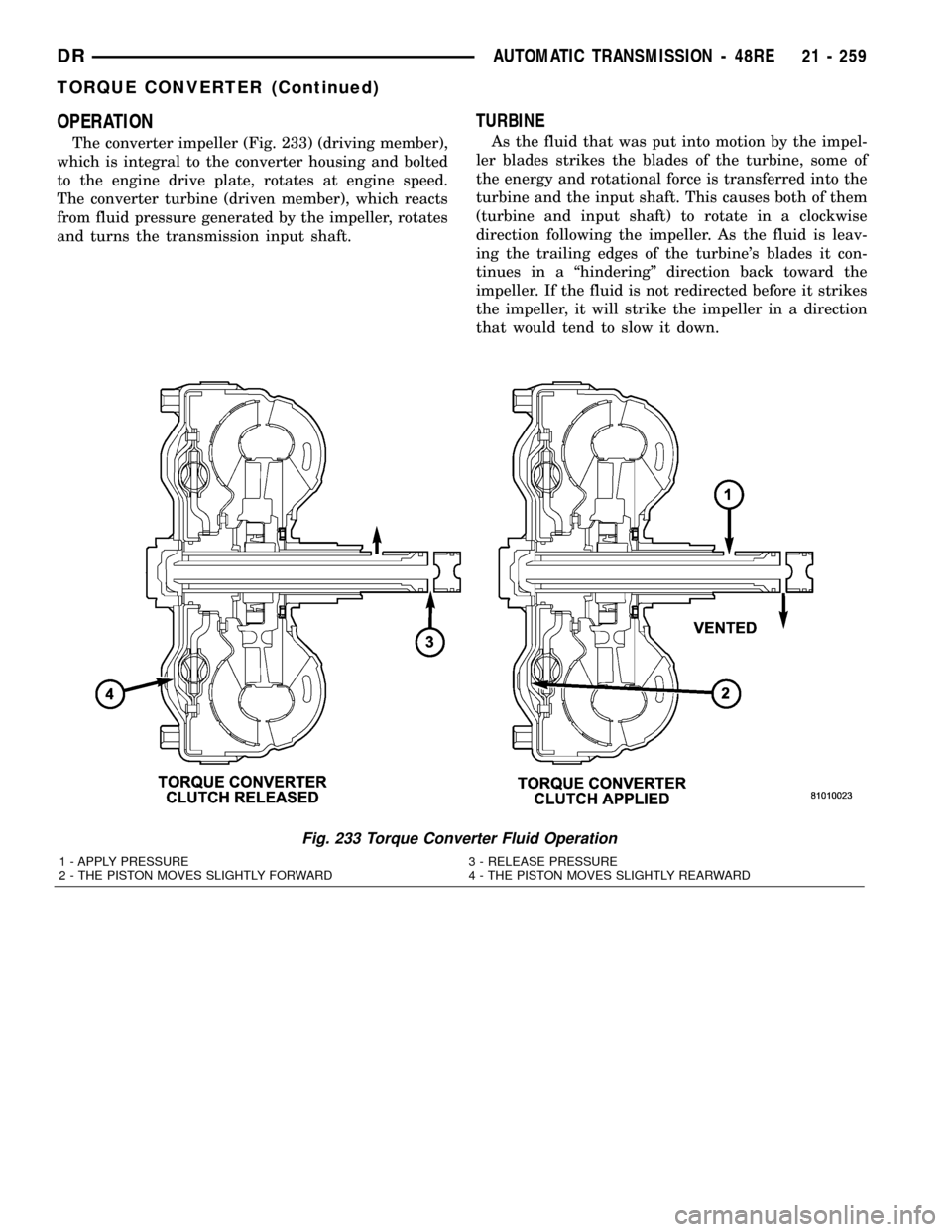

OPERATION

The converter impeller (Fig. 233) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in a direction

that would tend to slow it down.

Fig. 233 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

DRAUTOMATIC TRANSMISSION - 48RE 21 - 259

TORQUE CONVERTER (Continued)

Page 1964 of 2627

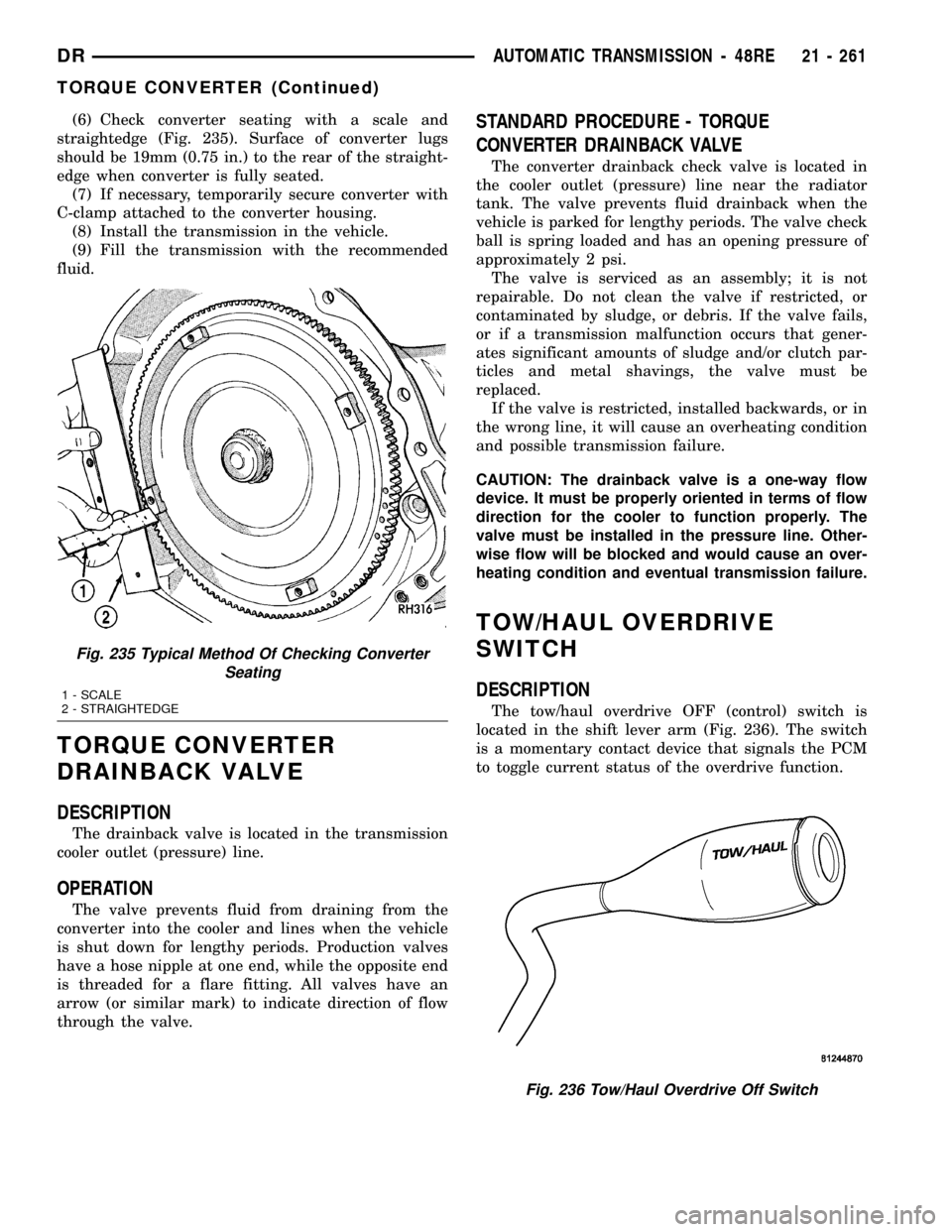

(6) Check converter seating with a scale and

straightedge (Fig. 235). Surface of converter lugs

should be 19mm (0.75 in.) to the rear of the straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle.

(9) Fill the transmission with the recommended

fluid.

TORQUE CONVERTER

DRAINBACK VALVE

DESCRIPTION

The drainback valve is located in the transmission

cooler outlet (pressure) line.

OPERATION

The valve prevents fluid from draining from the

converter into the cooler and lines when the vehicle

is shut down for lengthy periods. Production valves

have a hose nipple at one end, while the opposite end

is threaded for a flare fitting. All valves have an

arrow (or similar mark) to indicate direction of flow

through the valve.

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE

The converter drainback check valve is located in

the cooler outlet (pressure) line near the radiator

tank. The valve prevents fluid drainback when the

vehicle is parked for lengthy periods. The valve check

ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not

repairable. Do not clean the valve if restricted, or

contaminated by sludge, or debris. If the valve fails,

or if a transmission malfunction occurs that gener-

ates significant amounts of sludge and/or clutch par-

ticles and metal shavings, the valve must be

replaced.

If the valve is restricted, installed backwards, or in

the wrong line, it will cause an overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow

device. It must be properly oriented in terms of flow

direction for the cooler to function properly. The

valve must be installed in the pressure line. Other-

wise flow will be blocked and would cause an over-

heating condition and eventual transmission failure.

TOW/HAUL OVERDRIVE

SWITCH

DESCRIPTION

The tow/haul overdrive OFF (control) switch is

located in the shift lever arm (Fig. 236). The switch

is a momentary contact device that signals the PCM

to toggle current status of the overdrive function.

Fig. 235 Typical Method Of Checking Converter

Seating

1 - SCALE

2 - STRAIGHTEDGE

Fig. 236 Tow/Haul Overdrive Off Switch

DRAUTOMATIC TRANSMISSION - 48RE 21 - 261

TORQUE CONVERTER (Continued)

Page 1965 of 2627

OPERATION

At key-on, overdrive operation is allowed. Pressing

the switch once causes the tow/haul overdrive OFF

mode to be entered and the Tow/Haul lamp to be illu-

minated. Pressing the switch a second time causes

normal overdrive operation to be restored and the

tow/haul lamp to be turned off. The tow/haul over-

drive OFF mode defaults to ON after the ignition

switch is cycled OFF and ON. The normal position

for the control switch is the ON position. The switch

must be in this position to energize the solenoid and

allow a 3-4 upshift. The control switch indicator light

illuminates only when the tow/haul overdrive switch

is turned to the OFF position, or when illuminated

by the transmission control module.

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS

The tow/haul overdrive off switch, valve body sole-

noid, case connectors and related wiring can all be

tested with a 12 volt test lamp or a volt/ohmmeter.

Check continuity of each component when diagnosis

indicates this is necessary.

Switch and solenoid continuity should be checked

whenever the transmission fails to shift into fourth

gear range.

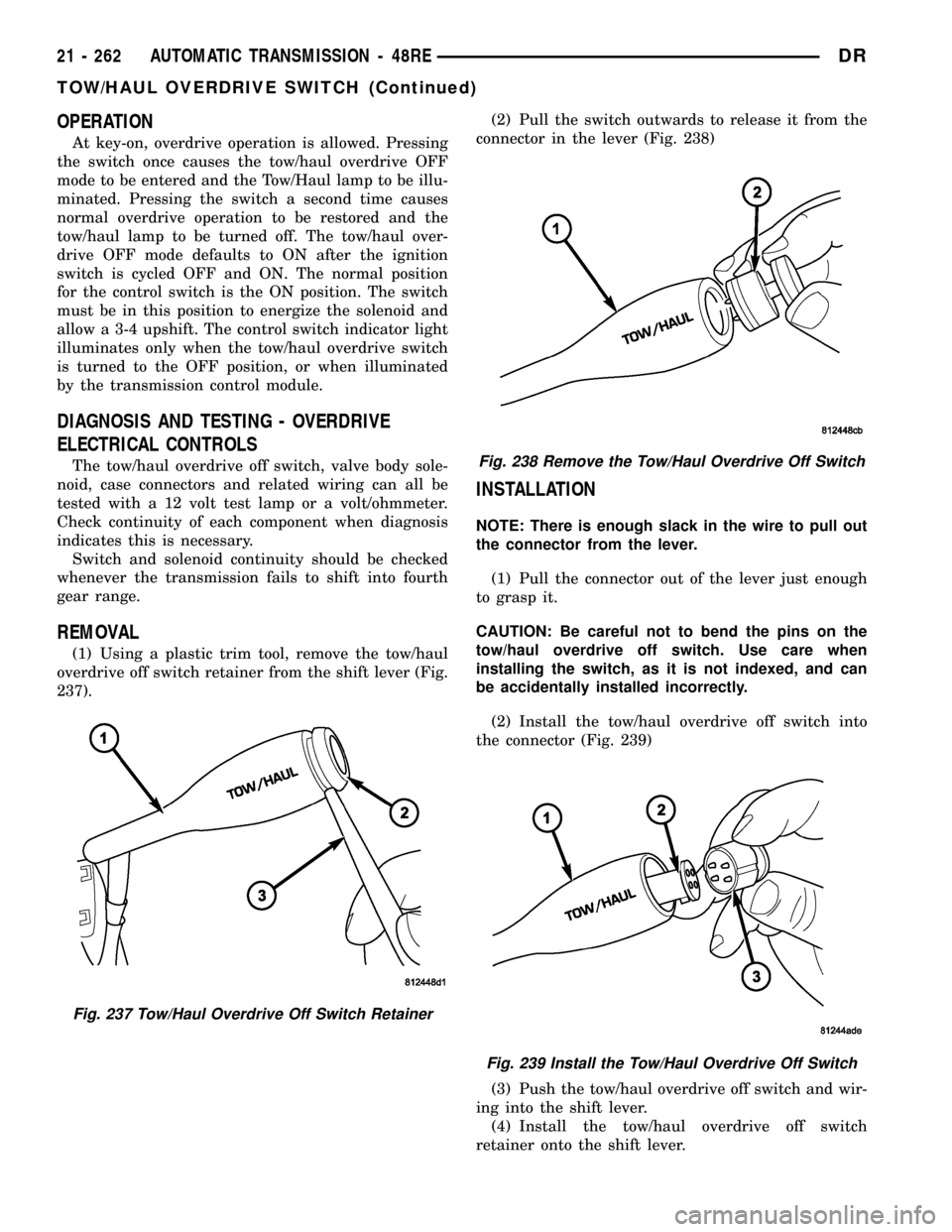

REMOVAL

(1) Using a plastic trim tool, remove the tow/haul

overdrive off switch retainer from the shift lever (Fig.

237).(2) Pull the switch outwards to release it from the

connector in the lever (Fig. 238)

INSTALLATION

NOTE: There is enough slack in the wire to pull out

the connector from the lever.

(1) Pull the connector out of the lever just enough

to grasp it.

CAUTION: Be careful not to bend the pins on the

tow/haul overdrive off switch. Use care when

installing the switch, as it is not indexed, and can

be accidentally installed incorrectly.

(2) Install the tow/haul overdrive off switch into

the connector (Fig. 239)

(3) Push the tow/haul overdrive off switch and wir-

ing into the shift lever.

(4) Install the tow/haul overdrive off switch

retainer onto the shift lever.

Fig. 237 Tow/Haul Overdrive Off Switch Retainer

Fig. 238 Remove the Tow/Haul Overdrive Off Switch

Fig. 239 Install the Tow/Haul Overdrive Off Switch

21 - 262 AUTOMATIC TRANSMISSION - 48REDR

TOW/HAUL OVERDRIVE SWITCH (Continued)

Page 1970 of 2627

TRANSMISSION

TEMPERATURE SENSOR

DESCRIPTION

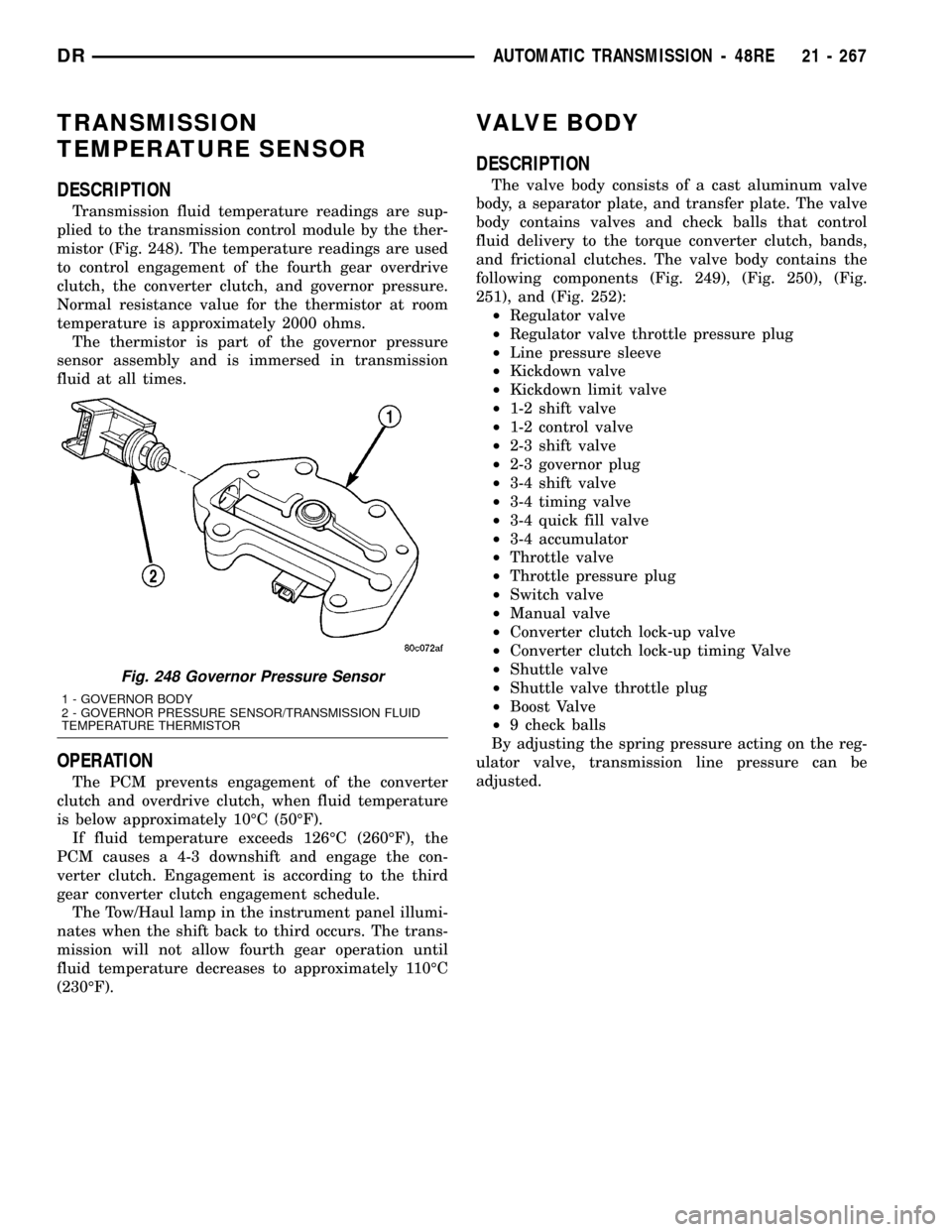

Transmission fluid temperature readings are sup-

plied to the transmission control module by the ther-

mistor (Fig. 248). The temperature readings are used

to control engagement of the fourth gear overdrive

clutch, the converter clutch, and governor pressure.

Normal resistance value for the thermistor at room

temperature is approximately 2000 ohms.

The thermistor is part of the governor pressure

sensor assembly and is immersed in transmission

fluid at all times.

OPERATION

The PCM prevents engagement of the converter

clutch and overdrive clutch, when fluid temperature

is below approximately 10ÉC (50ÉF).

If fluid temperature exceeds 126ÉC (260ÉF), the

PCM causes a 4-3 downshift and engage the con-

verter clutch. Engagement is according to the third

gear converter clutch engagement schedule.

The Tow/Haul lamp in the instrument panel illumi-

nates when the shift back to third occurs. The trans-

mission will not allow fourth gear operation until

fluid temperature decreases to approximately 110ÉC

(230ÉF).

VALVE BODY

DESCRIPTION

The valve body consists of a cast aluminum valve

body, a separator plate, and transfer plate. The valve

body contains valves and check balls that control

fluid delivery to the torque converter clutch, bands,

and frictional clutches. The valve body contains the

following components (Fig. 249), (Fig. 250), (Fig.

251), and (Fig. 252):

²Regulator valve

²Regulator valve throttle pressure plug

²Line pressure sleeve

²Kickdown valve

²Kickdown limit valve

²1-2 shift valve

²1-2 control valve

²2-3 shift valve

²2-3 governor plug

²3-4 shift valve

²3-4 timing valve

²3-4 quick fill valve

²3-4 accumulator

²Throttle valve

²Throttle pressure plug

²Switch valve

²Manual valve

²Converter clutch lock-up valve

²Converter clutch lock-up timing Valve

²Shuttle valve

²Shuttle valve throttle plug

²Boost Valve

²9 check balls

By adjusting the spring pressure acting on the reg-

ulator valve, transmission line pressure can be

adjusted.

Fig. 248 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

DRAUTOMATIC TRANSMISSION - 48RE 21 - 267

Page 1980 of 2627

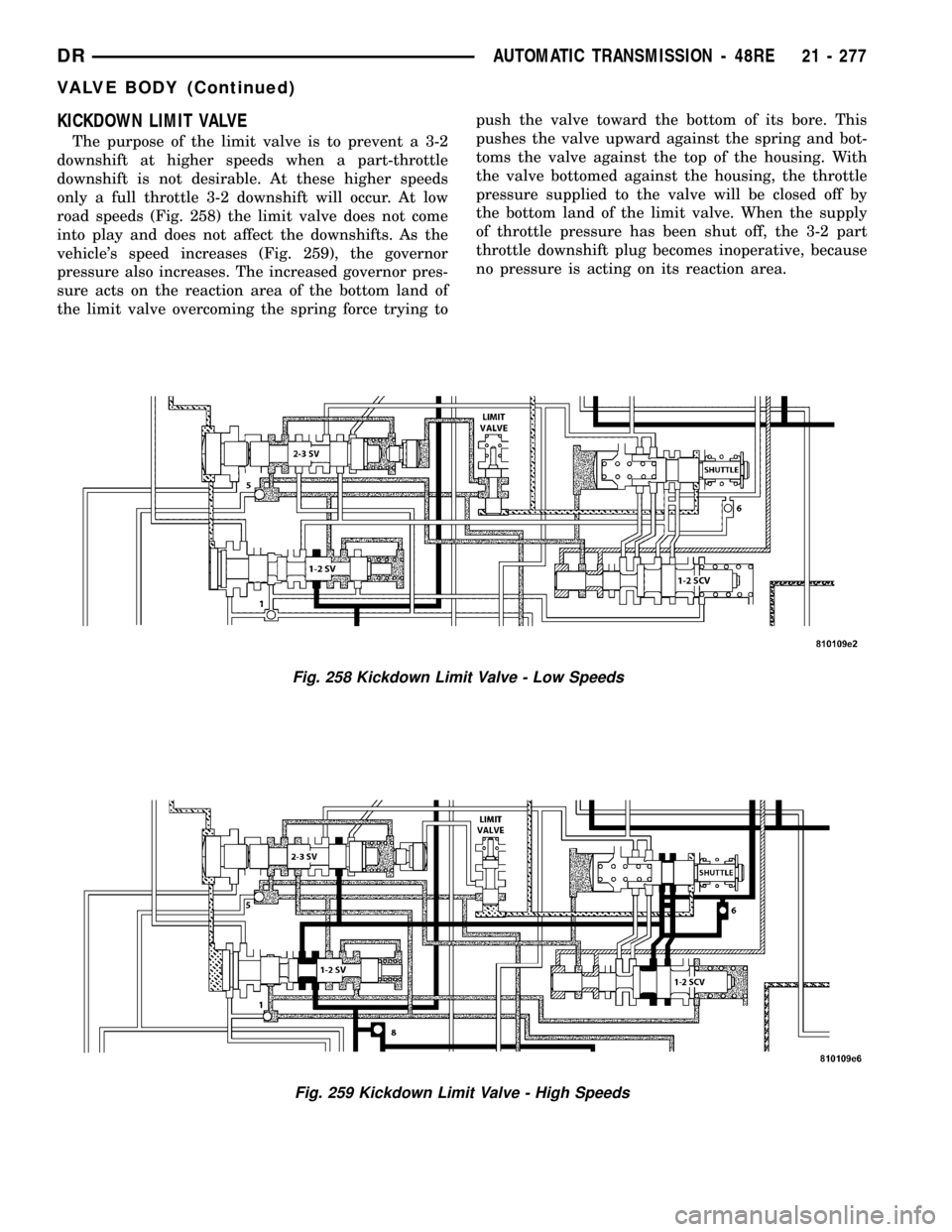

KICKDOWN LIMIT VALVE

The purpose of the limit valve is to prevent a 3-2

downshift at higher speeds when a part-throttle

downshift is not desirable. At these higher speeds

only a full throttle 3-2 downshift will occur. At low

road speeds (Fig. 258) the limit valve does not come

into play and does not affect the downshifts. As the

vehicle's speed increases (Fig. 259), the governor

pressure also increases. The increased governor pres-

sure acts on the reaction area of the bottom land of

the limit valve overcoming the spring force trying topush the valve toward the bottom of its bore. This

pushes the valve upward against the spring and bot-

toms the valve against the top of the housing. With

the valve bottomed against the housing, the throttle

pressure supplied to the valve will be closed off by

the bottom land of the limit valve. When the supply

of throttle pressure has been shut off, the 3-2 part

throttle downshift plug becomes inoperative, because

no pressure is acting on its reaction area.

Fig. 258 Kickdown Limit Valve - Low Speeds

Fig. 259 Kickdown Limit Valve - High Speeds

DRAUTOMATIC TRANSMISSION - 48RE 21 - 277

VALVE BODY (Continued)

Page 1985 of 2627

3-4 TIMING VALVE

The 3-4 timing valve is moved by line pressure

coming through the 3-4 shift valve (Fig. 266) or the

converter clutch valve. After the shift, the timing

valve holds the 2-3 shift valve in an upshift position.

The purpose is to prevent the 2-3 valve from down-

shifting while either the overdrive clutch or converter

clutch is applied (Fig. 265).

3-4 QUICK FILL VALVE

The 3-4 quick fill valve provides faster engagement

of the overdrive clutch during 3-4 upshifts. The valve

temporarily bypasses the clutch piston feed orifice at

the start of a 3-4 upshift (Fig. 265). This exposes a

larger passage into the piston retainer resulting in a

much faster clutch fill and apply sequence. The quick

fill valve does not bypass the regular clutch feed ori-

fice throughout the 3-4 upshift. Instead, once a pre-

determined pressure develops within the clutch, the

valve closes the bypass (Fig. 266). Clutch fill is then

completed through the regular feed orifice.

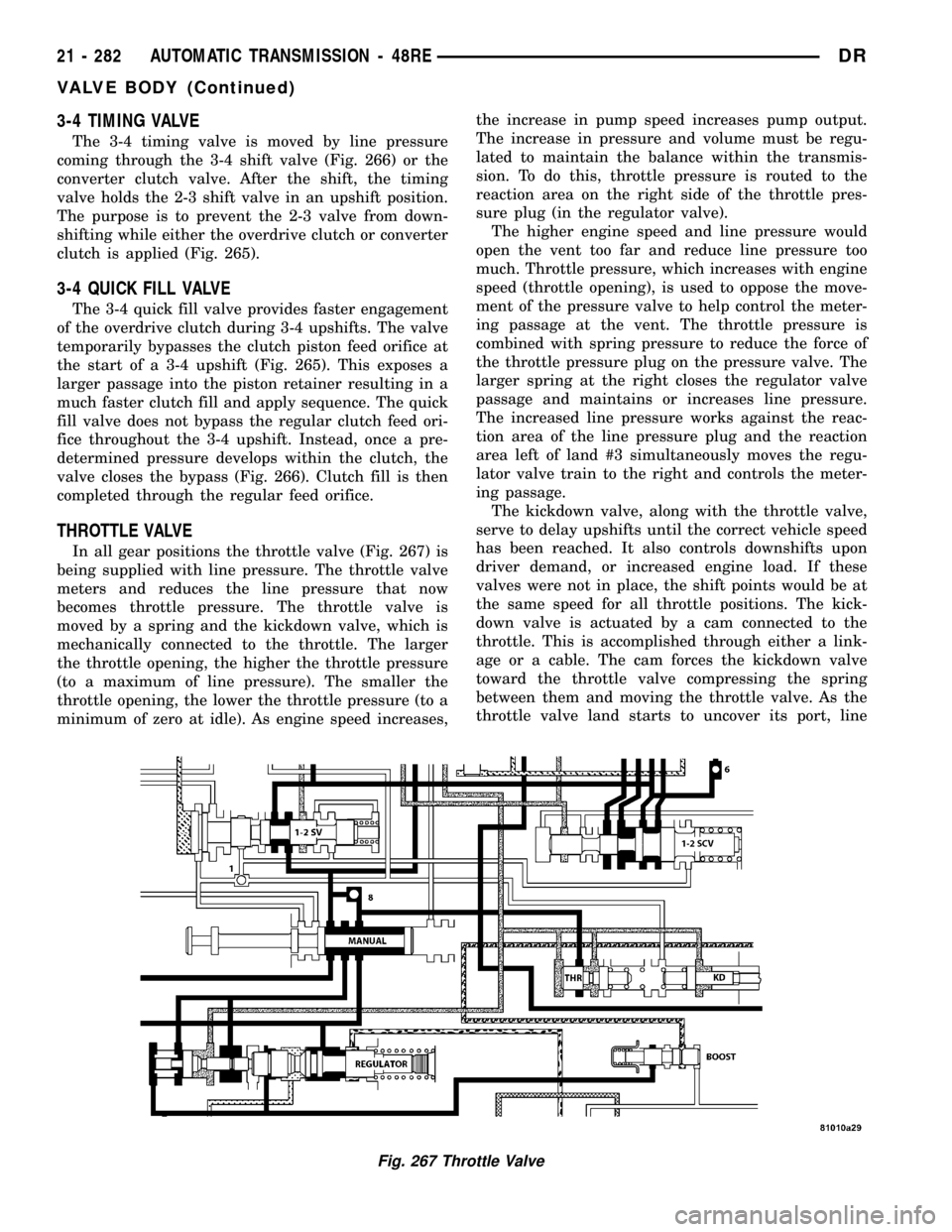

THROTTLE VALVE

In all gear positions the throttle valve (Fig. 267) is

being supplied with line pressure. The throttle valve

meters and reduces the line pressure that now

becomes throttle pressure. The throttle valve is

moved by a spring and the kickdown valve, which is

mechanically connected to the throttle. The larger

the throttle opening, the higher the throttle pressure

(to a maximum of line pressure). The smaller the

throttle opening, the lower the throttle pressure (to a

minimum of zero at idle). As engine speed increases,the increase in pump speed increases pump output.

The increase in pressure and volume must be regu-

lated to maintain the balance within the transmis-

sion. To do this, throttle pressure is routed to the

reaction area on the right side of the throttle pres-

sure plug (in the regulator valve).

The higher engine speed and line pressure would

open the vent too far and reduce line pressure too

much. Throttle pressure, which increases with engine

speed (throttle opening), is used to oppose the move-

ment of the pressure valve to help control the meter-

ing passage at the vent. The throttle pressure is

combined with spring pressure to reduce the force of

the throttle pressure plug on the pressure valve. The

larger spring at the right closes the regulator valve

passage and maintains or increases line pressure.

The increased line pressure works against the reac-

tion area of the line pressure plug and the reaction

area left of land #3 simultaneously moves the regu-

lator valve train to the right and controls the meter-

ing passage.

The kickdown valve, along with the throttle valve,

serve to delay upshifts until the correct vehicle speed

has been reached. It also controls downshifts upon

driver demand, or increased engine load. If these

valves were not in place, the shift points would be at

the same speed for all throttle positions. The kick-

down valve is actuated by a cam connected to the

throttle. This is accomplished through either a link-

age or a cable. The cam forces the kickdown valve

toward the throttle valve compressing the spring

between them and moving the throttle valve. As the

throttle valve land starts to uncover its port, line

Fig. 267 Throttle Valve

21 - 282 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2001 of 2627

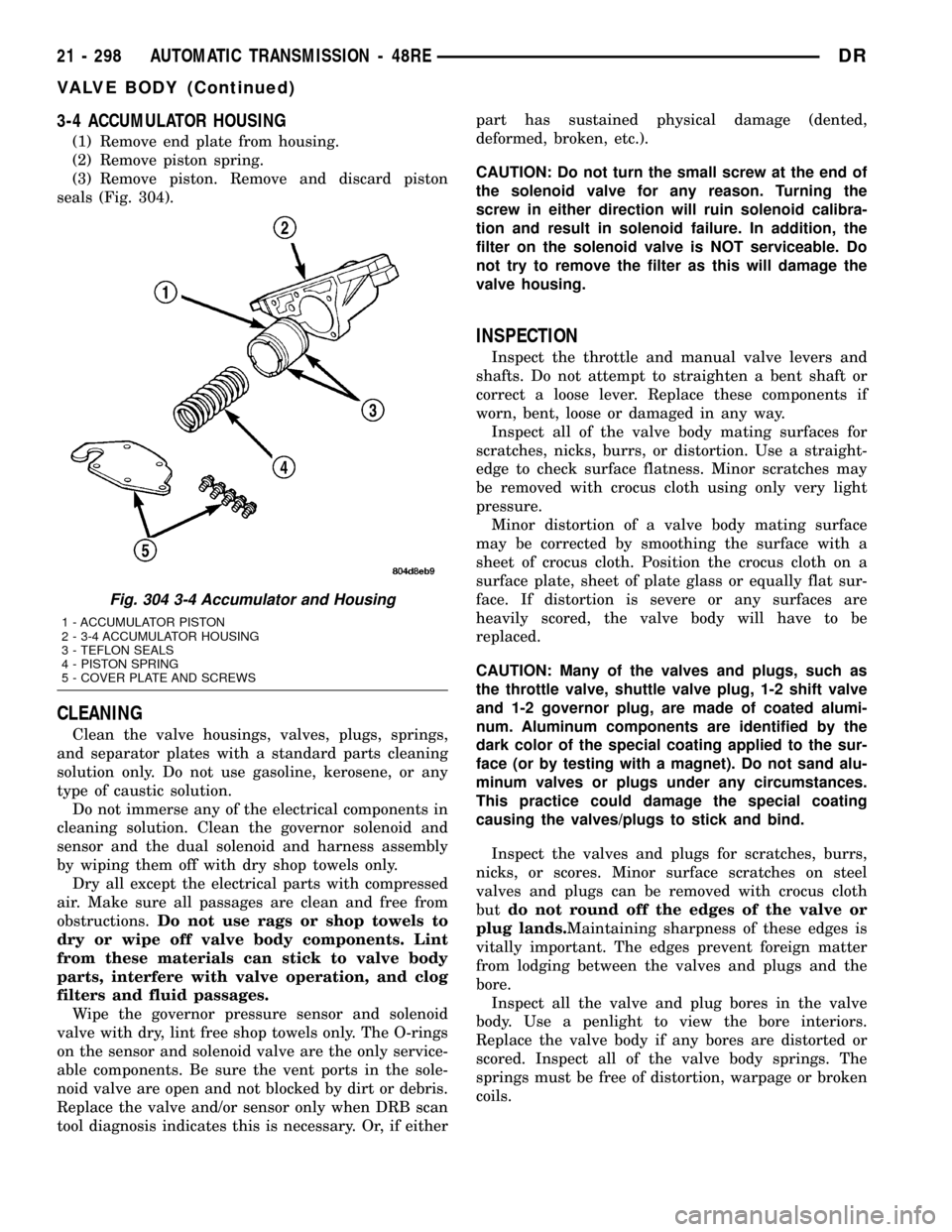

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 304).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if eitherpart has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, the

filter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Fig. 304 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 298 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2015 of 2627

INSTALLATION........................391

OUTPUT SPEED SENSOR

DESCRIPTION........................391

OPERATION..........................391

REMOVAL............................391

INSTALLATION........................392

TOW/HAUL OVERDRIVE SWITCH

DESCRIPTION........................392

OPERATION..........................392

REMOVAL............................392

INSTALLATION........................393

PISTONS

DESCRIPTION........................393

OPERATION..........................393

PLANETARY GEARTRAIN

DESCRIPTION........................395

OPERATION..........................396

DISASSEMBLY........................396

CLEANING...........................396

INSPECTION.........................397

ASSEMBLY...........................397

SHIFT MECHANISM

DESCRIPTION........................398

OPERATION..........................398

SOLENOID SWITCH VALVE

DESCRIPTION........................398

OPERATION..........................398

SOLENOIDS

DESCRIPTION........................398OPERATION..........................399

TORQUE CONVERTER

DESCRIPTION........................399

OPERATION..........................403

REMOVAL............................404

INSTALLATION........................404

TRANSMISSION CONTROL RELAY

DESCRIPTION........................405

OPERATION..........................405

TRANSMISSION RANGE SENSOR

DESCRIPTION........................405

OPERATION..........................405

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................406

OPERATION..........................406

REMOVAL............................407

INSTALLATION........................408

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................408

OPERATION..........................408

VALVE BODY

DESCRIPTION........................408

OPERATION..........................408

REMOVAL............................410

DISASSEMBLY........................410

CLEANING...........................412

INSPECTION.........................413

ASSEMBLY...........................414

INSTALLATION........................414

AUTOMATIC TRANSMISSION -

45RFE/545RFE

DESCRIPTION

The 45RFE/545RFE automatic transmissions is a

sophisticated, multi-range, electronically controlled

transmission which combines optimized gear ratios

for responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range.

The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

21 - 312 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR